Method for preparing graphene powder material

A technology of graphene powder and bulk material, applied in the field of graphene, can solve the problems of high cost, long time, complicated synthesis process, etc., and achieve the effects of high production efficiency, reduced consumption and avoided pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

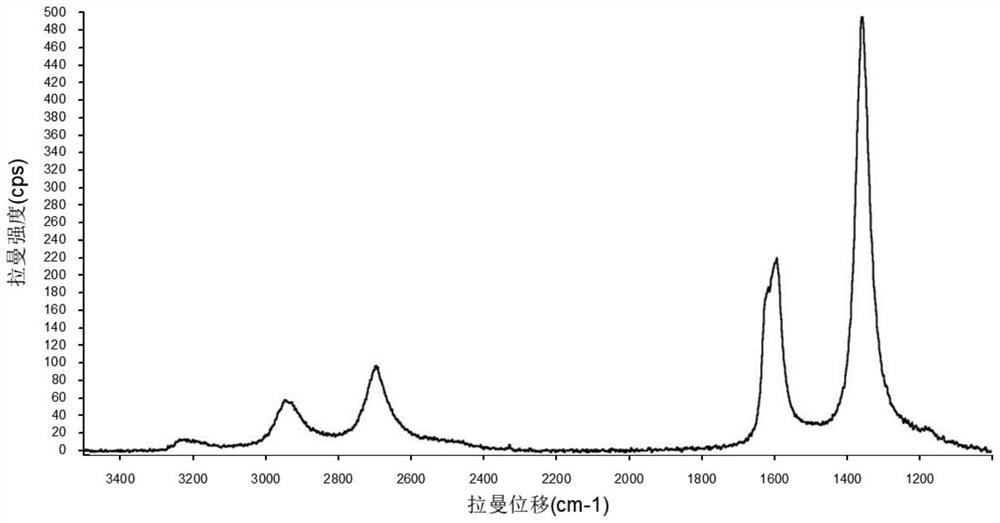

Image

Examples

Embodiment 1

[0026] Embodiment 1: Use roll-to-roll plasma-enhanced chemical vapor deposition equipment to continuously prepare a vertical graphene array on a 25-micron-thick special-purpose rolled copper foil for Kejing graphene. The winding forward speed is 0.5cm / min, and the plasma source is Inductively coupled radio frequency plasma source, the plasma intensity is 800W, the gas source is hydrogen 10sccm and methane 50sccm, and the reaction temperature is 600 degrees Celsius. The vertical graphene copper foil prepared by the chemical vapor deposition process is passed through the PMMA spray area by a winding system, and the PMMA solution is evenly sprayed on the side with the vertical graphene. Then slowly pass through an oven at a temperature of 105 degrees Celsius to heat and solidify, and the time for passing through the heating zone is 5 minutes. After taking it out, using the characteristics of poor bonding between the vertical graphene array and the copper foil, the cured vertical ...

specific Embodiment 2

[0027] Specific embodiment two: Use roll-to-roll plasma-enhanced chemical vapor deposition equipment to continuously prepare vertical graphene arrays on a 25-micron-thick Kejing graphene special-purpose rolled copper foil, the winding forward speed is 0.5cm / min, and the plasma source It is an inductively coupled radio frequency plasma source, the plasma intensity is 800W, the gas source is 20 sccm of hydrogen and 50 sccm of methane, and the reaction temperature is 600 degrees Celsius. The vertical graphene copper foil prepared by the chemical vapor deposition process is passed through the PMMA spray area by a winding system, and the PMMA solution is evenly sprayed on the side with the vertical graphene. Then slowly pass through an oven at a temperature of 105 degrees Celsius to heat and solidify, and the time for passing through the heating zone is 5 minutes. After taking it out, using the characteristics of poor bonding between the vertical graphene array and the copper foil,...

specific Embodiment 3

[0028] Specific embodiment three: Use roll-to-roll plasma-enhanced chemical vapor deposition equipment to continuously prepare vertical graphene arrays on a 25-micron-thick Kejing graphene special-purpose rolled copper foil, the winding forward speed is 0.5cm / min, and the plasma source It is an inductively coupled radio frequency plasma source, the plasma intensity is 800W, the gas source is 10 sccm of hydrogen and 50 sccm of methane, and the reaction temperature is 800 degrees Celsius. The vertical graphene copper foil prepared by the chemical vapor deposition process is passed through the PMMA spray area by a winding system, and the PMMA solution is evenly sprayed on the side with the vertical graphene. Then slowly pass through an oven at a temperature of 105 degrees Celsius to heat and solidify, and the time for passing through the heating zone is 5 minutes. After taking it out, using the characteristics of poor bonding between the vertical graphene array and the copper foi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com