Patents

Literature

186results about How to "Increase injection speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

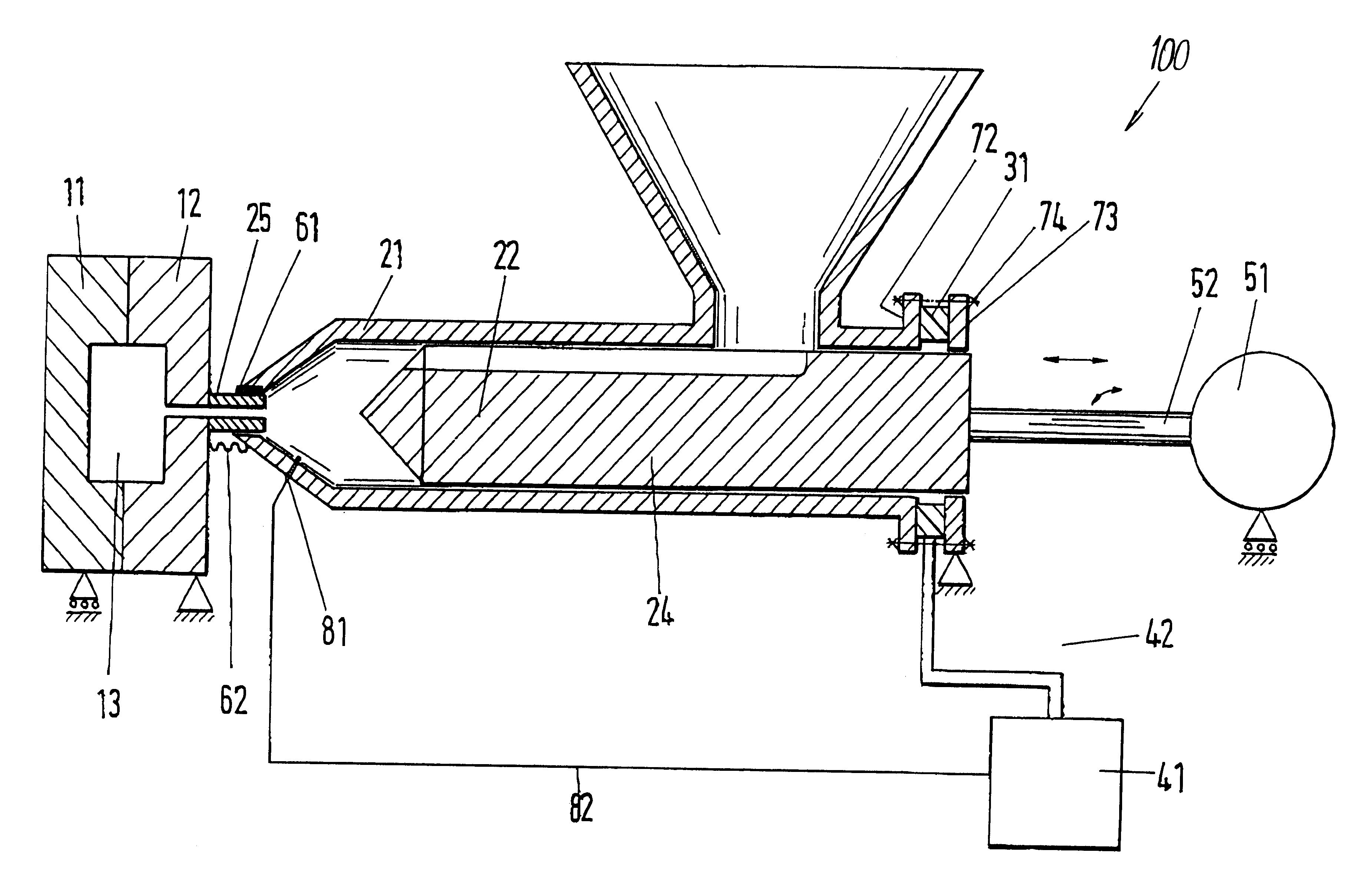

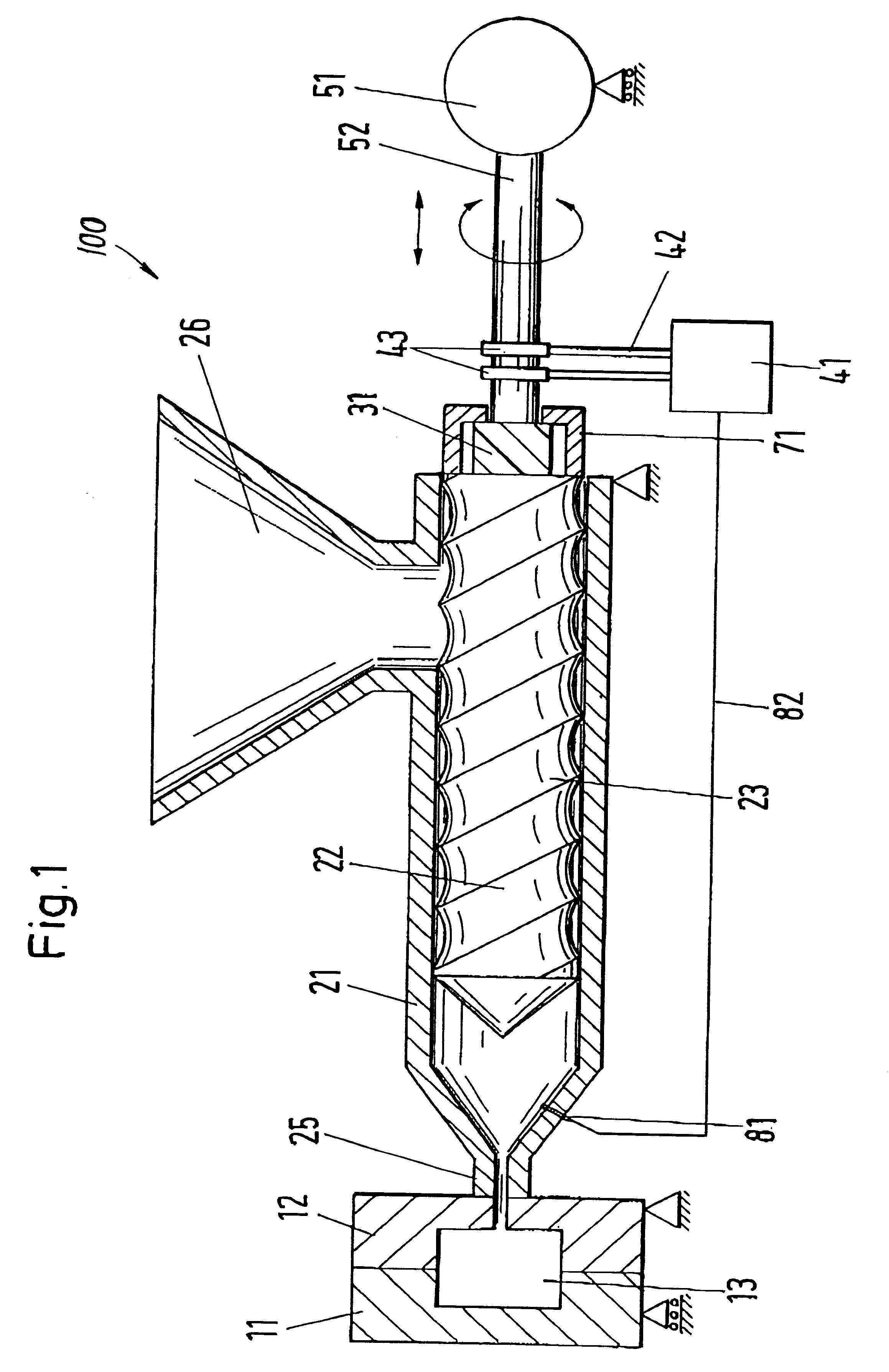

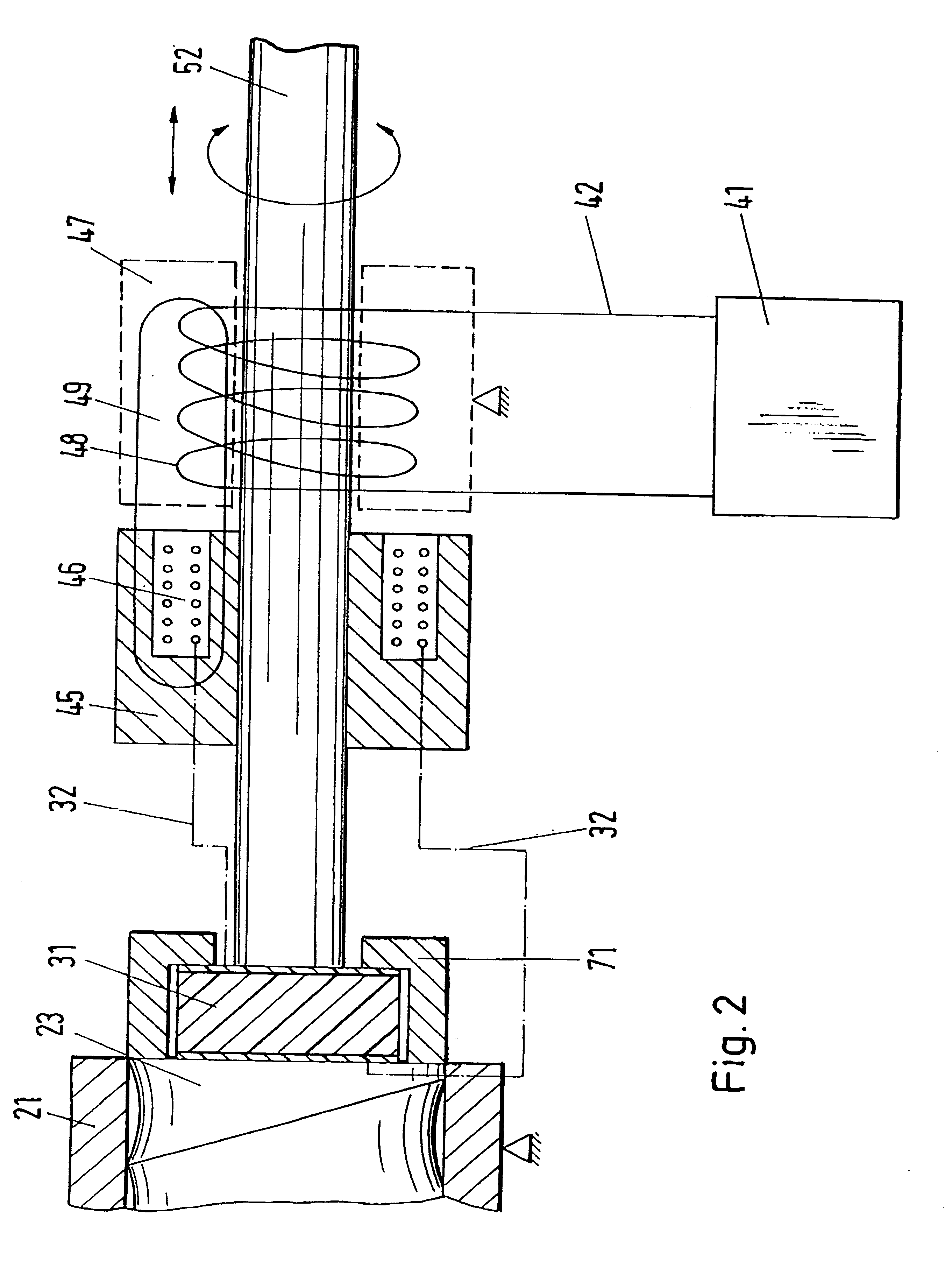

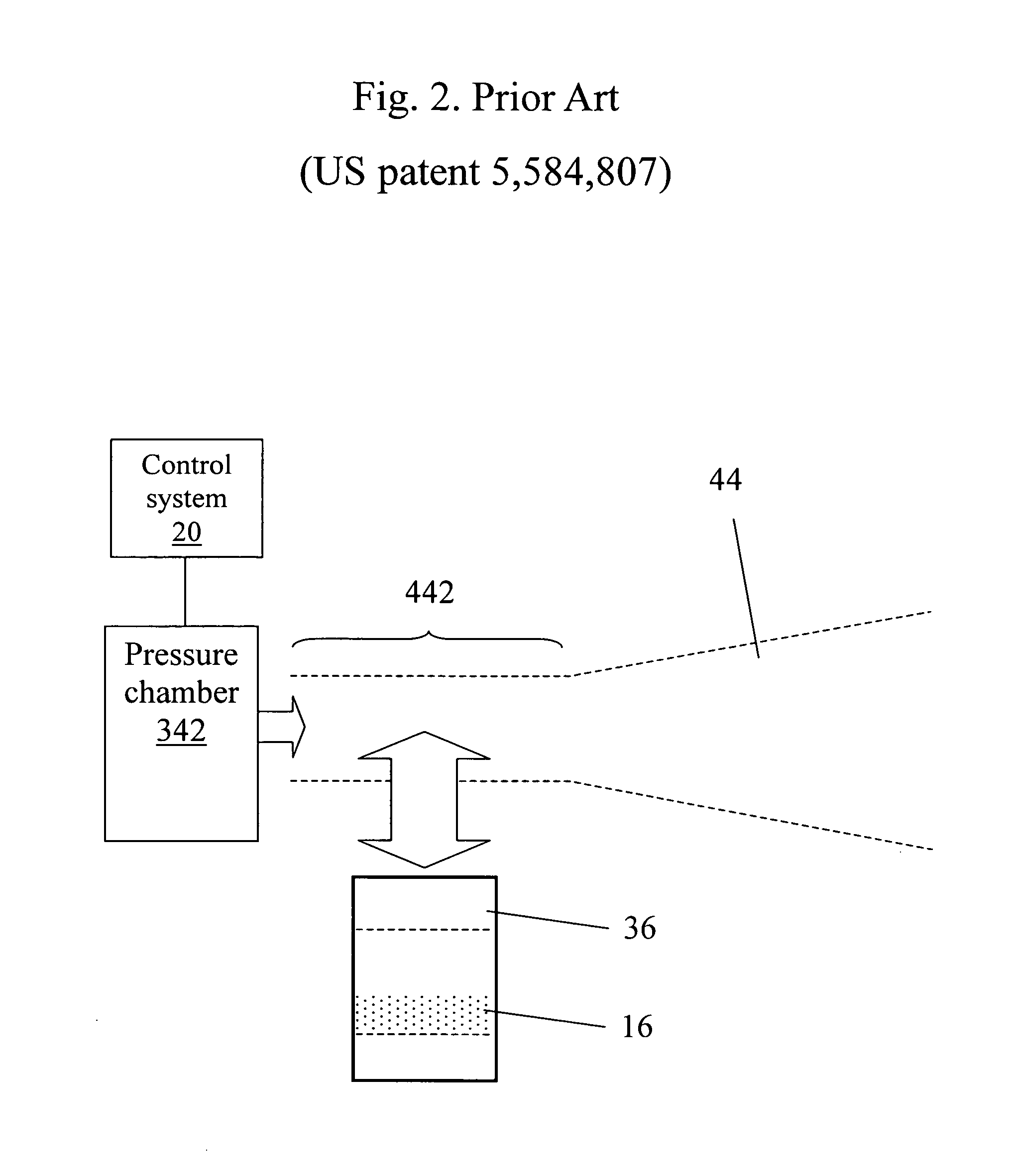

Resonating injection molding machine and process for its operation

InactiveUS6203747B1Reducing internal molecular frictionImprove the mixing effectRotary stirring mixersFrozen sweetsEngineeringInjection moulding

An injection molding machine includes an injection molding cylinder with a material supply at one end and an injection nozzle at the other end and a material conveyance unit attached to a drive and movable in the injection molding cylinder. The injection molding machine also includes a vibration element for inducing a flow of melt within the injection molding cylinder for homogenizing the melt.

Owner:ATECS MANNESMANN GMBH +1

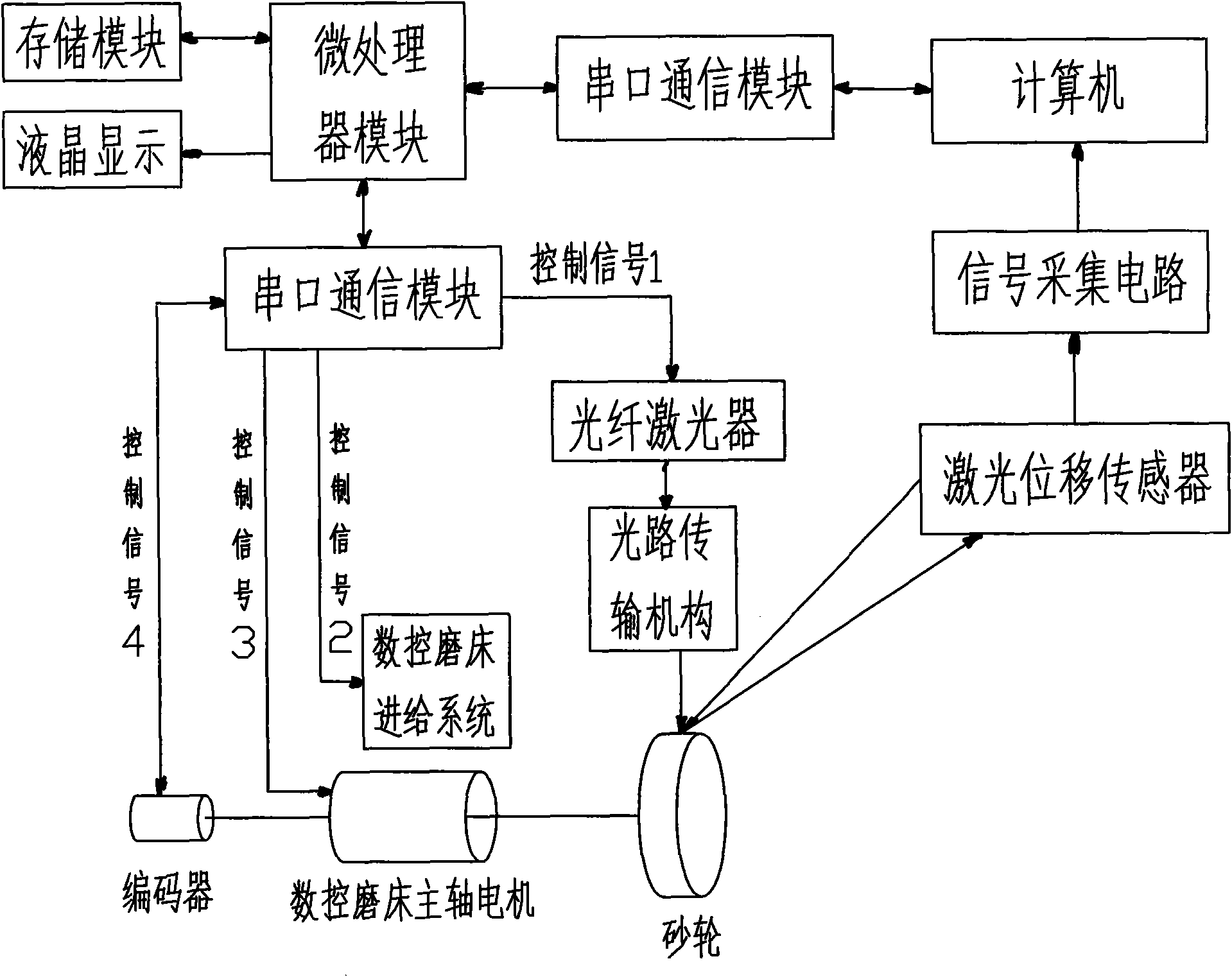

Laser trimming method for super-abrasive grinding wheel

InactiveCN101642895ANo lossImprove power densityAbrasive surface conditioning devicesNumerical controlControl signal

The invention discloses a laser trimming method for a super-abrasive grinding wheel, comprising the following steps: a, a grinding wheel is mounted on a numerical control grinding machine and is driven to rotate; b, a laser displacement sensor is aligned to the surface of the grinding wheel, does axial feeding movement relative to the grinding wheel and scans the surface of the grinding wheel, scanning data is input into a computer storing an ideal profile of the grinding wheel to form an actual profile of the grinding wheel on the surface, the actual profile is compared with the ideal profileof the grinding wheel to obtain a distribution condition of allowance removal; c. the computer sends trimming control signals to the numerical grinding machine and a laser through a microprocessor controller, so that the laser emits an appropriate laser pulse to burn a point to be trimmed on the grinding wheel according to the control signals, the laser displacement sensor detects present remained allowance of the point, and the allowance of the point in the computer is updated timely; and d, the step c is carried out repeatedly till the trimming precision as required is achieved.

Owner:HUNAN UNIV

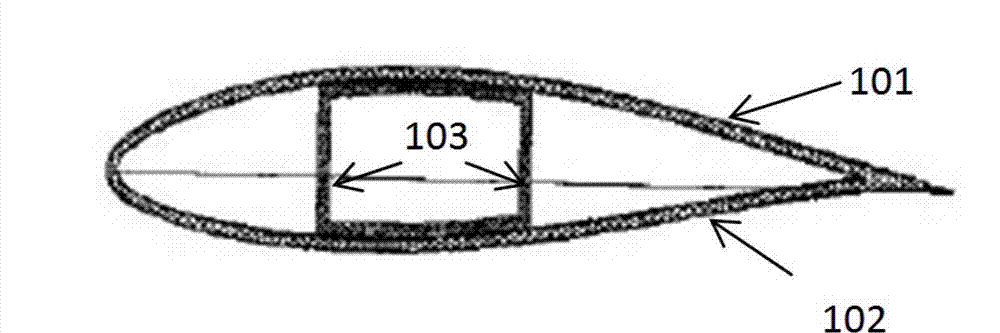

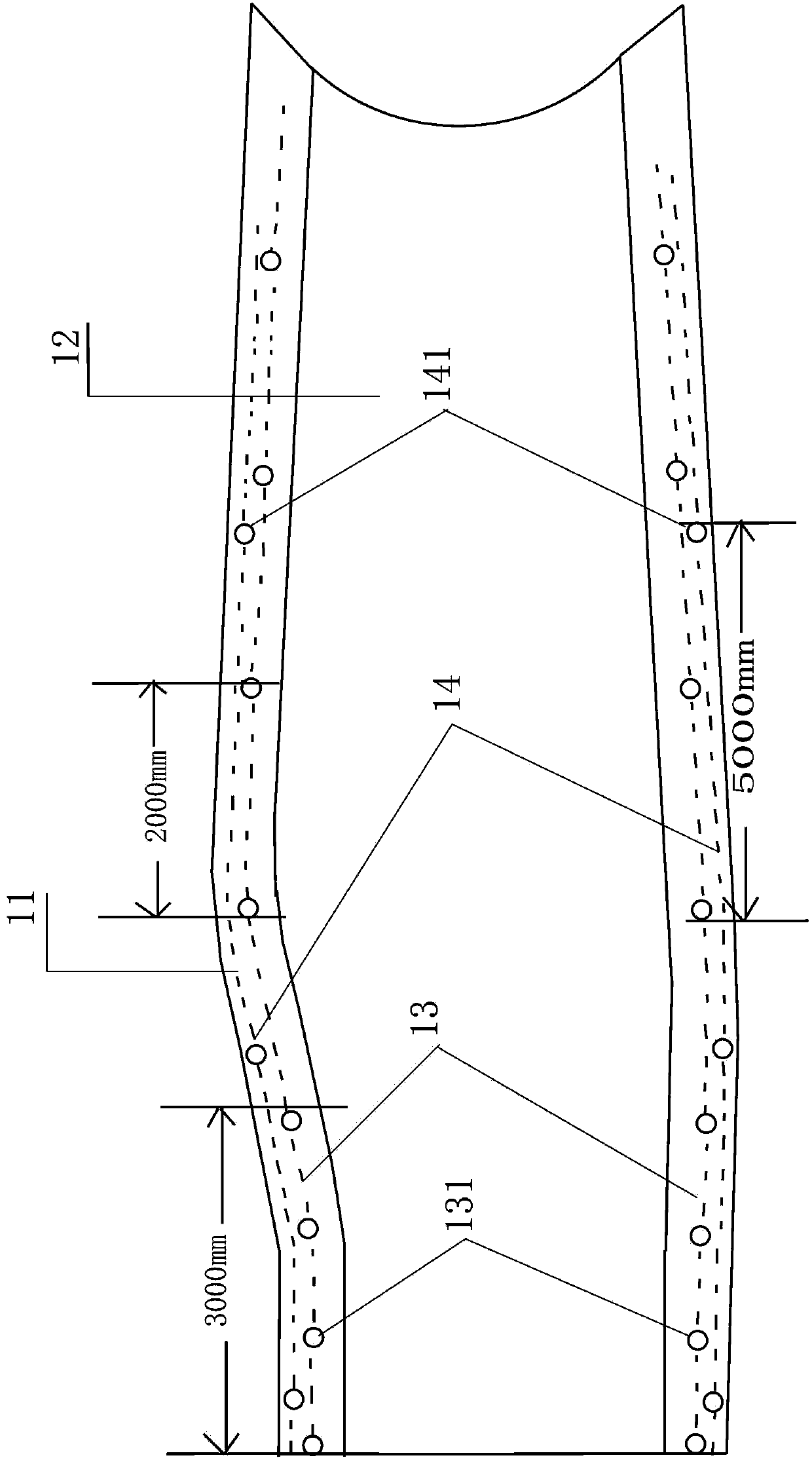

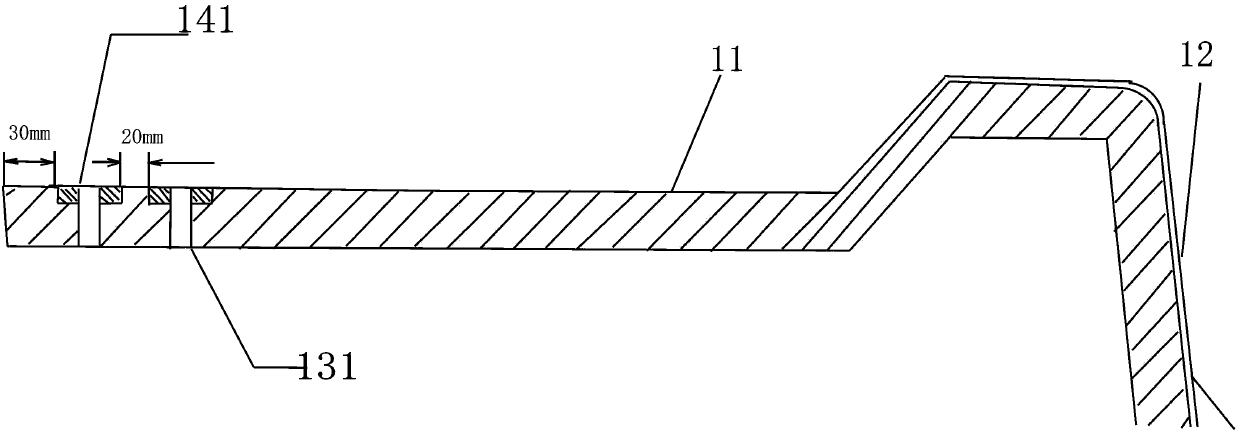

Integrated forming method and device for segmented blade

ActiveCN103042700ASolve the problem of integrated moldingImprove finished product qualityDomestic articlesElectricityPositive pressure

The invention relates to a manufacturing process method for integrated formation of a horizontal shaft segmented wind power blade and an integrated device applicable to the method. The wind power blade at least comprises two segments of composite material blade segments. A metal bolt sleeve is embedded into the connecting part of the two adjacent segments during manufacturing, and integrated formation is realized by a positive pressure auxiliary vacuum perfusion mode, so the defects of the traditional perfusion process are overcome, and the manufacturing problem of the segmented blade is solved. In addition, the integrated formation process avoids various disadvantages and risks caused by that the traditional process shell adopts adhesive to adhere.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

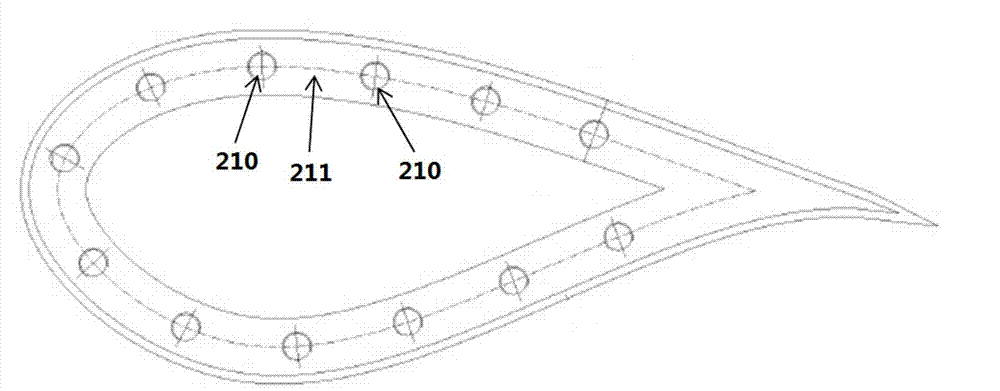

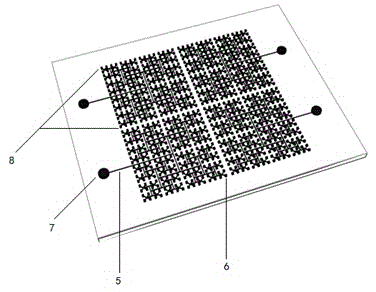

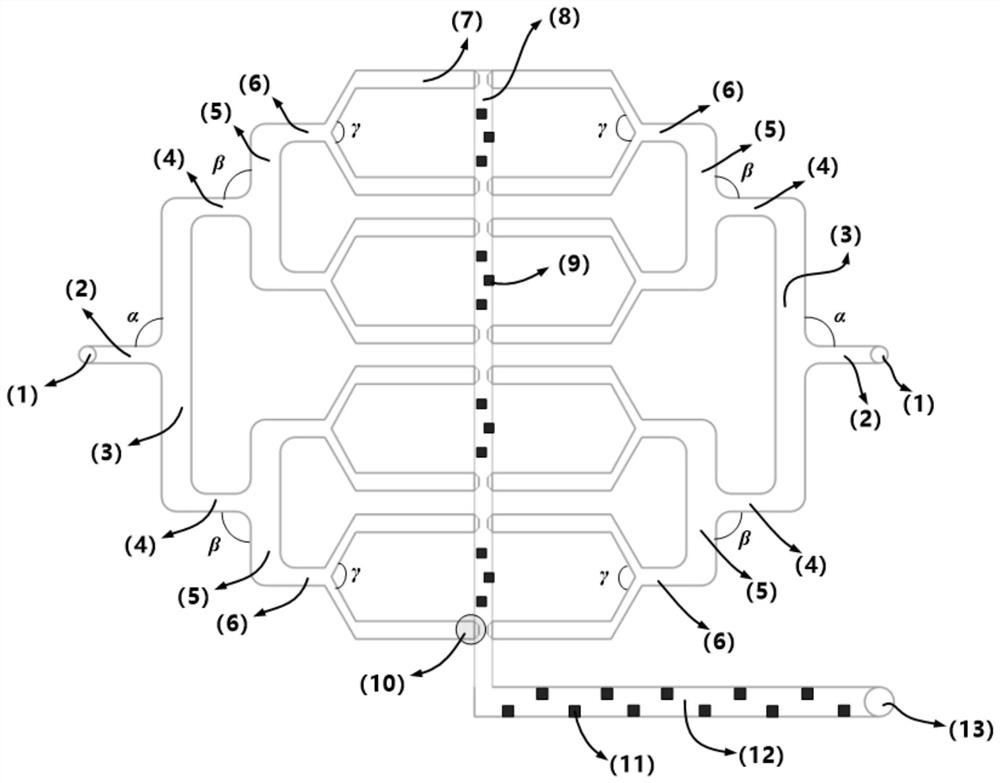

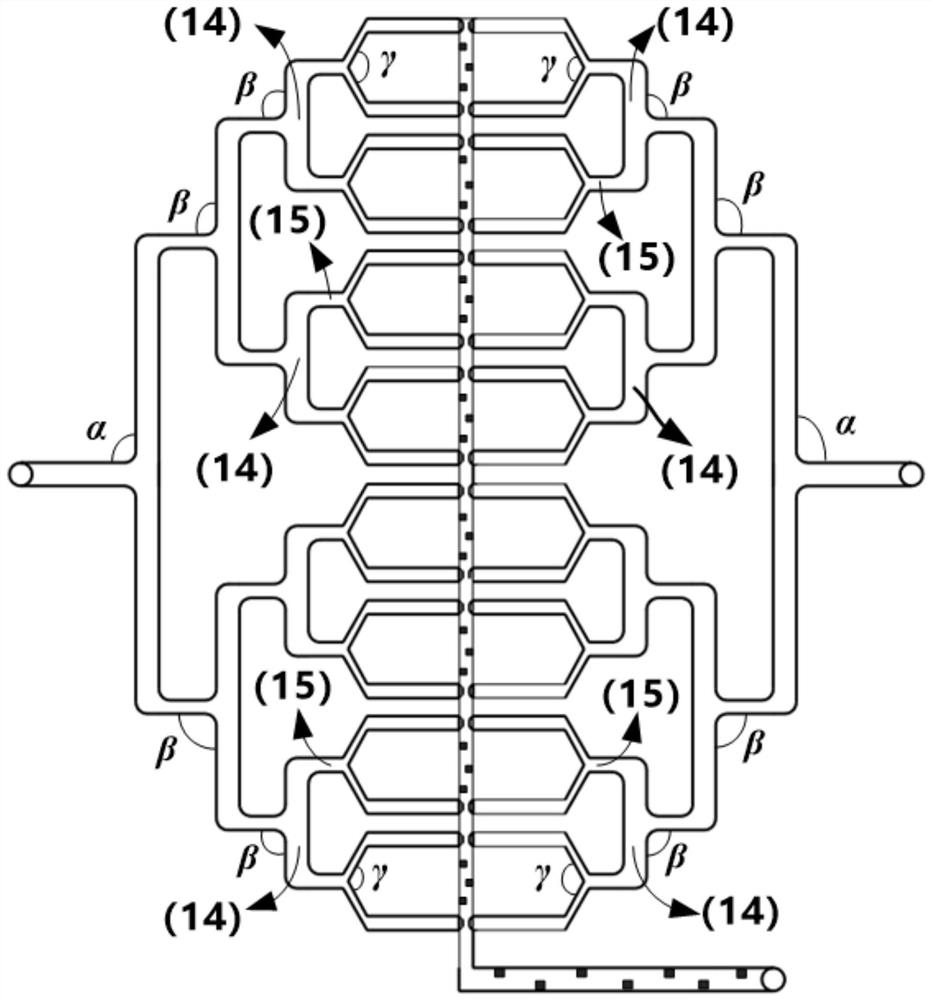

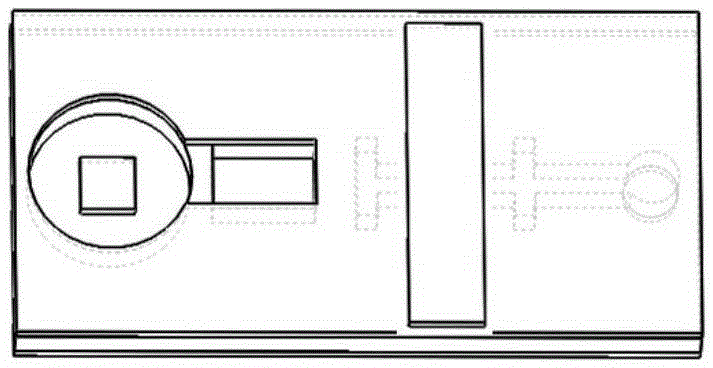

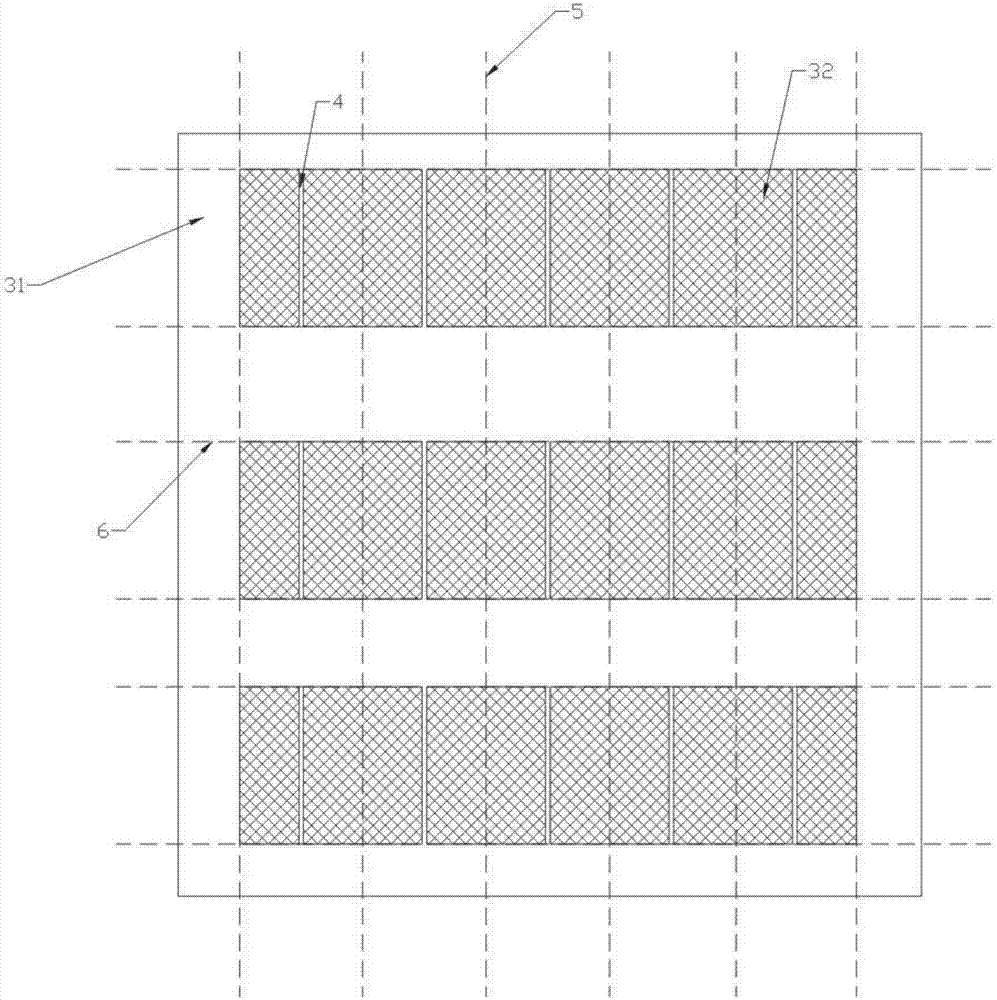

High-integration equidistance equipartition nucleic acid amplification micro-fluidic chip and application

InactiveCN104894106AReduce consumptionAutomatic fast and even dispersionBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringCell separation

The invention provides a high-integration equidistance equipartition nucleic acid amplification micro-fluidic chip. The high-integration equidistance equipartition nucleic acid amplification micro-fluidic chip sequentially consists of a cover glass layer, a reaction layer, a decorative layer and a sealing layer from bottom to top in a thermal bonding manner, wherein the reaction layer is provided with n reaction modules, and each reaction module is provided with a circulation passage, a reaction micro-cavity and a sample feeding opening by utilizing a multilayer soft photoetching technology. By adopting the chip, the circulation distance of the sample before being introduced into a small chamber is identical, the sample feeding quantity is identical, and an error caused by the non-uniformity of the reaction volume can be avoided. The experiment cost is reduced. The sample feeding speed is increased. Quantitative detection in real time can be realized. The chip is reasonable in design, simple in structure, simple to operate and low in production cost and can be applied in the real-time fluorescent quantitative nucleic acid amplification, digital nucleic acid amplification, single-cell separation of nucleic acid amplification, SNP detection, detection of single-base mutation, detection of copy number imbalance, research of single-cell gene expression profile, early detection of cancer marker, stem cell differentiation identification, cell separation identification and the like.

Owner:ZHEJIANG UNIV

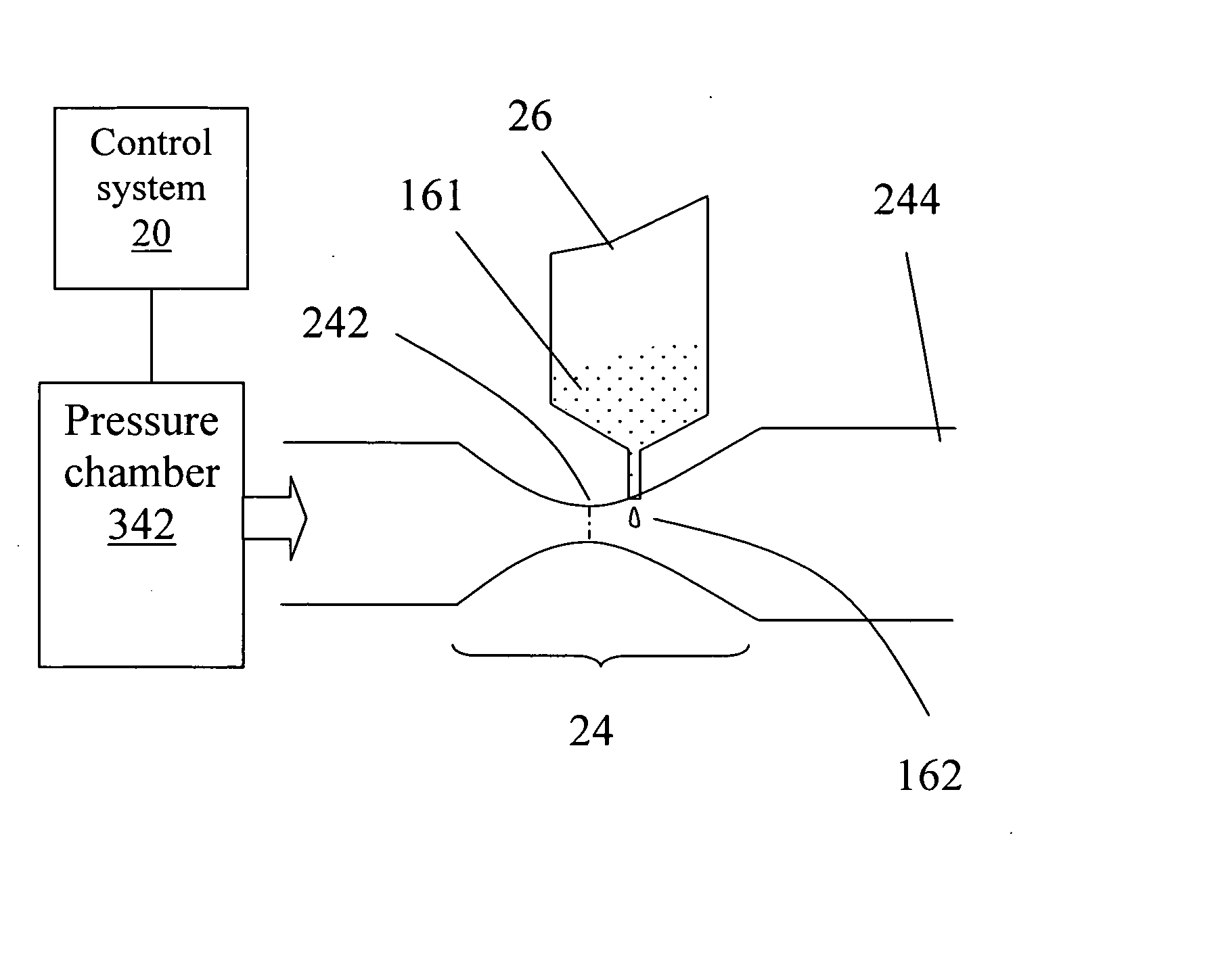

Gene injection instrument nozzle

InactiveUS20050177098A1Increase pressureIncrease injection speedJet injection syringesAutomatic syringesBiological bodyThroat

The nozzle of a gene injection gun is lined inside with a conduit, which has a narrow throat. The throat has a convergent inlet and a divergent outlet. Compressed gas is fed from the inlet, and accelerates to supersonic speed in the throat region. Liquid drug is released to the throat region as droplets, and carried by the accelerated gas flow toward the outlet of the muzzle for injection into a biological body.

Owner:SONDLIN TECH CORP

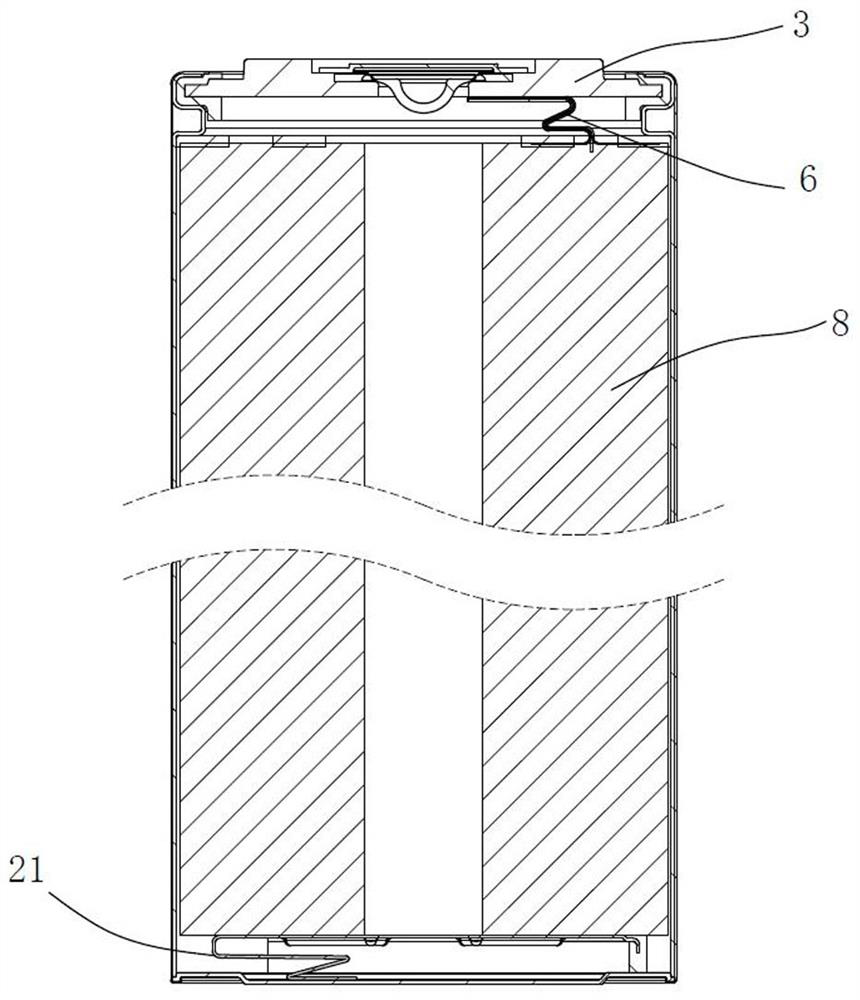

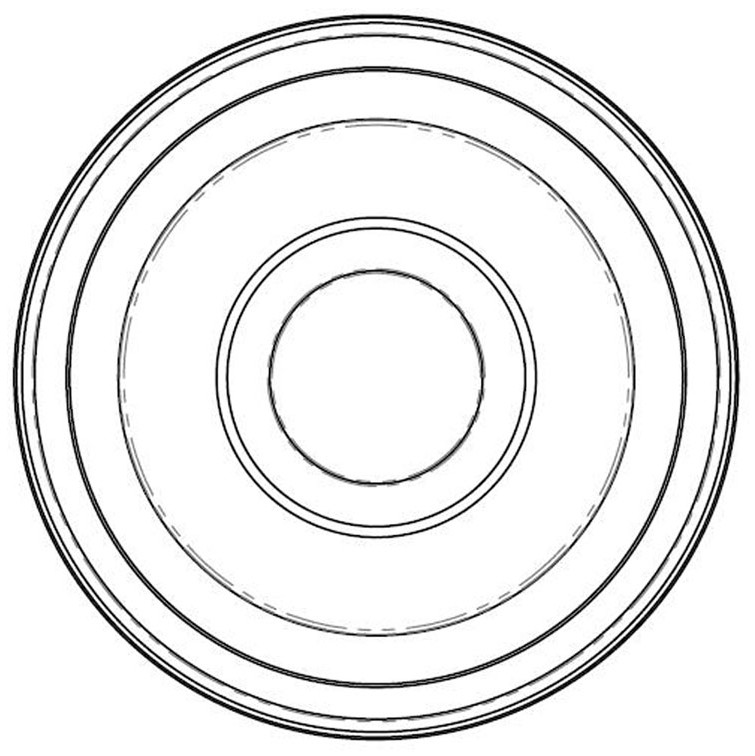

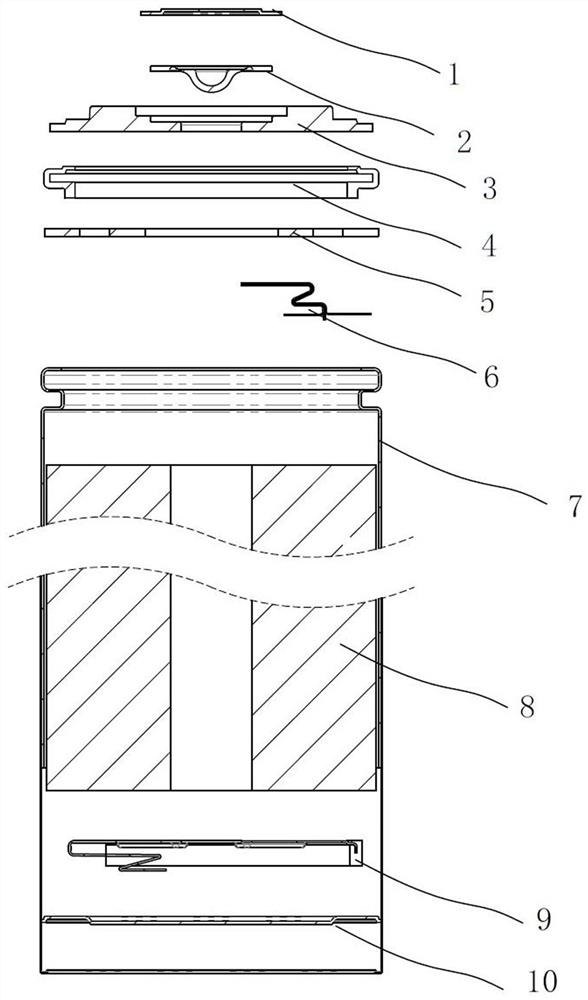

Circular lithium battery and production method thereof

PendingCN112151732AGuaranteed overcurrent capabilityEasy injectionFinal product manufactureSmall-sized cells cases/jacketsMechanical engineeringBattery cell

The invention discloses a circular lithium battery and a production method thereof. The lithium battery comprises a shell, a battery cell, a positive electrode battery cover plate assembly and a negative electrode battery cover plate assembly. A positive electrode foil and a negative electrode foil are separated by a diaphragm and then wound into a cylindrical battery cell. A positive electrode isa multi-tab structure, and a negative electrode is a full-tab structure. A sealing body is fixed on the anode battery cover plate in surrounding manner, and a safety valve is arranged in the middle.The negative electrode battery cover plate assembly comprises a current collector, a negative electrode battery cover plate and a current collector bracket; and the current collector body is fixedly connected to the upper part of the current collector bracket and is electrically connected with the negative electrode battery cover plate through a current collector connecting part. According to theinvention, an over-current capability of the battery is ensured, liquid injection and formation of the battery are facilitated, and installation is convenient and reliable.

Owner:星恒电源(滁州)有限公司

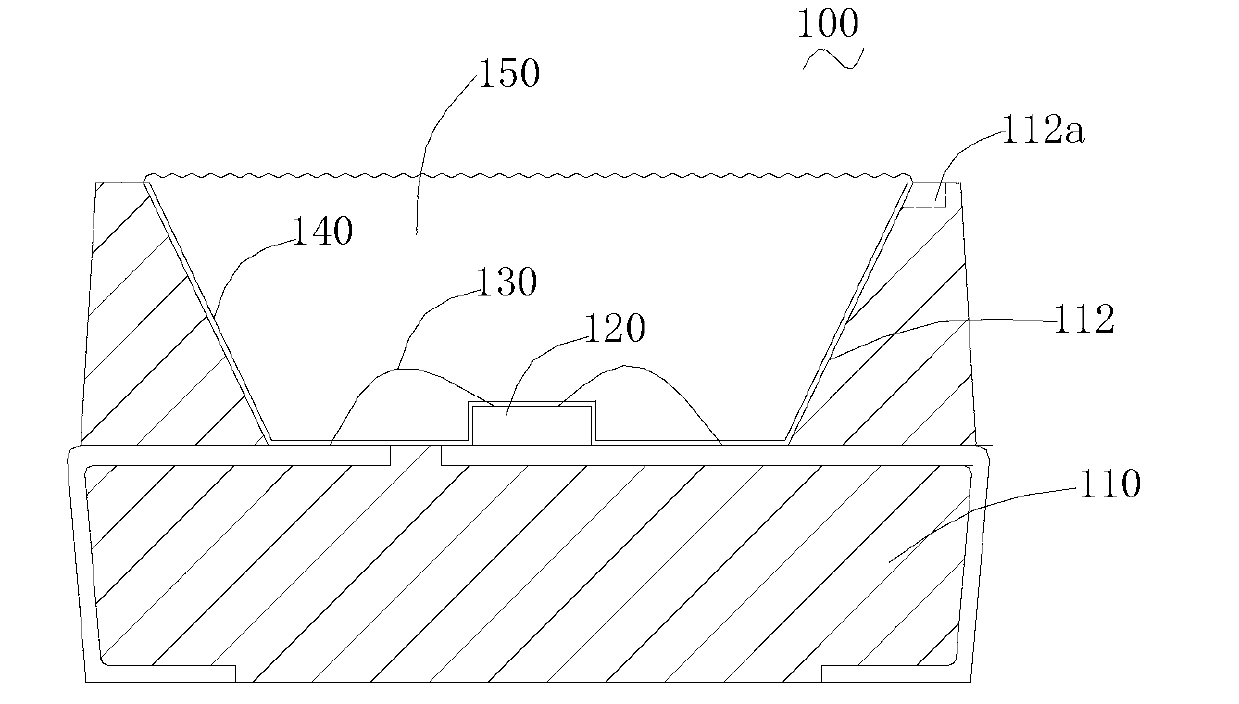

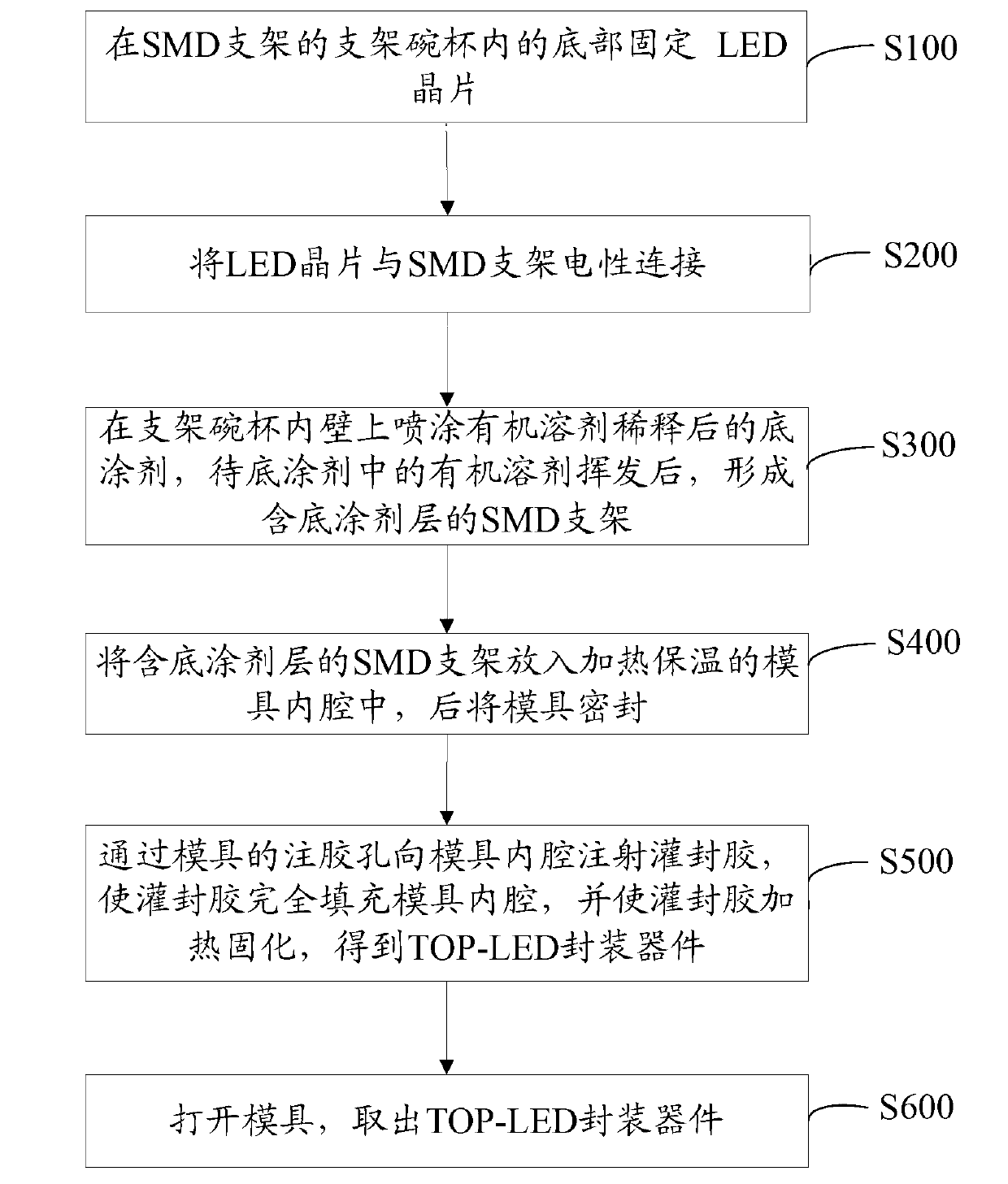

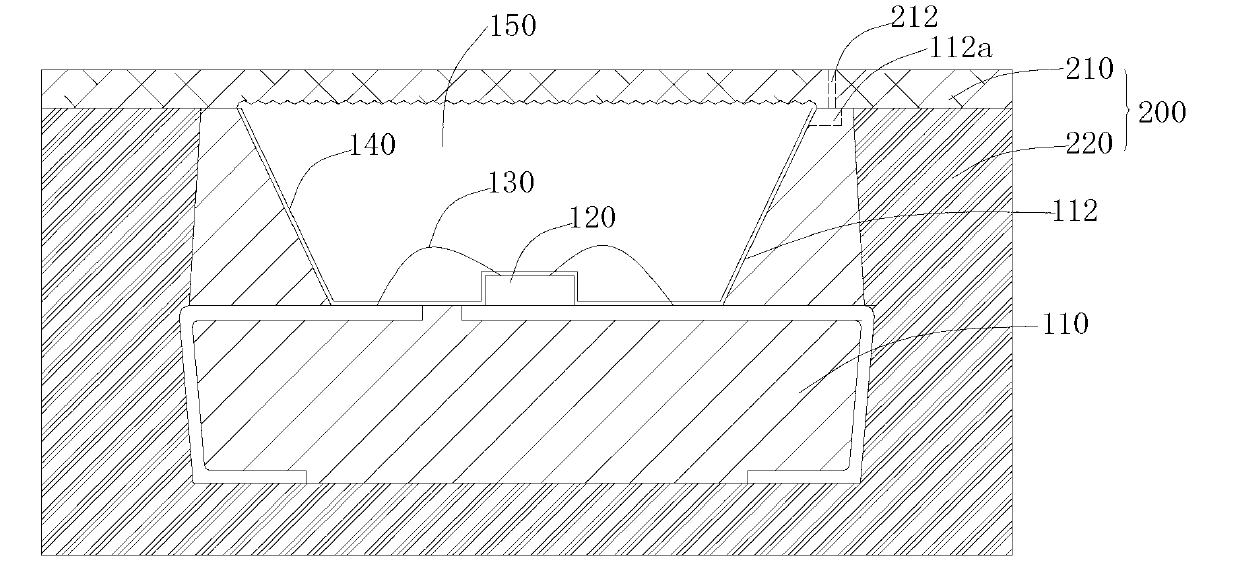

TOP-LED packaging device and preparation method thereof

ActiveCN103219447AImprove long-term stabilityImprove safety and reliability performanceSolid-state devicesSemiconductor devicesEngineeringSealant

The invention provides a TOP-LED packaging device and a preparation method of the TOP-LED packaging device. The TOP-LED packaging device comprises an SMD support, an LED wafer, an undercoat and pouring sealant. The SMD support is electrically connected with the LED wafer. A support bowl cup is arranged at one end of the SMD support. The LED wafer is arranged at the bottom of the interior of the support bowl cup. The undercoat is arranged on the inner wall of the support bowl cup. The interior of the support bowl cup is filled with the pouring sealant. Due to the fact that the undercoat is arranged on the inner wall of the support bowl cup of the SMD support, the TOP-LED packaging device has the advantages of being capable of improving bonding strength between the SMD support and the pouring sealant, being beneficial to long-term using stability, and improving safety performance and reliable performance.

Owner:LEDMAN OPTOELECTRONICS

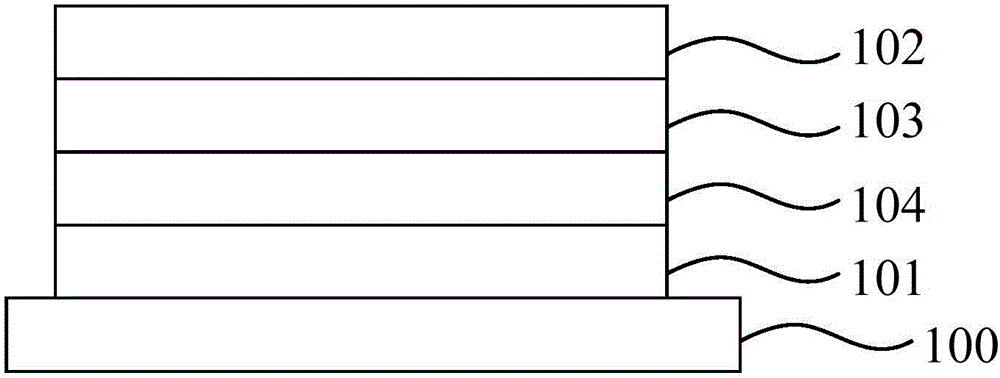

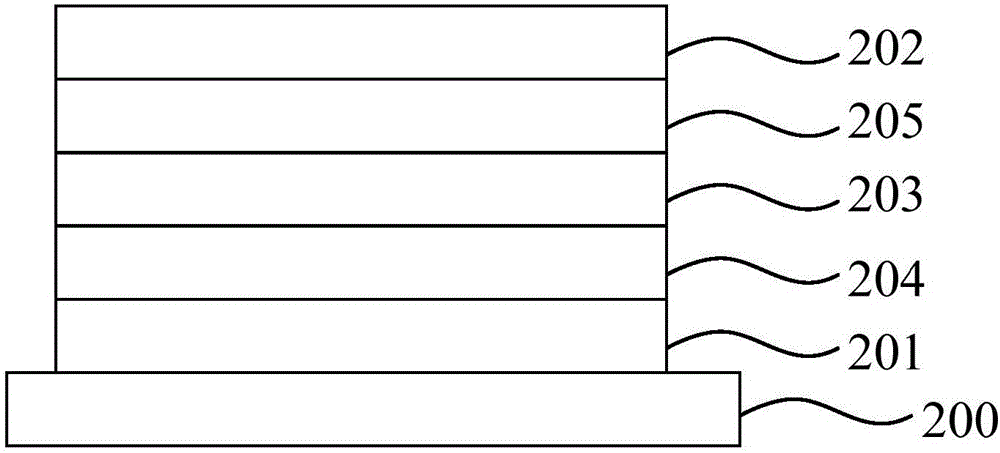

OLED display panel, production method and electronic equipment containing same

ActiveCN106848084AIncrease injection speedBalance injectionSolid-state devicesSemiconductor/solid-state device manufacturingHost materialLight-emitting diode

The invention relates to an OLED display panel. The OLED display panel comprises a first electrode and a second electrode which are oppositely arranged and a laminate arranged between the first electrode and the second electrode, wherein the laminate at least comprises a first auxiliary light emitting layer and a light emitting layer which are sequentially arranged from the first electrode; the first auxiliary light emitting layer selects a host-guest doped form, a radialene compound is doped in a host material, hole injection rate is improved by utilizing stronger hole injection capacity of the radialene compound, voltage of a device is reduced, further light emitting efficiency is improved, and a horizontal leakage current phenomenon is reduced.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD +1

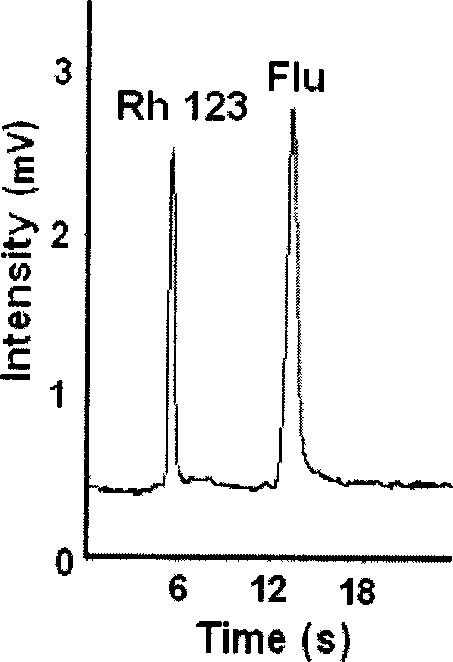

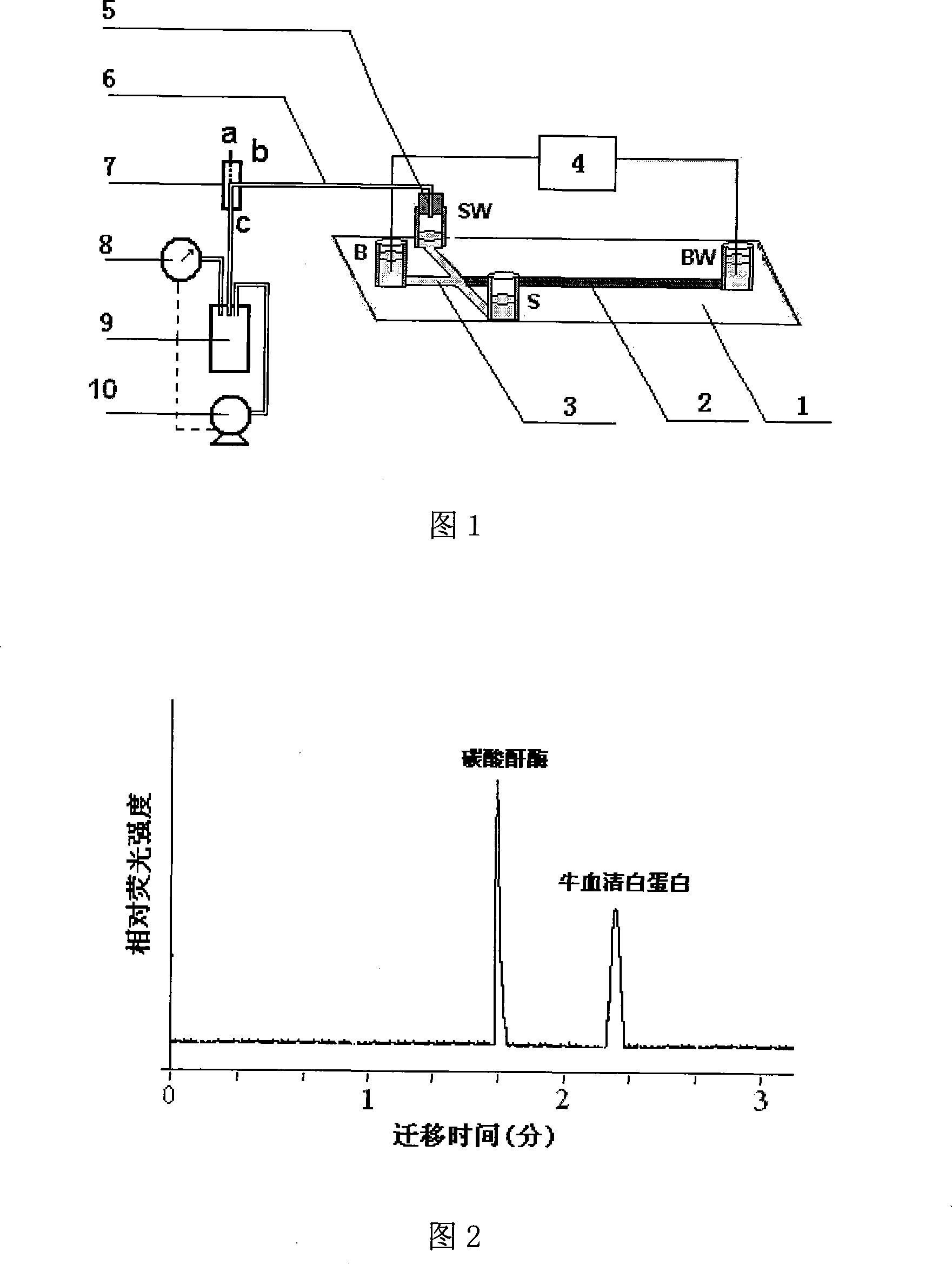

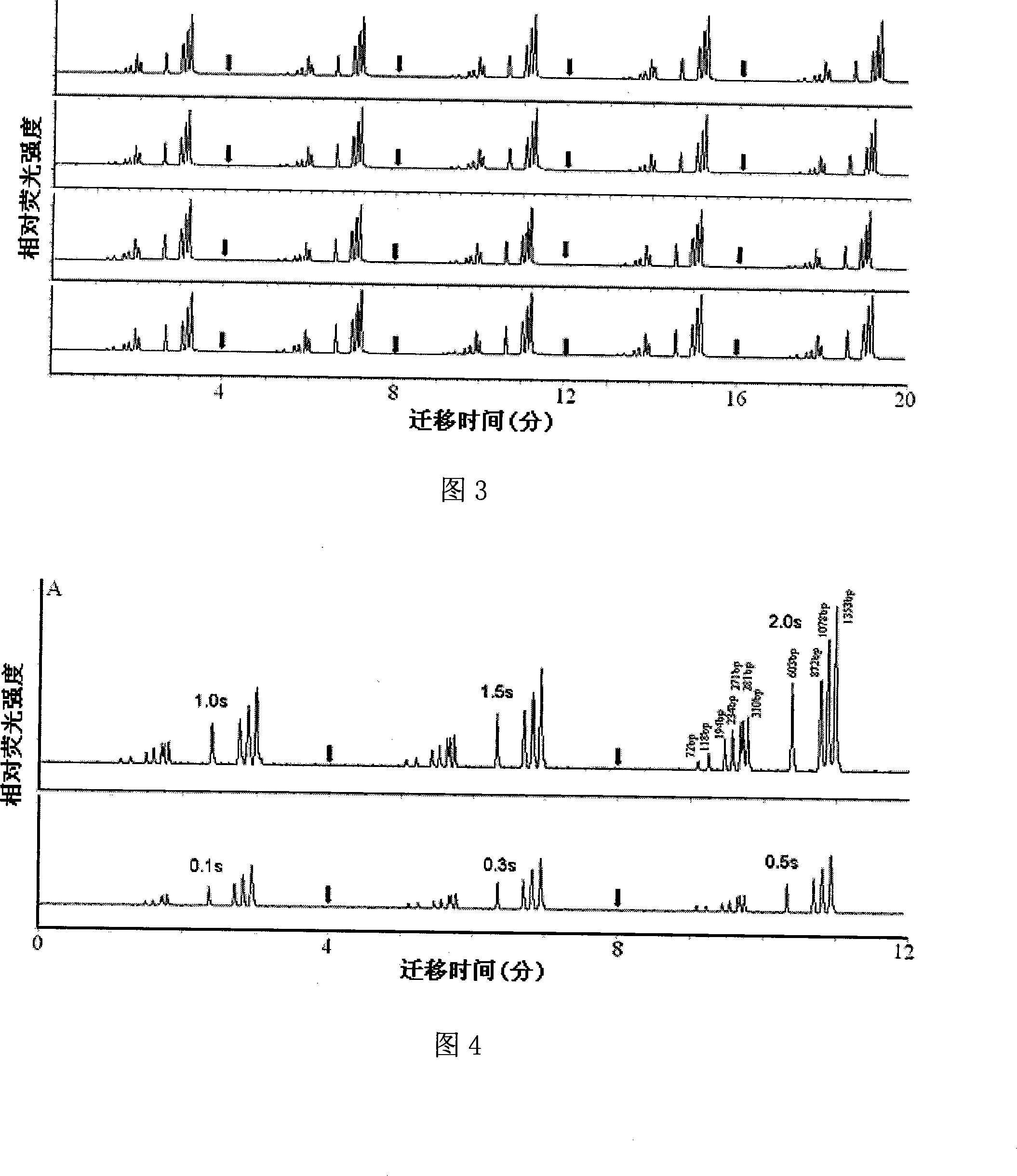

Micro flow control chip capillary electrophoresis negative pressure sampling method

InactiveCN1737562AAvoid discriminatory effectsAvoid dependenceSemi-permeable membranesFixed microstructural devicesElectricityCapillary electrophoresis

This invention relates to one electrophoresis sample in and isolation method of micro flow control capillary, which is characterized by the following: using micro flow control chip network structure; adopting column plug pump and taking sample from waste pool air through three-way valve and interface to form negative pressure; the micro flow chip and other sample solution and buffer liquid flowing downward and forming stable sample plug in the crossing place of sample in channel and isolation channel and connecting the valve with air through three-way valve.

Owner:ZHEJIANG UNIV

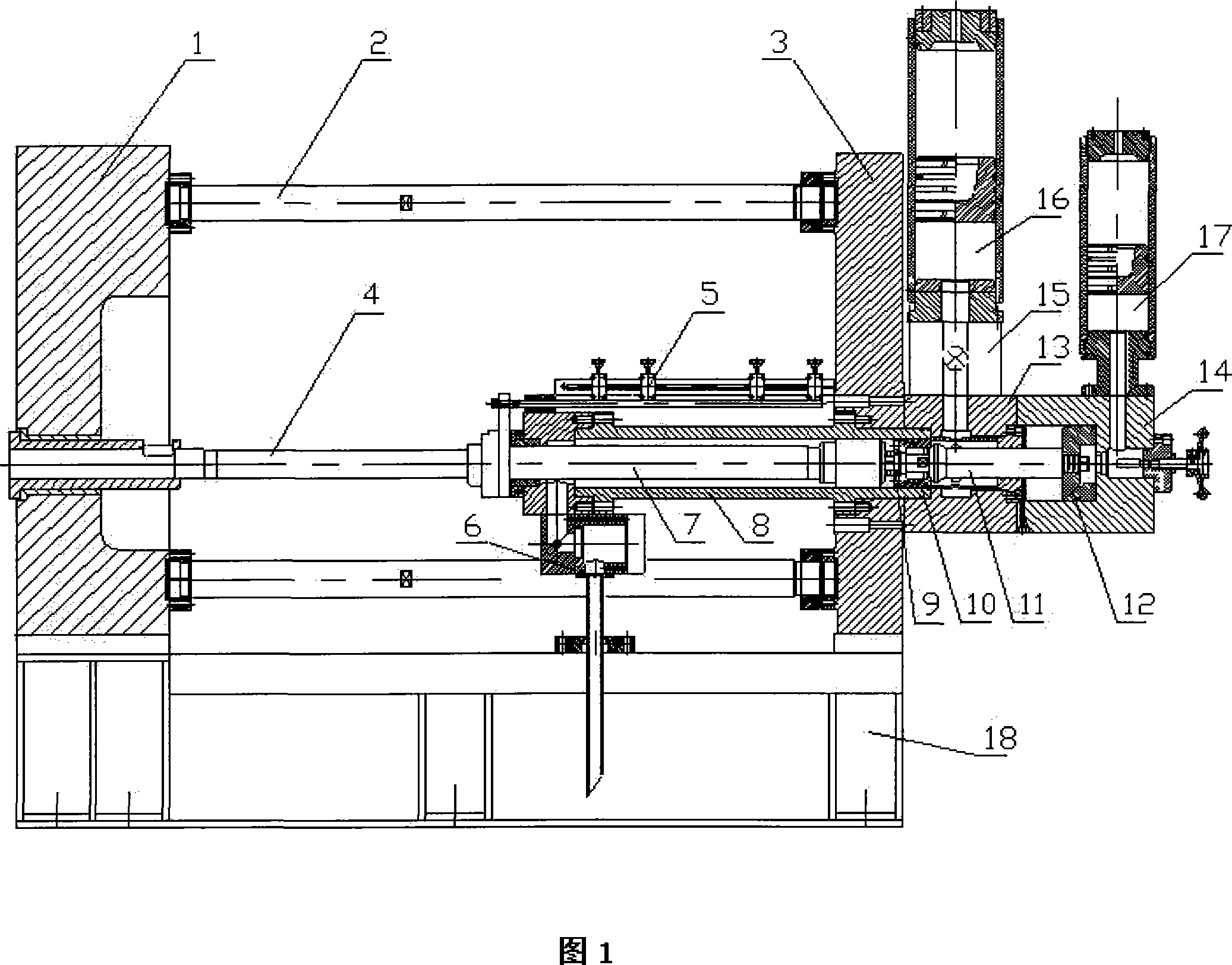

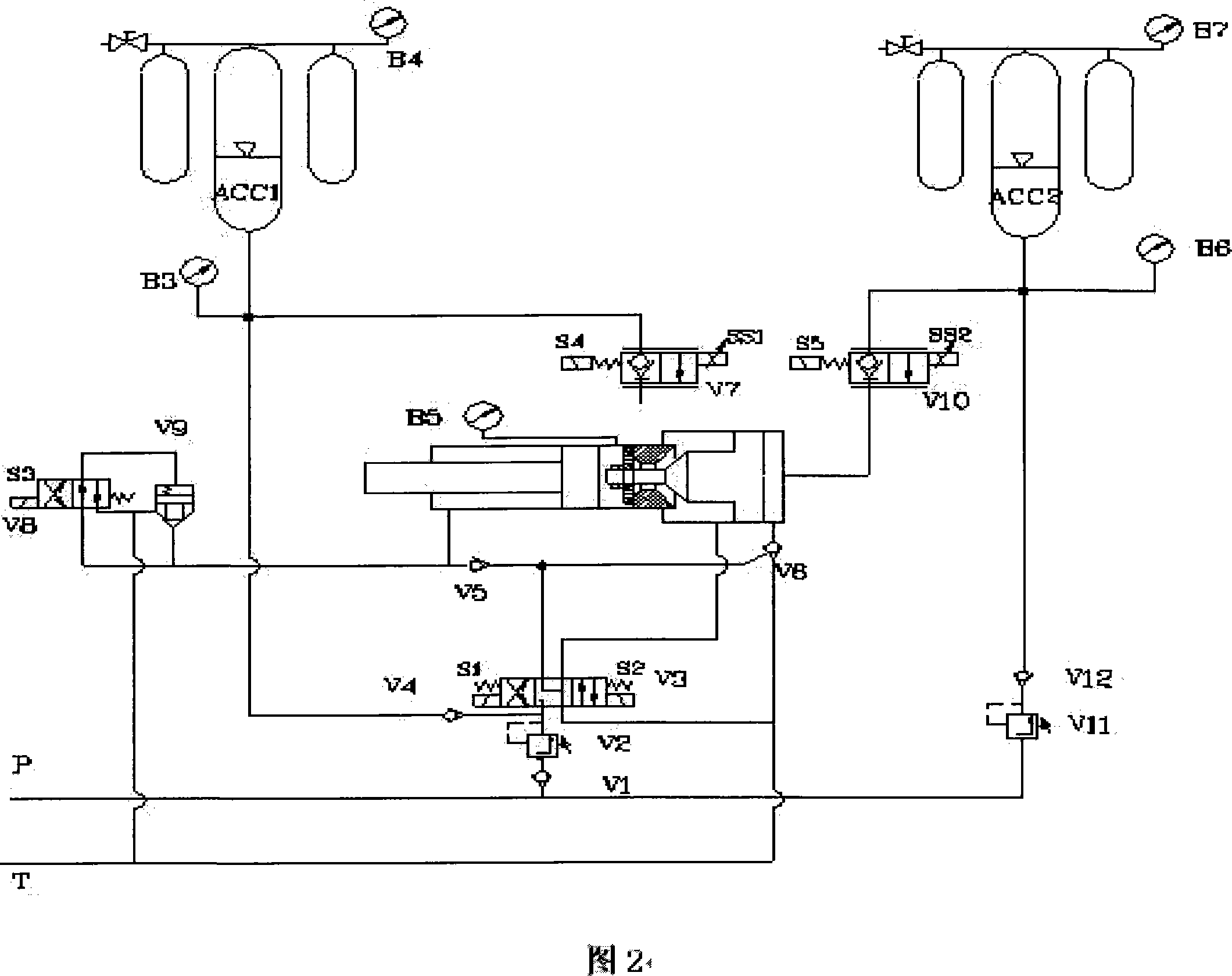

Vertical pressure charging press-shoot system

The invention provides a vertical pressure charging pressing system capable of enhancing pressing property, stability and safety of a die casting machine by using a structure with a pressure charging oil cylinder perpendicular to an injection oil cylinder. The slow-press hydraulic oil and the quick-press hydraulic oil enter the rear cavity of an injection oil cylinder through a large-through-diameter solo valve. The pressure charging oil cylinder is perpendicular to the injection oil cylinder, disposed at the upper or lower part and between the solo valve and the injection plug. Two pressure charting starting modes are provided, one depends on pressure feedback of the injection oil cylinder rear cavity, and the other depends on displacement feedback of the injection oil cylinder. When the PLC or the process control machine receives the feedback signal, the pressure charging valve opens, the pressure charging oil cylinder starts to work, the pressure in the rear cavity of the injection oil cylinder increases quickly, the solo valve closes at the same time, and the pressure charging function is completed. The invented system is provided with following advantages: quick injection, the pressure charging channel is large and shot, quick injection speed, short pressure build-up time, long pressure charging distance, and high energy charging type.

Owner:SUZHOU SANJI FOUNDRY EQUIP

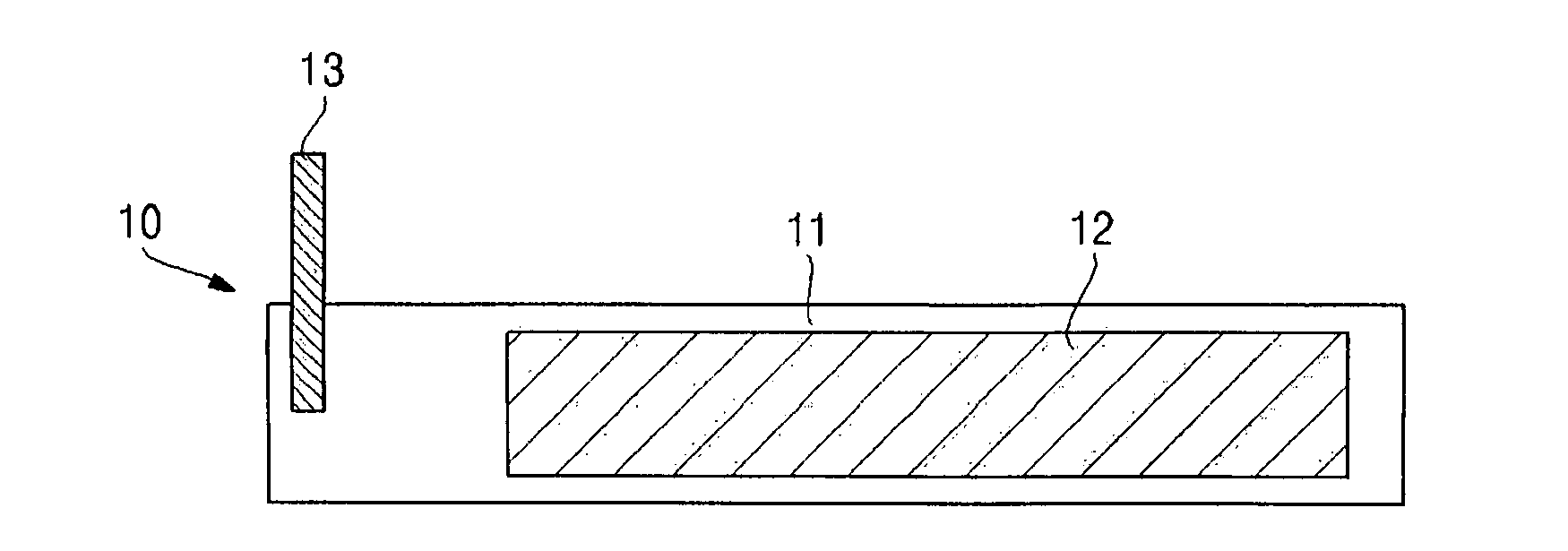

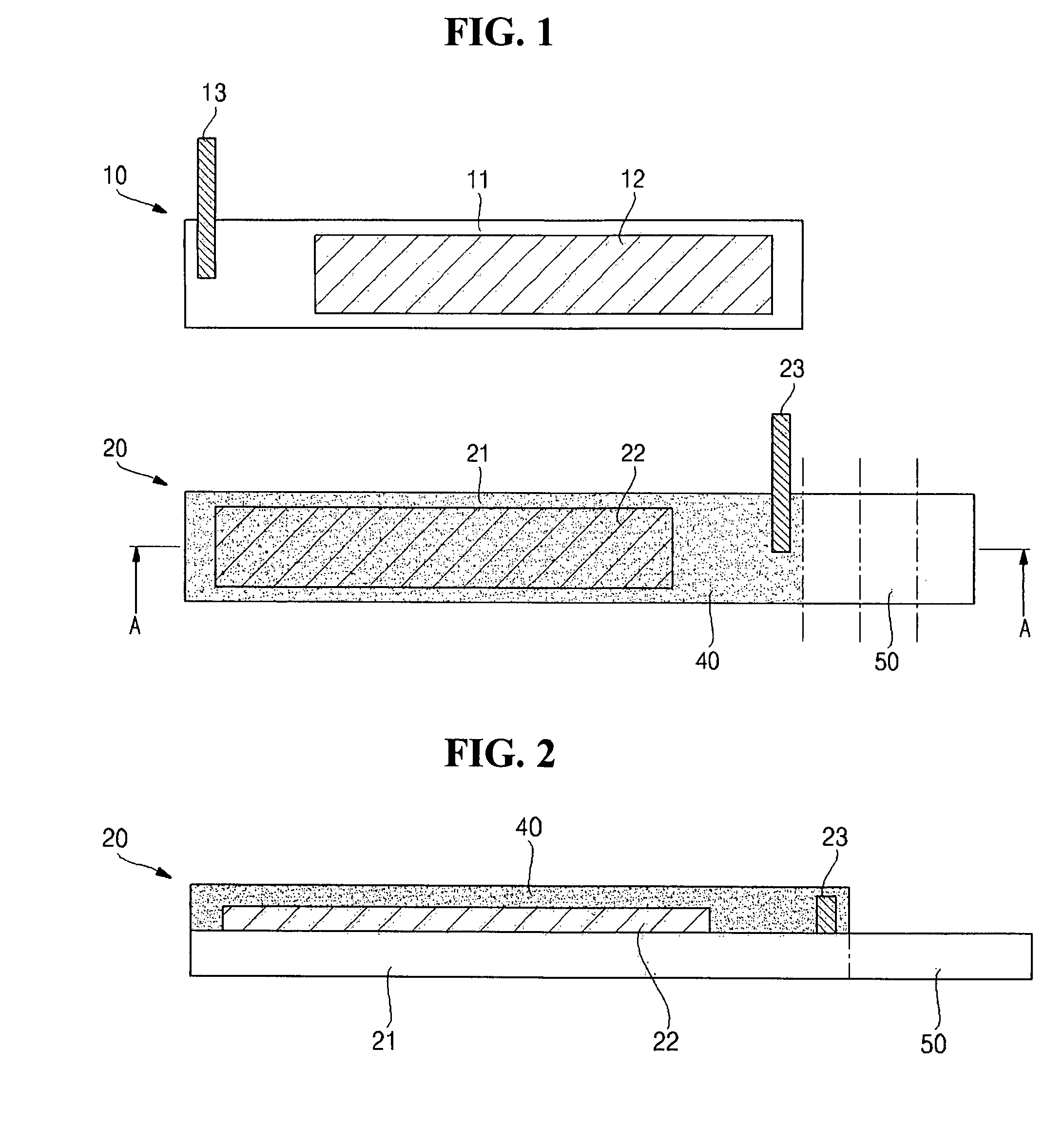

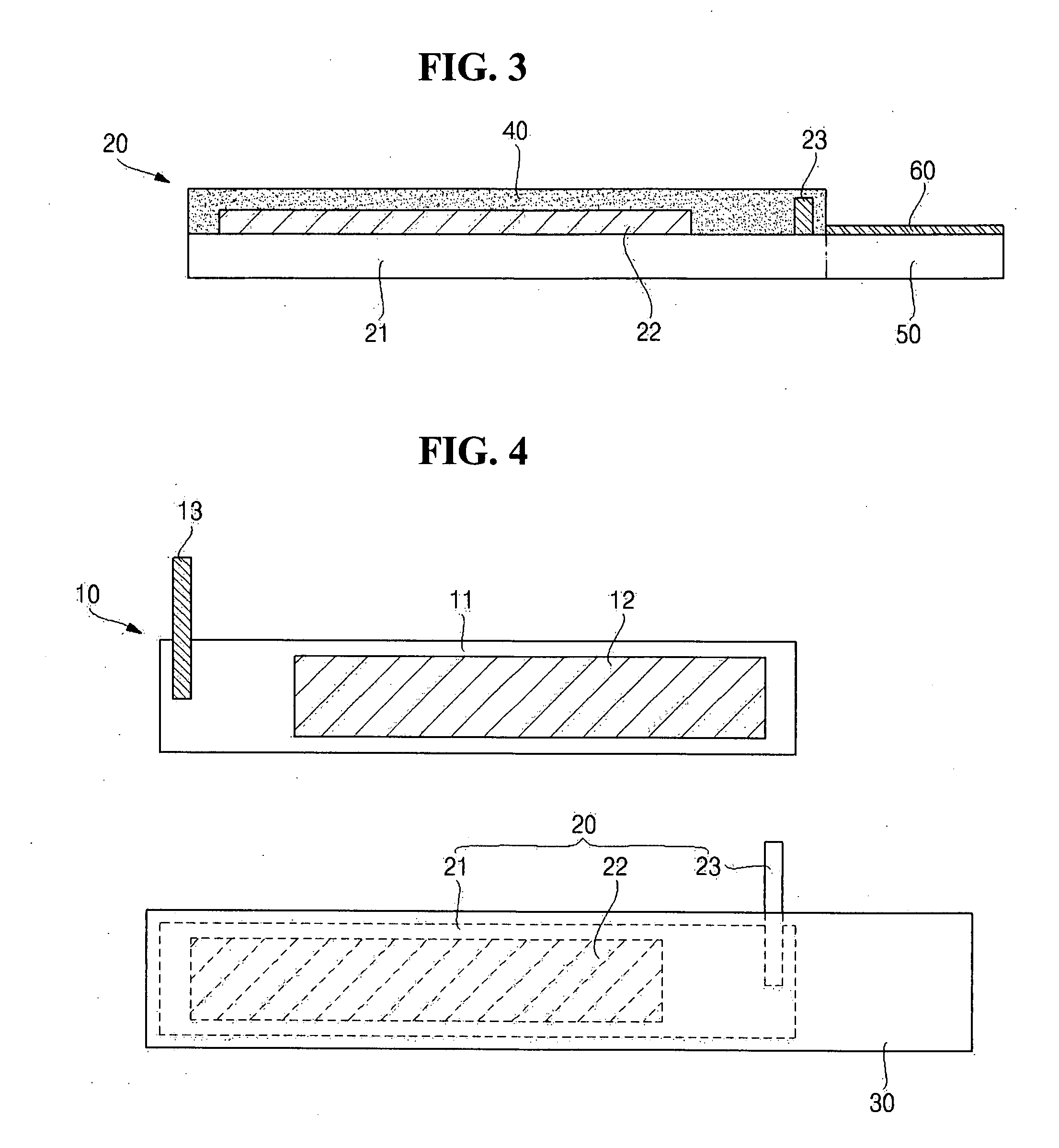

Jelly roll electrode assembly and secondary battery using the assembly

InactiveUS20080138699A1Easily woundImprove reliabilityFinal product manufactureCell electrodesEngineeringElectrode material

A jelly roll electrode assembly, including a ceramic separator instead of a film separator and a secondary battery using the assembly, can be easily wound by forming a long non-coating portion of plate instead of the film separator to prevent cross-winding of the electrode assembly and the mandrel due to a friction by separating the wound electrode assembly from the mandrel, and to improve reliability. The jelly roll electrode assembly, including a positive electrode plate and an negative electrode plate, includes: a ceramic layer coated on at least one of the positive electrode plate or the negative electrode plate to prevent an electrical short between the positive electrode and negative electrode plates; a non-coating portion of the positive electrode and negative electrode plates, having no active material coated thereon, and an extended contact part, of the same electrode material as the non-coating portion, extending from one end of the non-coating portion of the positive electrode plate or the negative electrode plate to contact a mandrel during winding of the assembly.

Owner:SAMSUNG SDI CO LTD

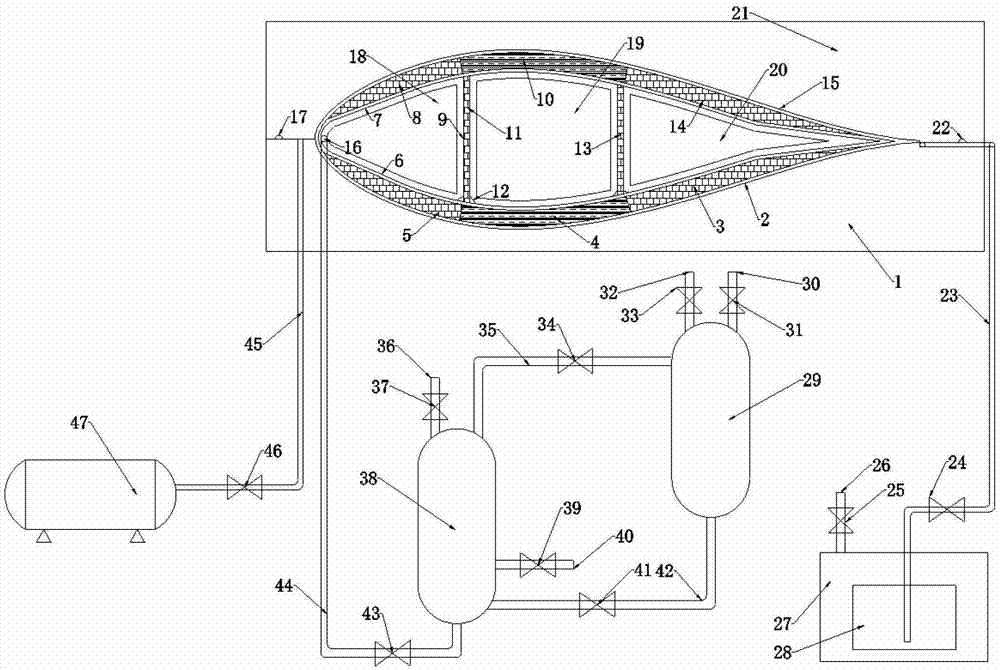

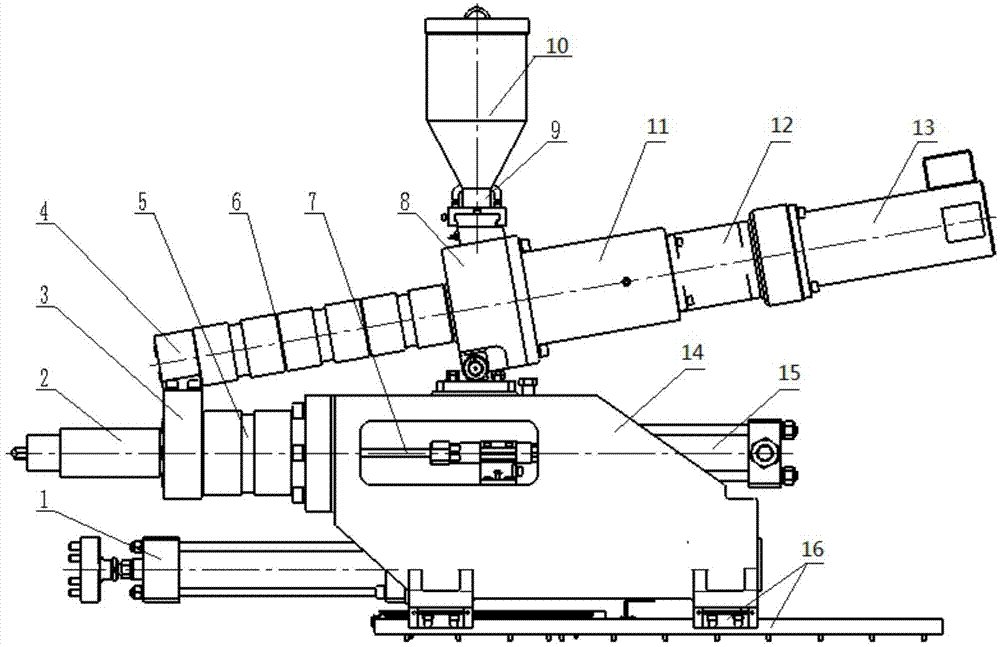

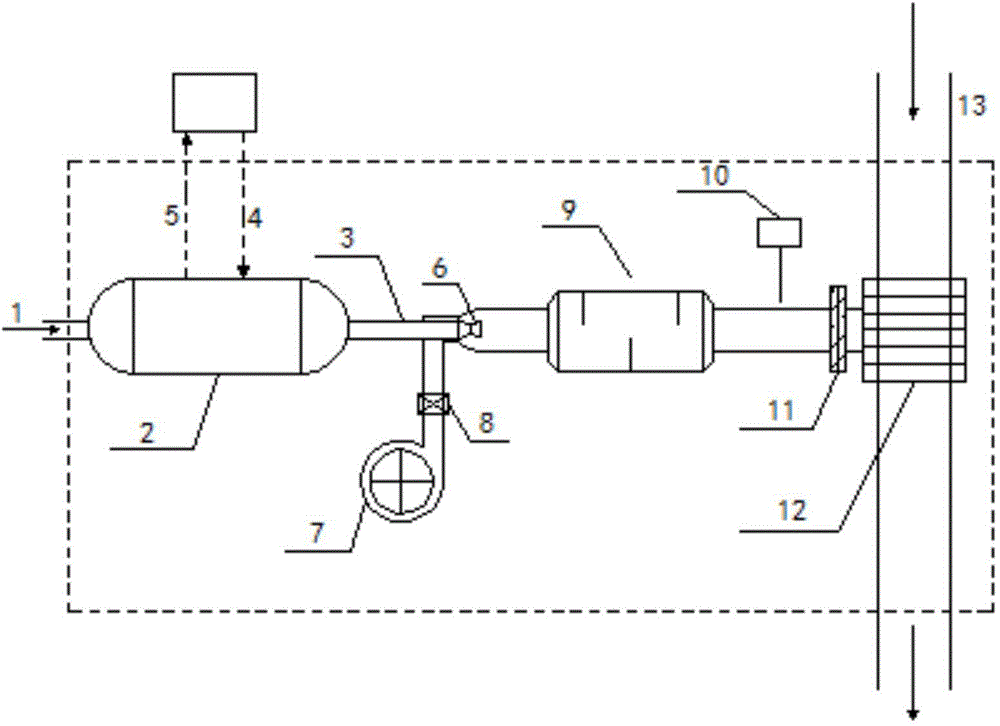

Integrated formation device and method for wind power blade

The invention relates to an integrated formation device and an integrated formation method for a horizontal shaft wind power blade. The device comprises a vacuum pumping system, pressurizing equipment, a resin defoaming system, a resin supply system and a resin collecting system. When the wind power blade is manufactured, integrated formation is realized by a positive pressure auxiliary vacuum perfusion mode, so that the defects of the traditional vacuum perfusion process are overcome, the blade-formation product quality is improved, and various disadvantages and risks caused by that the traditional process shell adopts adhesive to adhere are avoided.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

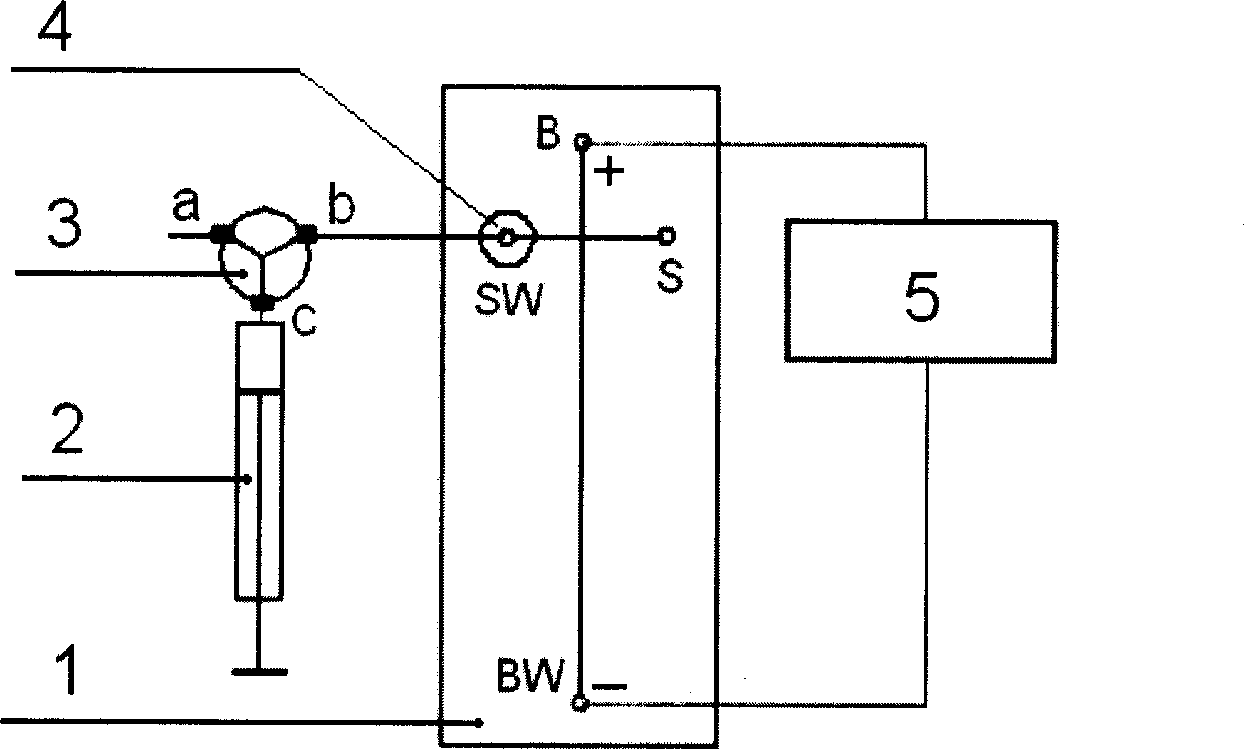

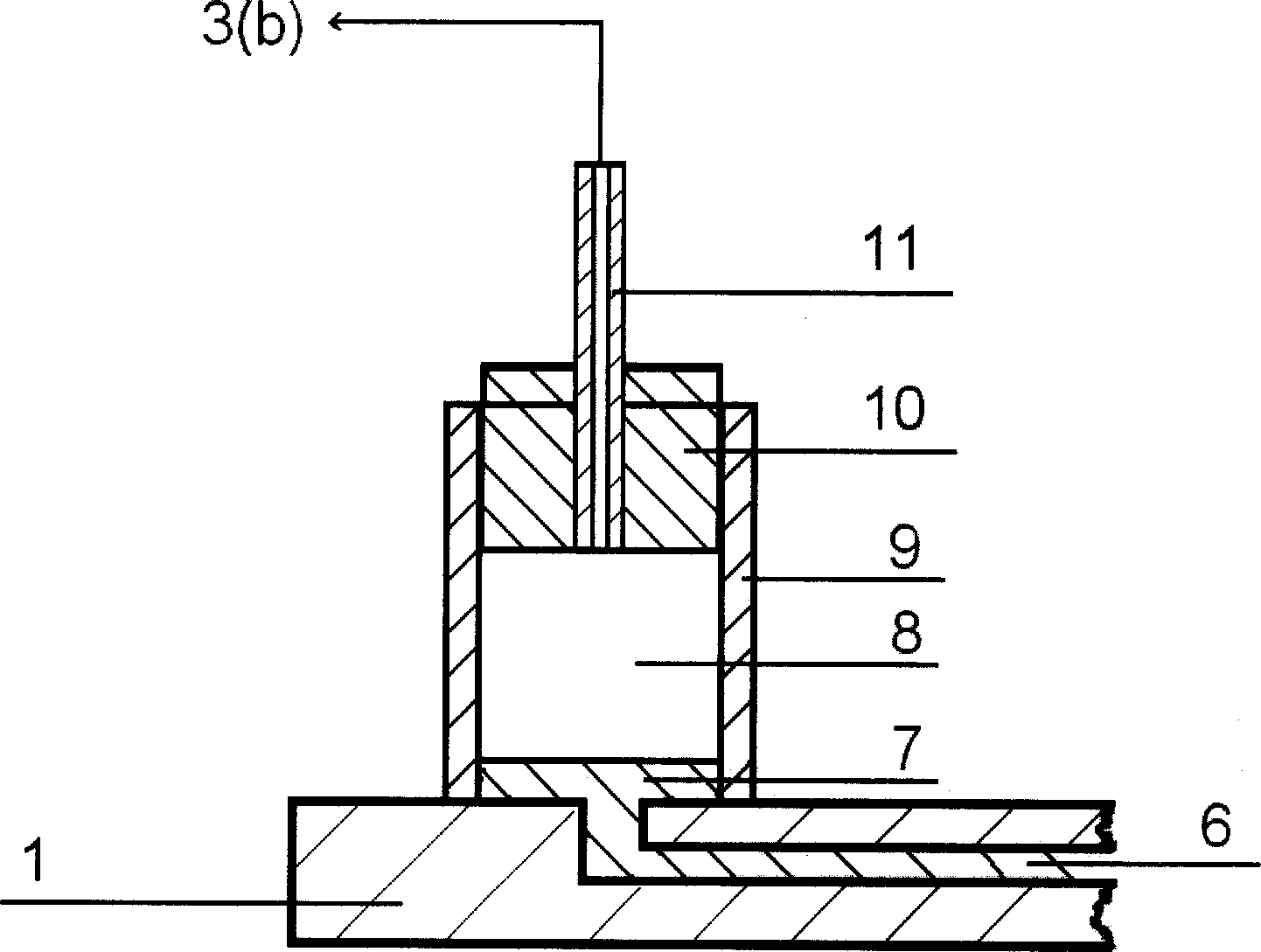

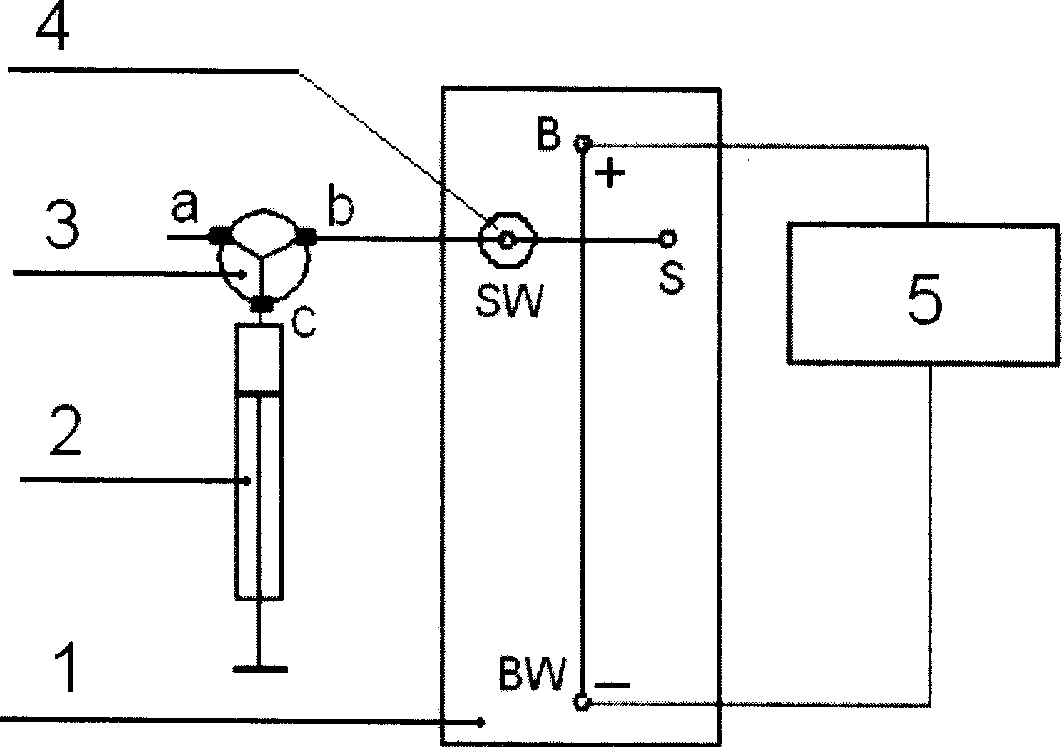

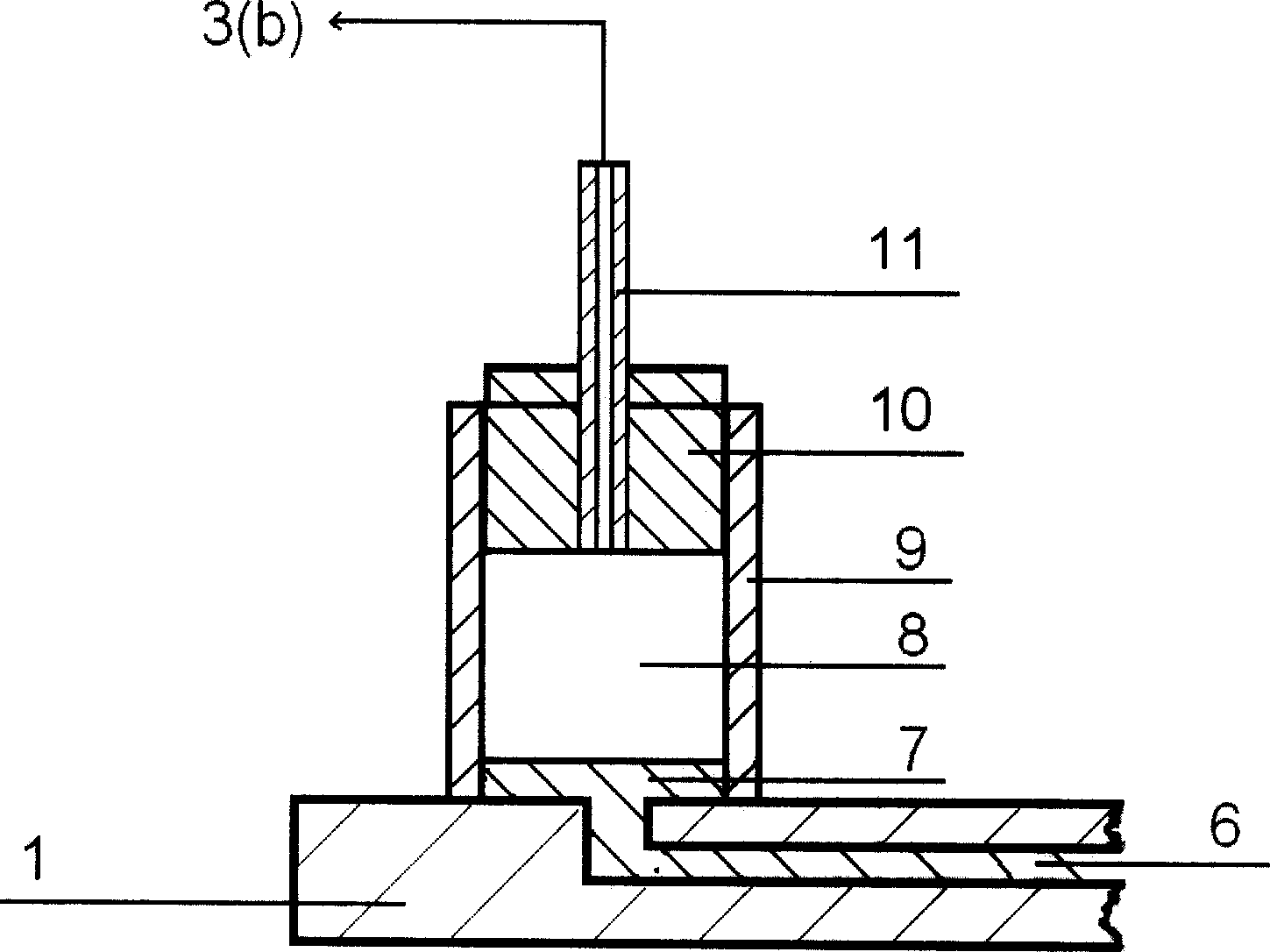

Micro flow control chip negative pressure sampling and separating device

InactiveCN1715903ASimple structureInjection speed is fastSamplingMicrobiological testing/measurementMicrofluidic chipPlunger pump

The negative pressure sampling and separating device with micro flow control chip consists of micro flow control chip, plunger pump, three-way valve, interface and high voltage power supply. It features the three-way valve with the first end communicated with atmosphere, plunger pump connected to the third end of the three-way valve, the second end of the three-way valve connected to the interface via connecting pipeline, the micro flow control chip with buffering liquid storing pond B, waste buffering liquid storing pond BW, sample storing pond S and waste sample storing pond SW, the interface on the waste sample storing pond SW, micro flow control chip sampling channel S-SW, separating channel B-BW, and the high voltage power source connected across the channel B-BW. The present invention has simple structure, fast sampling and operation safety.

Owner:ZHEJIANG UNIV

Multi-layer structure micro-channel mixer and fluid mixing method thereof

ActiveCN112206695ASpeed up the flowEfficient mixingFlow mixersTransportation and packagingEngineeringMixing effect

The invention relates to a multi-layer structure micro-channel mixer, which comprises a base plate and a sealing plate, wherein two sample injection liquid storage chambers, two inlet channels, two groups of fluid distribution channel nets, two groups of process fluid channels, a fluid collision mixing cavity, a fluid reinforced mixing channel and an outlet buffer chamber are arranged on the baseplate in a bilateral symmetry manner and are arranged on the two sides of the fluid collision mixing cavity. Two fluids to be mixed are respectively conveyed to two sample injection liquid storage chambers, respectively enter an inlet channel through the sample injection liquid storage chambers, enter a process fluid channel after being distributed through a multi-stage fluid distribution channel,and form two opposite impinging streams after flowing out of the process fluid channel,and after mixing, vortex or secondary flow is generated under the action that the fluid collides with a bafflingbaffle or an inner component in the mixing cavity, and finally the mixed fluid mixture flows out of the mixer through the outlet buffer chamber. The multi-layer structure micro-channel mixer has theadvantages of wide operation condition range, good mixing effect, high mass transfer coefficient, small pressure drop and low energy consumption.

Owner:FUDAN UNIV

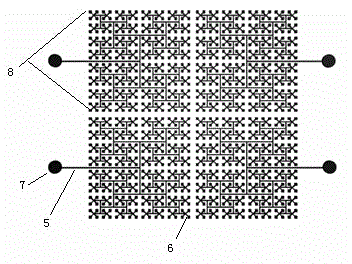

Submerge liquid supplying recovery controlling device for photoetching machine

InactiveCN101452219ASmall fluctuations in the flow fieldImprove stabilityPhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringProduct gas

The invention discloses an immersion liquid supply and recovery control device for a mask aligner. The immersion liquid supply and recovery control device is arranged between a projection lens group and a substrate to be exposed and consists of a liquid charging cover, a liquid charging disc, a flow control loop and a retainer ring. The external liquid charging and the internal liquid recovery are adopted. Liquid enters a slit flow field from the periphery with the fixed quantity and in the mode of high speed injection; and the balance and stability of the whole flow field is realized through coordination and control of the negative pressure acting on an internal recovery cavity. The mode of high speed liquid injection from outside to inside can not only effectively counteract the internal power of outward liquid leakage and reduce the infiltration of boundary air bubbles caused by a gas sealing device, but also quicken the updating rate of the flow field and consequently facilitate the timely removal of pollutants produced in the process of exposure.

Owner:ZHEJIANG UNIV +1

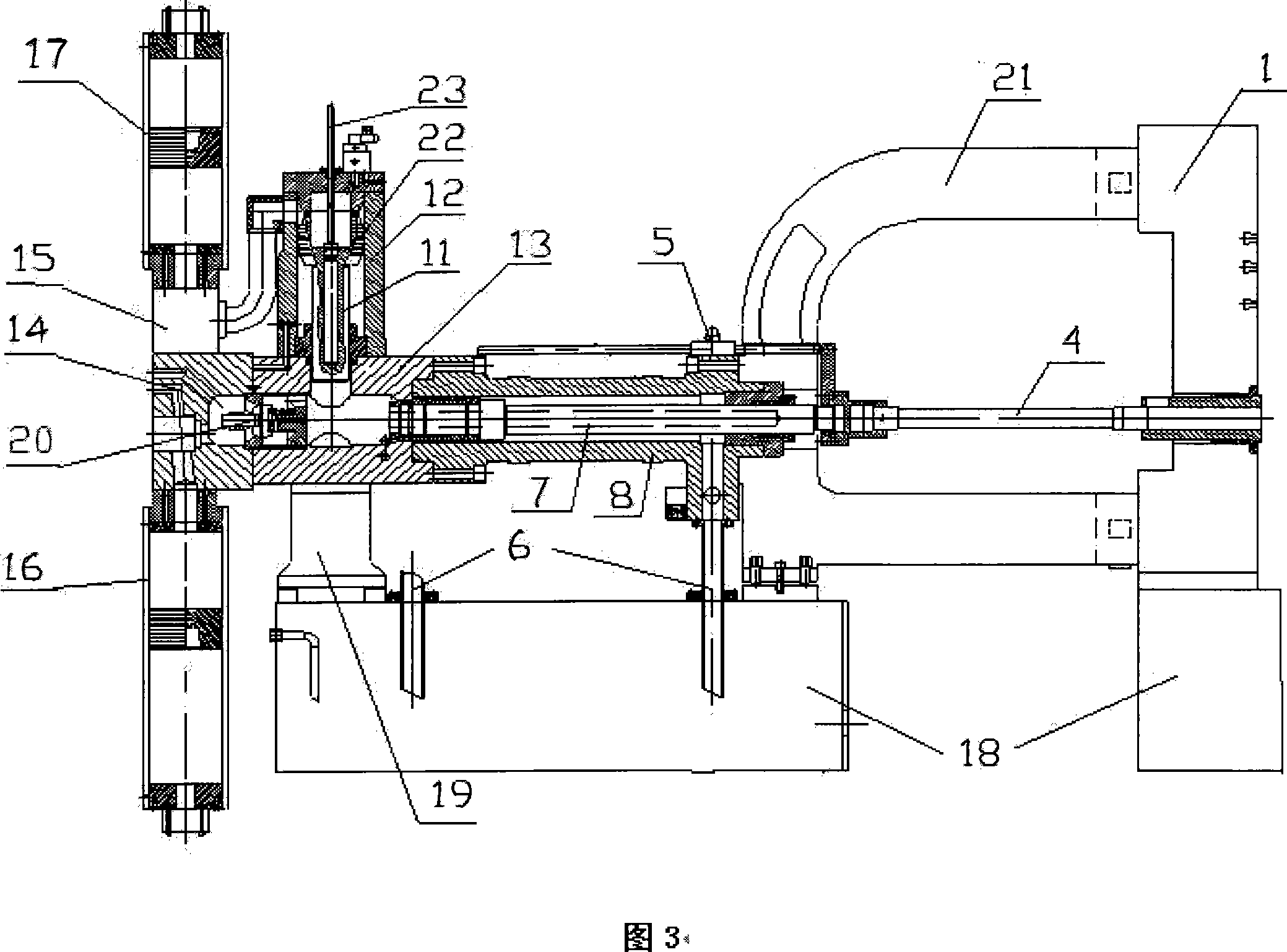

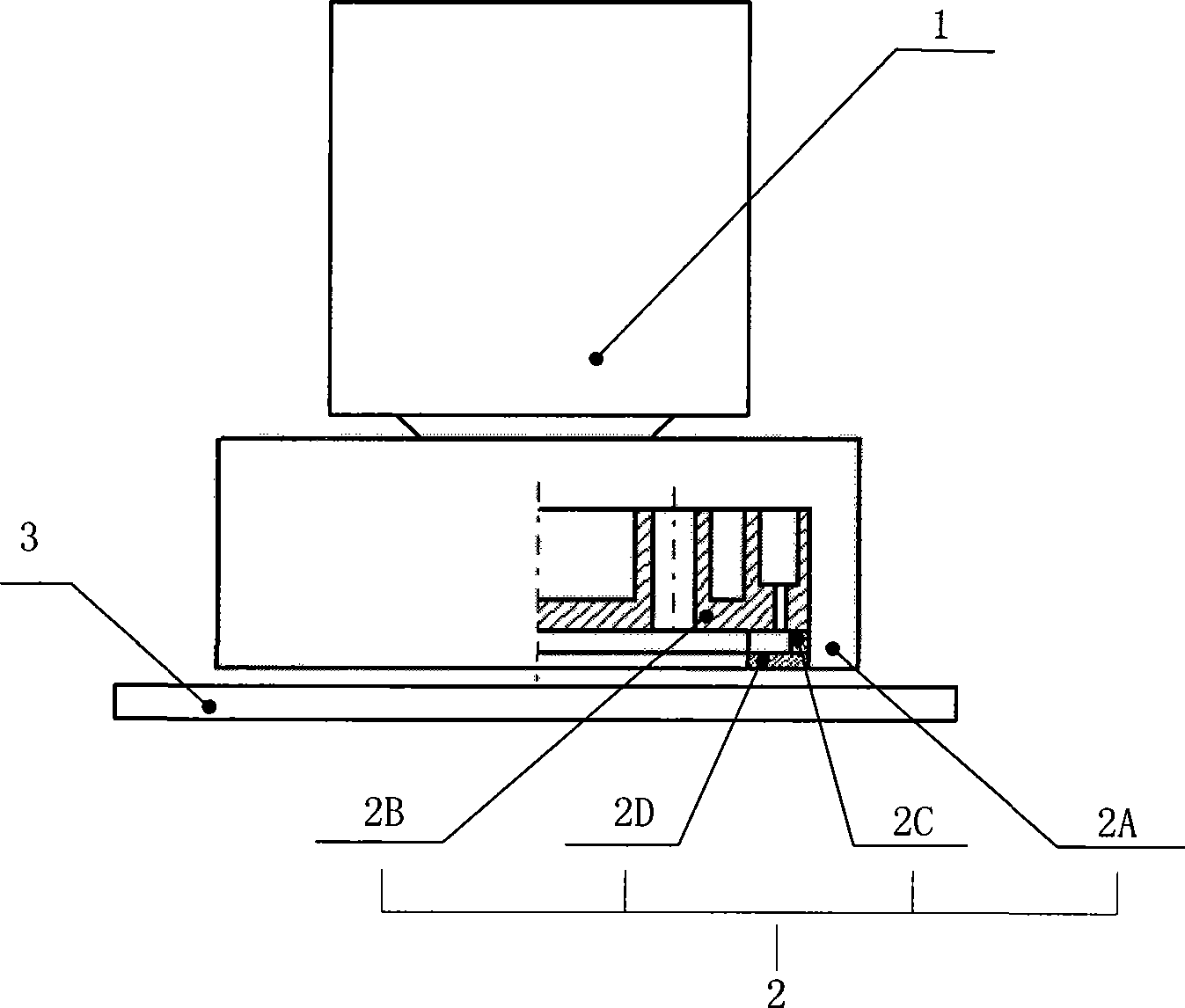

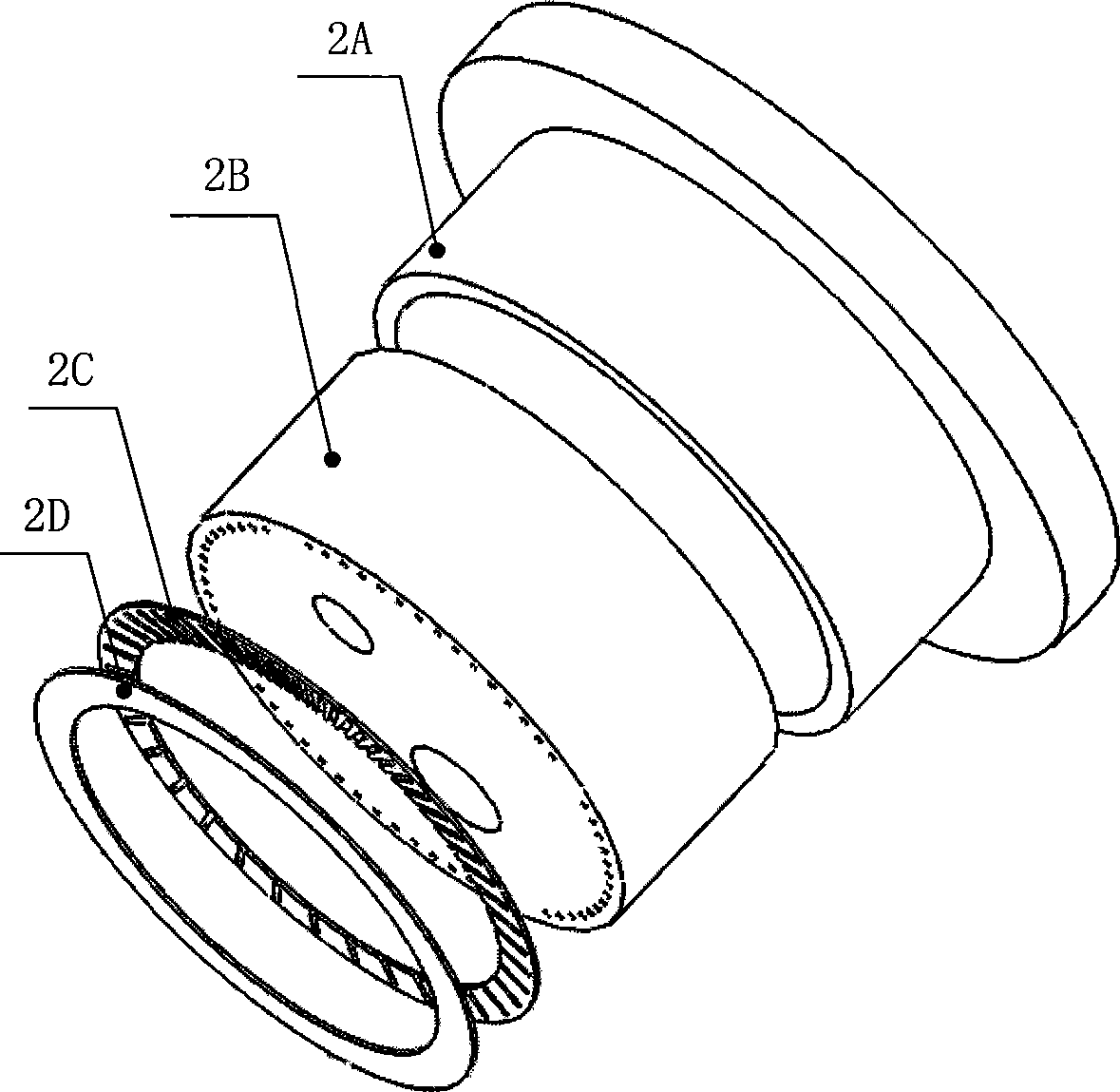

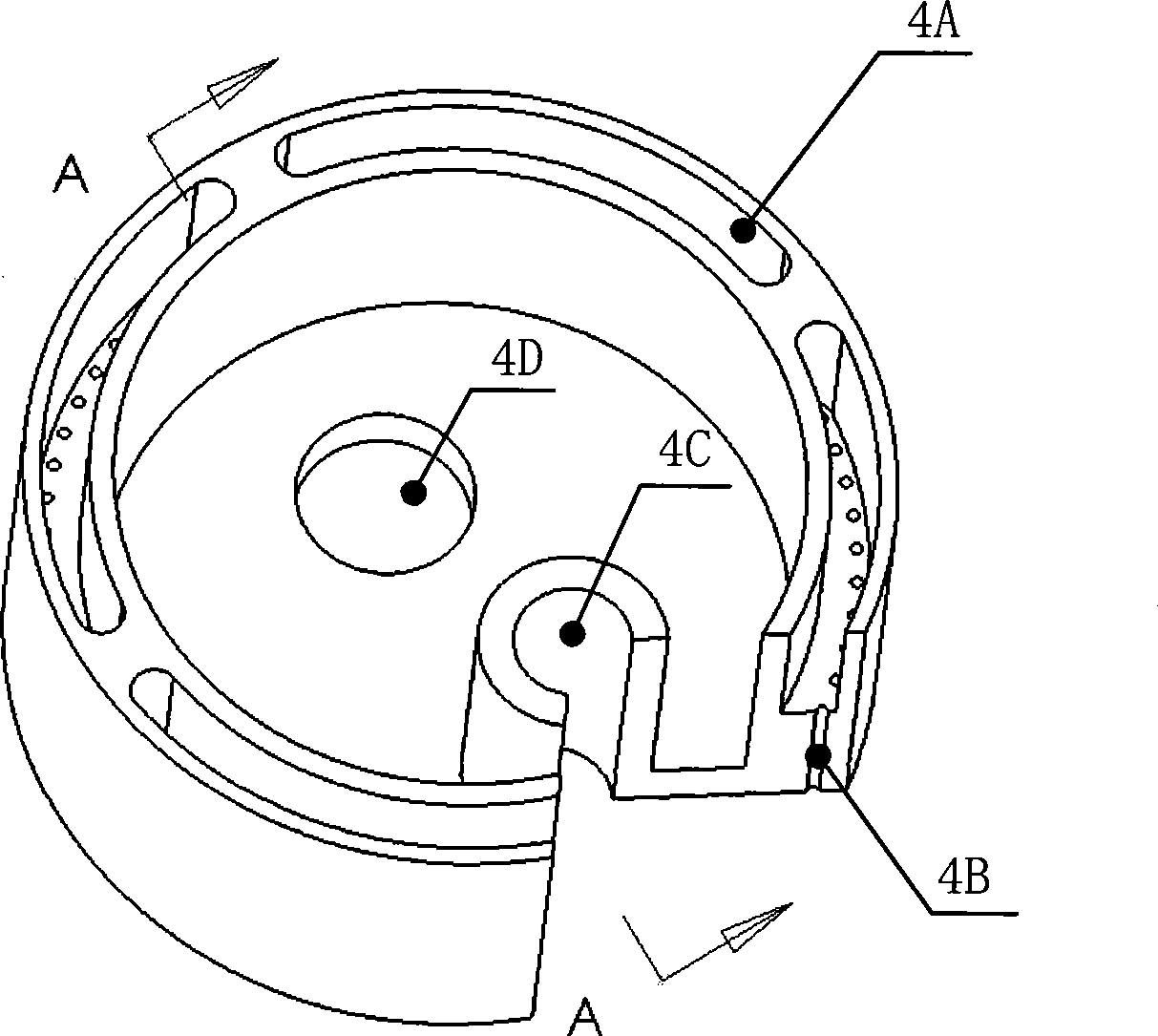

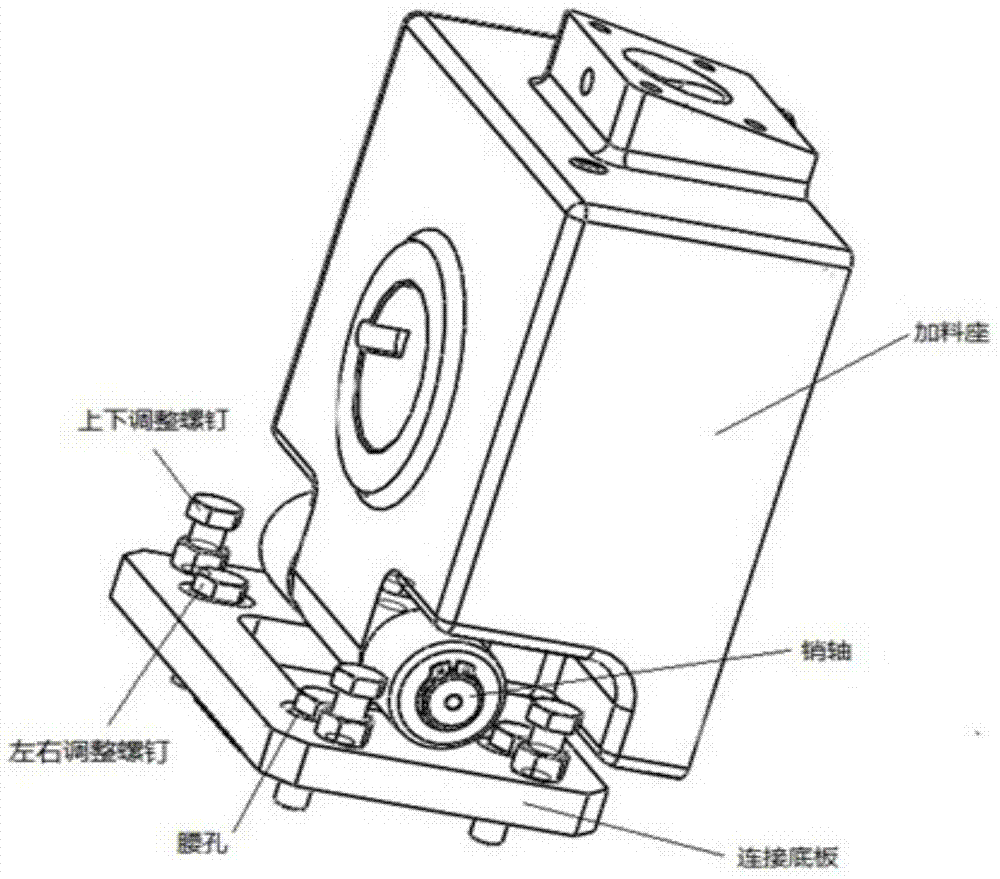

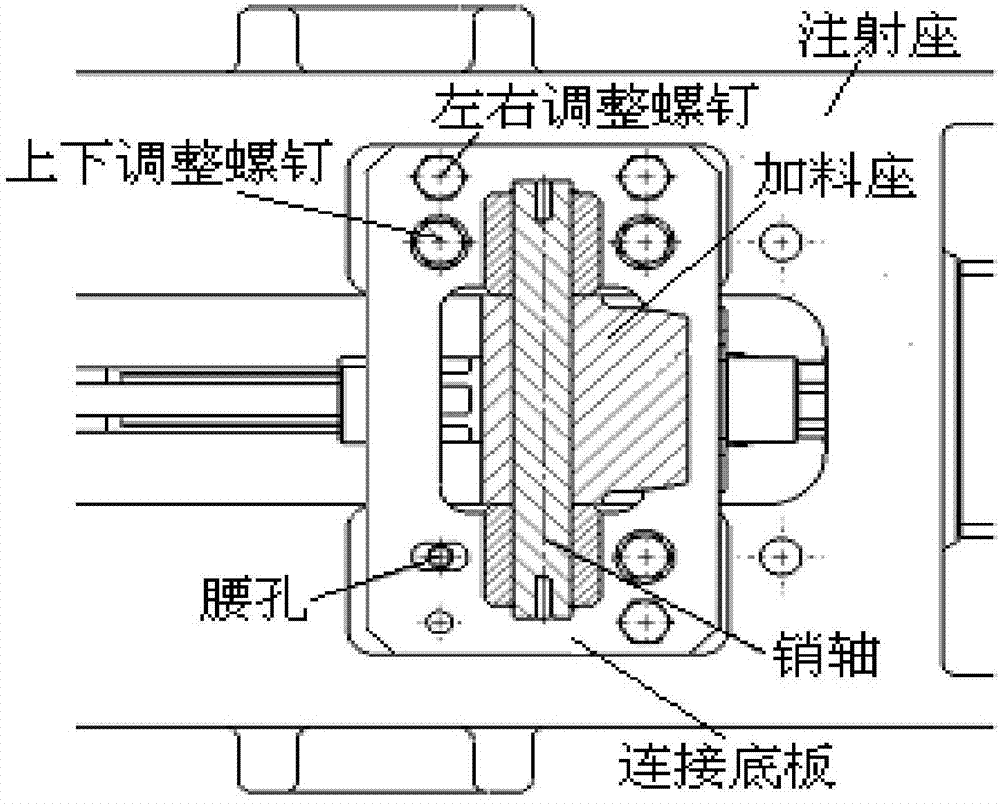

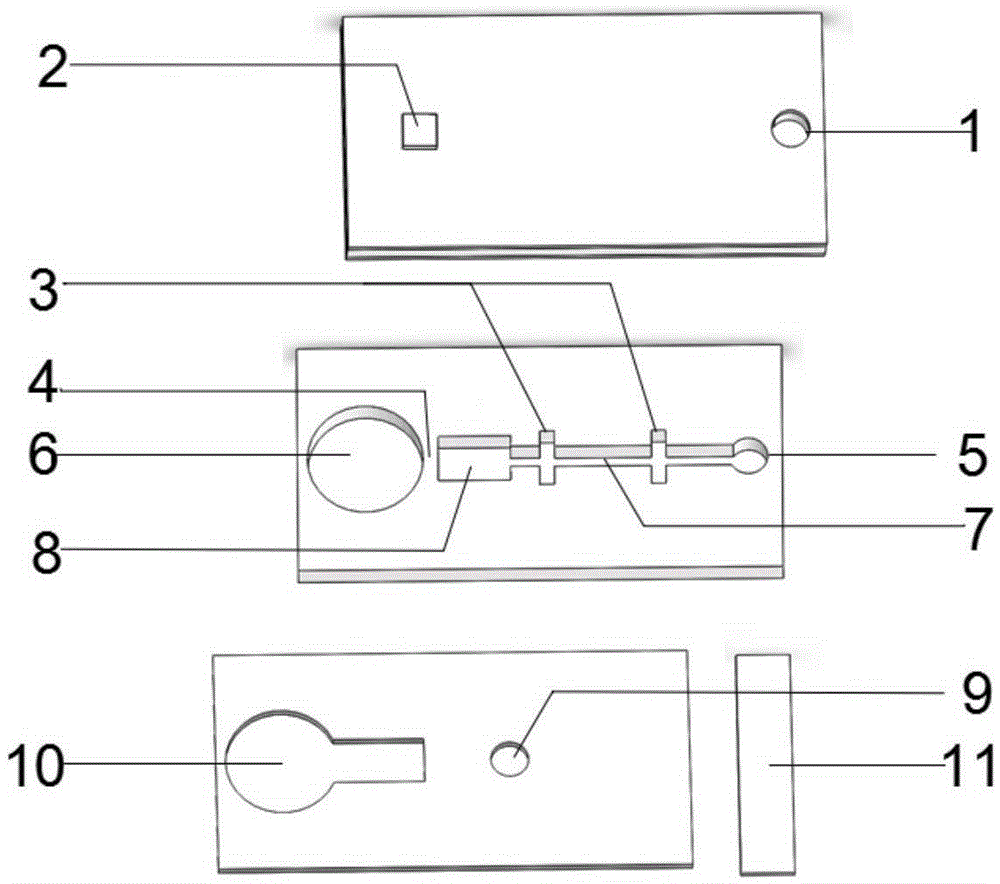

Injection molding machine microinjection device capable of realizing high-speed and high-precision injection

InactiveCN103692625AReduce deformation effectsQuality improvementHydraulic cylinderInjection molding machine

The invention relates to an injection molding machine microinjection device capable of realizing high-speed and high-precision injection. The device can be divided into five parts, namely a plasticization unit, an injection unit, a charging unit, an injection platform moving unit and other units; the plasticization unit adopts screw plasticization and is driven by a servo motor so as to improve the plasticization quality and the plasticization precision; the injection unit adopts plunger injection and is driven by a hydraulic cylinder equipped with an energy storage device so as to improve the injection precision and the injection speed. According to a plasticization and non-return transmission device of an injection device, a connecting passage between a plasticization cavity and an injection cavity can be blocked and opened intermittently, and the existence of a one-way valve is prevented, so that a flow passage between the plasticization cavity and the injection cavity is free of dead angle, and the melt retention can be effectively reduced; meanwhile, the system is provided with a testing device capable of detecting abraded quantity of a screw head, thus providing guarantee for overhaul and normal use of an injection molding machine.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH +1

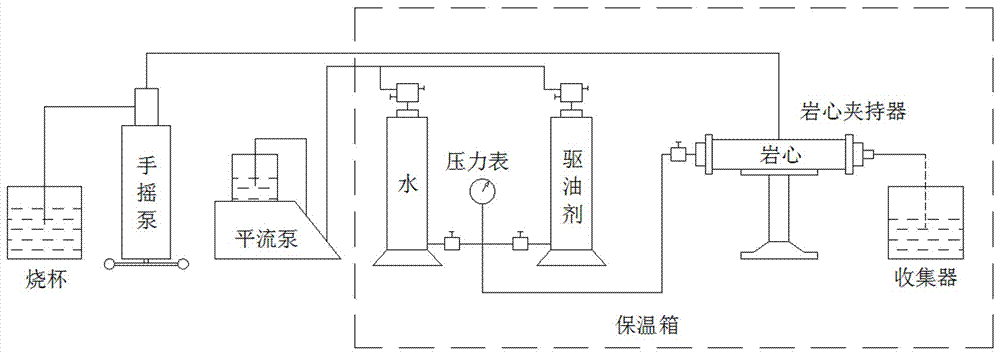

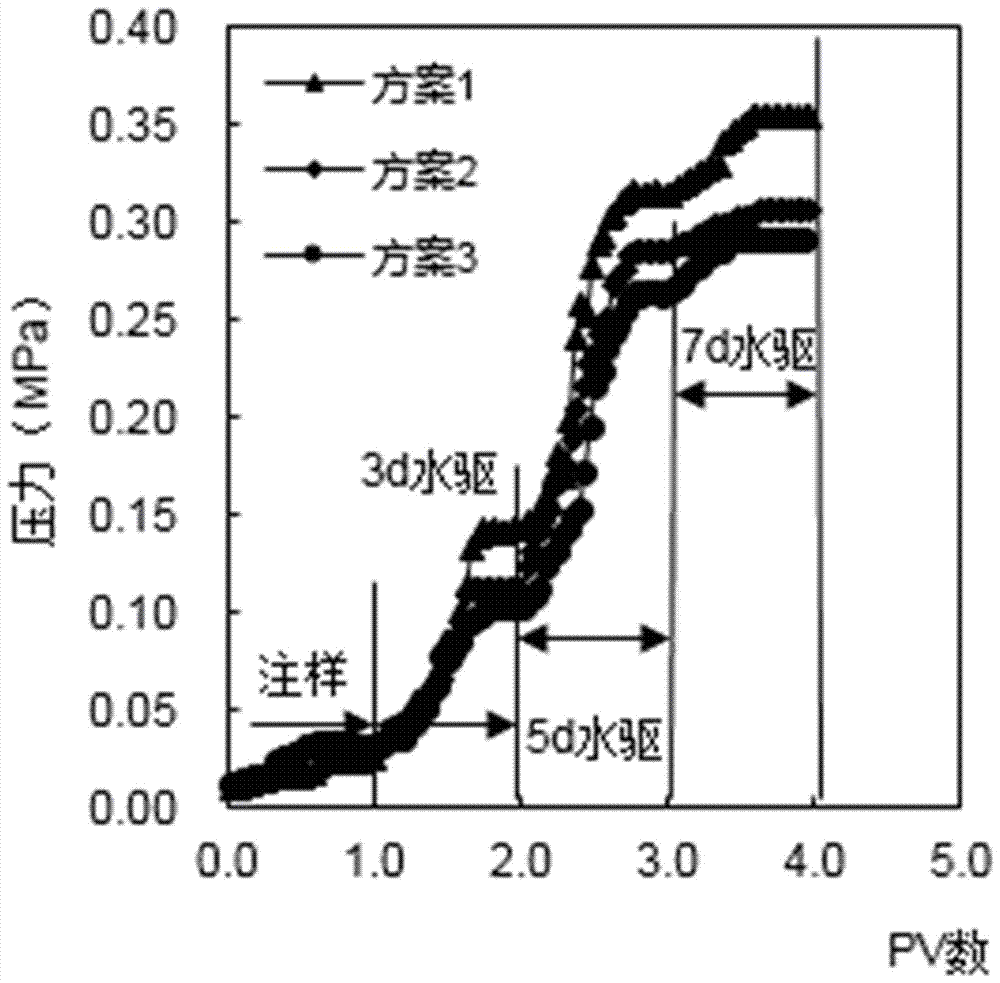

Experimental method for testing slow expansion performance in polymer microsphere rock core

InactiveCN107402286ASolve the problem that the effective concentration is reduced and the objectivity of the evaluation effect is poorEliminate the "bridge blocking" effectMaterial analysisEpoxyPorosity

The invention belongs to the technical field of petroleum reservoir exploitation, and in particular relates to an experimental method for testing the slow expansion performance in a polymer microsphere rock core. The method comprises the following steps: 1, making an artificial rock core: adopting a quartz sand epoxy resin bonding method to make the artificial homogeneous rock core; 2, pumping out the saturated water of the rock core: measuring the actual outline dimension of the rock core, calculating the overall volume of the rock core, weighing dry weight, pumping out the saturated water, weighing wet weight, and calculating the volume of the saturated water and the porosity; 3, calculating the water permeability of the rock core: establishing a relation curve of injection pressure difference and injection speed, and calculating the water permeability; 4, testing the slow expansion effect of polymer microspheres; 5, evaluating the slow expansion capacity of the polymer microspheres: finding out that the injection speed 0.3mL / min or 0.5mL / min corresponds to the injection pressure difference delta P0 on the water driving relation curve of injection pressure difference and injection speed established in the step 3, and calculating microsphere blocking rates at different moments.

Owner:NORTHEAST GASOLINEEUM UNIV +1

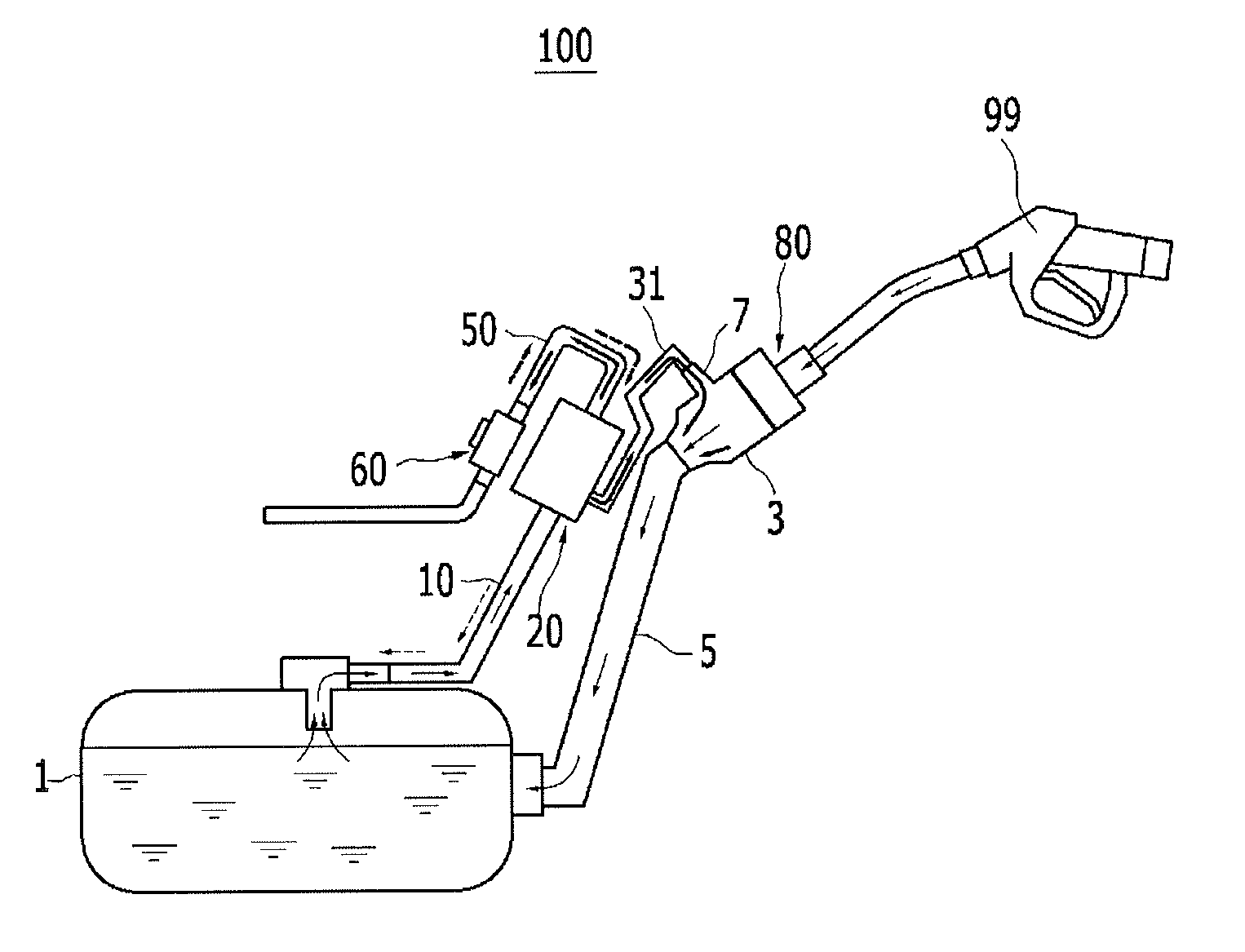

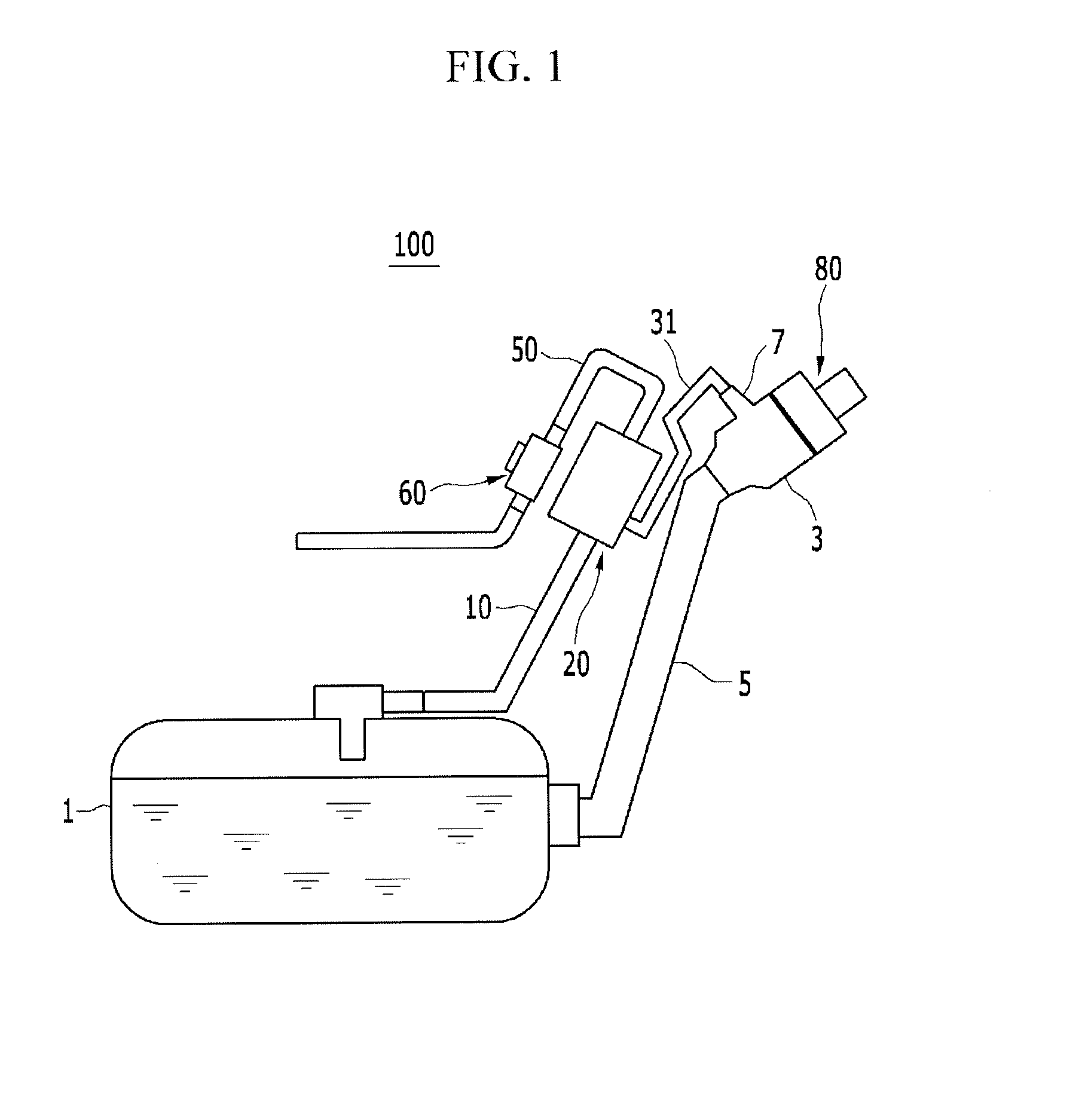

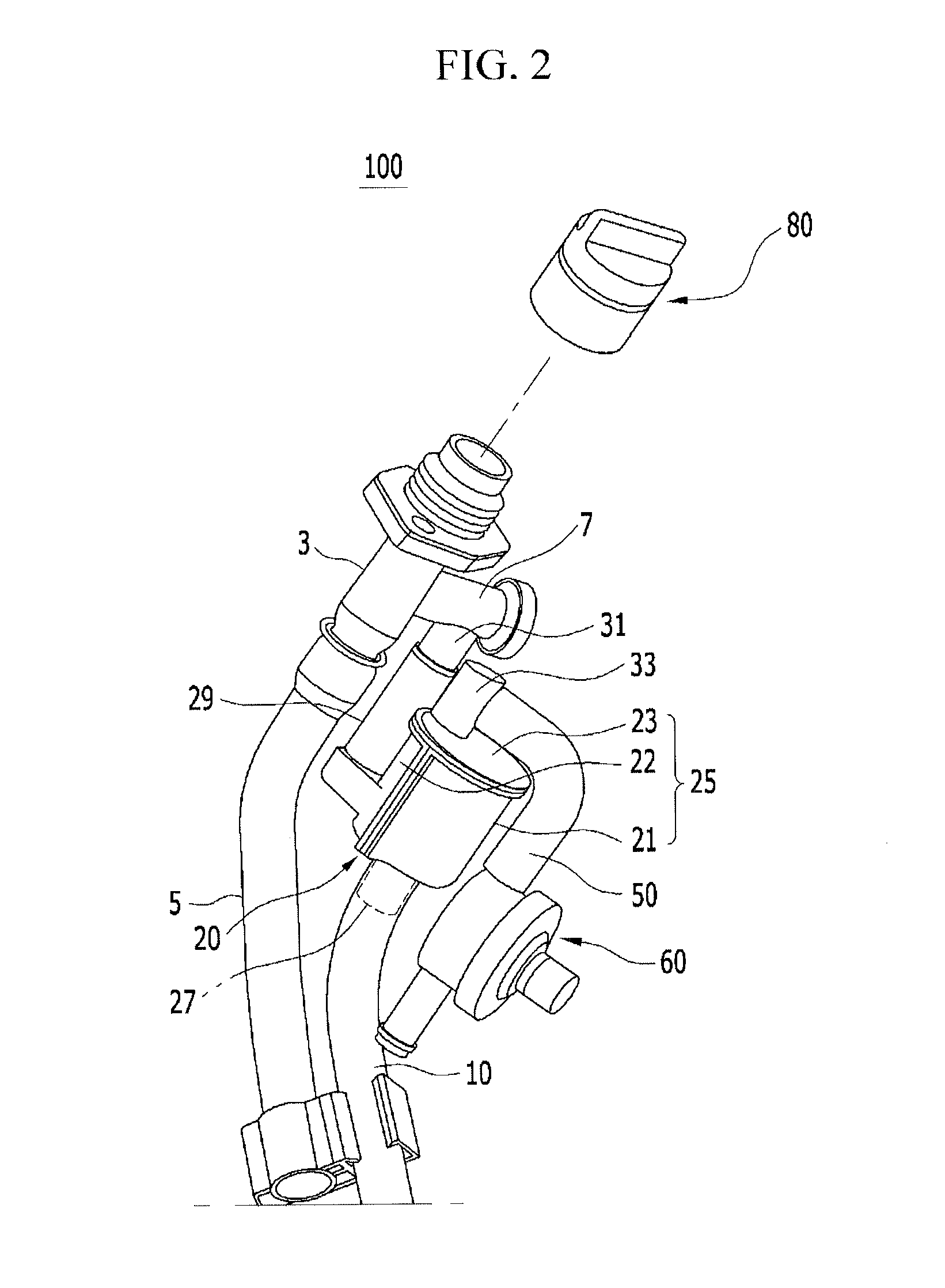

Urea injection device for selective catalyst reduction device

InactiveUS20150159531A1Guaranteed smooth progressIncrease injection speedInternal combustion piston enginesExhaust apparatusInjection portCheck valve

Disclosed is a urea injection device for a selective catalyst reduction device. The urea injection device for a selective catalyst reduction device serves to inject urea into a urea tank through a urea injection port and a urea injection line that connects the urea injection port and the urea tank. The urea injection device may include: i) a leveling pipe which is connected with the urea tank, ii) a separator which is installed to be connected with the leveling pipe, and connected to the urea injection port through a gas recirculation line, iii) a gas vent line which is connected with the separator, and iv) a check valve which is installed in the gas vent line.

Owner:HYUNDAI MOTOR CO LTD

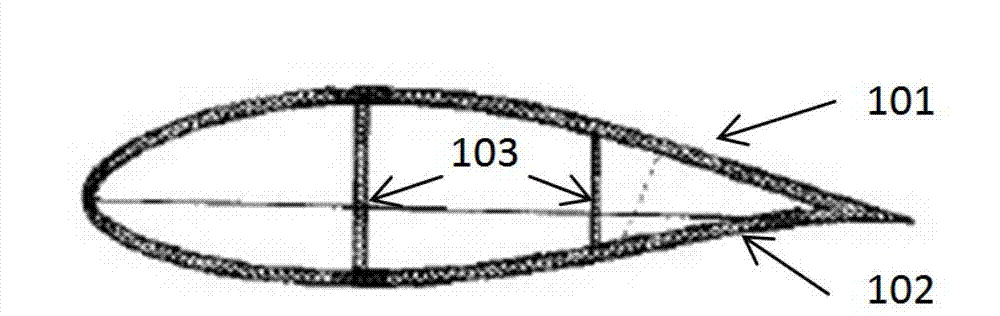

Wind turbine blade mold with double vacuum systems and method for making wind turbine blade by wind turbine blade mold

InactiveCN103862595AReduce labor costsImprove product qualityFinal product manufactureDomestic articlesAerospace engineeringTurbine blade

The invention provides a wind turbine blade mold with double vacuum systems and a method for making a wind turbine blade by the wind turbine blade mold. A first vacuum gas passage is connected to a resin collector by a pipe. A second vacuum gas passage is connected to vacuum extraction equipment by a pipe. The first vacuum gas passage and the second vacuum gas passage are connected respectively to the fixed vacuum pipes and vacuum extraction equipment. Before manufacture of the wind turbine blade mold, a pressure maintaining test is carried out. Compared with the prior art needing temporary establishment of an external vacuum system, the method provided by the invention saves a labor cost and improves product quality. The resin collector is made of a transparent material and the vacuum pipes are provided with multiple air exhaust points and are distributed at different positions of the wind turbine blade mold so that through observation of an increasing rate of a resin amount of the resin collector, it is easily determined if injecting rates at all injecting points are too fast, product process controllability is improved, collected overflowing resin can be directly recovered and recycled and a wind turbine blade manufacture cost is saved.

Owner:AVIC HUITENG WINDPOWER EQUIP

Sintering flue gas integrated type oxidization and denitration device and application thereof

InactiveCN104307325ARealize integrated controlEasy to operateDispersed particle separationOzone generatorButt joint

The invention provides a sintering flue gas integrated type oxidization and denitration device and application thereof. The integrated type device mainly comprises an ozone generator, a mixing draught fan, a Venturi, an ozone diluter and an ozone distributor. A sintering flue gas denitration function can be realized by butt joint with existing enterprise water, a gas source and a sintering waste gas flue. By virtue of the integrated type oxidization and denitration device, ozone generation, dilution, mixing and spraying control integrated operation can be realized; the integrated type oxidization and denitration device has the characteristics of simple system, strong maneuverability, small occupied space, small investment and the like; and compared with the current situations that the residual space of an existing steel enterprise sintering workshop is limited and almost newly-added denitration workshop sections are modification projects, the integrated type oxidization and denitration device has a very good application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

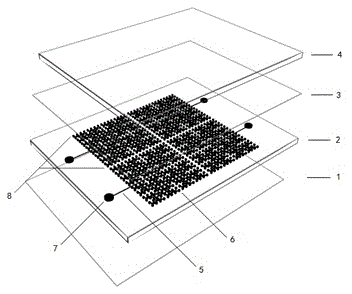

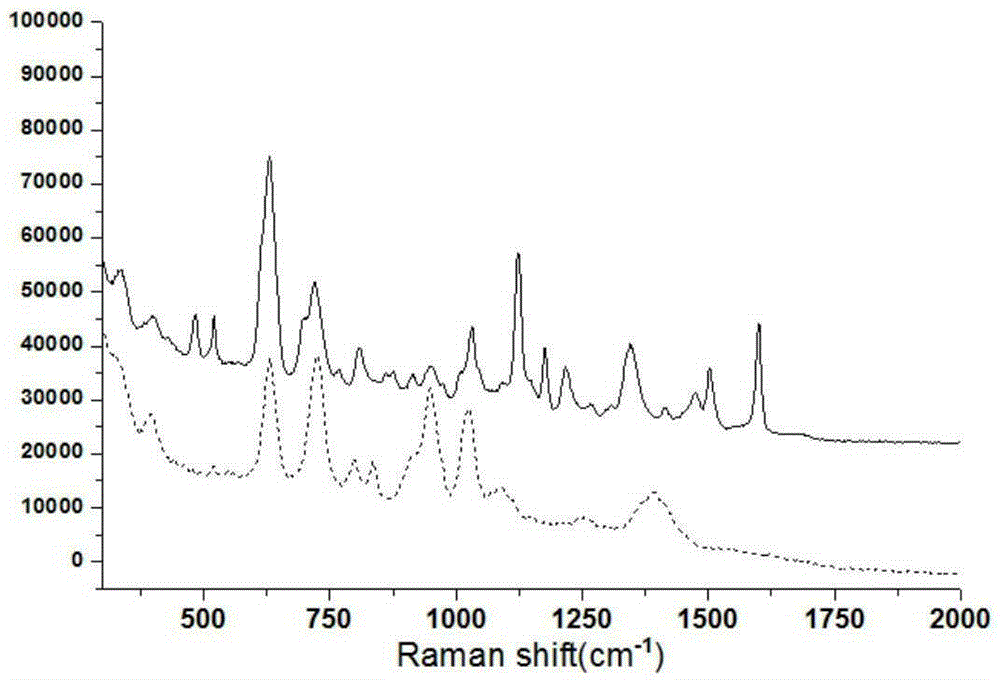

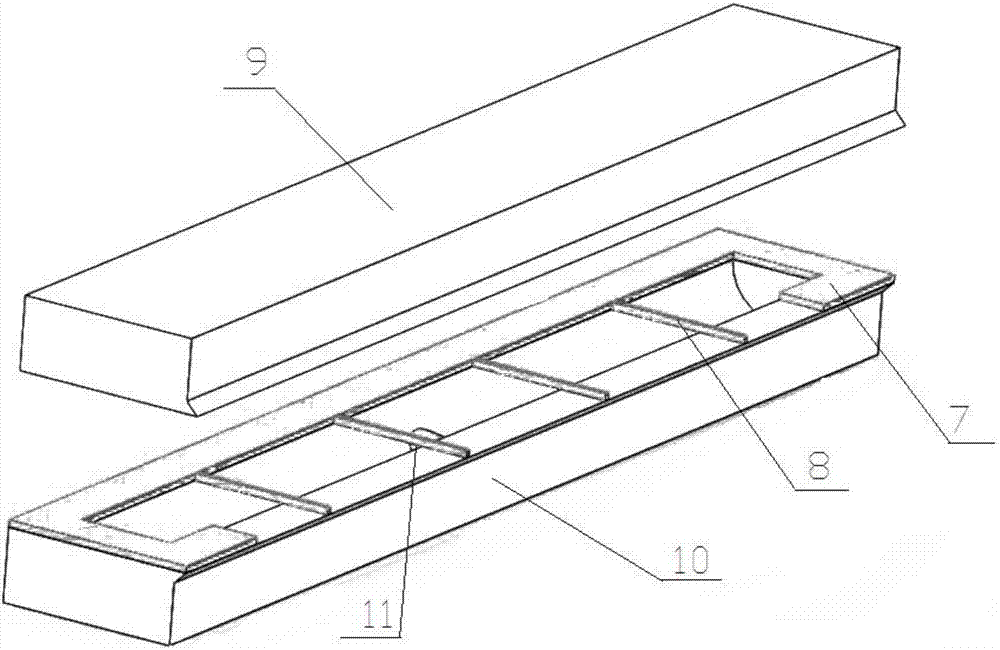

Solid phase extraction column integrated surface enhanced Raman detection chip

ActiveCN105466905AEasy to operateSimple processingPreparing sample for investigationRaman scatteringPhysicsMicrofluidic channel

The invention discloses a solid phase extraction column integrated surface enhanced Raman detection chip. The chip comprises an upper substrate, a middle substrate and a lower substrate, the middle substrate is provided with a microfluidic channel (7), a sample detection cell (6) and sieve plate grooves (3), one end of the microfluidic channel (7) is provided with a sample inlet (5), the other end of the microfluidic channel (7) gets close to the sample detection cell (6), and a dam (4) and two sieve plate grooves (3) are arranged between the sample inlet and the sample detection cell; the upper substrate is provided with a sample introduction port (1), and the bottom of the upper substrate is provided with a surface enhanced Raman detection substrate (2), wherein the surface enhanced Raman detection substrate (2) aligns at the sample detection cell (6) of the middle substrate, and the sample introduction port (1) aligns at the sample inlet (5) of the microfluidic channel of the middle substrate; and the lower substrate is provided with a detection cell outlet (10), and the detection cell outlet (10) is positioned right below the sample detection ell and is connected with the sample outlet (8) of the middle substrate. The chip realizes online Raman detection and SPE operation integration of a sample to be detected.

Owner:XIAMEN PUSHI NANO TECH CO LTD

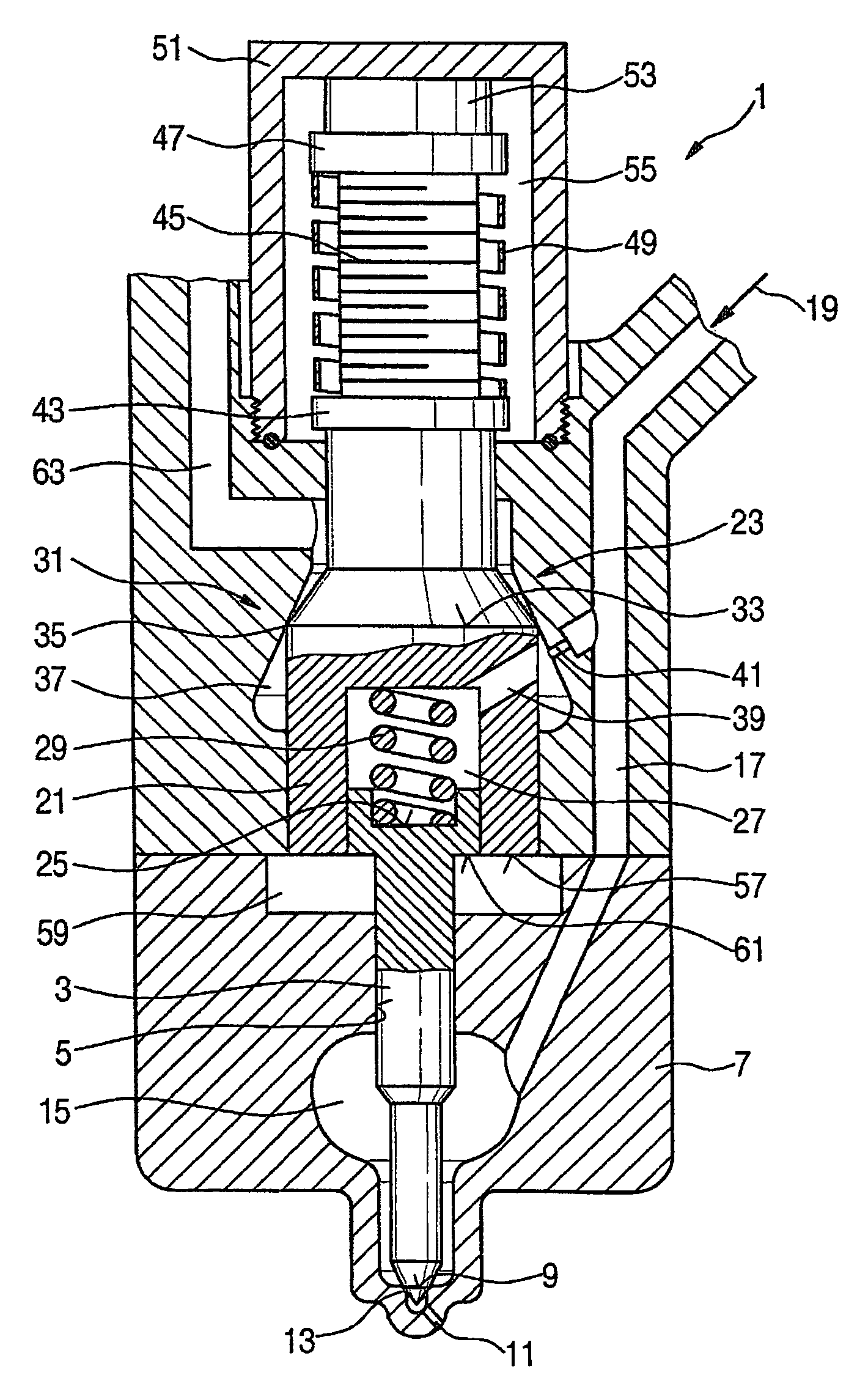

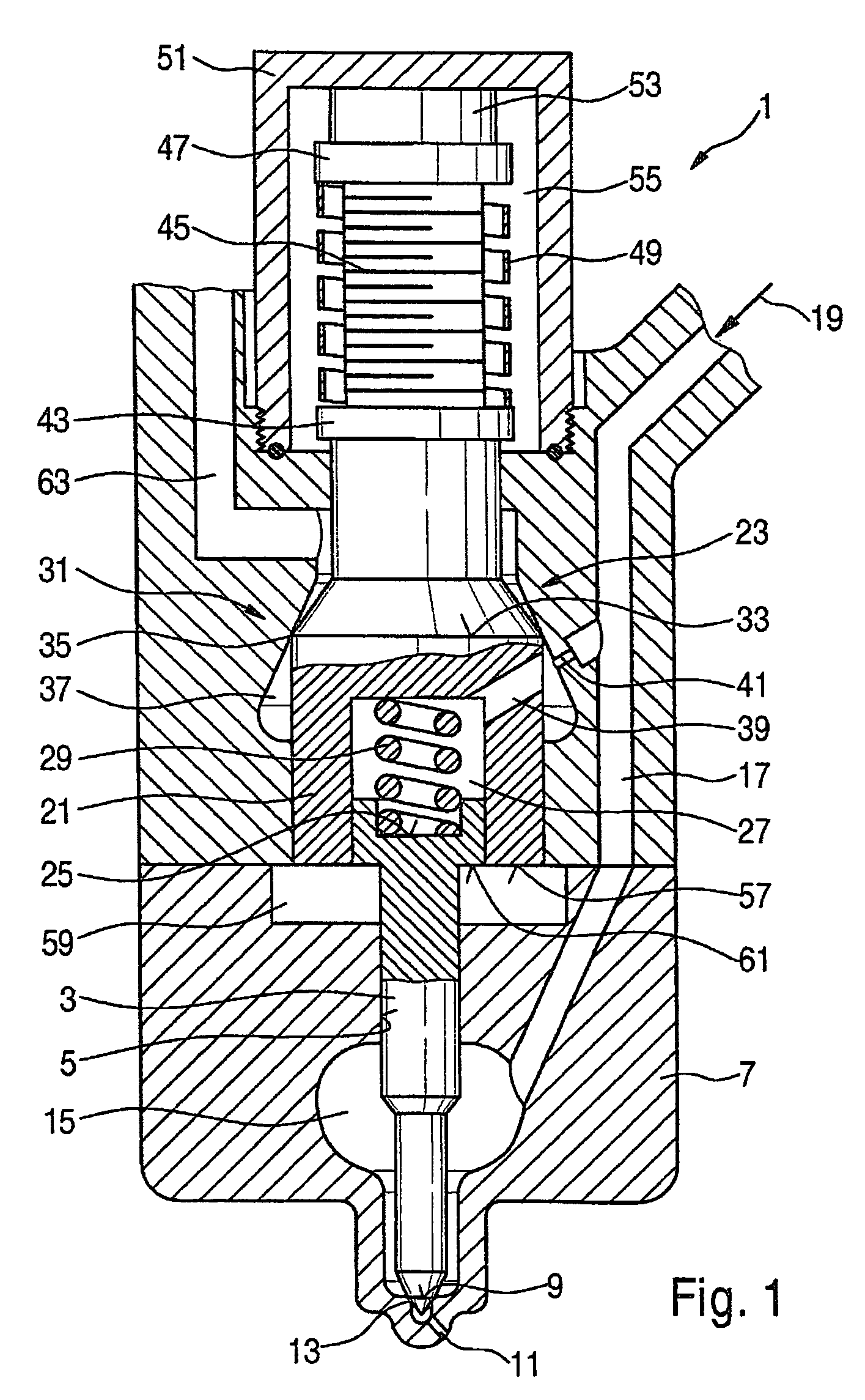

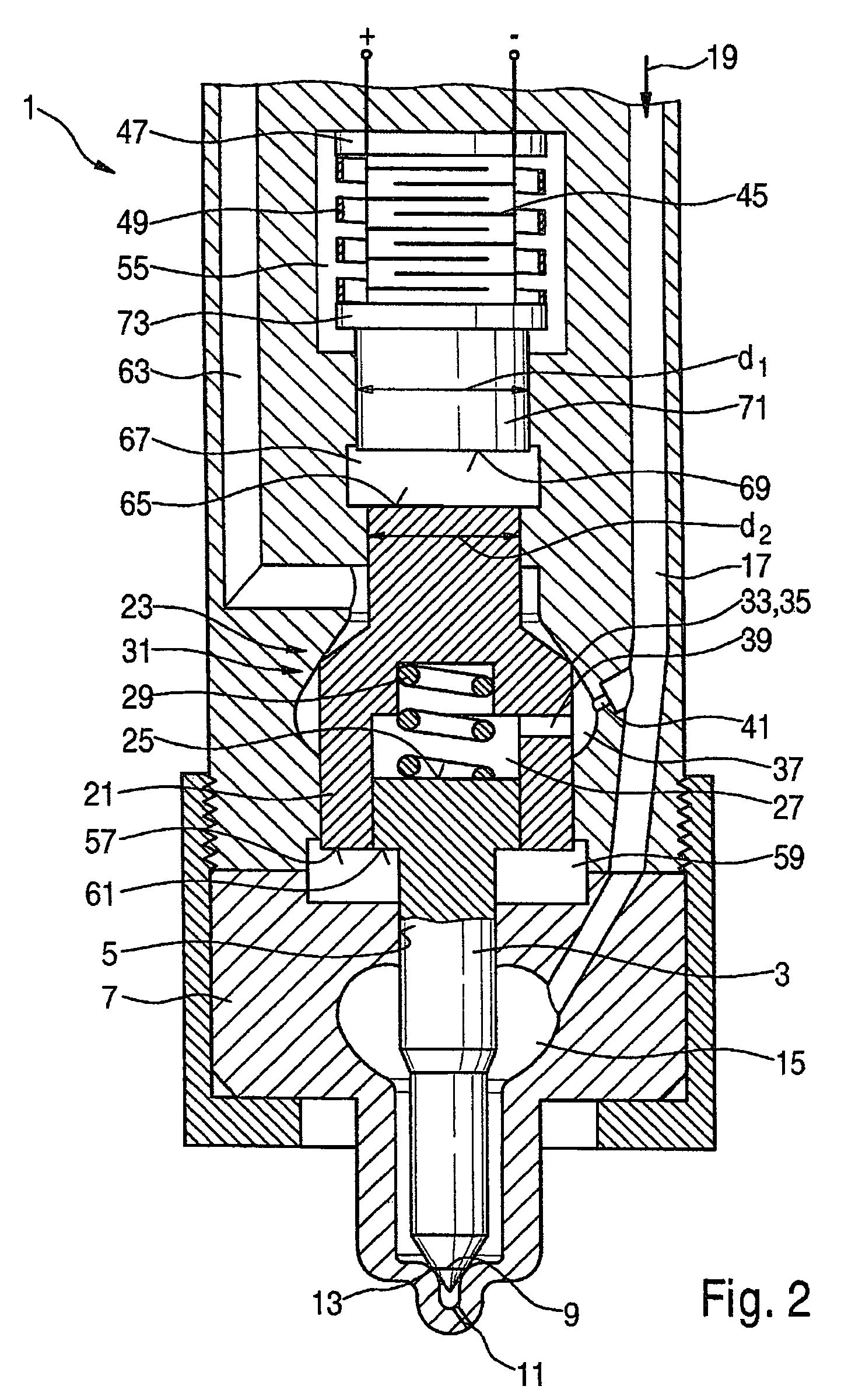

Fuel injector with direct needle control and servo valve support

InactiveUS7946509B2Reduce the height of the structureSmall structure sizeMovable spraying apparatusSpray nozzlesCombustion chamberLine tubing

The invention relates to an injector for injecting fuel into a combustion chamber of an internal combustion engine. The injector is actuated by an actuator and is connected to a fuel supply line via which fuel is supplied under system pressure. At least one injection opening can be opened or closed off by an injection valve member, which is activated by a control piston via a control chamber to which the control piston and a piston section of the injection valve member are exposed with respective pressure faces. The control piston is a valve piston of a control valve. The pressure face of the control piston and the pressure face of the piston section of the injection valve member are exposed to the control chamber at the same side. The control piston and the piston section of the injection valve member also enclose a further control chamber which is connected to a fuel return line when the control valve is open and to the fuel supply line when the control valve is closed.

Owner:ROBERT BOSCH GMBH

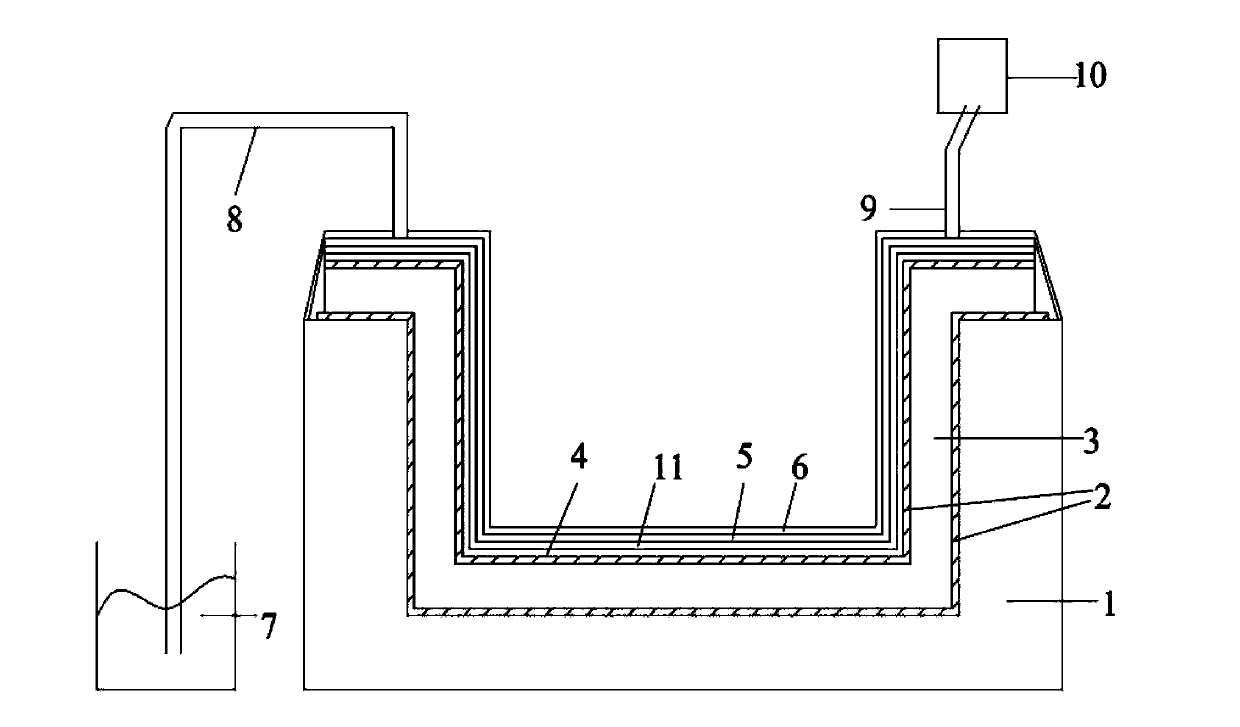

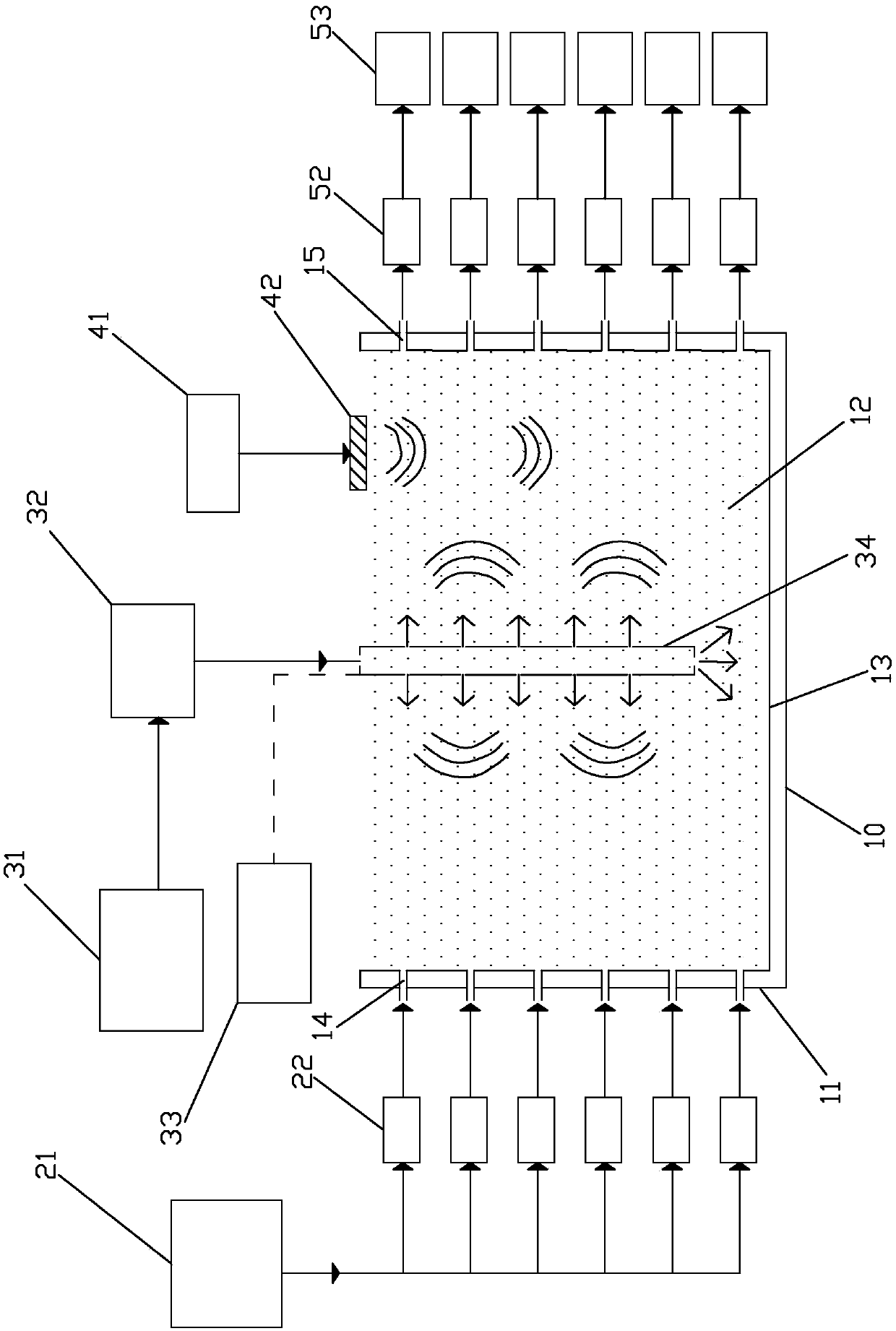

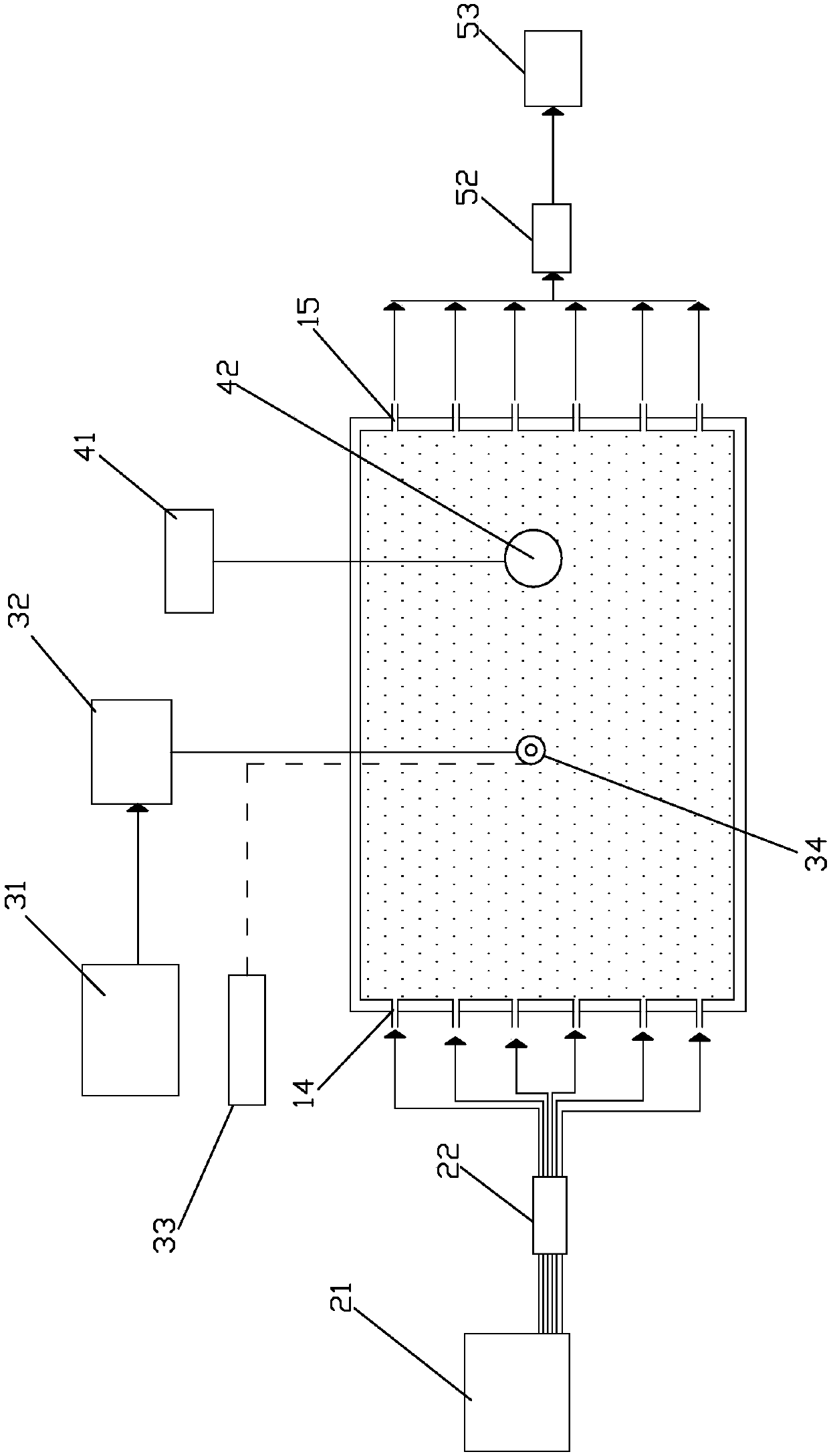

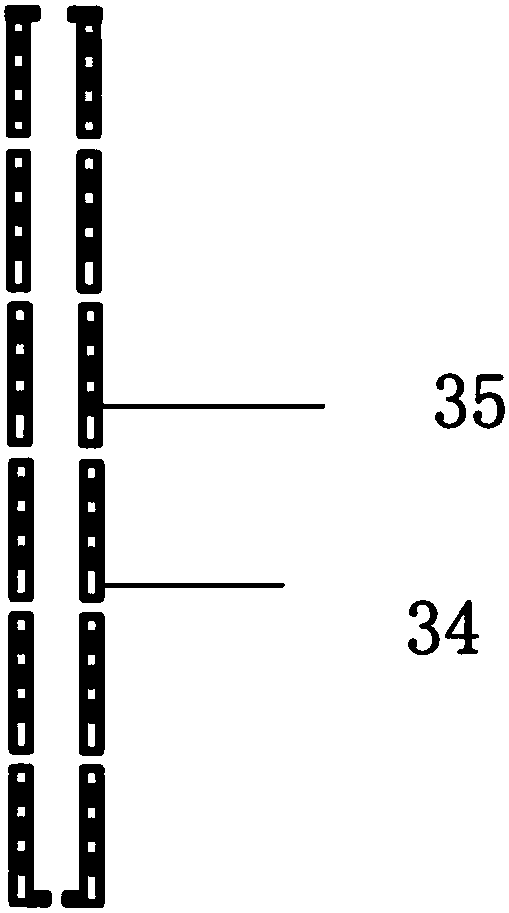

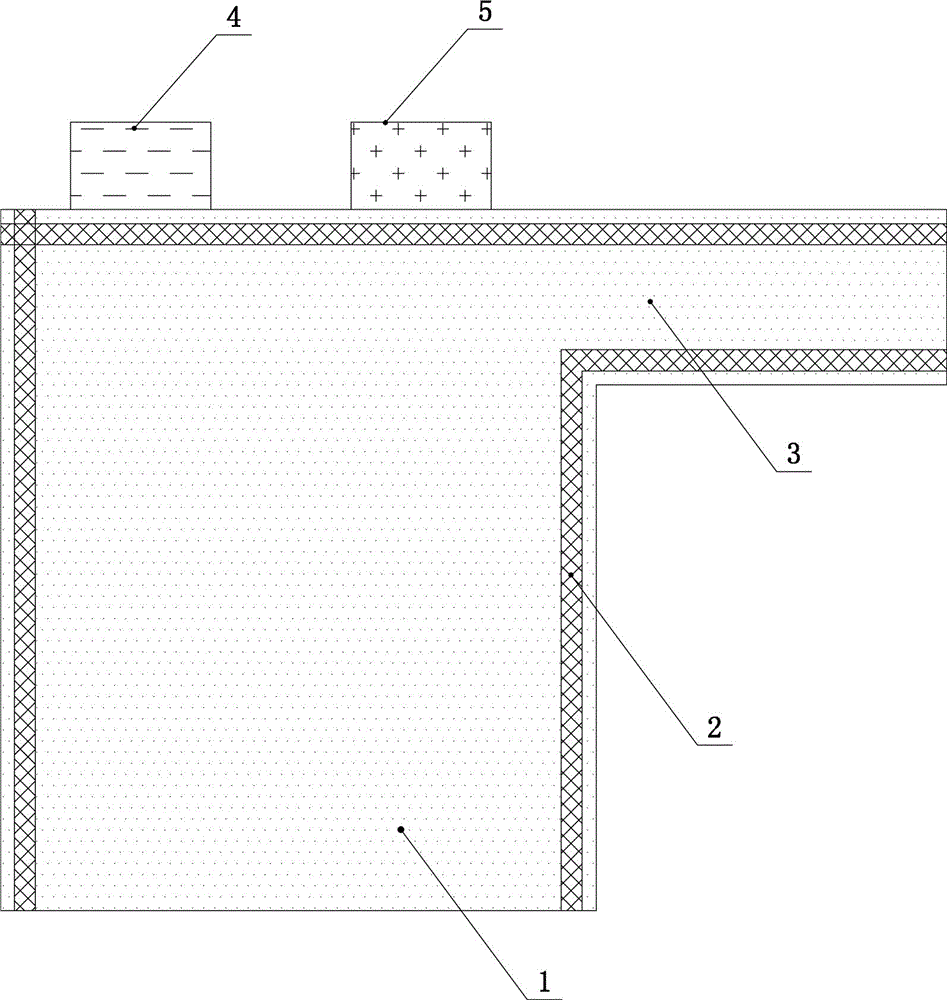

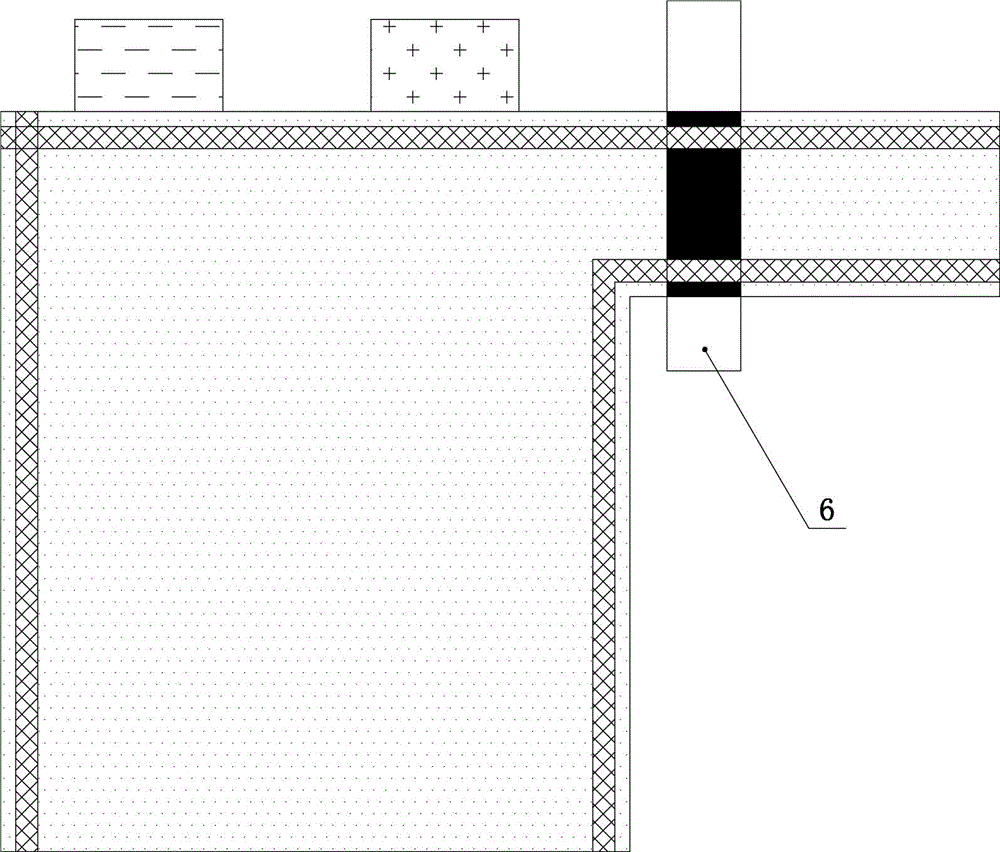

Elastic wave-assisted cement grouting water stop model test device

PendingCN107796929AEnhance the effect of grouting and waterproofingEnhanced pourabilityHydrodynamic testingMaterial testing goodsGround water pollutionCement grout

The invention discloses an elastic wave-assisted cement grouting water stop model test device which comprises a model test box, an underground water injection system, a low-frequency elastic wave grouting system, a high-frequency grout strengthening system and a measurement system. Water injection openings and water outlets are formed in the circumferential side wall of the model test box; a water-bearing medium for simulating a real underground flowing water condition is arranged in the model text box; the underground water injection system is used for injecting underground water into the model test box to simulate the real underground flowing water condition; the low-frequency elastic wave grouting system is used for injecting cement grout to the water-bearing medium in the model test box; the high-frequency grout strengthening system is used for accelerating hydration reaction of the cement grout in the water-bearing medium; the measurement system comprises multiple measurement minisystems; the measurement mini systems are connected with the water outlets and are used for measuring a migration condition of the grout in the water-bearing medium and the pollution degree of the grout to the underground water. The elastic wave-assisted cement grouting water stop model test device has the advantages that the grouting water stop range can be quickly and efficiently expanded, andthe grouting water stop effect can be enhanced.

Owner:HUAQIAO UNIVERSITY

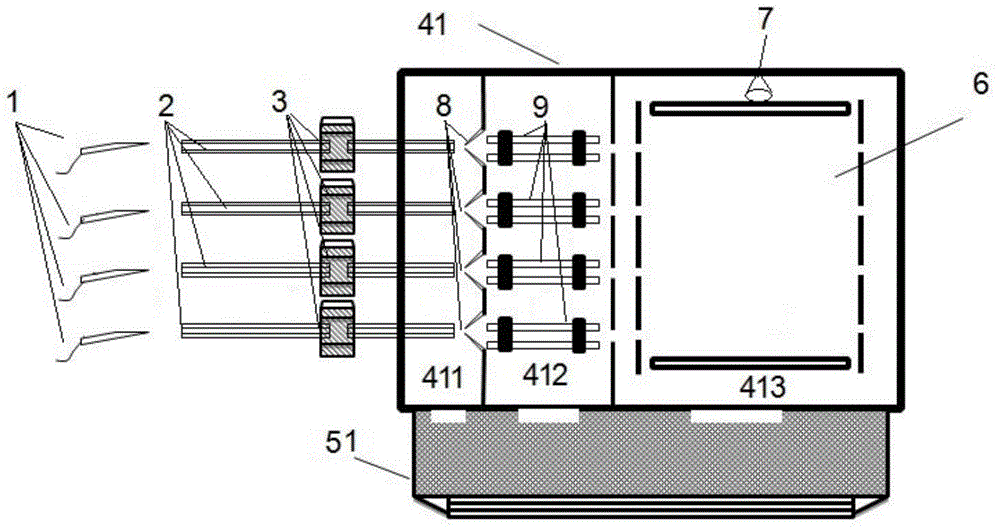

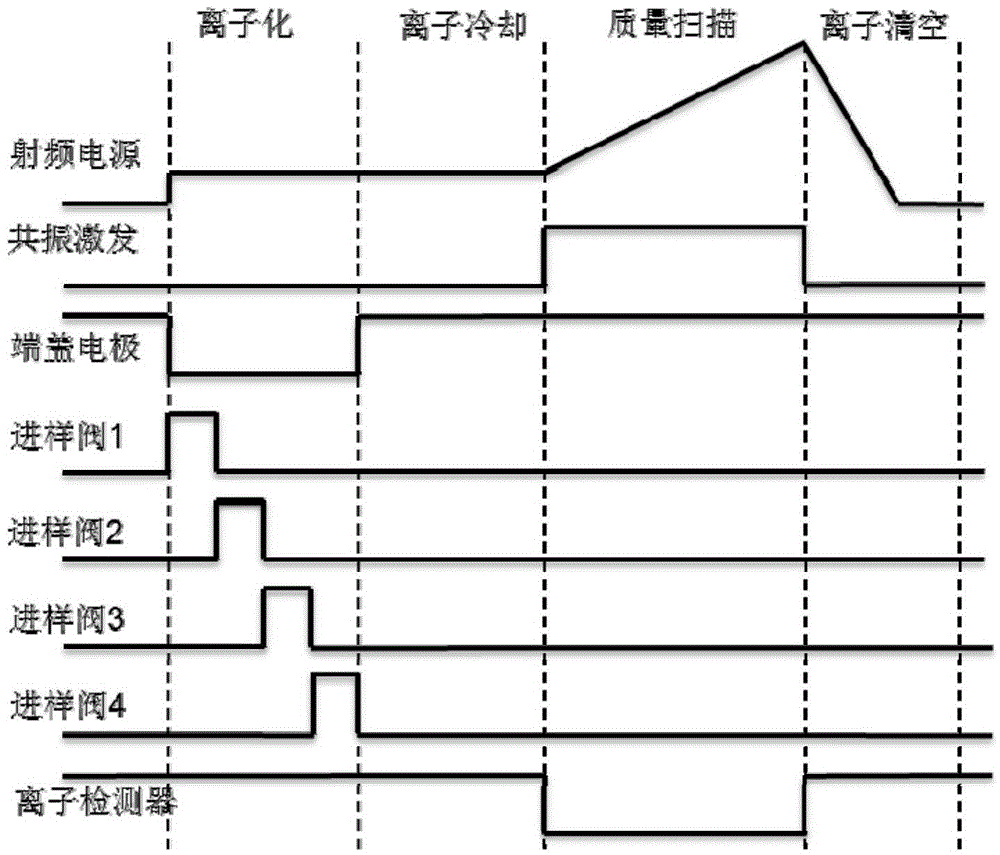

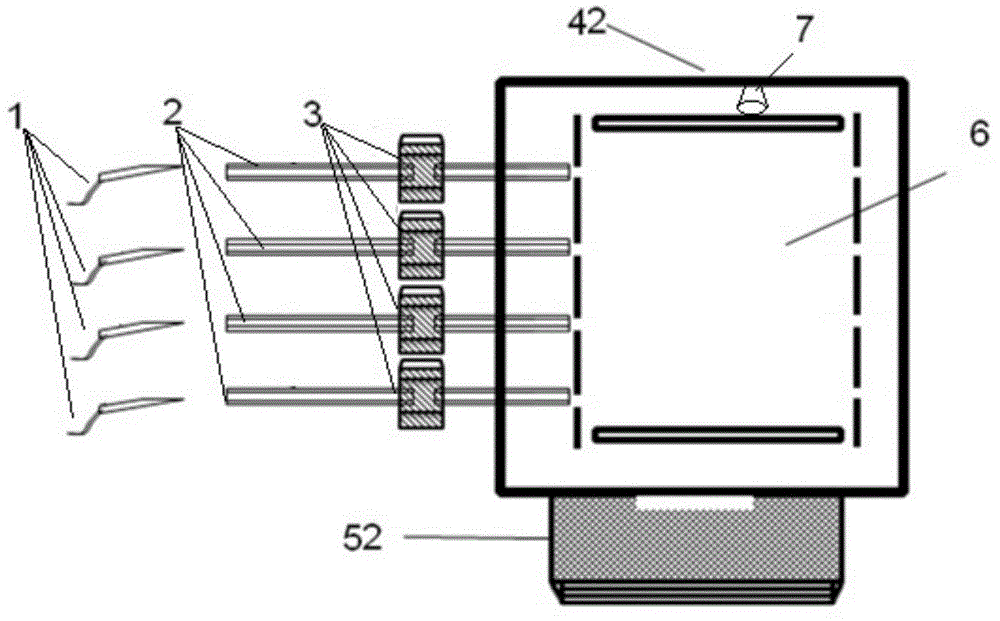

Ion sample introduction method and multi-channel array ion trap mass spectrum system

InactiveCN104792856AIncrease injection speedImprove injection efficiencySamples introduction/extractionPreparing sample for investigationMass analyzerVacuum pump

The invention discloses an ion sample introduction method which comprise the steps of arranging sample introduction valves on ion channels of a multi-channel array ion trap, opening part of the sample introduction valves between ion sources and a vacuum cavity in a timed alternate opening manner, allowing ions to enter the vacuum cavity through the sample introduction valves, and accomplishing an ion sample introduction process. The invention further discloses a multi-channel array ion trap mass spectrum system which comprise ion sources, ion transmission capillary tubes, sample introduction valves, a vacuum cavity, a vacuum pump system, an array ion trap mass analyzer and an ion detector, wherein the front ends of the ion transmission capillary tubes are connected with the ion sources; the rear ends of the ion transmission capillary tubes are connected with the vacuum cavity; the sample introduction valves are arranged on the ion transmission capillary tubes; the vacuum pump system is connected with the vacuum cavity; and the vacuum cavity is internally provided with the array ion trap mass analyzer and the ion detector sequentially. The method and equipment can improve sample introduction efficiency and mass spectrum resolution.

Owner:SUZHOU UNIV

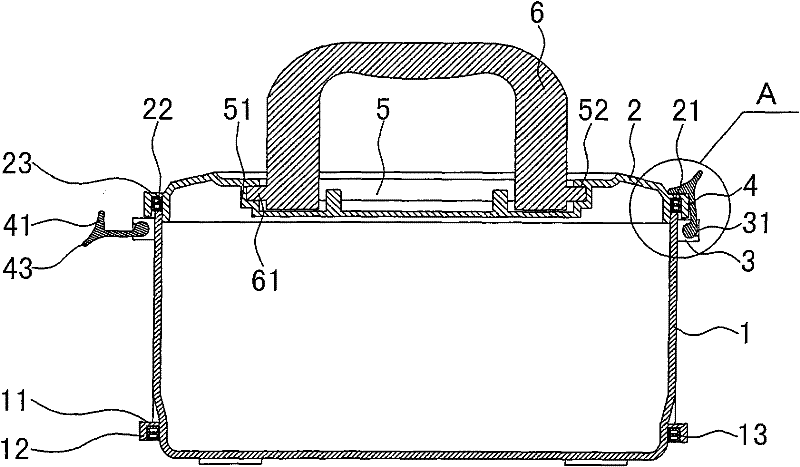

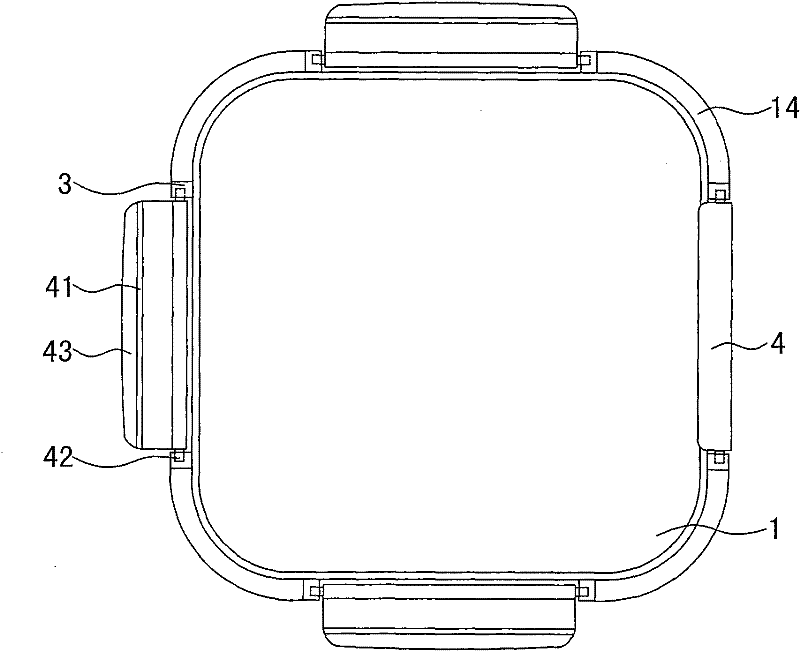

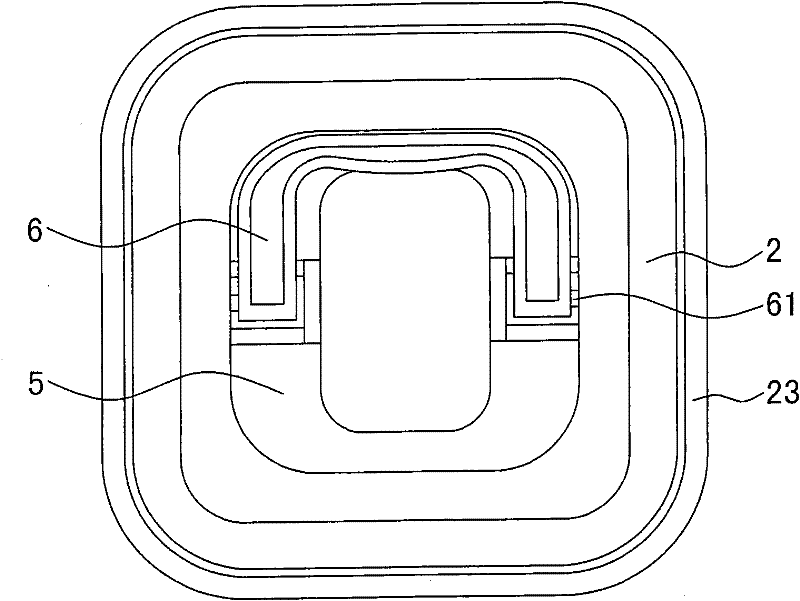

Split-type wrenching-type preservation box

InactiveCN102219082AWill not be scrappedWill not cause scrapSealingRigid containersEngineeringInjection moulding

The invention relates to a split-type wrenching-type preservation box, comprising a box body and a box cover, wherein a fixed slot is arranged below the box cover, the fixed slot is provided with a seal ring, and the seal ring is sealed with the opening of the box body. The split-type wrenching-type preservation box is characterized in that the outer wall of the box body is provided with a connection block, the connection block is provided with a connecting slot, the connecting slot is internally provided with a wrench, the two ends of the wrench are provided with blocking tenons, the blocking tenons are movably connected with the connecting slot in the connection block, the wrench is provided with a clip, the box cover is provided with a fixed side, and the clip of the wrench is clamped and matched with the fixed side. The outer side of the box body is provided with the connection block, the connection block is provided with the connecting slot, the connecting slot and the wrench are connected, the wrench is independently injected and moulded, the two ends of the wrench are provided with the blocking tenons, and the wrench is arranged in the connecting slot of the box body by virtue of the blocking tenons, thus mounting is convenient, the generality is good, the blocking tenons and the connecting slot are connected in a rotating way by virtue of spindle and can not rebound or slip off, the influence of repeated rotation is avoided, the service life is long, the wrench and the box body or box cover are in a split structure, a die is easy to make, a demoulding mechanism is simple, the rejection rate is low, and the production efficiency is high.

Owner:张胜伟

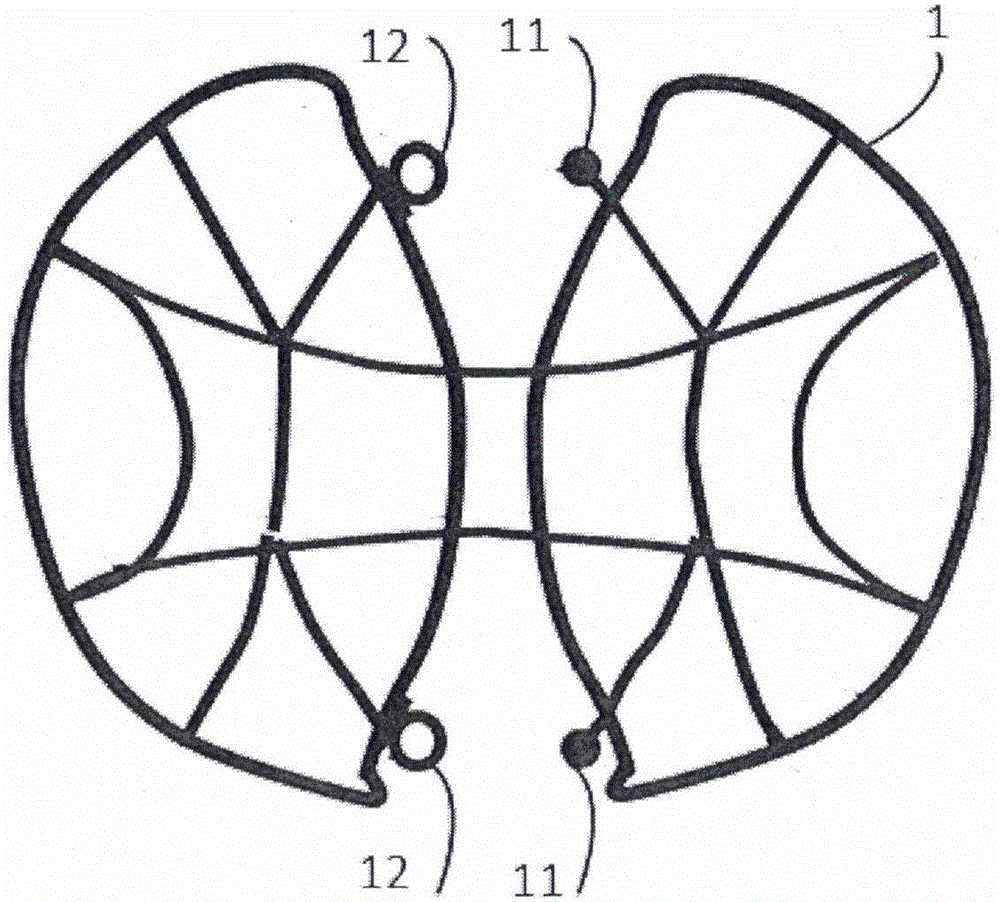

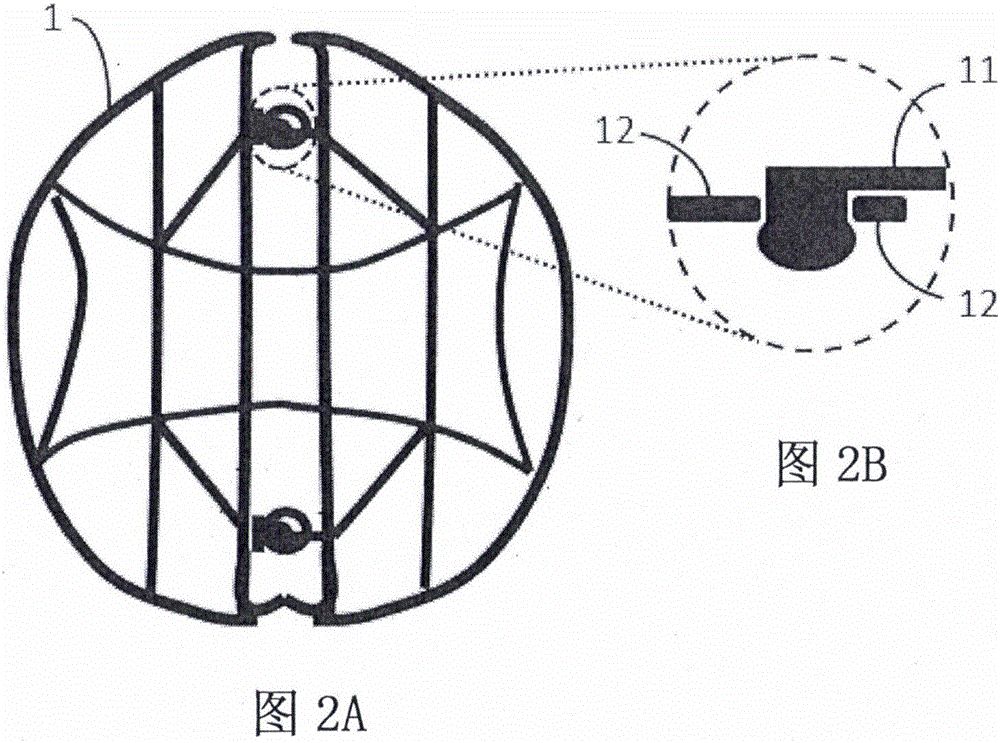

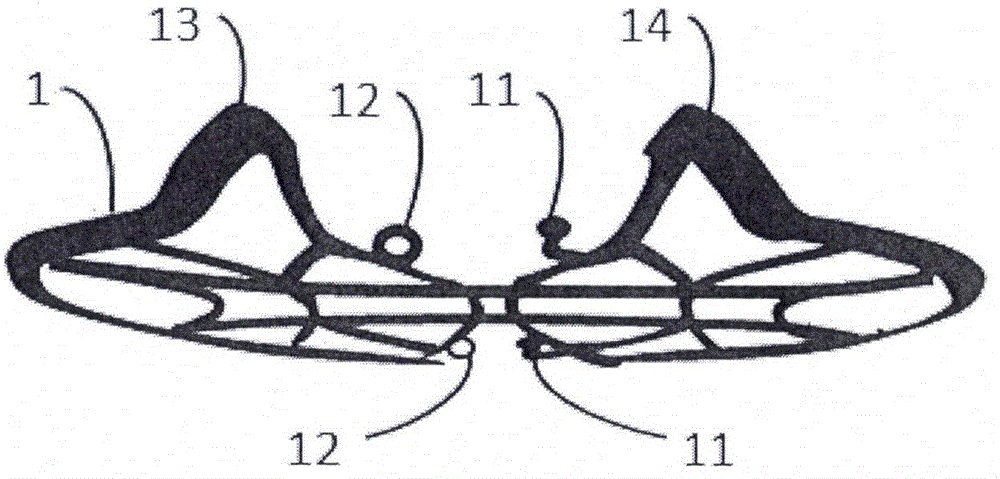

Planar support of three-dimensional mask and three-dimensional mask provided with planar support

A planar support of a three-dimensional mask is used for being mounted in a mask body provided with three-dimensional support space, adopts an elastic planar frame structure and comprises two support bodies which are symmetrically arranged, wherein adjacent side edges of the two support bodies are inner circumferential edges, and non-adjacent side edges are outer circumferential edges; a connecting body for connecting the two support bodies is arranged between the inner circumferential edges of the two support bodies, and mutually matched connectors for connecting the two support bodies are arranged on the inner circumferential edges or on inner sides of the inner circumferential edges on two sides of the connecting body; the two support bodies can bend and deform simultaneously around the connecting body towards one side surface of the planar support of the three-dimensional mask, and combine through corresponding connection by the connectors to form a three-dimensional support structure with the connecting body as the top, and outer circumferential edges of the two support bodies bend and combine to form a face attaching surface. The invention further provides the three-dimensional mask provided with the planar support. The three-dimensional mask is simple and convenient to package and store, automatic batch production is facilitated, and the three-dimensional mask producing efficiency is increased.

Owner:北京可可考拉科技有限公司

Liquid injecting, sealing and forming method of soft packaging lithium-ion battery

InactiveCN104600369ASimple processImprove pass rateFinal product manufactureCell component detailsEngineeringPlastic film

The invention relates to a liquid injecting, sealing and forming method of a soft packaging lithium-ion battery. The liquid injecting, sealing and forming method comprises the following operation steps of packaging an aluminum plastic film at one side of the soft packaging lithium-ion battery to form a tubular channel; carrying out vacuum liquid injection of a soft packaging battery cell by utilizing the tubular channel of the aluminum plastic film, and clamping the tubular channel of the aluminum plastic film by using a sealing clamp after liquid injection, so that the interior of the soft packaging lithium-ion battery is isolated with outside; laying the soft packaging lithium-ion battery with the sealing clamp aside after liquid injection, and forming after laying aside; and in the event of forming, connecting the tubular channel of the aluminum plastic film of the soft packaging lithium-ion battery with a vacuum pipeline, then, opening the sealing clamp fixed on the tubular channel of the aluminum plastic film of the soft packaging lithium-ion battery, so that the interior of the soft packaging lithium-ion battery is connected with the vacuum pipe, forming by vacuumizing the interior of the soft packaging lithium-ion battery, and clamping the tubular channel of the aluminum plastic film of the soft packaging lithium-ion battery by using the sealing clamp after forming.

Owner:SHANDONG SHENGONGHAITE ELECTRONICS TECH

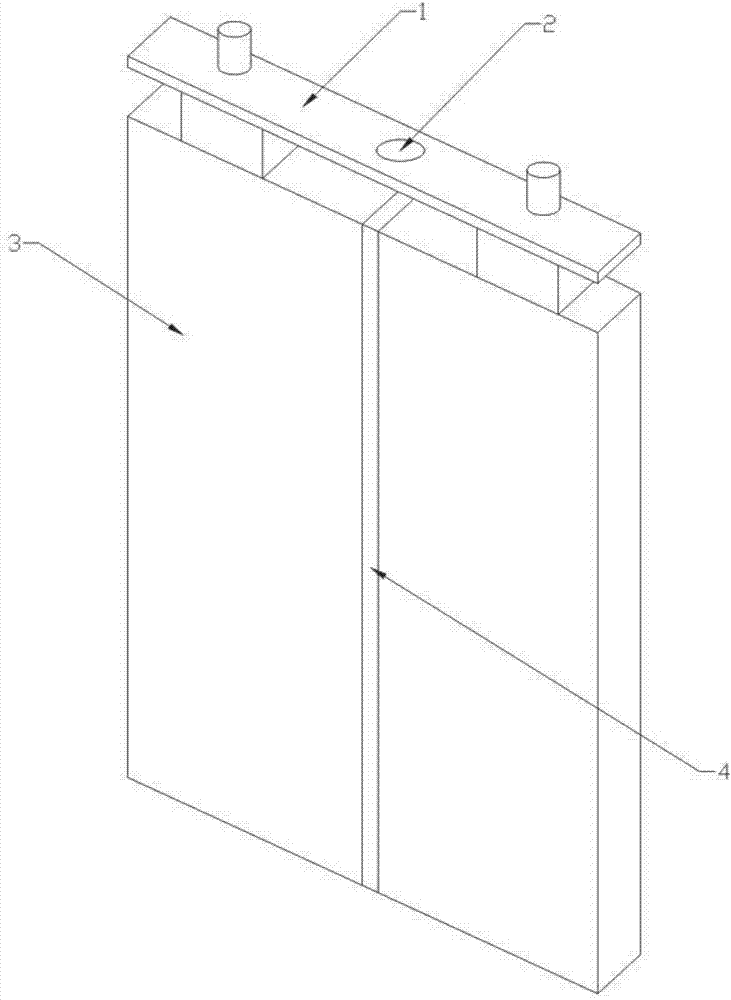

Sampling volume controllable micro-fluidic chip sieving electrophoresis analytical method

InactiveCN101216458AIncrease injection speedLow costDispersed particle separationMaterial analysis by electric/magnetic meansMicrofluidic chipMicro fluidic

A microfluidic chip sieving electrophoresis analytic method capable of controlling injection volume adopts a control device consisting of a microfluidic chip, a micro vacuum pump, a vacuum bottle, an electric contact vacuum meter, a three-way solenoid valve and a single high-voltage power supply. The method is characterized in that a sieving medium is filled in a separation channel between a buffer waster liquid tank (BW) and a channel cross intersection of the microfluidic chip; an electrophoretic buffer is filled the separation channel between other channels of the microfluidic chip, including an injection channel (S-SW) and a buffer tank (B), and the channel cross intersection; and two electrodes of the single high-voltage power supply are respectively with solution in the buffer tank (B) and the buffer waste liquid tank (BW) at both ends of the separation channel. The microfluidic chip sieving electrophoresis analytic method consists of injection and separation two stages. The injection volume can be adjusted arbitrarily through the duration time of the injection stage, and has the advantages of high injection speed, no discrimination effect, safe and reliable operation, low cost, etc.

Owner:ZHEJIANG UNIV

Fast-liquid-injection high-infiltration long-service-life lithium battery and manufacturing method and mold thereof

InactiveCN107403952AExtended service lifeIncrease injection speedFinal product manufactureCell component detailsSlurry coatingLiquid injection

The invention discloses a fast-liquid-injection high-infiltration long-service-life lithium battery and a manufacturing method and a mold thereof. The long-service-life lithium battery comprises a casing and a top cover, wherein the top cover seals a casing opening; a liquid injection opening is formed in the top cover; a plurality of mutually staggered and stacked positive and negative electrode plates are arranged in the casing; diaphragms are separated between the positive and negative electrode plates; each of the positive and negative electrode plates consists of a base plate and a slurry coating layer coating the surface of the base plate; a groove penetrating through the slurry coating layer to reach the base plate is at least formed in the positive electrode plate.

Owner:成都特隆美储能技术有限公司

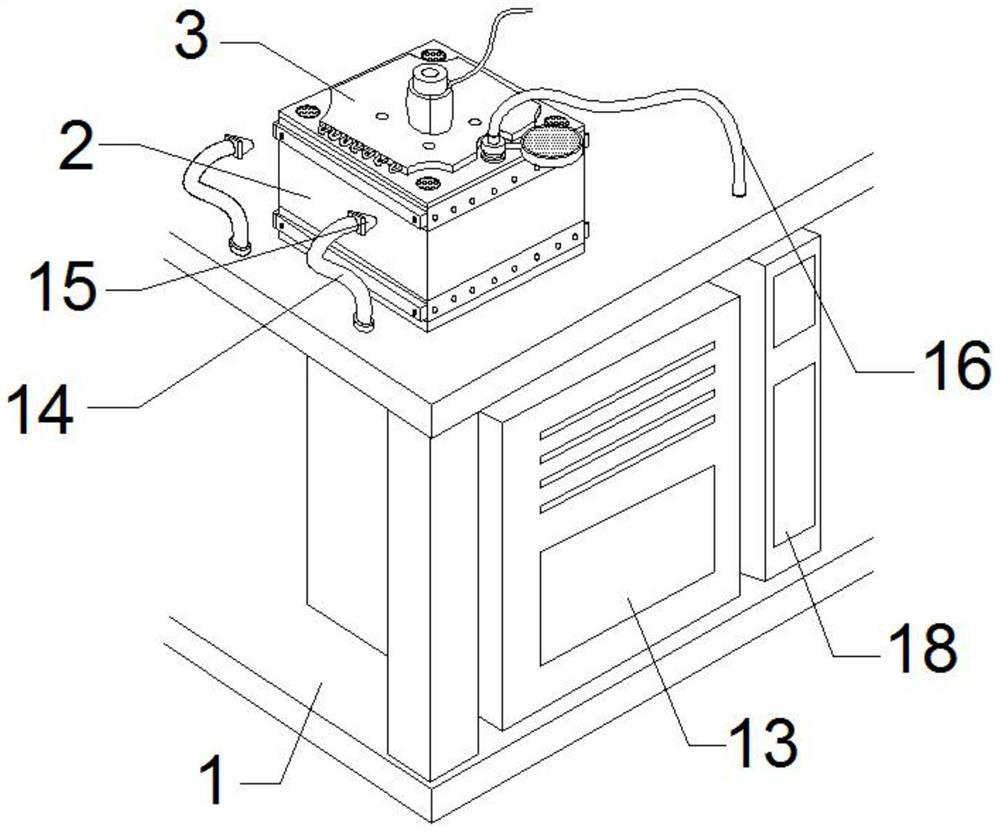

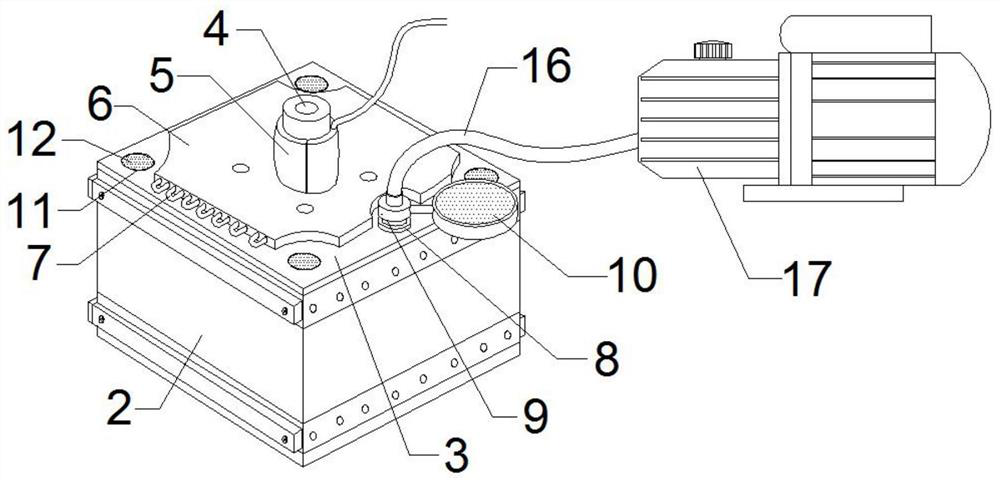

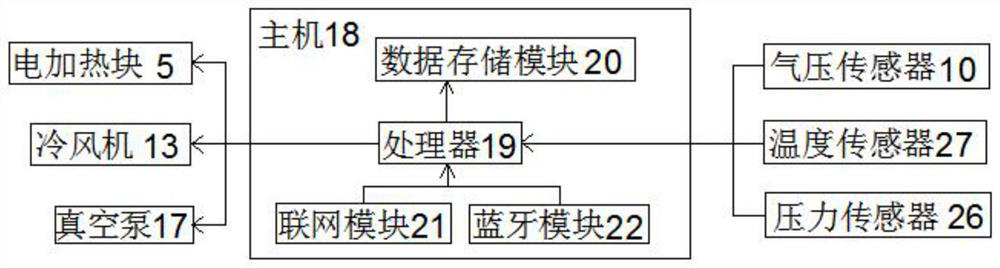

Machining equipment for improving machining precision of injection mold and machining method thereof

The invention discloses machining equipment for improving machining the precision of an injection mold and a machining method thereof. The machining equipment comprises a machining frame, a lower mold, an upper mold, a cooling plate, a pressure sensor and a temperature sensor, the lower mold is fixedly mounted at the top of the machining frame, the upper mold is arranged on an upper cover of the lower mold, and a material injection opening is formed in the middle of the top of the upper mold. The sealing pressure intensity between molds is detected through sensing detection of the multiple sets of sensors, so that the phenomenon that injected materials rapidly flow into gaps between cloth and mold grooves, and hollowing bubbles are greatly reduced are too loose and overflow is generated isavoided, negative-pressure air suction is conducted in the dies, injected materials can rapidly flow into gaps between cloth and die grooves, the phenomenon of hollowing bubbles is greatly reduced can be avoided, and the machining precision is effectively improved; and the temperature sensor is used for detecting the temperature of the material injection opening, after the temperature of the material injection opening is lower than a set value, a processor starts an electric heating sleeve to heat the material injection opening, and thus, the situation that normal circulation cannot be achieved due to the too low melting material injection temperature is avoided.

Owner:嘉兴天行健精密模具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com