Rare earth oxygen-free copper based alloy and production process thereof

A production process, oxygen-free copper technology, applied in the field of rare earth oxygen-free copper-based alloys and its production process, can solve the problem of inability to isolate oxidation, etc., and achieve the effect of high strength and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

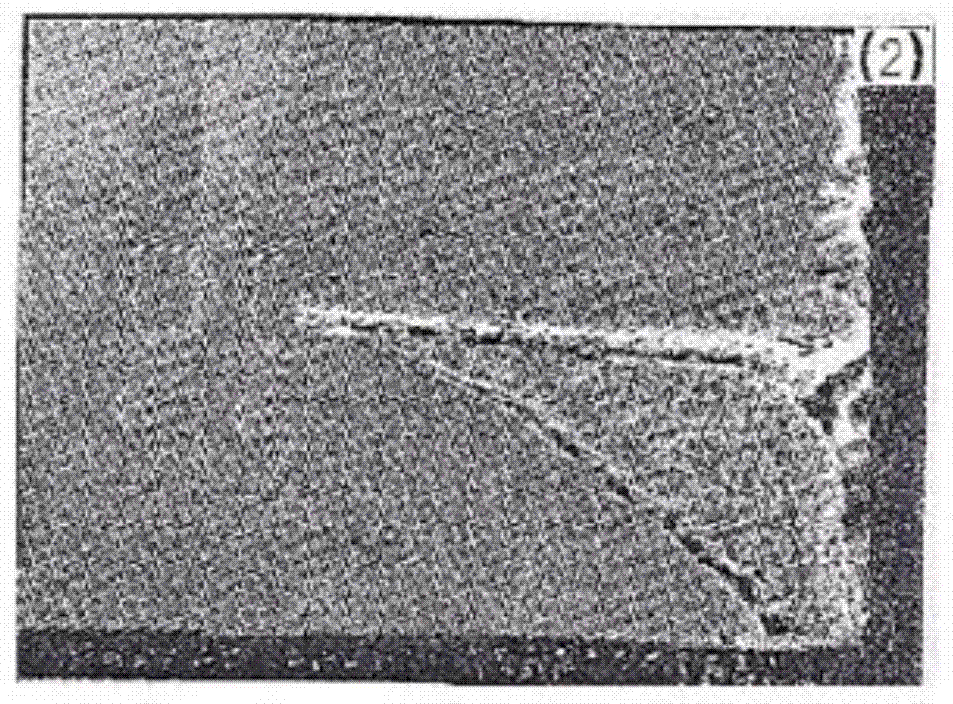

Image

Examples

Embodiment 1

[0051] A rare-earth oxygen-free copper-based alloy, copper is added with rare-earth elements La, Mn and lithium. The capacity of the industrial frequency furnace for melting, heat preservation and lead rod production is 300kg, and the copper in the furnace is 300kg when it is full. After the copper temperature in the melting furnace reaches 1260°C, add additives gradually with a feeder, add La0.12kg, Mn0.03kg in one furnace, add lithium as Li-Cu master alloy, and the ratio of lithium in Li-Cu master alloy is 10.1w %, add lithium 0.15kg in one furnace. At the same time, use green tree sticks to continuously stir mechanically for 20 minutes, then use six lead rods in the holding furnace to start using the crystallizer lead rods according to the process, and the copper-based alloy rods will start to be continuously drawn upwards, producing 800kg per hour and melting at power frequency Copper and additives are also continuously added to the furnace. Copper and La, Mn, Li-Cu mast...

Embodiment 2

[0055] A rare-earth oxygen-free copper-based alloy, copper is added with rare-earth elements Ce, Mn and lithium. The capacity of the industrial frequency furnace for melting, heat preservation and lead rod production is 300kg, and the copper in the furnace is 300kg when it is full. After the copper temperature in the melting furnace reaches 1350°C, add additives gradually with a feeder, add Ce0.24kg, Mn0.06kg in one furnace, lithium is added as Li-Cu master alloy, and the proportion of lithium in Li-Cu master alloy is 10.2w %, add lithium 0.45kg in one furnace. At the same time, use an electromagnetic rod to continuously stir electromagnetically for 30 minutes, and then use six lead rods in the holding furnace to start using the crystallizer lead rods according to the process, and the copper-based alloy rods will start to be continuously drawn up, and the production will be 800kg per hour. Keep adding copper and . Copper and additives, Ce, Mn, Li-Cu master alloy are added se...

Embodiment 3

[0059] A rare earth oxygen-free copper-based alloy, copper is added with rare earth elements La and Ce, Mn, and lithium, and the mass ratio of La and Ce is 1:2. The capacity of the industrial frequency furnace for melting, heat preservation and lead rod production is 300kg, and the copper in the furnace is 300kg when it is full. After the copper temperature in the melting furnace reaches 1300°C, add additives gradually with a feeder. Add La and Ce in one furnace, a total of 0.18kg, and Mn0.036kg. Lithium is added as a Li-Cu master alloy, and the proportion of lithium in the Li-Cu master alloy is 9.5w%, add 0.45kg of lithium in one furnace. At the same time, use electromagnetic rods to continuously electromagnetically stir for 25 minutes, and then use six lead rods in the holding furnace to start using crystallizer lead rods according to the procedure. Add copper and additives. Copper, La and Ce, Mn, and Li-Cu master alloy are added sequentially, and the speed is kept uniform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com