A kind of purification method of electronic grade octamethylcyclotetrasiloxane

A technology of octamethylcyclotetrasiloxane and hexamethylcyclotetrasiloxane, which is applied in the field of purification of electronic grade octamethylcyclotetrasiloxane, can solve problems such as eliminating uncleanness, and achieve a simple and convenient method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1 ton of octamethylcyclotetrasiloxane with a content of 99% (weight) enters the light removal tower of the electronic grade silane refining system through a silane compressor. The number of theoretical plates is 50. 0.03Mpa, the temperature at the bottom of the tower is heated by a temperature program until the temperature of the fraction received at the top of the tower is 96°C, which is mainly isolated hexamethylcyclotrisiloxane (D3) after detection. When the distillate volume becomes smaller and smaller until it does not come out, the temperature at the top of the tower begins to rise, and there is no D3 in the bottom component inspection.

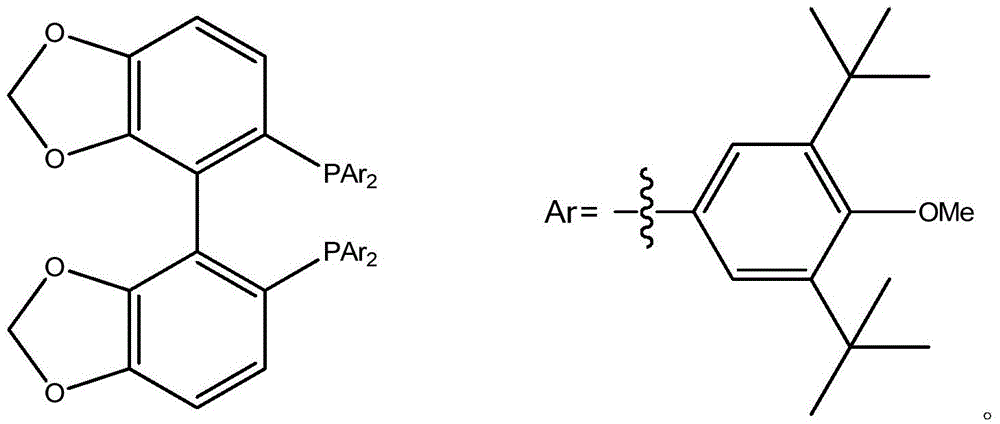

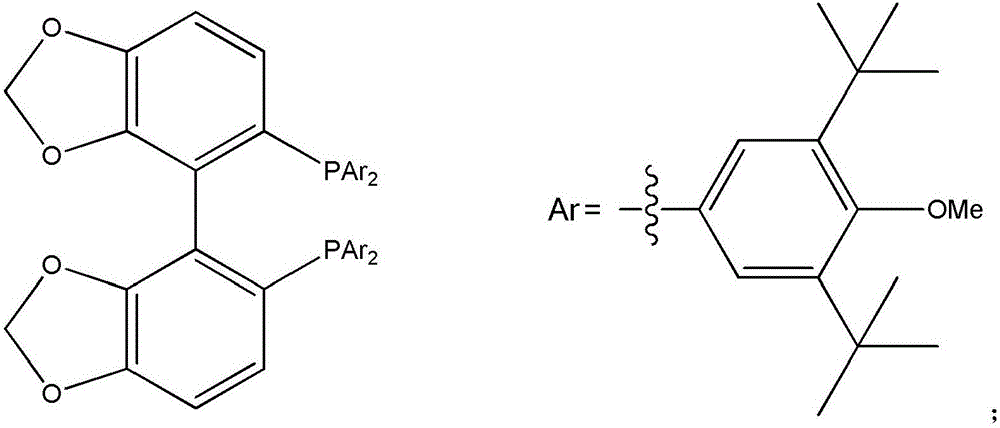

[0019] The octamethylcyclotetrasiloxane that has been removed from D3 flows from the bottom of the tower into the reaction kettle of the de-heavy rectification tower, and the de-light tower restarts the next batch of rectification. Add 0.5kg of the high-efficiency ligand shown above to the reactor, heat to 100°C, react for 5 hour...

Embodiment 2

[0023] The octamethylcyclotetrasiloxane with a content of 99% (weight) enters the light removal tower of the electronic grade silane refining system through the silane compressor. The number of theoretical plates is 50. The light removal tower is operated under reduced pressure, and the pressure is maintained at 0.03Mpa , the temperature at the bottom of the tower was heated by a temperature program until the temperature of the fraction received at the top of the tower was 96°C. It was detected that it was mainly separated hexamethylcyclotrisiloxane (D3). When the distillate volume becomes smaller and smaller until it does not come out, the temperature at the top of the tower begins to rise, and there is no D3 in the bottom component inspection.

[0024] The octamethylcyclotetrasiloxane that has been removed from D3 flows from the bottom of the tower into the reaction kettle of the de-heavy rectification tower, and the de-light tower restarts the next batch of rectification. A...

Embodiment 3

[0028] The octamethylcyclotetrasiloxane with a content of 99% (weight) enters the light removal tower of the electronic grade silane refining system through the silane compressor. The number of theoretical plates is 50. The light removal tower is operated under reduced pressure, and the pressure is maintained at 0.03Mpa , the temperature at the bottom of the tower was heated by a temperature program until the temperature of the fraction received at the top of the tower was 96°C. It was detected that it was mainly separated hexamethylcyclotrisiloxane (D3). When the distillate volume becomes smaller and smaller until it does not come out, the temperature at the top of the tower begins to rise, and there is no D3 in the bottom component inspection.

[0029] The octamethylcyclotetrasiloxane that has been removed from D3 flows from the bottom of the tower into the reaction kettle of the de-heavy rectification tower, and the de-light tower restarts the next batch of rectification. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com