Pressure-equalizing bleeding device for ejecting furnace-top tank gas by high pressure gas

A technology of high-pressure gas and furnace top, which is applied in blast furnaces, blast furnace details, blast furnace parts, etc., can solve environmental pollution and other problems, and achieve the effects of avoiding environmental pollution and resource waste, good economic and social benefits, and consistent operating procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

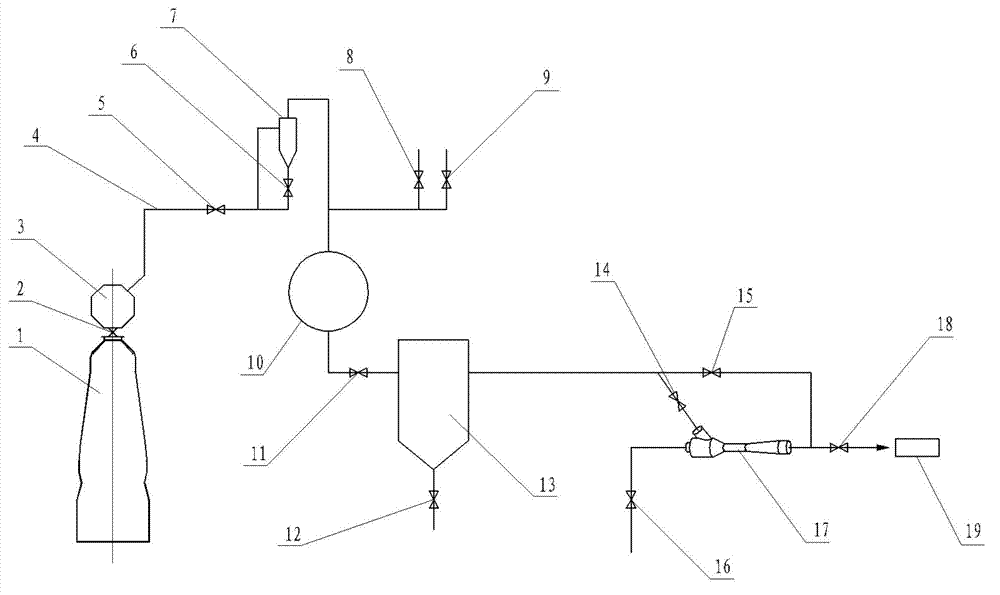

[0040] When equalizing the pressure on the top of the blast furnace, the traditional pressure equalizing method is adopted, that is, the pressure equalizing valve 8 and the equalizing pressure relief valve 5 are opened once, and the semi-clean gas that has been dedusted by the gravity dust collector enters the weighing material tank 3 through the equalizing pressure relief pipe 4, And the dust in the cyclone dust collector 7 is blown back into the weighing tank 3 . If the primary pressure equalization cannot meet the requirements, open the secondary pressure charging valve 9 again, and carry out secondary pressure equalization on the weighing tank 3 with nitrogen to meet the appropriate pressure requirement; after the equalization is completed, close the relevant valves and open the feeding gate 2 , the charge enters the blast furnace from the weighing tank 3 through the blanking gate 2.

[0041] When venting from the top of the blast furnace, open the pressure equalizing vent...

Embodiment 2

[0043]During pressure equalization, the traditional pressure equalization method is adopted, that is, the pressure equalization valve 8 and the pressure equalization release valve 5 are opened once, and the semi-clean gas that has been dedusted by the gravity dust collector enters the weighing material tank 3 through the pressure equalization release pipe 4, and the cyclone The dust in the dust collector 7 is blown back into the weighing tank 3 . If the primary pressure equalization cannot meet the requirements, open the secondary pressure charging valve 9 again, and carry out secondary pressure equalization on the weighing tank 3 with nitrogen to meet the appropriate pressure requirement; after the equalization is completed, close the relevant valves and open the feeding gate 2 , the charge enters the blast furnace from the weighing tank 3 through the blanking gate 2.

[0044] When releasing, open the pressure equalizing release valve 5, the bag filter valve 11 and the natura...

Embodiment 3

[0046] During pressure equalization, the traditional pressure equalization method is adopted, that is, the pressure equalization valve 8 and the pressure equalization release valve 5 are opened once, and the semi-clean gas that has been dedusted by the gravity dust collector enters the weighing material tank 3 through the pressure equalization release pipe 4, and the cyclone The dust in the dust collector 7 is blown back into the weighing tank 3 . If the primary pressure equalization cannot meet the requirements, open the secondary pressure charging valve 9 again, and carry out secondary pressure equalization on the weighing tank 3 with nitrogen to meet the appropriate pressure requirement; after the equalization is completed, close the relevant valves and open the feeding gate 2 , the charge enters the blast furnace from the weighing tank 3 through the blanking gate 2.

[0047] When releasing, open the pressure equalizing release valve 5, the bag filter valve 11 and the natur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com