Patents

Literature

395 results about "Head-on collision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A head-on collision is a traffic collision where the front ends of two vehicles such as cars, trains, ships or planes hit each other when traveling in opposite directions, as opposed to a side collision or rear-end collision.

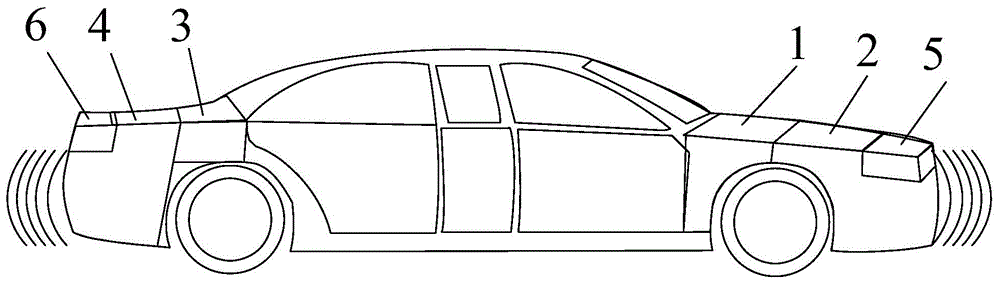

Deflecting Device for an Offset Frontal Collision for Motor Vehicles

InactiveUS20080023954A1Increase collision speedMore impact energyVehicle seatsPedestrian/occupant safety arrangementCouplingEngineering

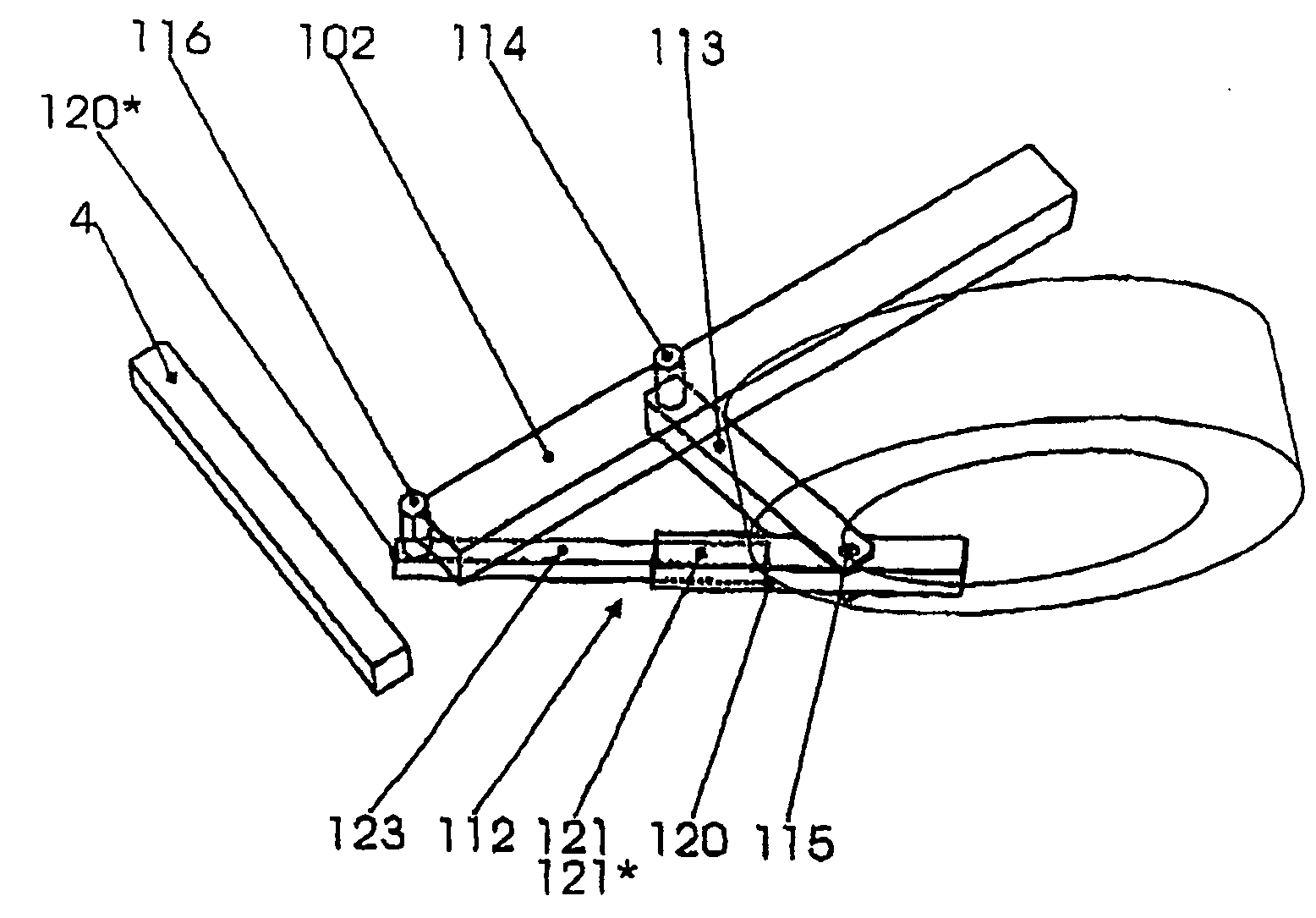

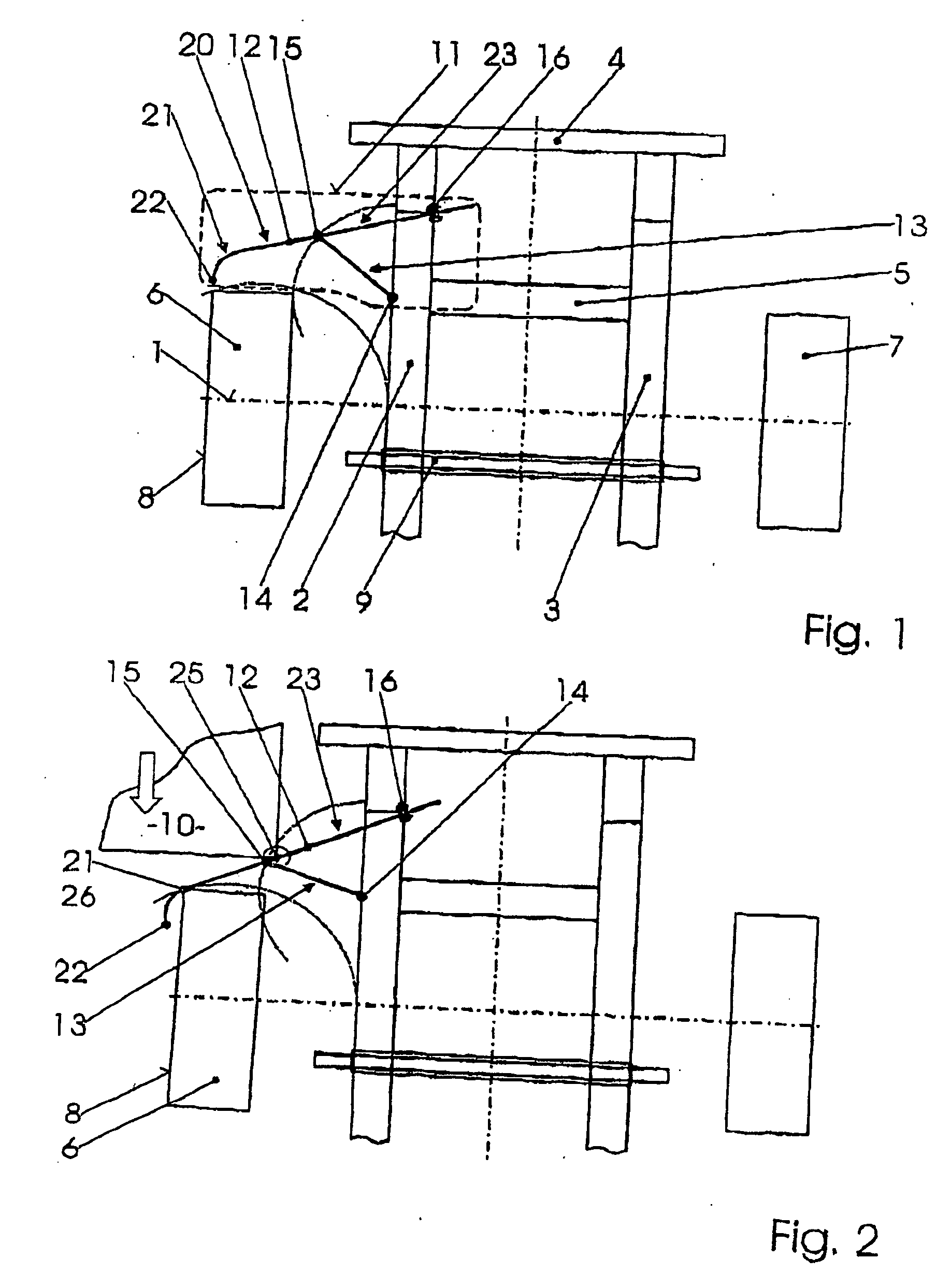

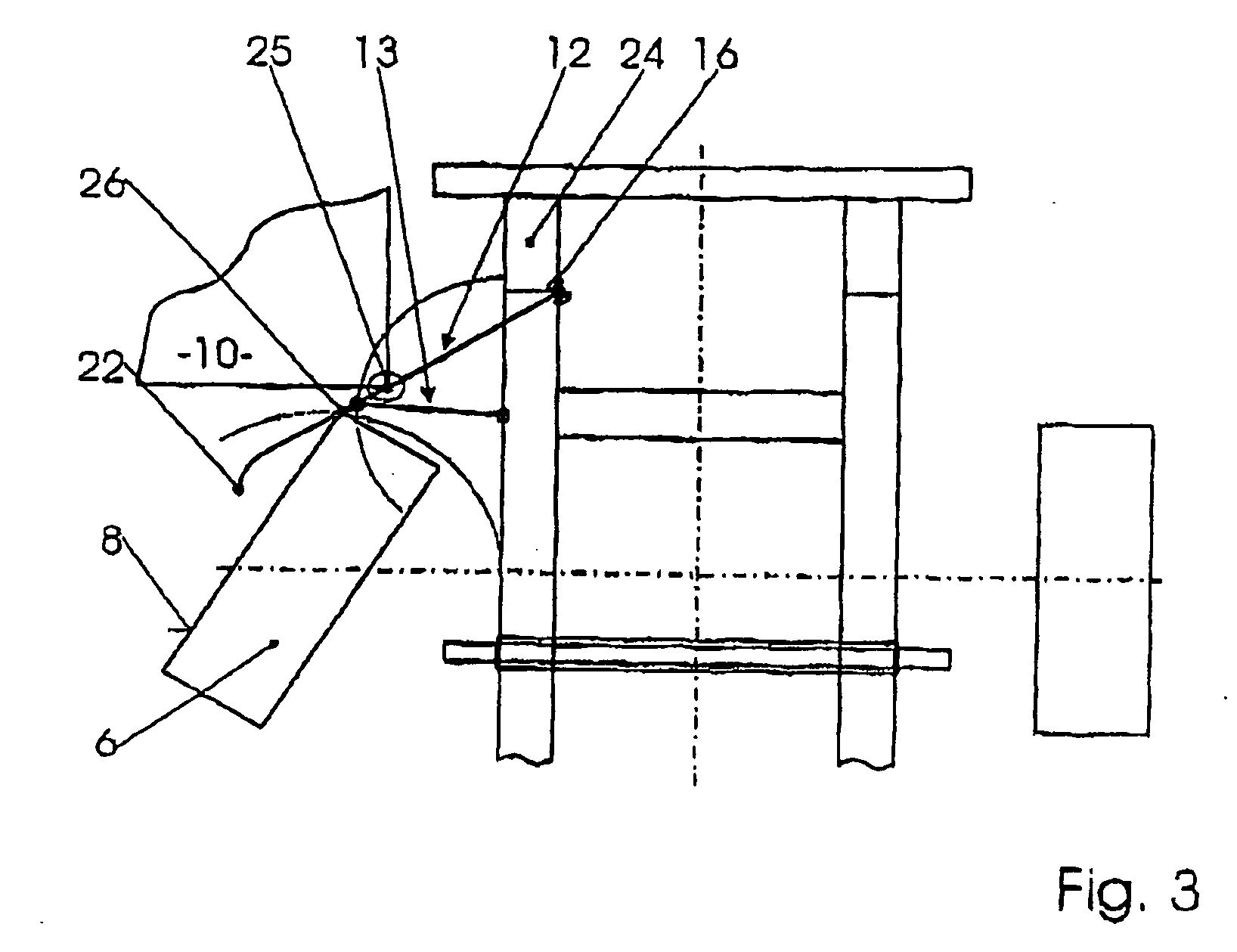

In a motor vehicle, a deflecting device (11) for an offset frontal collision for the motor vehicle is arranged in front of a front wheel (6). In order, in the event of a collision, to safely pivot the front wheel inward, the deflecting device (11) forms a kinematic chain, the coupling link of which is a deflector (12) which, under the action of a frontal impact, is pivoted to the rear and is displaced toward the outside of the vehicle. The kinematic chain is a slider crank mechanism comprising a swinging arm (13) which is pivotable about a bearing (14), a further bearing (16), a sliding guide (16) and the coupling link (12) which is connected to the outer end of the swinging arm at a pivot point (15) and is guided in the further bearing (16).

Owner:MAGNA STEYR FAHRZEUGTECHN

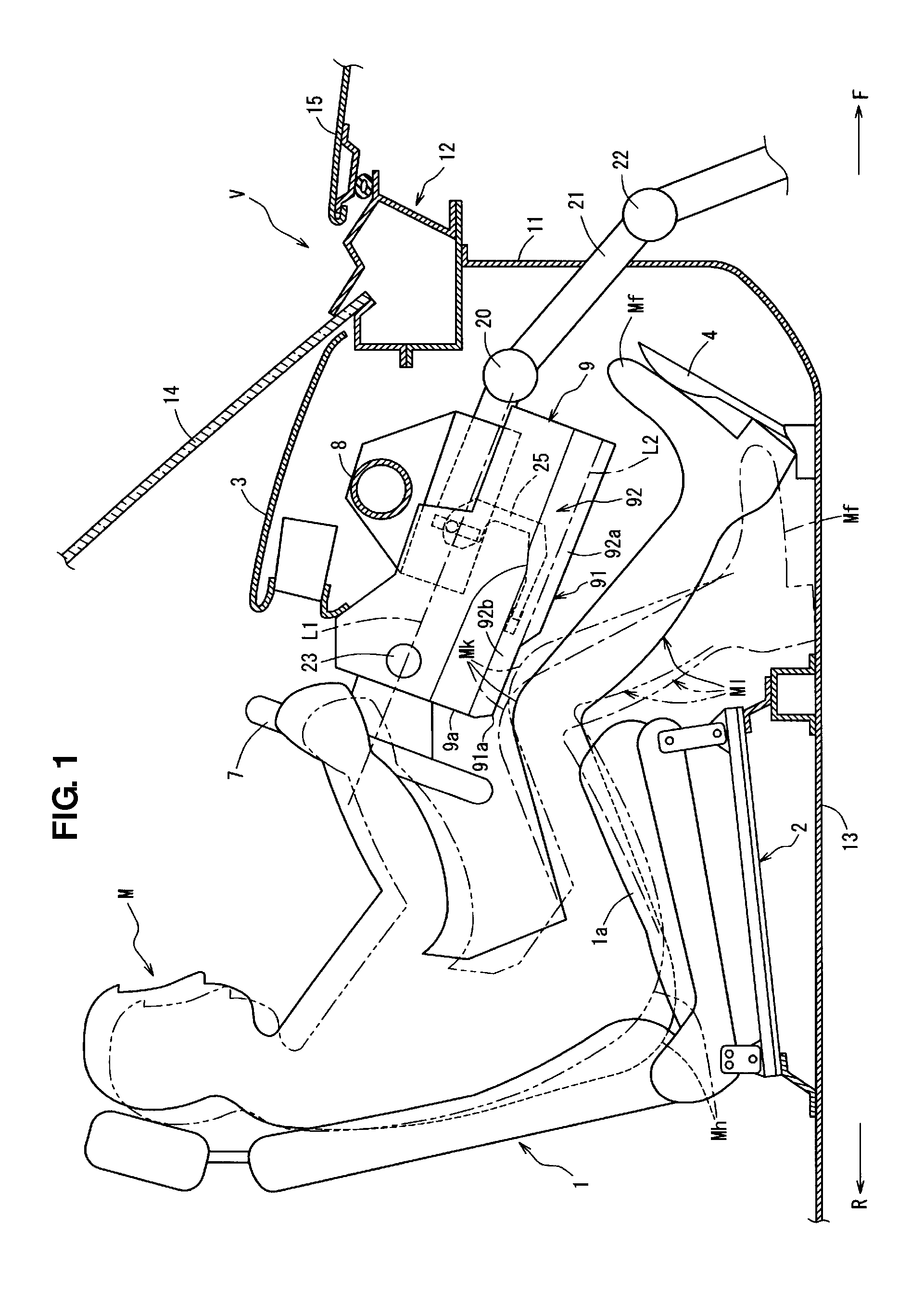

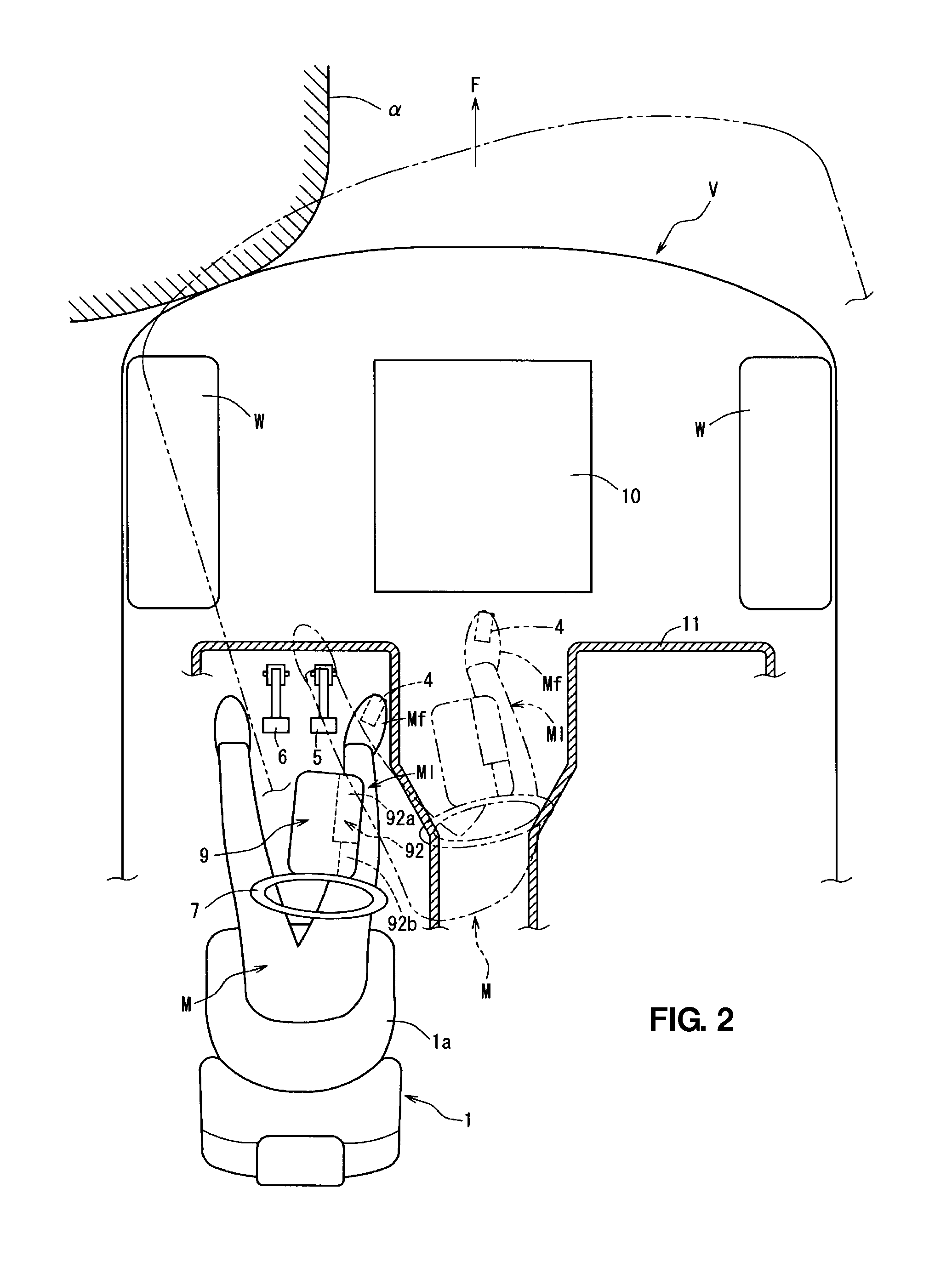

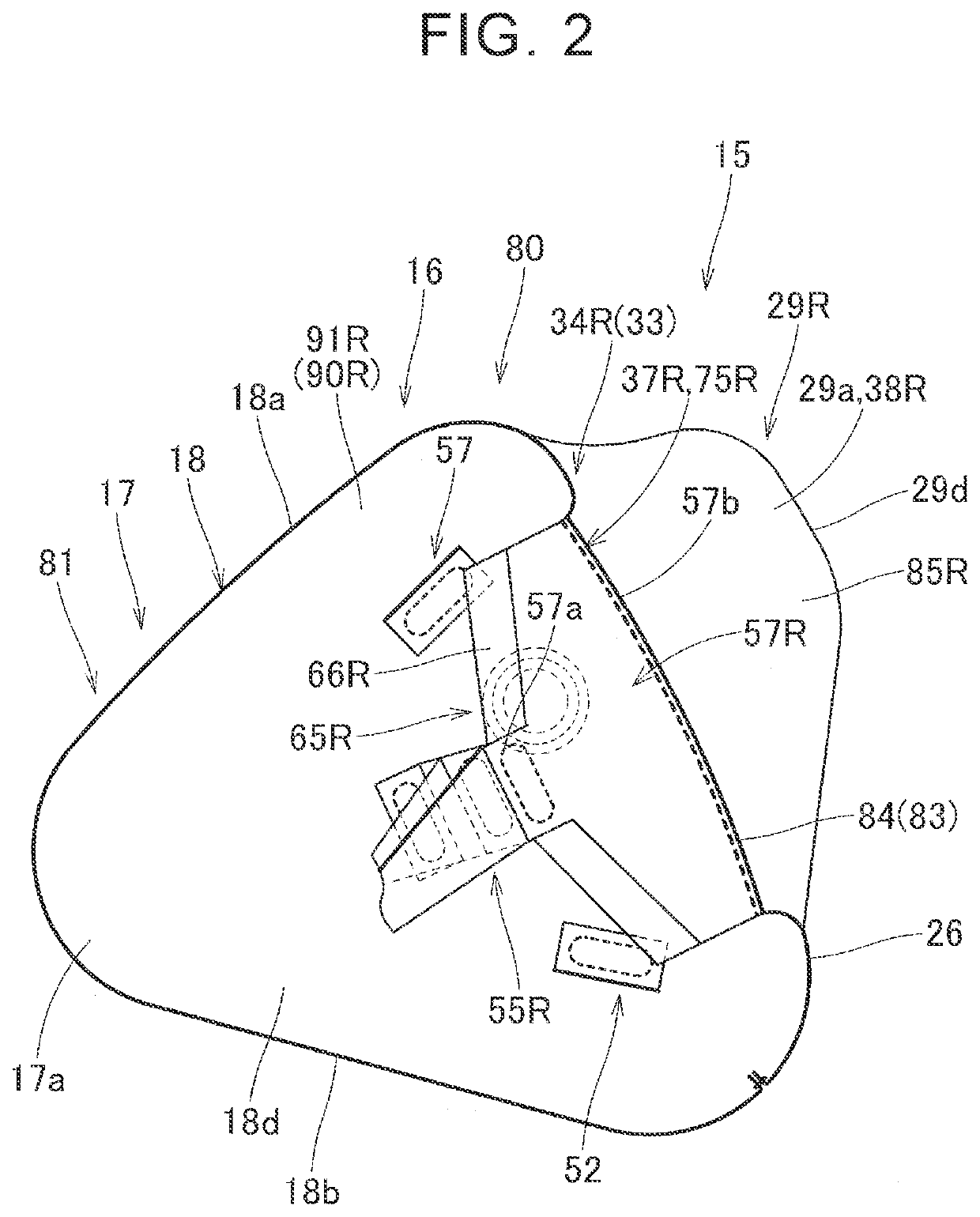

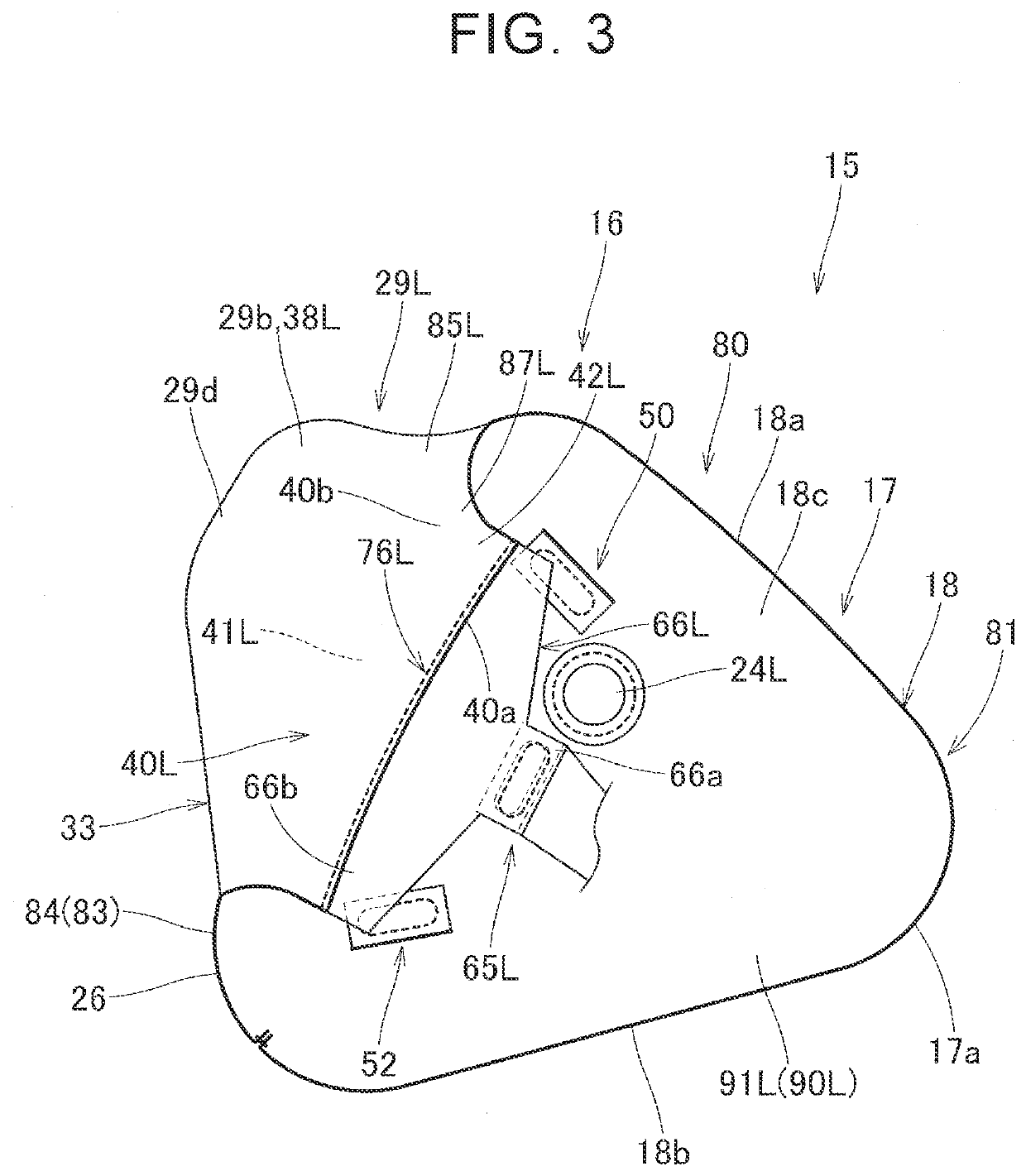

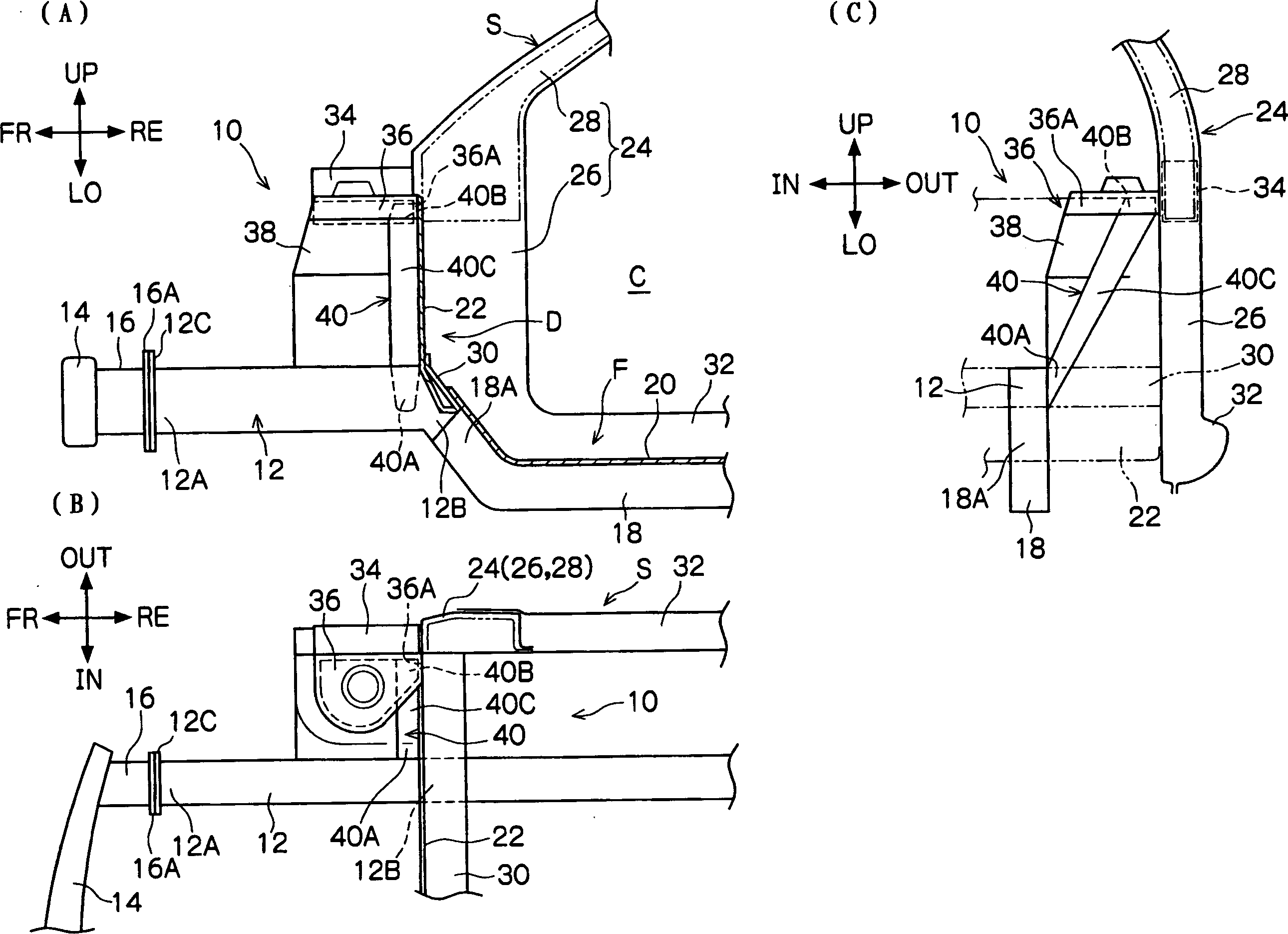

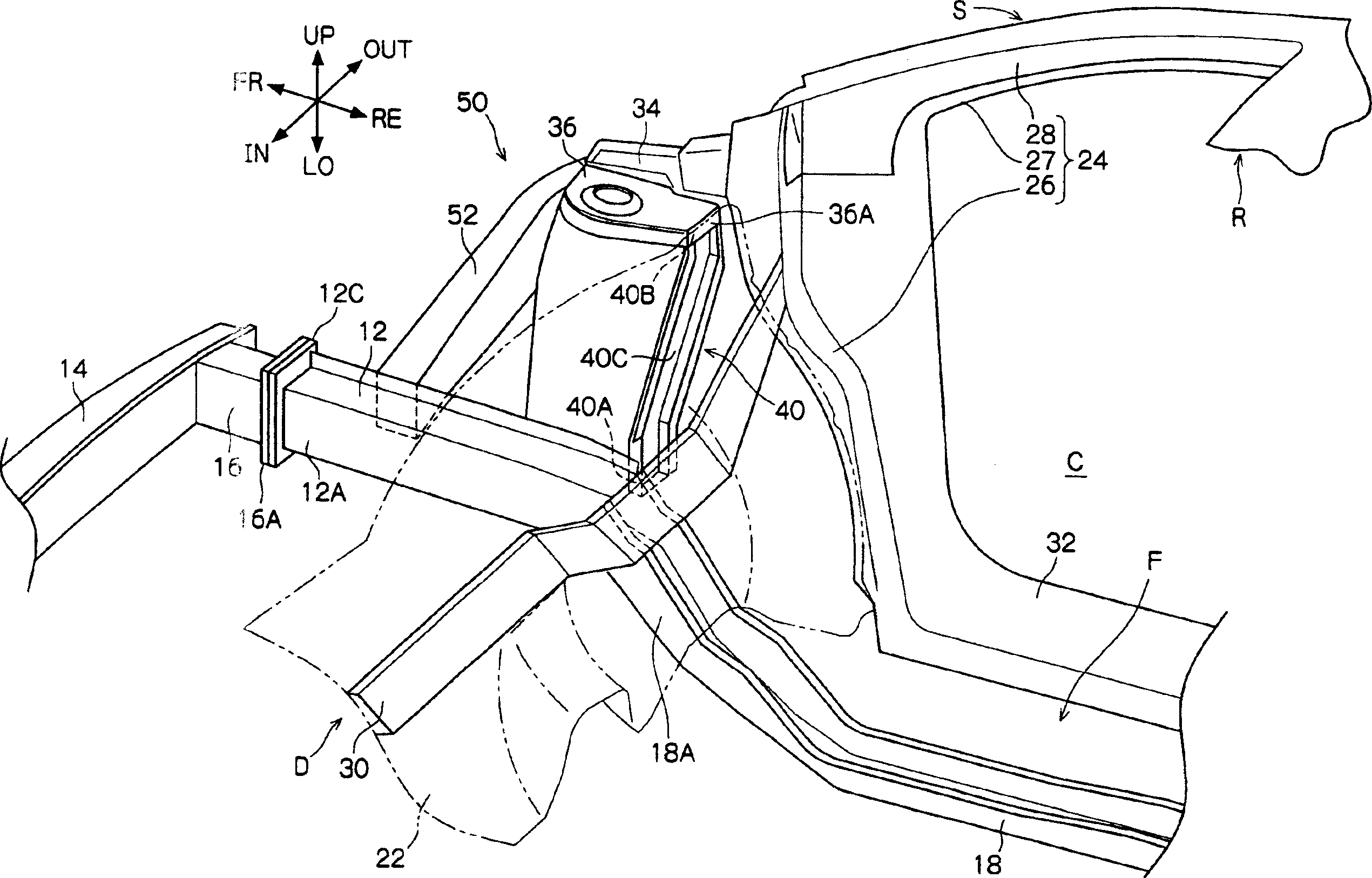

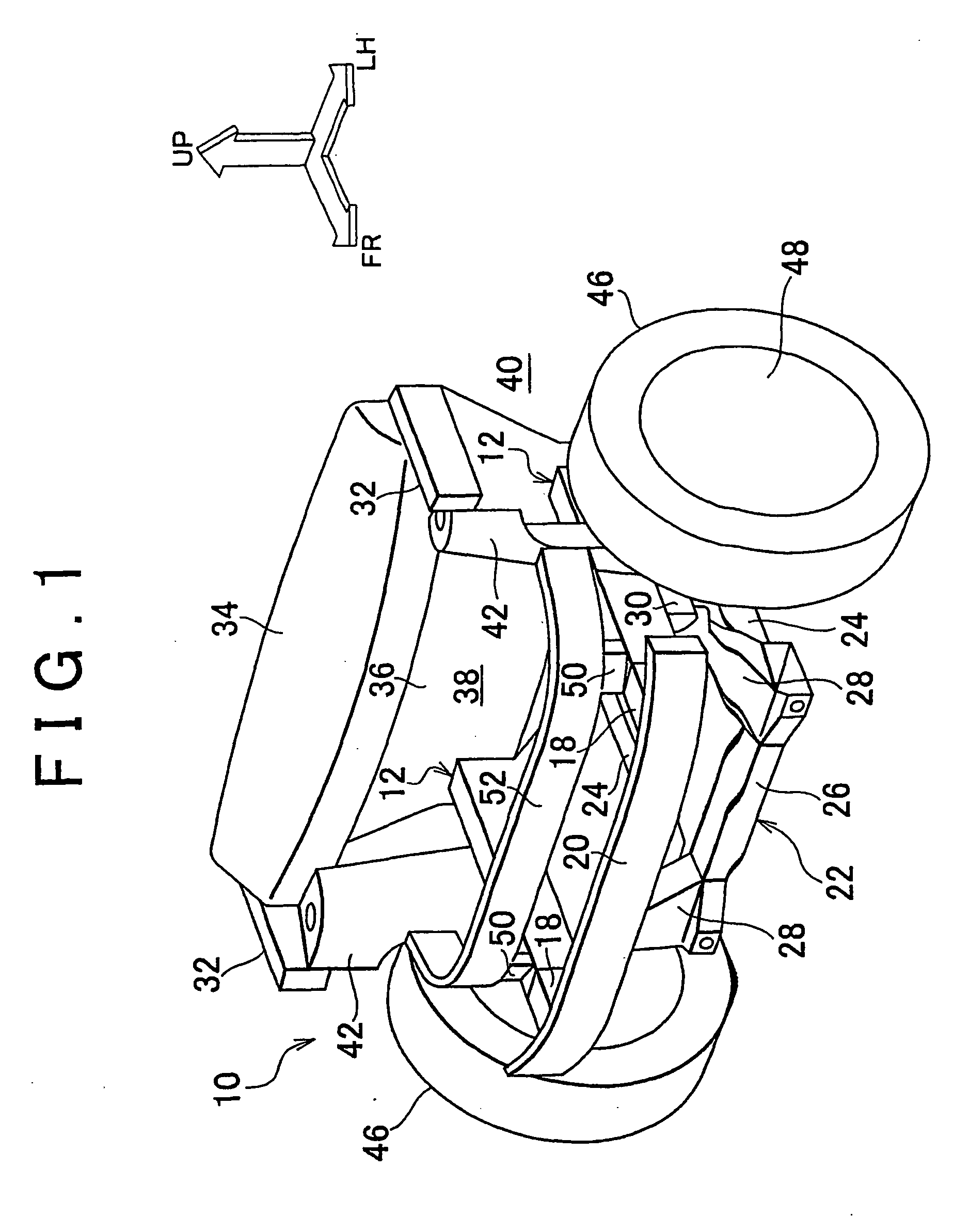

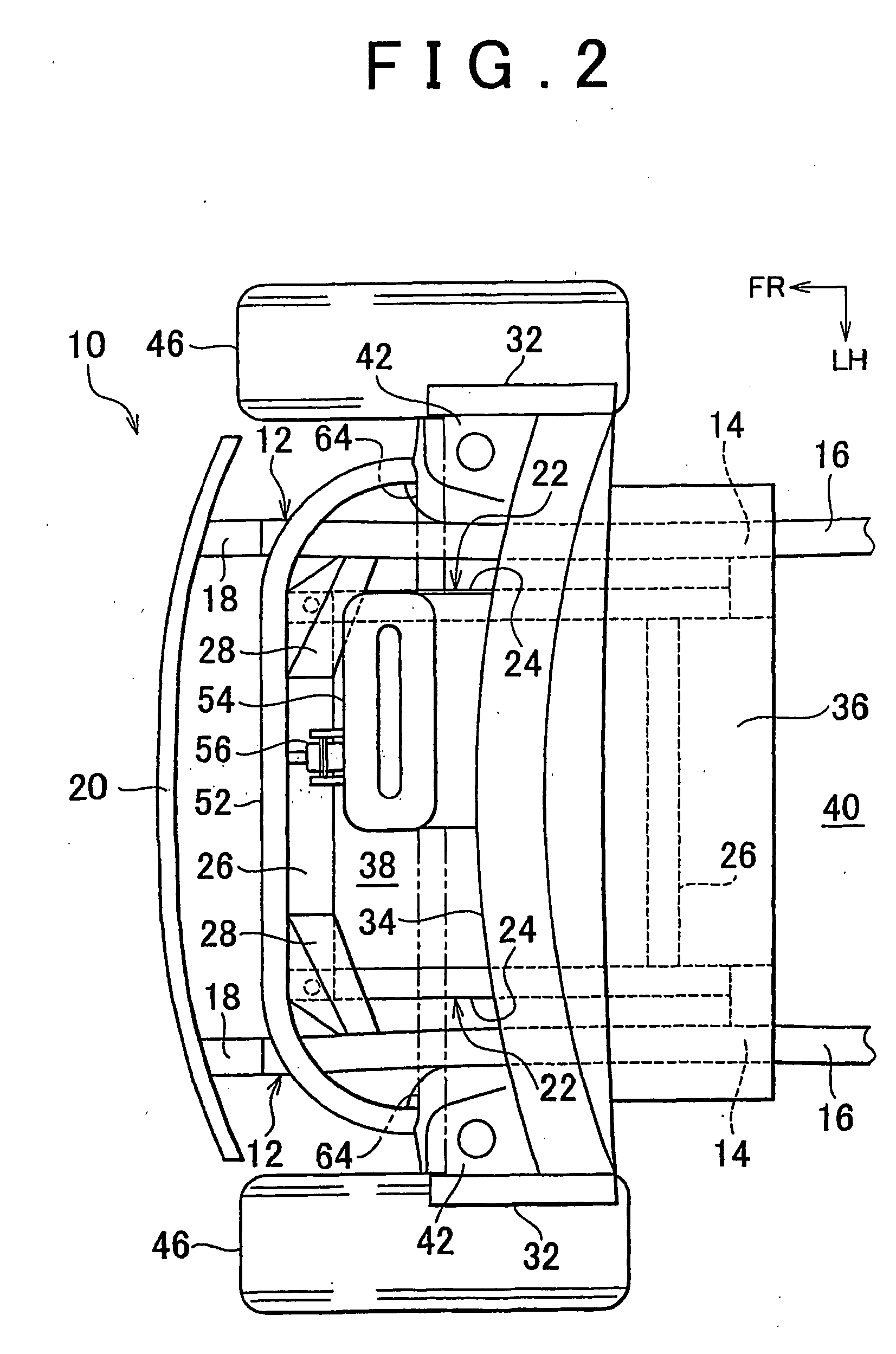

Steering column cover structure of automotive vehicle

InactiveUS20130087006A1Appropriate performanceControlling membersPedestrian/occupant safety arrangementHead-on collisionSteering column

An acceleration pedal is arranged on one side, in a vehicle width direction, of a steering column cover covering a steering column so as to move forward or slant forward through a press operation of a press face thereof. A guide face is provided at a specified portion of a lower face of the steering column cover which is positioned in front of a lower-face rear end portion in a steering-shaft axis direction and on an acceleration-pedal-arrangement side, wherein the guide face is configured to project downward below an extension line extending from the lower-face rear end portion in the steering-shaft axis direction and extend forward. Accordingly, a passenger's foot can be properly restrained from moving, in the vehicle width direction, off the pedal in a vehicle head-on collision, ensuring an appropriate ingress-and-egress performance of a passenger.

Owner:MAZDA MOTOR CORP

Automobile collision accident reappear method based on car body key point three-dimension distorsion

InactiveCN1724971ALinear/angular speed measurementSpecial data processing applicationsHead-on collisionElement model

The invention relates to reappear three dimensional deformation of a vehicle body in a collision accident, including the steps: building an accident occurrence environment and finite element models for the related vehicles in the accident; verifying the reliability of the finite element models; selecting vehicle body key points adaptive to head-on collision and oblique collision and processing the holes in a numeric model; using three-coordinate measurer to physically measure the fixed key point positions; to a finite element model for the whole vehicle, adopting key point deforming measuring method; by multiple iterative optimization calculation, if finding the numeric simulated result of the deformed key points is consistent with the actual collision measured result at a certain speed and collision angle, determining the accurate automobile speed and collision angle at the occurring time of the accident. The invention can recover the accident on the condition that the trace of the wheels and other field information are destroyed or not clear, and has better objectivity because of making three-dimensional measurement on the measured points of the main energy absorbing components.

Owner:SHANGHAI JIAO TONG UNIV

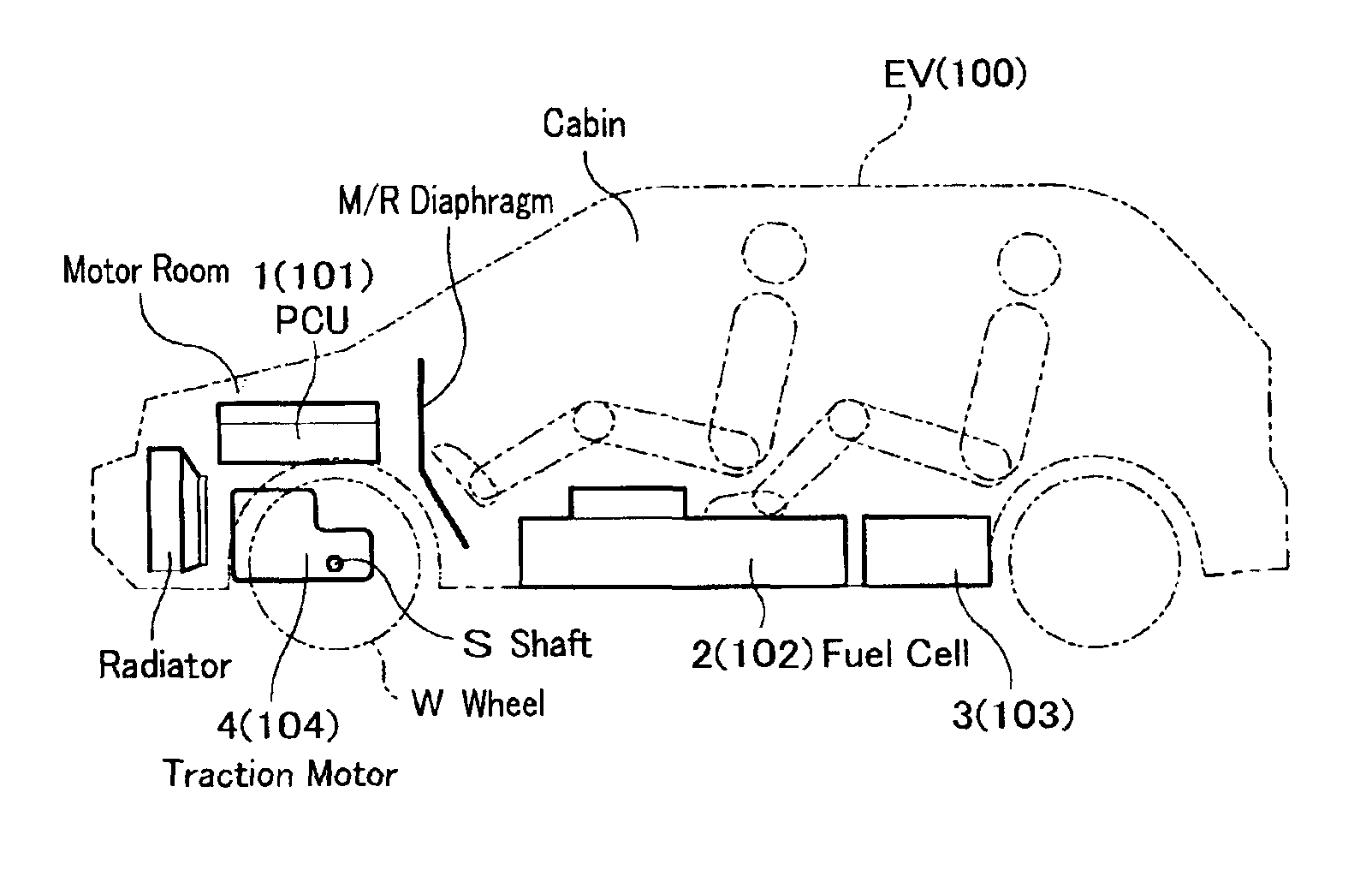

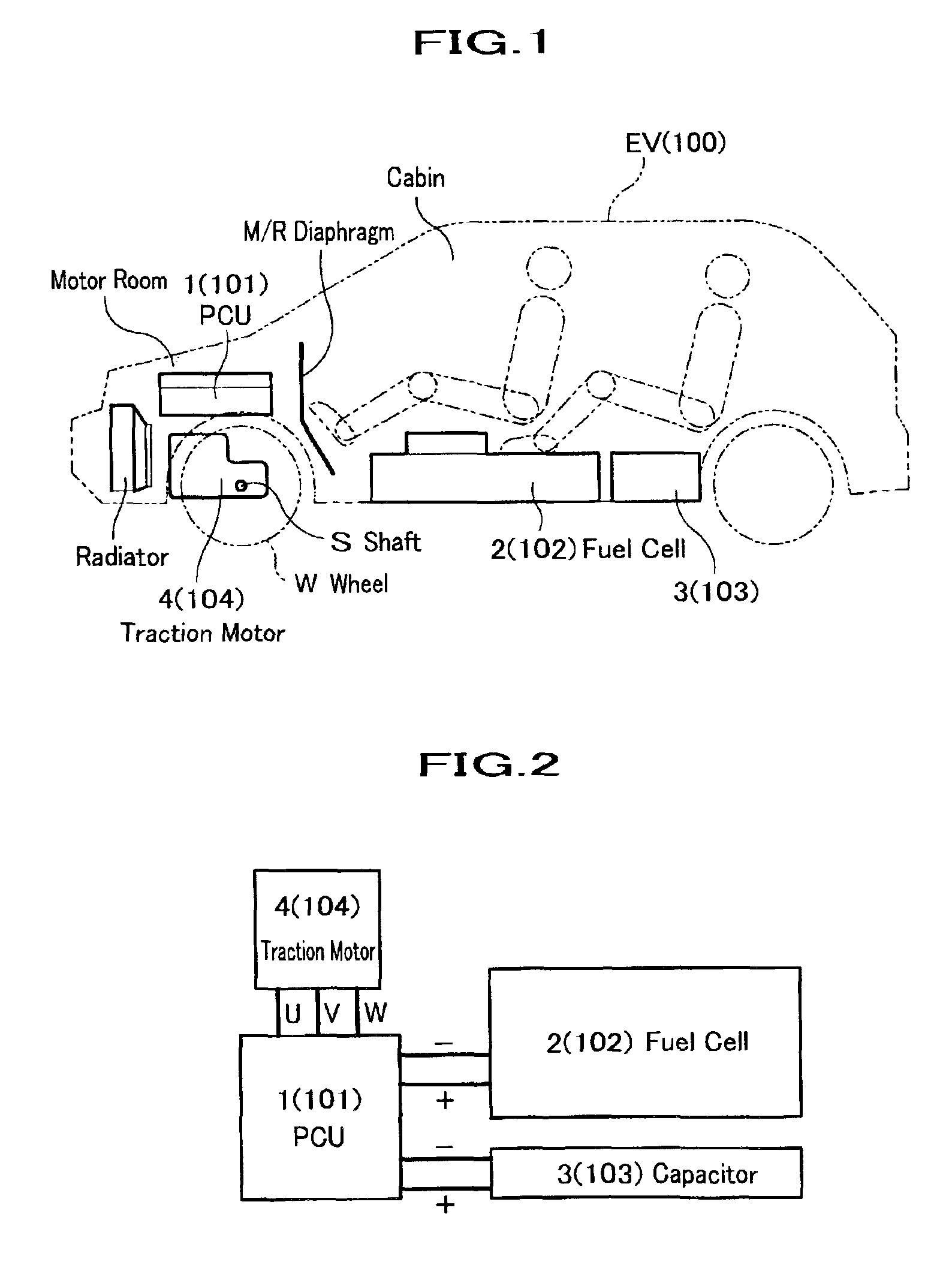

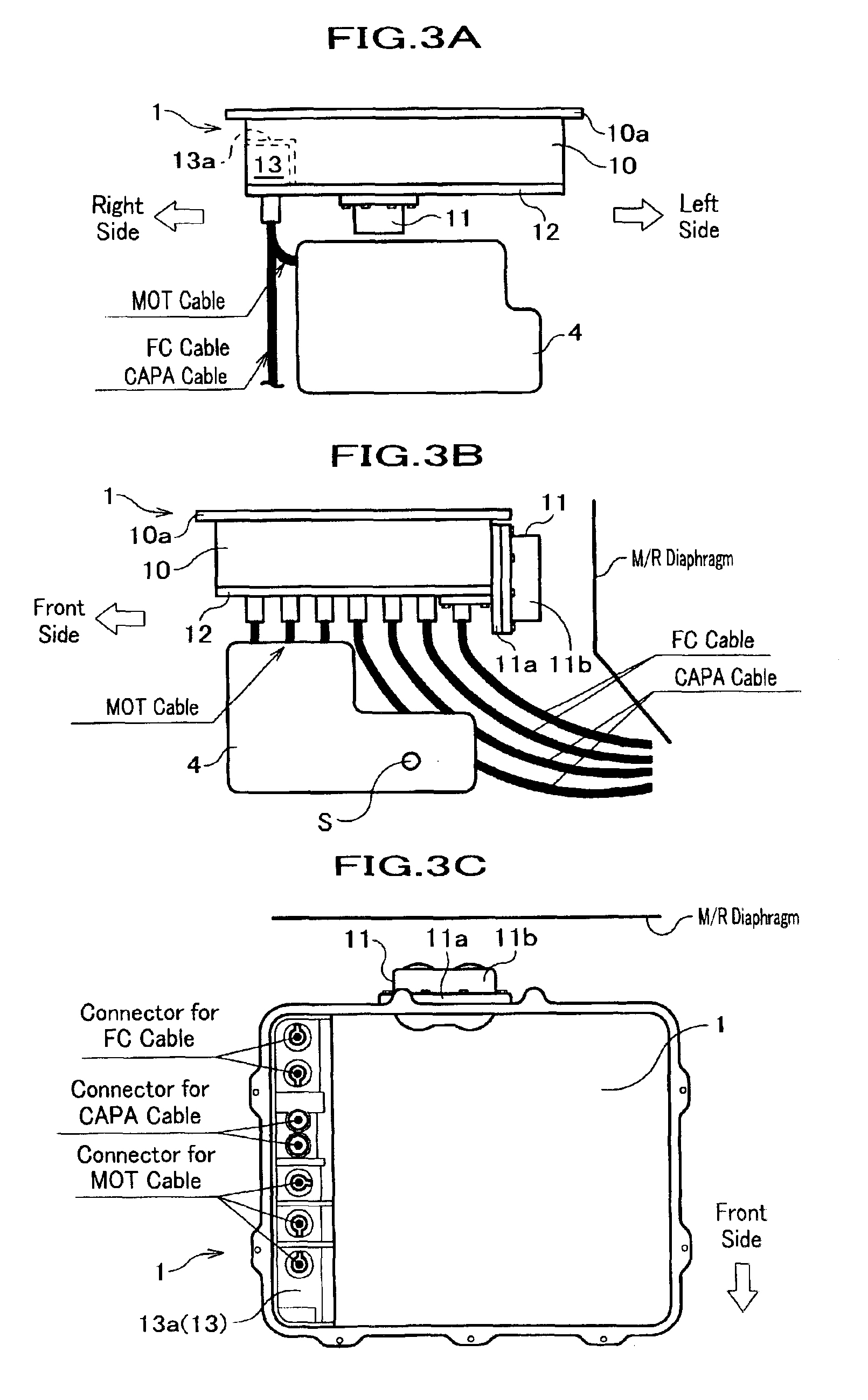

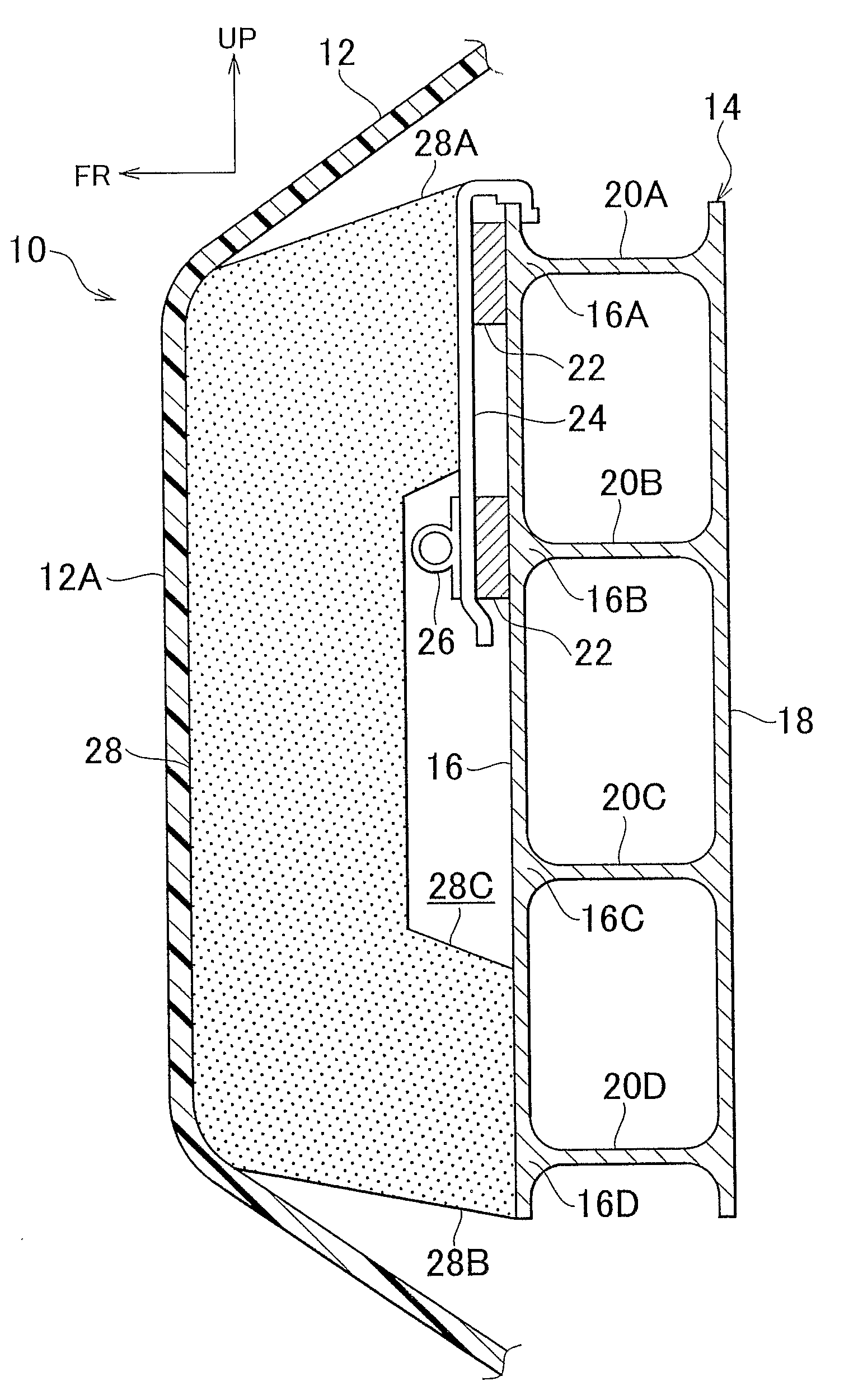

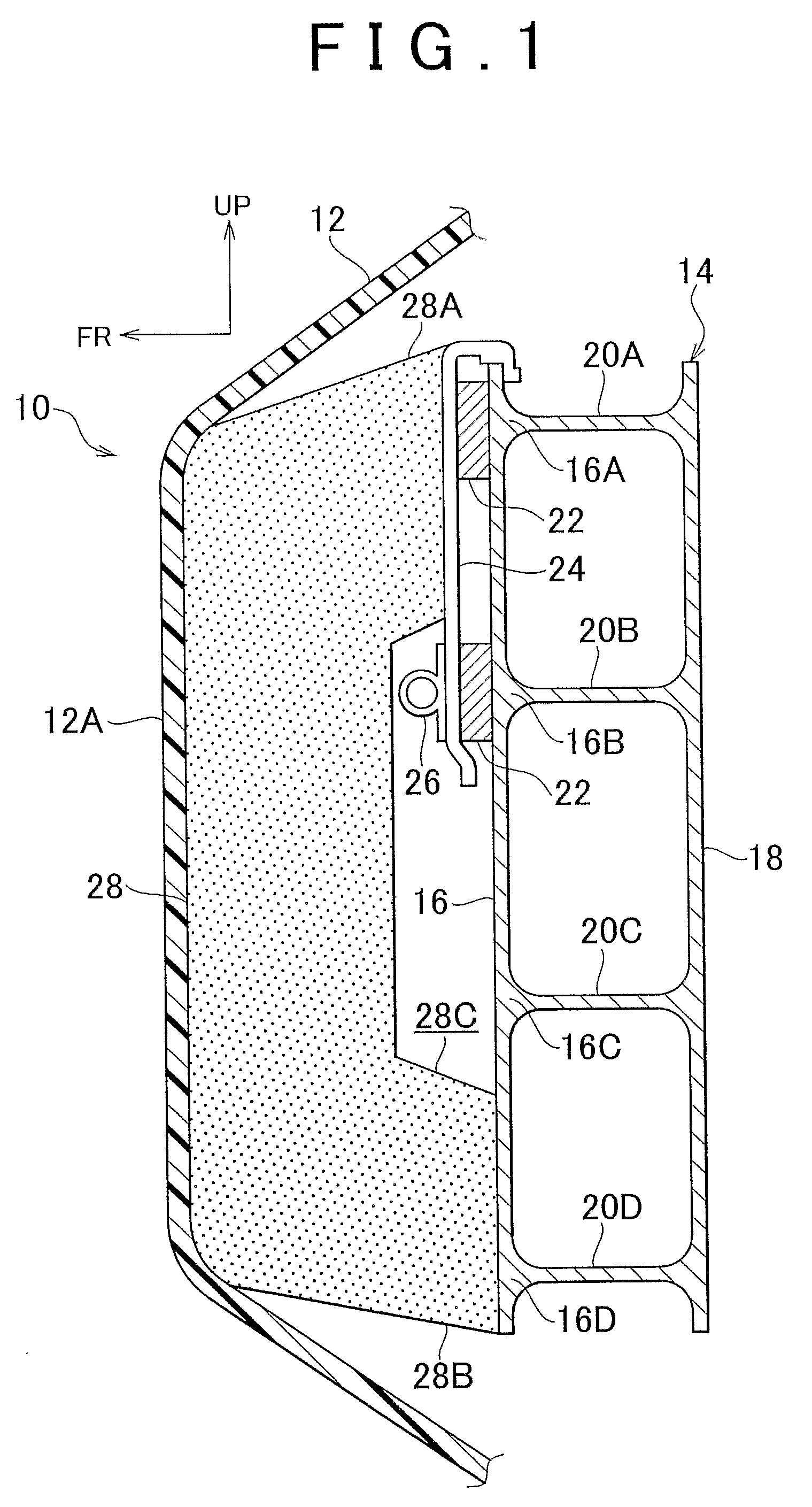

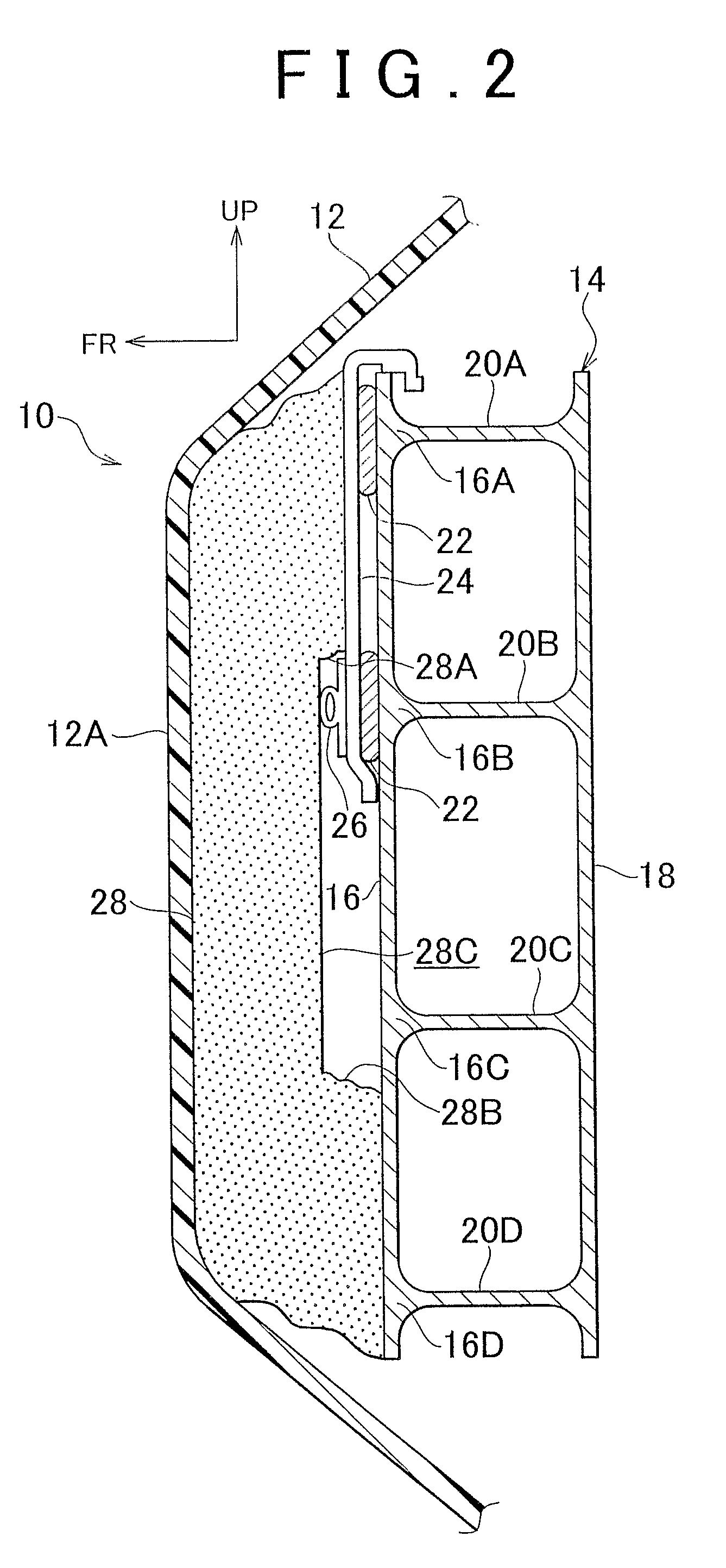

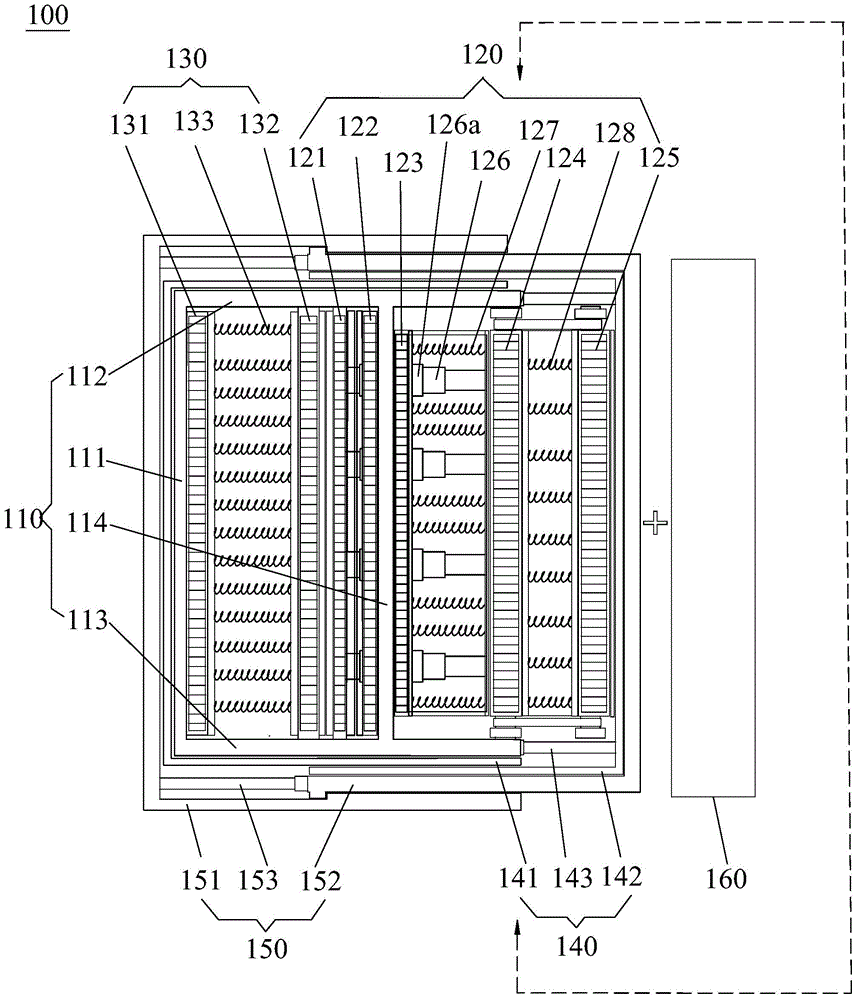

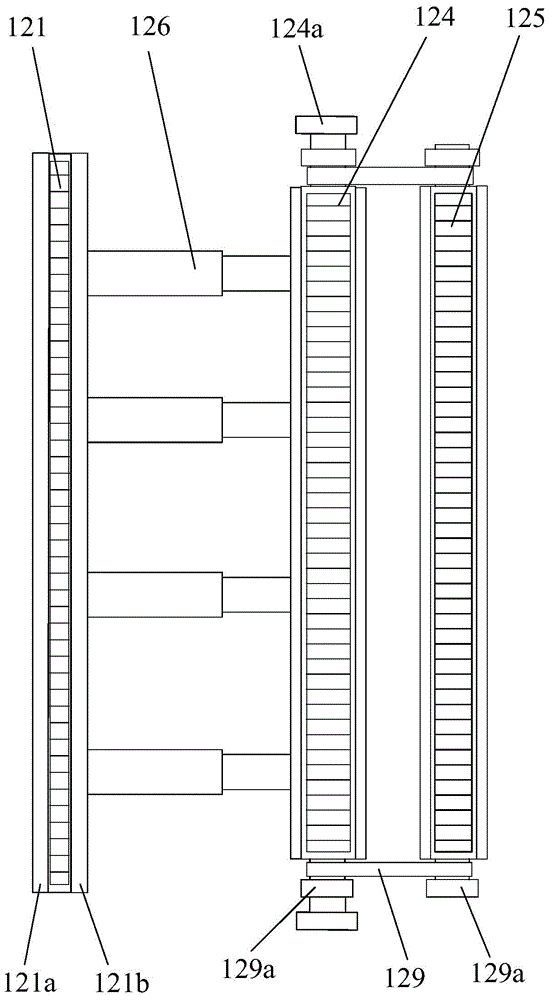

Power control unit for electric vehicle

InactiveUS6907947B2Easy to separateAvoid deformationPropulsion by batteries/cellsVehicular energy storageHead-on collisionEngineering

A power control unit for electric vehicle which can easily detach the high voltage cables even if the motor room is deformed, for example, by head-on collision and / or rear-end collision of the vehicle, which is difficult to be deformed, which can make small, and which can avoid an influence of heat generated by the reactor is disclosed. The power control unit 1 includes a box 10 which accommodates devices for controlling electric power supply of the electric vehicle; a reactor receiver 11a which is provided on a given external surface around the box 10 and supports a reactor R; a heat sink 12 connected to the lower end of the reactor receiver 11a, covering the bottom surface of the box 10, possessing passages including passage wall inside thereof, and performing heat-exchange with the box 10 by allowing coolant water to flow within the passage; and a partition 13a, which is laid on at least one side of the box 10 extending toward the longitudinal direction of the vehicle EV, and is detachably communicated with cables to be connected to the traction motor 4 disposed below the heat sink 12 to supply power.

Owner:HONDA MOTOR CO LTD

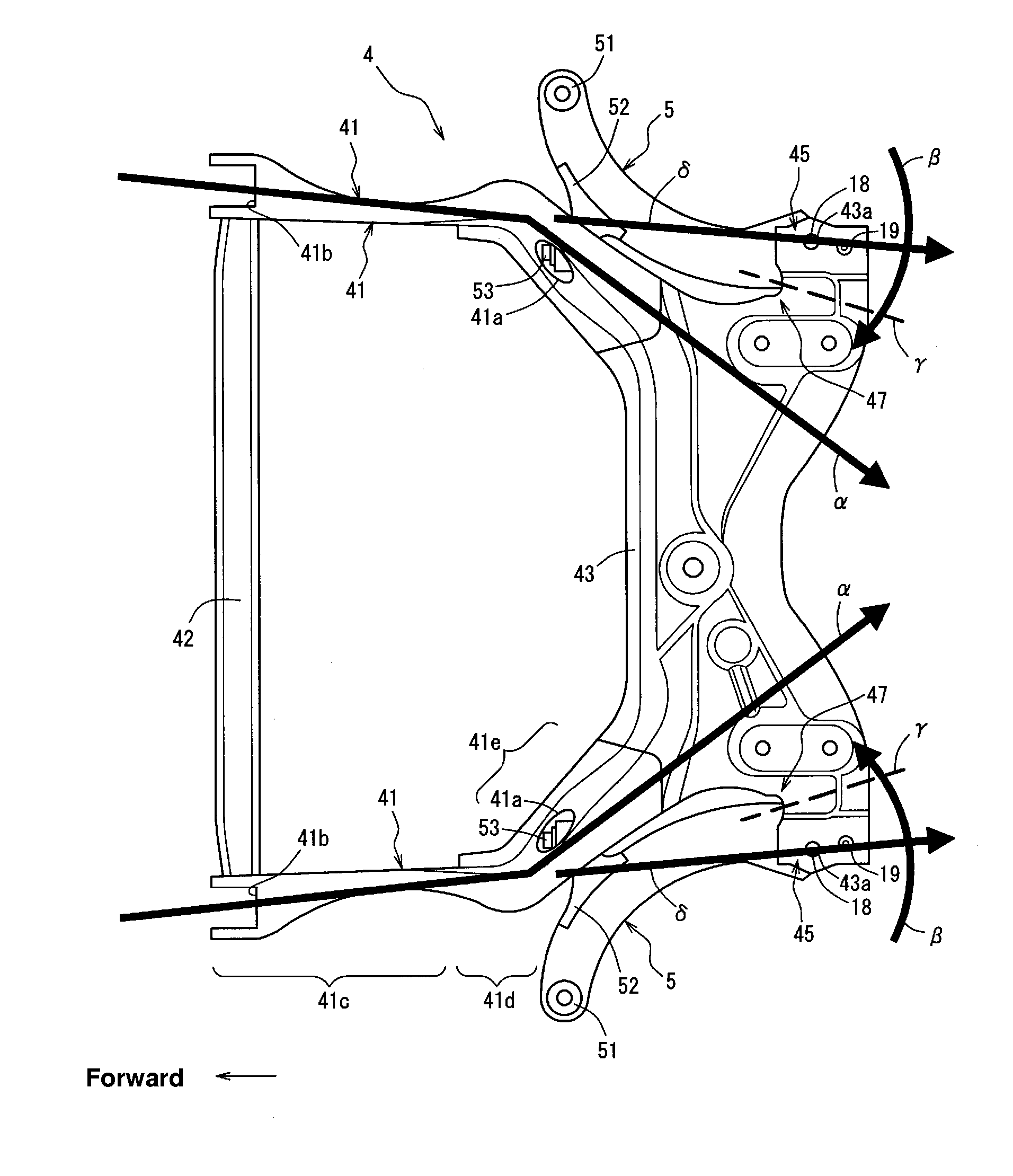

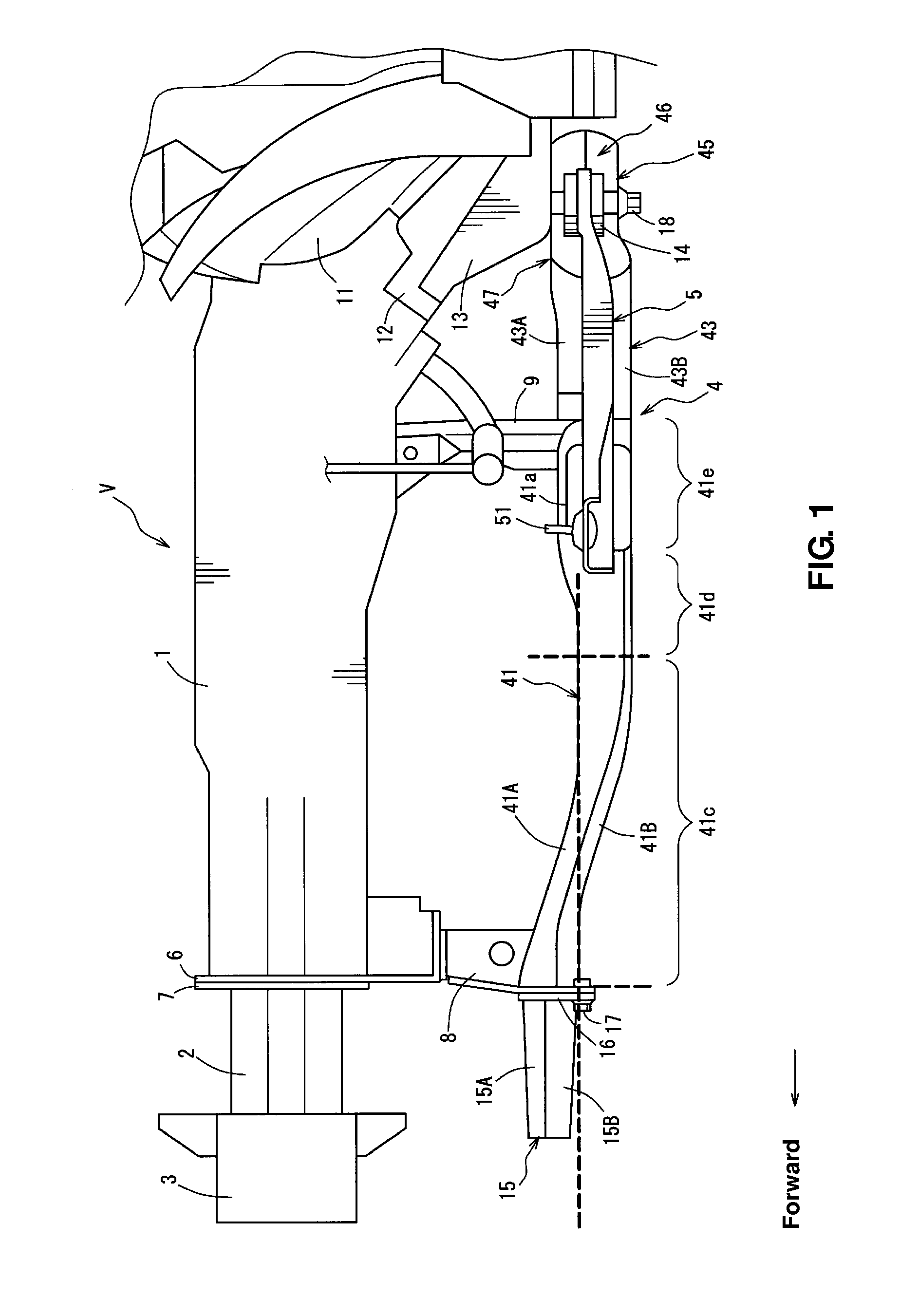

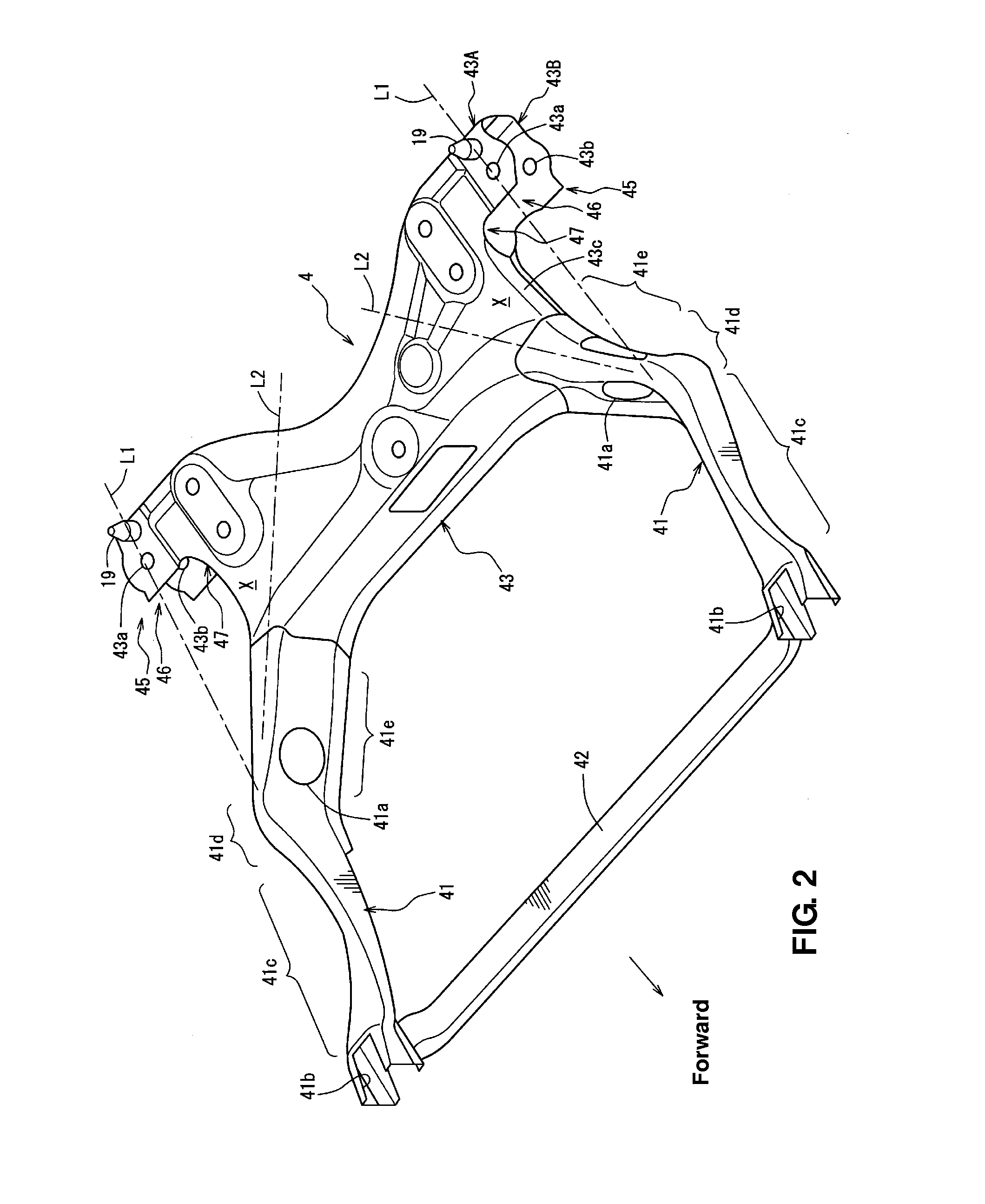

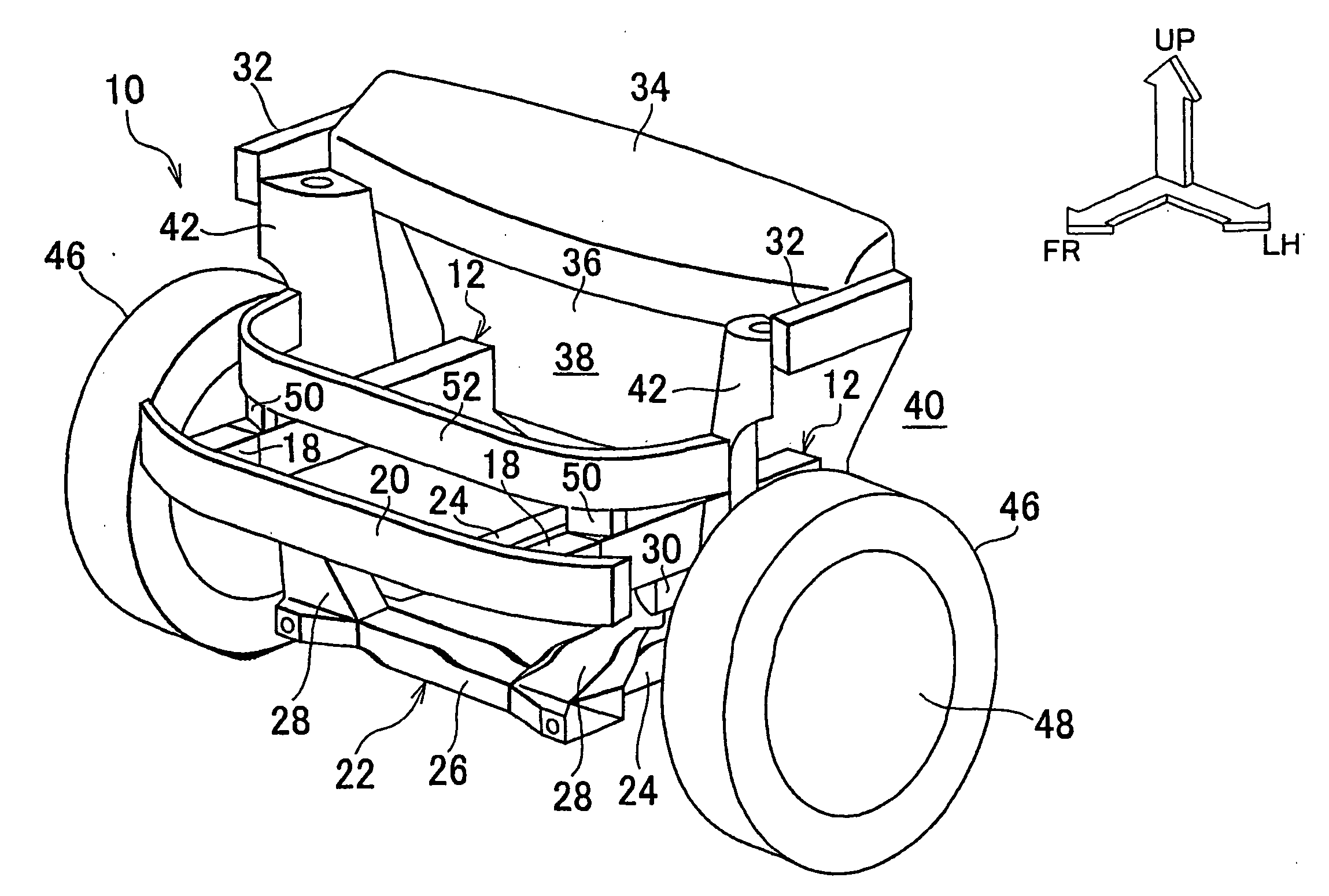

Front vehicle-body structure of vehicle

ActiveUS20140252739A1Correction of deformationEfficient executionUnderstructuresResilient suspensionsHead-on collisionEngineering

Owner:MAZDA MOTOR CORP

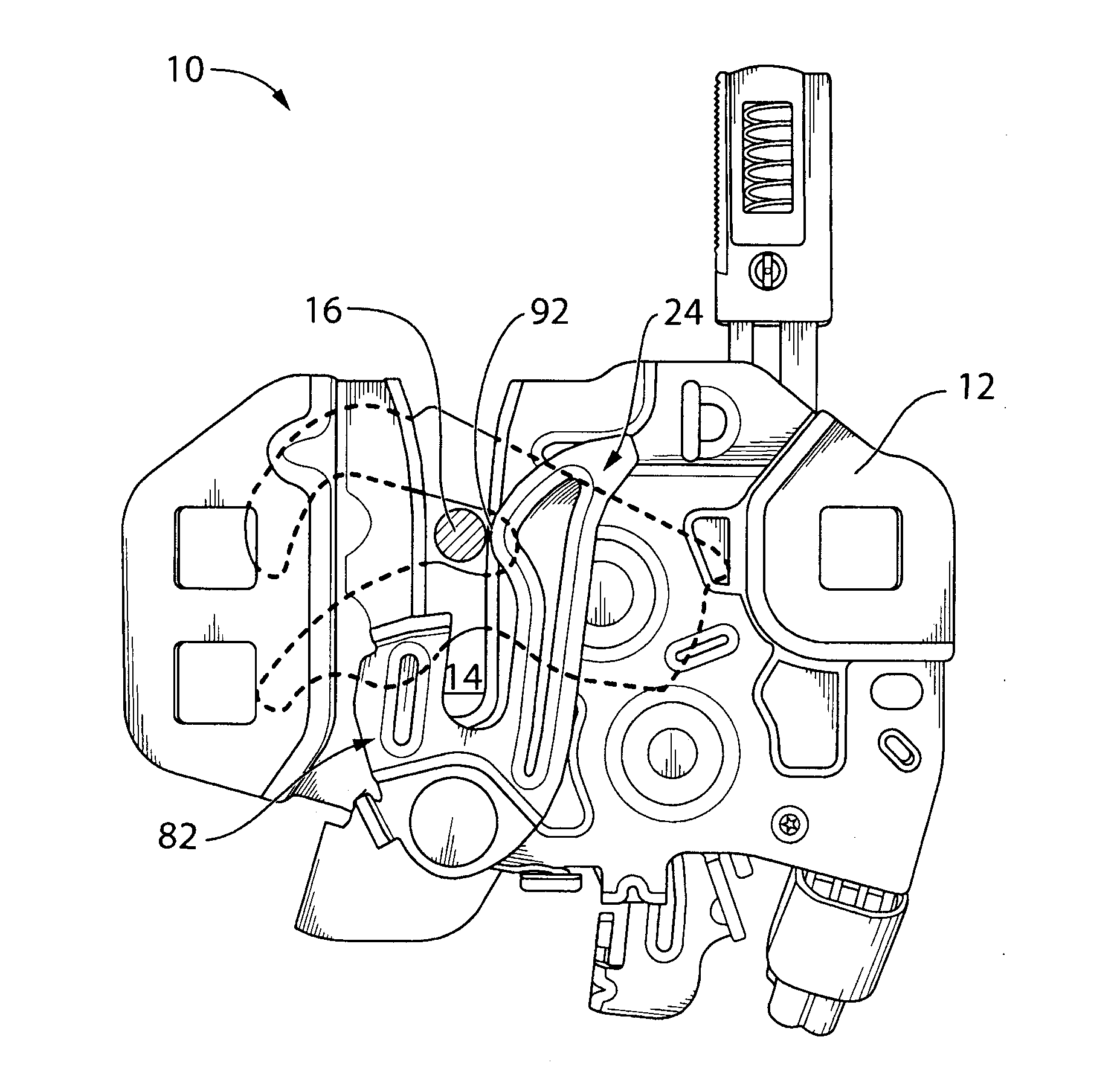

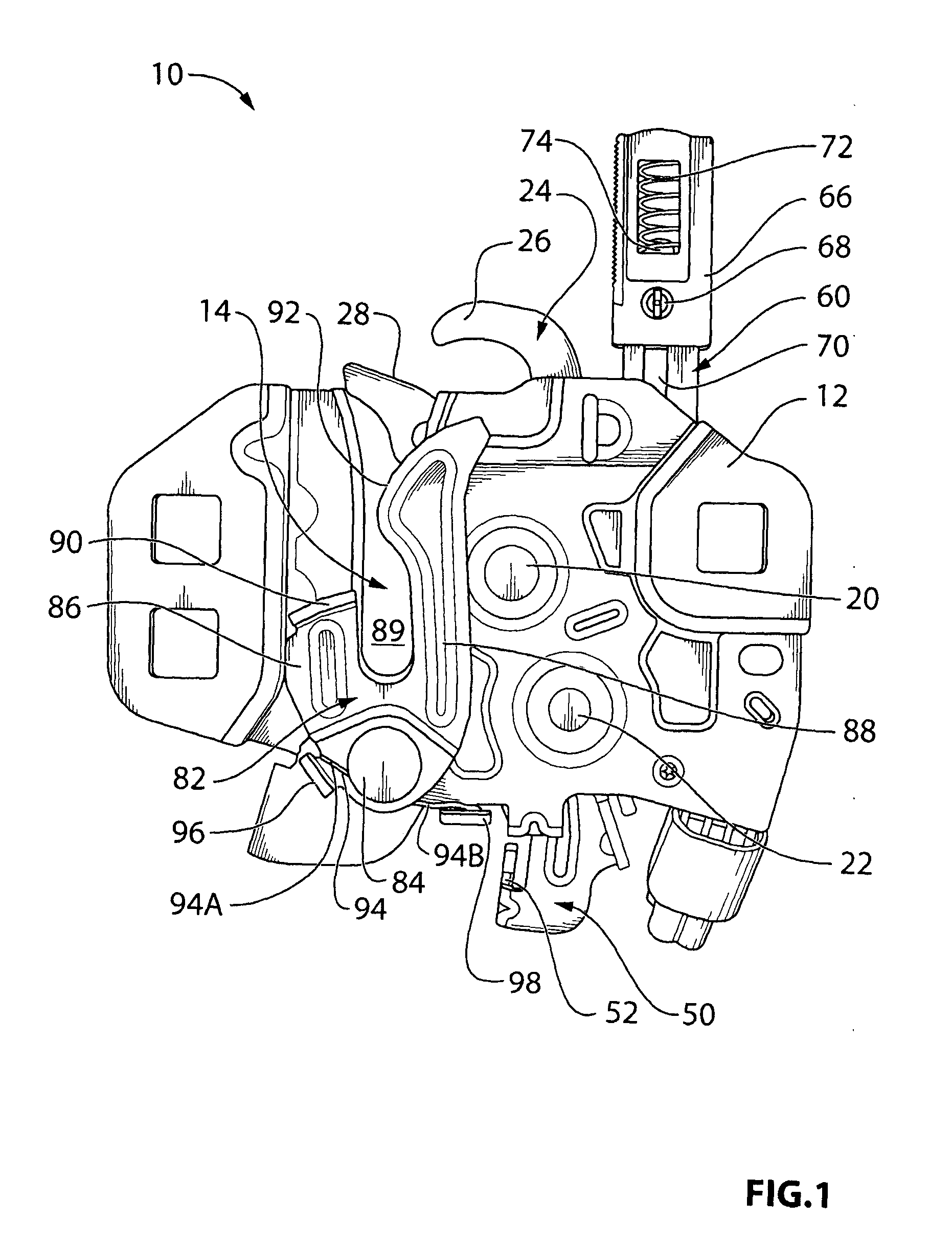

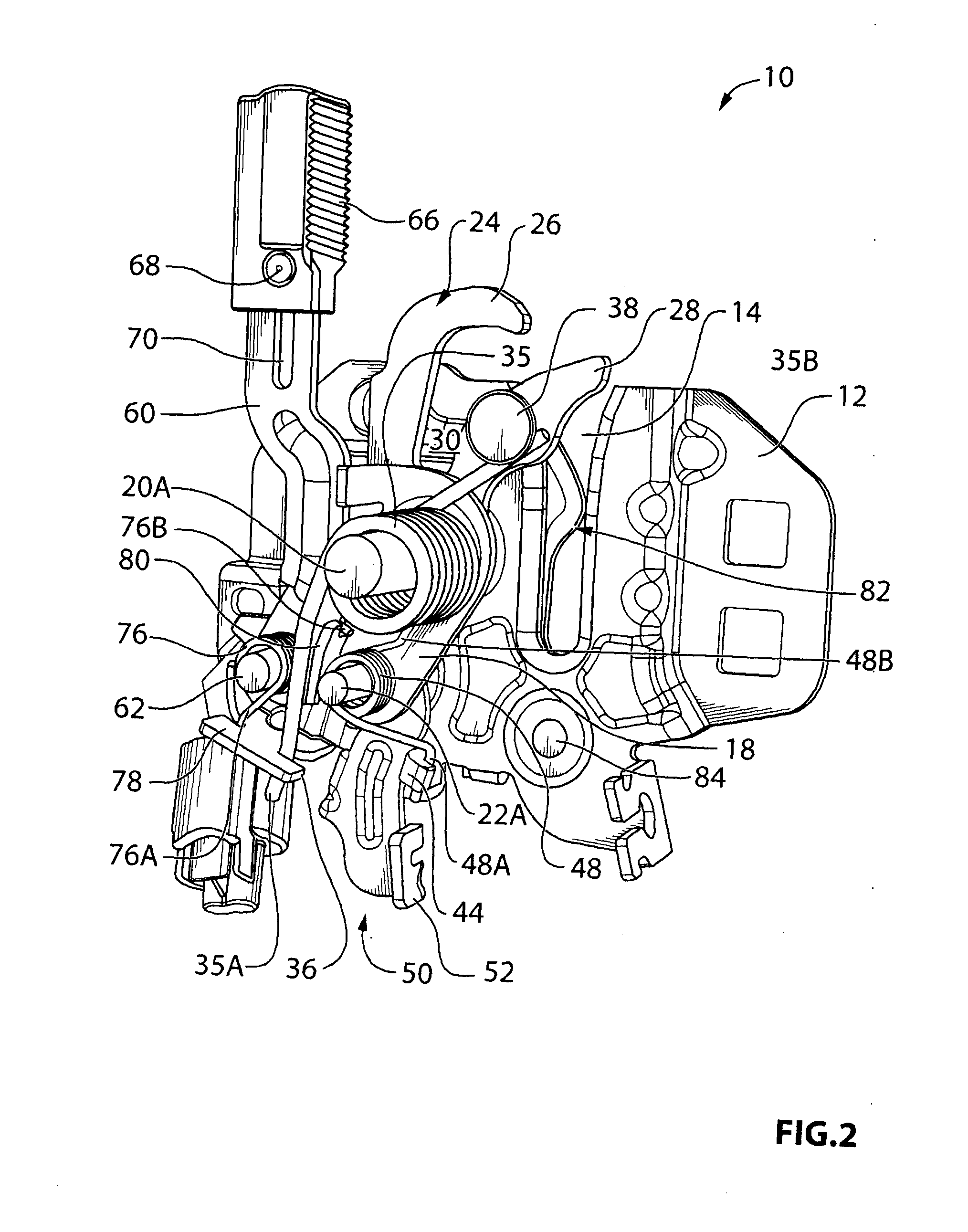

Over travel hood latch

ActiveUS20140015258A1Overcome biasSufficient forceNoise-prevention/anti-rattling lockingWing fastenersPedestrianElectrical and Electronics engineering

A hood latch having an extra-long fishmouth for enabling a vehicle hood to deflect downwardly upon impact, such as when hit by a pedestrian in a frontal crash. To prevent this deflection when the hood is slammed shut in ordinary use, a stop lever is pivotally mounted to the latch housing. The stop lever features first and second arms defining a slot therein. One arm has a proboscis thereon and is biased to align the slot with the fishmouth, with the proboscis jutting into the fishmouth. The proboscis receives an impact from the striker and rotates the stop lever to a blocking position wherein the non-proboscis arm intercepts the striker and prevents it from reaching the bottom end of the fishmouth. In the closed position the ratchet retains the striker at an intermediate depth in the fishmouth, enabling the striker to travel toward the bottom end thereof.

Owner:MAGNA CLOSURES INC

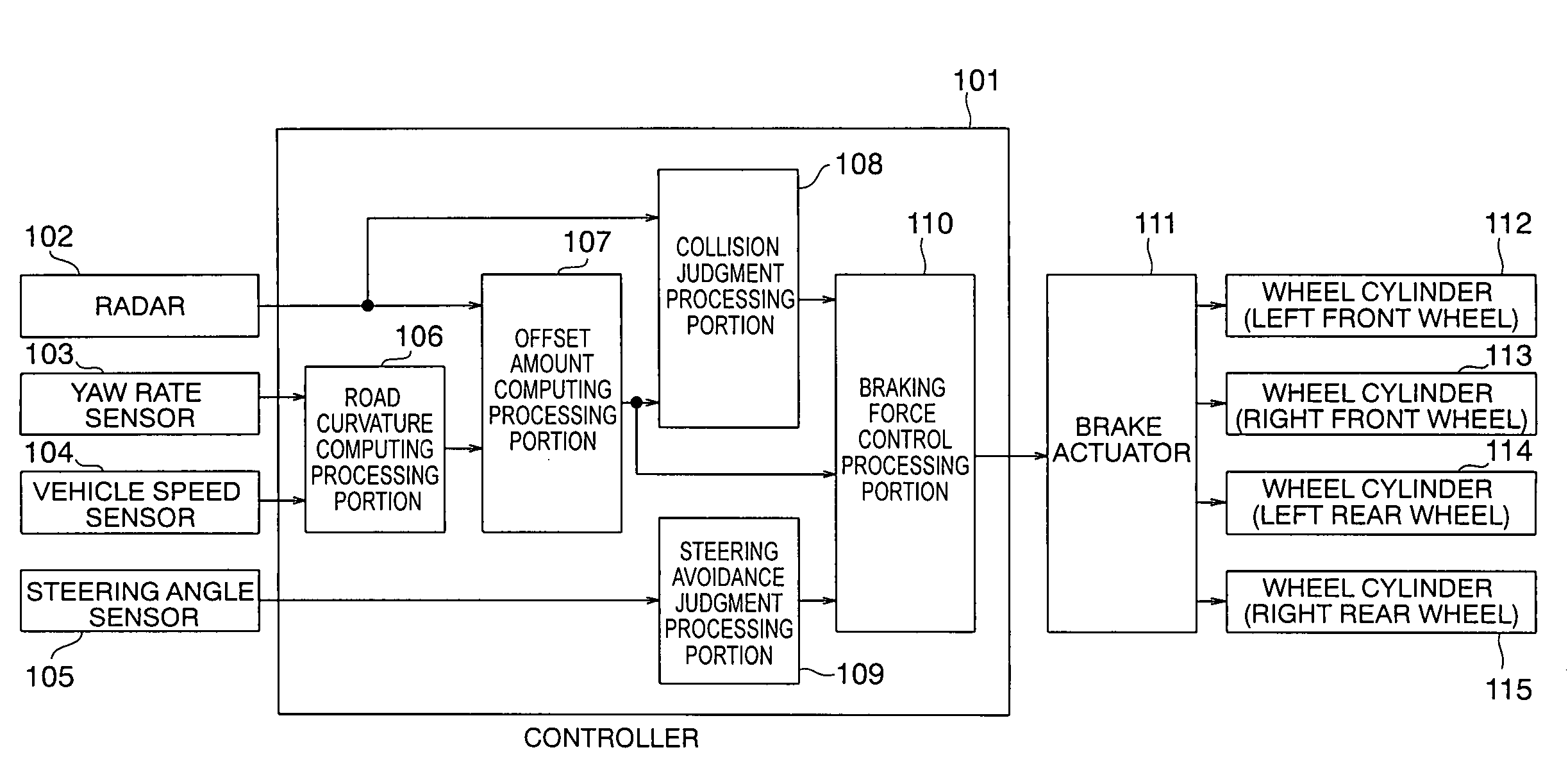

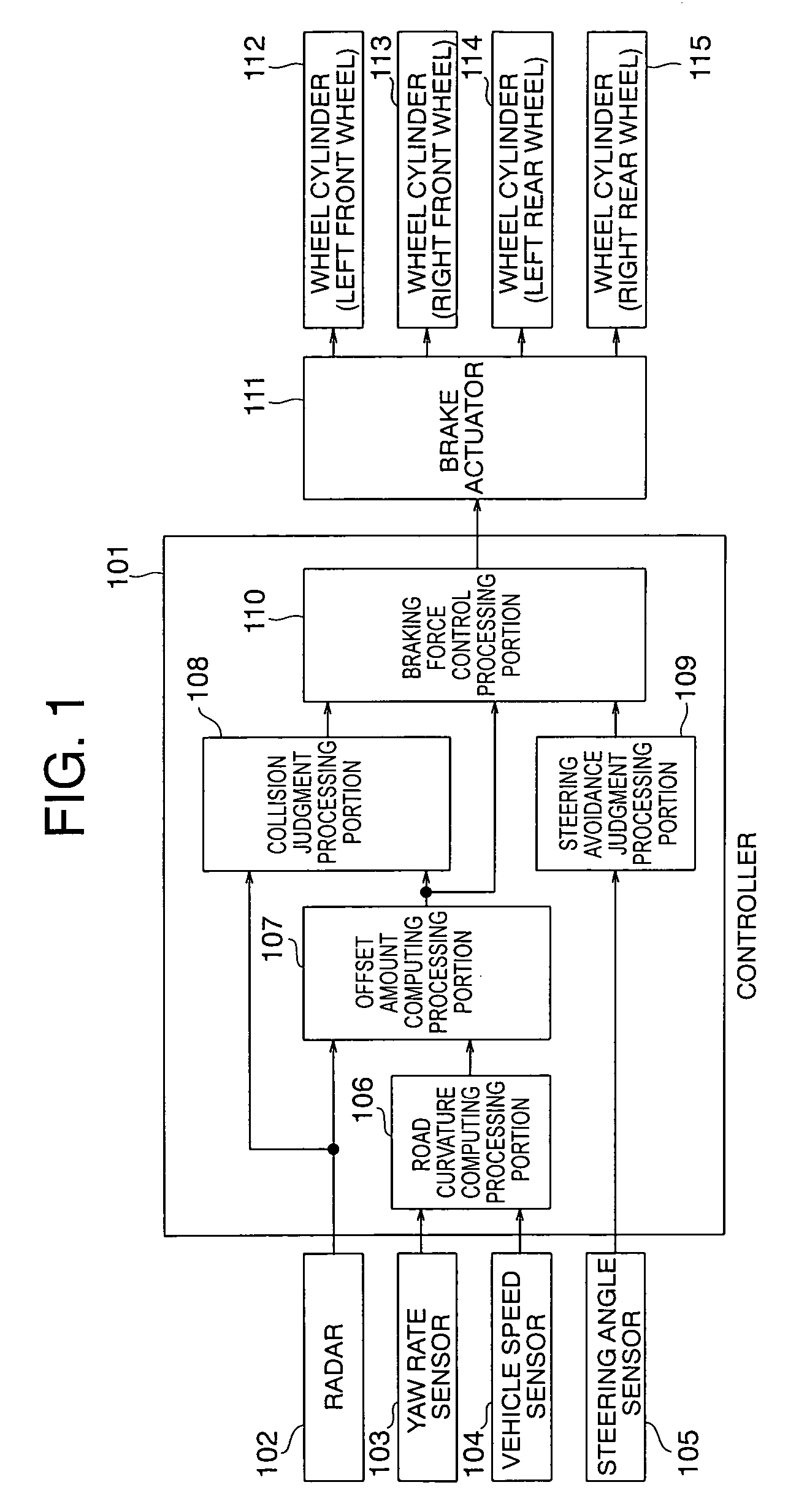

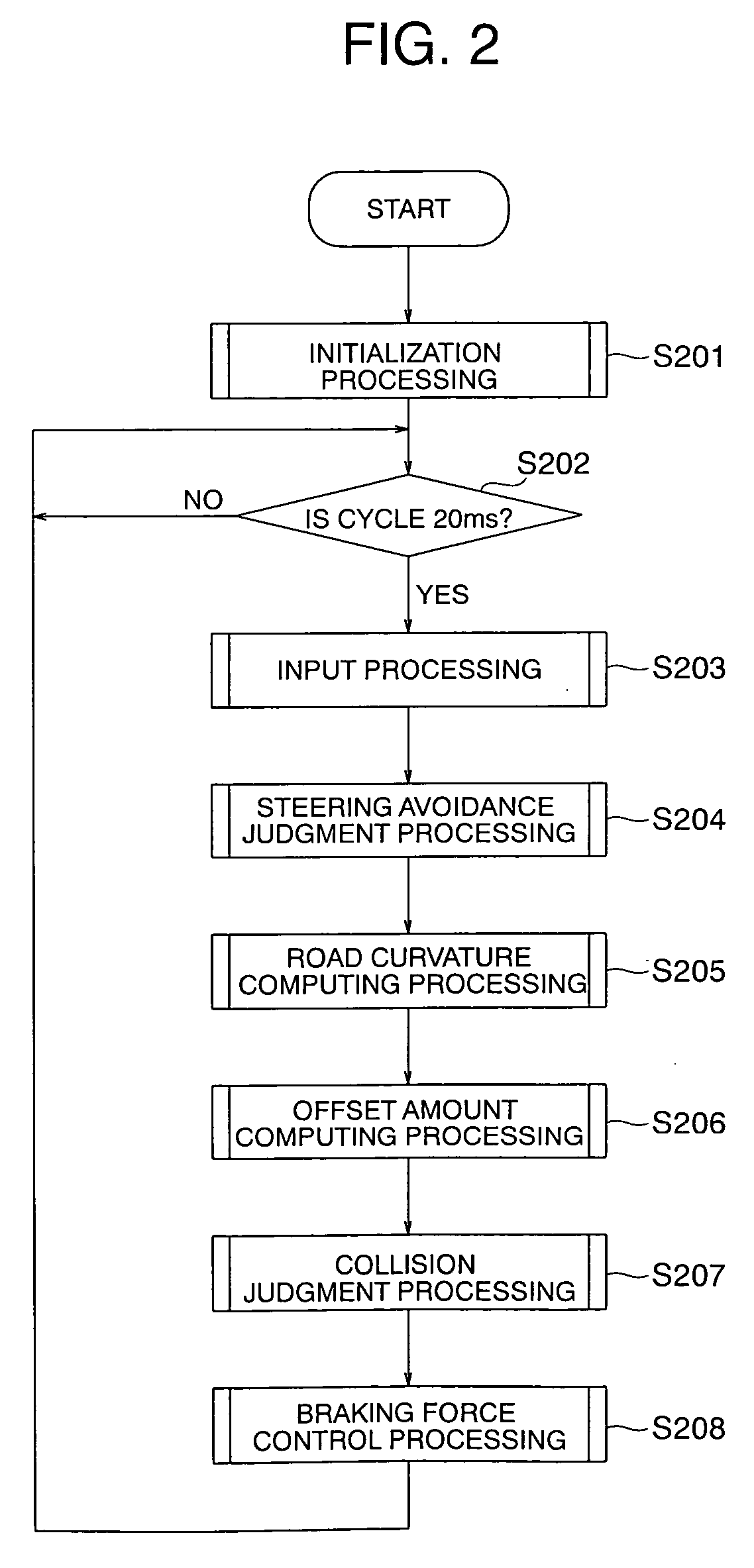

Automatic vehicle braking device

InactiveUS7734416B2Reduce harmVehicle stability deterioratesDigital data processing detailsAnti-collision systemsHead-on collisionDriver/operator

The automatic vehicle braking device is equipped with a braking force control processing portion which, based on the judgment result of a collision judgment processing portion and the judgment result of a steering avoidance judgment processing portion, imparts a turning property in a direction of head-on collision to the vehicle when the lateral position of the obstacle with respect to a travel route curve is large in a condition in which the driver is unconscious of a high possibility of collision between the vehicle and the obstacle and has taken no steering avoidance action yet. As a result, it is possible to reduce the speed of the vehicle and, at the same time, mitigate the damage suffered by the vehicle occupants at the time of collision.

Owner:MITSUBISHI ELECTRIC CORP

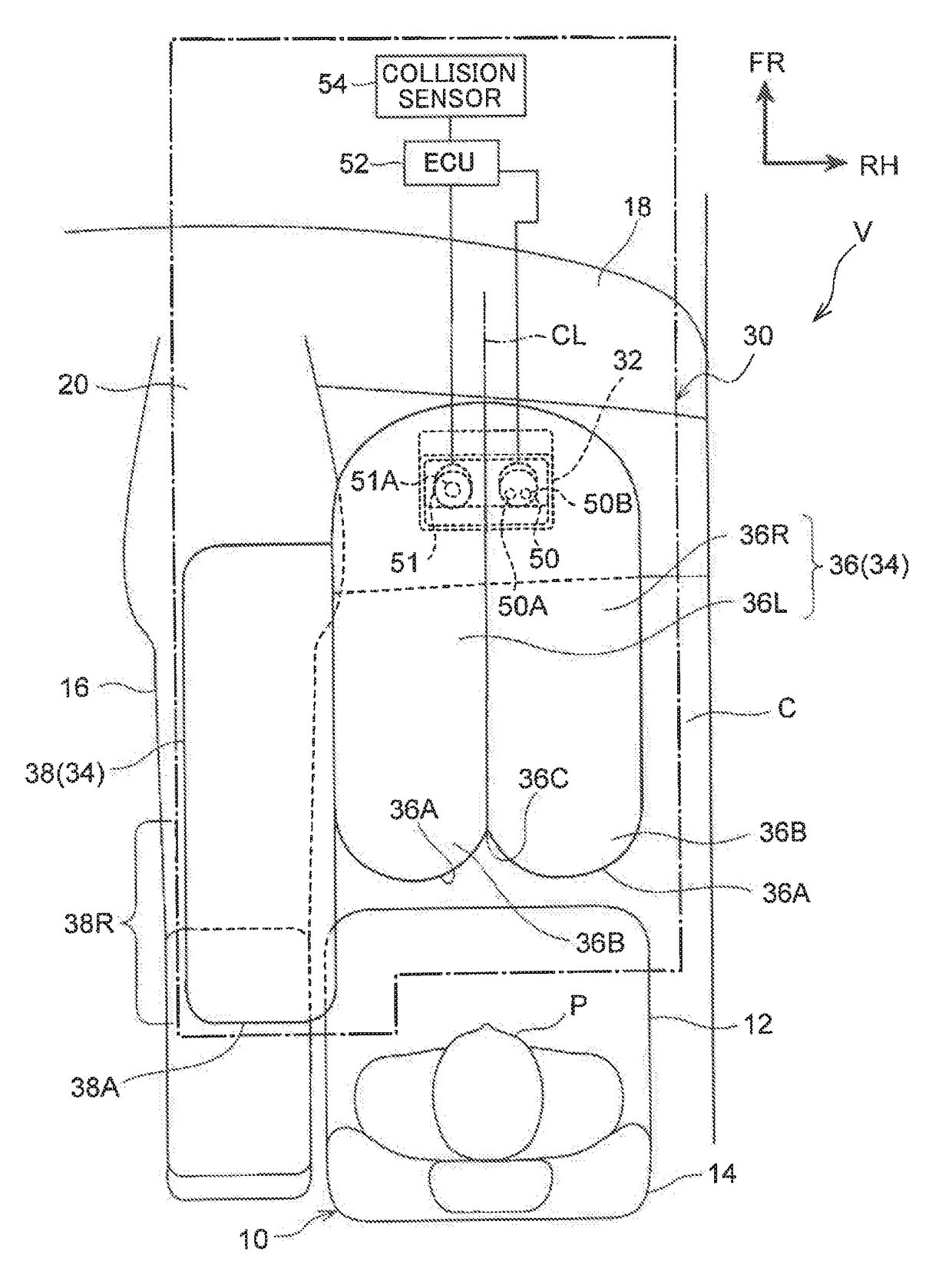

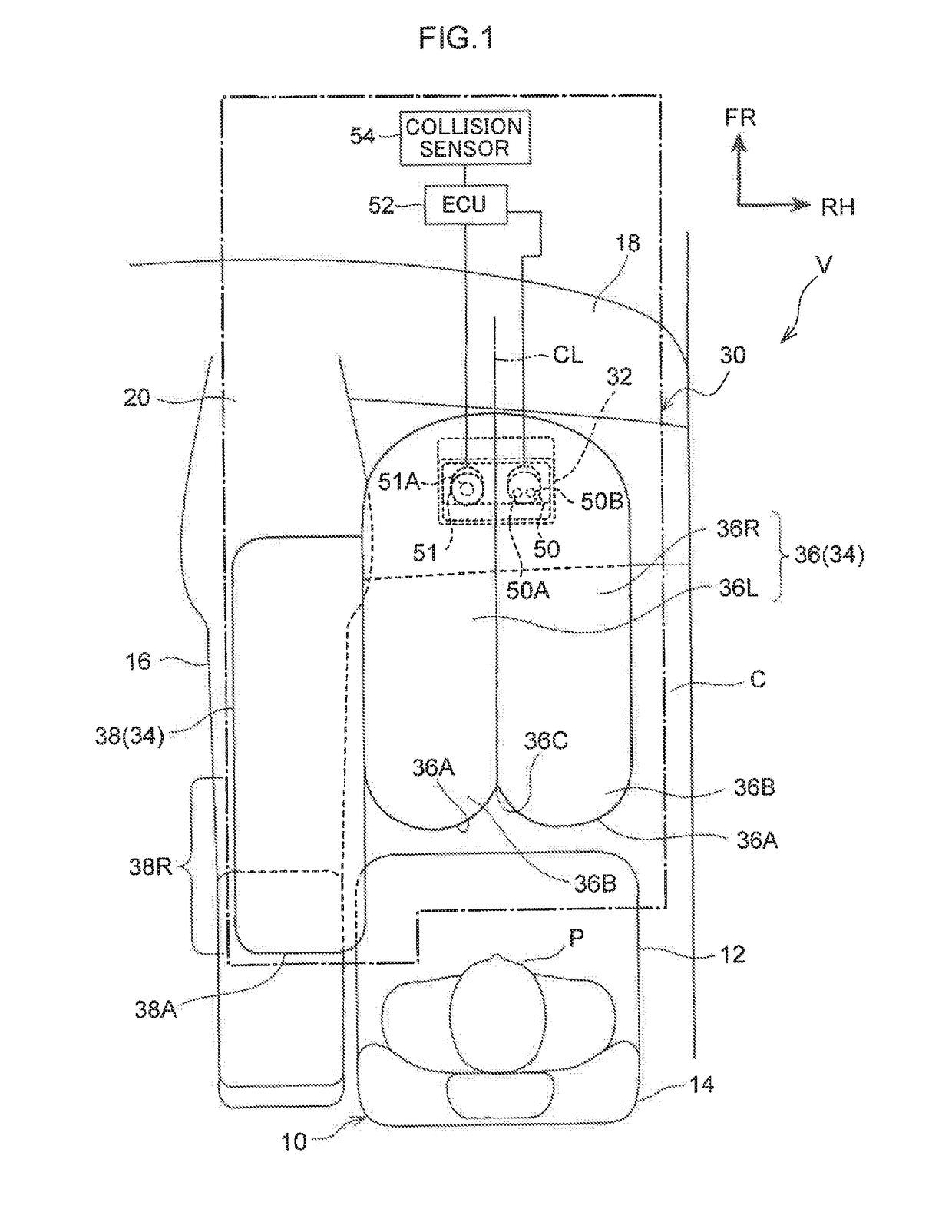

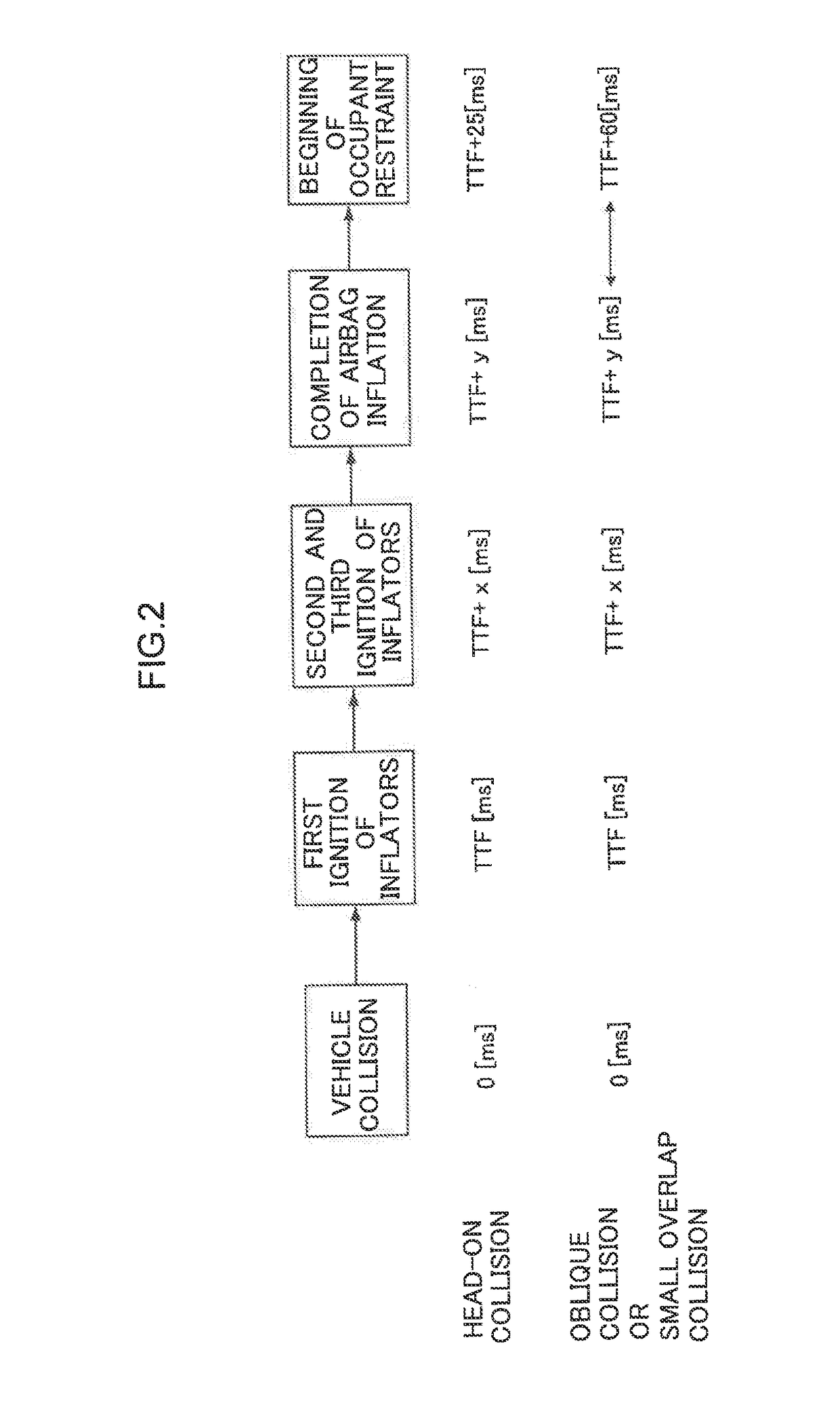

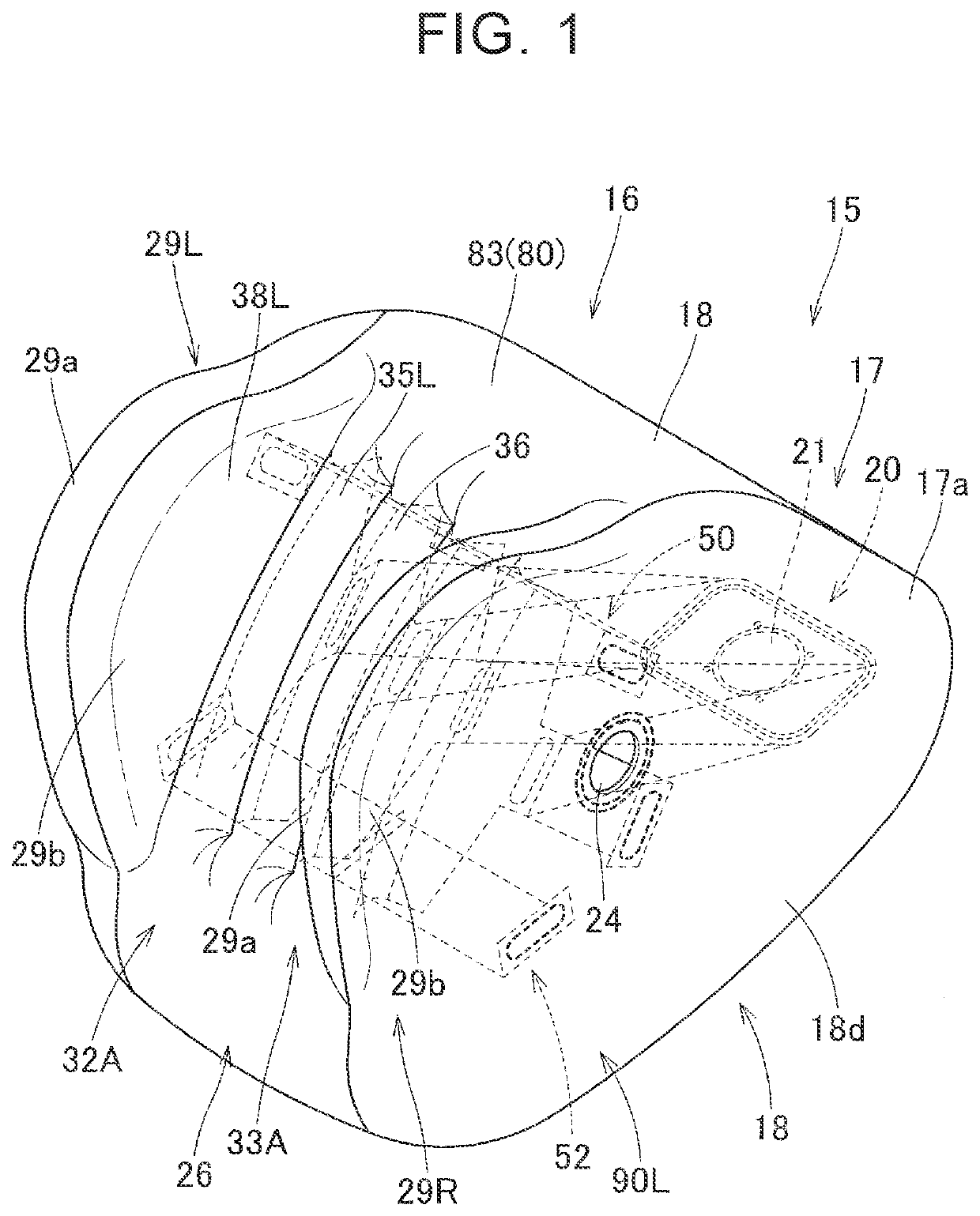

Vehicle front passenger seat airbag device

Present disclosure present a vehicle front passenger seat airbag device, which comprises: a plurality of inflators; an airbag including: a front passenger seat airbag, and a center airbag that includes a vehicle-rear-side end that projects out further toward a vehicle rear side when inflated and deployed than a rear end of the front passenger seat airbag when inflated and deployed; and a controller that controls timings for igniting each squib included in the plurality of inflators such that a peak internal pressure of the airbag inflated and deployed when an oblique collision or small overlap collision has occurred is delayed, compared to a peak internal pressure of the airbag inflated and deployed when a head-on collision has occurred.

Owner:TOYOTA JIDOSHA KK +1

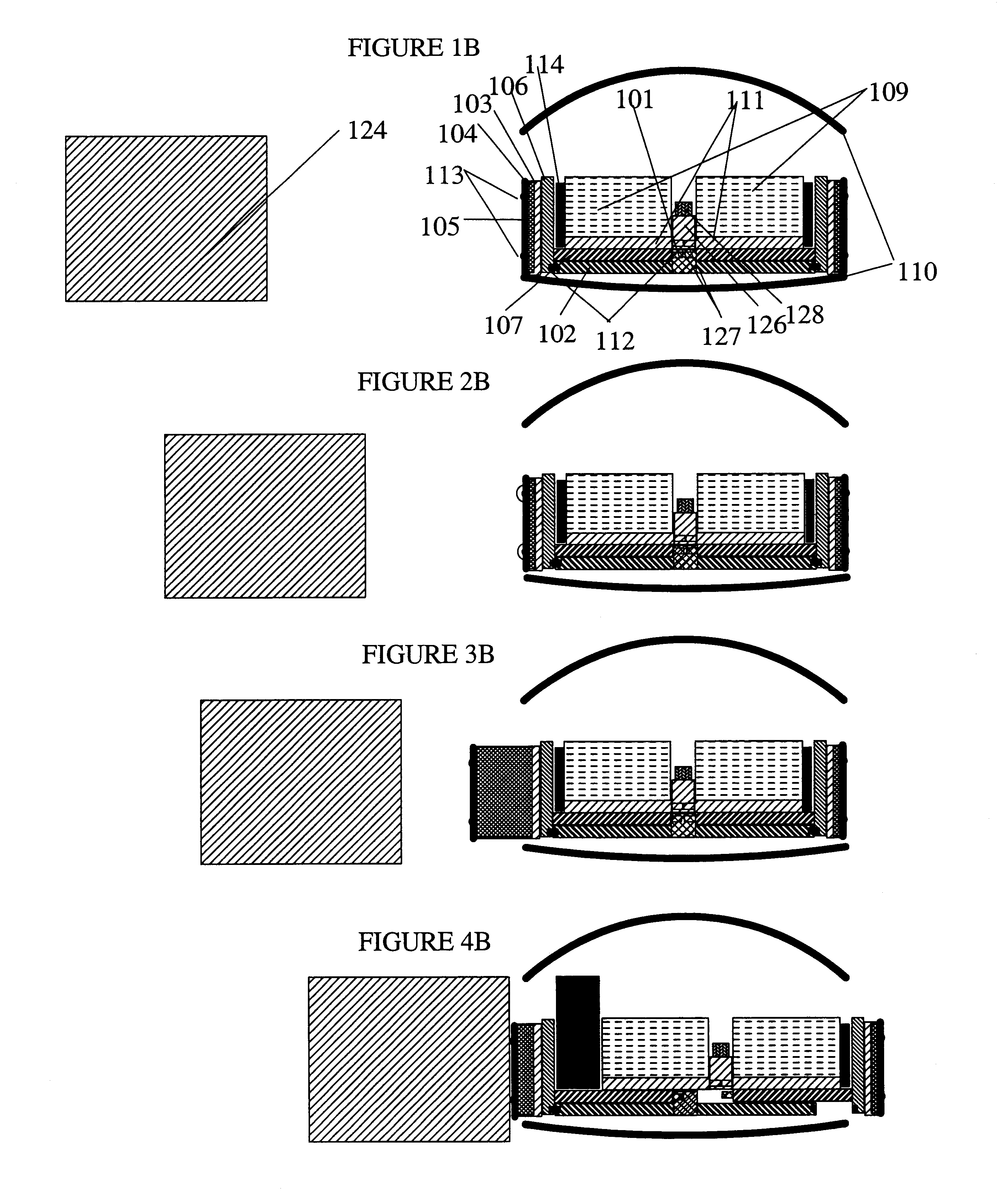

Tubular honeycomb articles for use in energy absorption

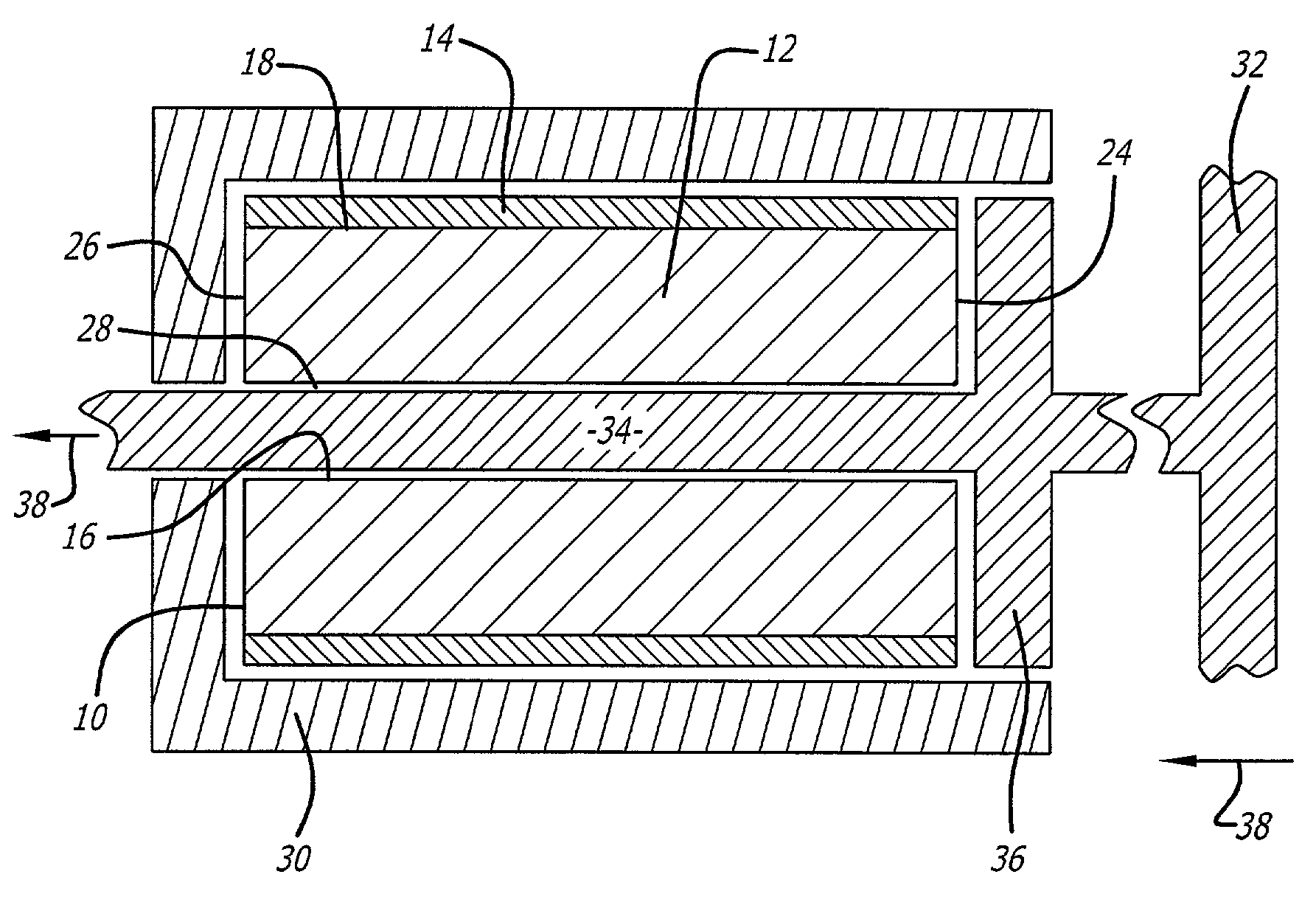

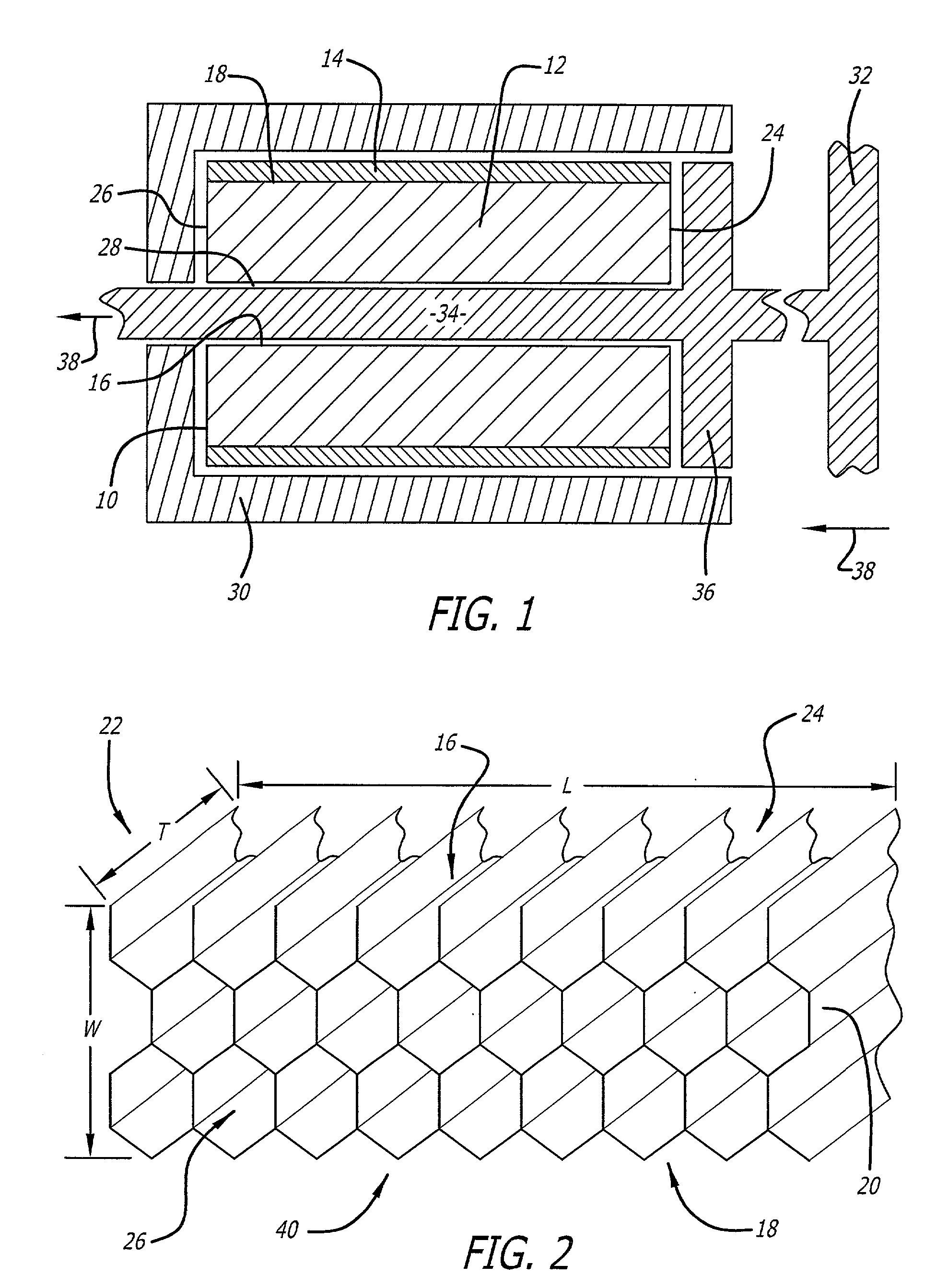

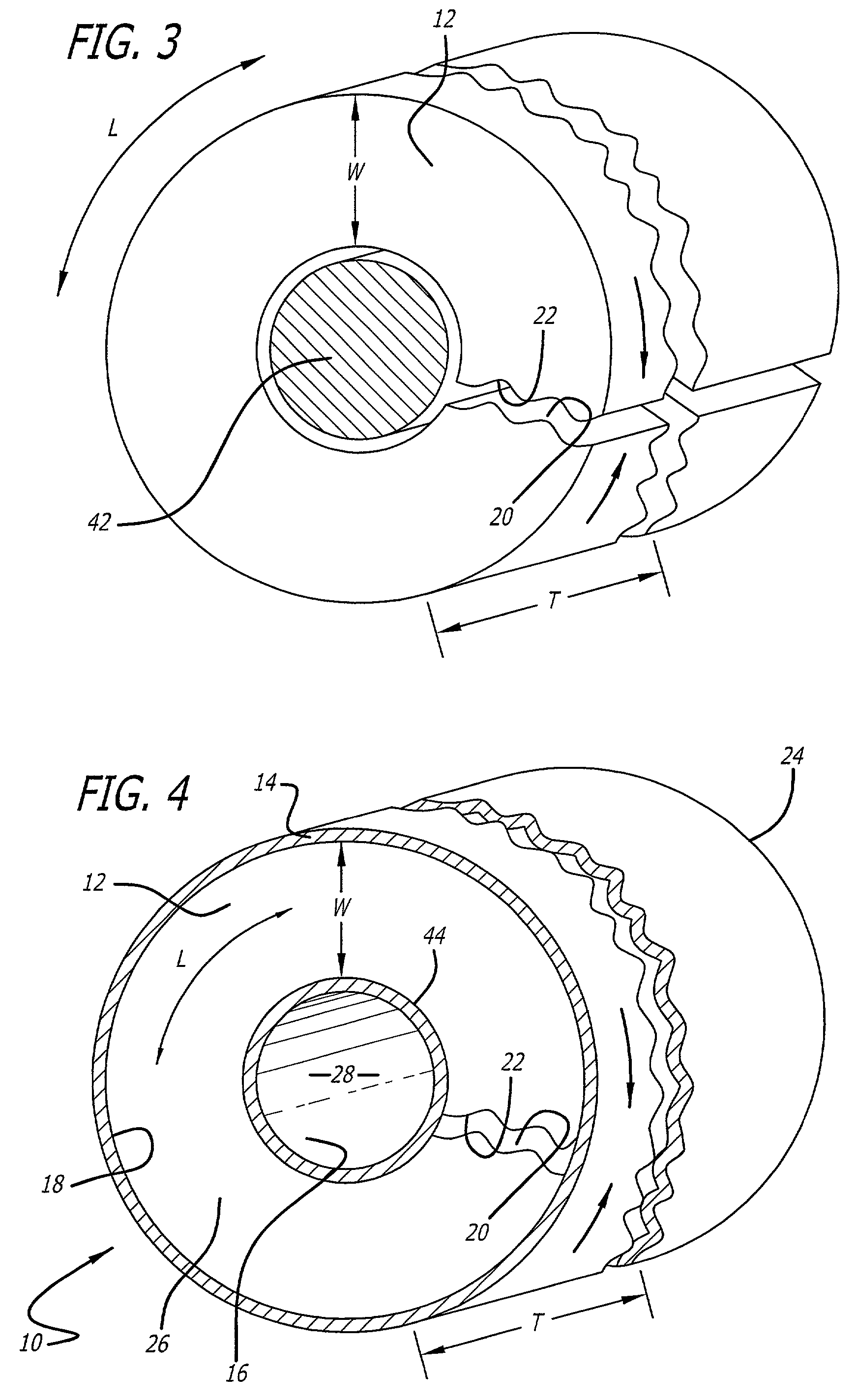

InactiveUS20030218326A1Simple and easy to fabricateReduce the amount requiredSteering columnsElastic dampersSteering columnEnergy absorption

A tubular honeycomb article for use in absorbing energy. The article is made by taking a planar honeycomb and forming it into a tube shaped honeycomb body. The tube shape of the honeycomb body is retained by providing a shell around the perimeter of the honeycomb body. The resulting tubular honeycomb article may be used as an insert or collar in automotive steering columns to provide absorption of energy during occupant loading in an frontal crash.

Owner:HEXCEL

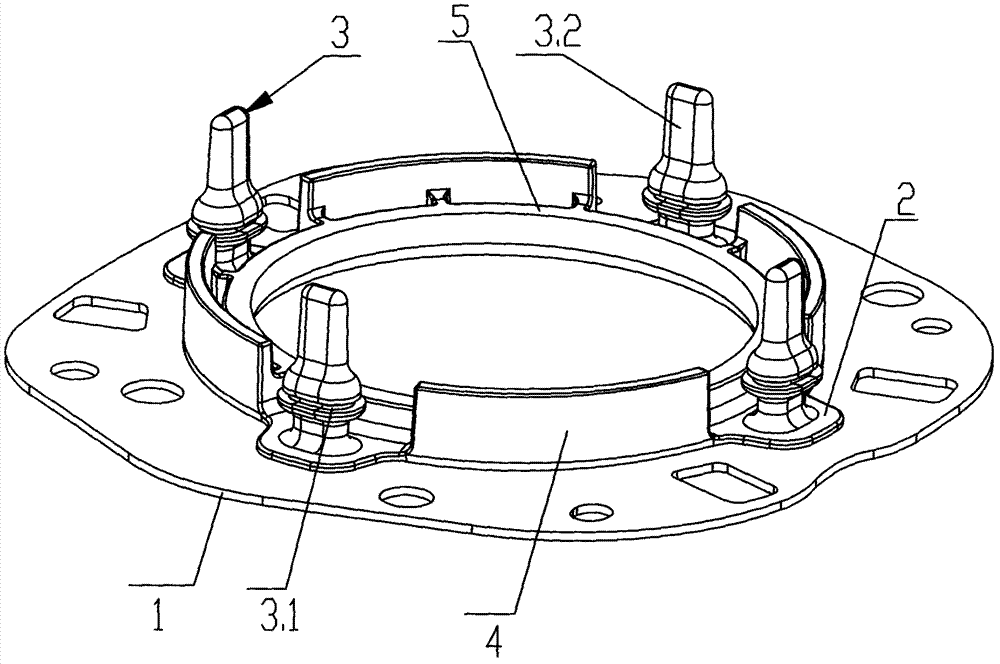

Air generator shock absorption device on steering wheel

ActiveCN103192788AReduce jitterIncrease contact timePedestrian/occupant safety arrangementHead-on collisionRubber material

The invention provides an air generator shock absorption device on a steering wheel and belongs to the technical field of automobile accessories. The air generator shock absorption device comprises a support wheel and a buffer assembly. An air generator is connected onto the buffer assembly made of a rubber material. When head-on collision of a vehicle occurs, the buffer assembly made of the rubber material in an air bag restraint module can effectively buffer recoil force produced by the detonated air generator, namely the contact time of an air bag and a person is prolonged, the buffer time of a safety belt is prolonged, inertia impact of the person is reduced to some extent, impact force between the person and the air bag is reduced, and injury level is reduced. In addition, due to the fact that the air generator is connected onto an elastic connecting column of the buffer assembly, the air generator shock absorption device has certain shaking capacity. When jolt shake produced by the whole vehicle in running is transmitted to the steering wheel, the steering wheel can transmit agglomerated energy to the air generator through the buffer assembly, the air generator and the elastic connecting column shake, the shaking degree of the steering wheel is reduced, noise is reduced, and driving comfort is improved.

Owner:建新赵氏科技股份有限公司

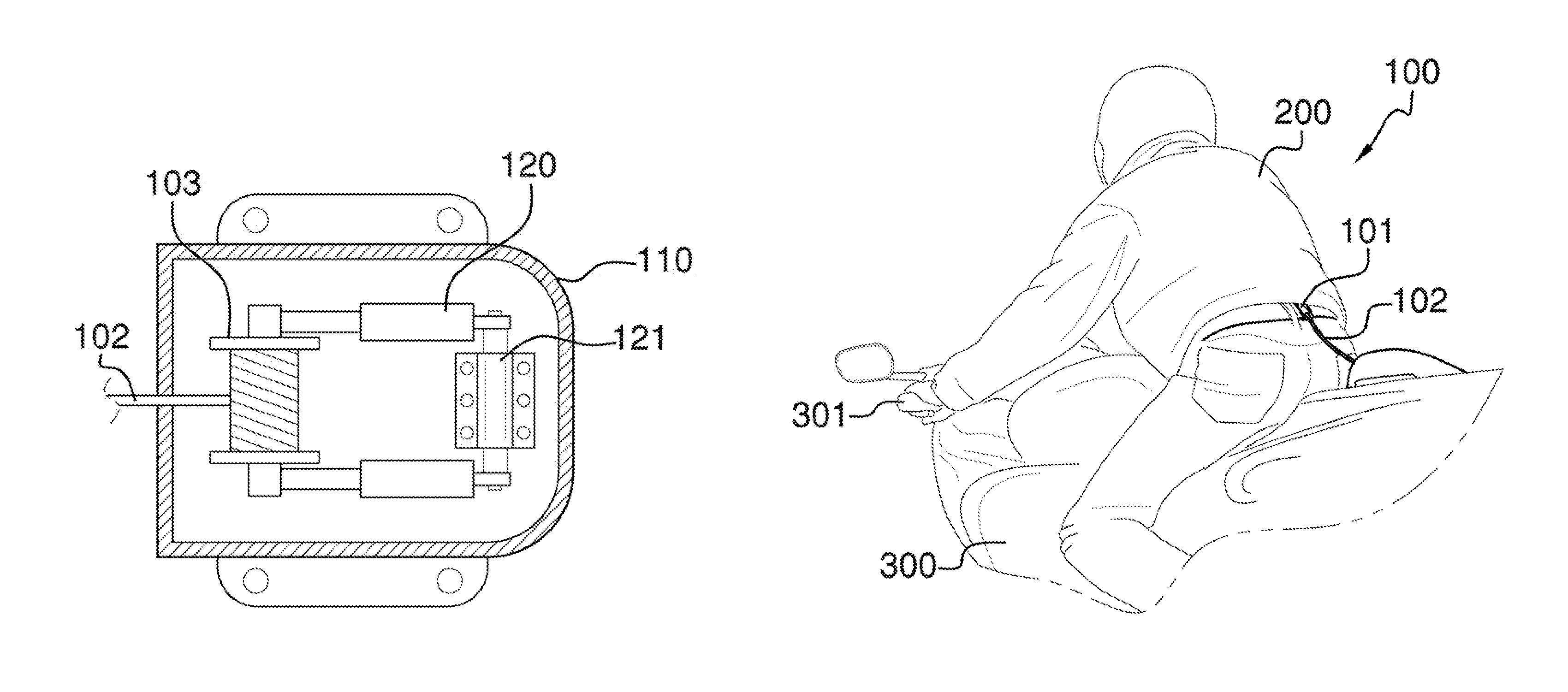

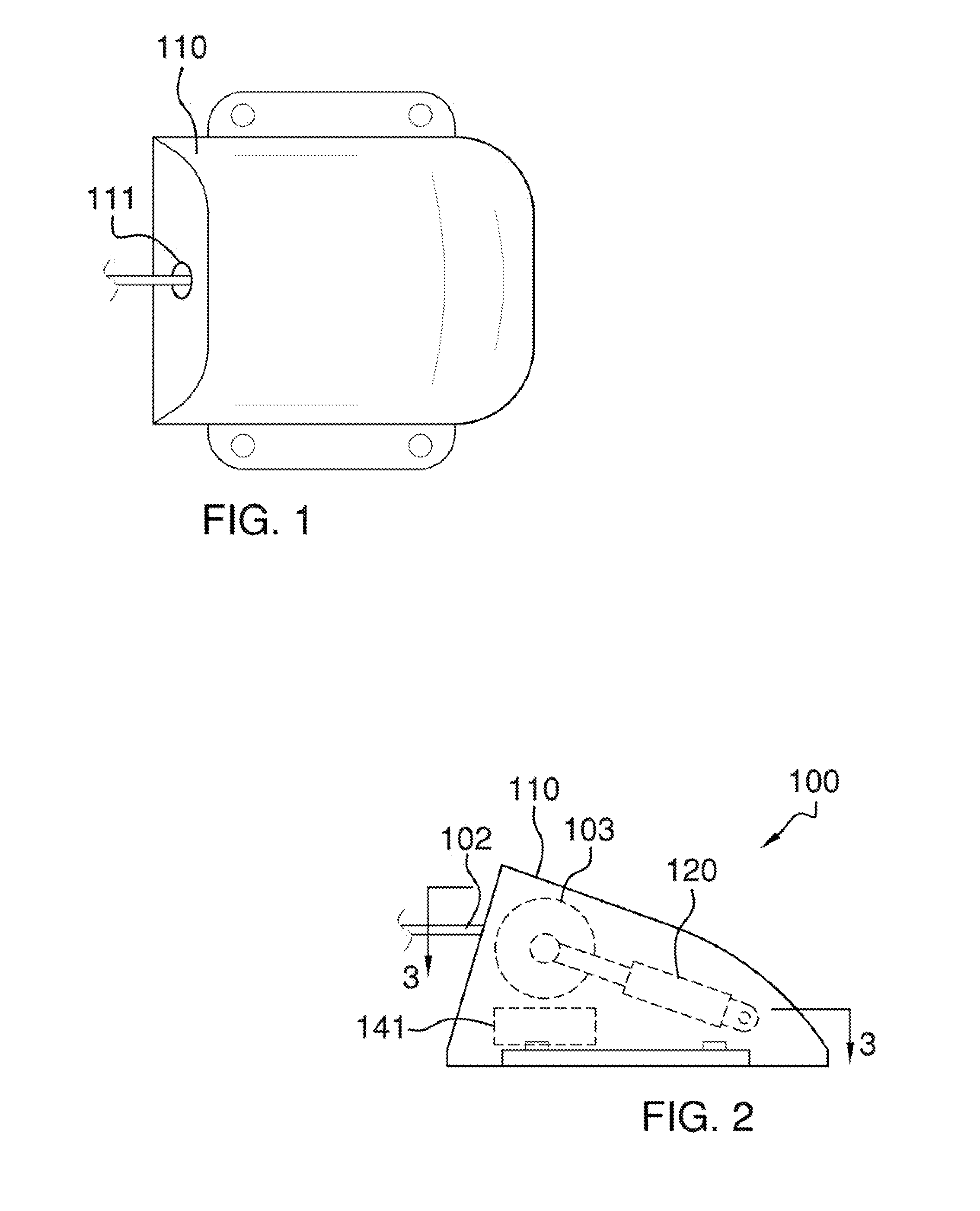

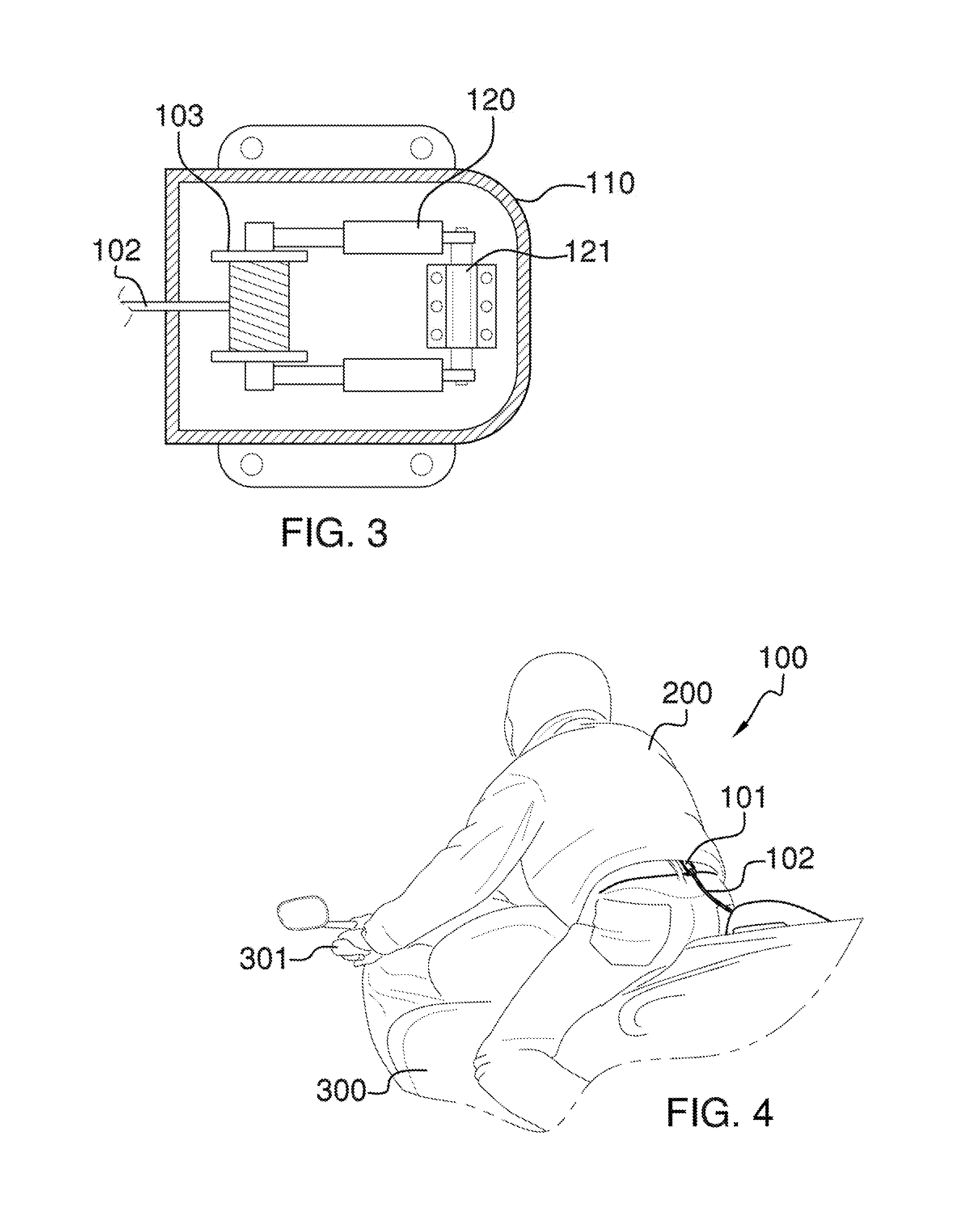

Self-releasing vehicular harness

The self-releasing vehicular harness is a harness designed to prevent a driver or rider of a motorcycle from flying over the handlebars during a head-on or upright collision. The self-releasing vehicular harness includes a tether that extends from the harness to a spring-loaded drum located in a housing positioned to the rear of the end user. The housing contains at least one tensioning means that releases the drum in order to enable the tether to unroll thereby releasing the end user from the vehicle in the event of a non-head-on collision or other parameter. An inclinometer detects the angle of the vehicle in order to determine whether to release or lock the spring-loaded drum. A kill switch and / or seat sensor may work in conjunction with the inclinometer to further define parameters for releasing or locking the tether.

Owner:GALLO GERALD F

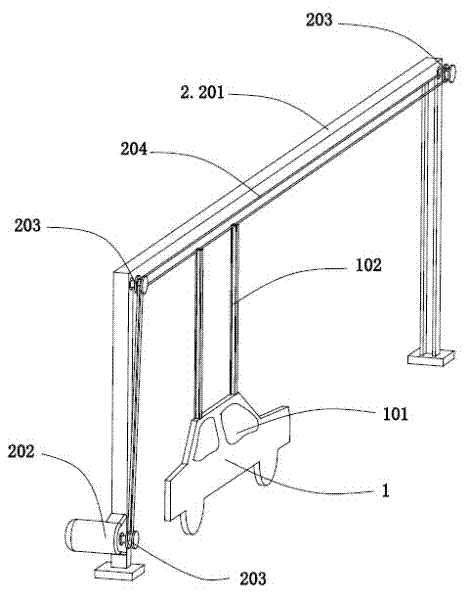

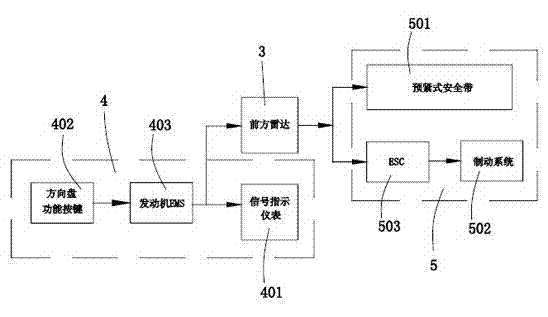

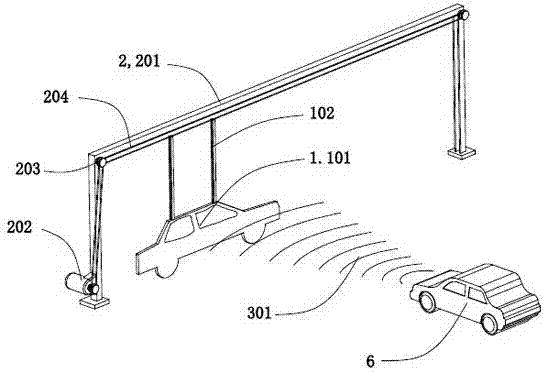

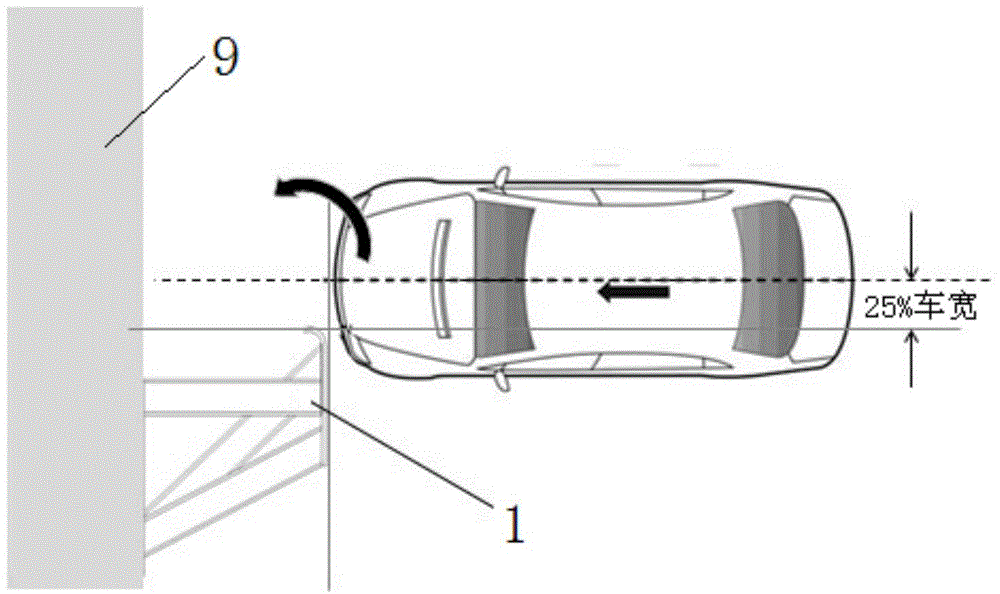

Test method and device for calibrating lateral coming vehicle by head-on collision prevention system

InactiveCN102564719AAbsolutely safeWide speed adjustment rangeVehicle testingWave based measurement systemsHead-on collisionControl system

The invention discloses a test device for calibrating a lateral coming vehicle by a head-on collision prevention system. The head-on collision prevention system comprises a control system, a radar arranged on a test vehicle and a vehicle passive safety control device; the test device comprises a simulated object positioned at the periphery of the test vehicle; the control system is provided with at least four control stages, namely a normal stage, a tracking stage, a prewarning stage and a collision buffering stage, and at least four corresponding instruction signals; the simulated object is a lateral coming vehicle simulation plate; the size of the simulation plate is the same as that of an actual vehicle; a vehicle lateral image is arranged on the surface of the simulation plate; and the simulation plate does motion along a direction vertical to a running direction of the test vehicle right in front of the test vehicle under the driving of a driving device. Therefore, the simulation plate can be effectively used for simulating the front lateral coming vehicle, so that traffic accidents easily caused by calibration by using a real vehicle and a real person are avoided, and the safety of testers is guaranteed effectively.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

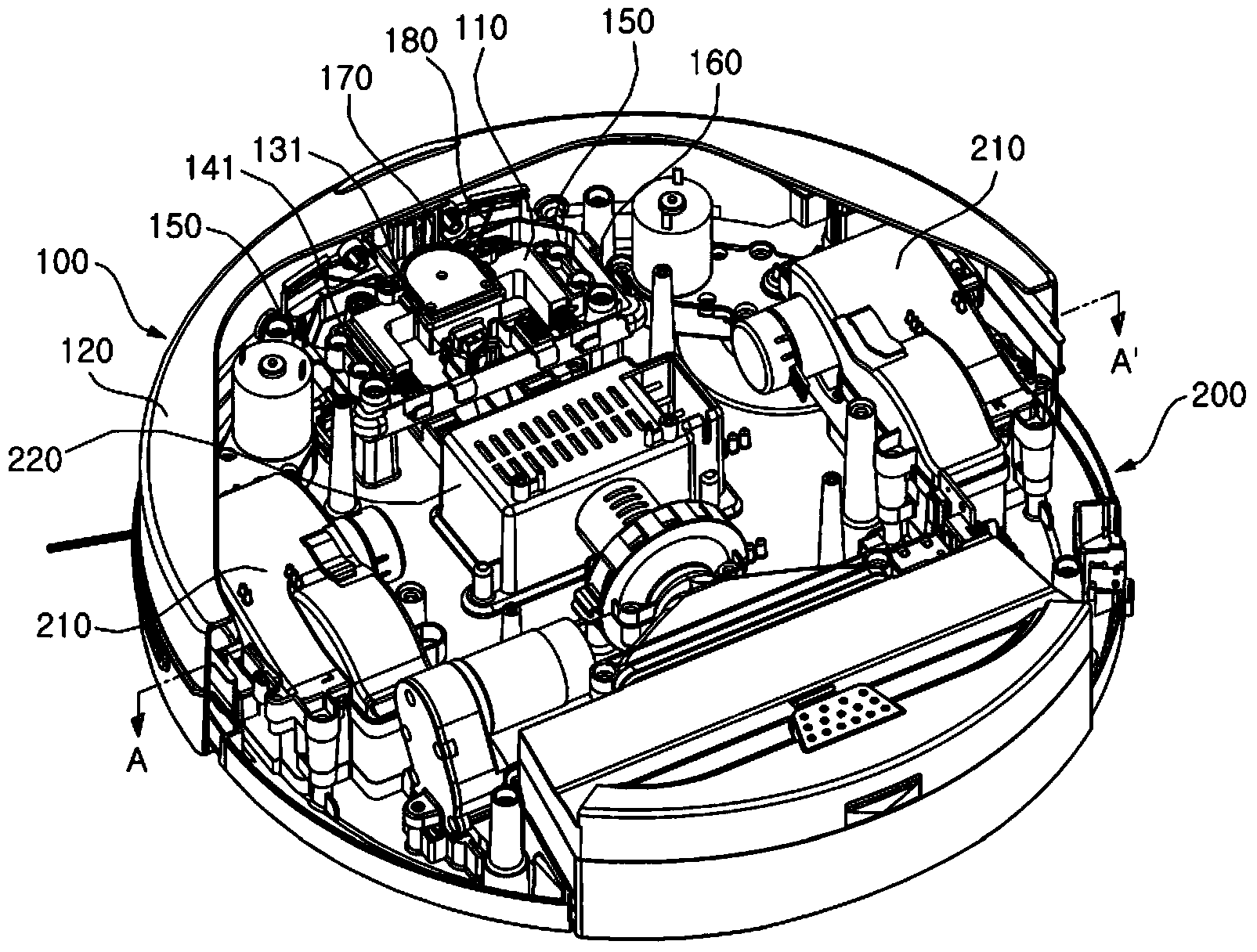

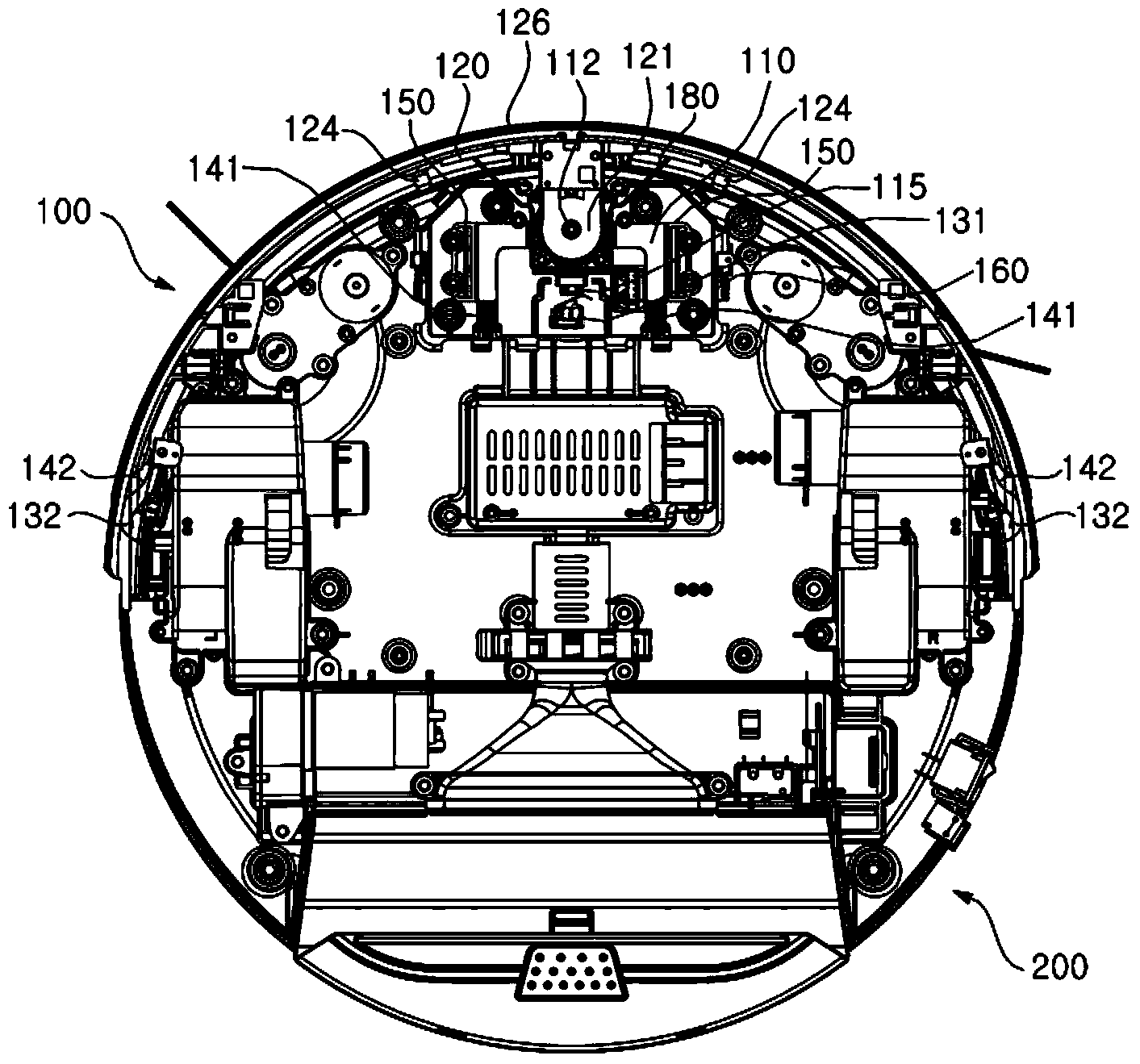

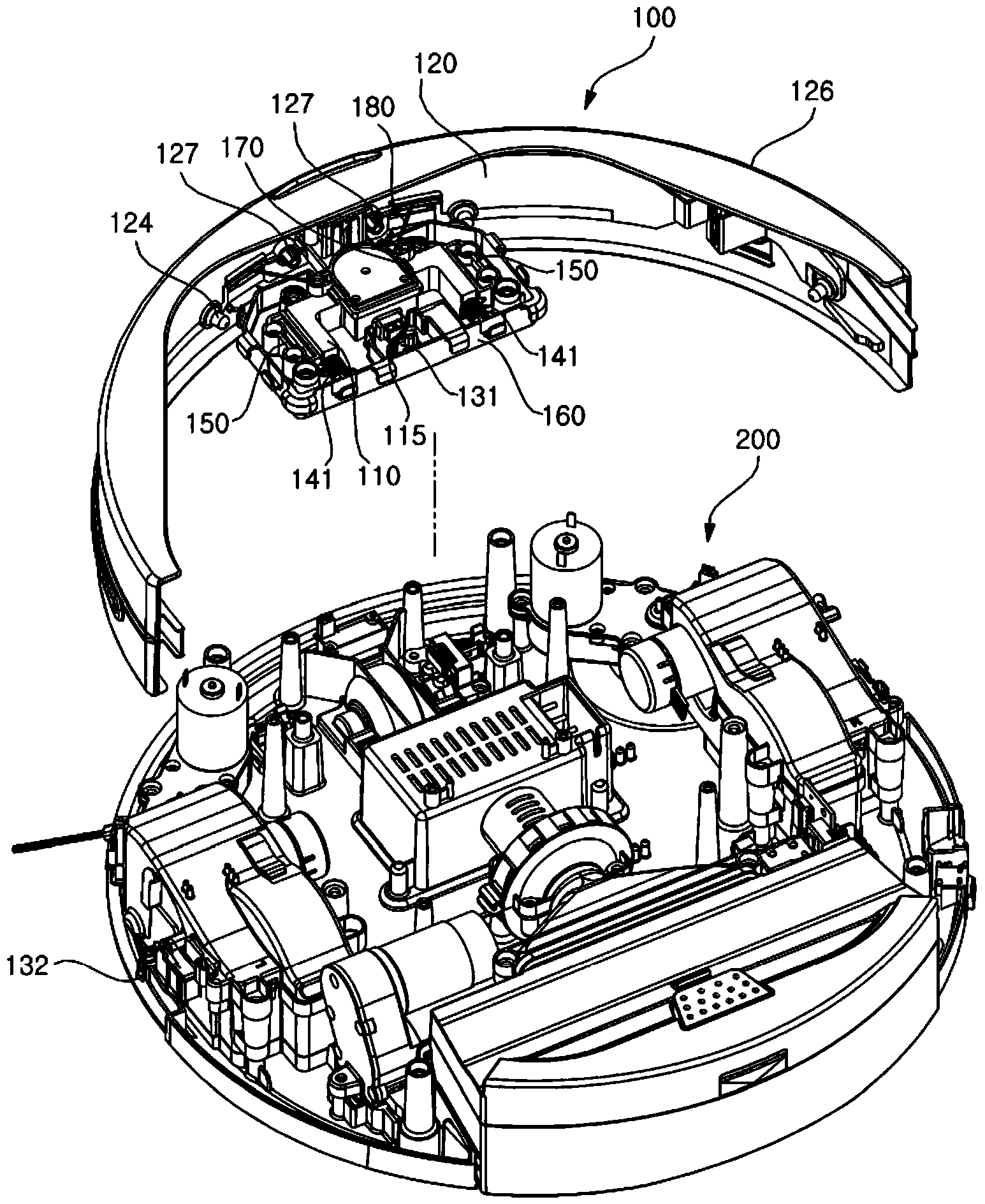

Bumper assembly of mobile robot

InactiveCN103702805ACollision sensing range expandedEliminate shadows that cannot sense collisionsAutomatic obstacle detectionTravelling automatic controlHead-on collisionEngineering

Owner:YUJIN ROBOT

Airbag control device

InactiveCN101048299ASuppress unneeded openingPedestrian/occupant safety arrangementHead-on collisionEngineering

Owner:MITSUBISHI ELECTRIC CORP

Bumper structure

InactiveUS7484779B2Easy to detectAvoid deformationPedestrian/occupant safety arrangementBumpersHead-on collisionEngineering

In a bumper, a touch sensor and a load detection sensor detect a load applied to the bumper in the event of a head-on collision, when pressed by an absorber. The touch sensor and the load detection sensor are provided in front of reinforced portions of a front wall of a bumper reinforcement. The touch sensor is provided in front of the load detection sensor with a load transfer plate interposed the touch sensor and the load detection sensor. In addition, in the event of a head-on collision, deformation of the front wall is suppressed by the reinforced portions and the load is appropriately applied to the touch sensor and the load detection sensor, and the load is appropriately applied from the touch sensor to the load detection sensor. Thus, the detection performance of the touch sensor and the load detection sensor can be stabilized.

Owner:TOYOTA JIDOSHA KK

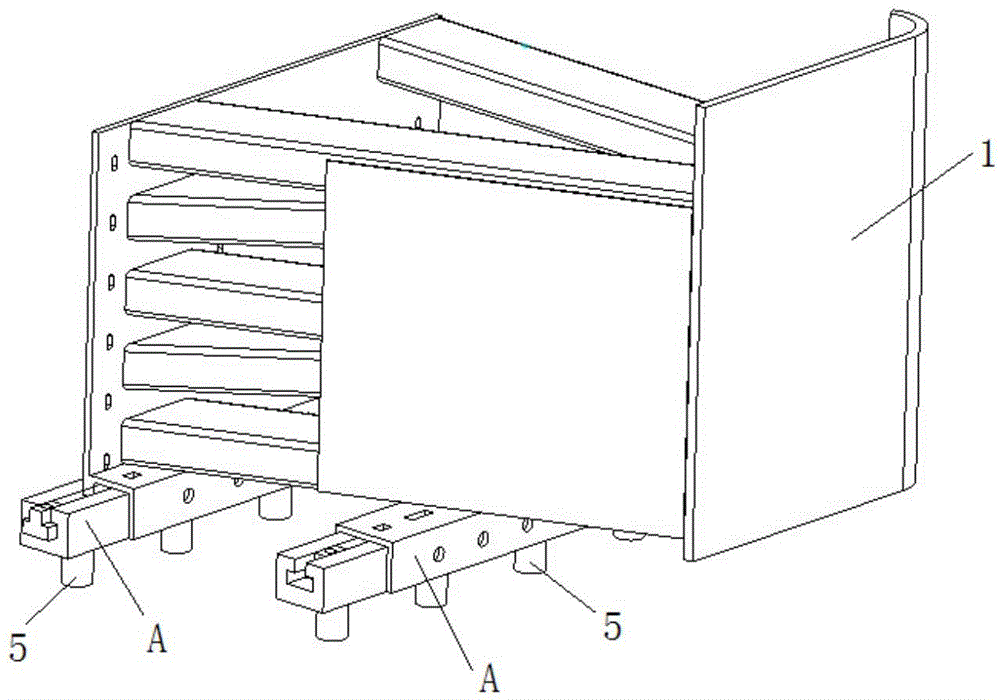

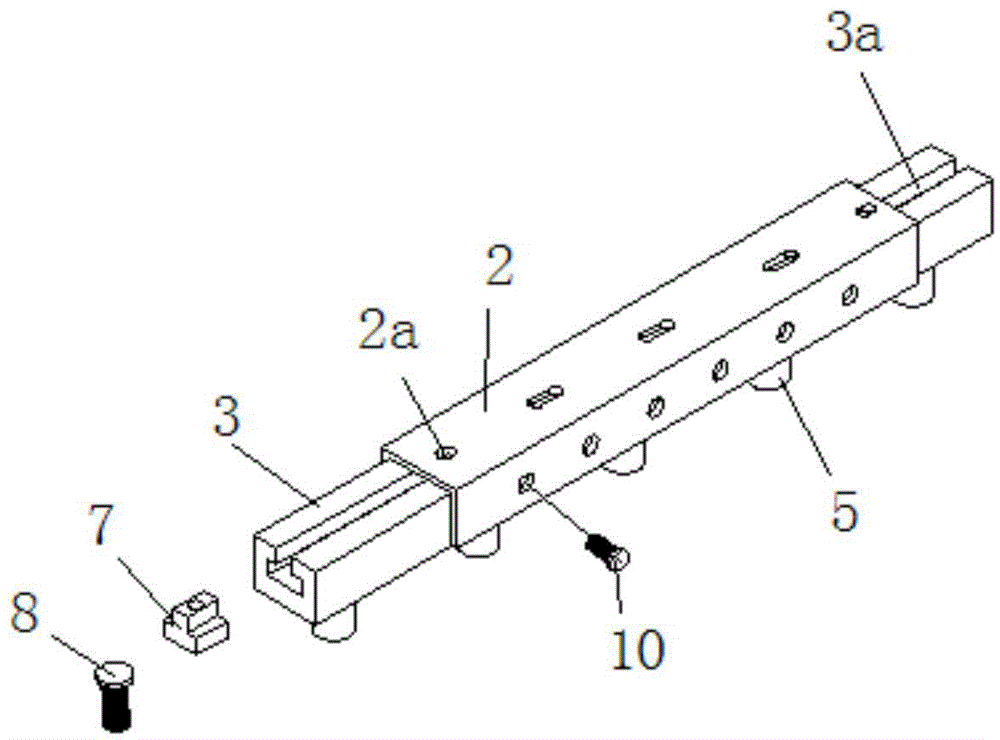

Counterguard system for small-bias head-on collision of vehicles

ActiveCN104458186AAvoid secondary collisionLow input costVehicle testingShock testingHead-on collisionRigid wall

The invention discloses a counterguard system for small-bias head-on collision of vehicles. The counterguard system comprises a small-bias counterguard (1), two installing supports (A) parallel to each other are welded to the bottom of the small-bias counterguard, each installing support is correspondingly provided with a row of ground anchors (4) laid on a firm foundation, a cylinder (5) matched with an inner cavity of the ground anchor is placed in each ground anchor, each ground anchor corresponds to one first fastening screw (6), and the first fastening screws sequentially penetrate through the installing supports and the cylinders to be locked with the ground anchors from top to bottom. An existing automobile test site is ingeniously improved, the investment cost is low, the project amount is small, the installing mode of horizontally installing the small-bias counterguard on the ground anchors laid on the firm foundation is creatively changed from the installing mode of vertically installing the small-bias counterguard on a fixed rigid wall, secondary collision after vehicle bodies collide is avoided, and the bottleneck that at present, a small-bias collision test can not be performed due to limitation of sites and equipment in China is broken through.

Owner:CHINA AUTOMOTIVE ENG RES INST

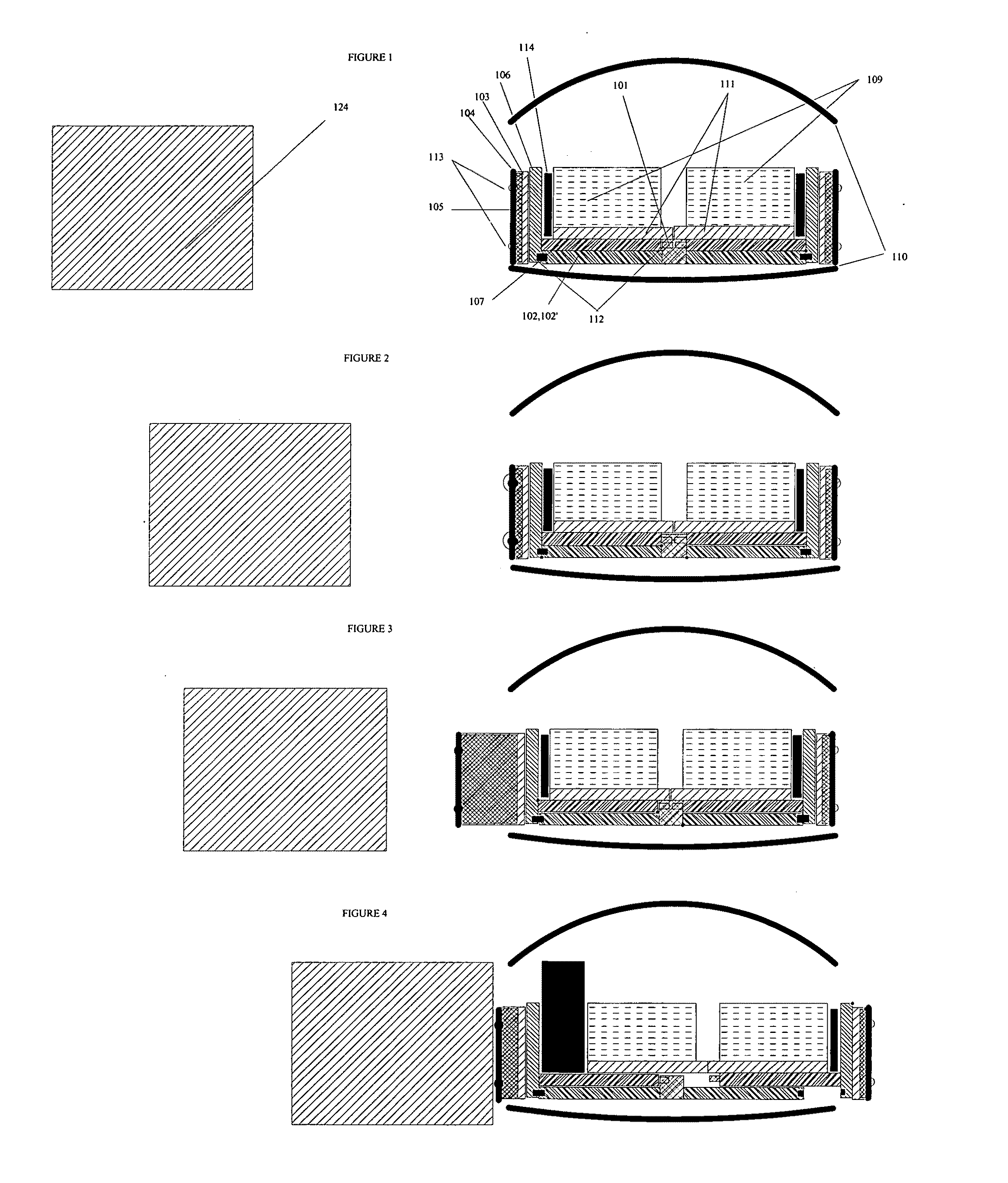

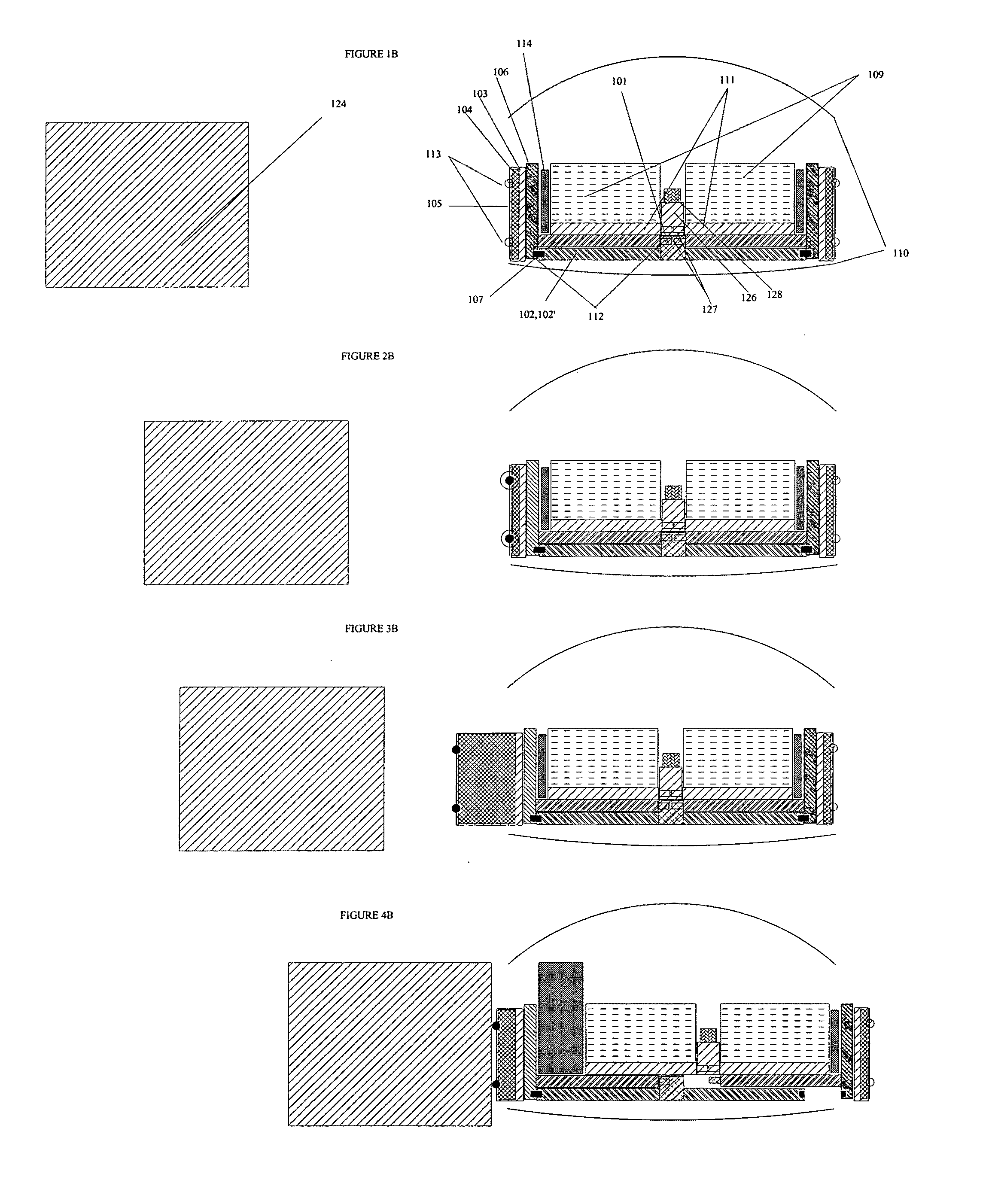

Easy ejector seat with skeletal crash safety beam

An arrangement in passenger vehicles, that diverts the impact energy in lateral or side impacts away from the passengers to the remaining mass of the vehicle thereby protecting the passengers, and in the same arrangement provides utilitarian access to the vehicle, such utilitarian access making it possible to both install multi-element contoured surround seats for passengers and the driver, and also a safety device for head-on collision protection that obviates the need for conventional seat belts and front impact airbags. An indo-skeletal structural arrangement proposed for the vehicle, provides further benefits by targeting the strength of the vehicle to protect passengers while minimizing other massive elements in the vehicle.

Owner:MMILLENNIUMM GRP

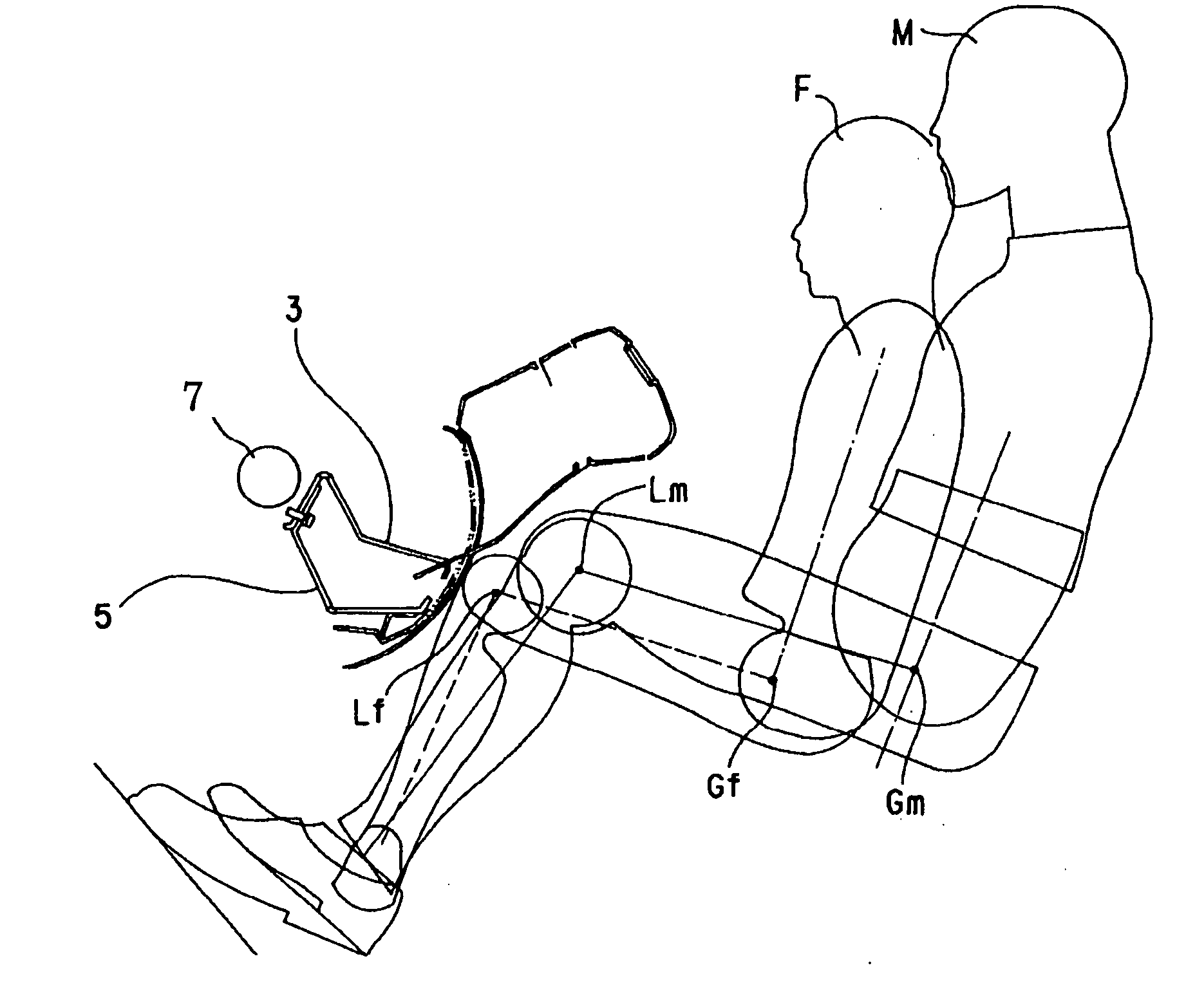

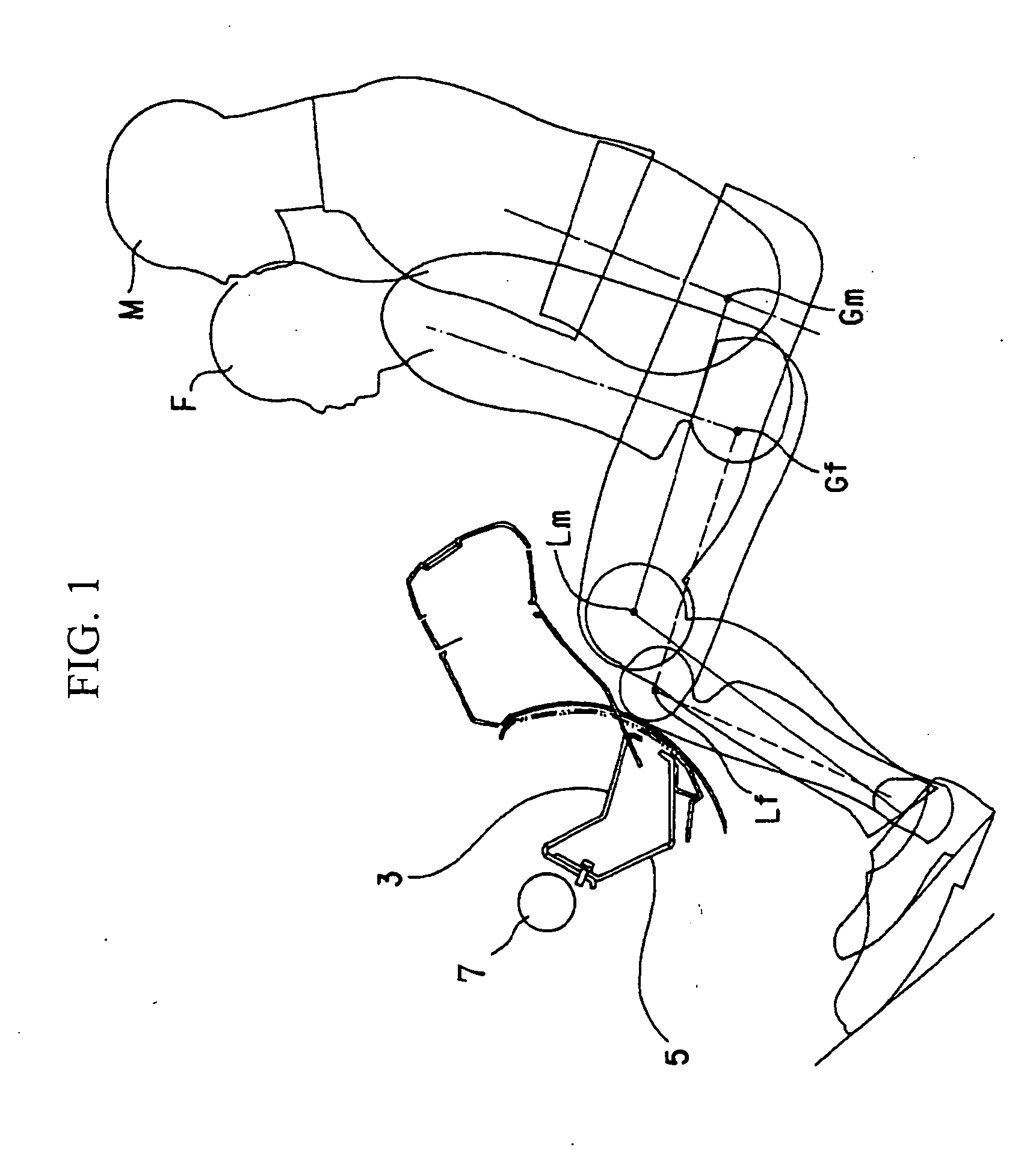

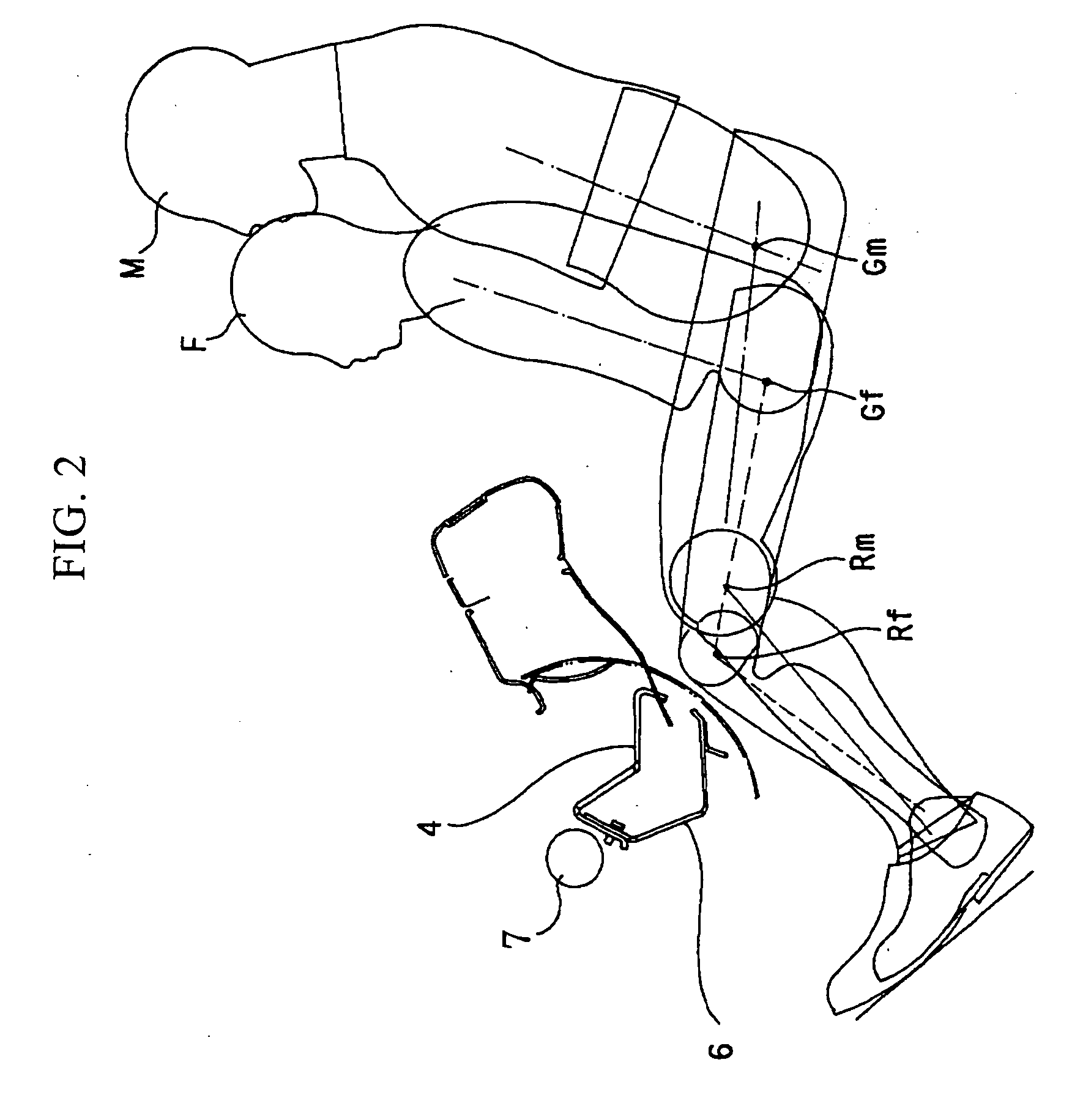

Knee bolster

A knee bolster whose load receiving parts absorb load from the knees of seated occupants of various physical sizes is provided. An upper knee bolster and a lower knee bolster are each provided with a load receiving part that receives load from the knees of a seated occupant who moves forward in the direction of vehicle length in the event of a vehicle head-on collision, and a deforming part that moves the load receiving part, which has been deformed by the load, forward in the direction of vehicle length.

Owner:MITSUBISHI MOTORS CORP

Easy ejector seat with skeletal crash safety beam

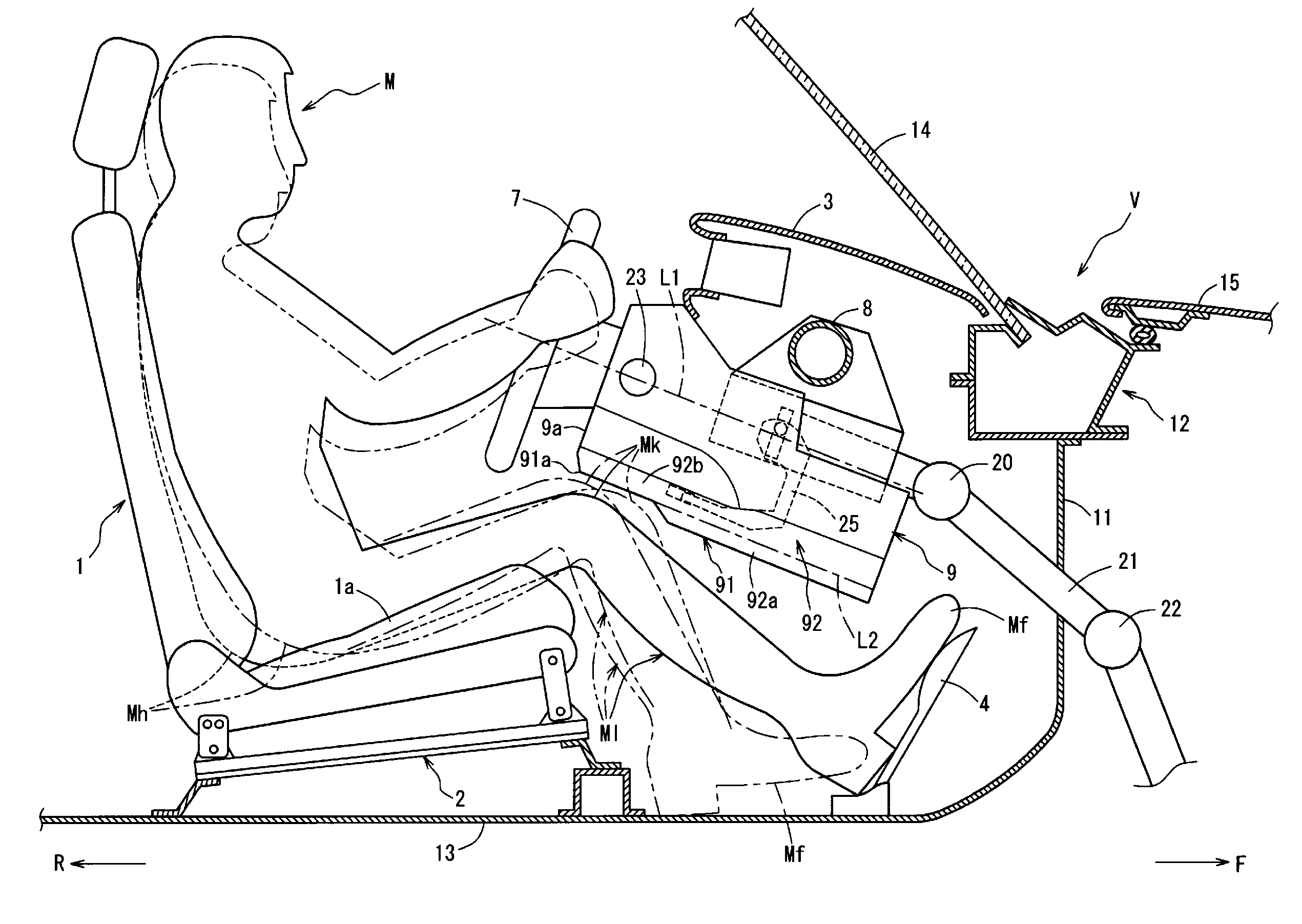

ActiveUS20110031055A1Save energyWeight savingElectric devicesBack restsHead-on collisionMulti element

An arrangement in passenger vehicles, that diverts the impact energy in impacts away from the passengers to the remaining mass of the vehicle thereby protecting the passengers, and in the same arrangement provides utilitarian access to the vehicle, such utilitarian access making it possible to both install multi-element contoured surround seats for passengers and the driver, and also safety devices and arrangements for head-on collision protection that protect the passenger. An indo-skeletal structural arrangement proposed for the vehicle, provides further benefits by targeting the strength of the vehicle to protect passengers while minimizing other massive elements in the vehicle.

Owner:COZY INC

Airbag device for front passenger seat

ActiveUS20200010044A1Sufficient protectionStability protectionPedestrian/occupant safety arrangementHead-on collisionControl theory

An airbag device includes an airbag. A passenger protection portion of the airbag has a frontal collision restraint surface, an oblique collision restraint surface, and a restraint recess portion. The airbag has a recess portion tether that couples a tip side of a recess of the restraint recess portion and a front end side of the airbag to each other, and at least one longitudinal tether that couples the front end side of the airbag and a recess portion-side region that is located on the restraint recess portion side with respect to a center of the frontal collision restraint surface in a lateral direction to each other, inside the airbag. The frontal collision restraint surface has at least two protruding surfaces that are configured to protrude backward, due to the longitudinal tether. The at least two protruding surfaces are arranged in alignment in the lateral direction.

Owner:TOYODA GOSEI CO LTD

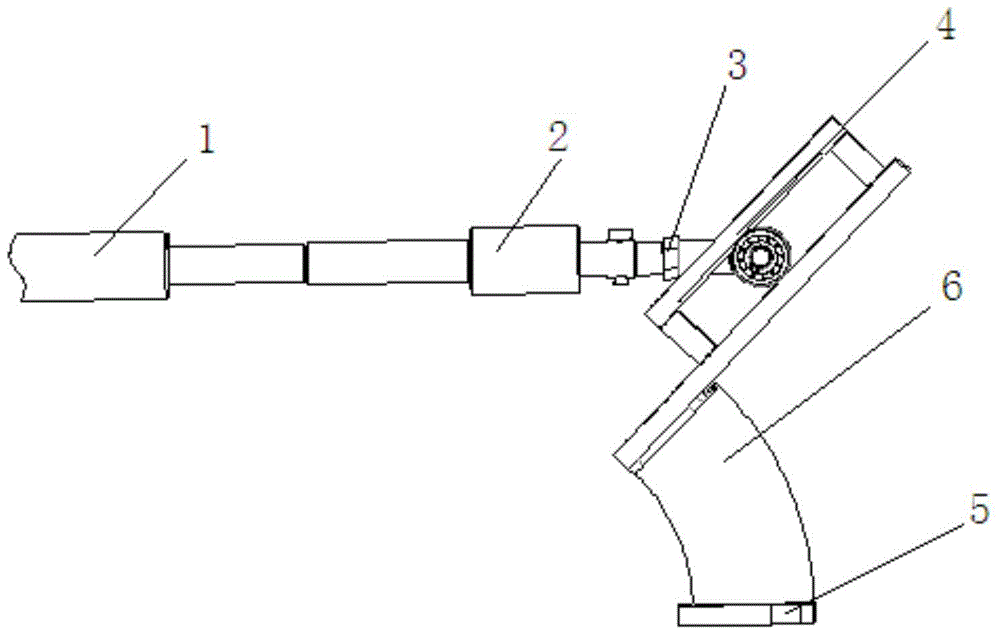

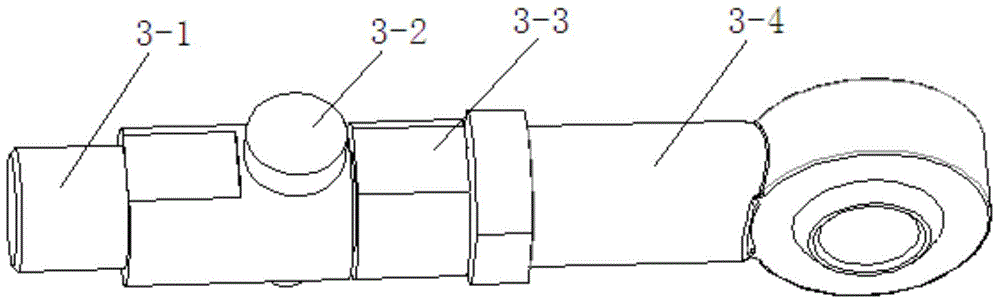

Automobile head-on collision dummy lumbar vertebra calibrator

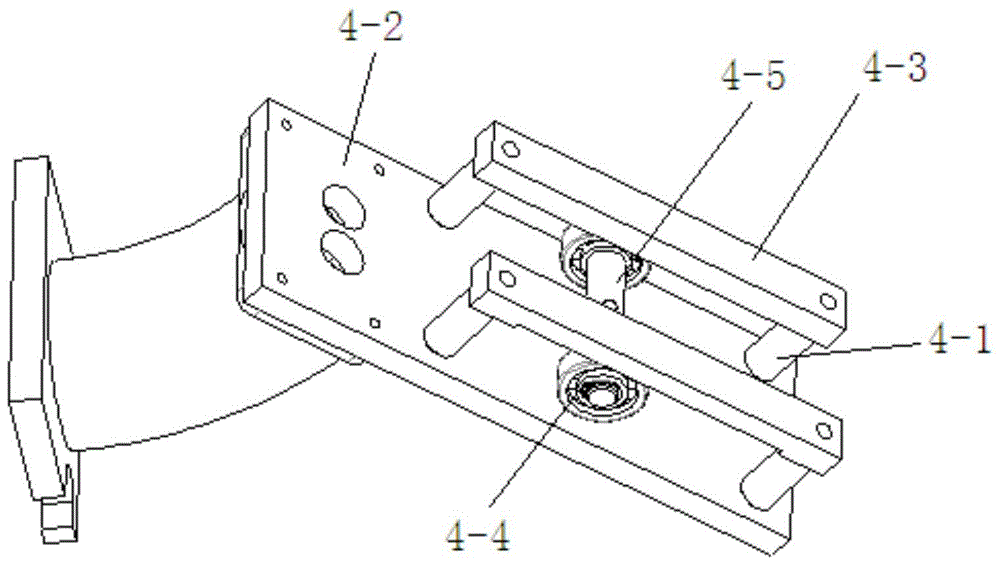

InactiveCN104792544AEliminate the effects ofSimple structureVehicle testingHydraulic cylinderHead-on collision

An automobile head-on collision dummy lumbar vertebra calibrator comprises a hydraulic cylinder, a tension sensor, a rigid connector, a connecting assembly and a fixed base, wherein the hydraulic cylinder is connected with the tension sensor, the tension sensor is connected with the connecting assembly slidably by the rigid joint, the bottom of the connecting assembly is fixed with the dummy lumbar vertebra, and the bottom end of the dummy lumbar vertebra is fixedly connected with the fixed base. The automobile head-on collision dummy lumbar vertebra calibrator is simple in structure, low in manufacturing cost and stable in motion, the hydraulic cylinder is used as power output as compared with swing arm collision in lateral-collision dummy lumbar vertebra calibration as power, test accuracy is high, and dynamic performance of the dummy lumbar vertebra can be detected so as to judge whether the dummy can be used for test again or not after several collision tests, so that response accuracy of the dummy in the collision test is guaranteed, and test data is more persuasive. The automobile head-on collision dummy lumbar vertebra calibrator is wide in application range, applicable to calibrating the lumbar vertebra of the Hybrid III 50th male head-on collision dummy and the Hybrid III 5th female head-on collision dummy.

Owner:湖南赛孚汽车科技股份有限公司

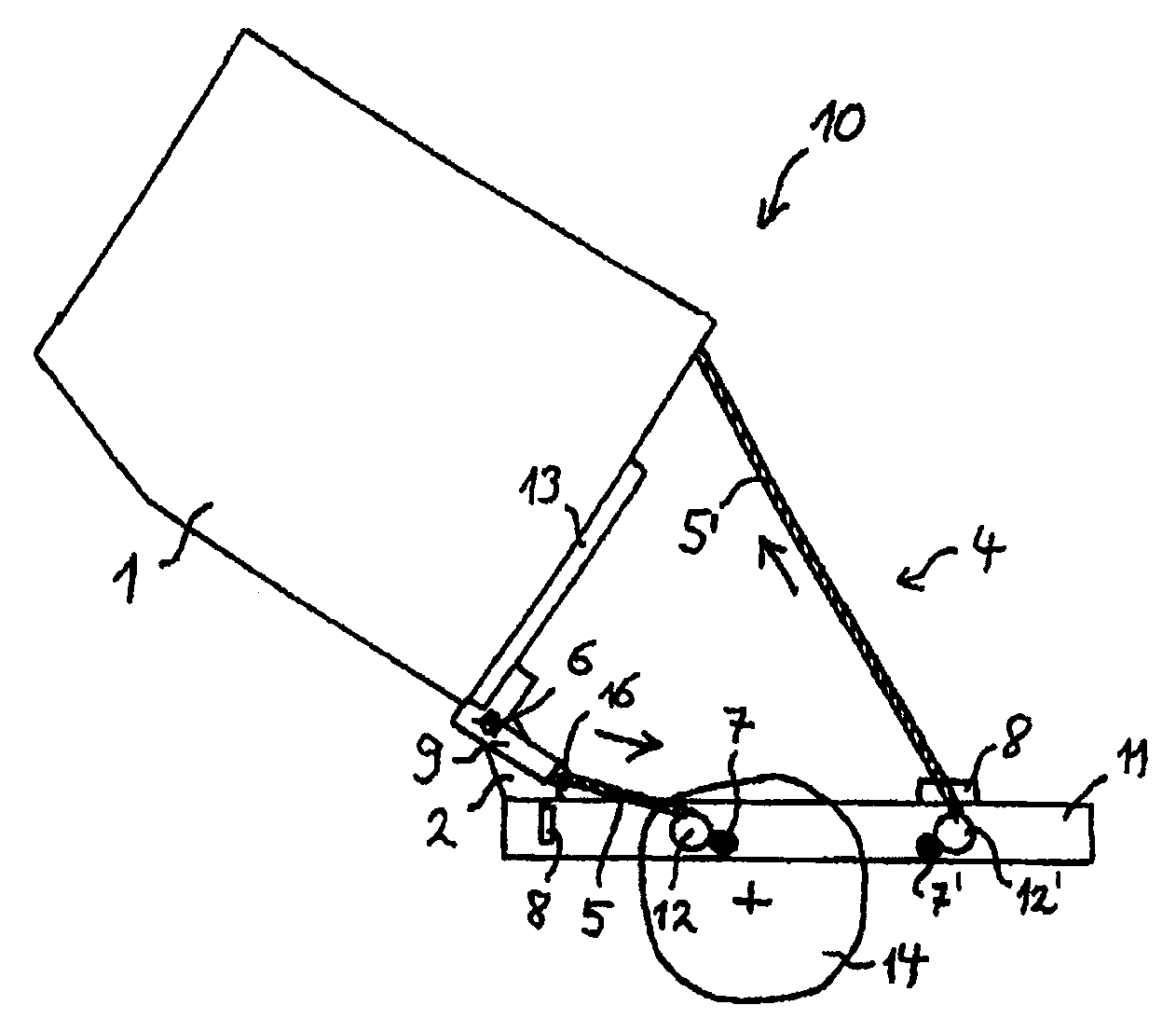

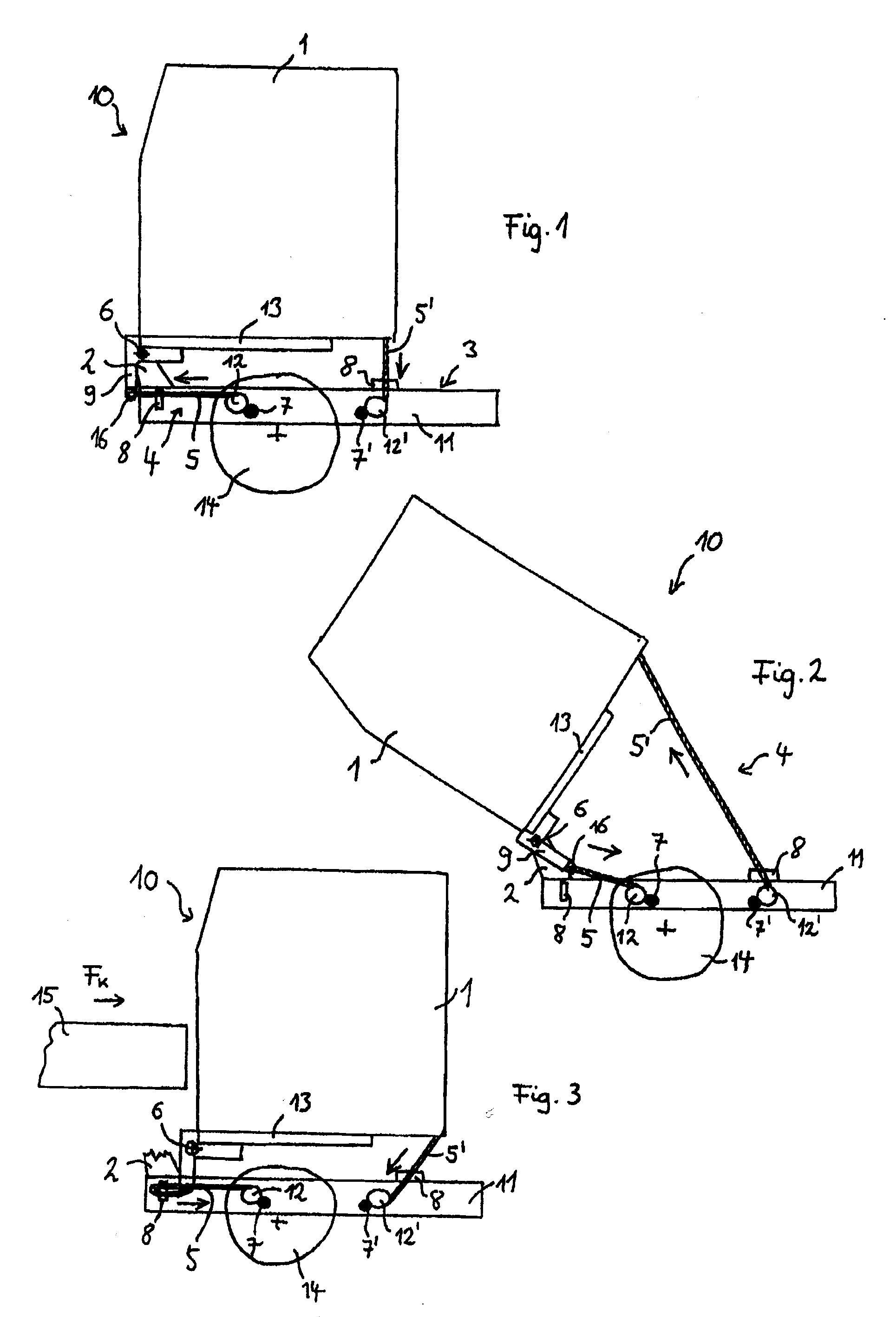

Truck Comprising a Rope-Operated Tilting Device for the Cab

InactiveUS20080265625A1Simple structureFunction can be ensuredVehicle seatsUnderstructuresHead-on collisionEngineering

A truck has a cab that is hinged to a chassis via a bearing about a rotational shaft. A tilting device is provided for raising the cab into a forward-tilted open position for access to the engine compartment located thereunder, and the cab is able to be fixed in the closed position to the chassis. The tilting device includes at least one tractive element that may be actuated via a drive for raising and closing the cab. The tractive element is mounted between the cab and the chassis such that in the case of a head-on collision with an obstruction, level with the cab, it forms a catching device for the cab.

Owner:DAIMLER AG

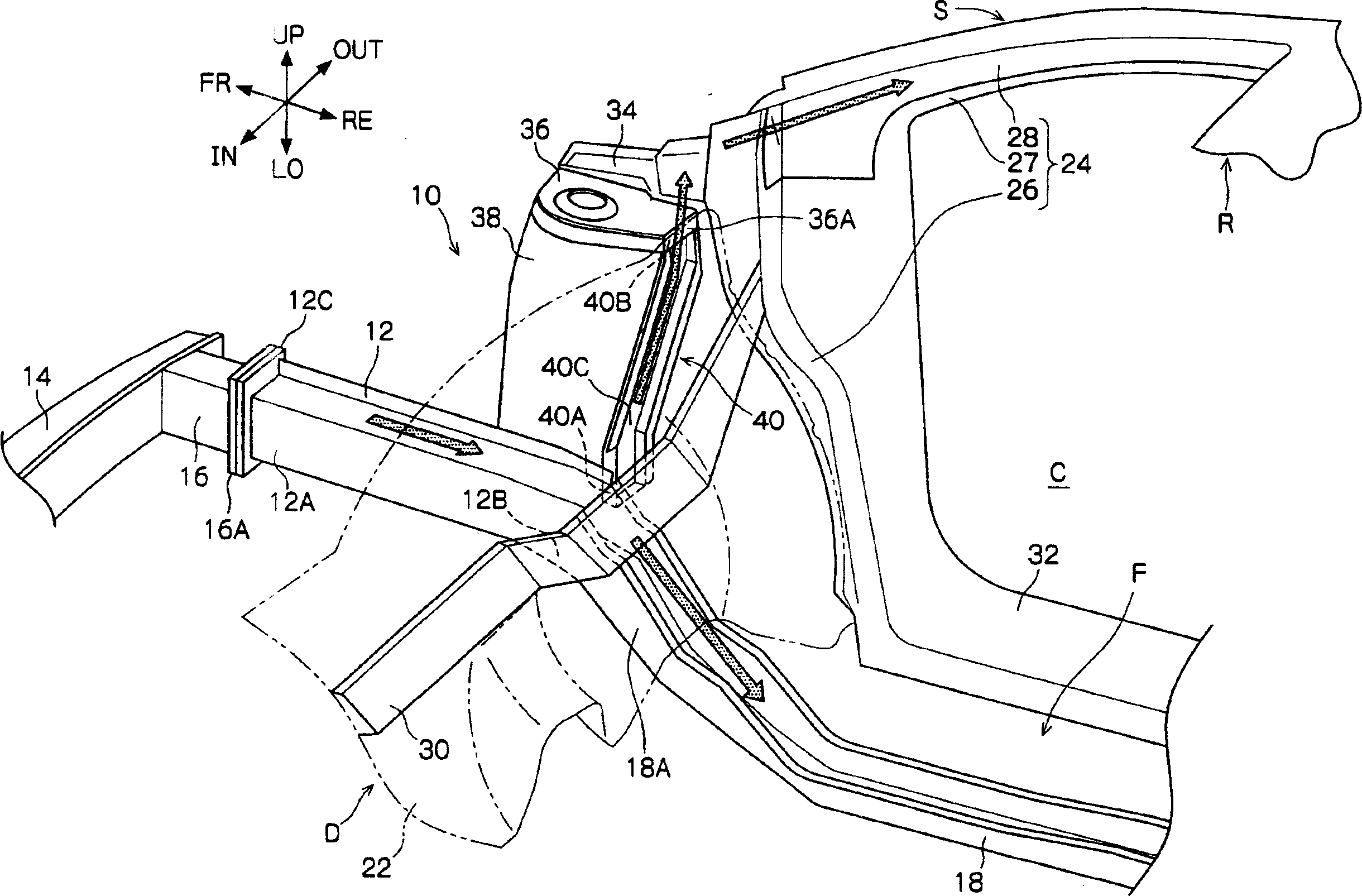

Vehicle body foreside structure

InactiveCN1824563AAvoid deformationUnderstructuresSuperstructure subunitsHead-on collisionAerospace engineering

Provided is a vehicle body front structure capable of suppressing cabin deformation when the vehicle makes head-on collision while the weight of the vehicle body is suppressed. The vehicle body front structure is equipped with a front side member whose longitudinal direction stretches fore and aft of the vehicle and with the front end coupled with a bumper reinforcement, a floor under reinforcement with its front end coupled with the tail of the front side member and supporting the load input to the front side member from the bumper reinforcement, a front pillar reinforcement with its rear top coupled with the roof structure of the body and reinforcing the front pillar upper, and a coupling member to couple the tail of the front side member with the front bottom of the front pillar reinforcement and transmitting part of the load input to the front side member from the bumper reinforcement to the front pillar.

Owner:TOYOTA JIDOSHA KK

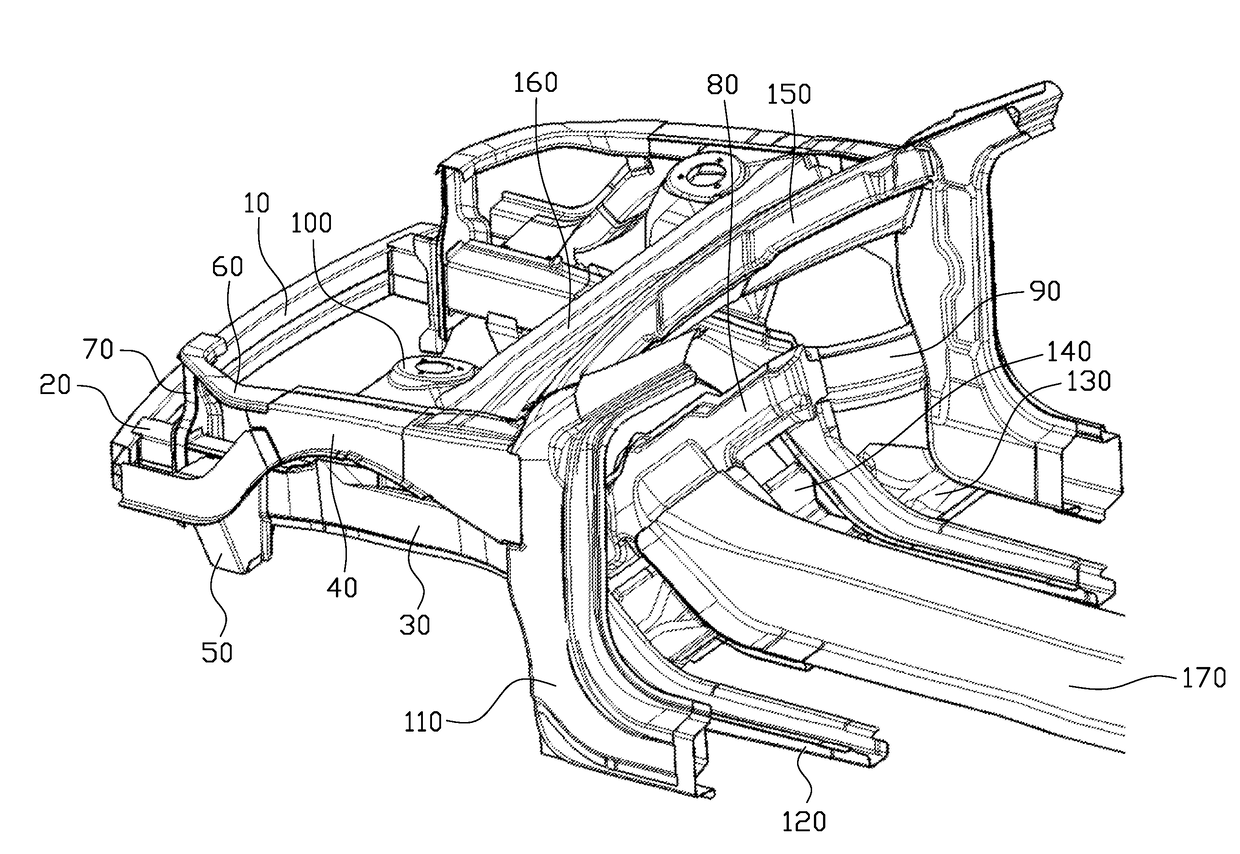

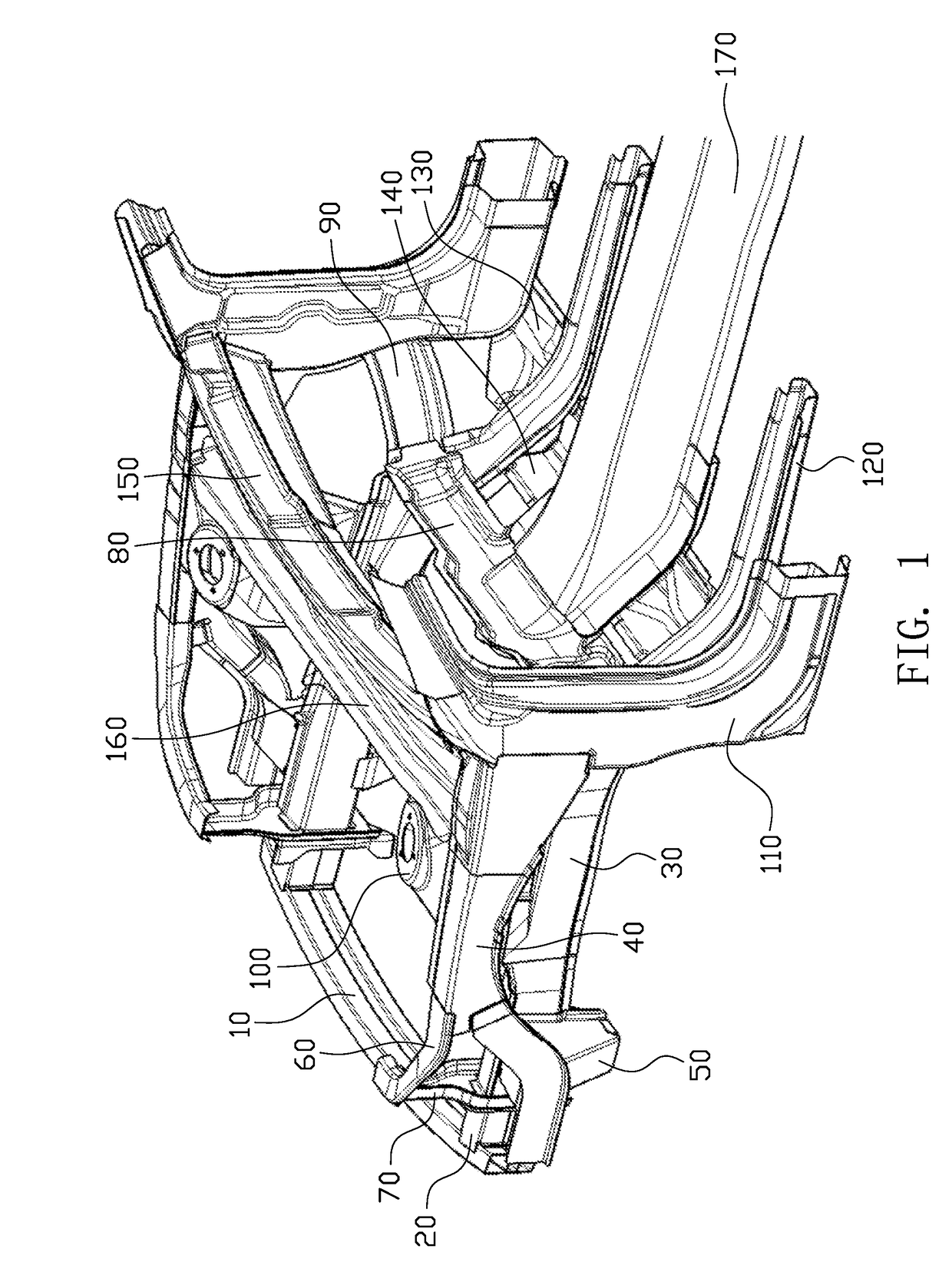

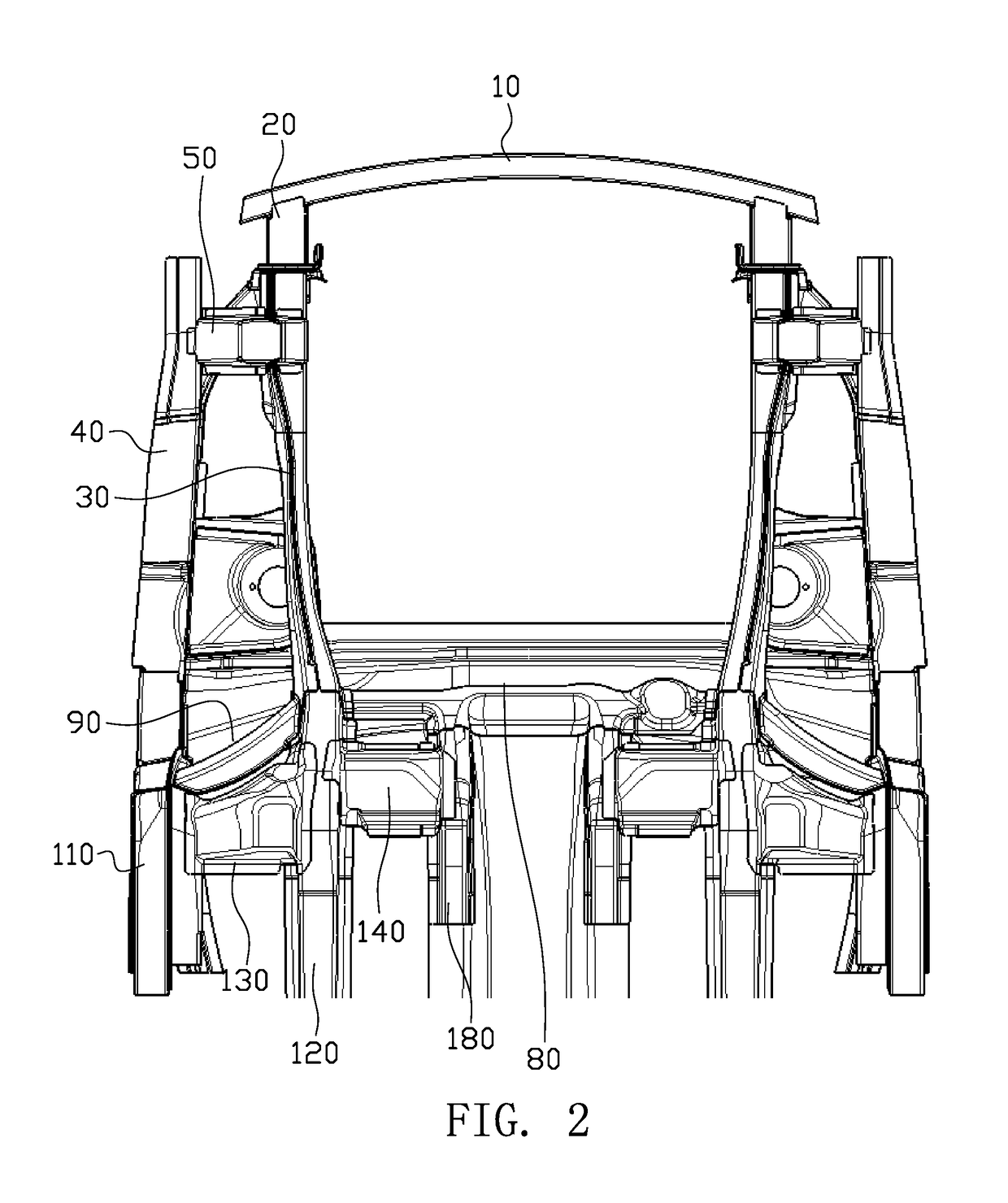

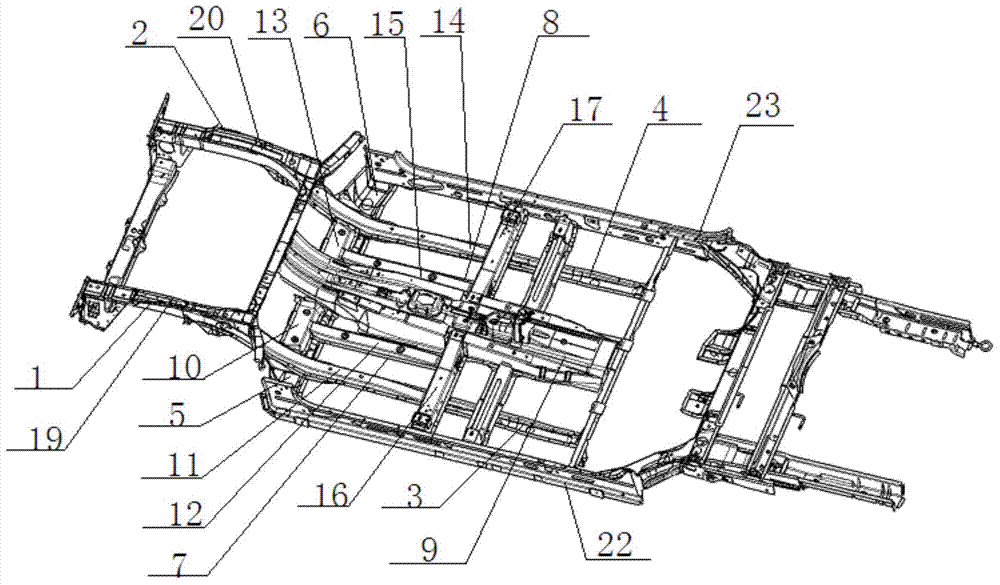

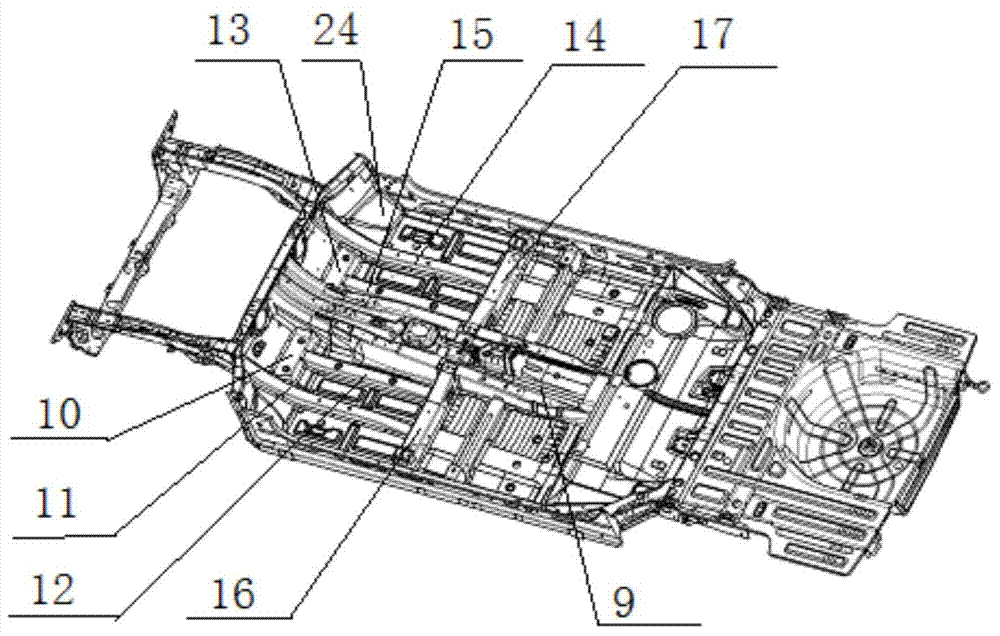

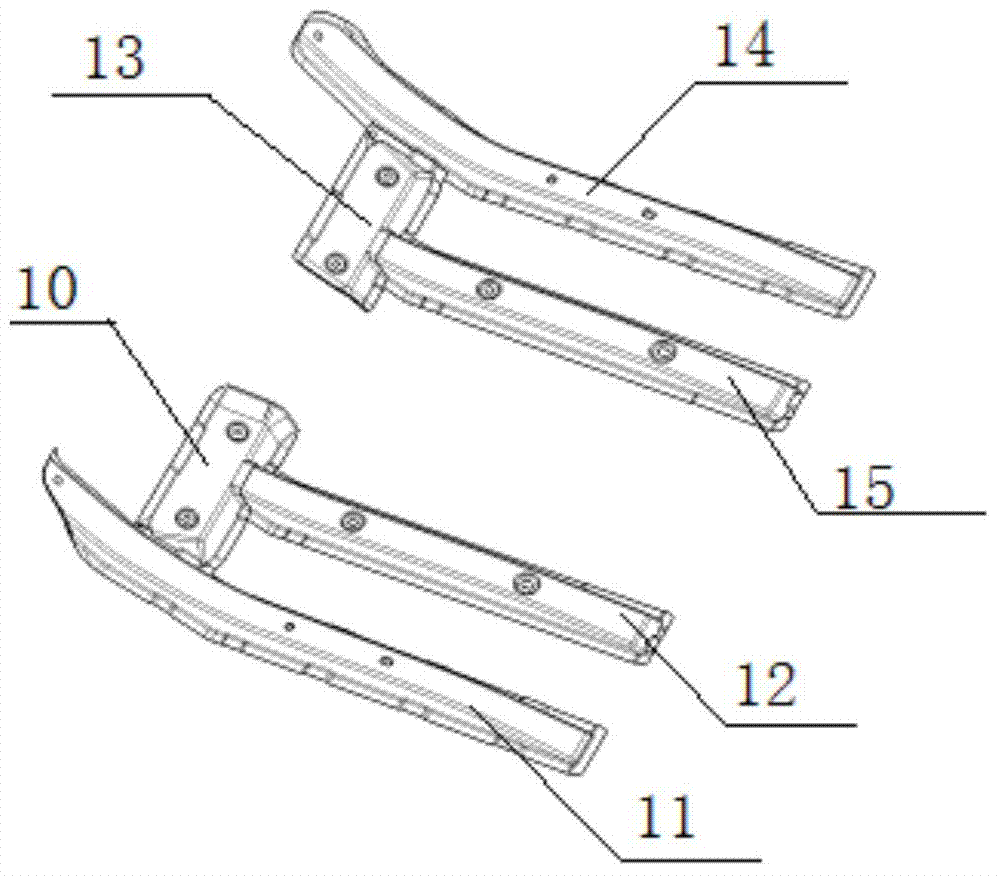

Front cabin frame assembly

ActiveUS20180201326A1Reduce deformationReduce injuriesUnderstructuresSuperstructure subunitsHead-on collisionEngineering

A front cabin frame assembly includes a front beam front section, an upper side beam, a cowl reinforcement crossbeam, a cowl outer reinforcement and an A-pillar. A front end of the front beam front section is laterally connected with a front end of the upper side beam. A root portion of the front beam front section is connected with the cowl reinforcement crossbeam. A root portion of the upper side beam is connected with the A-pillar. The cowl outer reinforcement is connected with the root portion of the front beam front section and the A-pillar. The front cabin frame assembly could effectively absorb the head-on collision energy and has reasonable load transfer paths, which improves the flexural and torsion stiffness, the collision safety and NVH performance of the entire vehicle.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

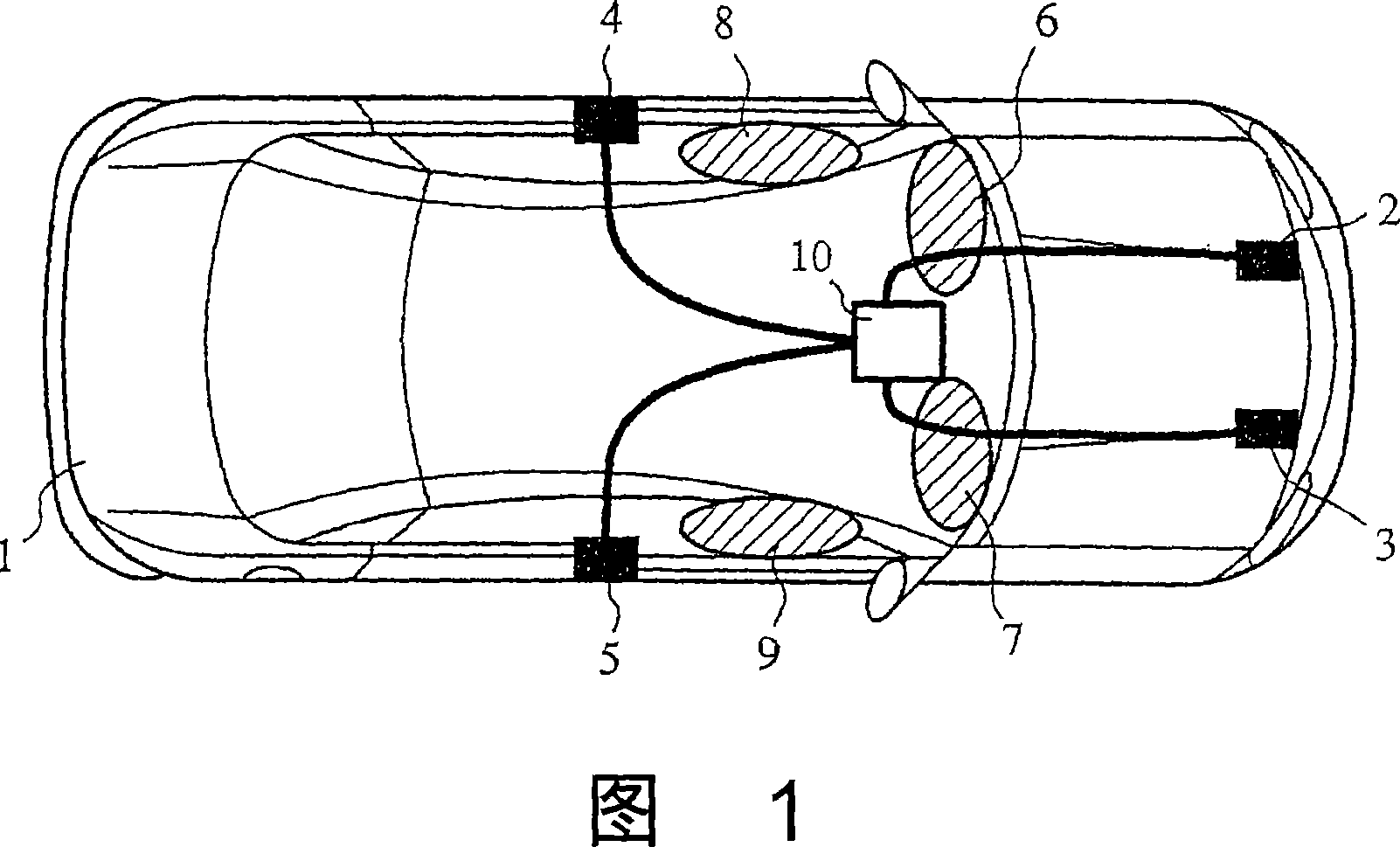

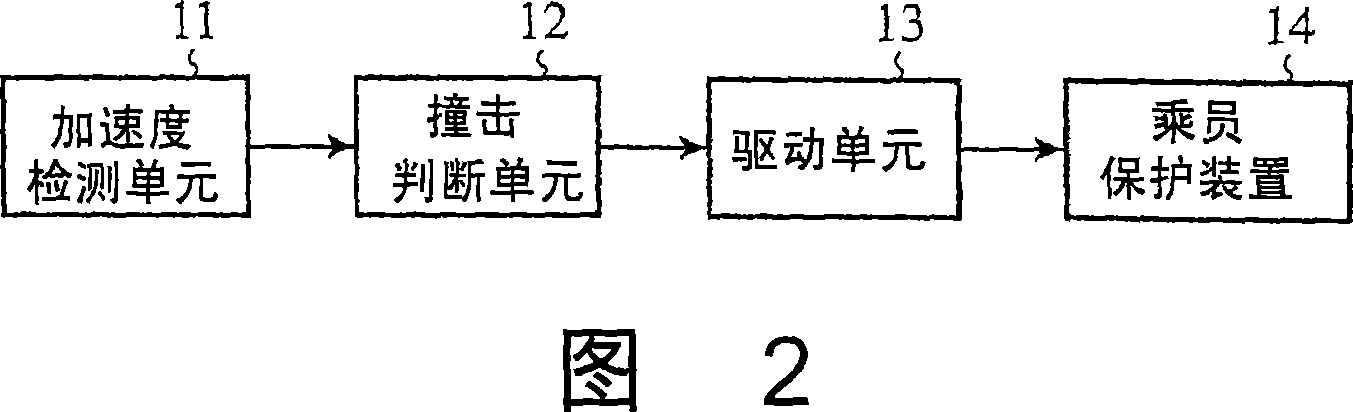

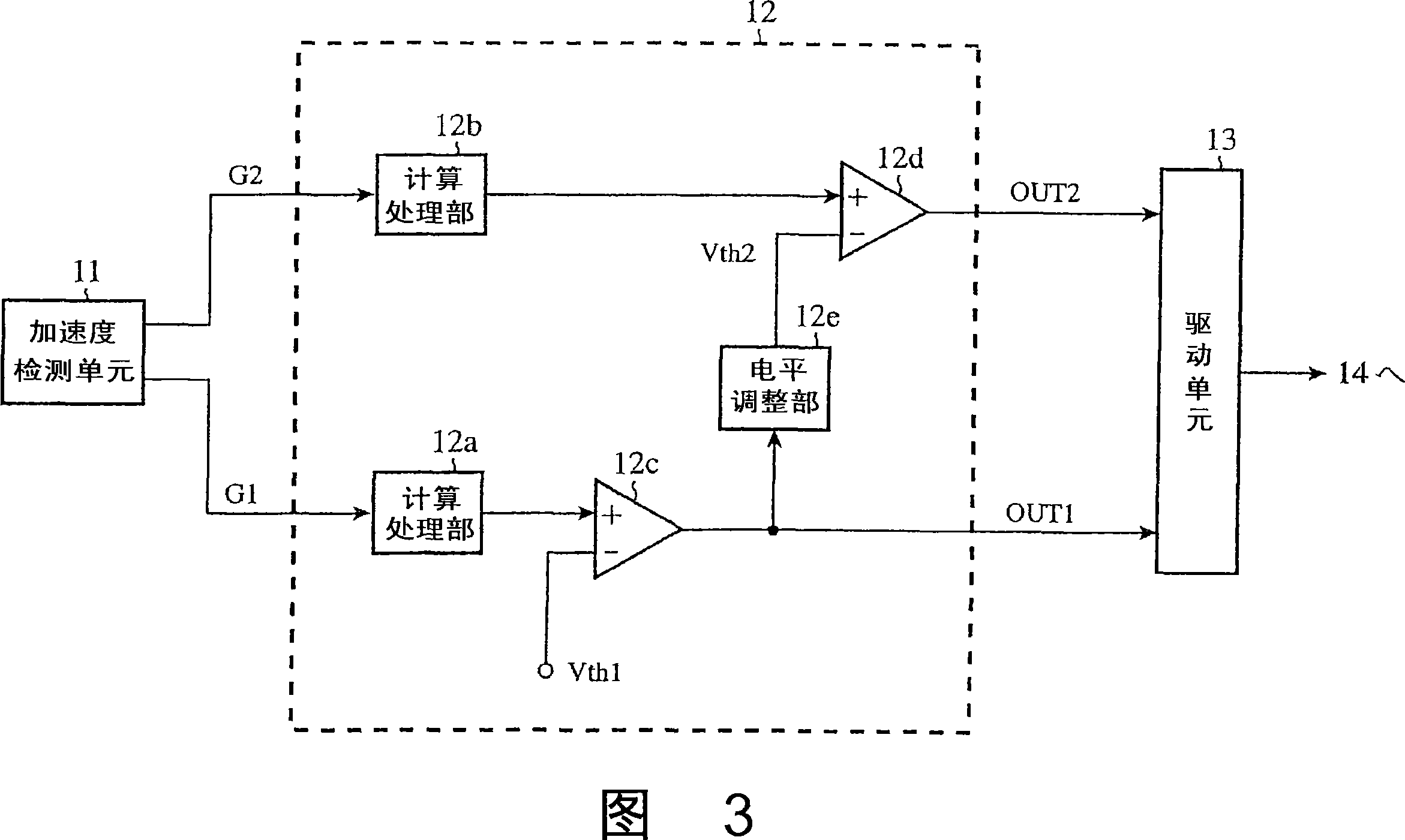

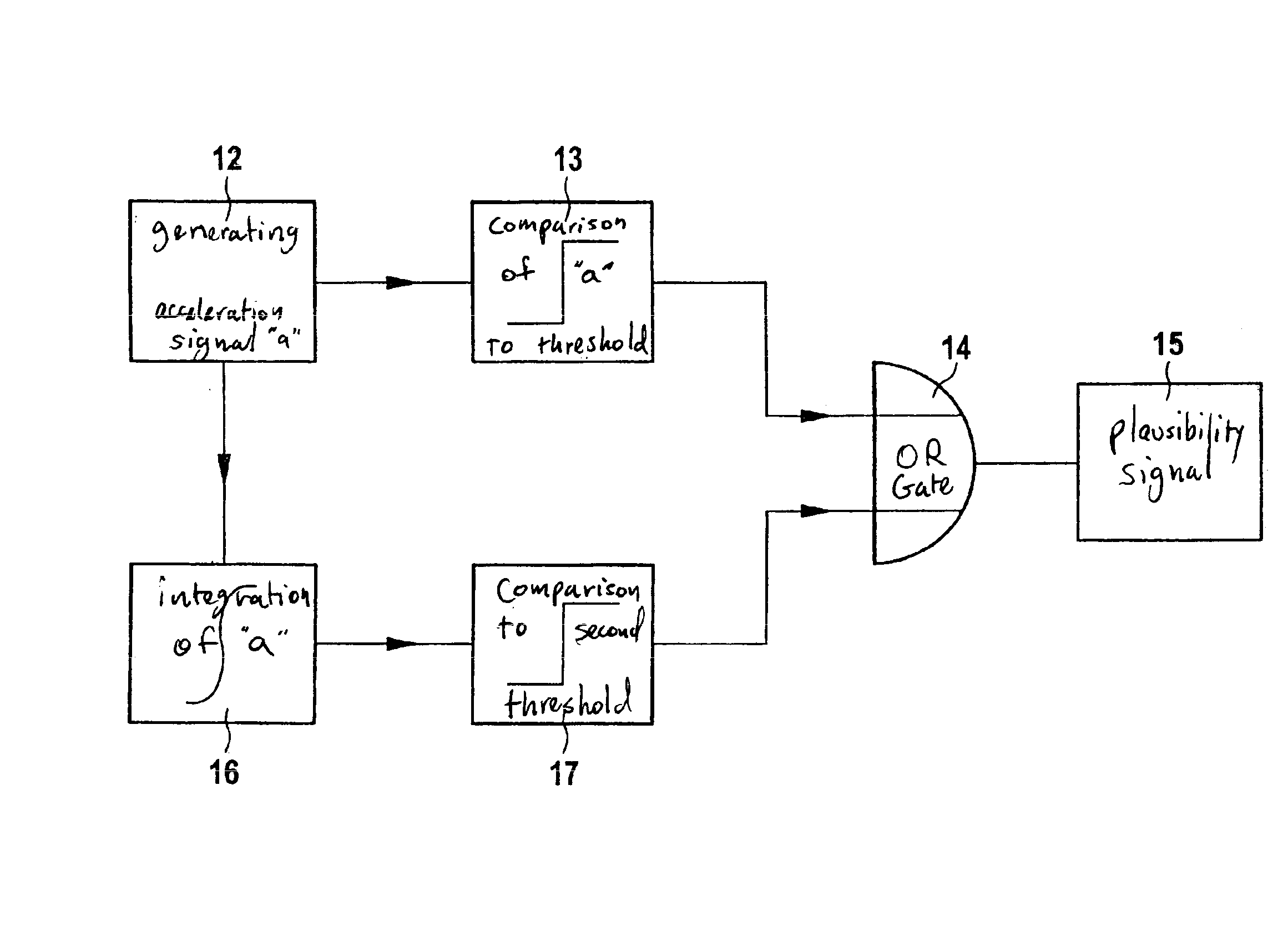

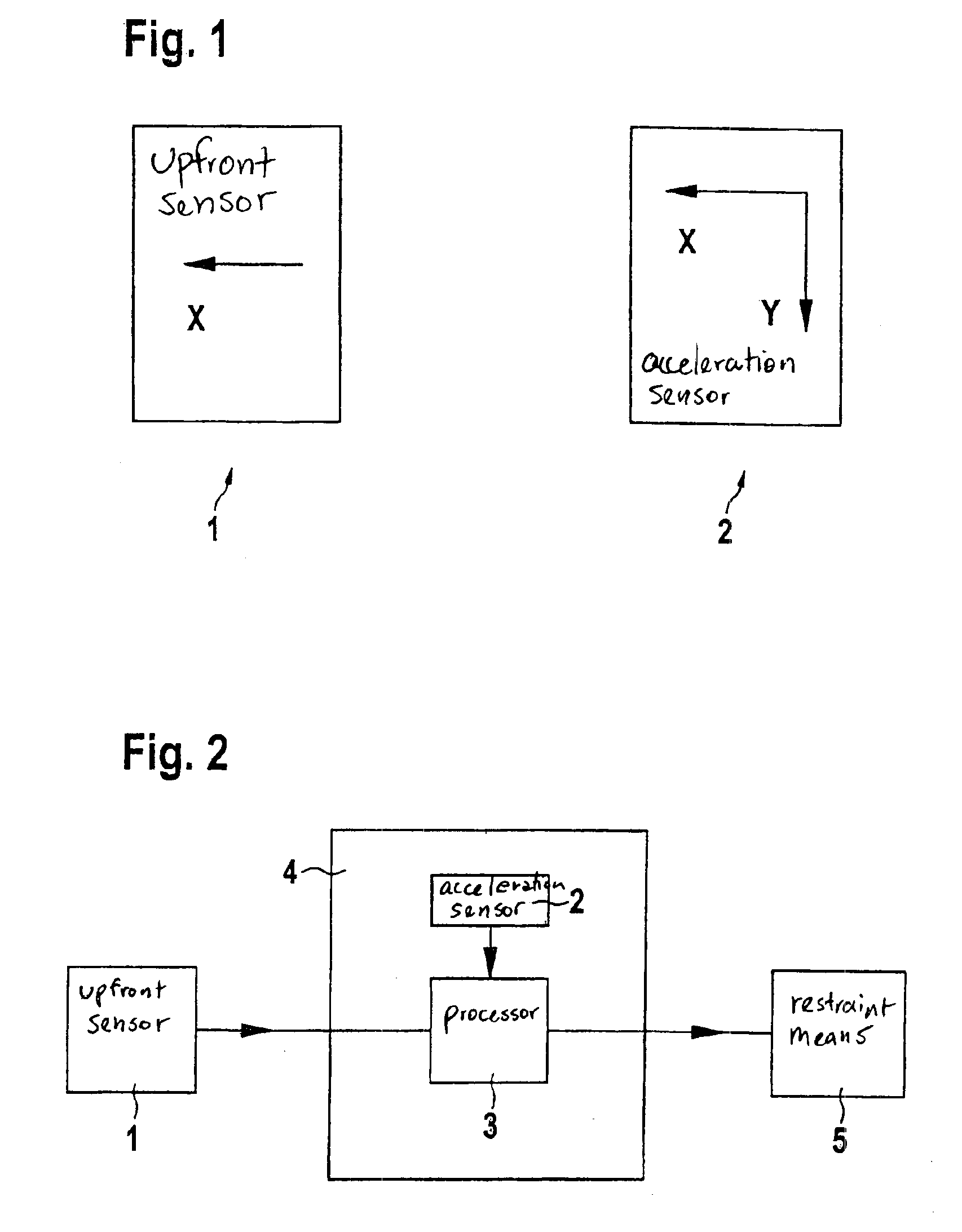

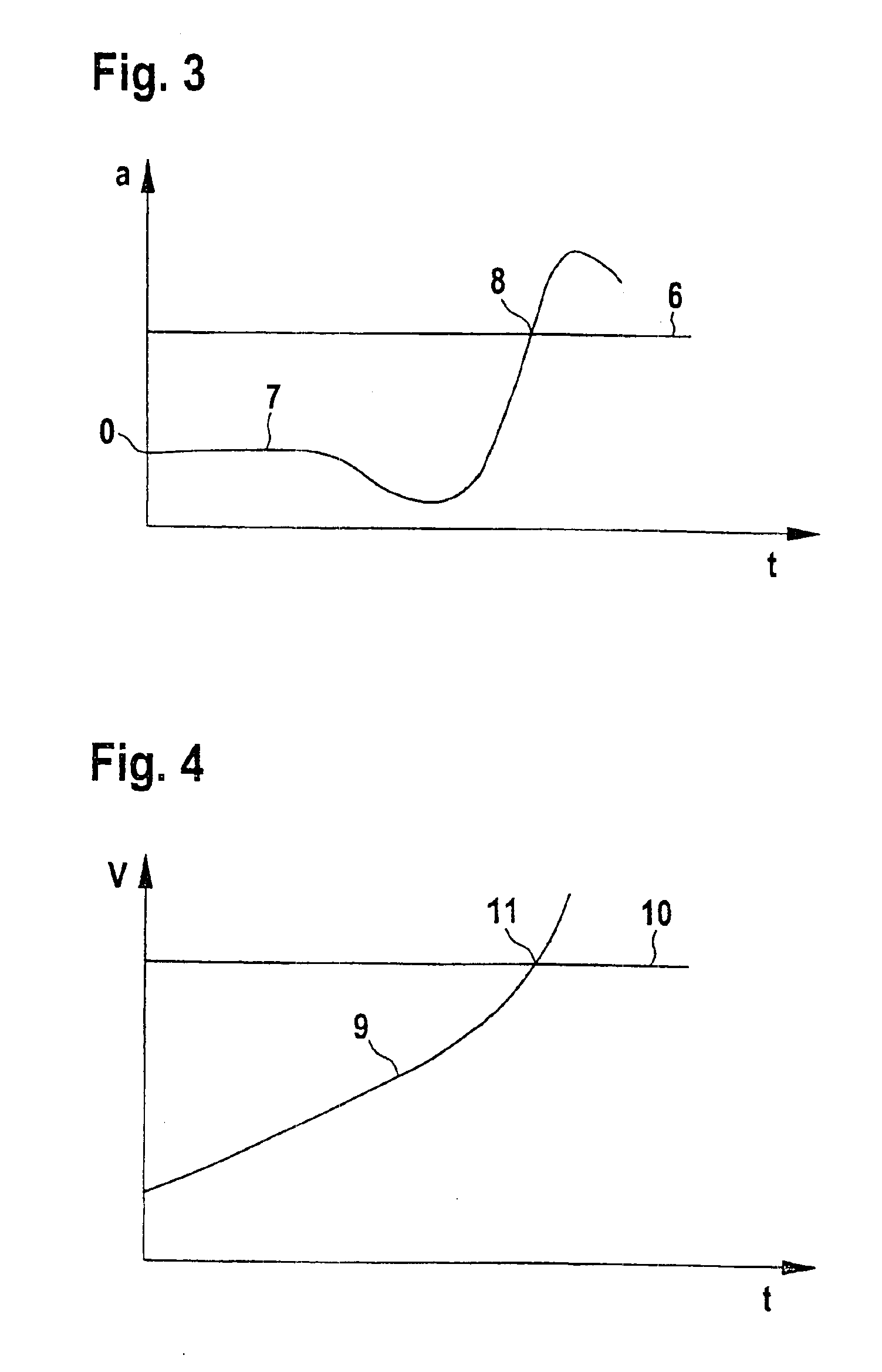

System for sensing a head-on collision in a motor vehicle

InactiveUS6906622B2Improve reliabilityIncreased safety marginArrangements for variable traffic instructionsBelt retractorsMobile vehicleHead-on collision

A system for sensing a head-on collision in a vehicle, where at least one upfront sensor is used as plausibility sensor, which provides a plausibility signal for a collision sensor located in the control device. The upfront sensor may be an acceleration sensor, which analyzes both the acceleration signal as well as the speed signal derived therefrom for a plausibility check. The results of this check are linked in an OR-operation in order to generate a plausibility signal. In an example embodiment, it is provided to buffer-store the plausibility signal in the control device for a predetermined time. This is of special interest for improved reliability in the event that the upfront sensor has been destroyed.

Owner:ROBERT BOSCH GMBH

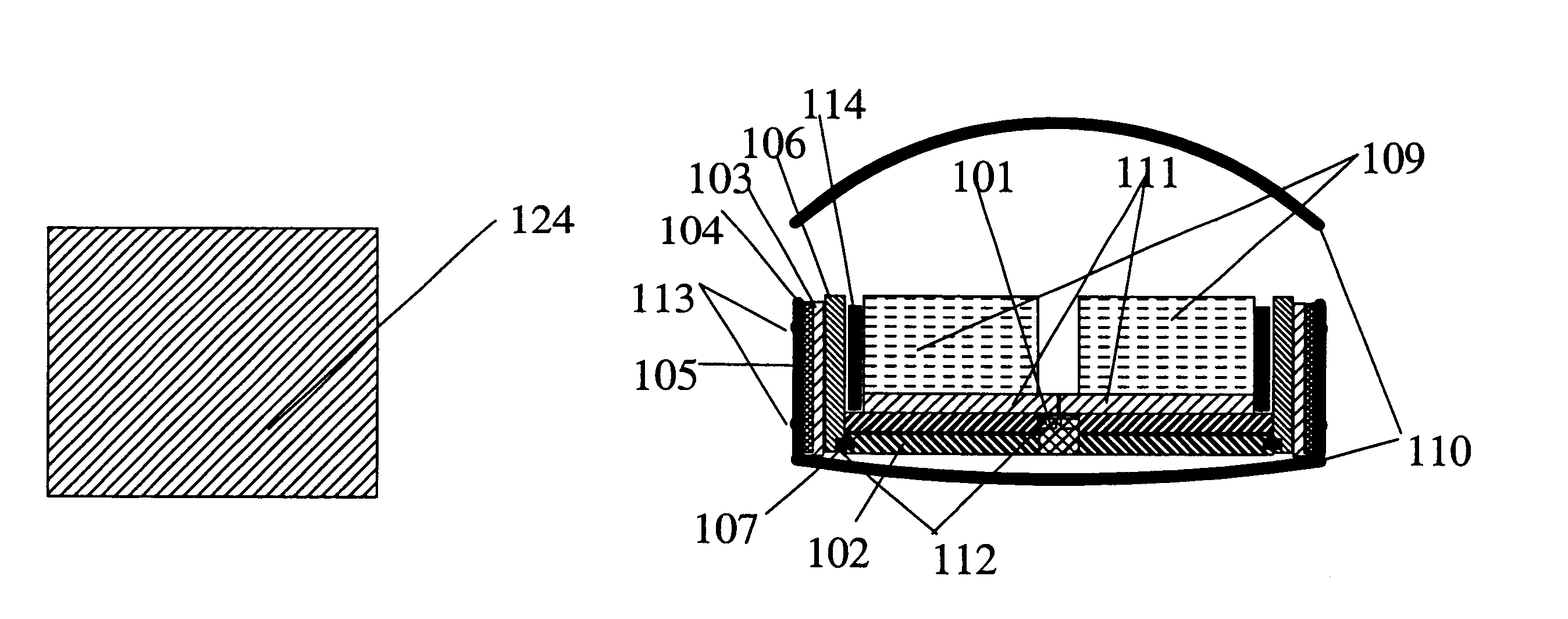

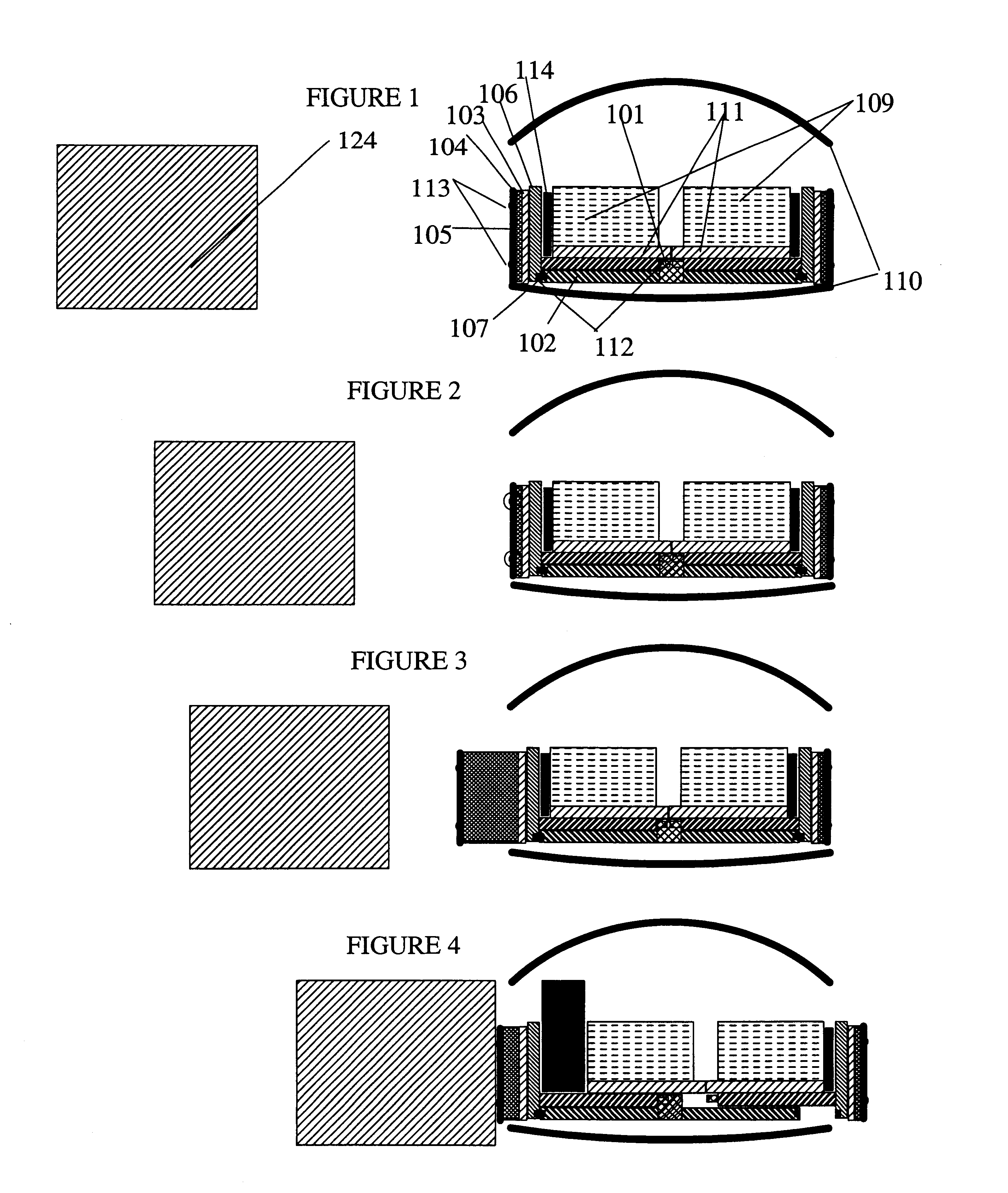

Electromagnetic active anticollision device for automobile

The invention discloses an electromagnetic active anticollision device for an automobile. The electromagnetic active anticollision device comprises a rigid inner protective frame, an energy absorption mechanism, a crush resisting and damping mechanism, an electromagnetic field safety shielding cover and a rigid outer protective frame. The energy absorption mechanism is a push-pull mechanism mainly composed of a plurality of electromagnets and a telescopic connecting piece, the crush resisting and damping mechanism is mainly composed of electromagnets, the energy absorption mechanism and the crush resisting and damping mechanism are connected to the rigid inner protective frame and use the rigid inner protective frame as a supporting point, and the shielding cover and the rigid outer protective frame cover the energy absorption mechanism and the crush resisting and damping mechanism in sequence so as to provide the electromagnetic field shielding function and the rigid anticollision function respectively. The strong and effective energy absorption and crush resisting and damping structure is constructed through a special electromagnet pole layout mainly based on the principle of homopolar repulsion and heteropole attraction of the electromagnets, strong impact force generated by the collision of the automobile is offset to the maximum limit, head-on collisions and rear-end accidents of the automobile are prevented or reduced, and the degree of secondary damage is effectively lowered.

Owner:邱洪武

Vehicle Front Structure

Owner:TOYOTA JIDOSHA KK

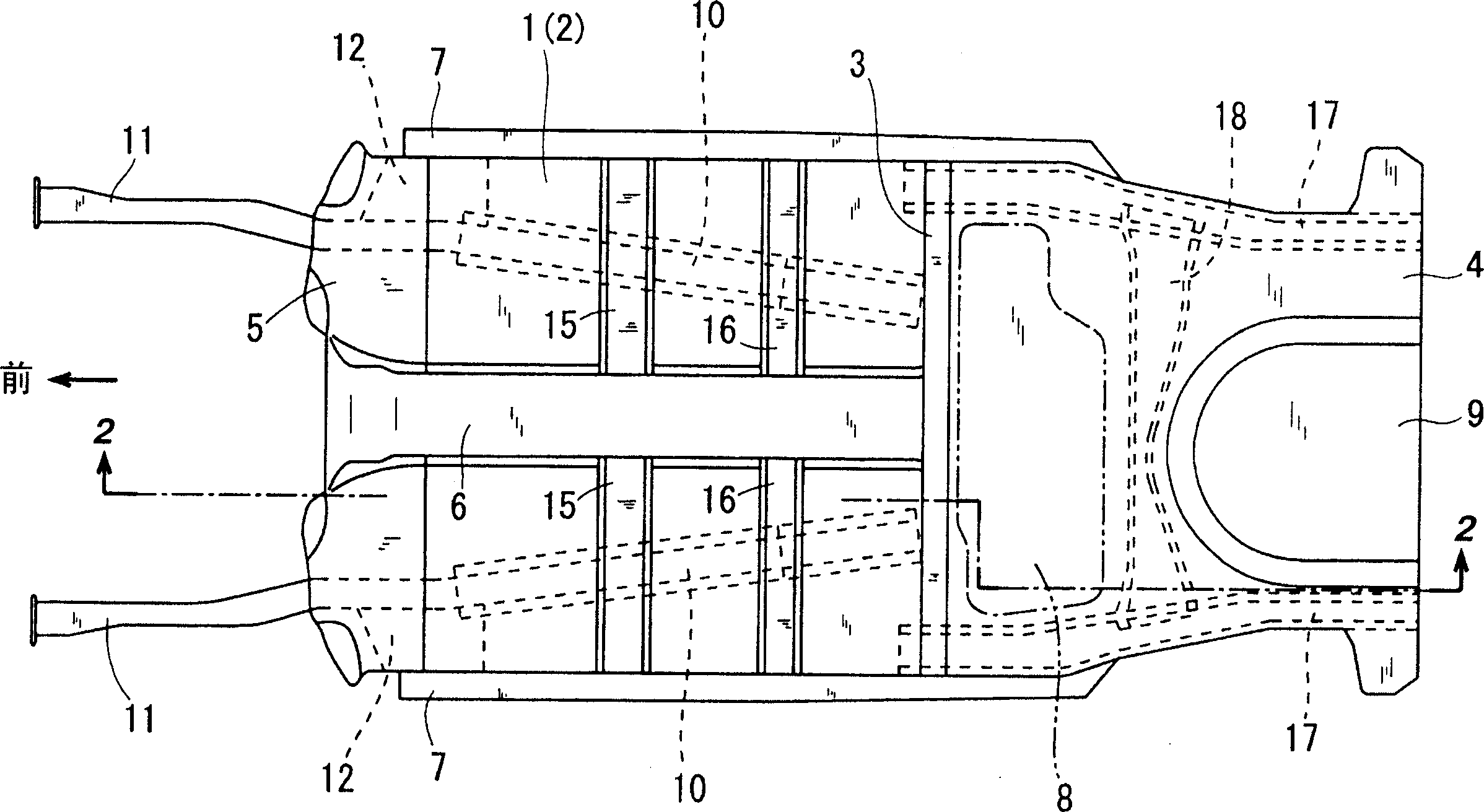

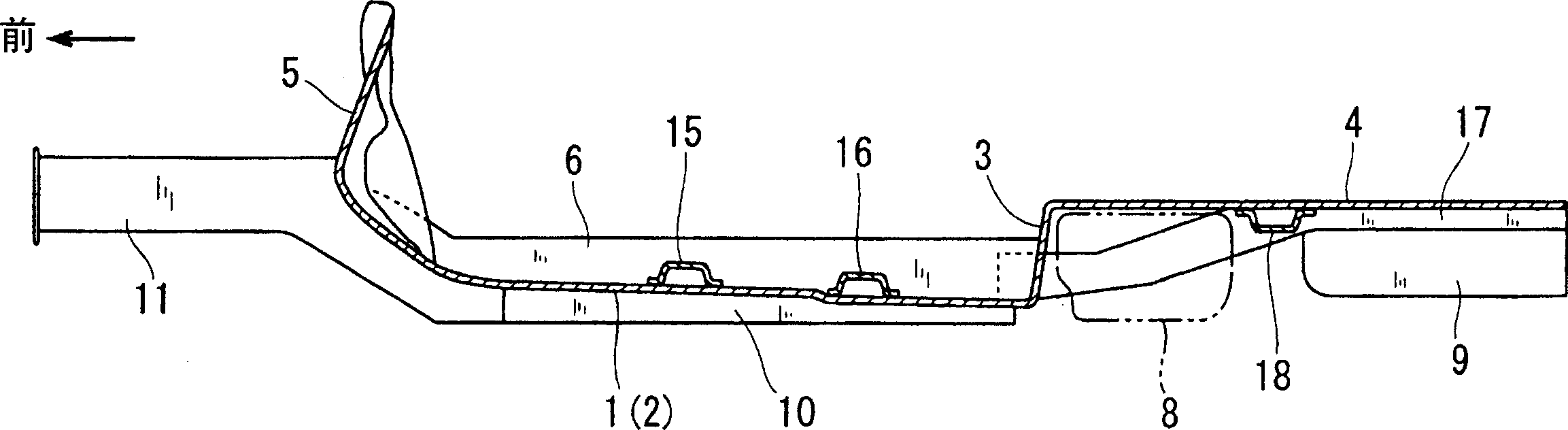

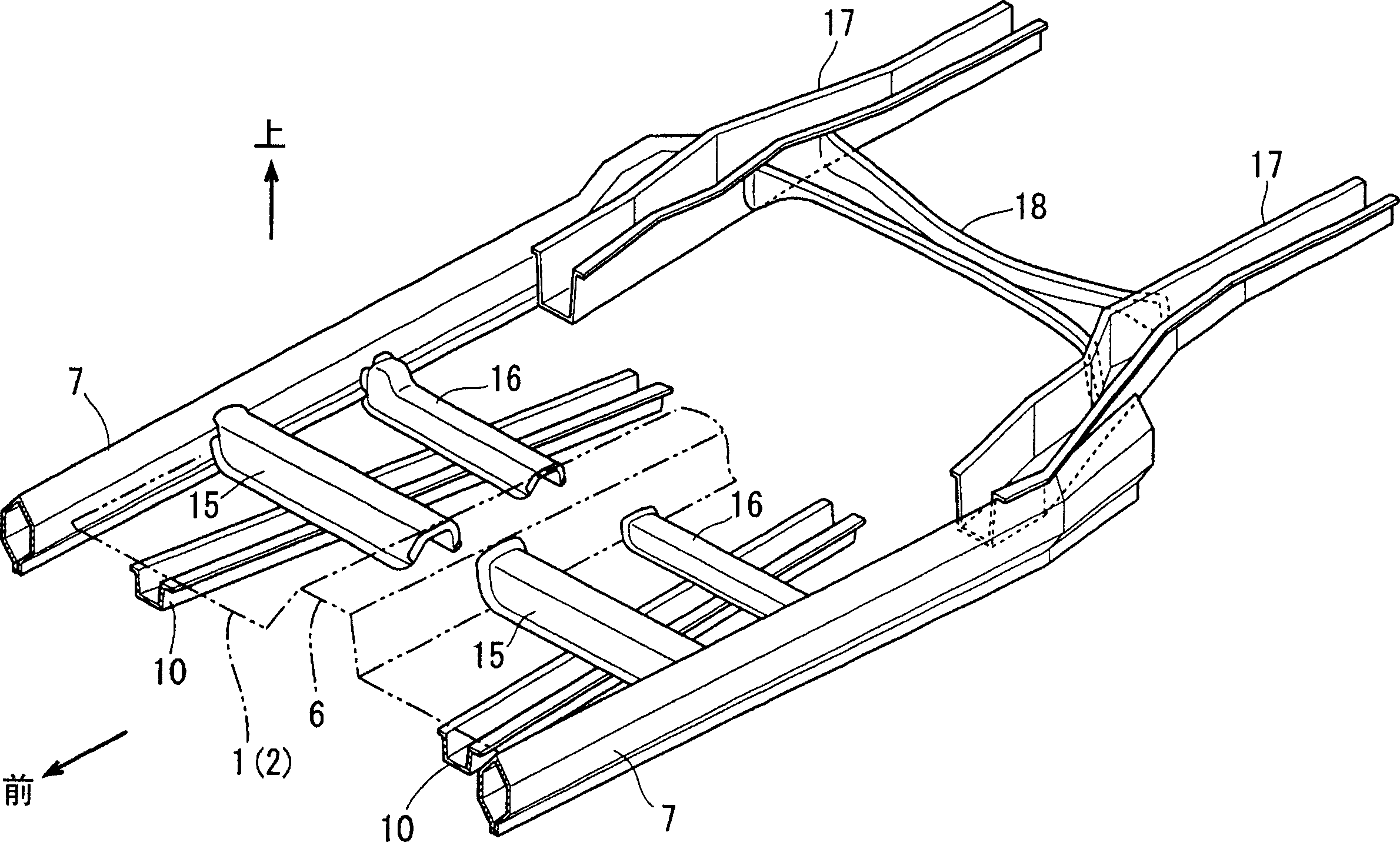

Automobile underbody structure

InactiveCN1751939ABear the loadThe role played when improving shock absorptionUnderstructuresSuperstructure subunitsHead-on collisionEngineering

Owner:MAZDA MOTOR CORP

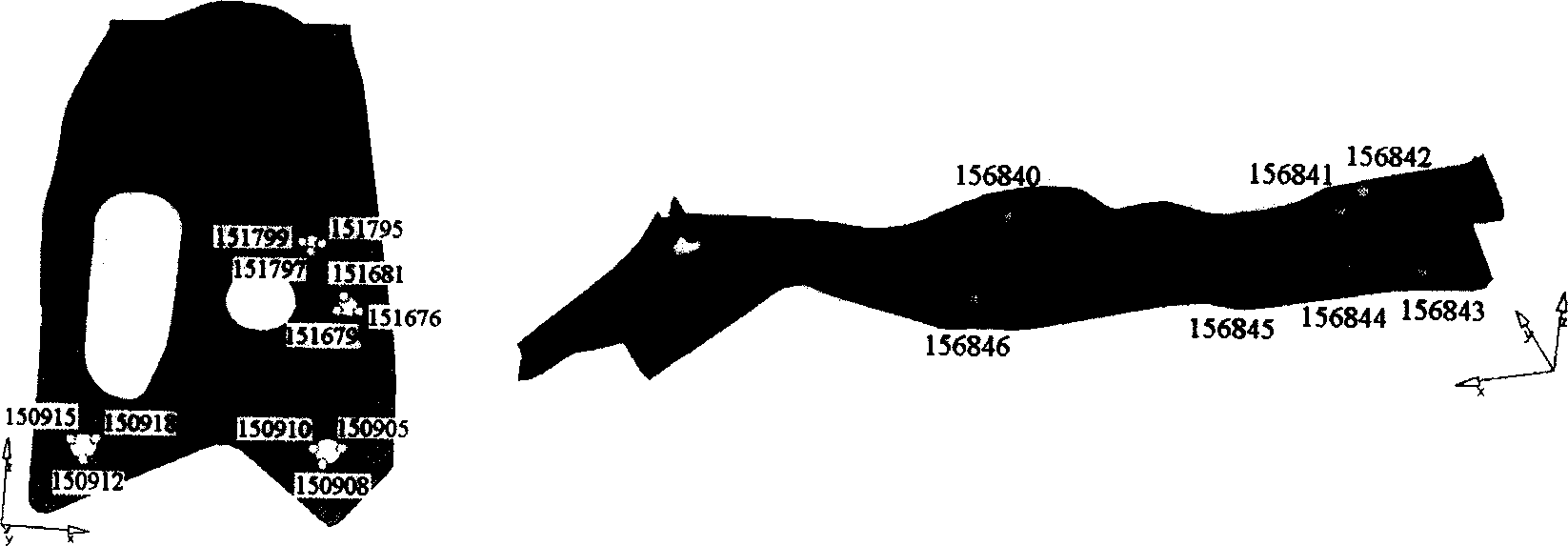

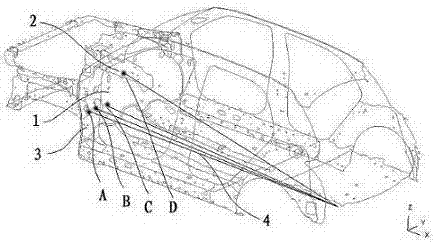

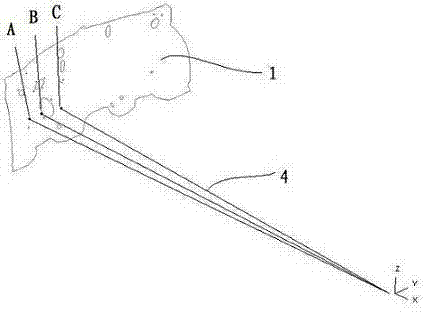

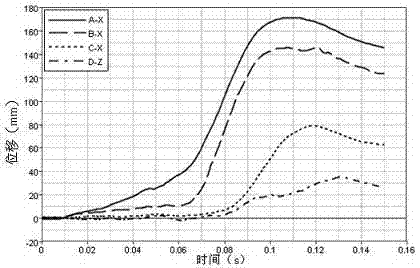

CAE (Computer Aided Engineering)-based method for measuring vehicle body deformation by simulating head-on collision

The invention relates to a CAE (Computer Aided Engineering)-based method for measuring vehicle body deformation by simulating head-on collision. The method comprises the following steps of: establishing a model based on a vehicle body structure; selecting one point from an non-deformation area in a longitudinal beam of a floor at the rear part of a vehicle body as a foundation, and creating a three-direction rigid beam unit; respectively selecting a plurality of measuring target points from a front wall baffle, a column A, an IP beam and a steering tubular column; arranging a three-direction spring unit between each measuring target point and the original point of a beam unit; loading collision conditions according to test requirements to implement the collision simulation; and outputting the deformation in each direction of the three-direction spring unit to each measuring target point of the model subjected to the collision. According to the CAE-based method, the deformations of the front wall baffle, the column A, the IP beam and the steering tubular column which are subjected to the collision are simulated through a computer so as to judge whether the vehicle body structure meets the design requirements, and the test cost in a vehicle design process can be reduced.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

Passenger vehicle front floor framework structure

ActiveCN103523099ASmall amount of deformationThe connection is tight and firmSuperstructure subunitsEngineeringHead-on collision

The invention discloses a passenger vehicle front floor framework structure. A left longitudinal beam connection plate cover plate is arranged above a front floor and corresponds to a left longitudinal beam connection plate, the left end of the left longitudinal beam connection plate cover plate is connected with a front floor left inner longitudinal beam cover plate corresponding to a left inner longitudinal beam, and the middle of the left longitudinal beam connection plate cover plate is connected with a second left inner longitudinal beam cover plate corresponding to a second left inner longitudinal beam. A right longitudinal beam connection plate cover plate is arranged above the front floor and corresponds to a right longitudinal beam connection plate, the right end of the right longitudinal beam connection plate cover plate is connected with a front floor right inner longitudinal beam cover plate corresponding to a right inner longitudinal beam, and the middle of the right longitudinal beam connection plate cover plate is connected with a second right inner longitudinal beam cover plate corresponding to a second right inner longitudinal beam. Reinforcing parts are ingeniously added above the floor, the longitudinal rigidity of a front floor framework beam and the strength of a front bracket rear installation point are improved, the deformation amount of the inner longitudinal beams in the collision process and the backward movement amount of the front bracket rear installation point are decreased, a living space of passengers is further enlarged, and the head-on collision performance of a passenger vehicle is improved.

Owner:DONGFENG MOTOR CORP HUBEI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com