A round printed part shell potting tool and its holding method

A shell and circular technology, which is applied in the field of potting and encapsulation tooling for circular printed parts and its blessing, can solve the problems of large curing expansion force of potting glue, and achieve the effect of convenient disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

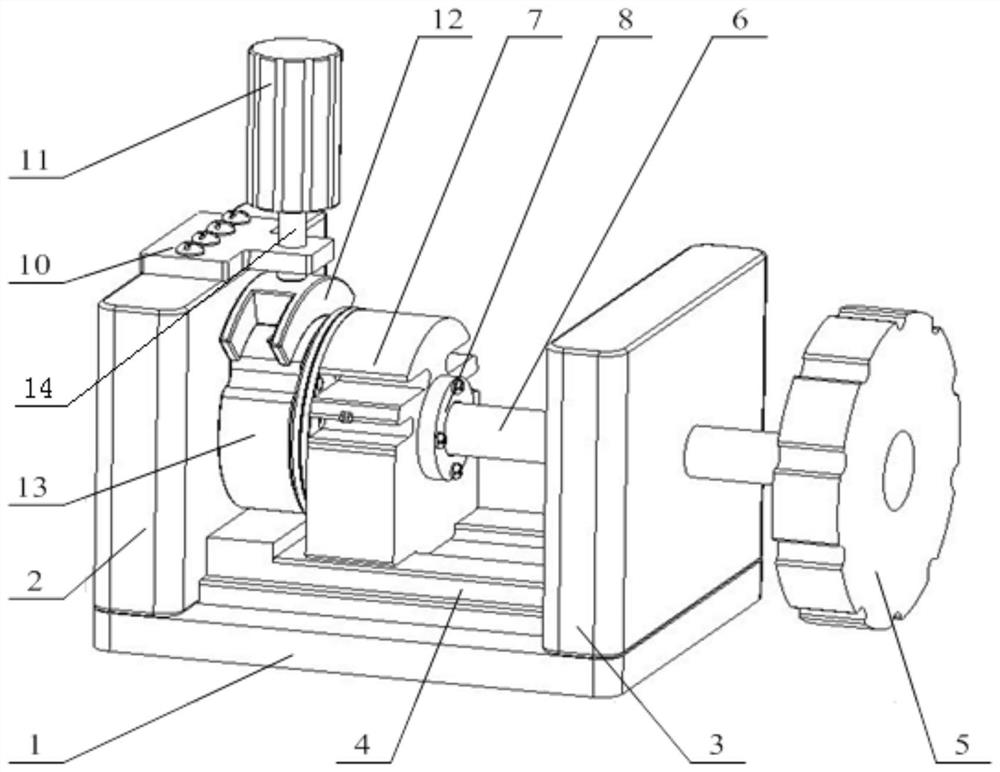

[0027] The present invention is described in further detail below in conjunction with accompanying drawing:

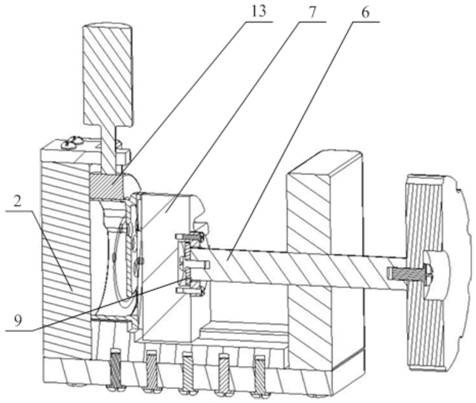

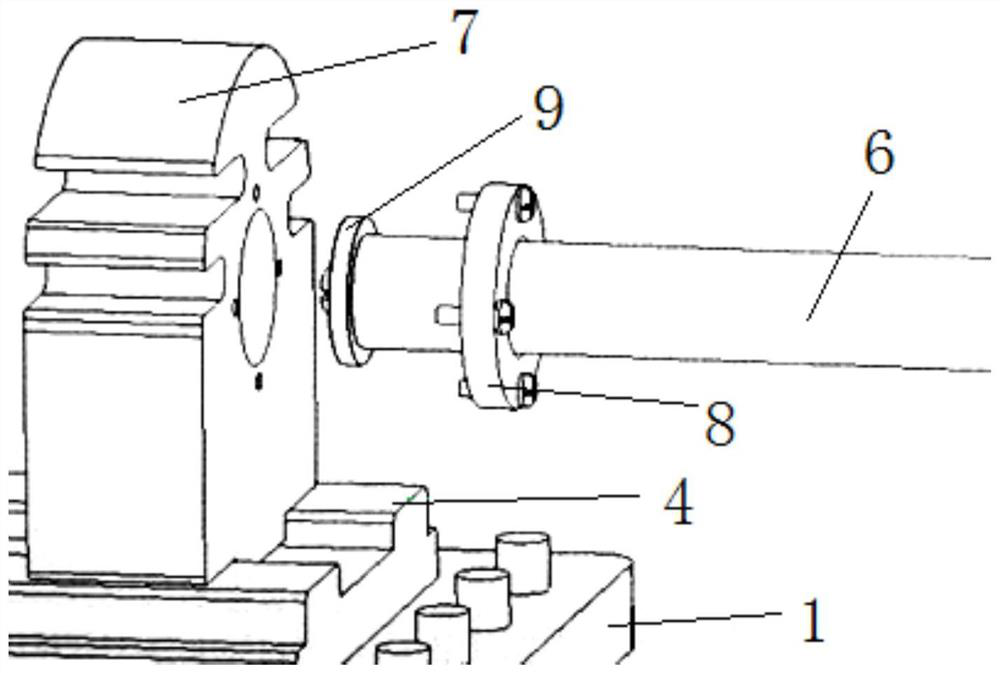

[0028] Such as figure 1 As shown, the tooling of the present invention includes a base 1 , a horizontal handle 5 , a horizontal pressing block 7 , a vertical handle 11 and an arc-shaped pressing block 12 .

[0029] The base 1 is arranged horizontally, and the two ends extend vertically respectively with a front baffle 3 and a rear baffle 2, and the three constitute the support of the tooling; , limit the horizontal pressure block 7, so that the horizontal pressure block 7 always moves in the horizontal direction, and the other end of the guide rail 4 is provided with a base plate in contact with the tailgate 2, the base plate is used to place the housing 13, and the length does not exceed the housing 13 flange positions, so that the housing 13 is always kept horizontal.

[0030] Horizontal handle 5 is arranged on base 1 outside, and horizontal handle 5 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com