Sampling volume controllable micro-fluidic chip sieving electrophoresis analytical method

A technology of microfluidic chip and electrophoresis analysis, which is applied in separation methods, material analysis through electromagnetic means, and material analysis, etc., can solve the problems of fixed sample volume and slow sample injection speed, and achieve fast sample injection speed and negative The effect of stable pressure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

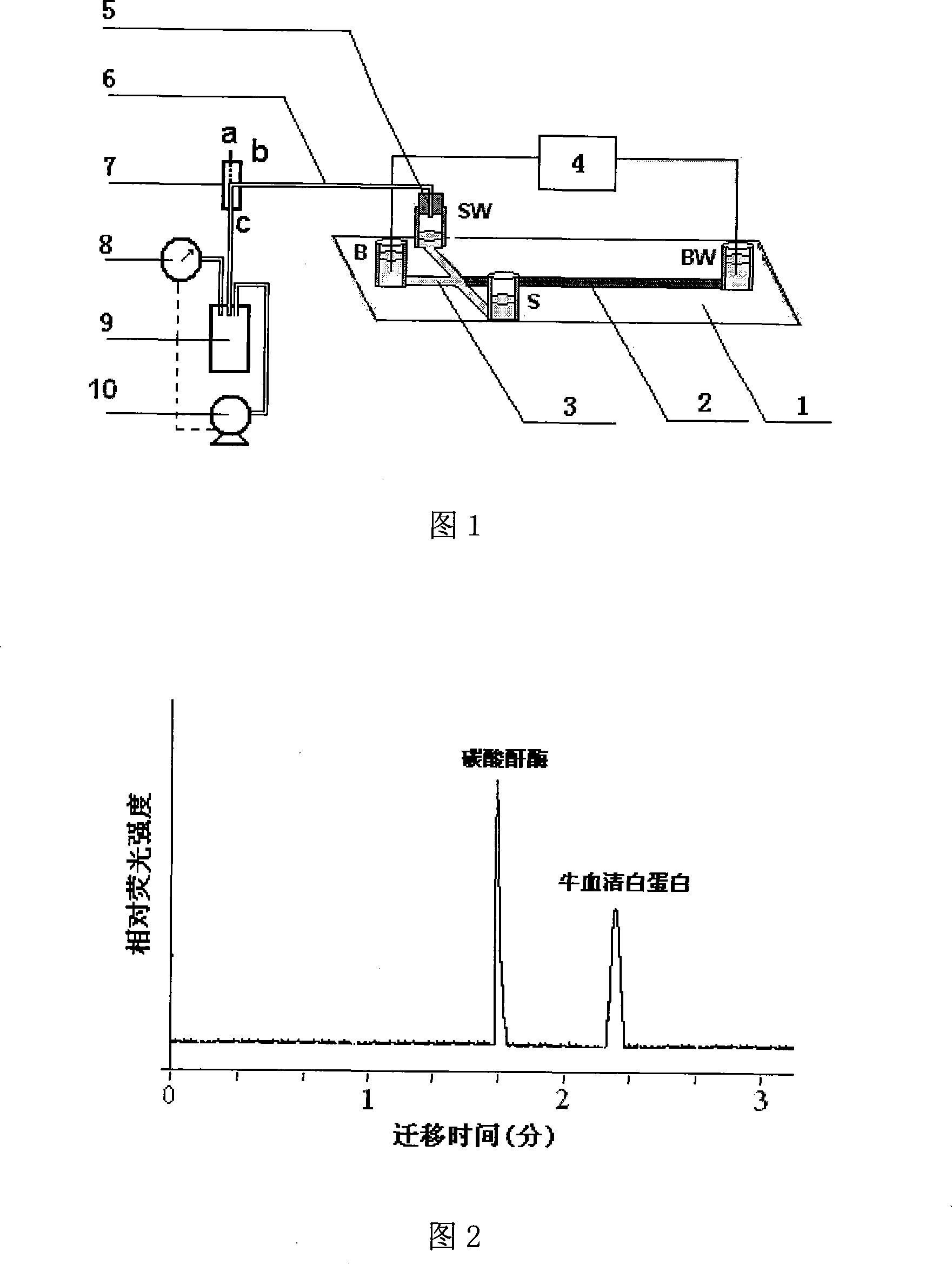

[0022] Referring to Fig. 1, the channel between the buffer pool (B) and the buffer waste pool (BW) on the microfluidic chip 1 is a separation channel (B-BW), and the sample liquid pool (S) and the sample waste pool ( The channel between SW) is the sampling channel S-SW. Add the sieving medium 2 to the buffer waste pool (BW), and fill the sieving medium 2 only in the separation channel from the buffer waste pool (BW) to the crossing of the channel, while the microfluidic chip The other channels, including the sampling channel (S-SW) and the separation channel between the buffer pool (B) and the channel crossing, are filled with electrophoresis buffer 3. Add the sample solution into the sample reservoir (S) on the microfluidic chip, add different volumes of electrophoresis buffer into the reservoir B and SW, and keep the height of the liquid level in the sample reservoir (S) lower than that of the buffer The height of the liquid level in the liquid pool (B), the height of the l...

Embodiment 2

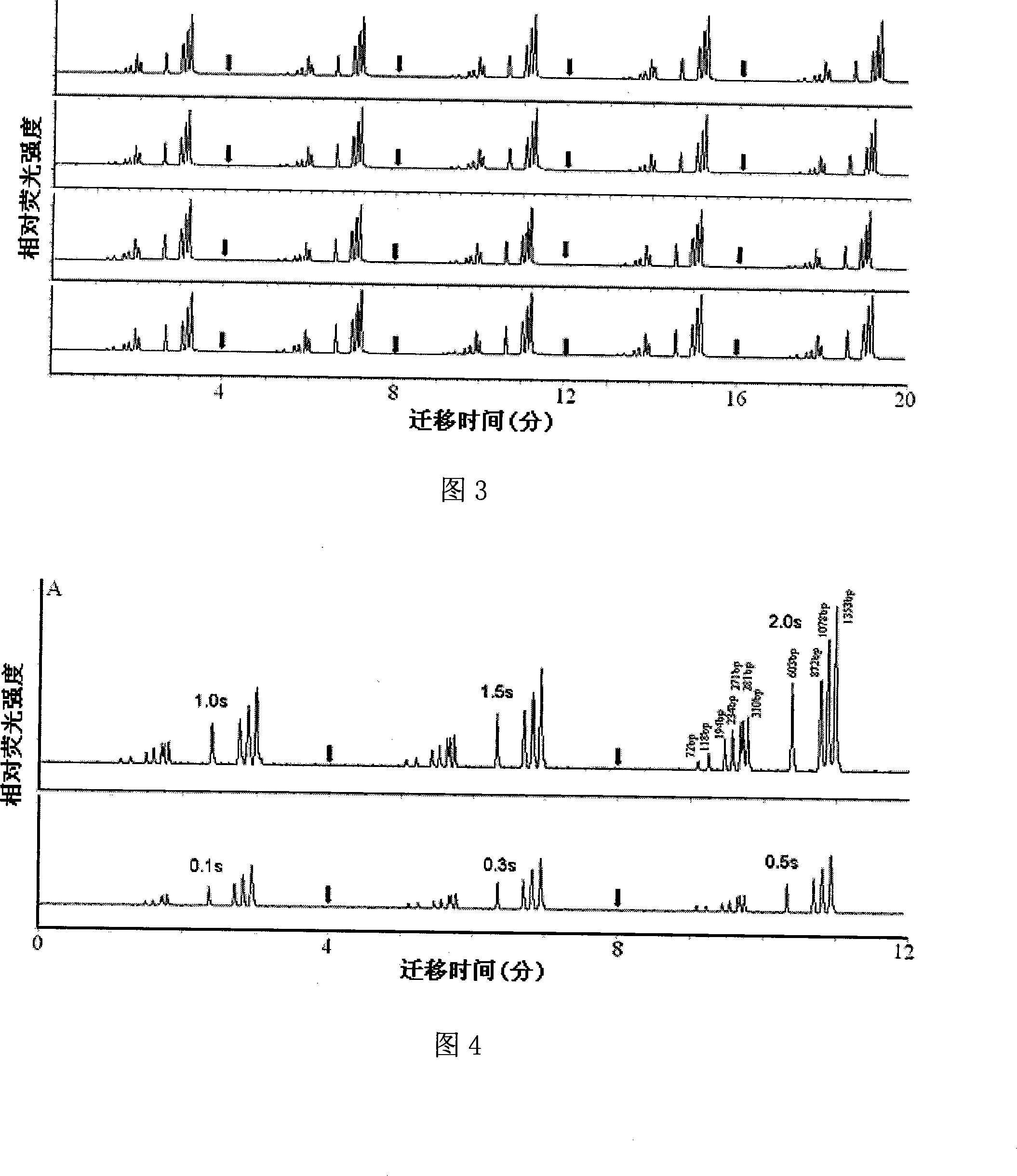

[0026]According to Example 1, an example of separating different proteins by sieving electrophoresis on a microfluidic chip is provided. Referring to Figure 1, the width of the channel on the microfluidic chip is 60 μm, and the depth is 20 μm. The channel between S and SW is a sampling channel with a length of 10 mm, and the channel between B and BW is a separation channel with a length of 50 mm. The separation channel crosses the injection channel. Drill small holes at both ends of the sampling channel and the separation channel, and use adhesive to bond the micro plastic liquid storage tank on the small holes. The outer diameter of the plastic liquid storage tank is 6mm, the inner diameter is 4mm, and the height is 6mm. Use S, SW, B, and BW to represent the sample pool, sample waste pool, buffer pool, and buffer waste pool, respectively. Add 190 μL of sieving medium 12% linear polyacrylamide to the reservoir BW, and use a 20mL syringe to fill the 12% linear polyacrylamide i...

Embodiment 3

[0032] Another example of isolating DNA fragments is provided according to Example 1. The schematic diagram of the microfluidic chip sieving and electrophoretic separation device is shown in Figure 1, and the size of the microfluidic chip used is the same as that in Example 2. Use 2% hydroxyethyl cellulose as the sieving medium, use 1×TBE (90mmol / L Tris, 90mmol / L boric acid, 2mmol / L EDTA, pH8.2) as the electrophoresis buffer solution, and the DNA sample solution is fluorescent The concentration of reagent SYBR labeled is 5 μmol / L ΦX 174-hae III digest. Except that the separation voltage was adjusted from 1000V to 550V, other operating steps were the same as in Example 2. The electropherogram of the DNA sample analyzed 20 times with the injection time of 2 s is shown in Fig. 3 . It can be seen from Fig. 3 that the standard relative deviation of the DNA fragment migration time is 1.1-1.3%, and the standard relative deviation of the peak height is 5.0-9.0%. The electropherogra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com