Wall deposition and wall abrasion loss prediction method based on numerical simulation

A numerical simulation and wall technology, applied in the field of forecasting, can solve problems such as time-consuming, inability to provide data, support and operation guidance, and achieve the effects of less storage space, overcoming long simulation time, and reliable data support.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

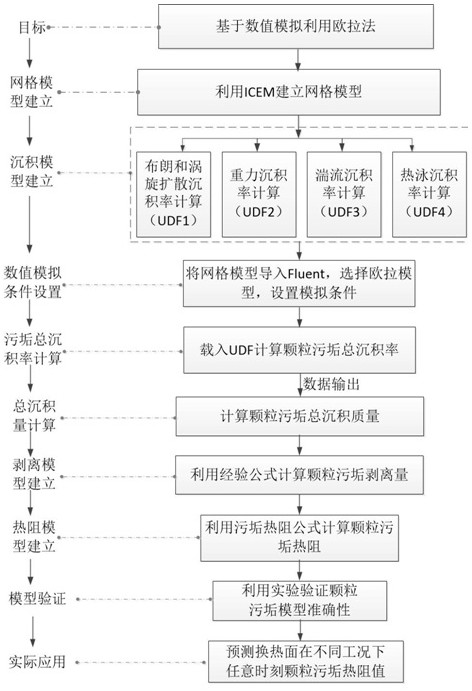

[0085] to combine figure 1 , this embodiment discloses a method for predicting wall deposition based on numerical simulation, using the Euler method, specifically including:

[0086] (1) Build a grid model

[0087] Based on the specific shape and size of the heat exchange equipment, a mesoscopic three-dimensional geometric model of the sewage heat exchange equipment is established. According to the actual situation in the calculation domain, ICEM CFD software is used to divide the unstructured tetrahedral mesh, so as to realize the discrete calculation domain.

[0088] In order to accurately simulate the flow field of sewage in the heat exchange equipment, grid independence verification is required. The specific verification method is as follows: the global element seed size of the calculation domain is given more than two setting forms, and the sewage The grids at the entrance and exit and the wall need to be locally refined, define the maximum size of more than three grids...

Embodiment 2

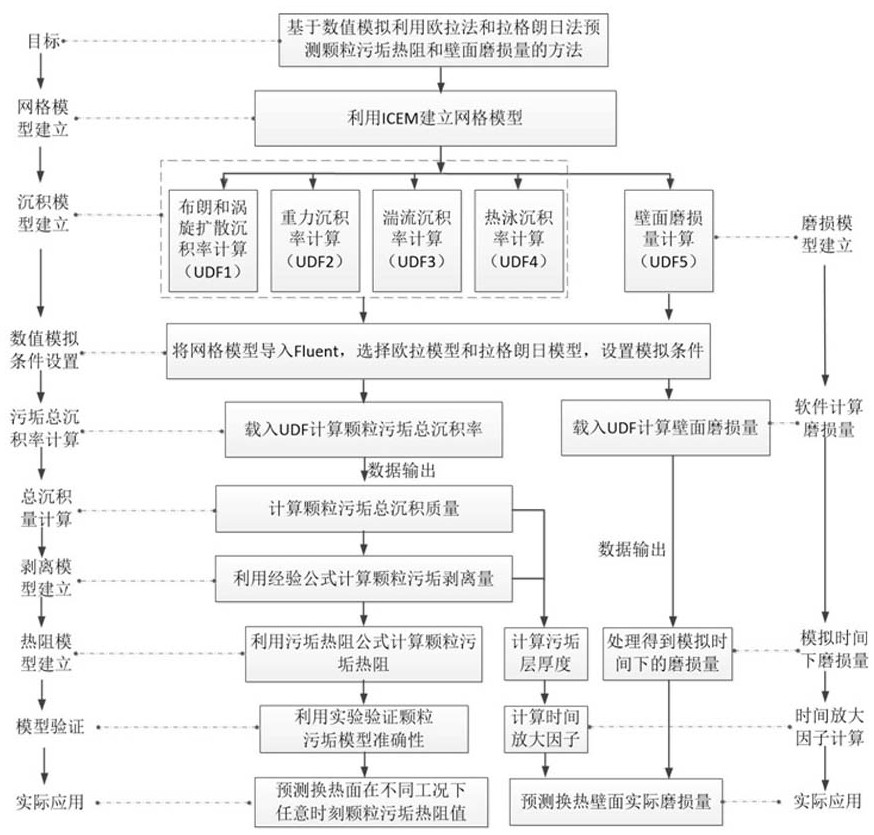

[0135] This embodiment discloses a method for simultaneously predicting wall deposition and wall wear based on numerical simulation. The prediction method for fouling thermal resistance is the same as in Example 1, and the prediction method for wall wear is also based on the previously established grid model. Therefore, the network The process of building the lattice model will not be repeated here.

[0136] see figure 2 ,exist figure 1 Based on the examples, we established a wear model and imported it into Fluent, and selected the Lagrange model (also called DPM discrete model, Dense Discrete phaseModel, DPM for short) on the basis of the previous Euler model, and set Under the simulation conditions, load the wear model to calculate the mass wear amount of the wall surface per unit heat transfer area per unit time, and output and process the data to obtain the wear amount under the simulation time; finally, the time amplification factor is obtained by combining the thickne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com