Solar battery laser back electrode window opening end point judging method

A technology for solar cell and endpoint judgment, applied in the field of solar cells, can solve the problem that the laser back electrode window opening process is difficult to be directly applied to large-scale battery production, the laser back electrode window window opening process is difficult, and the cell surface layer silicon lattice structure. Damage and other problems, to achieve the effect of simple and easy-to-operate, shortened detection time and low cost of window end point judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0027] The method for judging the end point of window opening of the solar cell laser back electrode window in the embodiment of the present invention includes the following steps:

[0028] Step 1. Select a cell from the same batch of cells as a sample sample. A back passivation layer with a uniform thickness is deposited on the back of the cell sample. In this example, the back passivation layer is a silicon nitride layer.

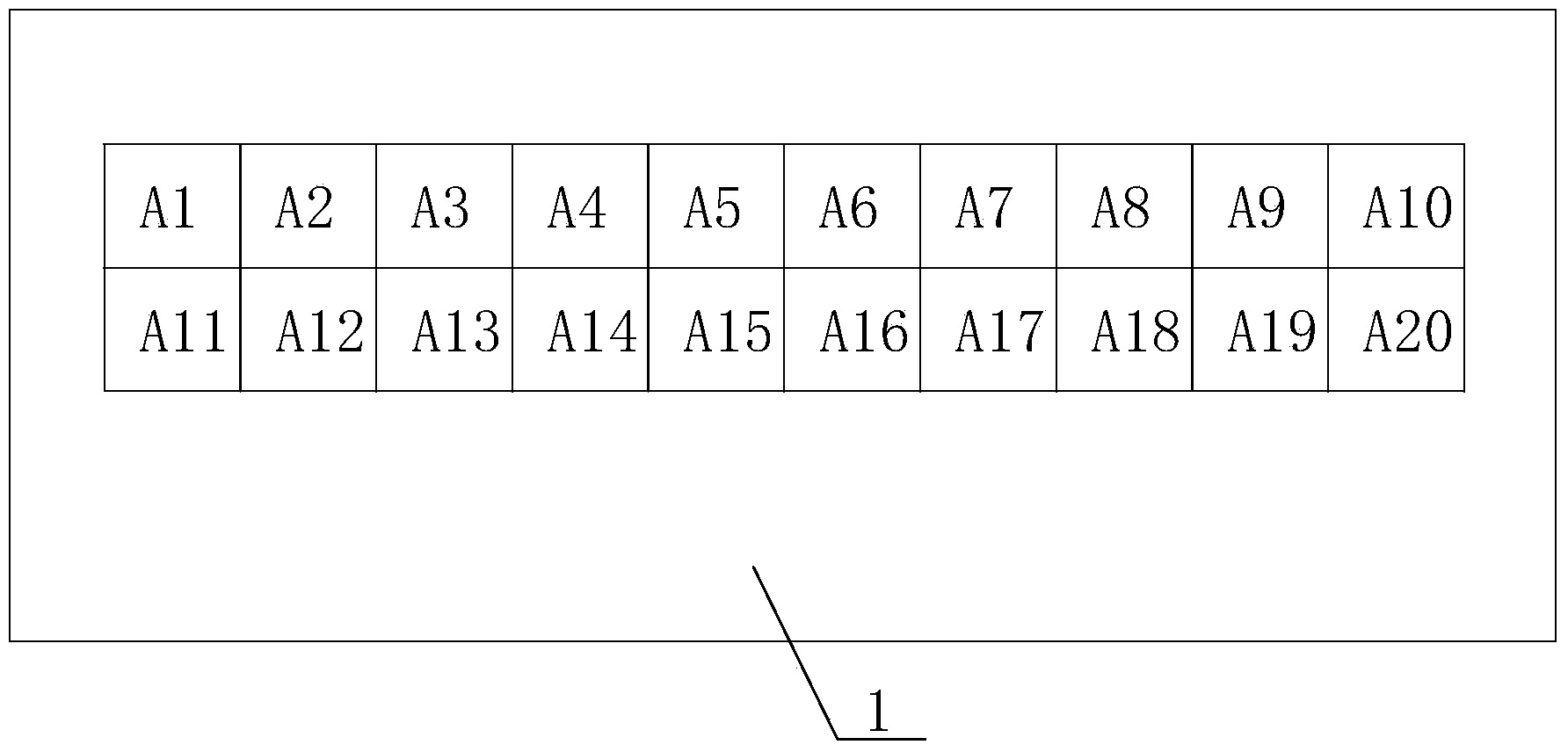

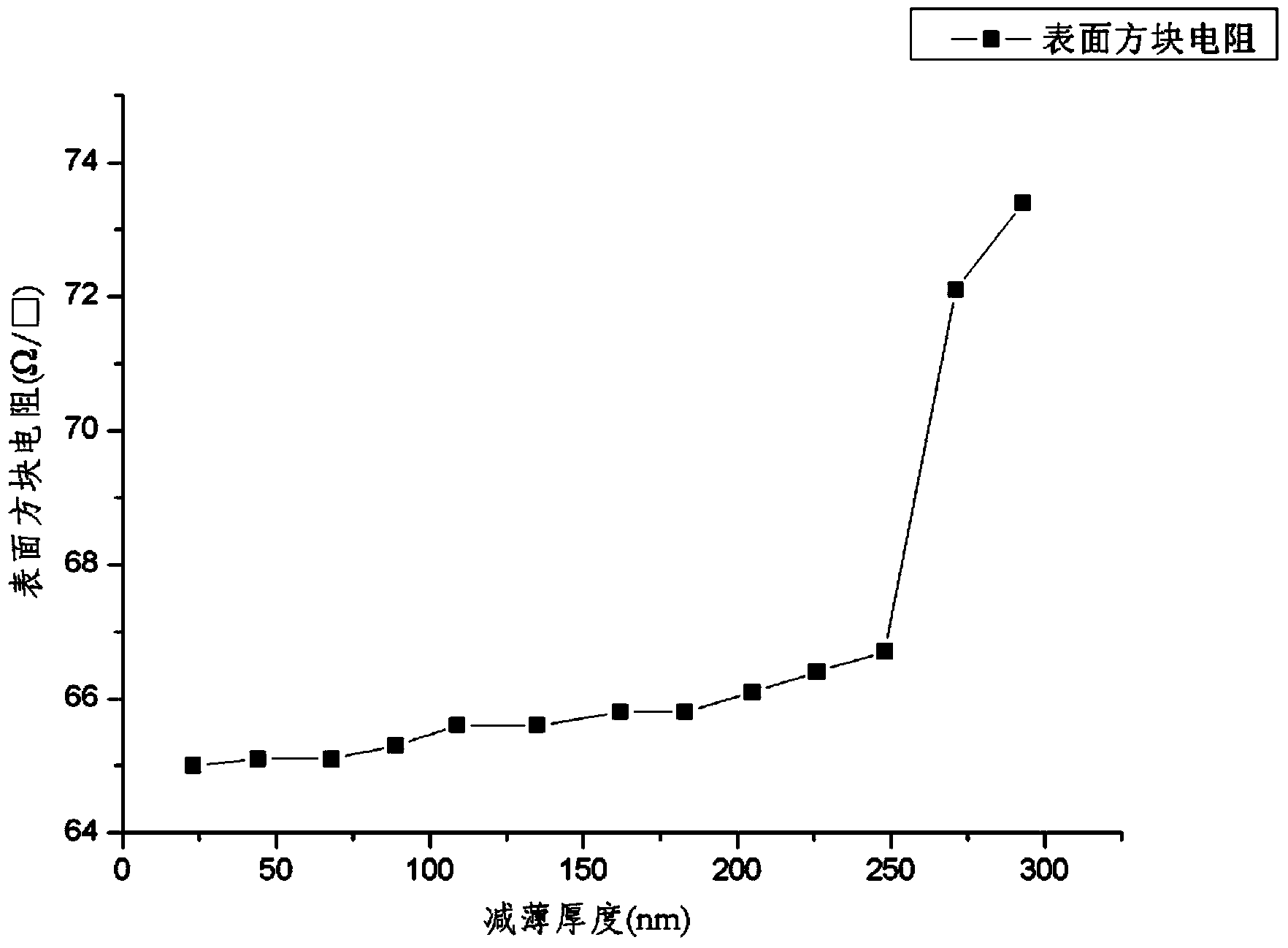

[0029] Step 2. In an oxygen-free environment, use a pulsed laser with the same wavelength and pulse frequency to etch the back of the cell sample 20 times. The area of the first etching is 20*100mm 2 , the second etching area is 19*100mm 2 , and so on, the area of the 10th etching is 100mm 2 , the area of the second etching is within the area of the first etching, the area of the third etching is within the are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com