Fireproof valve for oil smoke pipeline of setting machine

A technology for smoke pipes and fire dampers, which is applied to valve details, valve devices, mechanical equipment, etc., can solve problems affecting the normal operation of fire dampers, troublesome disassembly and installation of fire dampers, and expansion of blade groups, so as to achieve long-term protection. Deformation, easy cleaning and maintenance, easy disassembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

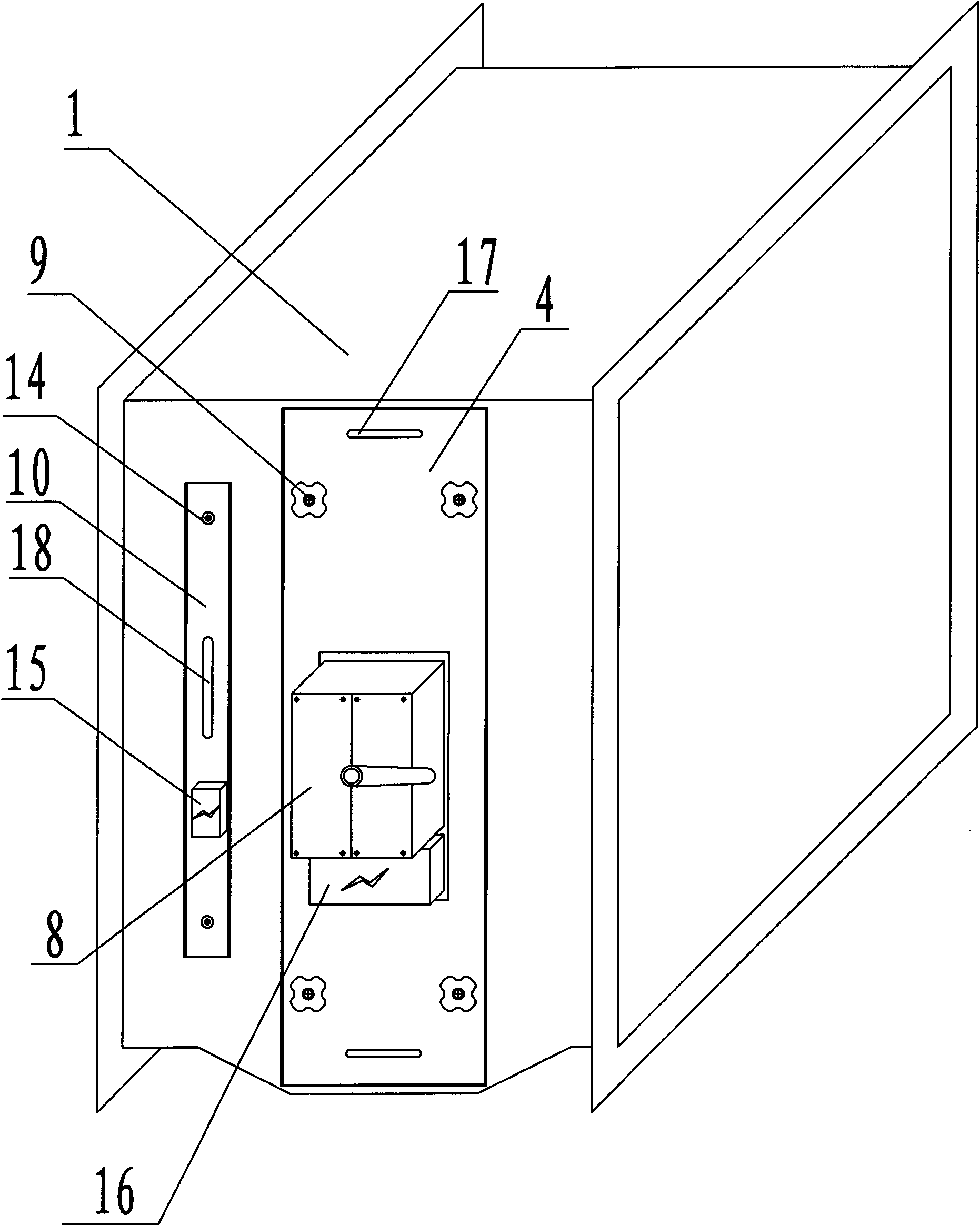

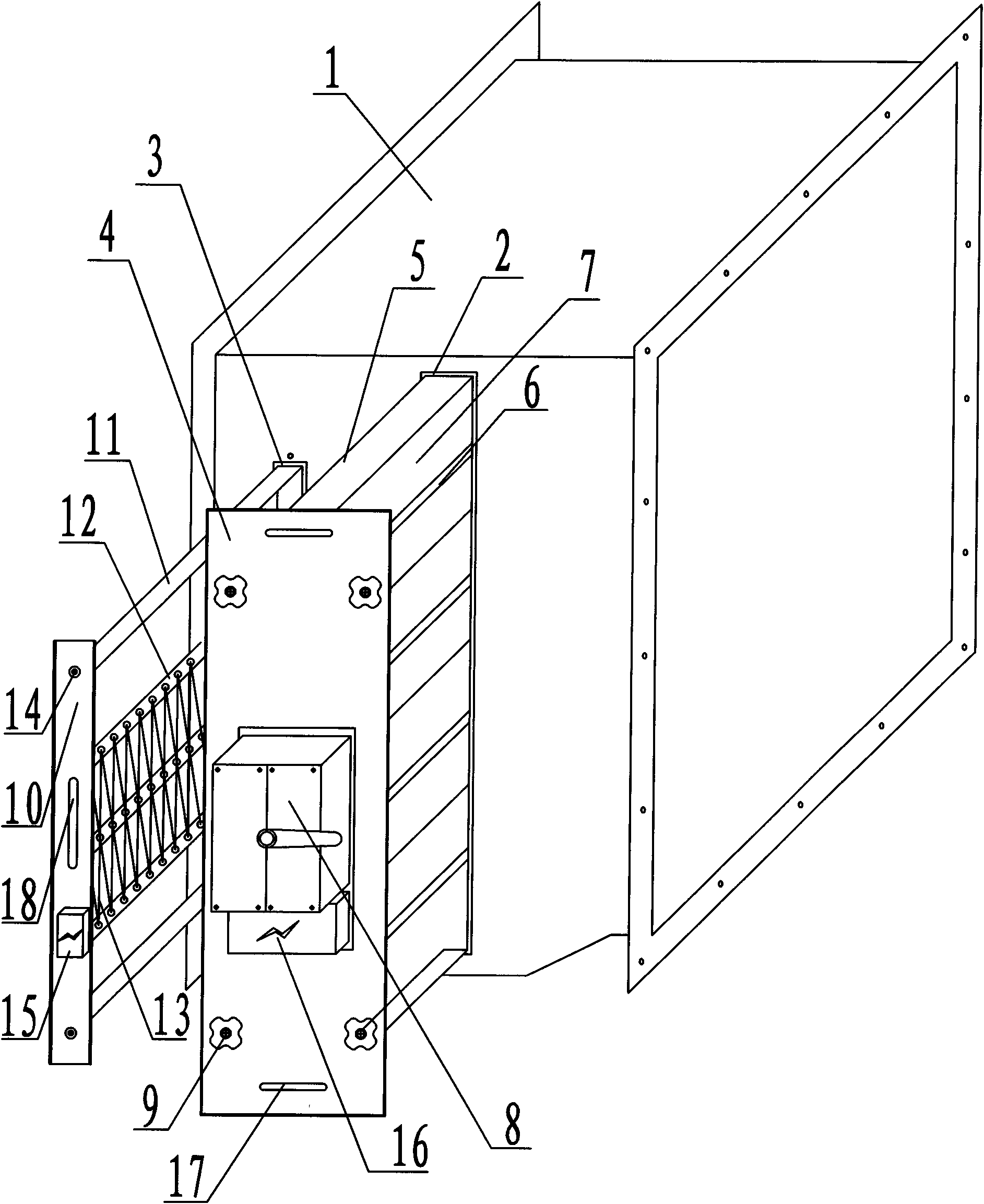

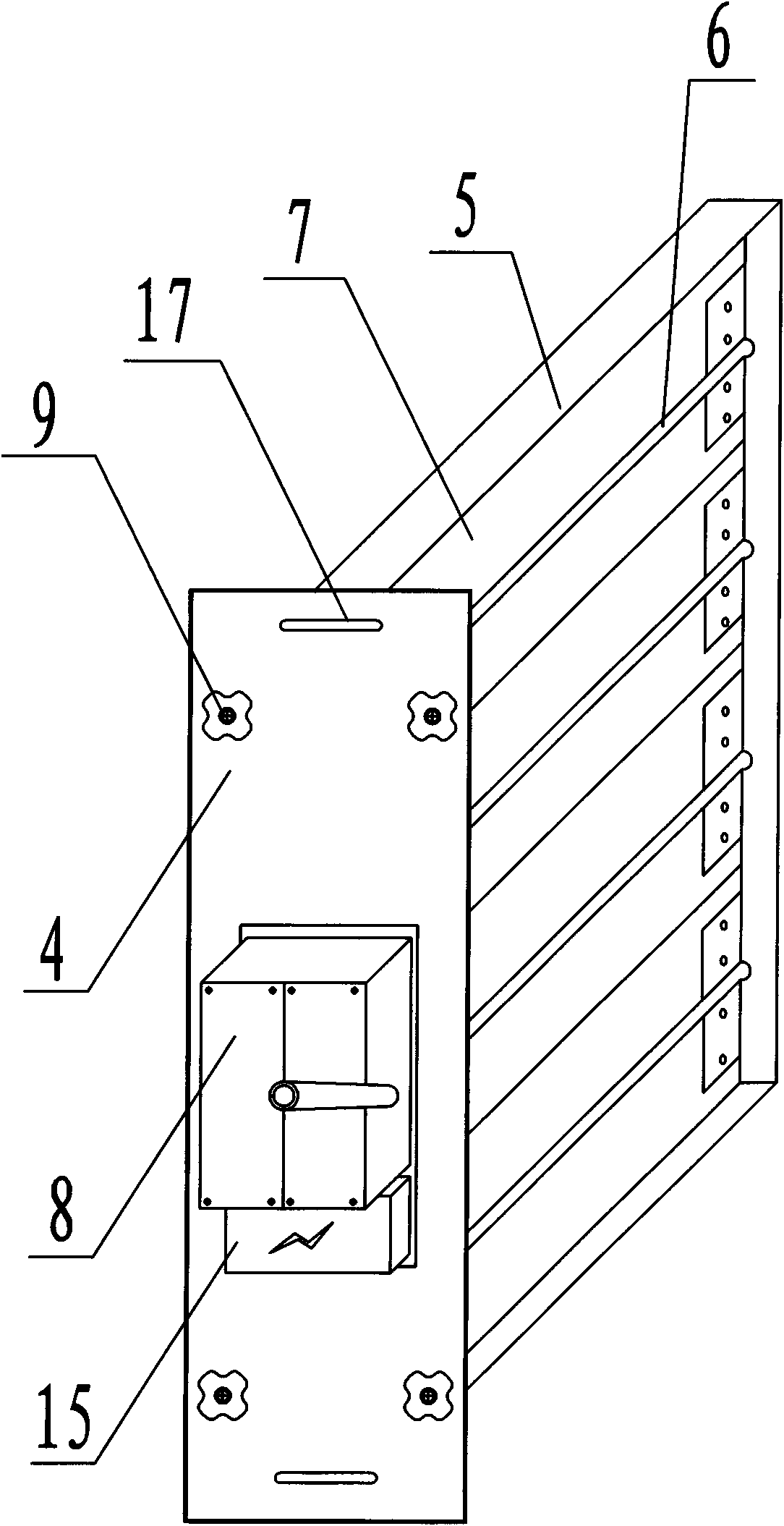

[0013] Such as figure 2 As shown, the fire damper used in the oil fume pipeline of the stereotyped machine includes: a casing 1, and a track-type valve core installation cavity 2 and a track-type fire sensor installation cavity 3 are respectively opened on one side of the casing 1, and the track-type valve A valve core and a fire alarm sensor are respectively arranged in the core installation cavity 2 and the track-type fire alarm sensor installation cavity 3 . Such as figure 2 , image 3 As shown, the structure of the spool includes: a spool fixing plate 4, a spool outer frame 5 connected to the spool fixing plate 4, several rotating shafts 6 that are movably arranged on the spool outer frame 5, fixedly arranged on the rotating shaft 6 The vane 7 and the spool actuator 8 arranged on the spool fixing plate 4, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com