Preparation method of coated lithium ion battery ternary positive electrode material

A technology for lithium-ion batteries and positive electrode materials, which is applied in the field of preparation of ternary positive electrode materials for coated lithium-ion batteries, and can solve problems such as difficult control of process conditions, inability to scale production, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The invention provides a method for preparing a coated lithium-ion battery ternary positive electrode material, which is characterized in that it comprises the following steps:

[0042] a) ultrasonically dispersing the nano-oxide in the dispersion medium to obtain a dispersion;

[0043] The nano-oxide is nano-silica or nano-zirconia;

[0044] The dispersion medium is isopropanol, ethanol or acetone;

[0045] b) combine the dispersion with the ternary cathode material LiNi x co y mn z o 2 to mix, to stir, to obtain a mixture;

[0046] Among them, 0.5≤x≤0.6, 0.1≤y≤0.2, 0.2≤z≤0.3, x+y+z=1;

[0047] c) drying and sintering the mixture to obtain a coated lithium-ion battery ternary positive electrode material.

[0048] The present invention adopts the physical coating method to prepare the nano-oxide-coated ternary positive electrode material, the preparation process is simple and easy, the cost is low, and it can be mass-produced on a large scale, which meets the ind...

Embodiment 1

[0065] 1.1 Preparation of ternary cathode materials for coated lithium-ion batteries:

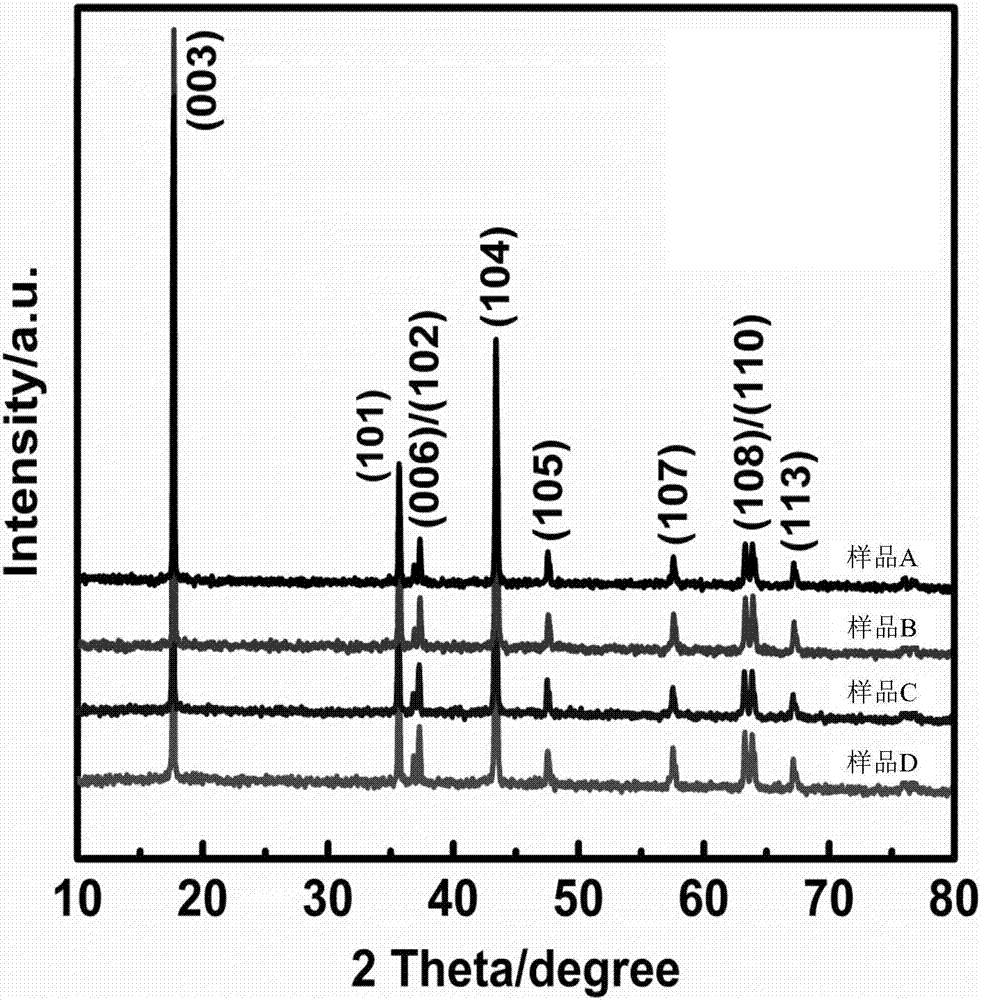

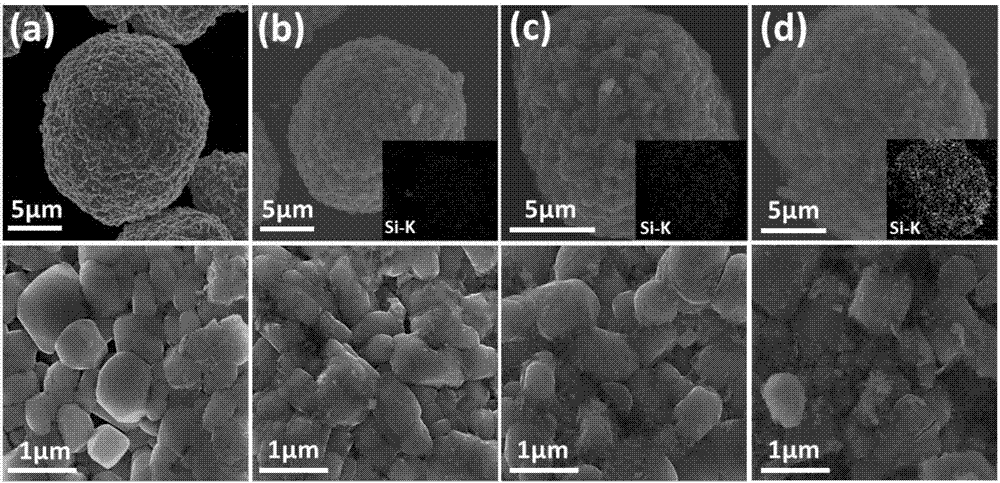

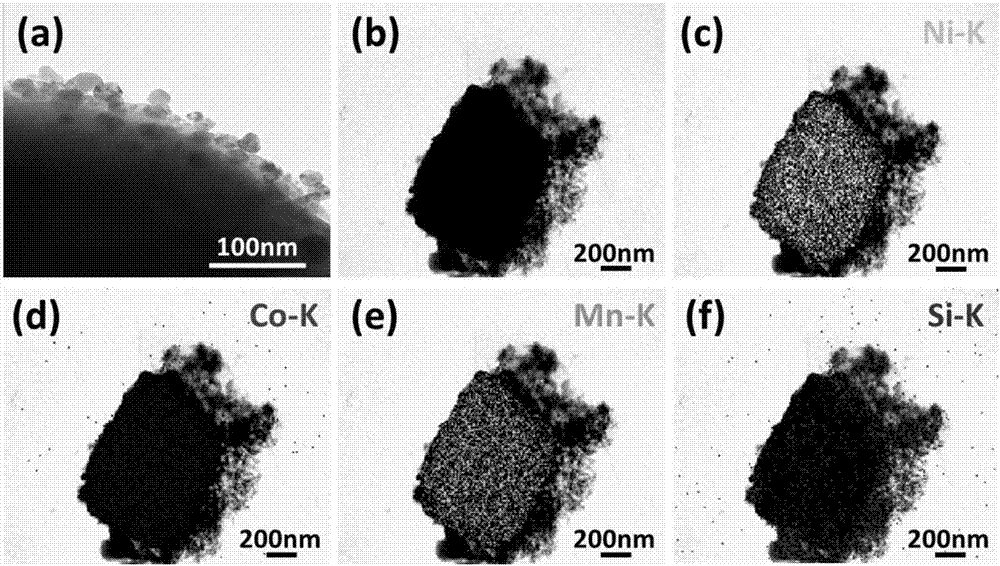

[0066] Weigh 40mL of isopropanol, respectively take 0.01g, 0.02g and 0.04g of nano-silica for ultrasonic dispersion (power of 700W, dispersion time of 2h) in isopropanol to form dispersions B, C and D respectively. Weigh three parts of 2g ternary cathode material LiNi 0.5 co 0.2 mn 0.3 o 2 , add the above-mentioned dispersions B, C, D, and stir magnetically at 60°C and 500r / min for 6-7h; after stirring, dry the obtained material at 120°C for 12h; place the dried material in a horse-boiling furnace, Raise the temperature to 450°C at a rate of 2°C / min and hold it for 5 hours to obtain nano-silica-coated LiNi with coating amounts of 0.5wt%, 1.0wt%, and 2.0wt%, respectively. 0.5 co 0.2 mn 0.3 o 2 The cladding materials (respectively denoted as B, C, D).

[0067] 1.2 Set the control sample:

[0068] Carry out the preparation process according to the above 1.1, the difference is that nan...

Embodiment 2

[0081] 2.1 Preparation of ternary cathode materials for coated lithium-ion batteries:

[0082] Weigh 40mL of isopropanol, respectively take 0.01g, 0.02g and 0.04g of nano-sized zirconia for ultrasonic dispersion (power of 700W, dispersion time of 2h) in isopropanol to form dispersions E, F and G respectively. Weigh three parts of 2g ternary cathode material LiNi 0.6 co 0.2 mn 0.2 o 2 , add the above-mentioned dispersions E, F, G, and stir magnetically at 60°C and 500r / min for 6-7h; after stirring, dry the obtained material at 120°C for 12h; place the dried material in a horse-boiling furnace, Raise the temperature to 450°C at a rate of 2°C / min and hold it for 5 hours to obtain nano-zirconia-coated LiNi with coating amounts of 0.5wt%, 1.0wt%, and 2.0wt%, respectively. 0.6 co 0.2 mn 0.2 o 2 The cladding materials (denoted as E, F, G respectively).

[0083] 2.2 Set the control sample:

[0084] The preparation process was carried out according to the above-mentioned 2.1, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com