Paddle type adsorption air dryer and system and air drying method

An air dryer and paddle technology, which is applied to chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of large one-time investment and inconvenient maintenance, and achieve convenient installation and movement, simple structure, and high air intake volume. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

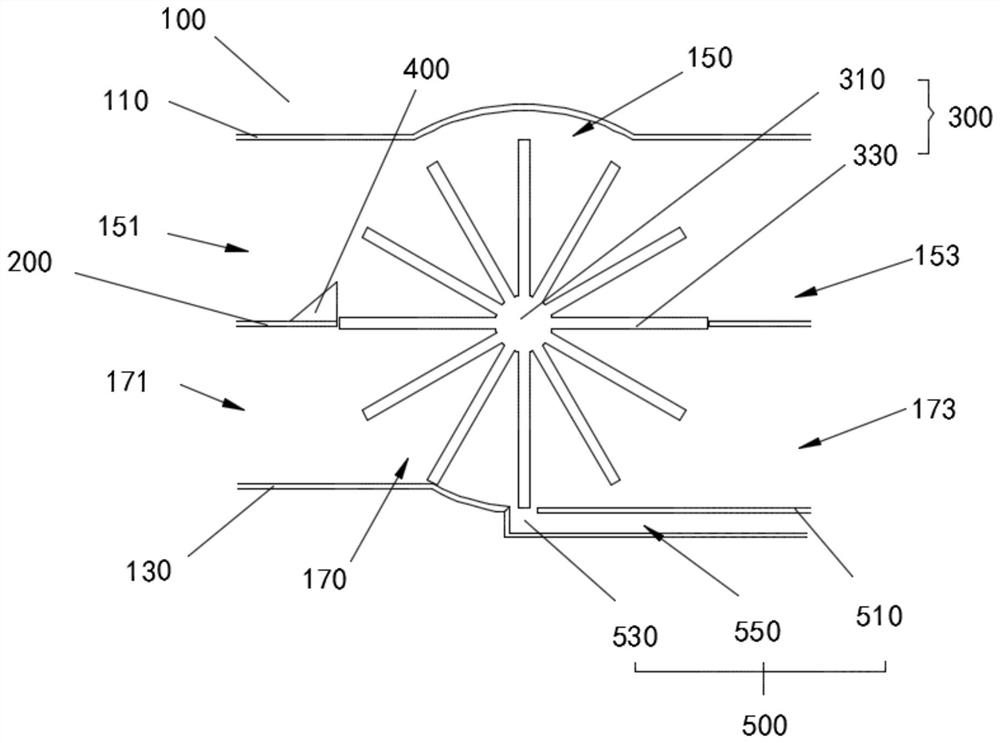

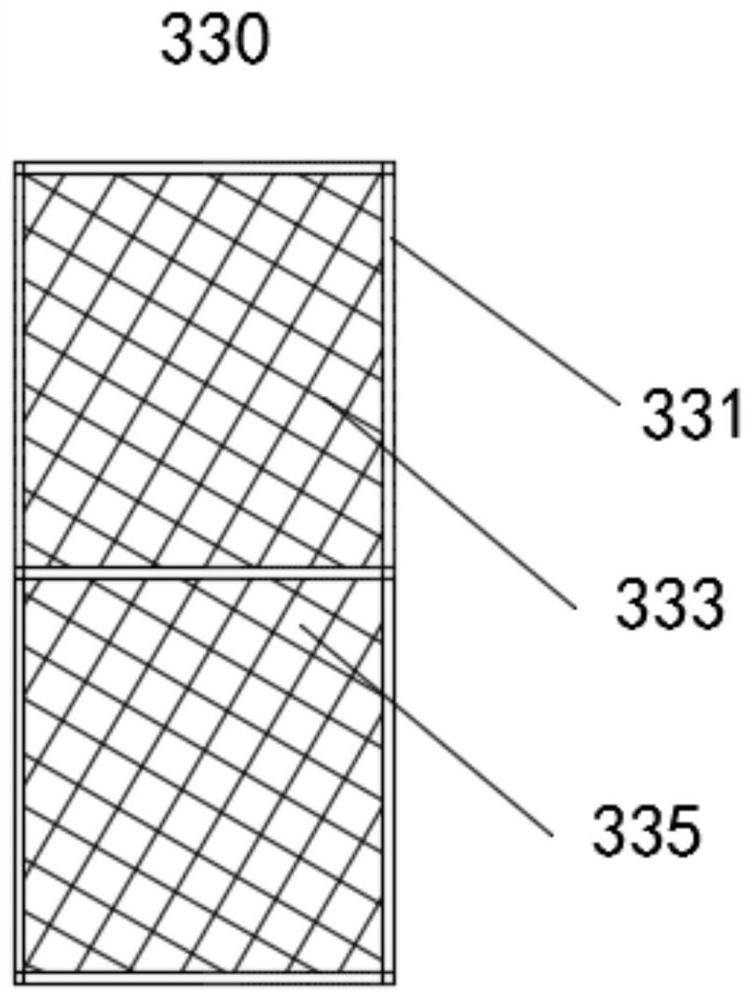

[0042] see Figure 1-2 , the present embodiment provides a paddle type adsorption air dryer, which includes a vent pipe 100 , an isolation frame 200 , a paddle machine 300 , a protrusion 400 and a drain pipe 500 . The ventilation tube 100 includes a first outer frame 110 and a second outer frame 130, the isolation frame 200 is arranged in the ventilation tube 100, and the isolation frame 200 isolates the ventilation channel of the ventilation tube 100 into upper and lower parts, wherein the isolation frame 200 and the first outer frame The frame 110 forms an upper air passage 150 , and the isolation frame 200 and the second outer frame 130 form a lower air passage 170 . The upper airway 150 is blown into hot air from the upper airway inlet 151. The hot air generally comes from high-temperature process air or air heated by a heating device. Usually, the temperature of the hot air is best at 80°C-120°C. The upper airway 150 is exhausted by an upper airway exhaust port 153 . Th...

no. 2 example

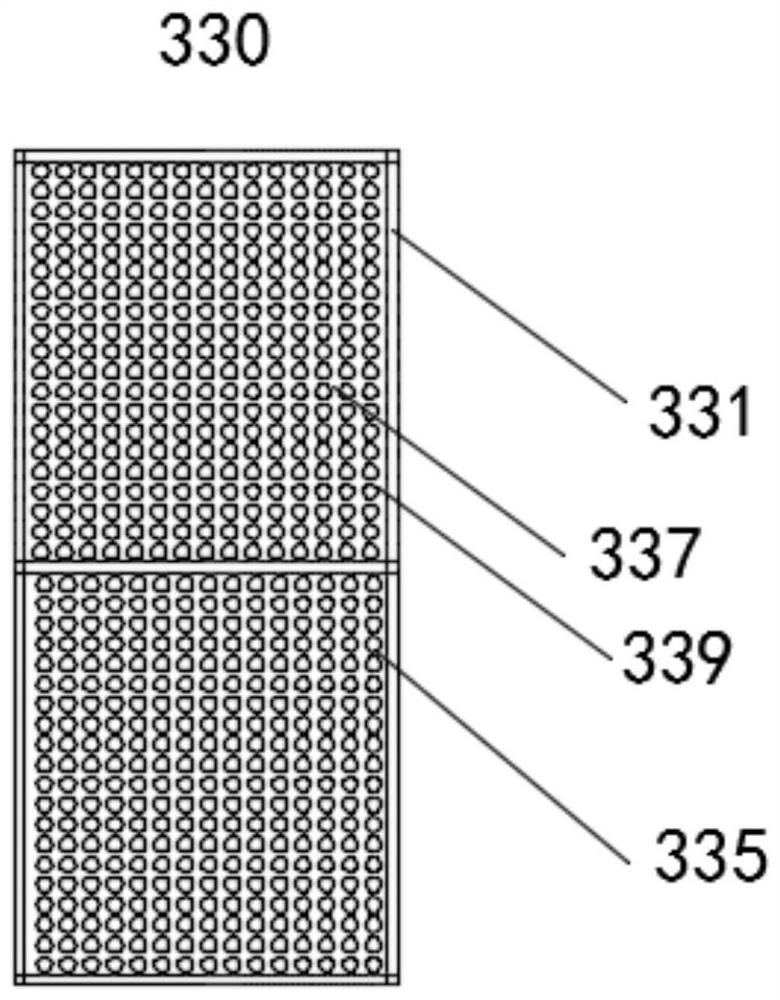

[0055] see image 3 , a paddle type adsorption air dryer provided in the second embodiment of the present invention is different from the first embodiment in that in the second embodiment, the paddle 330 includes an outer frame 331, a first porous plate 337 , the second porous plate 339 and the adsorption material 335 . One frame of the outer frame 331 is connected to the crankshaft 310, and is arranged on the outer circumferential surface of the crankshaft 310, and the connection method can be a fixed connection or a detachable connection. The first porous plate 337 and the second porous plate 339 are disposed in the outer frame 331 opposite to each other, and there is a certain distance between the first porous plate 337 and the second porous plate 339 . The first porous plate 337 and the second porous plate 339 can be connected to the outer frame 331 in a fixed connection or a detachable connection. The materials of the outer frame 331 , the first porous plate 337 and the...

no. 3 example

[0059] The third embodiment of the present invention provides a paddle type adsorption air dryer system. The paddle type adsorption air dryer system includes any paddle type adsorption air dryer in the first embodiment or the second embodiment, and also includes a heating device, an air supply device, a water treatment device, a dry air receiving and processing device, and a humid heat Wind receiving and processing equipment. Wherein the heating device is connected with the air inlet 151 of the upper air passage, and is used for collecting and preparing hot air and blowing the hot air into the upper air passage 150 . The air supply device is connected with the air inlet 173 of the lower air passage, and is used for collecting and preparing humid air and blowing the humid air into the lower air passage 170 . The water treatment device is connected to the drain pipe 500 for collecting and treating the water discharged from the drain pipe 500 . The dry air receiving and process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com