Patents

Literature

68 results about "Natural recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Natural recovery refers to a situation where an individual is able to escape their alcohol or drug dependence without the benefit of any type of treatment. The individual just arrives at a point in their life where they feel able to quit.

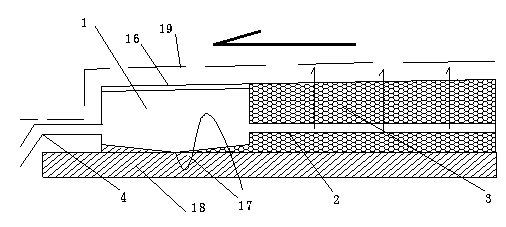

Water eco-environment protection method based on water plant harvesting

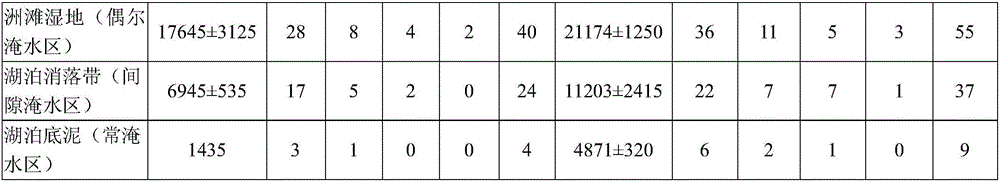

InactiveCN102491522AAvoid overgrowthPrevent algal bloomsSustainable biological treatmentBiological water/sewage treatmentPropaguleEutrophication

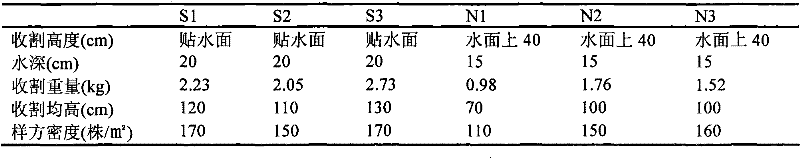

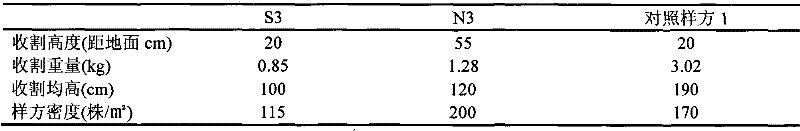

A water eco-environment protection method based on water plant harvesting. The invention relates to a water eco-environment protection method, which is characterized in that water plants are cultivated in a water body or naturally recovered water plants are utilized; nitrogen and phosphorous nutrients are absorbed by water plant growth; the water plants are harvested in growth period by manual work or waterweed harvesting equipment so as to promote the regrowth of the water plants; harvesting is carried out for multiple times, ends in the growth period and is carried out for the last time after the water plants grow seeds or vegetative propagule so as to extract the nitrogen and phosphorus nutrients from water in the form of water plant residues. The invention aims to maximize the accumulated biomass of the water plants during the whole growth period or optimize the water quality purifying effect and simultaneously remove nutrients in the water body and deposits, alleviate the eutrophication process of the water body and prevent the water plants from decaying and polluting the water body once again. The method provided by the invention is suitable for daily ecological maintenance of shallow lakes, urban landscape water, slow flow rivers, small reservoirs, wetlands and ponds.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI +1

Pressure-equalizing and bleeding method for injecting furnace roof tank coal gas by using high-pressure gas

InactiveCN102864257AAvoid pollutionAvoid wastingBlast furnace componentsBlast furnace detailsNatural recoveryHigh pressure

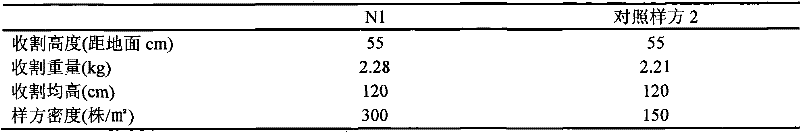

The invention discloses a pressure-equalizing and bleeding method for injecting furnace roof tank coal gas by using high-pressure gas, which comprises the following steps: when pressure equalization is performed at the roof of a blast furnace, if primary pressure equalization can not meet the requirements, further opening a secondary pressurization valve, and performing secondary pressure equalization on a weighing tank with nitrogen gas; when bleeding is performed at the roof of the blast furnace, opening a pressure-equalizing and bleeding valve, a bag-type dust remover valve and a natural recovery valve; performing preliminary dust removal on coal gas in the weighing tank with a cyclone dust remover, and then performing fine dust removal with a bag-type dust remover; when the pressure of the coal gas in the weighing tank is lowered to a preset value, closing the natural recovery valve, opening a forced recovery valve and a working gas valve, and introducing high-pressure cleaning gas into an injector; and under the injection effect of the high-pressure cleaning gas, enabling the remaining coal gas in the weighing tank to quickly move into a clean coal gas pipe network, thus realizing the bleeding and recovery of the coal gas in the weighing tank. By introducing the facilities such as the bag-type dust remover, the injector and the like, the invention can prevent the pressure-equalized coal gas from being directly exhausted to the atmosphere, thereby reducing environmental pollution and waste of resources.

Owner:WISDRI ENG & RES INC LTD

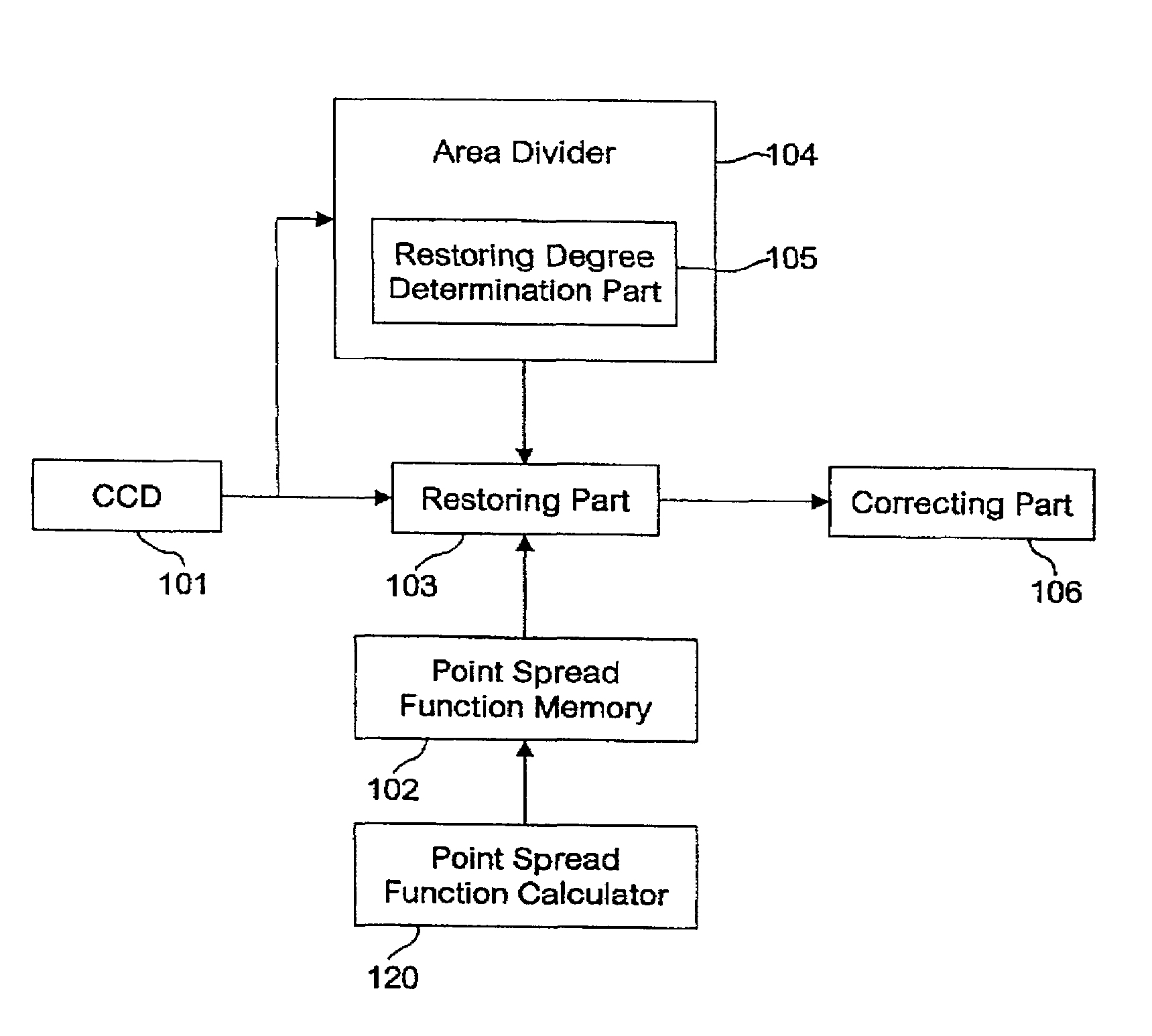

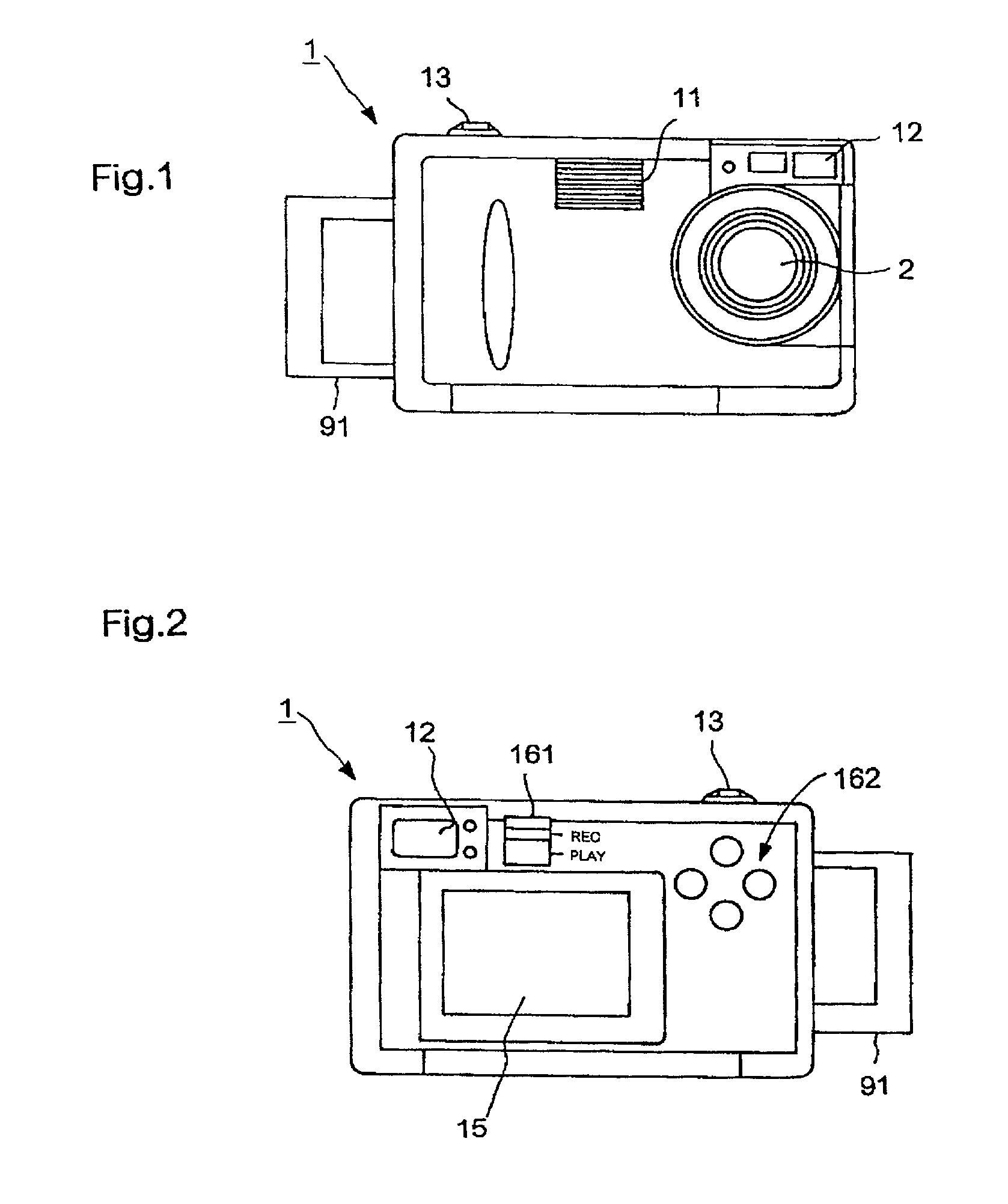

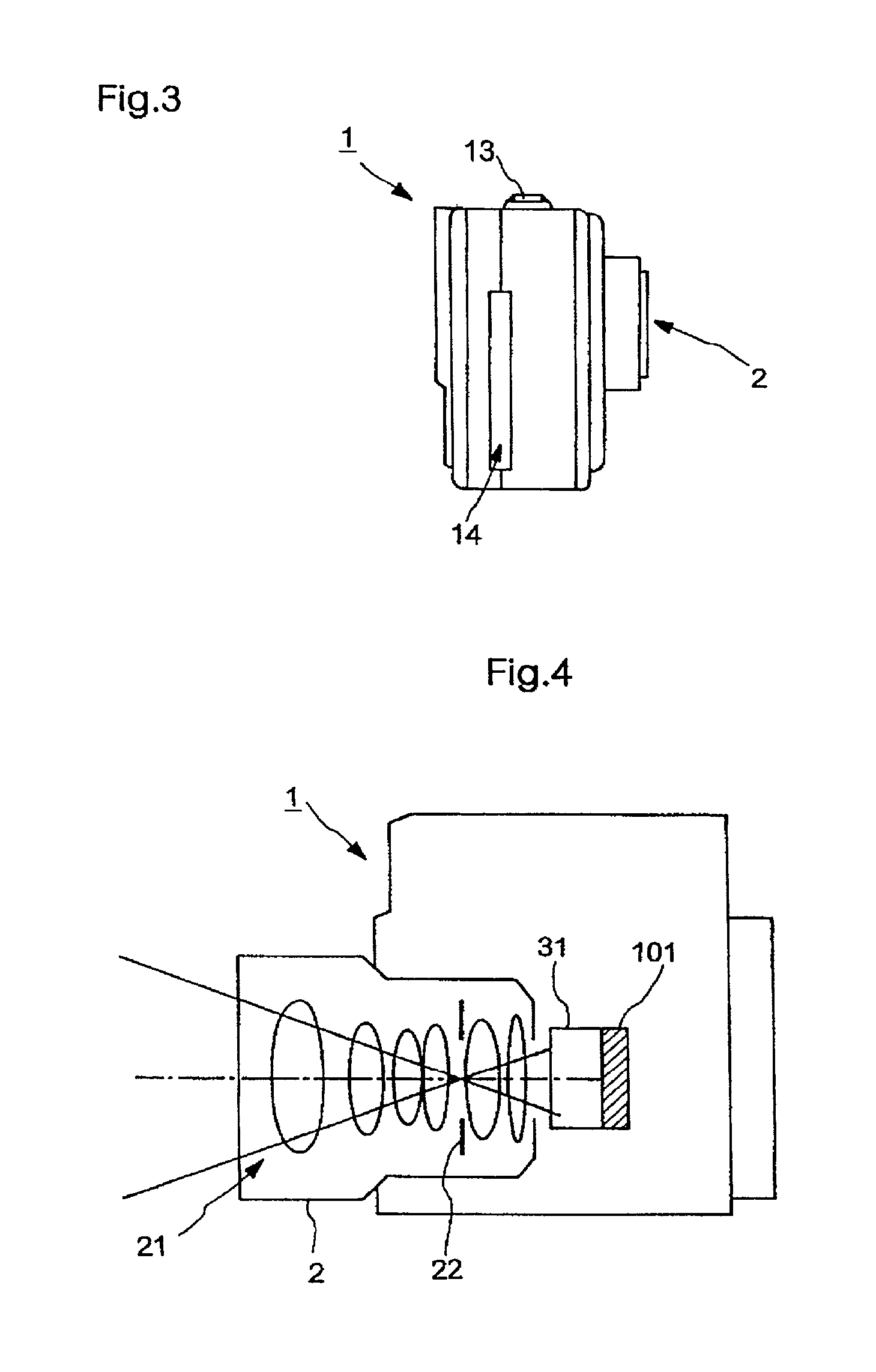

Apparatus, method, program and recording medium for image restoration

InactiveUS7190395B2Suppress noiseDiscontinuity on borderImage enhancementTelevision system detailsComputer graphics (images)Natural recovery

An image of which restoration degree is determined based on the difference between each pixel and a neighboring pixel of the pixel in a light receiving element array 101 is divided into a plurality of areas based on the determined restoration degree, and the areas of the image are each restored in accordance with the determined restoration degree. By doing this, not only ringing and noise enhancement can effectively be suppressed but also the border between the areas which is conspicuous when the image is divided into two kinds of areas becomes less conspicuous, so that a natural restored image can be obtained.

Owner:MINOLTA CO LTD

Treating method for improving g strength and toughness of magnesium alloy materials

The invention discloses a treating method for improving strength and toughness of magnesium alloy materials. The treating method for improving the strength and the toughness of the magnesium alloy materials comprises solution treatment and aging treatment, and further comprises subzero treatment after the aging treatment and ultrasonic filed shock treatment in the process of the subzero treatment. The process of the subzero treatment comprises the steps of cooling the magnesium alloy materials to ultralow temperature at minus 196DEG C from the starting room temperature at the cooling speed 1-10DEG C / min, and holding the temperature for 12-30 hours. Preferably, the ultrasonic filed shock treatment is carried out at the late period of the subzero treatment, the intensity of an ultrasonic field is 1-50Kw / m2, the frequency of the ultrasonic field is 10-40KHz, and the treating time in the ultrasonic field is 60-200 seconds. The magnesium alloy materials after the subzero treatment and the ultrasonic field shock treatment are put into an oven which is 170DEG C at temperature, the holding time is 2-6 hours, and then the magnesium alloy materials in the oven are put in air to recover to the room temperature naturally. The treating method for improving the strength and the toughness of the magnesium alloy materials enables the magnesium alloy materials to be compact in structure and high in hardness and roughness.

Owner:CHANGZHOU RUNYUAN WARP KNITTING MACHINERY

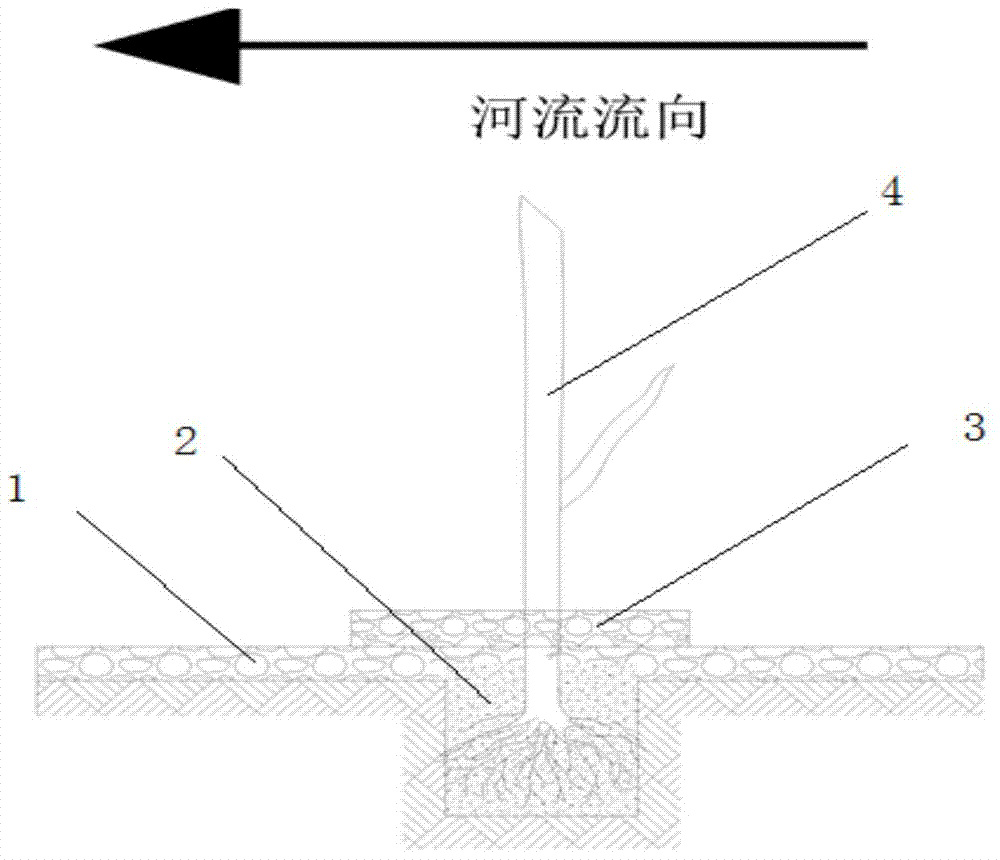

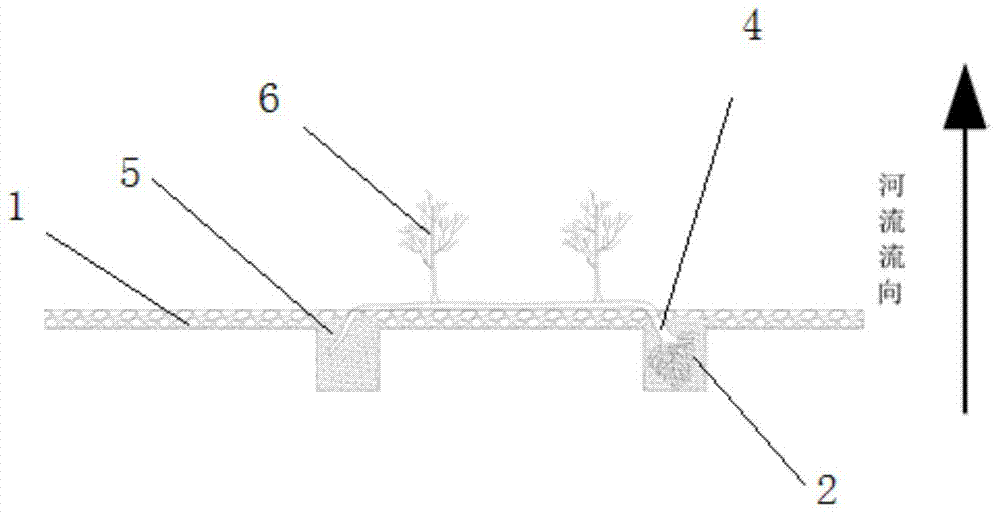

Method for planting river bank water-land ecotone vegetation

The invention relates to the technical field of river bank greening, in particular to a method for planting river bank water-land ecotone vegetation. According to the method, the two ends of each planted plant are pressed and buried, vertical hole planting is adopted, in this way, the impact function of a flood on the plants is greatly reduced, the risk that tree trunks are broken is reduced, and therefore the survival rate of the water-land gravel ecotone vegetation is improved; the transversely planted plants have the function of intercepting floating objects and retaining silt, the scouring of water flow on herb between every two planting holes is reduced, and therefore natural recovery and growth of the gravel ecotone vegetation are promoted; in a flood season, the plants can absorb many harmful elements in water, so that pollution is eliminated, water is purified, the quality of a water body is improved, and the ecological function of the water body is recovered; after the vegetation grows up, the water-land ecotone has certain ornamental value even in a dry season.

Owner:BEIJING FORESTRY UNIVERSITY

Low cover degree sand stabilizing method

InactiveCN101705679AGive full play to the advantages of side travelBroaden the formation processHorticultureSoil preservationNatural recoveryEngineering

The invention provides a low cover degree sand stabilizing method, comprising the steps of planting one row to four rows of arbor and / or bush and / or subshrub in parallel to form a sand stabilizing forest shelter belt, and reserving a vegetation natural restoration belt between the forest shelter belts; and the forest shelter belts play roles of biological barrier for stabilizing sand, protection the stabilization of sand surface and promoting natural restoration of vegetation in the vegetation natural recovering belt, wherein the cover area of the arbor and the bush is 15-25 percent and the cover area of the vegetation natural restoration belt is 75-85 percent. By adopting a row-belt sand stabilizing mode, when the cover degree is 15-25 percent, the effect of stand stabilizing forests distributed in a row-belt mode for reducing the wind speed is 25-50 percent higher than that of the stand stabilizing forests an evenly-distributed and randomly-distributed mode for reducing the wind speed, the border-row advantages of forests can be fully exerted; and after the sand surface is stabilized, wide enough interband is beneficial to the infiltration of rainfall and natural recovery of the vegetation, and forms complex sand stabilizing vegetation for promoting natural recovery at zonality vegetation occupying 85-75 percent of land under the protection of forest belt occupying 15-25 percent of the land.

Owner:RES INST OF FORESTRY NEW TECH CHINESE ACAD OF FORESTRY

Method for recovering cold temperate zone forest wetland vegetation after extremely severe fire

InactiveCN103703972AAvoid reverse successionImprove stabilityHorticultureSoil-working methodsRevegetationSelf maintenance

The invention relates to a method for recovering cold temperate zone forest wetland vegetation after extremely severe fire. The method mainly comprises the steps of recovery border determination, field cleaning, tree species selection, seedling planting configuration, soil preparation, seedling planting, tending management and the like. The method for recovering the cold temperate zone forest wetland vegetation after the extremely severe fire aims at solving the problems that spontaneous recovery time is long and retrogressive succession is caused after cold temperate zone ecologically vulnerable area forest wetland severe degeneration, and can recover the vegetation as soon as possible, build an optimized wetland vegetation community structure, effectively improve stability and self maintenance of the degenerated forest wetland, achieve positive succession development, and rapidly recover ecosystem functions.

Owner:大兴安岭林业集团公司农业林业科学研究院

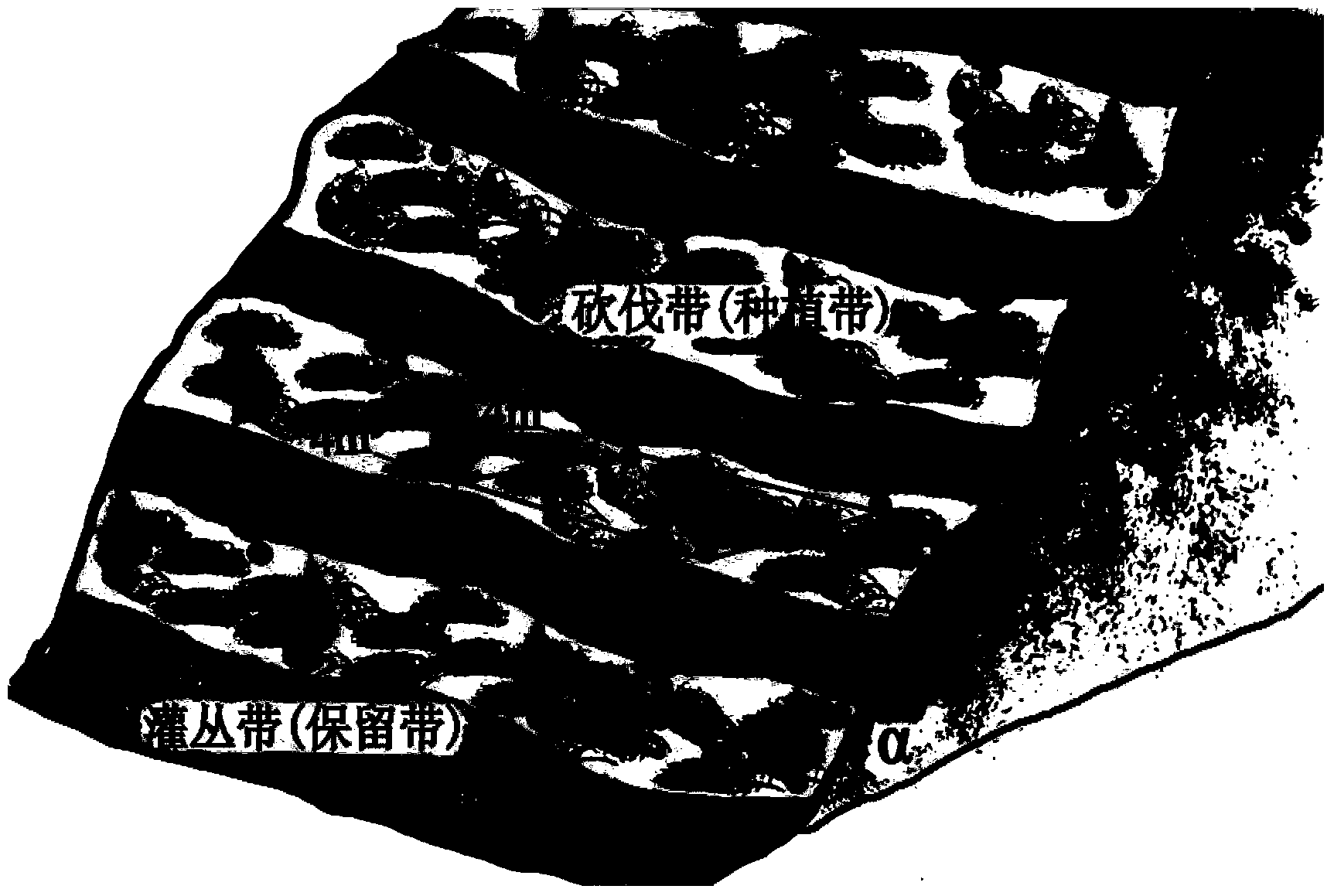

Technical method for recovering and reconstructing ecological public welfare forest of mountain area and sloping land

InactiveCN103404405AReduce management costsReduce the cost of afforestationClimate change adaptationAfforestationHectareNatural recovery

The invention relates to a technical method for recovering and reconstructing an ecological public welfare forest in combination of natural recovering update and manual afforestation based on countryside diversity and local conservation of resources thereof. The technical method comprises the following steps that afforestation is carried out in planting areas in a sloping scrub according to the scheme of staggered arrangement of planting areas and retaining areas along contours, the planting areas play the role of promoting growth of target tree species, and retaining areas bring the local conservation of countryside biological diversity into play. Generally, in the slope of 15-25 degrees, the felling width of each planting area is usually designed to be 2.0-5m, and each scrub area with the width of 1.5-3m is retained. The initial afforestation density is controlled to be 1500-2100 trees per hectare, when a slope is relatively small (5-15 degrees), the initial afforestation density can be increased to 2300 trees per hectare, and the maximum afforestation density is not over 2500 trees per hectare. The technical method is carried out by utilizing the afforestation method of common pit planting, a planting pit is as deep as 40-50cm, the diameter of a pit surface is 30-40cm, and the pits are horizontally arranged or in a triangular shape.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

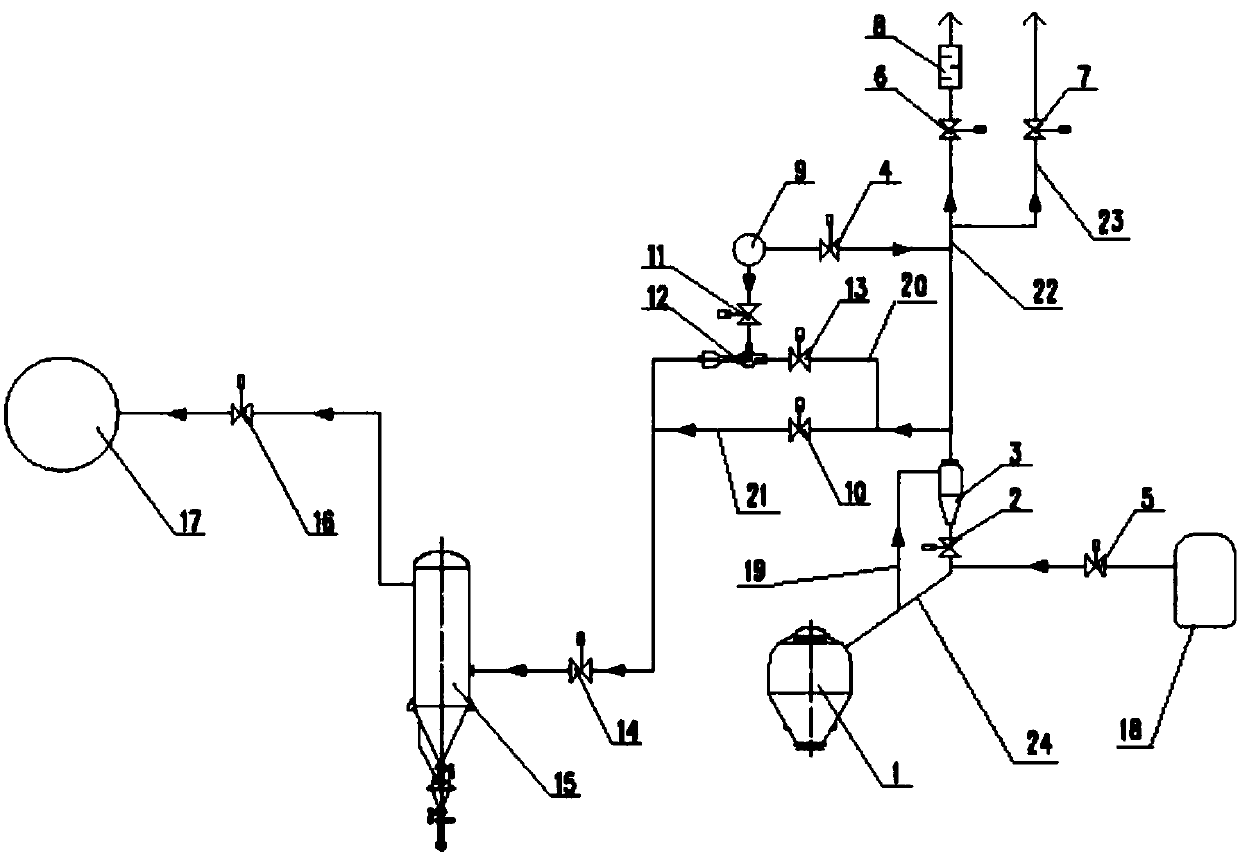

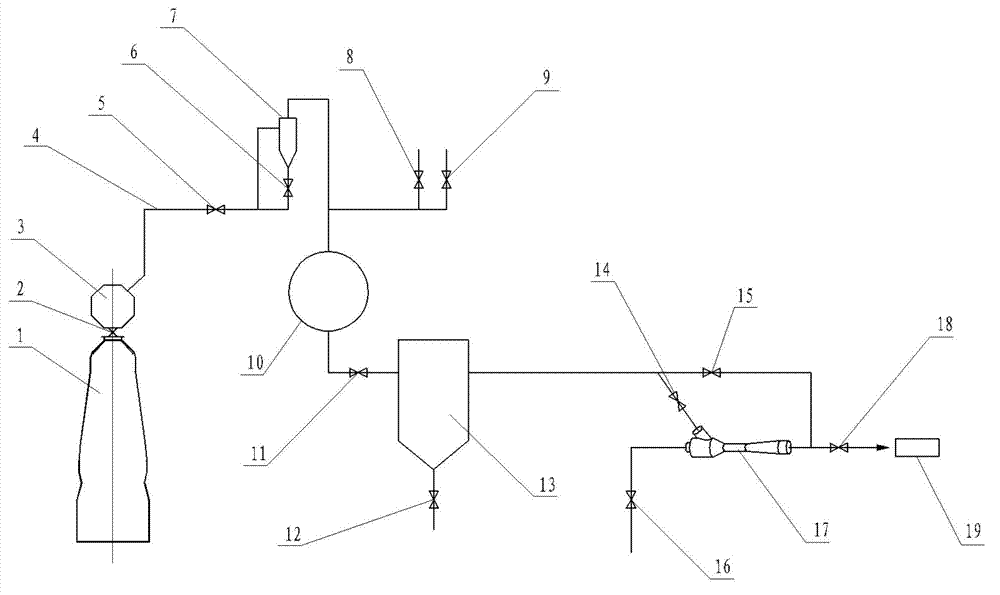

Complete recovery system and method for iso-pressure blow-off gas at blast furnace top

The invention discloses a complete recovery system for iso-pressure blow-off gas at blast furnace top. The complete recovery system comprises a furnace top charging bucket of a blast furnace, a cyclone dust collector, an ejector and a bag-type dust collector, wherein the furnace top charging bucket is communicated with the cyclone dust collector through a first pipe; an outlet of the first pipe iscommunicated with an inlet of a three-way joint; a first outlet of the three-way joint is communicated with a second pipe; the ejector and a forced recovery valve are arranged on the second pipe; anoutlet of the ejector is communicated with an inlet of the bag-type dust collector; an outlet of the bag-type dust collector is communicated with a purified gas pipe network; a natural recovery valveis arranged on a third pipe, and an outlet of the third pipe is communicated with an inlet valve of the bag-type dust collector; a second outlet of the three-way joint is communicated with a fourth pipe. The invention further discloses a complete recovery method for the iso-pressure blow-off gas at the blast furnace top. The complete recovery system and method for the iso-pressure blow-off gas atthe blast furnace top have the following beneficial effects: two recovery measures are taken correspondingly according to the change of pressure in the furnace top charging bucket, environmental pollution and resource waste caused by direct blow-off of iso-pressure gas into the atmosphere are avoided, and the requirements for energy saving, emission reduction and environmental production are met.

Owner:WISDRI ENG & RES INC LTD

Preparation method and use method of biologically degradable shape memory tubular support stent

The invention discloses a preparation method and a use method of biologically degradable shape memory tubular support stent, wherein the steps of the preparation method comprises physical blending technology, in which the vitrification point of at least one component is below 37 DEG C and that of at least one component is beyond 37 DEG C, or chemical copolymerizing technology, in which two monomers are chemically polymerized to form degradable shape memory high polymer material composed of chain segment 1 and chain segment 2; the vitrification point of the chain segment 1 is below 37 DEG C; and the vitrification point of the chain segment 2 is beyond 37 DEG C; according to FOX formulation, the mass ratio of each polymer in physical blending technology is calculated, and the mass ratio of two monomers in chemical blending technology is also calculated, thereby ensuring that the prepared stent can recover to memorized shape at 37 DEG C of body temperature; therefore, the stent can recover to memorized shape naturally without external heating if the stent is implanted into human body; the stent is featured with convenient operation, high compliance of patients, easy preparation, no toxic matter introduced, high biocompatibility and safety.

Owner:SOUTHWEST JIAOTONG UNIV

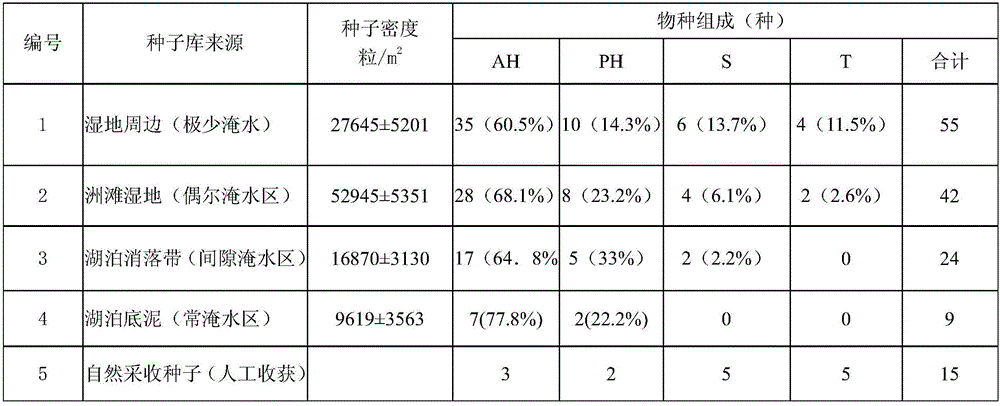

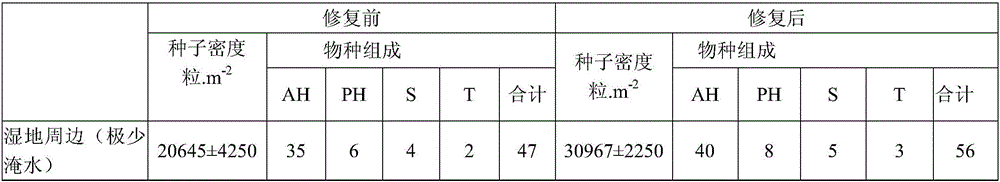

Method for restoring degraded wetland vegetation by improved wetland soil seed banks

InactiveCN105993260AHigh retention ratePromote recoveryInvasive species monitoringSoil-working methodsRevegetationWetland soils

The invention discloses a method for restoring degraded wetland vegetation by improved wetland soil seed banks. The method comprises the following steps: 1) according to a principle of adjusting measures to local conditions, selecting a soil seed bank from natural wetland seed banks, wherein the seed density of the seed bank is not less than 5000 grains.m<-2>; 2) mixing soil seed banks with different sources, or adding naturally harvested seeds; 3) preparing a biological rhzomorph; 4) adding the biological rhzomorph obtained in the step 3) to obtain an improved soil seed bank; and 5) covering improved seed bank soil on a wetland with degraded vegetation by adopting an exotic soil method, thereby forming vegetation by natural germination. The method for restoring the degraded wetland by using the soil seed banks, disclosed by the invention, has the following advantages: 1) materials are easy to obtain, the cost is low, and the operation is simple and feasible; 2) a wetland succession law is followed, the degraded wetland vegetation is restored quickly and naturally, and the invasion of alien species is controlled; and 3) multiple species coexist, the structure is stable and can realize self-renewal, and ecological landscapes are rich.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Method for producing general-purpose hot melt adhesive

InactiveCN102190985AHigh bonding strengthGood flexibilityMonocarboxylic acid ester polymer adhesivesMolten stateCross-link

The invention discloses a method for producing a general-purpose hot melt adhesive. A product to be produced is an ethylene-vinylacetate copolymer hot melt agent, a working principle of which is different from that of other types of adhesives; the hot melt adhesive is not cross-linked when bonded, is solidified without dependence on volatilization of a glue solvent, and restores to a solid-state naturally from a heating molten state via a cooling process. Thus, the bonding effect of the hot melt adhesive is realized based on the good wetting property of the hot melt adhesive to a bonding surface in the molten state, and the bonding strength generated in a cooling solidified state. The hot melt adhesive is mainly applied to corrosion-resistant coating for wireless binding of books, packages, furniture side sealing, assembly of automobiles and household appliances, shoemaking, carpet coatings and metal products. The hot melt adhesive comprises the following main components: 40 percent of ethylene-vinylacetate copolymer resin, terpene resin, paraffin wax, calcium carbonate, barium sulfate, titanium dioxide and barium stearate.

Owner:张耀华

Treating method for improving strength and toughness of aluminum alloy materials

The invention discloses a treating method for improving strength and toughness of aluminum alloy materials. The treating method for improving the strength and the toughness of the aluminum alloy materials comprises solution treatment and aging treatment, and further comprises subzero treatment after the aging treatment and ultrasonic filed shock treatment in the process of the subzero treatment. The process of the subzero treatment comprises the steps of cooling the aluminum alloy materials to ultralow temperature at minus 196DEG C from the starting room temperature at the cooling speed 1-10DEG C / min, and holding the temperature for 12-30 hours. Preferably, the ultrasonic filed shock treatment is carried out at the late period of the subzero treatment, the intensity of an ultrasonic field is 1-50Kw / m2, the frequency of the ultrasonic field is 10-40KHZ, and the treating time in the ultrasonic field is 60-200 seconds. The aluminum alloy materials after the subzero treatment and the ultrasonic field shock treatment are put into an oven which is 110DEG C in temperature, the holding time is 2-6 hours, and then the aluminum alloy materials in the oven are put in air to recover to the room temperature naturally. According to the treating method for improving the strength and the toughness of the aluminum alloy materials, the aluminum alloy materials are made to be compact in structure and small in residual stress, and the roughness is synchronously improved to a large extent.

Owner:CHANGZHOU RUNYUAN WARP KNITTING MACHINERY

Method for deep cooling extruded magnesium-zinc magnesium alloy

A method for deep cooling an extruded magnesium-zinc magnesium alloy is provided, and comprises the following steps of: putting the extruded magnesium-zinc magnesium alloy into low-temperature liquid nitrogen or low-temperature helium gas at the temperature of 43 K to 243 K for deep cooling, wherein the deep cooling time is longer than or equal to 2 h; and after deep cooling, taking out the magnesium alloy, and recovering naturally to room temperature. The magnesium-zinc magnesium alloy is an Mg-Zn-X ternary alloy, wherein X is aluminum, lanthanum, cerium, praseodymium, neodymium, promethium, samarium, europium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, ytterbium or lutetium. The method has the advantages of simple process, convenient operation and low production cost, has great improvement of abrasion resistance, and enables abrasion rate to be reduced by at least more than 30%; and the method is suitable for the industrializing-scale improvement of the abrasion resistance of the magnesium alloy.

Owner:NANCHANG UNIV

Method for carrying out enhancement processing on intensity and toughness of light alloy material

The invention discloses a method for carrying out enhancement processing on intensity and toughness of a light alloy material. The method comprises solution treatment and aging treatment which are carried out on the light alloy material. The method further comprises subzero treatment carried out after aging treatment and ultrasonic field impact treatment in the subzero treatment process. The subzero treatment process comprises the steps of cooling light alloy to minus 196 DEG C from the room temperature at a cooling speed of 1 to 10 DEG C per minute and carrying out heat preservation for 12 to 30 h. The ultrasonic field impact treatment is preferably carried out in the later period of the subzero treatment and has ultrasonic field intensity of 1 to 50 Kw / m<2>, sound field frequency of 10 to 40 KHZ and ultrasonic field processing time of 60 to 200 S. The light alloy subjected to subzero treatment and ultrasonic field impact treatment is placed into an oven with a temperature of 110 to 170 DEG C, is subjected to heat preservation for 2 to 6 h, then is placed in the air and is naturally recovered to the room temperature. The method can enable the light alloy material to have compact tissues and small residual stress and enable intensity and toughness of the light alloy material to be synchronously and greatly improved.

Owner:CHANGZHOU RUNYUAN WARP KNITTING MACHINERY

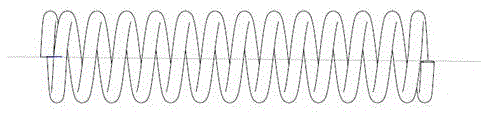

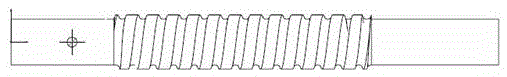

Nickel-titanium spring having high output force value ratio under high and low temperatures

InactiveCN105570362AIncreased high and low temperature output forceWound springsManufacturing technologyNatural recovery

The invention relates to a nickel-titanium spring having high output force value ratio under high and low temperatures. A manufacturing technology includes the steps that a nickel-titanium wire serves as a raw material and is subjected to drawing to form a wire with the diameter of 0.5-2 mm; the wire is wound on a core rod to form a spiral shape; after die release of the wire is conducted from the core rod, split shearing is conducted, and a spring in a preset shape is obtained; the spring is subjected to high-and-low-temperature training during which the spring is put into a low-temperature environment with the temperature ranging from minus 50 DEG C to minus 20 DEG C, the spring is fatigued and weakened, and specifically the shape of the compressed spring cannot recover; and the compressed spring is put into a high-temperature environment with the temperature ranging from 100 DEG C to 400 DEG C, heat insulation is conducted for 0.5-1 min, and the shape of the spring recovers naturally; the operation is repeated 50-100 times so that high-and-low-temperature training of the spring can be completed; and the nickel-titanium spring having the high output force value ratio is obtained. According to the nickel-titanium spring having the high output force value ratio under high and low temperatures, the output force value ratio of the nickel-titanium spring under the high and low temperatures is increased.

Owner:江阴佩尔科技有限公司

Pressure-equalizing bleeding device for ejecting furnace-top tank gas by high pressure gas

InactiveCN102864260AAvoid pollutionAvoid wastingBlast furnace componentsBlast furnace detailsDirect entryBaghouse

Owner:WISDRI ENG & RES INC LTD

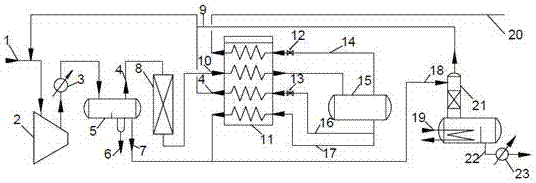

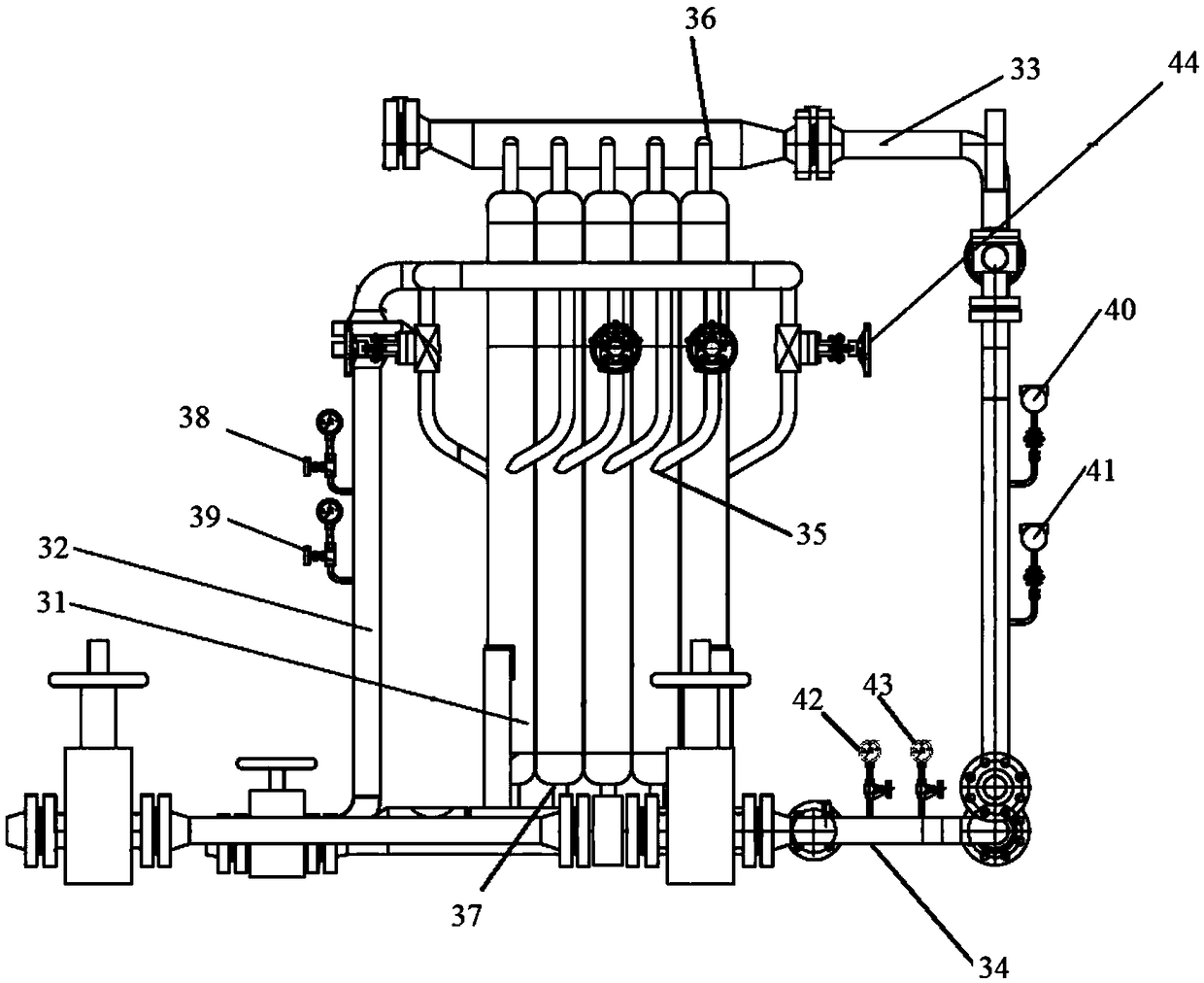

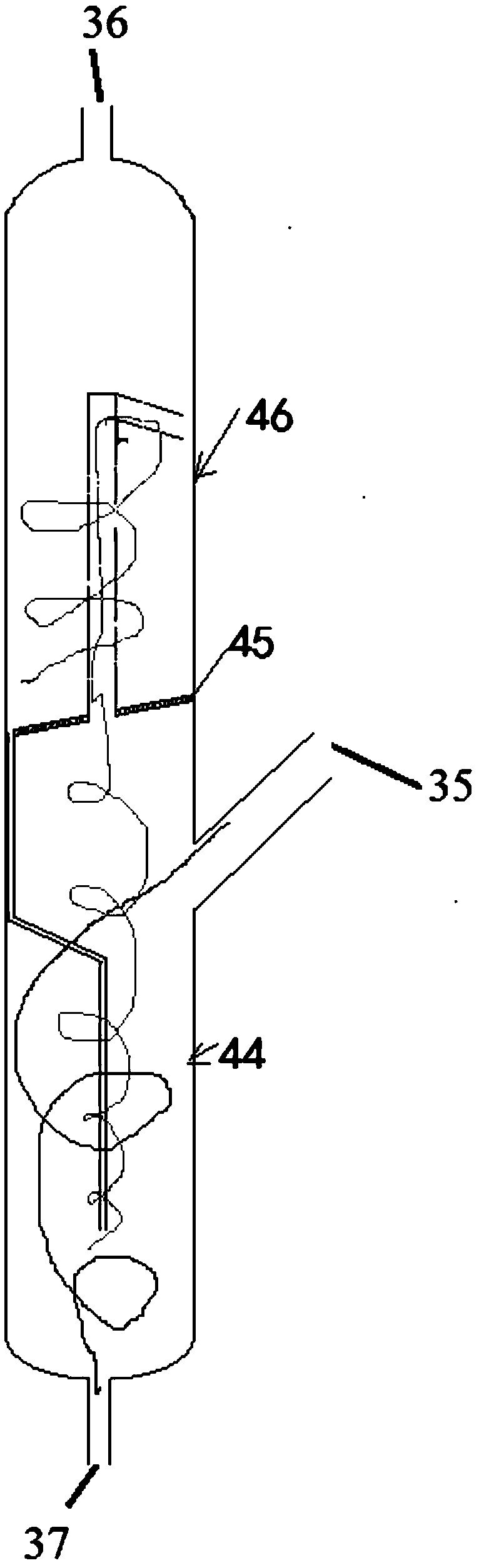

Simple natural gas liquid recovery system

InactiveCN107965970AEasy to separateImprove efficiencySolidificationLiquefactionMolecular sieveNatural recovery

The invention discloses a simple natural gas liquid recovery system, and belongs to the technical field of natural gas recovery. The simple natural gas liquid recovery system comprises a compressor, athree-phase separator, a molecular sieve, a cold box and a liquid stabilizer; the outlet end of the compressor is connected with a first cooler; the first cooler is connected with the three-phase separator; the gas outlet end of the three-phase separator is connected with the molecular sieve; the molecular sieve is connected with the cold box; the cold box is connected with a low temperature separator, the three-phase separator, the compressor and the liquid stabilizer; a finished natural gas output pipe is arranged on the cold box; and the liquid stabilizer is connected with a second cooler.Mixed light hydrocarbon in the recovery process is taken as a refrigerant for cooling natural gas, and a recovery technology is simplified. By improving the efficiency of separating oil, liquid and gas from a raw material, the recovery efficiency of natural gas liquid is improved, the water ratio of oil separated by a raw material separation device is low, and the water ratio of the gas separatedby the raw material separation device is low.

Owner:海盐派特普科技有限公司

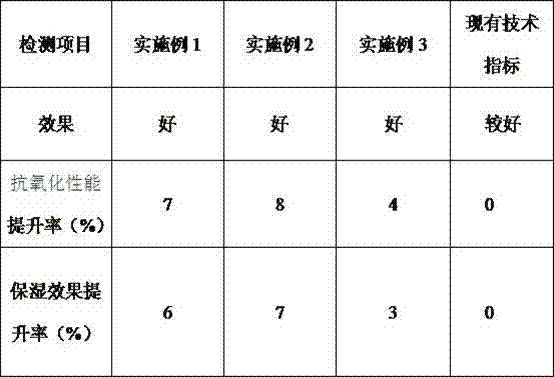

Active peptide stoste formula for natural recovery of skin

InactiveCN107320353ARelieve and repair discomfortHuge market potentialCosmetic preparationsToilet preparationsChemical compositionNatural recovery

The invention discloses an active peptide stoste formula for natural recovery of skin. The formula comprises essence and essence powder. Matters in the formula can interact with each other to form efficient moisturizing active peptide stoste, no any pigment and chemical component exist, the active peptide stoste formula is used for carrying out rapid repairing aiming at all levels, time periods and links of skin damage, the active peptide stoste formula is a natural moisturizing barrier which is used for moistening soft-texture skin, repairing fragile skin and strengthening the skin, and the active peptide stoste formula is capable of relieving and repairing discomfort to the skin caused by factors of environments and the like; by sustainably using the active peptide stoste formula, the skin which is carefully nursed can burst into smooth and bright radiance, the market potential is huge, and the prospect is wide.

Owner:广东轩源生物技术有限公司

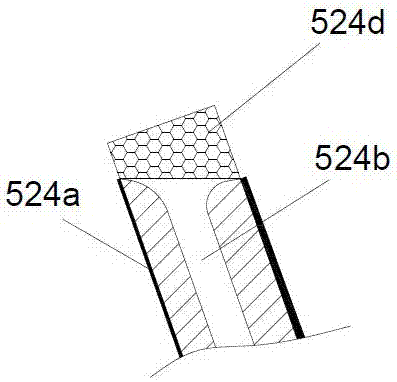

Ecological restoration method for performing warping on ecological bags in riparian water and land ecotone by using ecological bags

PendingCN109892133AHas the effect of blocking and anti-shockProtected SurvivalReceptacle cultivationBiological water/sewage treatmentRevegetationDry season

The invention relates to the technical field of riparian vegetation restoration and greening, in particular to an ecological restoration method for performing warping on ecological bags in a riparianwater and land ecotone by using the ecological bags. According to the ecological restoration method, the ecological bags have effects of blocking and scour prevention, can protect plants to survive inthe rainy season under the situation of water impact, and achieve the effect of ecological restoration; the ecological bags can also intercept silts brought by the partial water flow to achieve the effect of soil and water conservation; the ecological bags and the planted plants can play a warping role, thereby promoting natural restoration and growth of vegetations; the plants absorb many harmful elements in a water body in the flood season, thereby eliminating pollution, purifying the water quality, improving the quality of the water body, and restoring the ecological function of the waterbody; after the plants grow up, the water and land ecotone can also have good ornamental value in the dry season. The ecological restoration method has the advantages that the survival rate and preservation rate of vegetation planting in the water and land ecotone can be increased, and the method provided for the vegetation restoration of the water and land ecotone is simple and convenient, can beimplemented in a large area, and is low in cost.

Owner:BEIJING FORESTRY UNIVERSITY

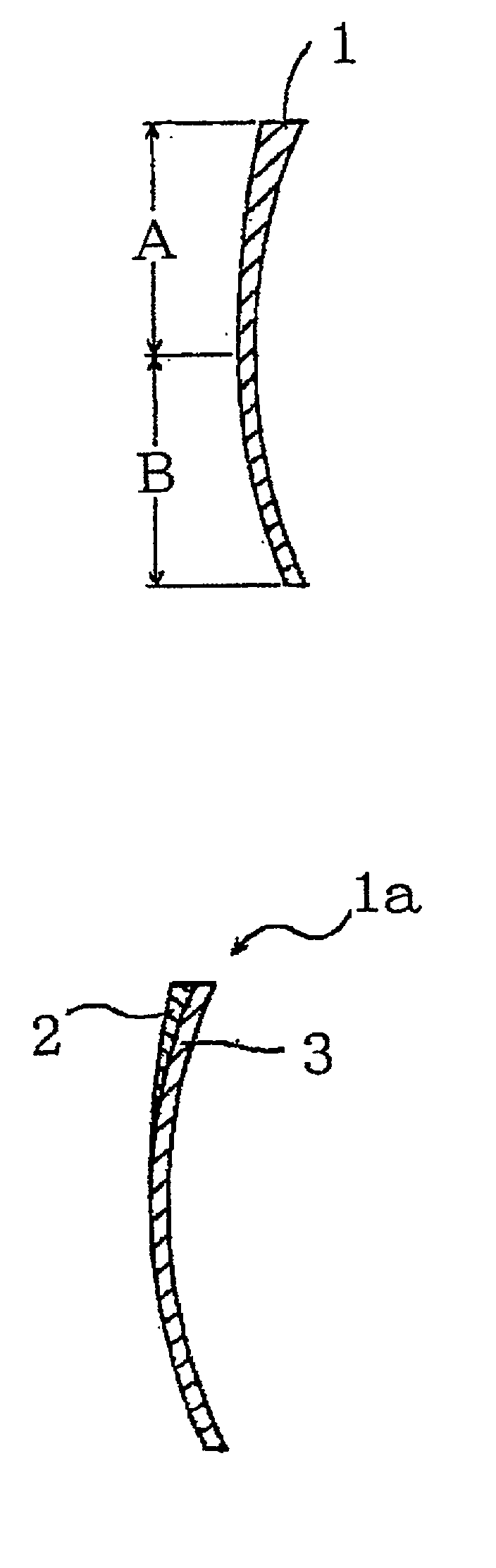

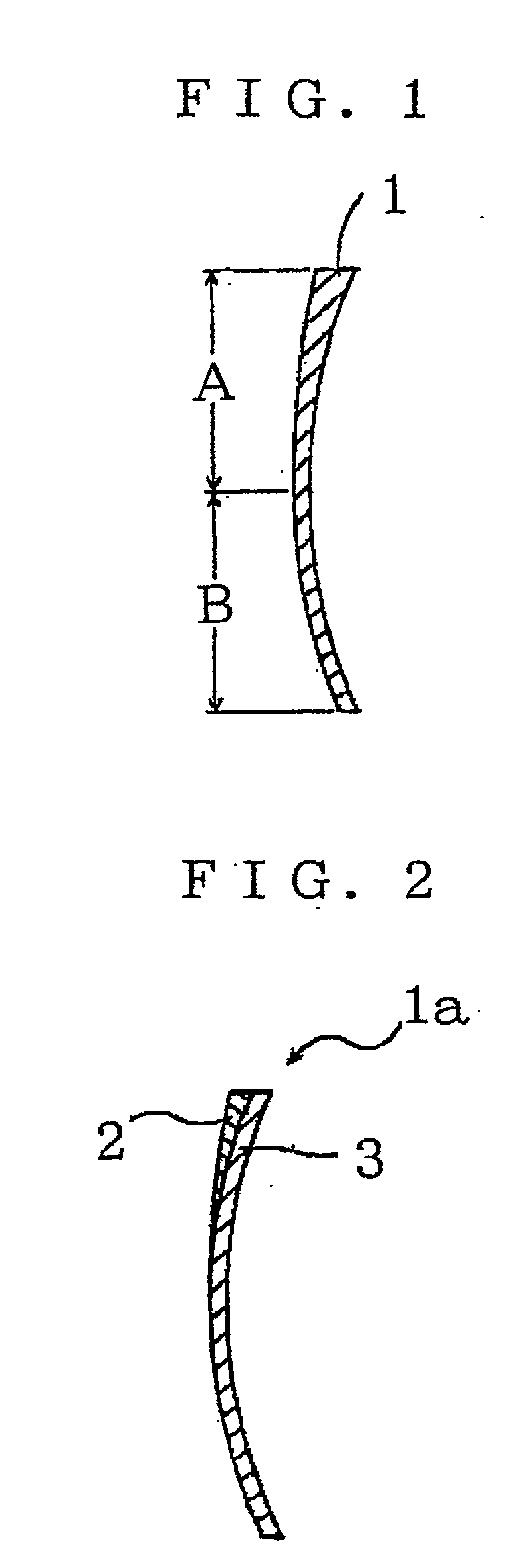

Lens for eyesight correction glasses

Problem To provide a lens for eyesight correction glasses that allows the user to see a nearby viewing object in a naked eye state. Means for Resolution An upper portion A of a lens to be mounted on glasses that is made an eyesight correction portion for far-viewing and its lower portion B that is made a portion for near-viewing that has no eyesight correction ability or has small eyesight correction ability are integrated with each other. The eyesight correction portion for far-viewing corrects farsightedness, nearsightedness, astigmatism, etc. The lower portion having no eyesight correction ability includes no correction diopter and provides the same effect as viewing with the naked eye. The reason why this portion is used to perform small eyesight correction is to minimize an undue load on the ciliary muscles in view of the facts that the effectuation of "adjustment" that is a function of stressing the ciliary muscles to increase the thickness of the crystalline lenses to thereby increase the refractive power varies from one person to another and that there are persons with astigmatism. It is preferable that the correction ability be as small as 0.00-1.00 diopter. In particular, the lens for eyesight correction glasses contributes to acceleration of natural recovery of infants from temporary nearsightedness.

Owner:ASAHI LITE OPTICAL

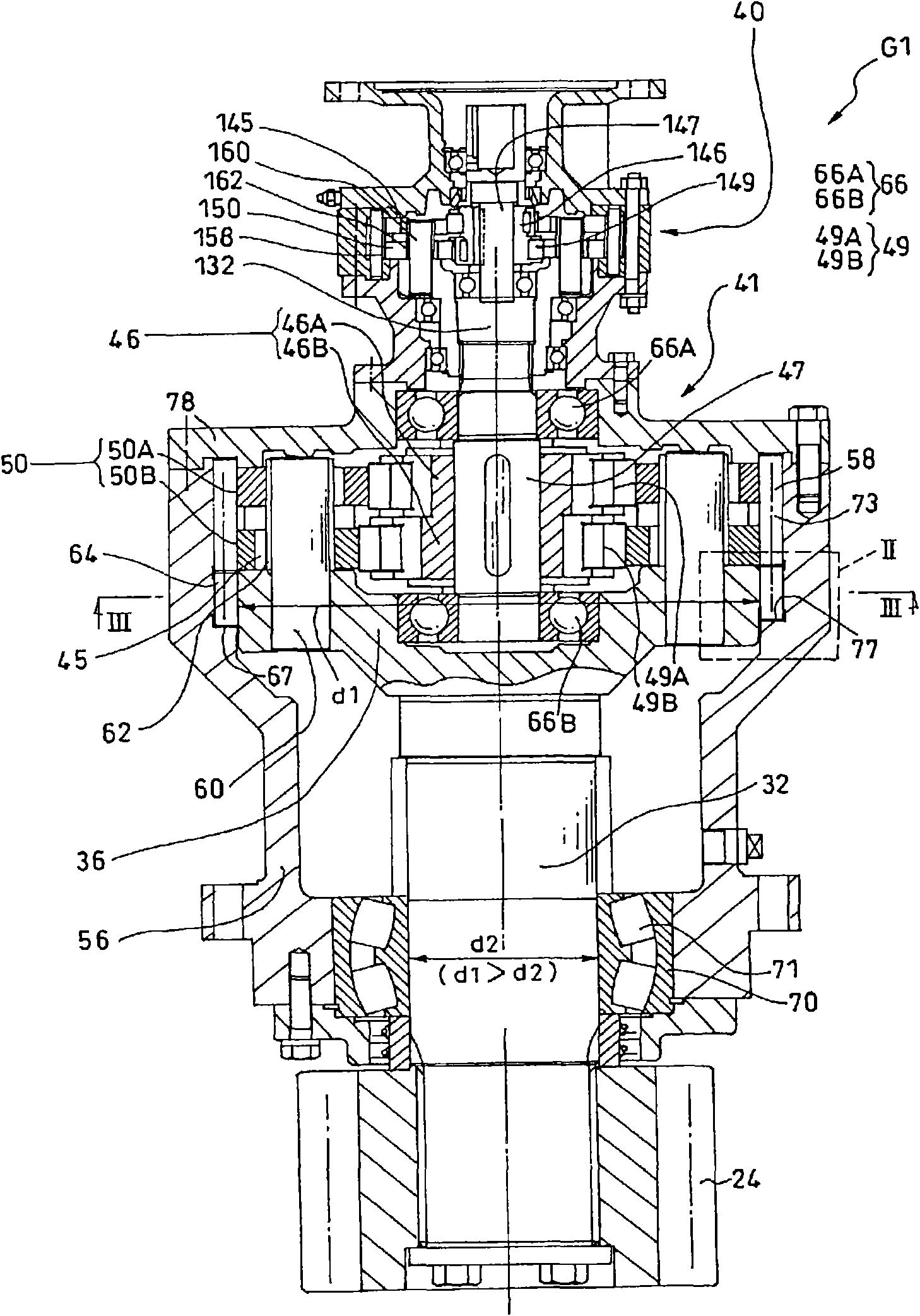

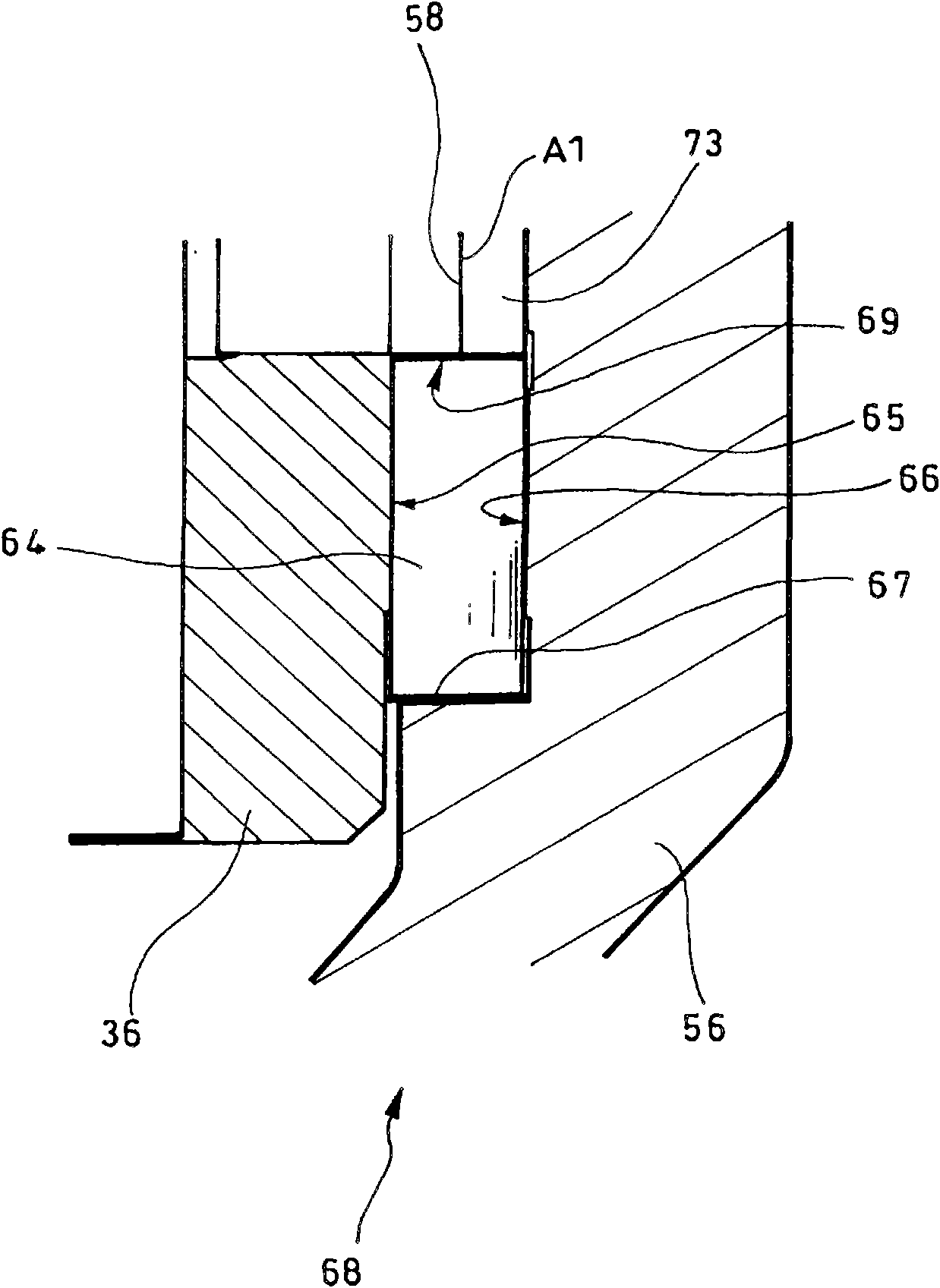

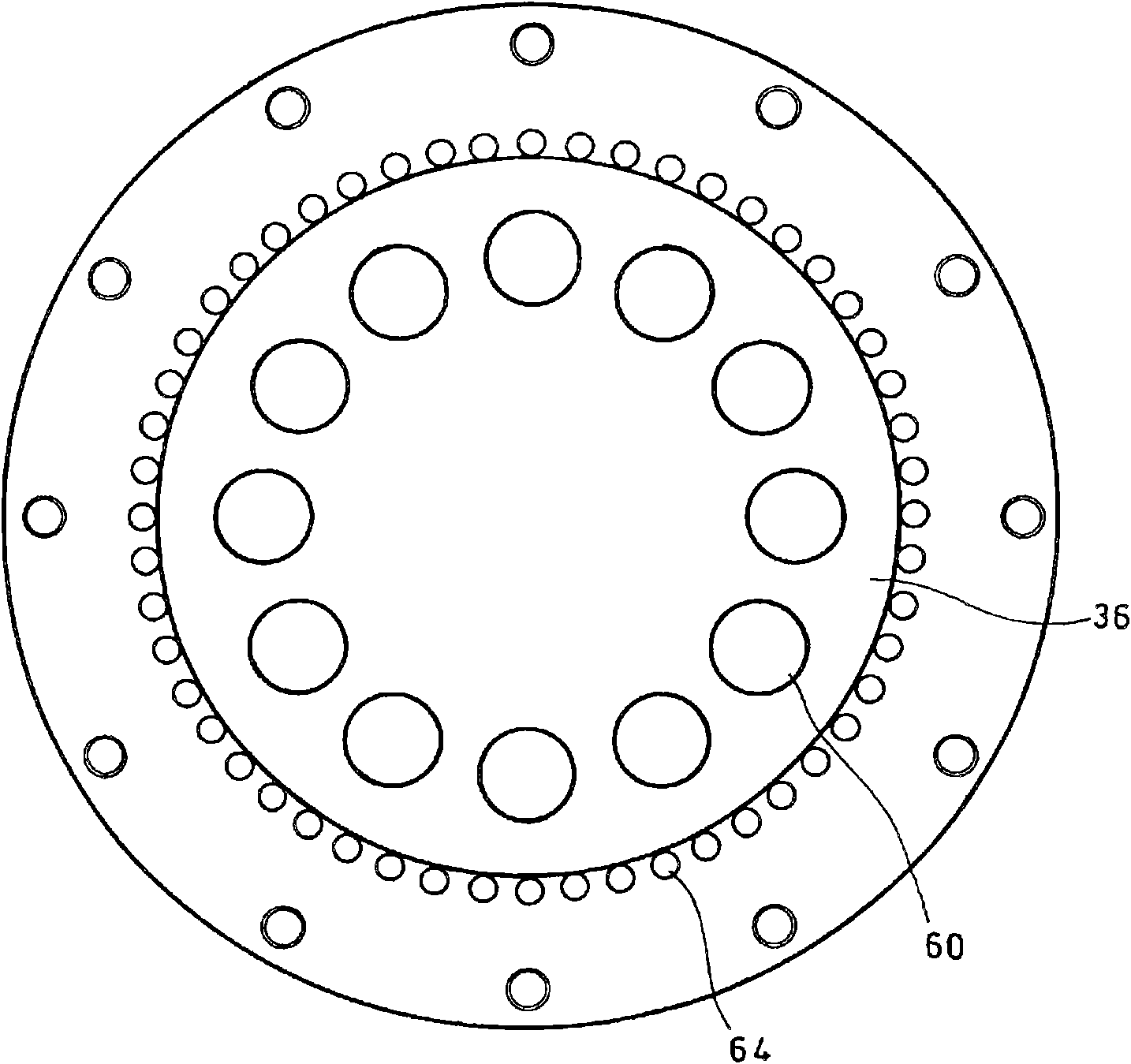

Reduction gear for natural energy recovery system

ActiveCN101839308AImprove impact resistanceWind motor controlToothed gearingsNatural recoveryImpact resistance

The present invention provides a reduction gear for a natural energy recovery system, which improves the impact resistance in a radial direction and prevent the transmission of radial load caused by external force to a speed reduction mechanism. In the reduction gear (G1) used in a natural energy recovery system, at a part of the reduction gear (G1), which is more next to the output side comparedwith the speed reduction mechanisms (40, 41), an output shaft (32) is supported by a first bearing (68) at the side of the speed reduction mechanisms (40, 41) and a second bearing (70) at the opposite side of the speed reduction mechanisms. Furthermore a shaft diameter (d1) of the part of output shaft (32), which is supported by the first bearing (68), is formed larger than the shaft diameter (d2) of the part that is supported by the second bearing (70).

Owner:SUMITOMO HEAVY IND LTD

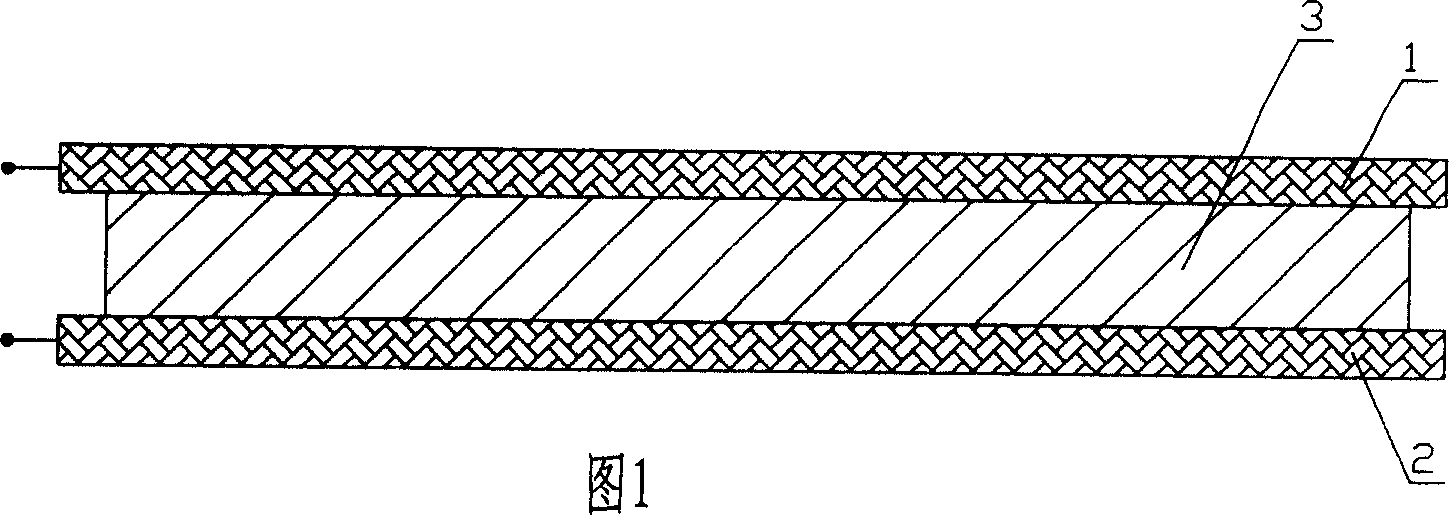

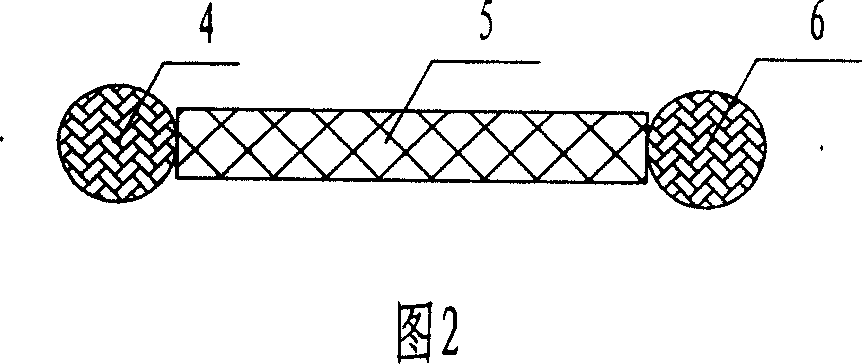

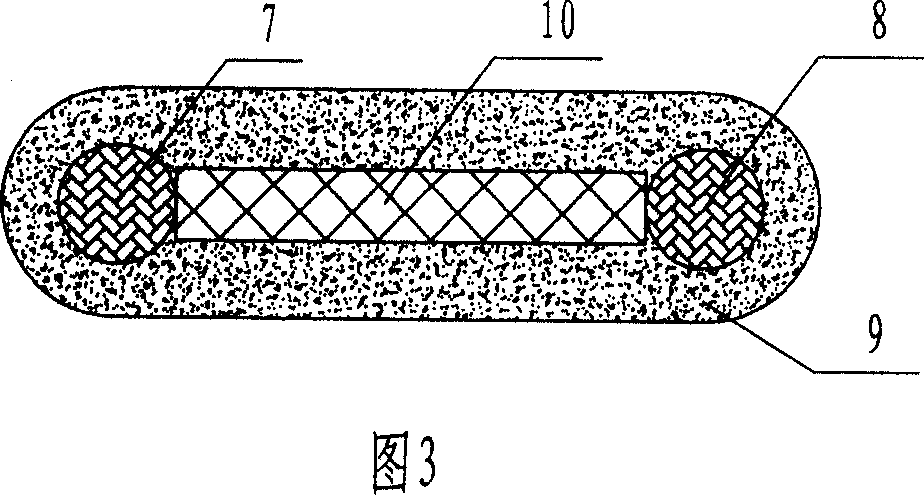

Analog linear temperature-sensing fire detecting cable based on PTC characteristic barrier layer

InactiveCN1941014AReversibleImprove reliabilityThermometers using electric/magnetic elementsInsulated cablesInsulation layerElectrical conductor

Owner:SURELAND IND FIRE SAFETY

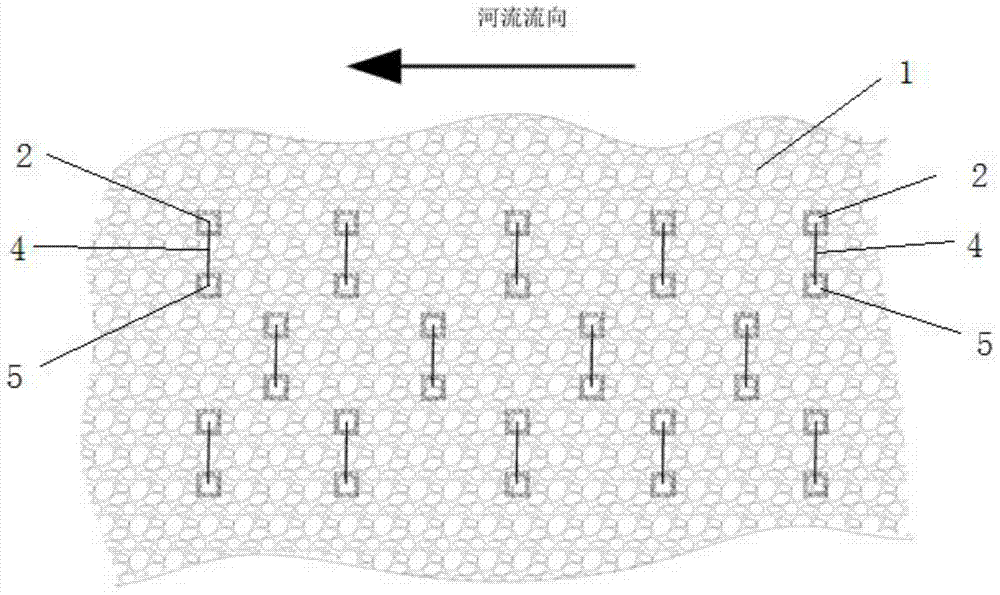

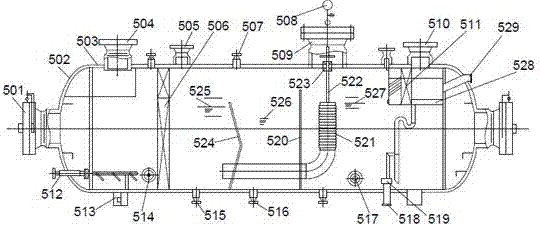

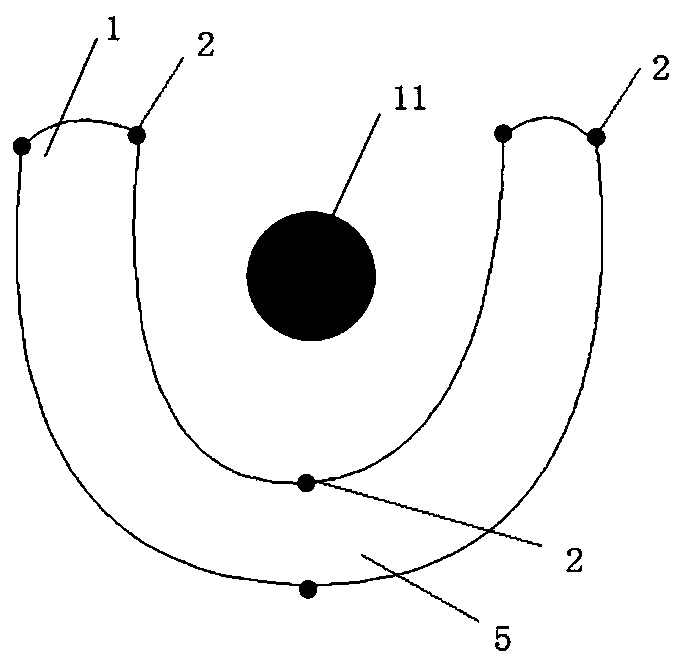

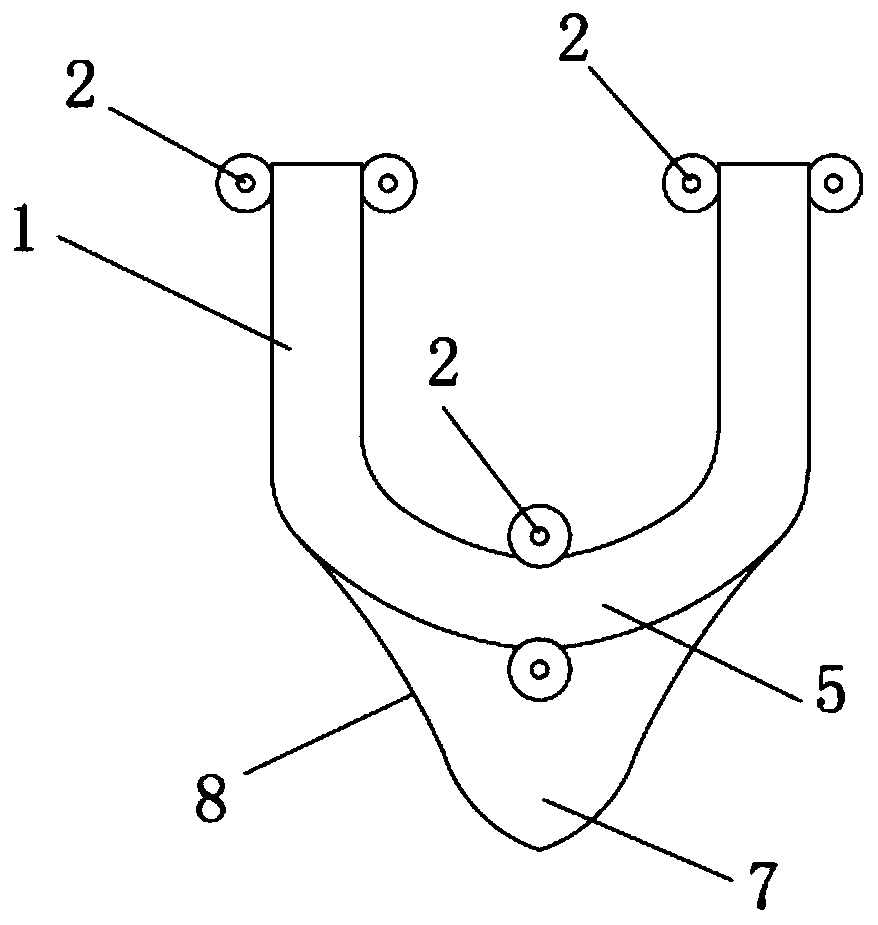

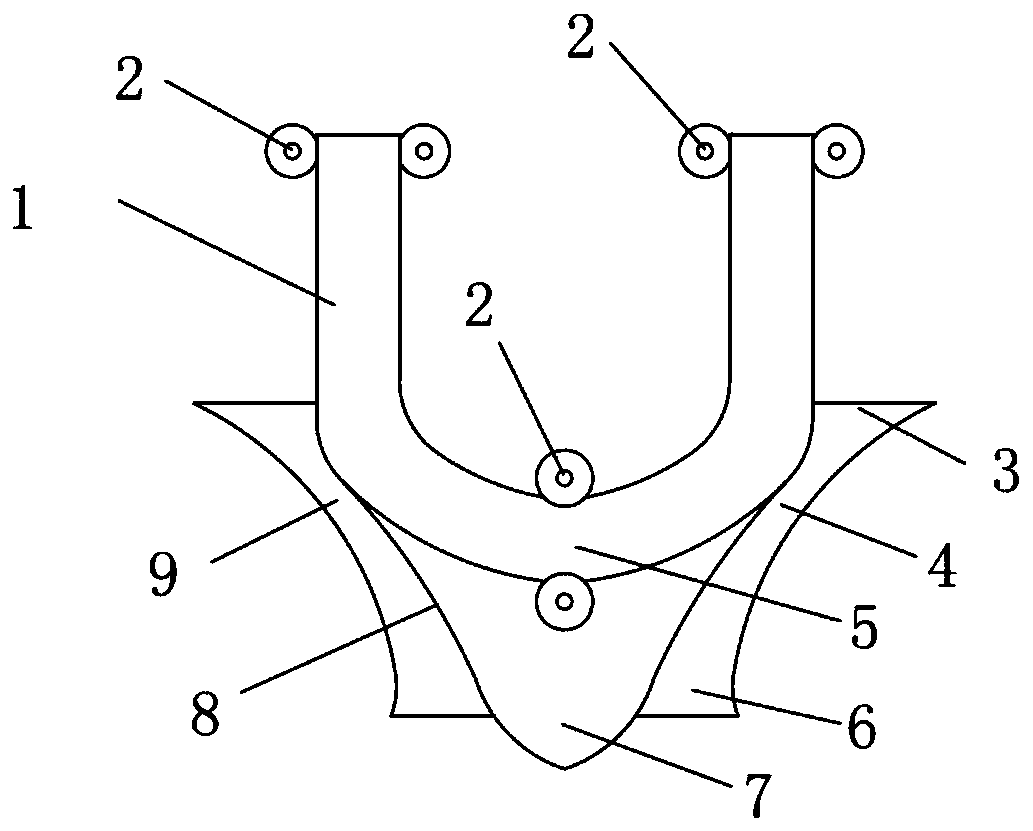

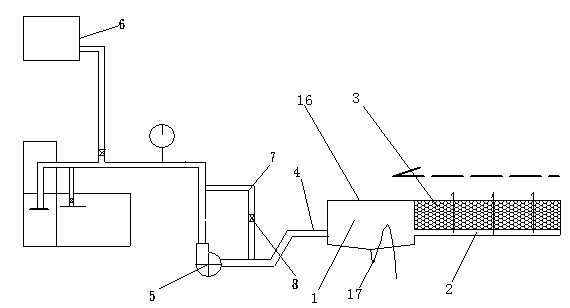

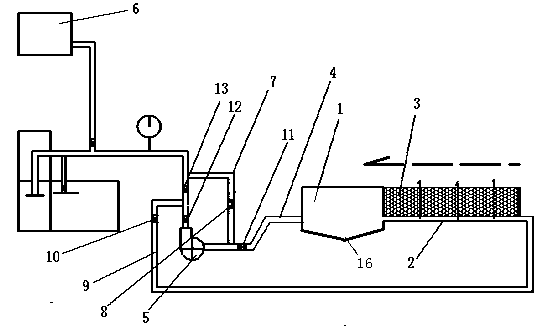

Water-seeping and water-taking device

ActiveCN104328820AQuick clean upEasy to operatePumping plantsDrinking water installationNatural recoveryPulp and paper industry

The invention discloses a water-seeping and water-taking device. In the design of a water-taking dam, a submerged structure is adopted. During use, a large amount of upstream water is used for flushing a water-seeping layer, so that a natural recovery water-seeping function is realized, and blockage of the water-seeping layer is prevented from the principle. The water-seeping and water-taking device comprises a water-taking dam, a water-seeping pond, a water-seeping pipe, a water-seeping layer, water-taking pipes, a water pump and a high-level water tower, wherein the water-seeping pipe is arranged at the lower end of the water-seeping layer; the end part of the water-seeping pipe is connected with the water-seeping layer; the water-taking pipes are communicated with the water-seeping layer and the high-level water tower; the water pump is arranged on the middle parts of the water-taking pipes; a bypass pipe is communicated with water-taking pipes at the two ends of the water pump; a bypass valve is arranged on the bypass pipe; when water in the water-seeping layer is pumped into the high-level water tower through the water pump, the bypass valve is in a closed state; when the valve is in an open state, water in the high-level water tower enters the water-seeping layer through the bypass pipe; the high-level water tower is higher than the water-seeping layer, and is higher than the highest point of the water-seeping layer.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Environmentally-friendly plastic product and making method thereof

The invention discloses an environmentally-friendly plastic product. The environmentally-friendly plastic product comprises, by weight, 30-50 parts of starch, 18-22 parts of botanical glycosides, 6-15 parts of polybutene hot melt adhesive, 6-12 parts of a plasticizer, 6-12 parts of a biodegradation agent, and 12-22 parts of a polycaprolactone-polyhydroxybutyrate-chitin chitosan alcohol copolymer. Compared with the prior art, the method has the following advantages: 1, the plastic product produced in the invention has fine quality and pleasant color; 2, the addition of the biodegradation agent promotes the degradation speed and realizes rapid natural recovery; 3, the addition of the plasticizer increases the mechanical strength of the product and improves the plasticity of the product; and 4, simple equipment, simple operation and low price of used raw materials (like starch) are realized.

Owner:ANHUI NINGGUO MINGHAO PACKAGING MATERIALS

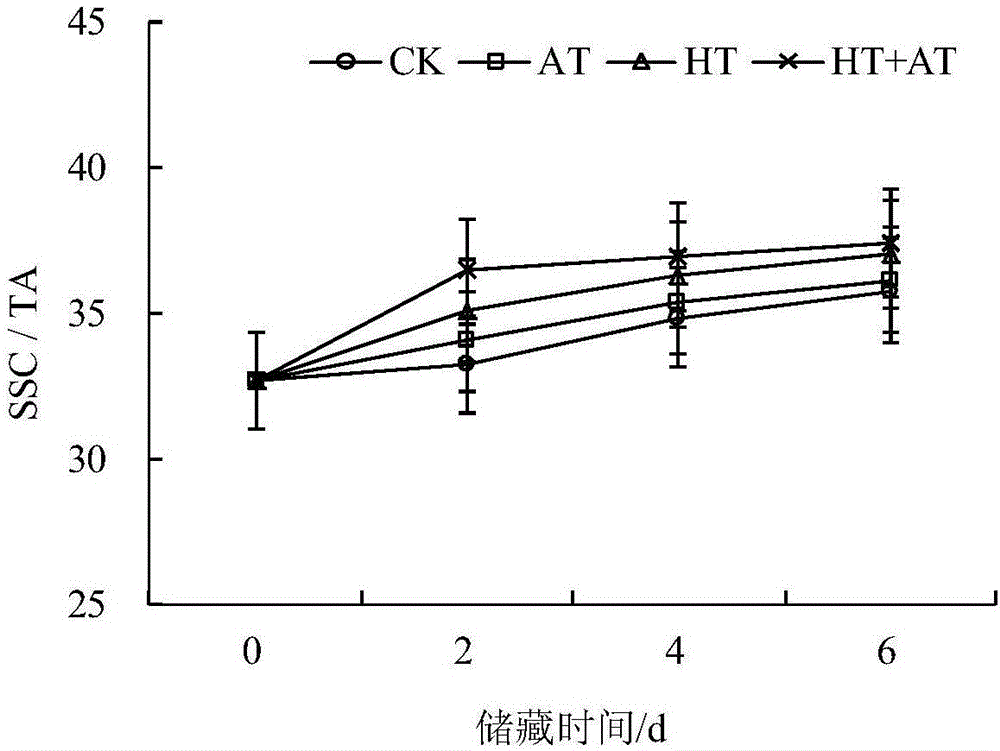

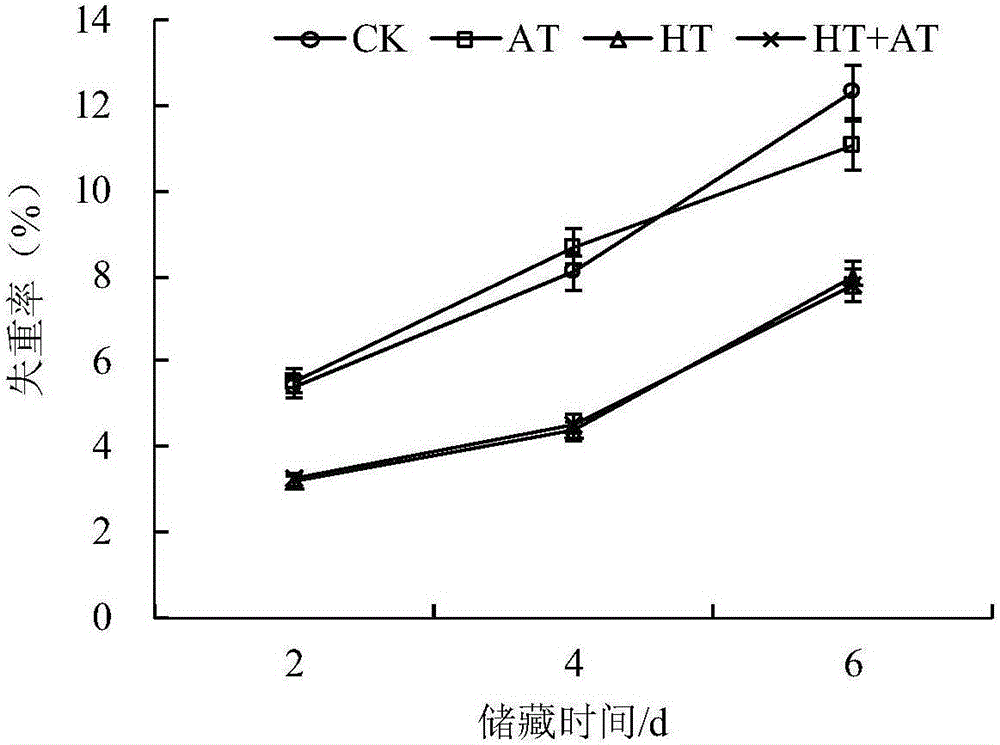

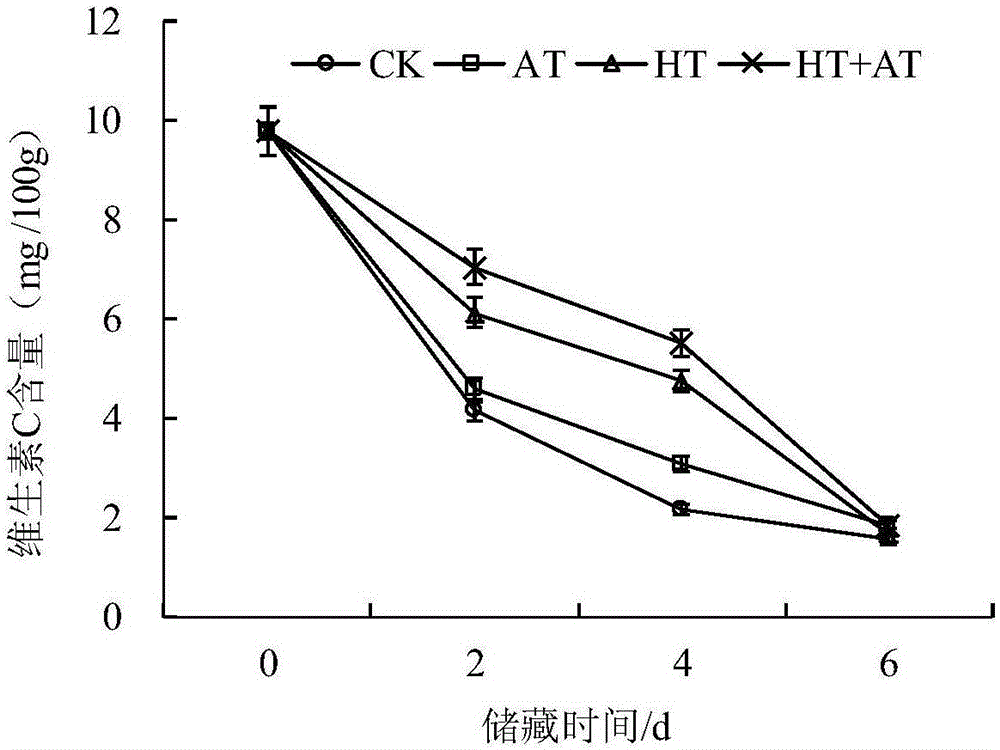

Method for preserving peaches based on yeast and in combination with thermal treatment

InactiveCN106665804AStay hydratedSimple stepsFruit and vegetables preservationMedicineNatural recovery

The invention discloses a method for preserving peaches based on yeast and in combination with thermal treatment. The method comprises the following steps: firstly, soaking peaches into a sodium hypochlorite liquid, cleaning and airing; treating the peaches in hot air and then recovering to room temperature; and soaking the fruits after thermal treatment into a yeast suspension, taking out and drying. The invention provides a safe and efficient postharvest preservation method for peaches. On the basis of the yeast and in combination with the thermal treatment, the aging of peaches can be obviously delayed and the preserving quality of fruits can be promoted. According to the method for preserving peaches, the water content of fruits can be effectively maintained, the ratio of soluble solid content to titration acid can be promoted and the content of vitamin and antioxidant in the fruits can be extremely maintained. The preserving method provided by the invention has the advantages of simple steps, low cost and easiness in popularization and application.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

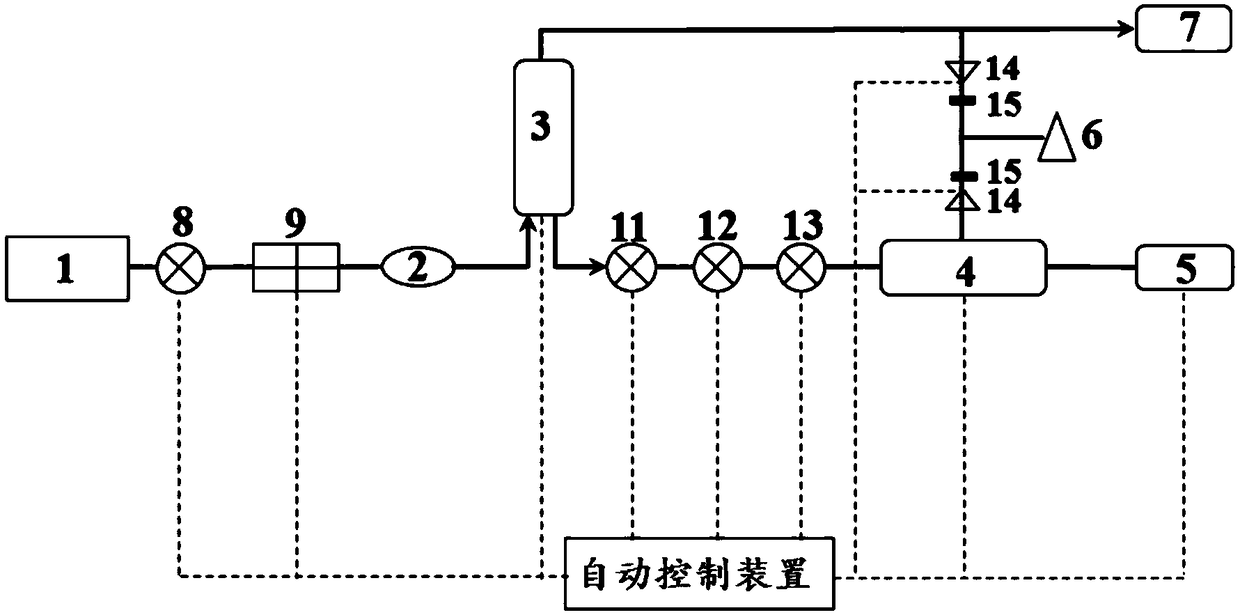

High pressure gas completion testing and natural gas recovery system

ActiveCN108979615ASimple processFluid removalWell/borehole valve arrangementsLine tubingNatural recovery

The invention provides a high pressure gas completion testing and natural gas recovery system. The high pressure gas completion testing and natural gas recovery system is characterized in that the high pressure gas completion testing and natural gas recovery system comprises a high pressure separator, a pressure relief device, a low pressure separator, a gas storage device, a liquid storage deviceand an ignition device; a Christmas tree device is sequentially connected with the high pressure separator, the pressure relief device, the low pressure separator and the liquid storage device; the high pressure separator performs the first gas-liquid separation on the gas-liquid mixture from the Christmas tree device; the pressure relief device performs a pressure relief operation on the first separated liquid; the low pressure separator performs the second gas-liquid separation of the first separated liquid; the gas storage device stores the gas acquired after the first gas-liquid separation; the liquid storage device stores the liquid after the second gas-liquid separation; the ignition device ignites the gas after the second gas-liquid separation. With a two-stage separator adopted and the gas separated by the high pressure separator stored in a gas storage tank, the high pressure gas completion testing and natural gas recovery system has the advantages of needing no compressor topressurize low pressure line gas to the pressure of high pressure gathering pipeline network, and enabling the system process to be simple.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

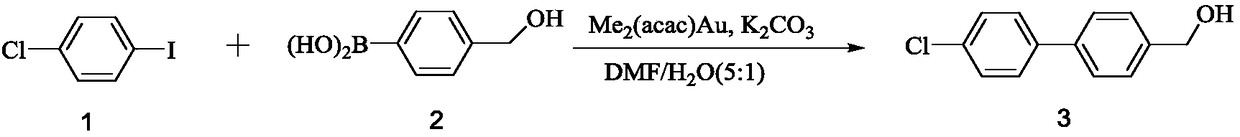

Preparation method and application of dimethyl acetylacetone gold

PendingCN108752179ASimple and fast operationMild conditionsOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPotassium tert-butoxideRoom temperature

The invention relates to a preparation method and application of dimethyl acetylacetone gold. The preparation method comprises the following steps: (1) dissolving gold chloride into ethyl ether, adding methyl iodide, and stirring for 1-2 hours at the room temperature so as to obtain a reaction liquid A; (2) putting potassium tert-butoxide into acetylacetone, and stirring for 10-15 minutes at the room temperature so as to obtain a reaction liquid B; (3) at ice bath, mixing the reaction liquid A with the reaction liquid B, recovering to the room temperature naturally, carrying out a stirring reaction for 30-40 minutes, diluting with the ethyl ether, washing with water, and carrying out vacuum concentration with an organic layer (an ethyl ether layer), and carrying out vacuum drying, therebyobtaining the dimethyl (acetylacetone) gold (III).

Owner:YANGZHOU POLYTECHNIC INST

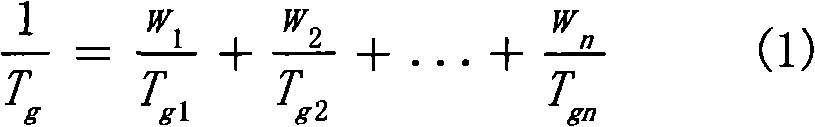

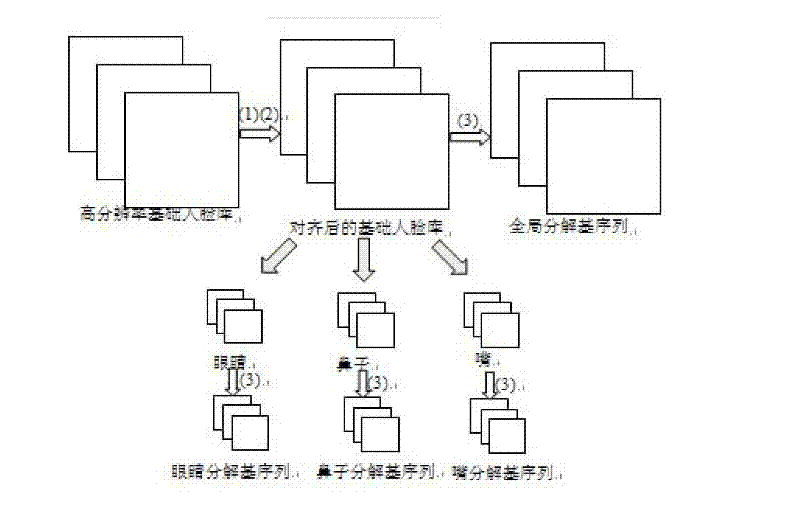

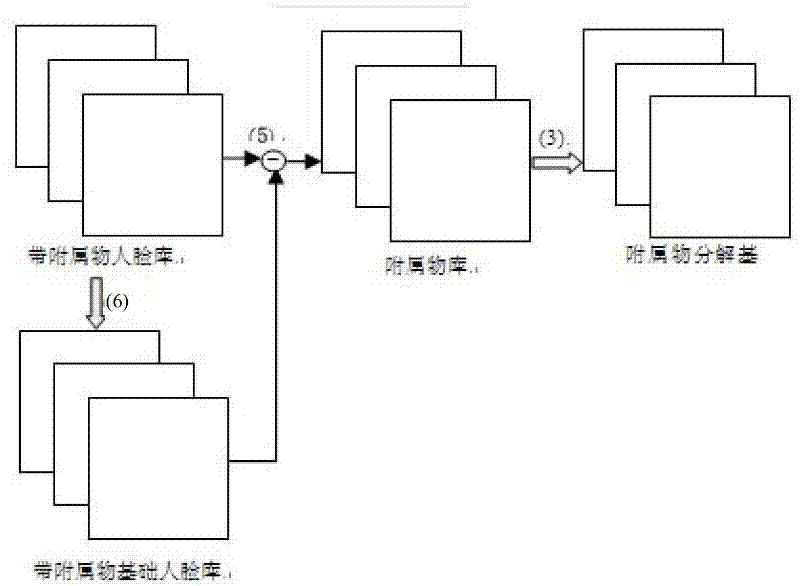

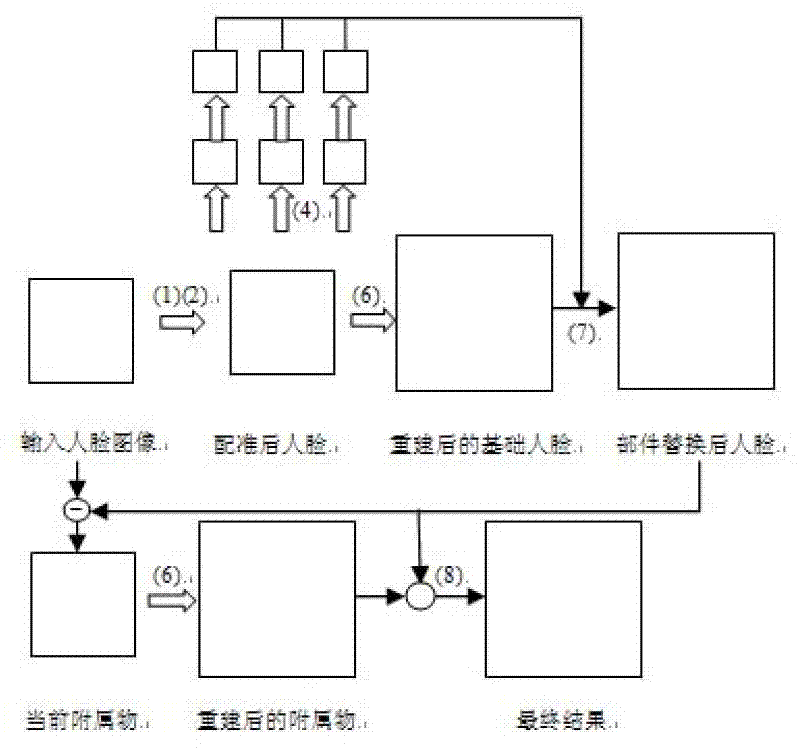

Highly noise-resistant single face automatic super-resolution method

ActiveCN102693416AHigh degree of automationStrong noise resistanceCharacter and pattern recognitionPattern recognitionImage resolution

The invention relates to a highly noise-resistant single face automatic super-resolution method. The method of the invention is characterized by comprising two main processes of training and reconstruction. The training process comprises a basic face model training and an adjunct model training. The reconstruction process comprises the following steps: a face image is input; face feature points are calibrated by an ASM algorithm and subjected to geometric transformation so that a registered face image is obtained; a reconstructed basic face is obtained by means of an iterative method according to an algorithm of formula (1) min(W*||A*B*X-I[L]||<2>); current adjuncts are obtained by subtracting the reconstructed basic face from the input face image; reconstructed adjuncts are obtained by reconstruction by applying the algorithm of formula (1) to the adjuncts; and a final reconstructed face image is obtained by adding the reconstructed adjuncts and the registered face image. The super-resolution method of the invention has abilities of strong-noise resistance and occlusion resistance, provides a process with a high automation degree and a fast calculating speed, and enables a clear and natural recovery effect complying with common face structures, wherein the face component is replaceable so as to output multiple effects.

Owner:ZHEJIANG ICARE VISION TECH

Method for preparing organic phosphonic gold chloride (I) compound

ActiveCN105859775AEfficient productionOvercome strong irritating odorGroup 1/11 organic compounds without C-metal linkagesGroup 5/15 element organic compoundsWater bathsIce water

The invention discloses a method for preparing an organic phosphonic gold chloride (I) compound. The method comprises the following steps: (1) adding chloroauric acid hydrated salt into a reaction container, dissolving with water, and uniformly stirring in an ice-water bath; (2) keeping the temperature of the ice water in the reaction container, dripping a glucosinolates diaryl compound or a derivative of the glucosinolates diaryl compound, and stirring uniformly; (3) dripping a mixed liquid of phosphine-containing ligand and ethanol into the reaction container one droplet by one droplet, removing the ice-water bath, recovering the room temperature naturally, and stirring for 2-5 hours; (4) stopping stirring, performing suction filtration, washing with cold methanol, dissolving the collected solid with an organic solvent, and performing suction filtration again so as to remove insoluble matters; (5) performing concentration spinning drying on the solution, recrystallizing with a solvent, and performing suction filtration again, thereby obtaining the organic phosphonic gold chloride (I) compound. As the glucosinolates diaryl compound or the derivative of the glucosinolates diaryl compound is taken as a reduction reagent, and due to reaction between the chloroauric acid hydrated salt and the phosphine-containing ligand in an ethanol-water system, environment-friendly, safe and efficient production of the organic phosphonic gold chloride (I) compound can be achieved, and moreover, industrial application of the organic phosphonic gold chloride (I) compound is facilitated.

Owner:EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com