Simple natural gas liquid recovery system

A recovery system and technology of natural gas, applied in the directions of liquefaction, solidification, refrigeration and liquefaction, can solve the problems of wasting natural gas energy, polluting the environment, and the recovery effect is not very good, to simplify the process flow and cost, expand space capacity, save The effect of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

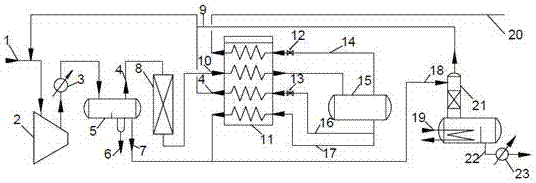

[0018] Such as figure 1 Shown: a simple natural gas condensate recovery system, including compressor 2, three-phase separator 5, molecular sieve 8, cold box 11 and condensate stabilization tower 21, characterized in that: the outlet end of compressor 2 is connected with a first cooling 3, the first cooler 3 is connected with a three-phase separator 5, the gas outlet end of the three-phase separator 5 is connected with a molecular sieve 8, and the molecular sieve 8 is connected with a cold box 11, and the cold box 11 is connected with the low-temperature separator 15 and the three-phase separator 5 respectively. , compressor 2, and condensate stabilization tower 21 are connected, and the cold box 11 is also provided with a product natural gas 20 output pipe, and the condensate stabilization tower 21 is connected with a second cooler 23, and the recovery system designed can realize the natural gas condensate recovery process The low-temperature mixed light hydrocarbon 17 multidi...

Embodiment 2

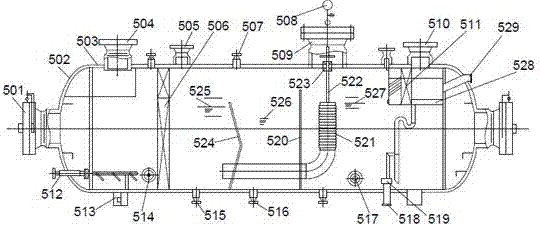

[0020] This embodiment further optimizes the technical scheme on the basis of embodiment 1 as follows: Figure 2-4The shown three-phase separator 5 is also provided with an unstabilized condensate outlet 529, the cold box 11 is connected with the unstabilized condensate outlet 529, the lower part of the three-phase separator 5 is connected with a saddle 513, and the three-phase separator 5 is provided with The separation internal part 506, the first weir plate 524 and the second weir plate 520 divide the interior of the three-phase separator 5 into an oil-water interface 525 space, an oil-liquid interface 527 space, and a water-liquid interface 527 space. The raw material inlet 504, the designed three-phase separator 5 can realize the separation of oil, water and gas, and use the principle of oil-water incompatibility and flowing water weir to realize oil-water separation, save oil-water separation equipment, simplify the separation process, and make natural gas Rapid separati...

Embodiment 3

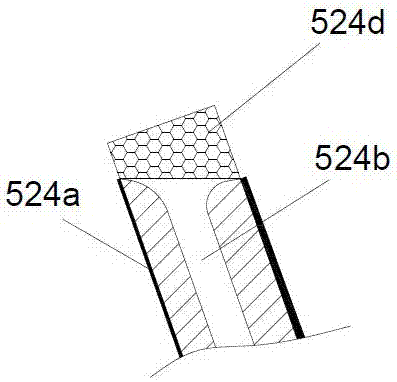

[0023] Such as image 3 As shown, the oleophobic coating 524a provided on both sides of the first weir plate 524 is composed of the following components and parts by weight: 18 parts of polyurethane prepolymer, 0.024 parts of polyglycerol fatty acid ester, 1-phenyl-5-mercaptotetrazole 0.03 parts of azole, 10 parts of polyethylene glycol, 3 parts of perfluoroalkylmethanol and 42 parts of organic solvent, the organic solvent is a mixed solution of acetone and toluene, and the structural formula of perfluoroalkylmethanol is CF3(CF2)nCH2OH, wherein n Representing an integer from 5 to 10, the oleophobic effect of the surface of the first weir plate 524 is improved through the oleophobic coating 524a, so as to prevent oil from adhering to the surface of the first weir plate 524 and affecting the efficiency and effect of phase separation of raw materials, and the oleophobic coating The static contact angle of 524a and oil is greater than 150°, has super-oleophobicity, and the oleopho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com