Complete recovery system and method for iso-pressure blow-off gas at blast furnace top

A technology for releasing gas and full recovery, applied in blast furnaces, blast furnace details, furnaces, etc., can solve problems such as large water and electricity consumption, complex equipment, and decline, and achieve the effects of high feasibility, simple operation, and low fixed investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

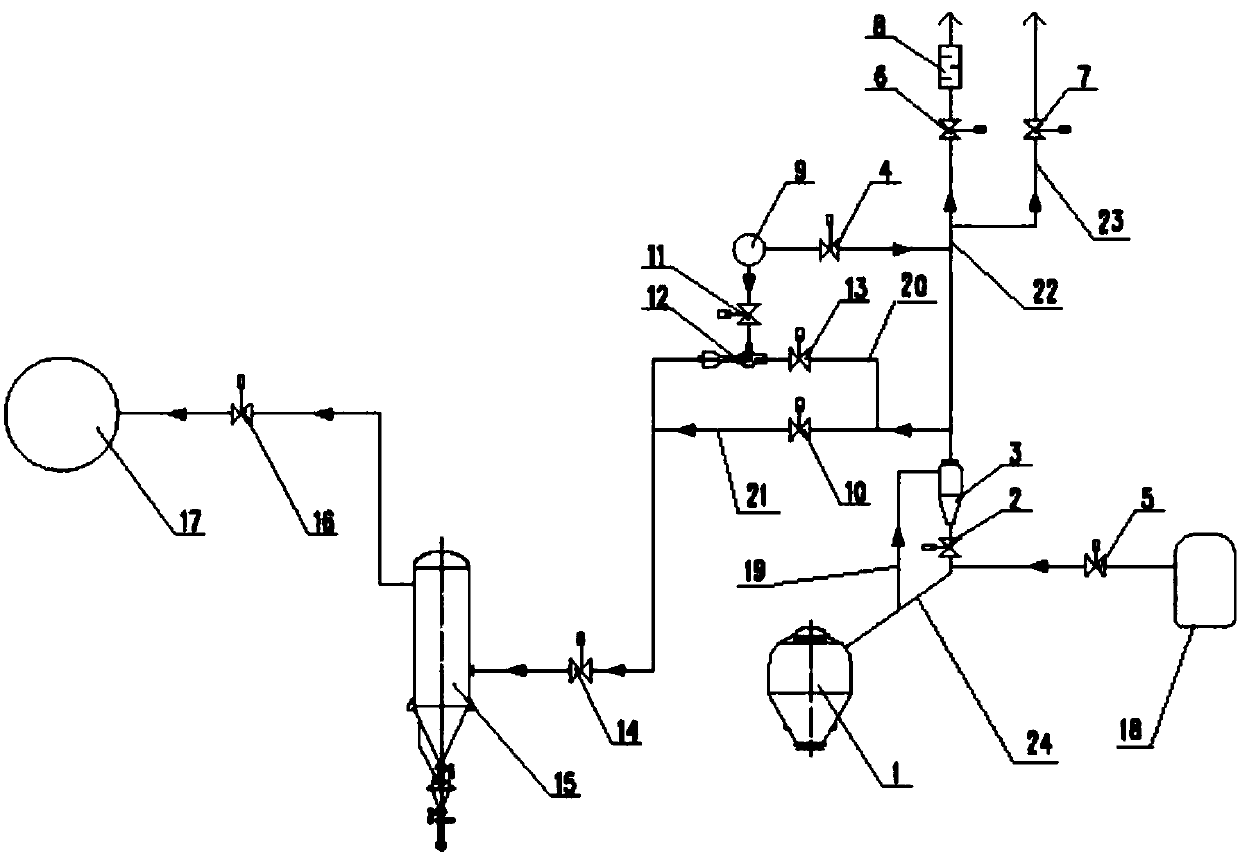

[0029] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0030] like figure 1 The shown one kind of blast furnace roof pressure equalization release gas full recovery system mainly includes a blast furnace top material tank 1, a cyclone dust collector 3, an ejector 12 and a bag filter 15, and the furnace top material tank 1 passes through the first A pipeline 19 is communicated with the cyclone dust collector 3, and the bottom of the cyclone dust collector 3 is provided with a cyclone ash unloading valve 2; the outlet of the first pipeline 19 is communicated with the entrance of a three-way joint, and the first outlet of the three-way joint is connected with the The second pipeline 20 communicates, and the ejector 12 and the forced recovery valve 13 are installed on the second pipeline 20. The ejector 12 includes two air inlets, and one inlet of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com