Machining equipment for improving machining precision of injection mold and machining method thereof

A technology of processing precision and injection mould, which is applied in the field of processing equipment to improve the processing precision of injection moulds, can solve the problems that the injection precision needs to be improved and there is no auxiliary detection, and achieve the effect of reducing air bubbles and improving the precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

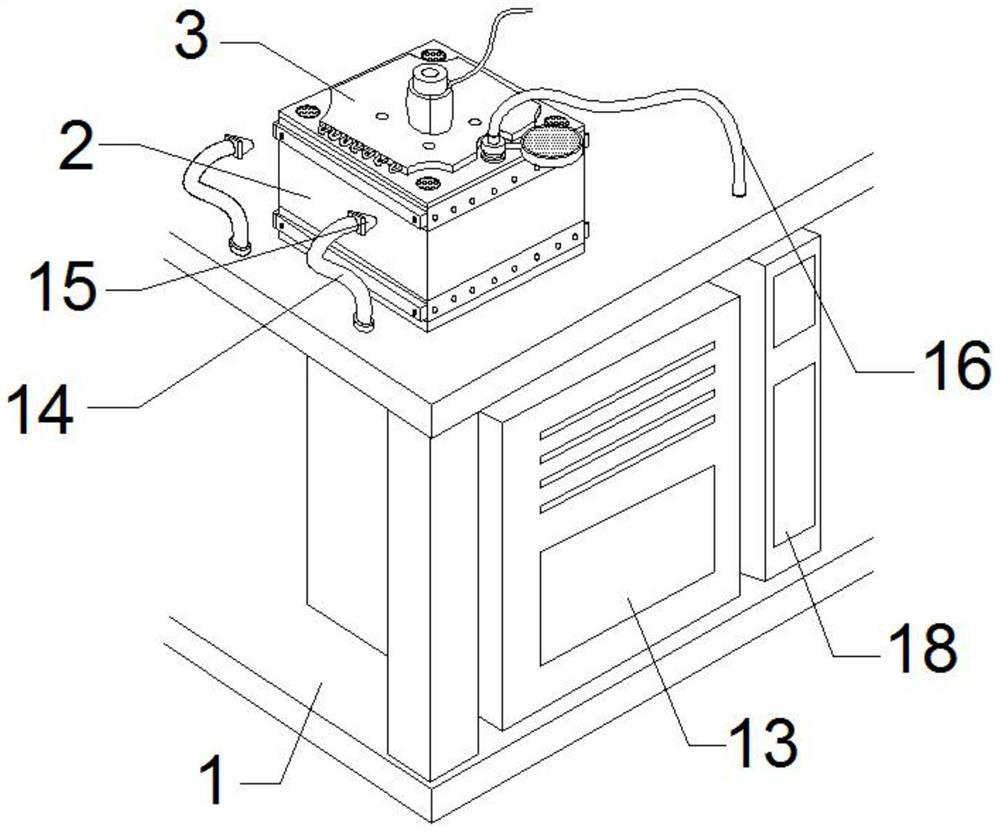

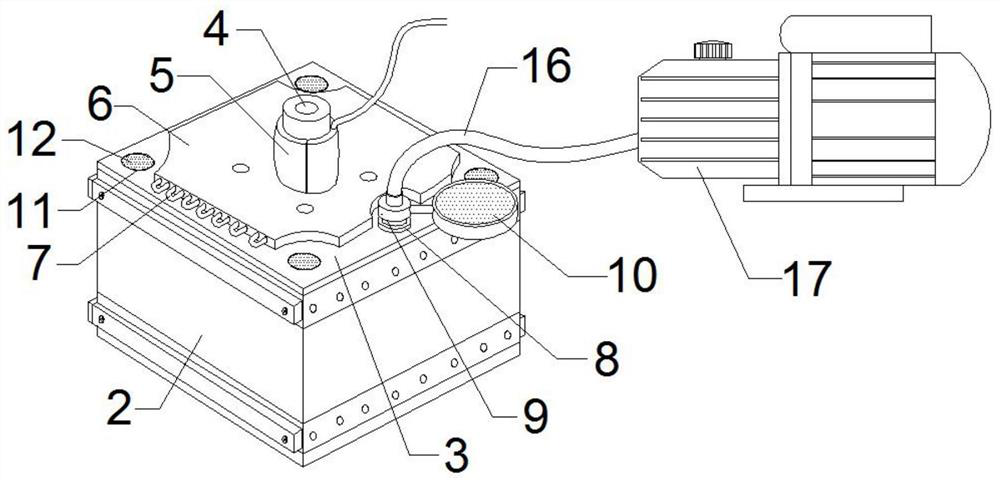

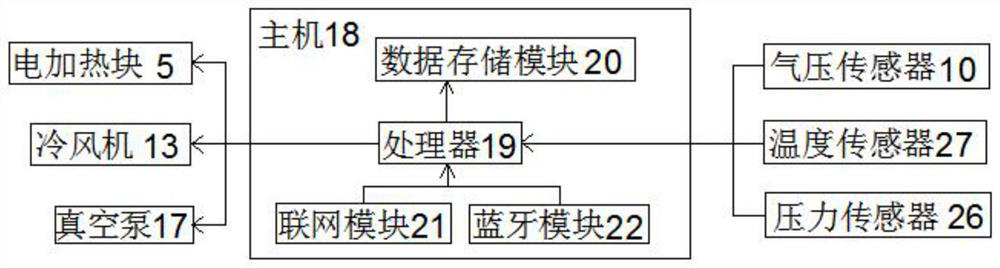

[0031] Such as Figure 1-3 As shown, a processing equipment for improving the processing accuracy of injection molds includes a processing frame 1, a lower mold 2, an upper mold 3, a cooling plate 6, a pressure sensor 26 and a temperature sensor 27, and the top of the processing frame 1 is fixedly installed with a lower mold 2. The upper cover of the lower mold 2 is provided with an upper mold 3, and the middle part of the top of the upper mold 3 is provided with a material injection port 4, and the two sides of the outer periphery of the bottom end of the said material injection port 4 are respectively clamped with electric heating sleeves 5, so The top of the upper mold 3 and the outer cover of the injection port 4 are provided with a cooling plate 6, and the inner serpentine is arranged with a cooling copper tube 7, and the top side of the upper mold 3 is provided with an exhaust nozzle 8. A one-way valve 9 is sleeved on the exhaust nozzle 8, and an air pressure sensor 10 i...

Embodiment 2

[0054] Such as Figure 1-3 As shown, a processing equipment for improving the processing accuracy of injection molds includes a processing frame 1, a lower mold 2, an upper mold 3, a cooling plate 6, a pressure sensor 26 and a temperature sensor 27, and the top of the processing frame 1 is fixedly installed with a lower mold 2. The upper cover of the lower mold 2 is provided with an upper mold 3, and the middle part of the top of the upper mold 3 is provided with a material injection port 4, and the two sides of the outer periphery of the bottom end of the said material injection port 4 are respectively clamped with electric heating sleeves 5, so The top of the upper mold 3 and the outer cover of the injection port 4 are provided with a cooling plate 6, and the inner serpentine is arranged with a cooling copper tube 7, and the top side of the upper mold 3 is provided with an exhaust nozzle 8. A one-way valve 9 is sleeved on the exhaust nozzle 8, and an air pressure sensor 10 i...

Embodiment 3

[0073]Such as Figure 1-3 As shown, a processing equipment for improving the processing accuracy of injection molds includes a processing frame 1, a lower mold 2, an upper mold 3, a cooling plate 6, a pressure sensor 26 and a temperature sensor 27, and the top of the processing frame 1 is fixedly installed with a lower mold 2. The upper cover of the lower mold 2 is provided with an upper mold 3, and the middle part of the top of the upper mold 3 is provided with a material injection port 4, and the two sides of the outer periphery of the bottom end of the said material injection port 4 are respectively clamped with electric heating sleeves 5, so The top of the upper mold 3 and the outer cover of the injection port 4 are provided with a cooling plate 6, and the inner serpentine is arranged with a cooling copper tube 7, and the top side of the upper mold 3 is provided with an exhaust nozzle 8. A one-way valve 9 is sleeved on the exhaust nozzle 8, and an air pressure sensor 10 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com