Mower

A lawnmower and machine body technology, applied in the field of weeding machinery, can solve problems such as insufficient suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

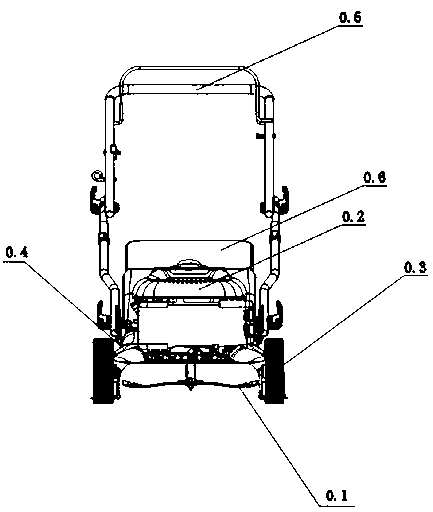

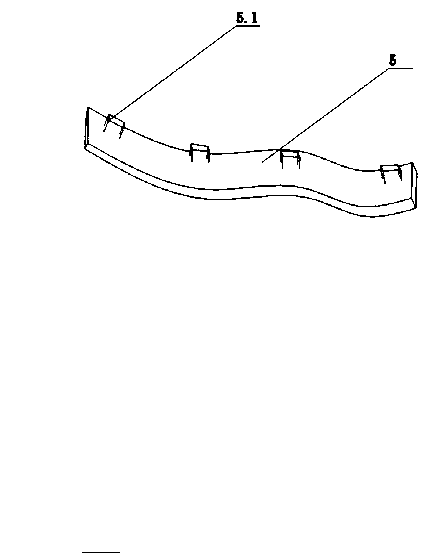

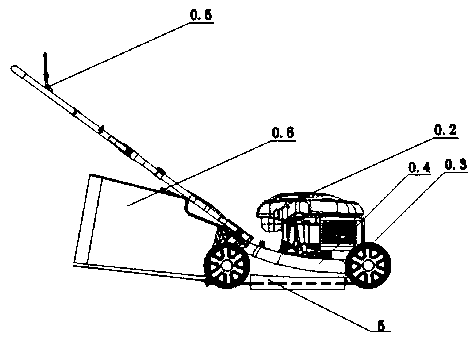

[0016] Attached below figure 1 , 2 And attached image 3 Embodiments of the present invention are further described.

[0017] as attached figure 1 , 2 , 3 and 4, the prior art weeder comprises a blade 0.1, a motor 0.2 and a mower body 0.3, the motor 0.2 is installed on the mower body 0.3, and the output shaft of the motor 0.2 is in phase with the blade 0.1 Connection; when the engine 0.2 is working, it can drive the blade 0.1 to rotate, so as to achieve the effect of trimming the weeds, but at the same time, due to the large gap between the body 0.3 of the weeder and the ground, many weeds will be interrupted. But when interrupting, the wind force caused by the rotation of blade 0.1 is not enough, so that a lot of weeds will fall on the ground; and a kind of baffle piece made of flexible material that adopts in the present invention is attached on the lawn mower and has reached enhancement. The blade-suction function of the fan of the lawnmower itself is a lawnmower, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com