Wind turbine blade mold with double vacuum systems and method for making wind turbine blade by wind turbine blade mold

A wind rotor blade and double vacuum technology, applied in the field of machining molds, can solve the problems of inability to guarantee, difficult to improve production efficiency, poor process controllability, etc., and achieve the effects of improving product quality, saving labor costs, and saving process costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

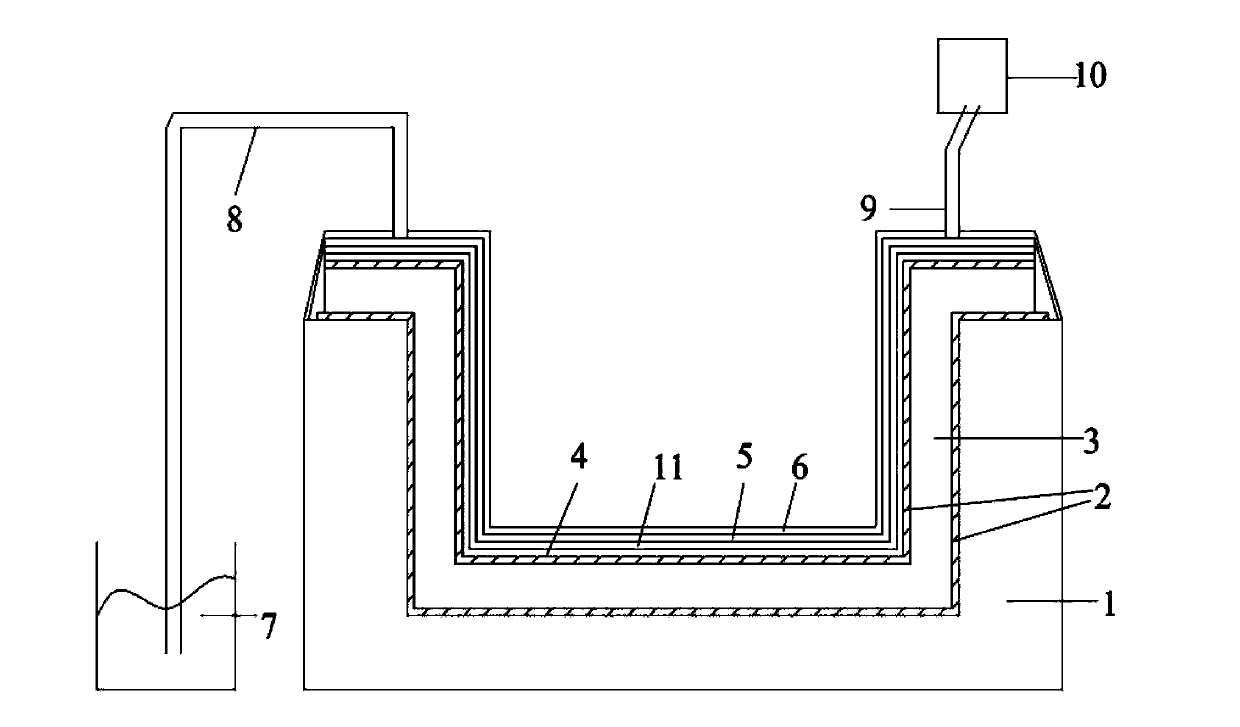

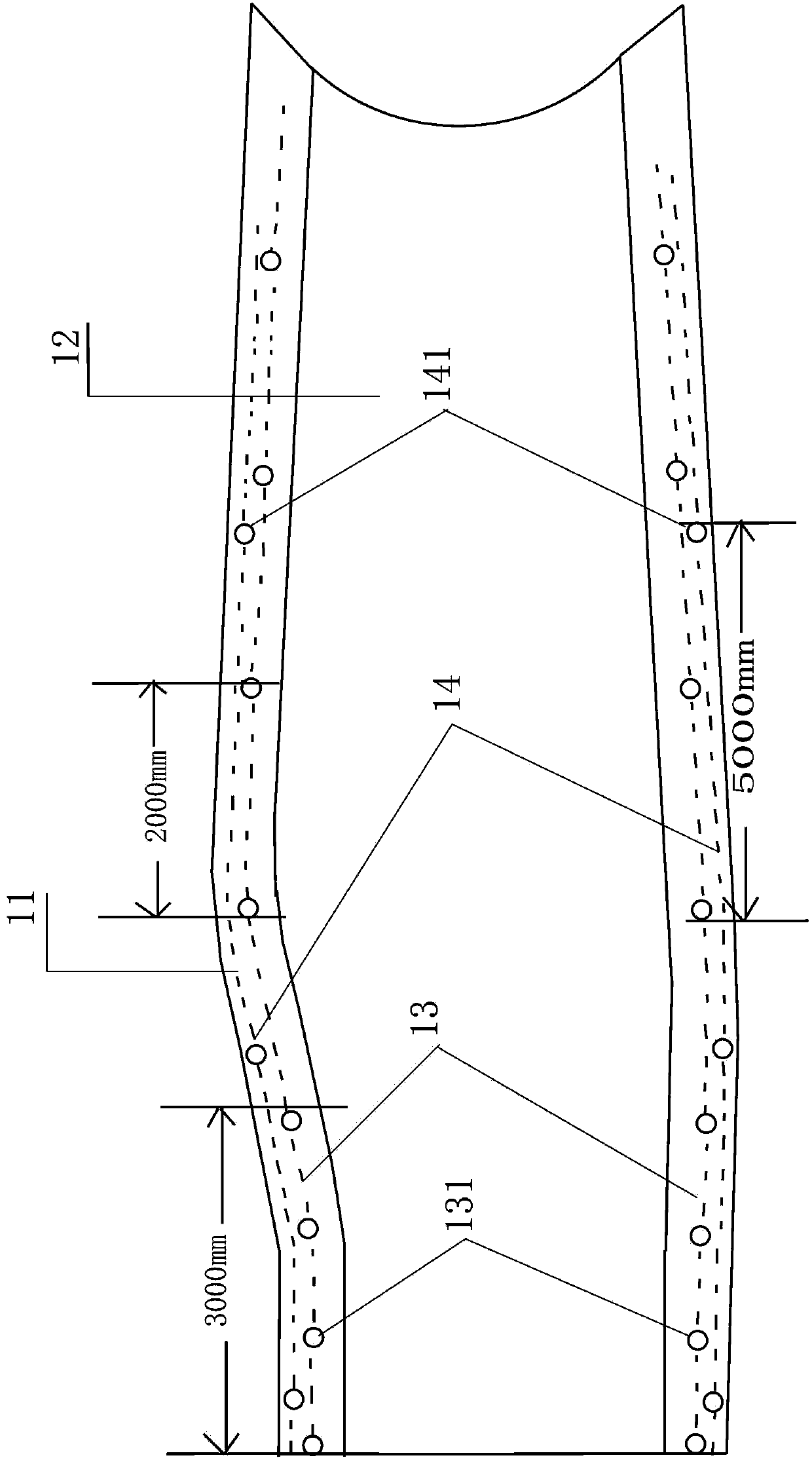

[0036] Such as figure 2 As shown, it is a schematic diagram of double vacuum air passages on the parting surface of the wind turbine blade mold of the present invention.

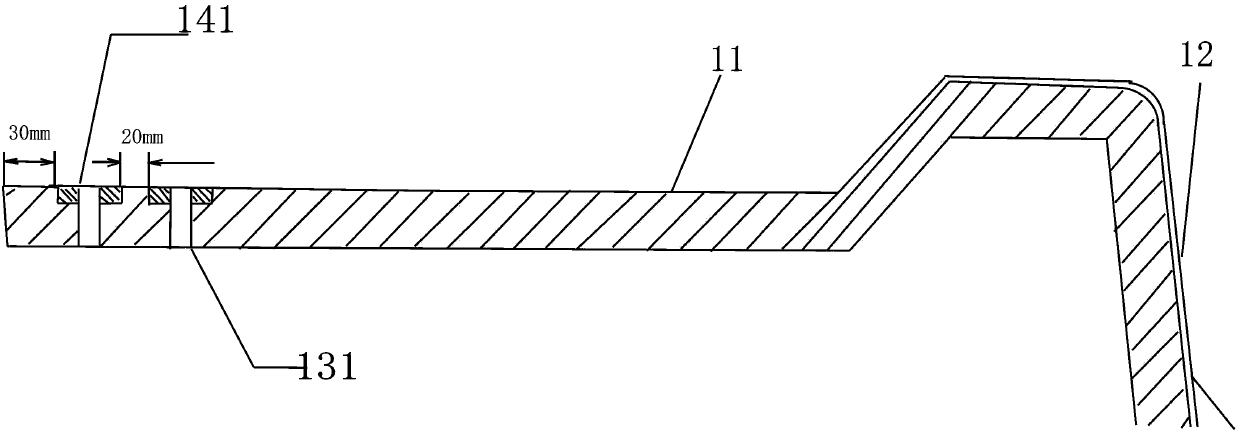

[0037] in figure 2 Shown in is a top view of the wind turbine blade mold, including a parting surface 11 in the mold 1, which is a surface where the upper mold and the lower mold are matched and joined with each other, and the inner side of the parting surface 11 is a mold cavity 12. A first vacuum air passage 13 and a second vacuum air passage 14 are formed on the parting surface 11 . Wherein the first vacuum air channel 13 is relatively located inside the parting surface 11, and the second vacuum air channel 14 is relatively located outside the parting surface 11, and the first vacuum air channel 13 and the second vacuum air channel 14 respectively include several intervals. The air extraction points 131 and 141 of each air extraction point 131 and 141 are perforations penetrating the parting surface. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com