Patents

Literature

101 results about "Suspension tower" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In an electric power transmission line, a suspension tower is where the conductors are simply suspended from the tower, the mechanical tension being the same on each side. In this case, the tower is supposed to carry a downward force, and a lateral force, but not a longitudinal force.

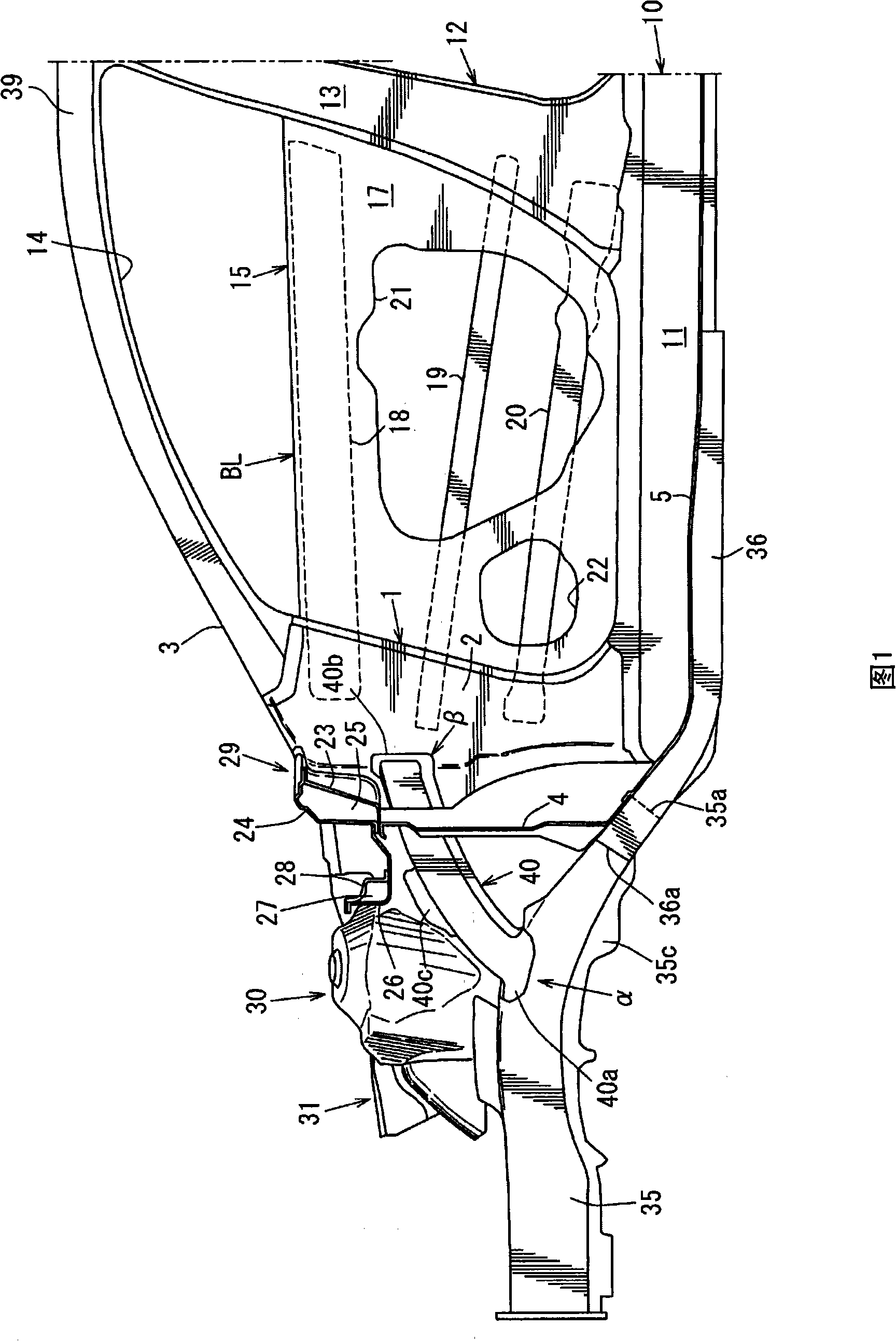

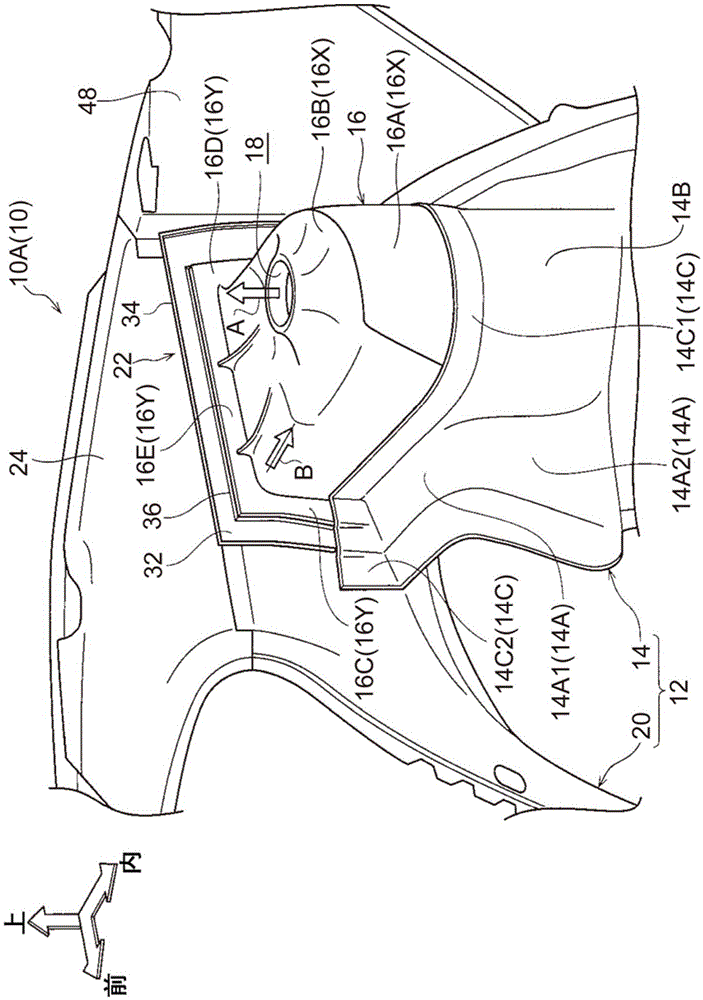

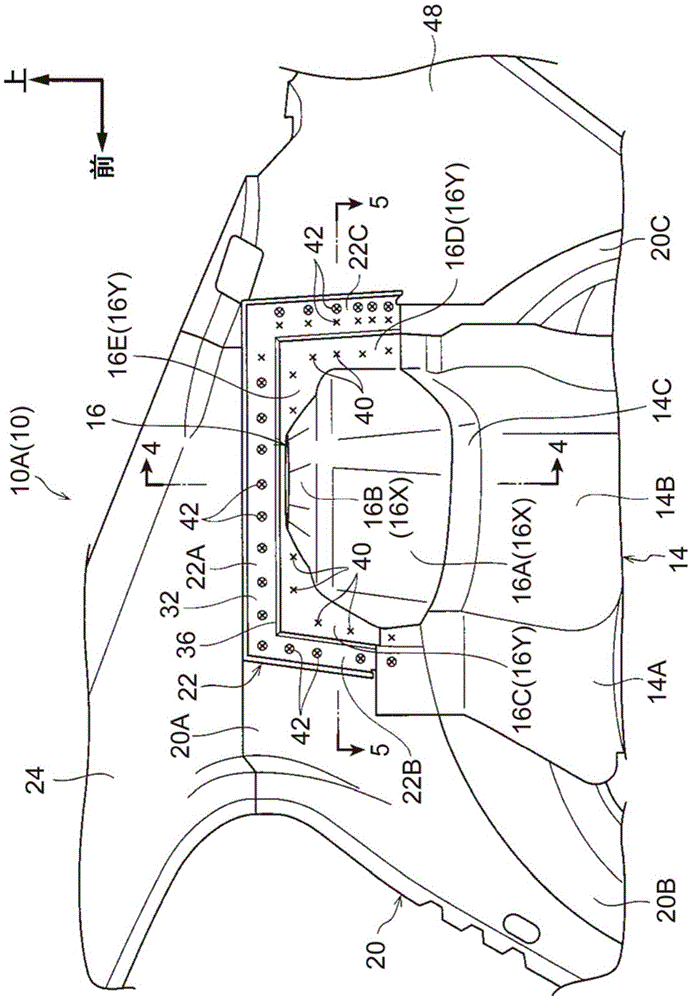

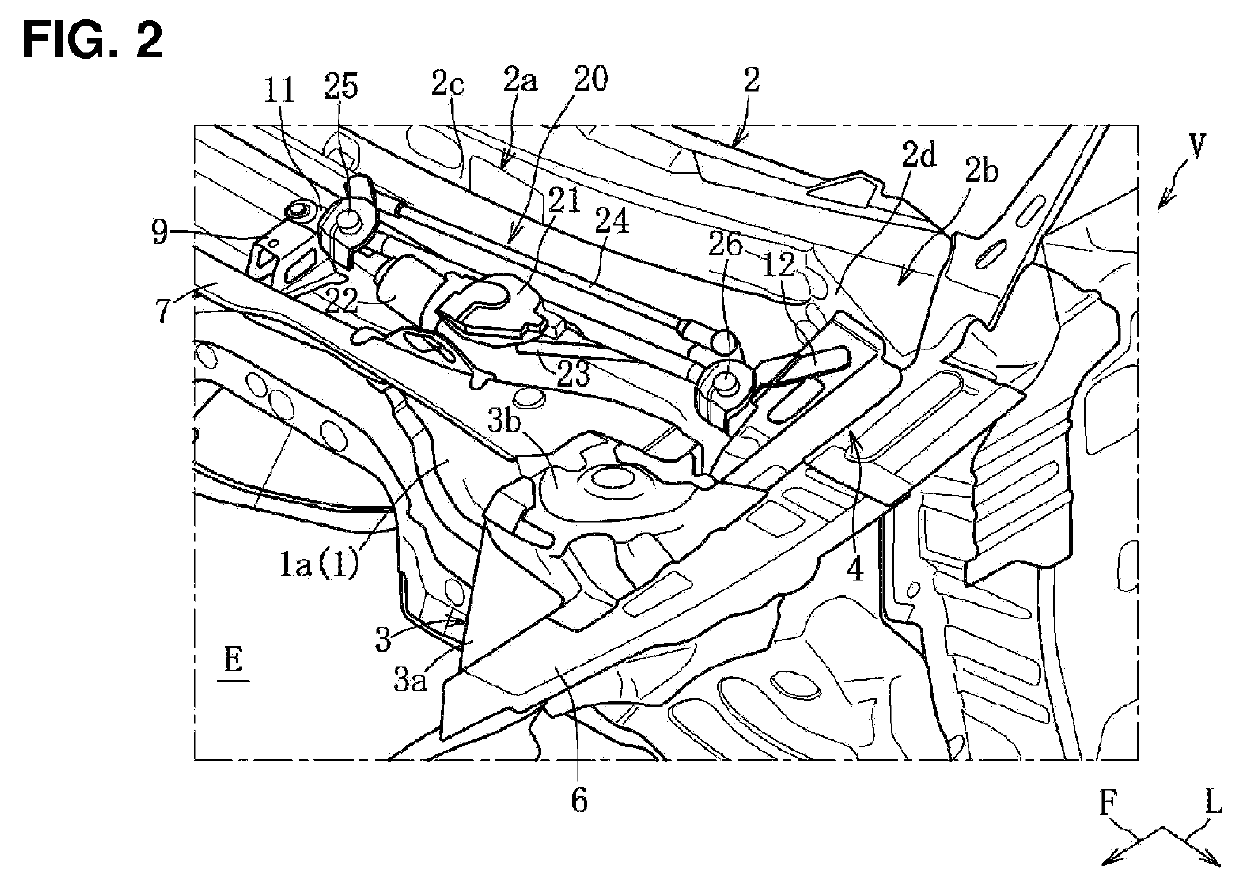

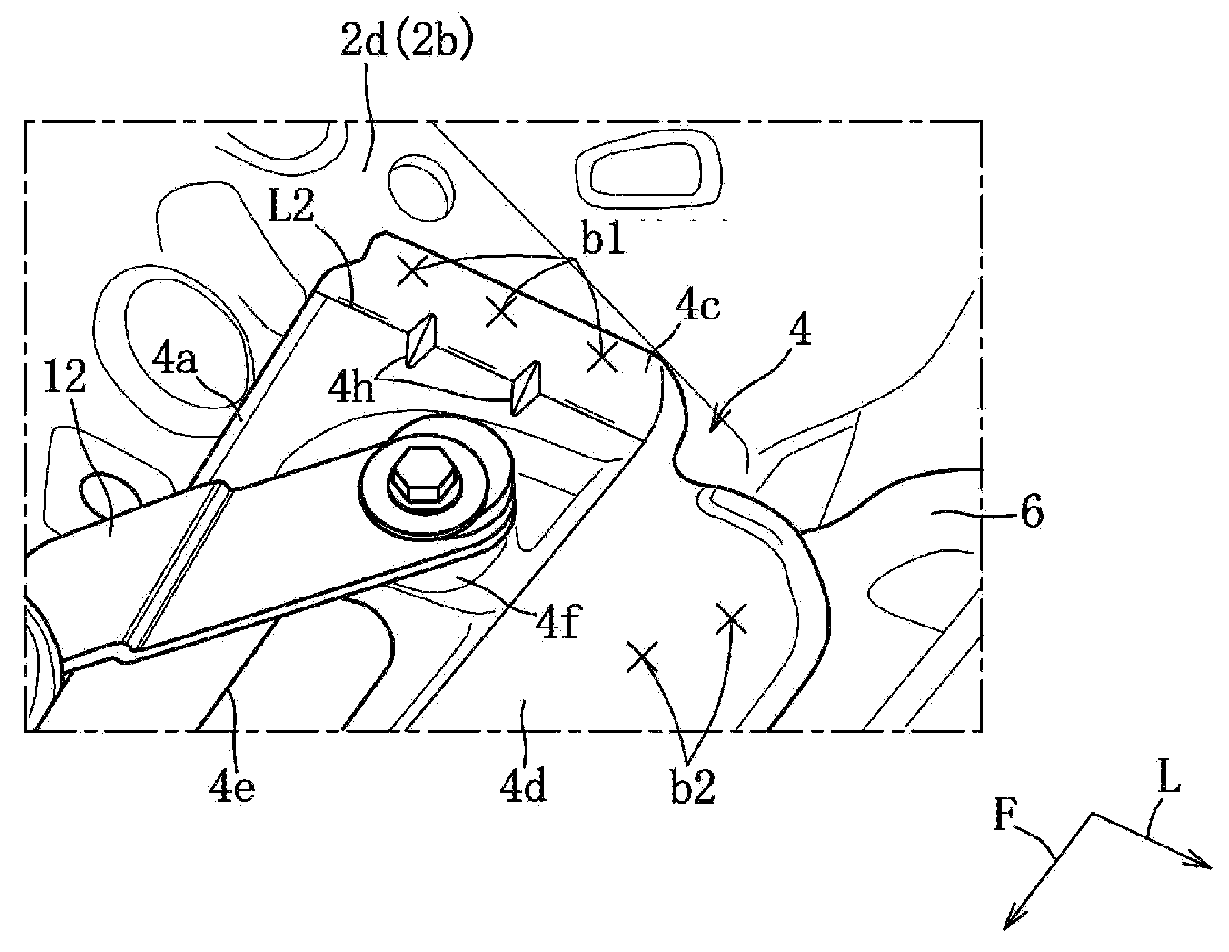

Vehicle front body structure

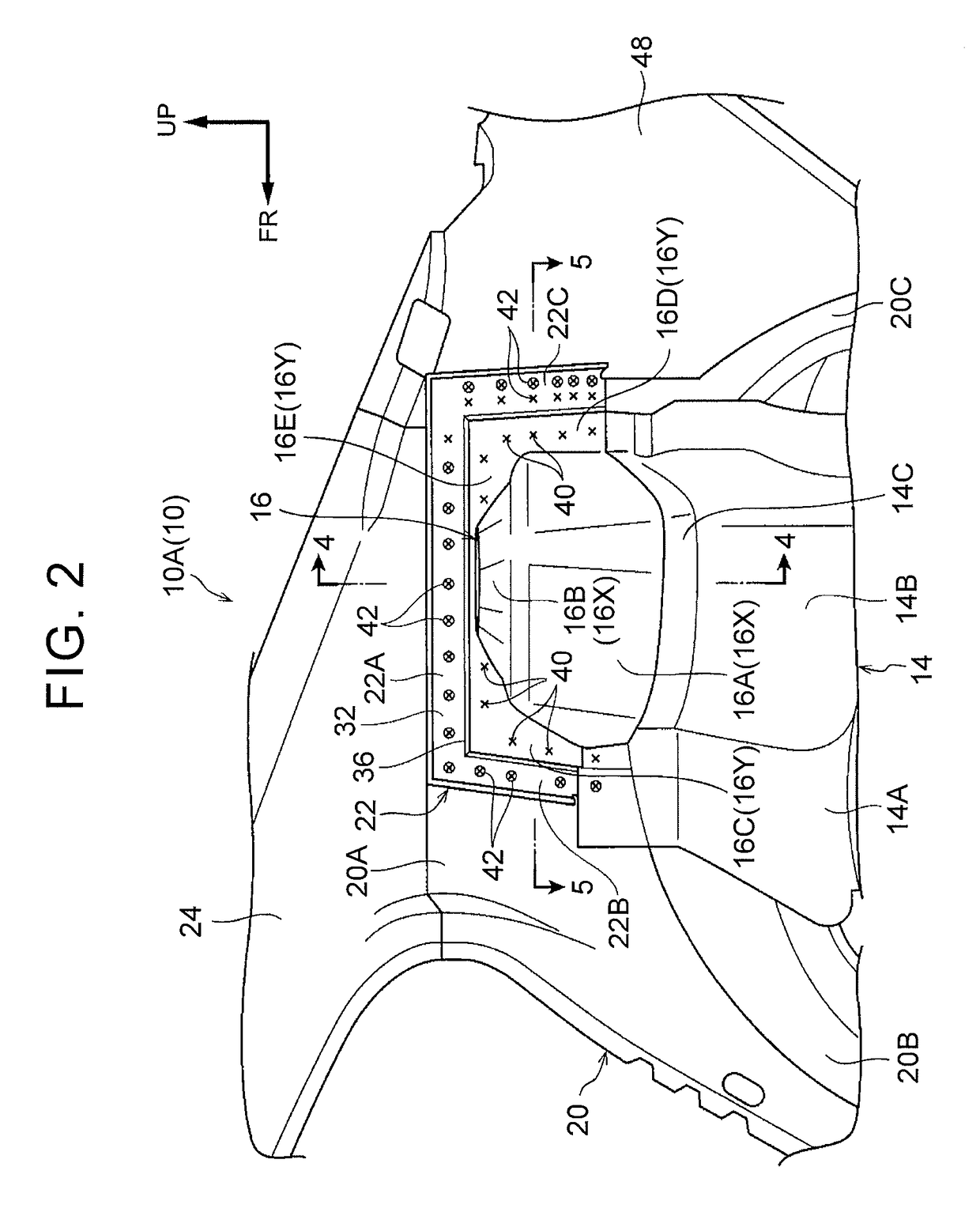

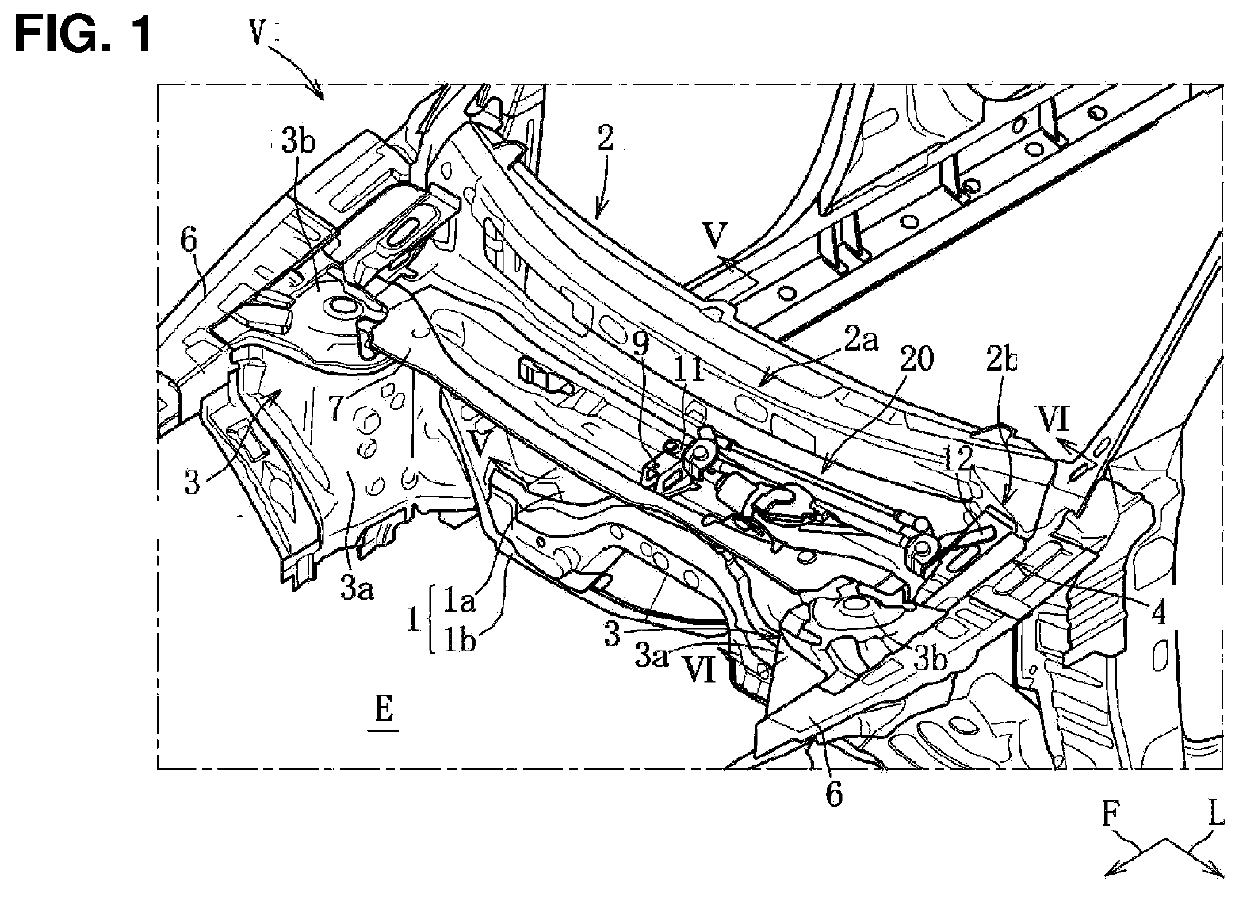

A bridge-shaped frame member is disposed on a front side frame in front of a suspension tower so as to extend vertically and stride over a No. 4 mount. Accordingly, there can be provided a vehicle front body structure that can attain a proper energy absorption of the front side frame with its axial compression can be attained at a vehicle crash.

Owner:MAZDA MOTOR CORP

Vehicle front body structure

InactiveCN101037118AImprove the delivery effectImprove impact absorption performanceSuperstructure subunitsSuspension towerAxial compression

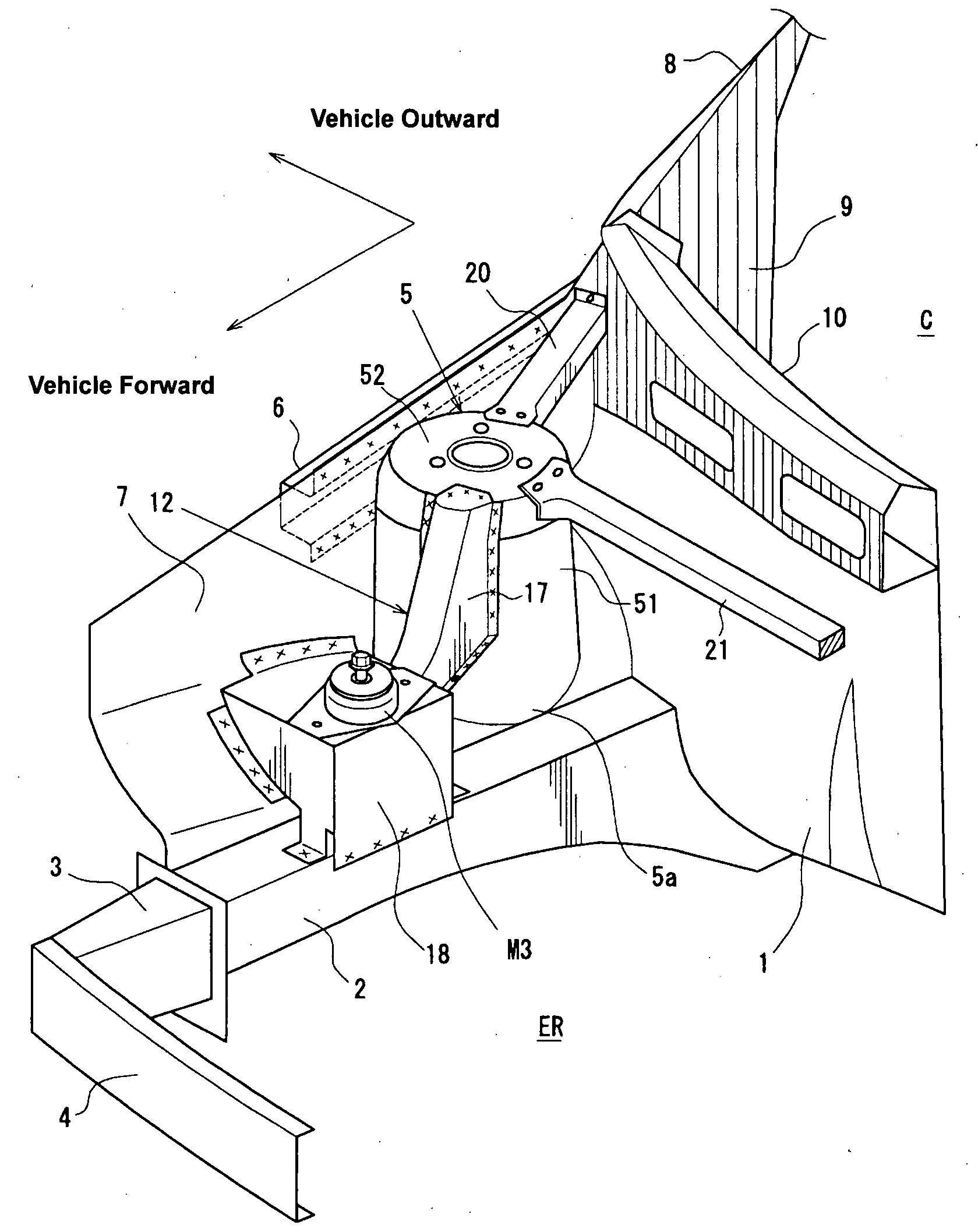

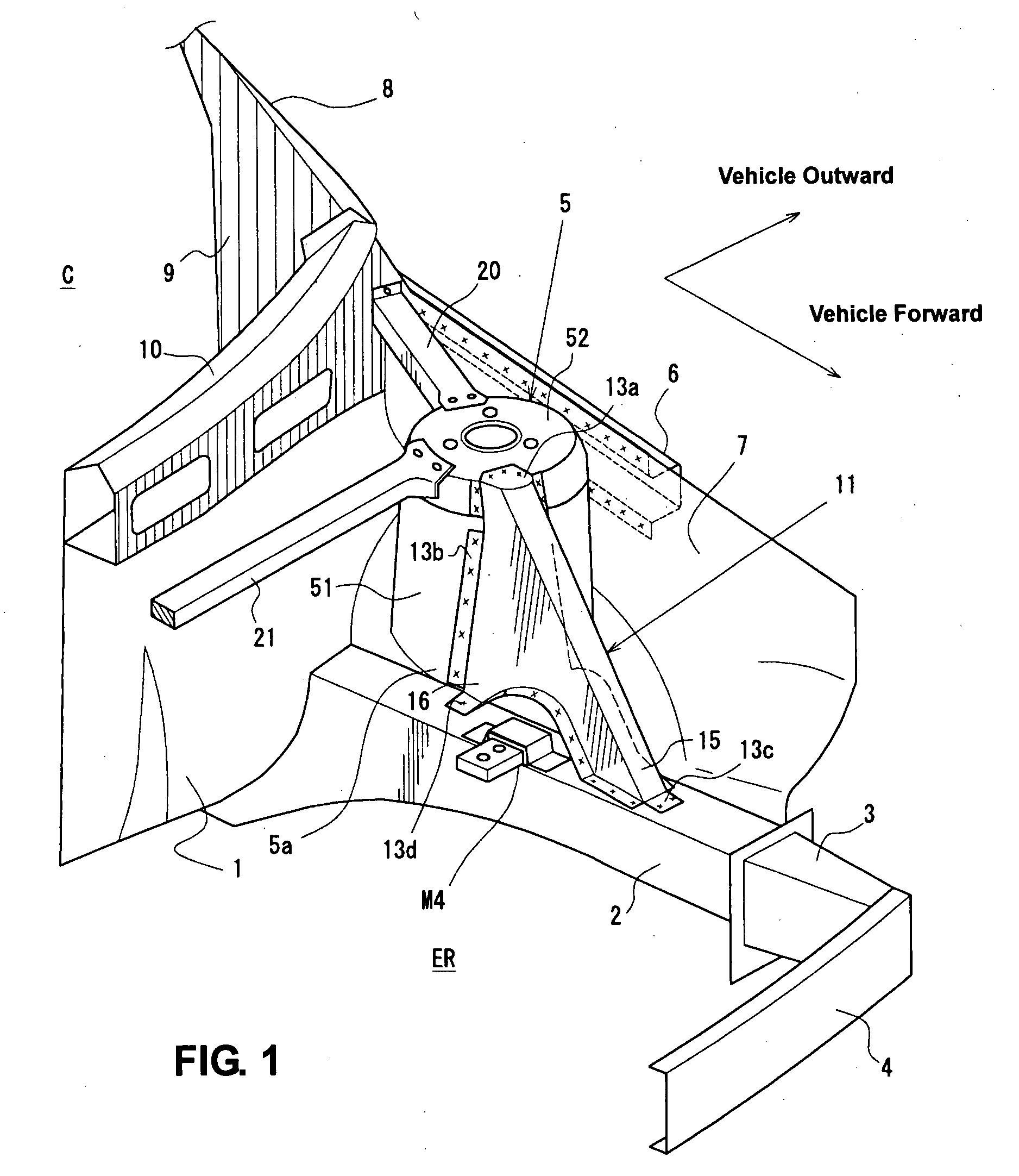

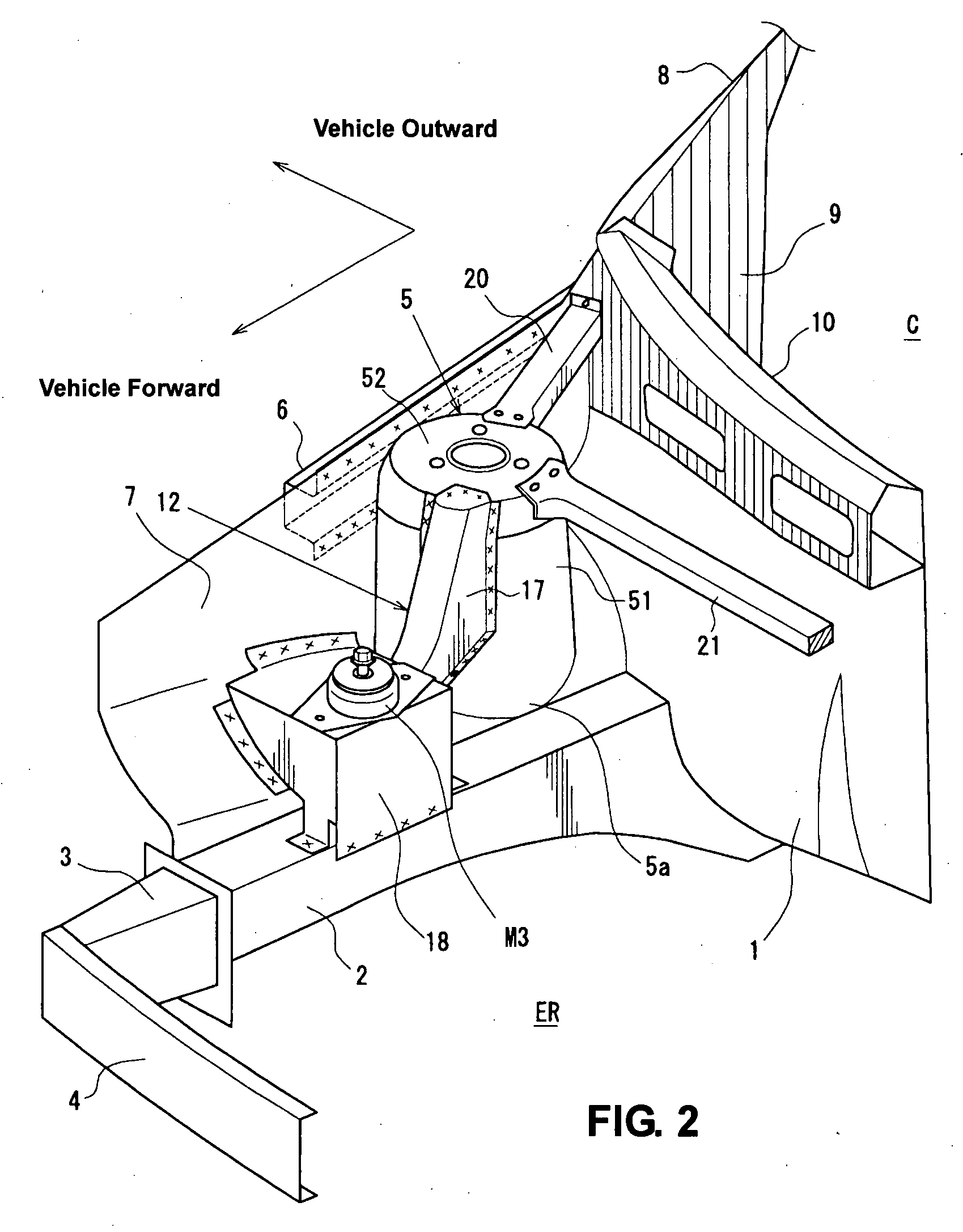

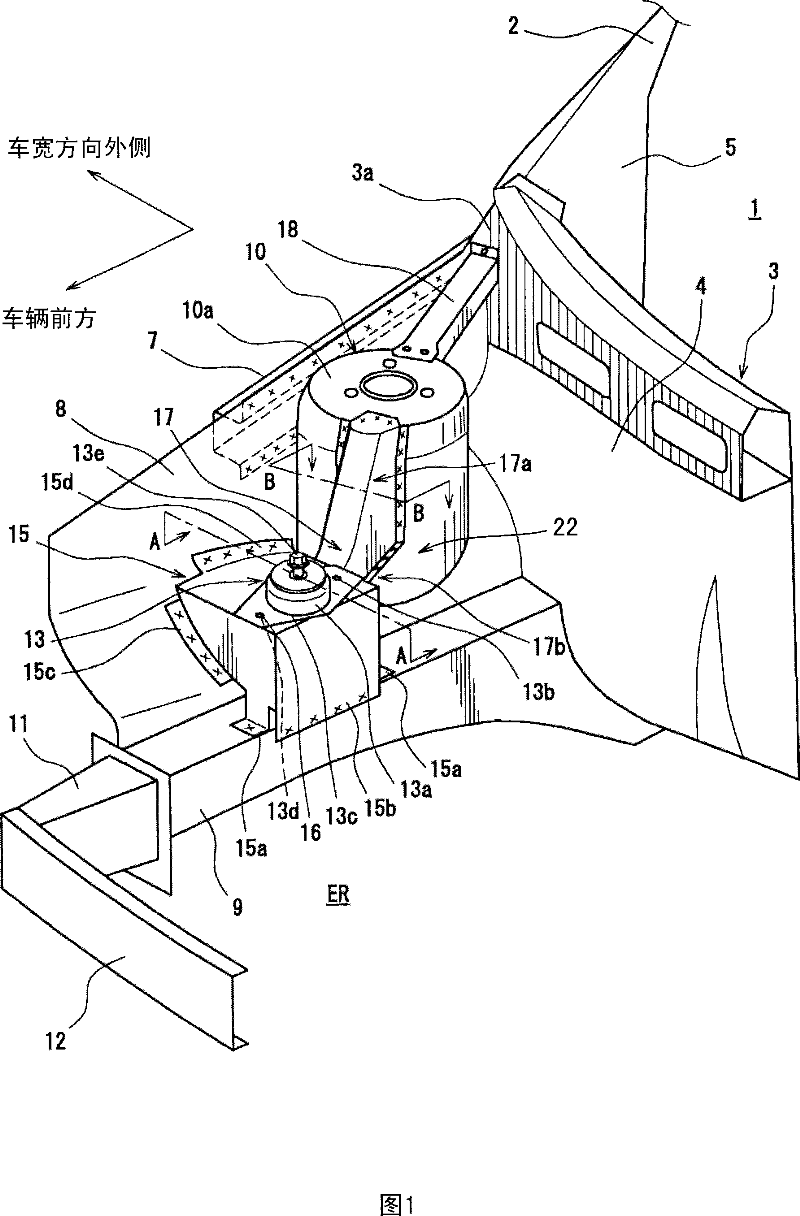

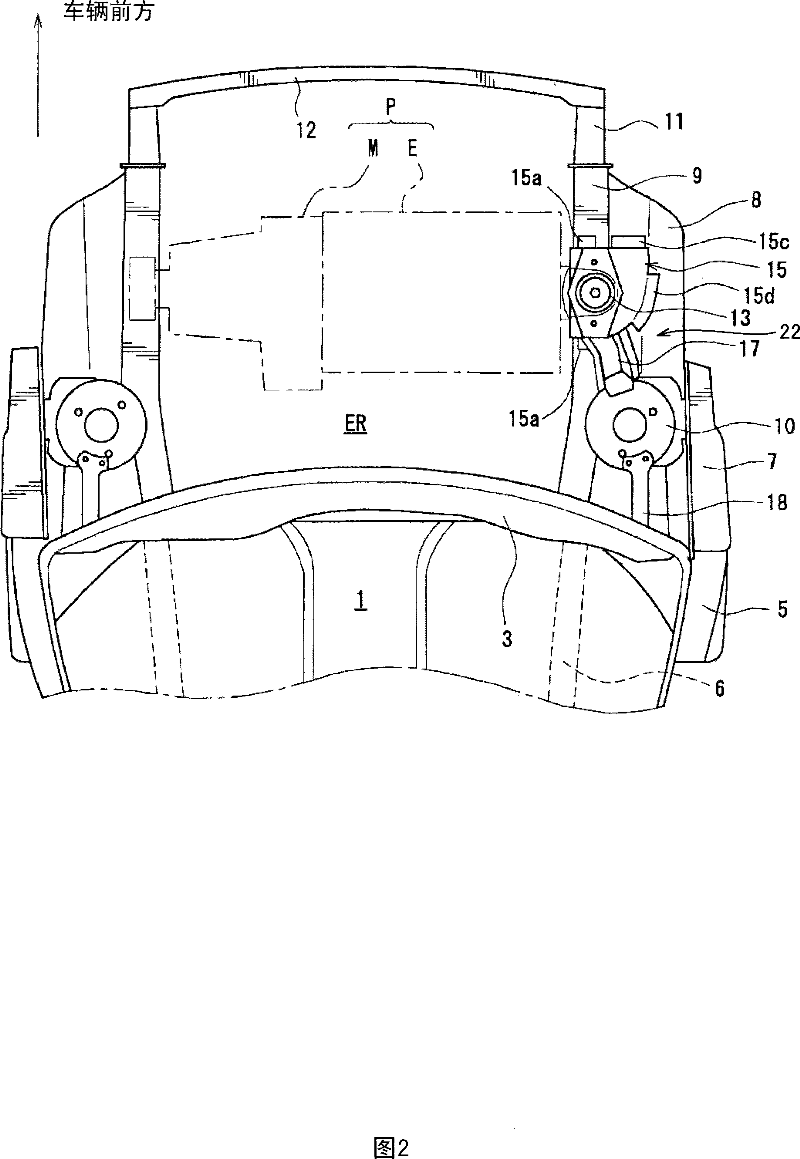

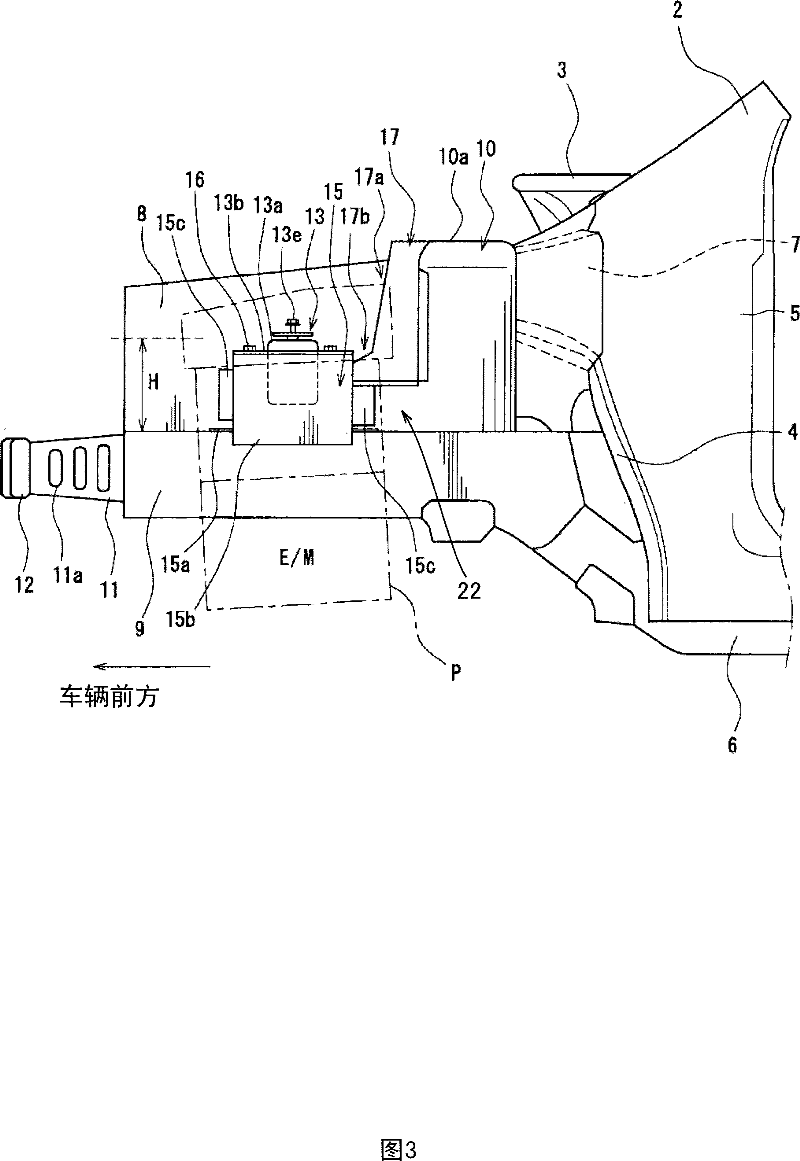

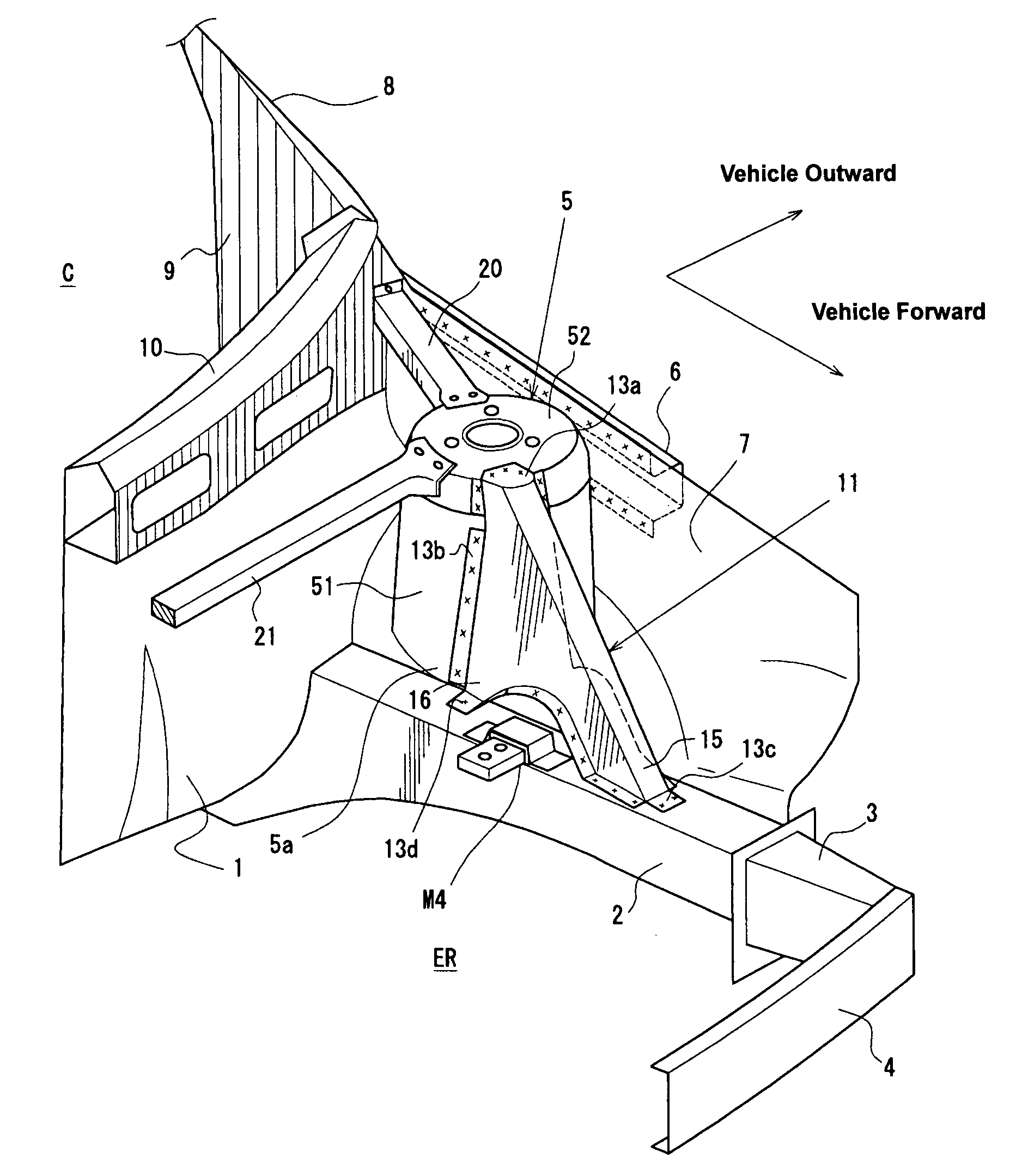

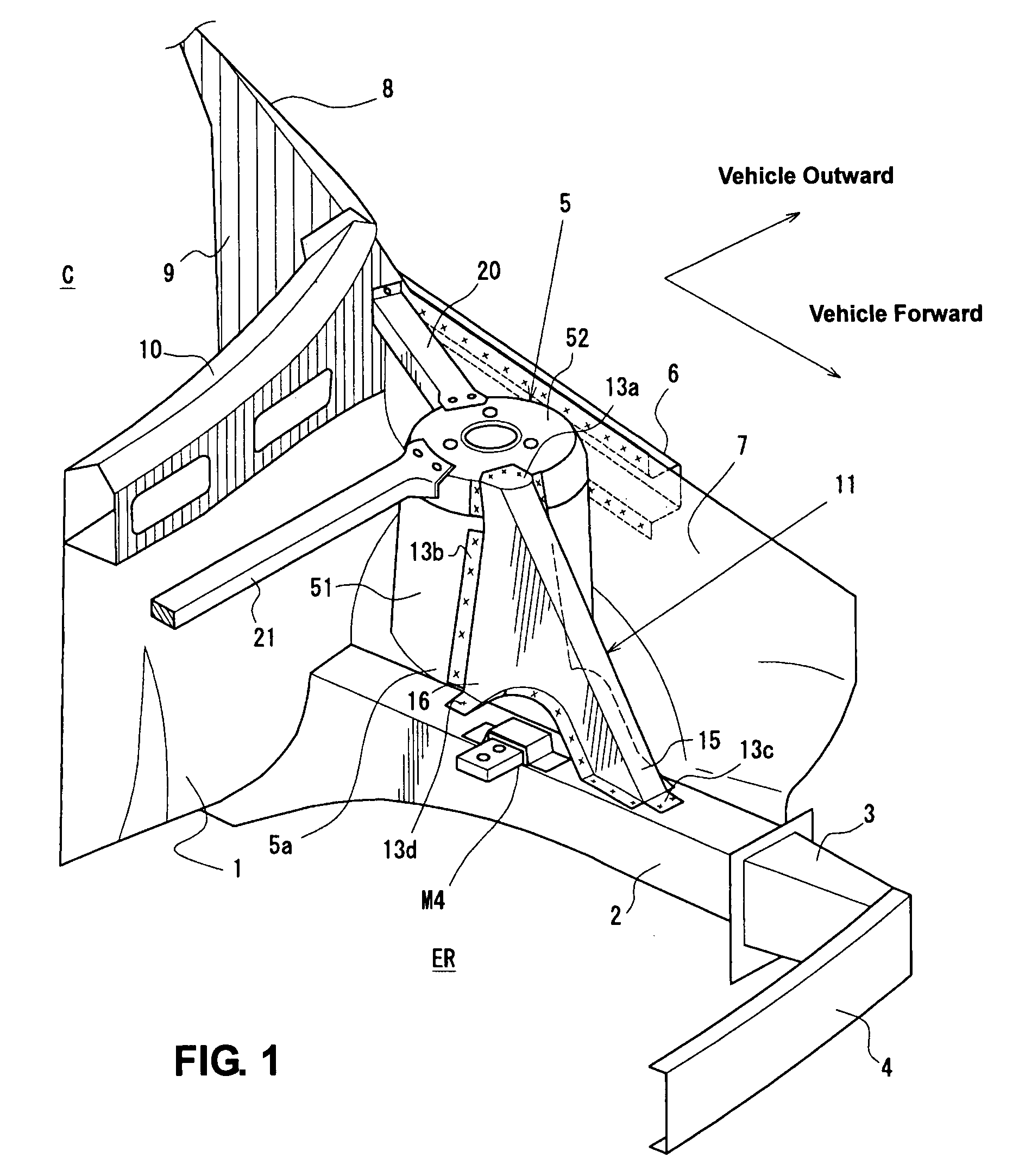

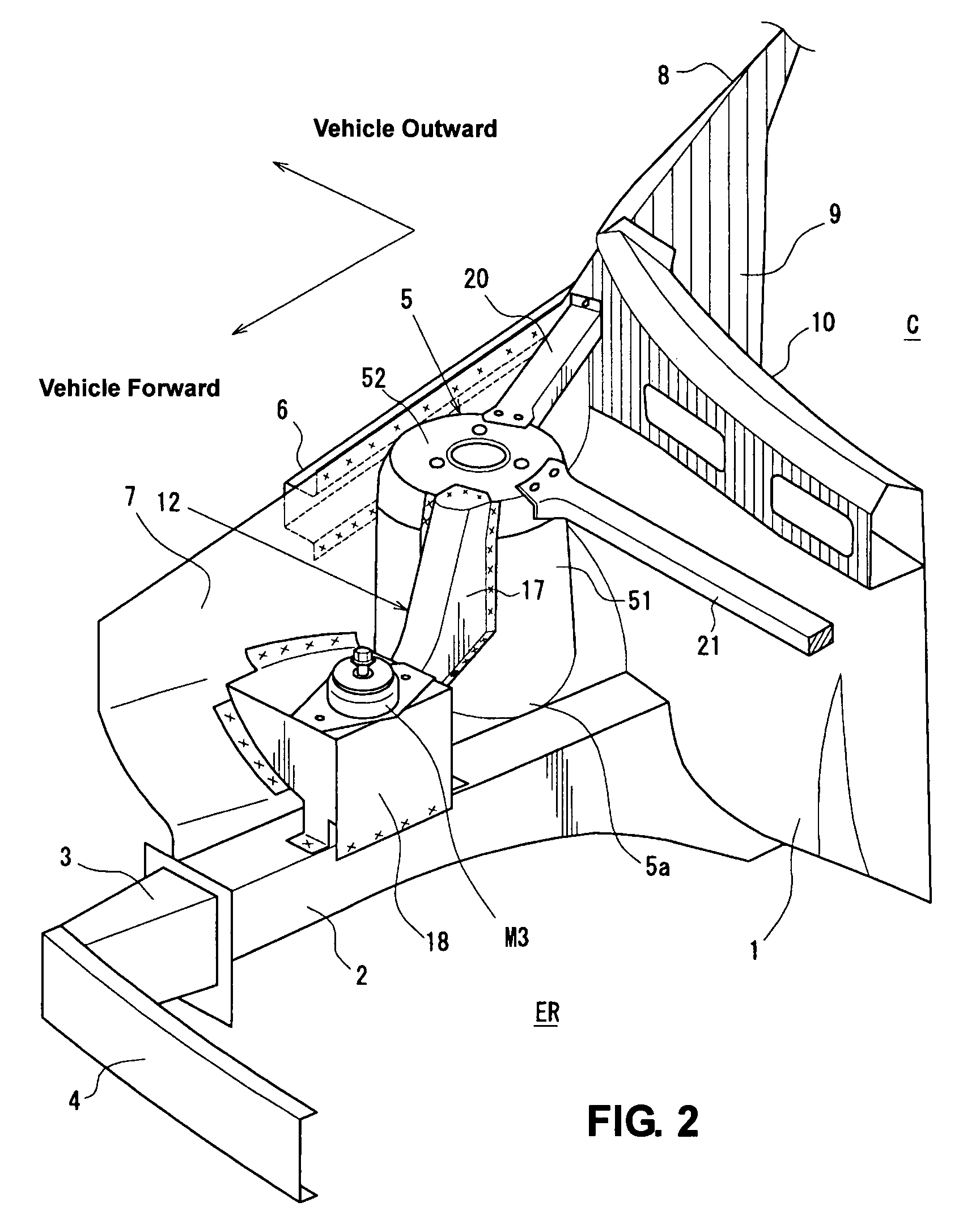

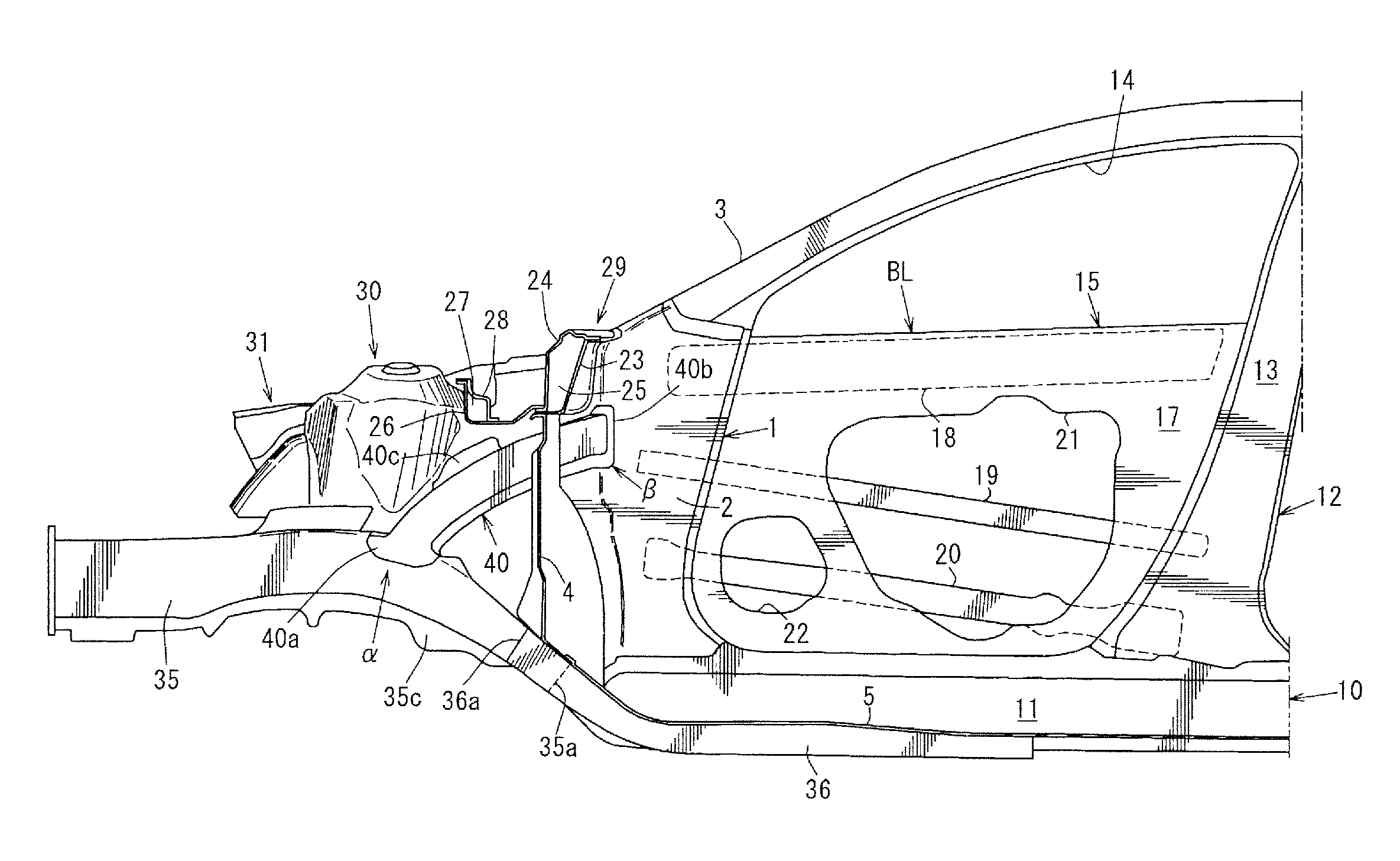

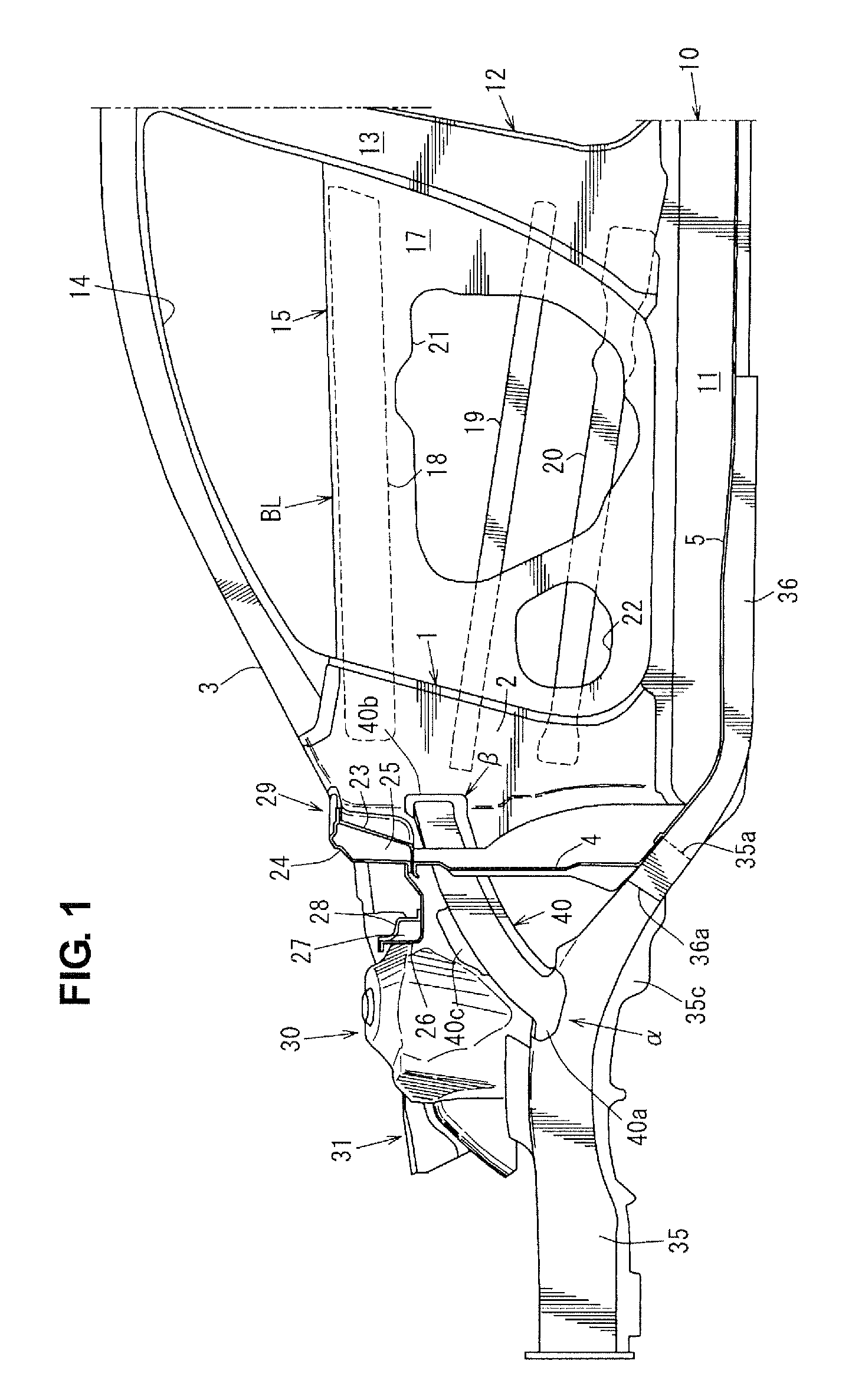

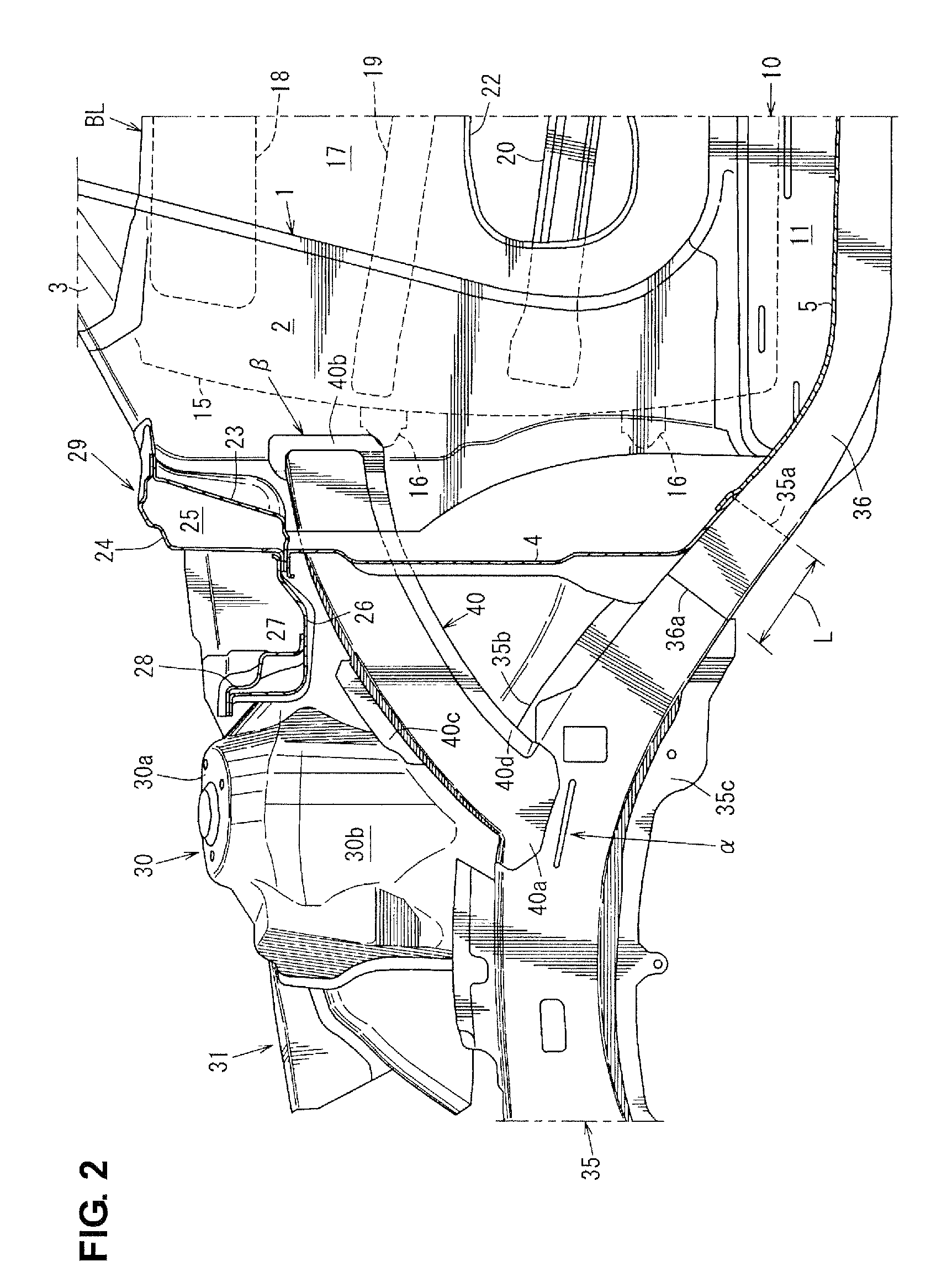

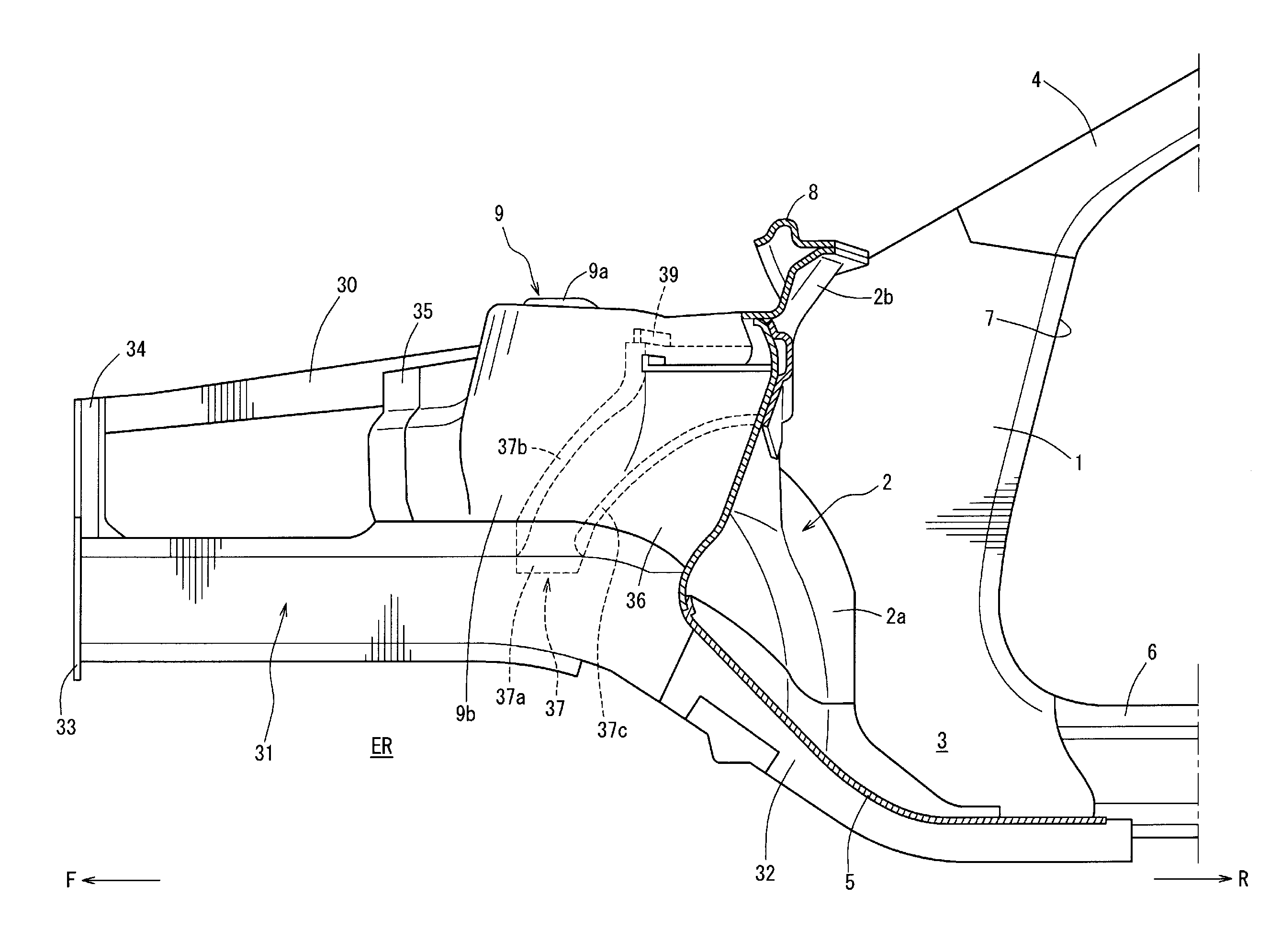

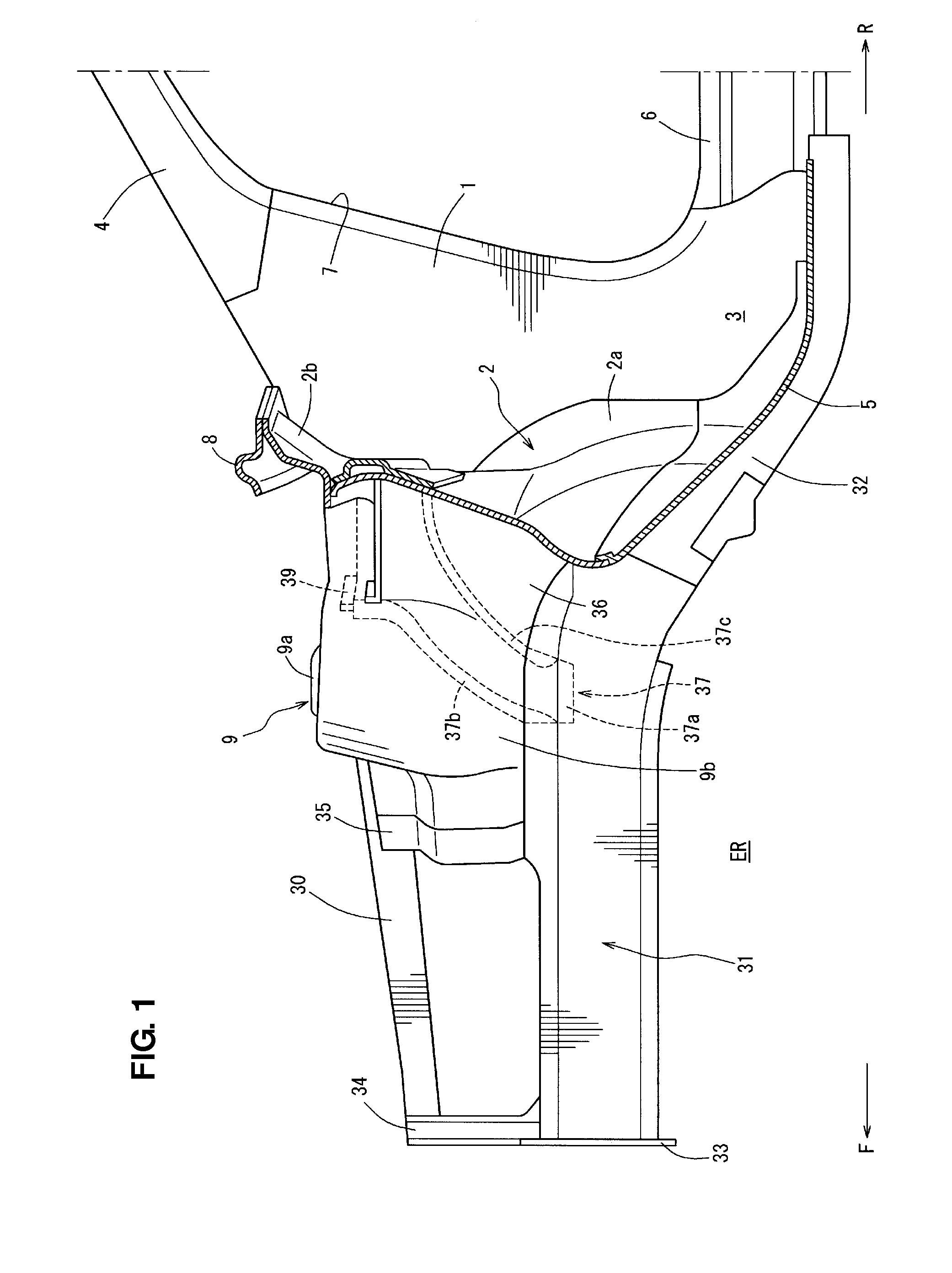

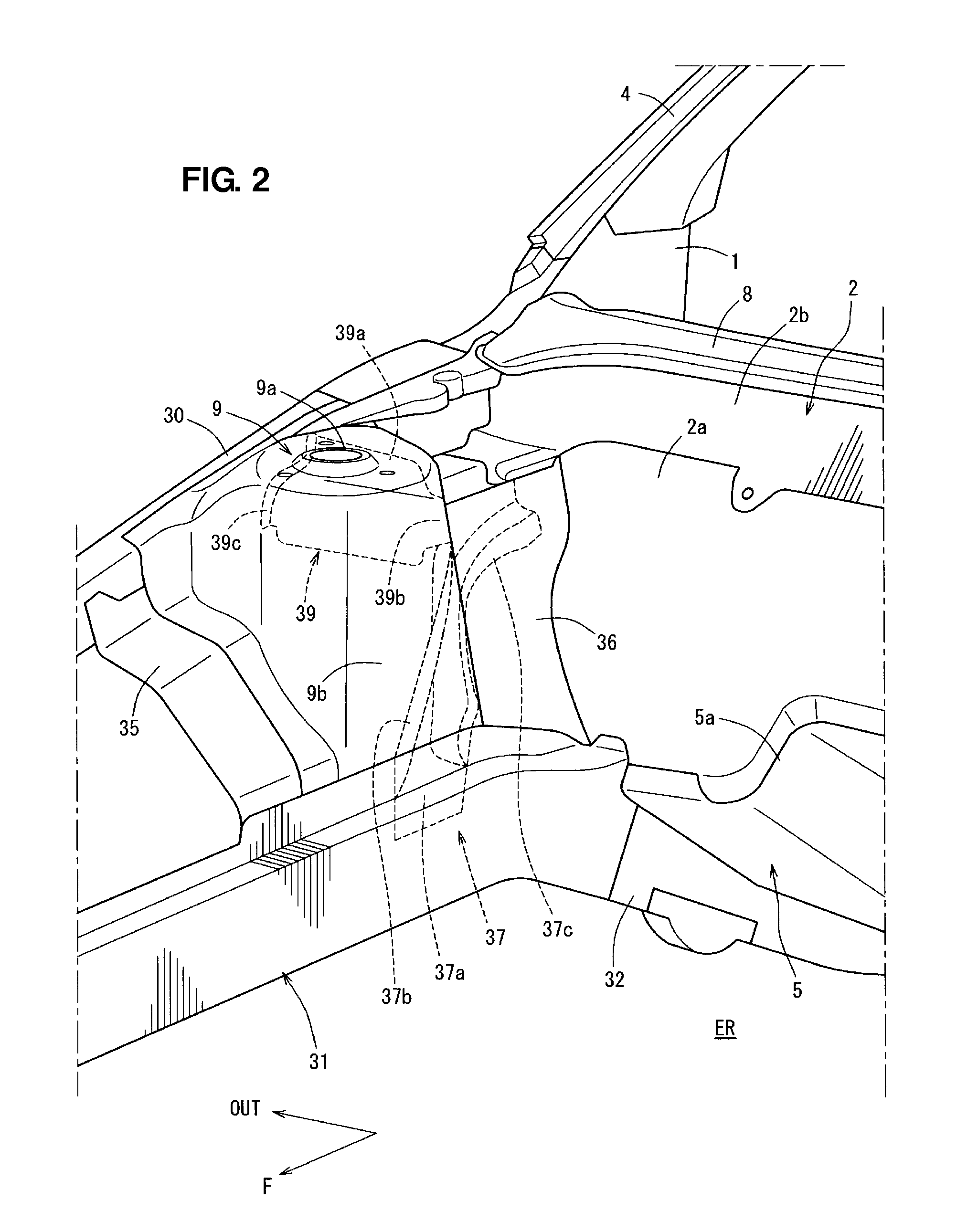

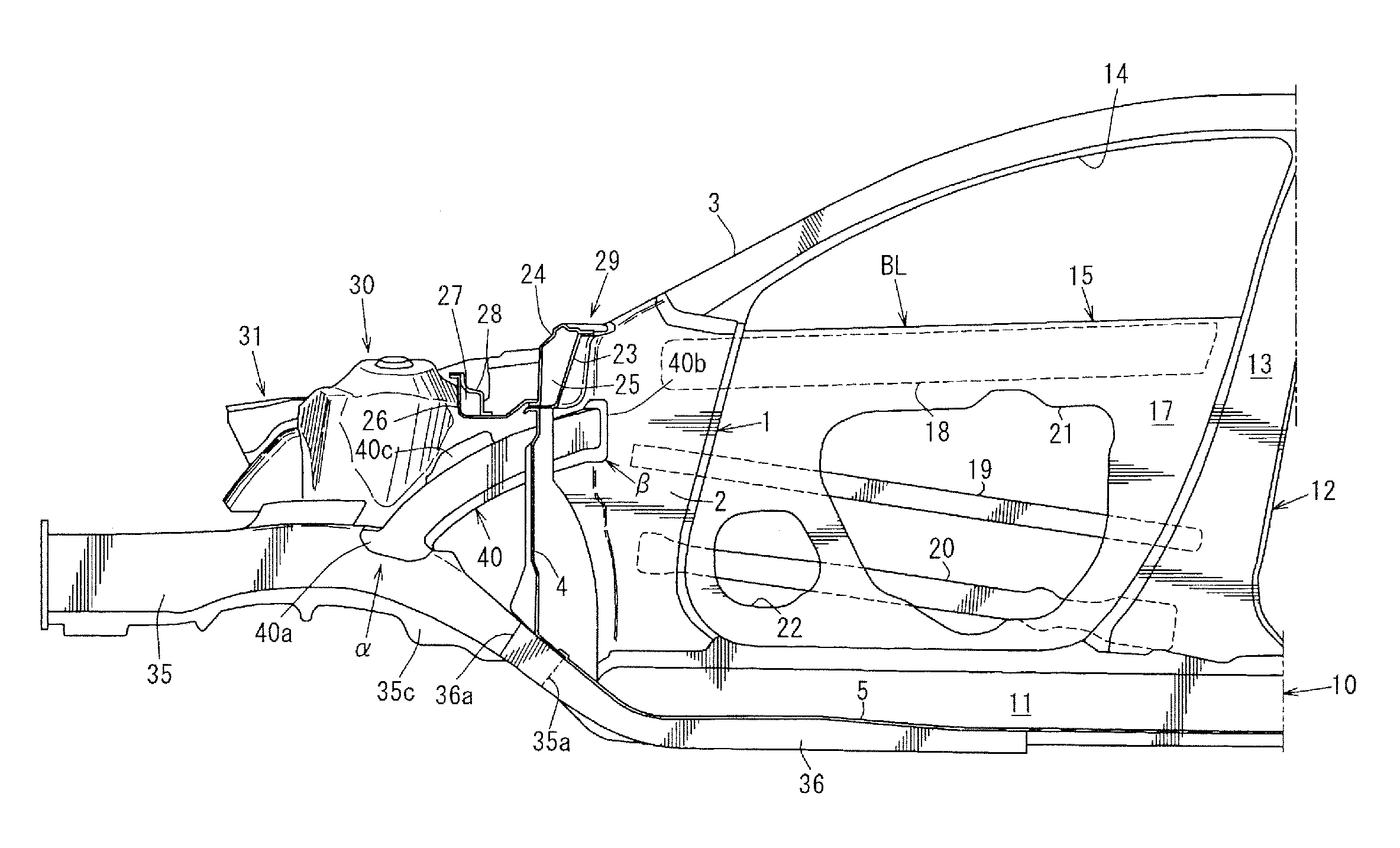

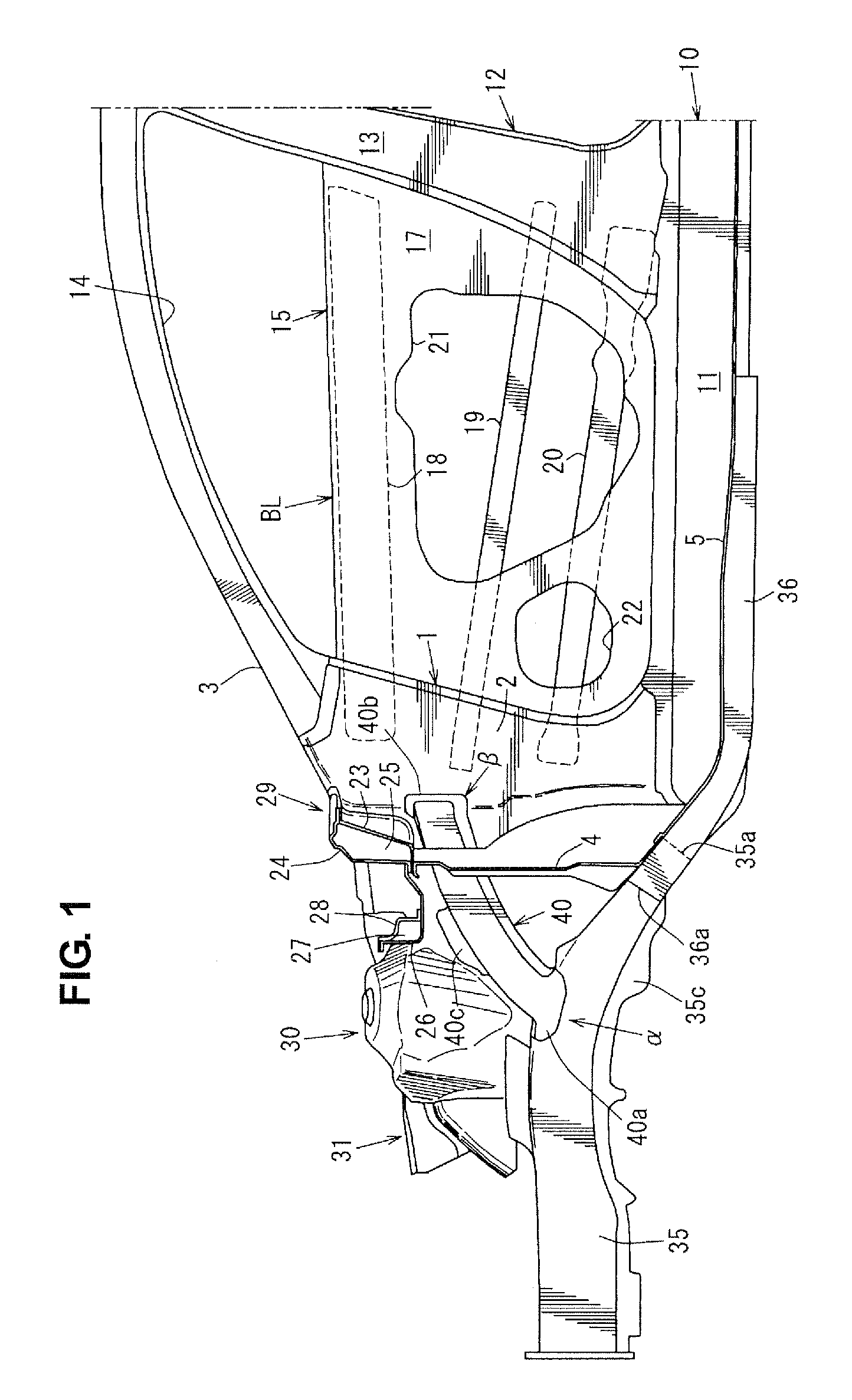

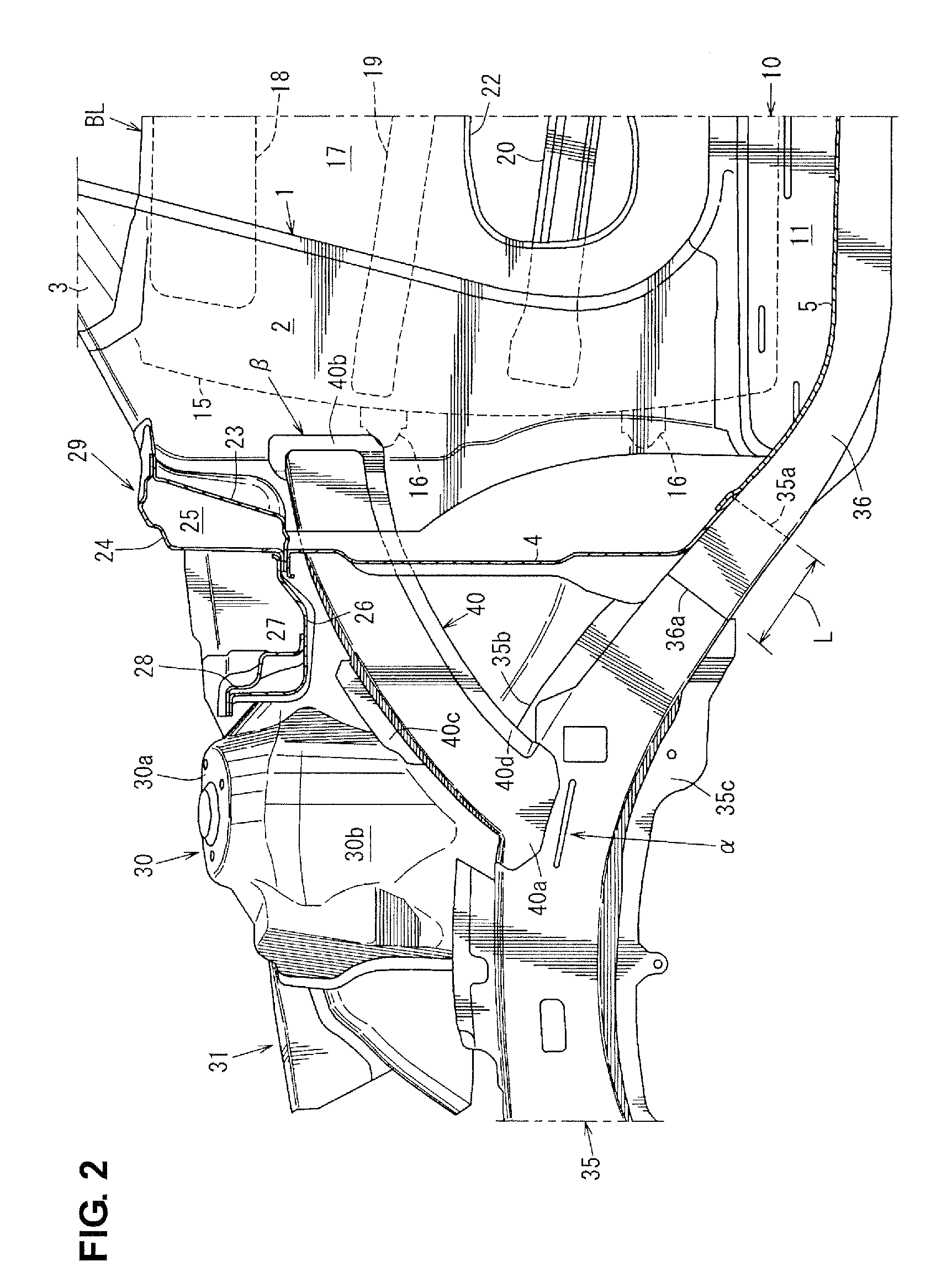

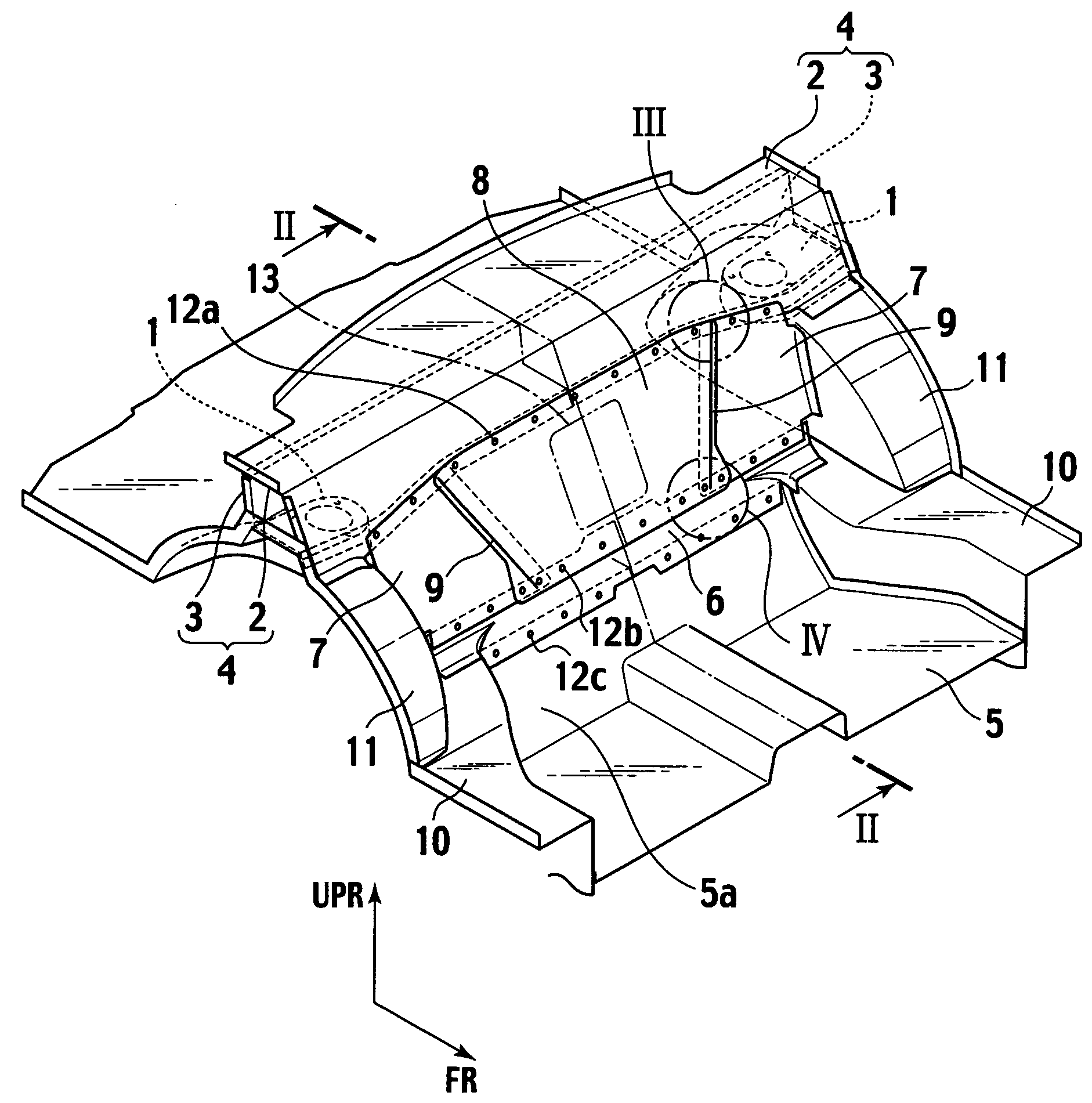

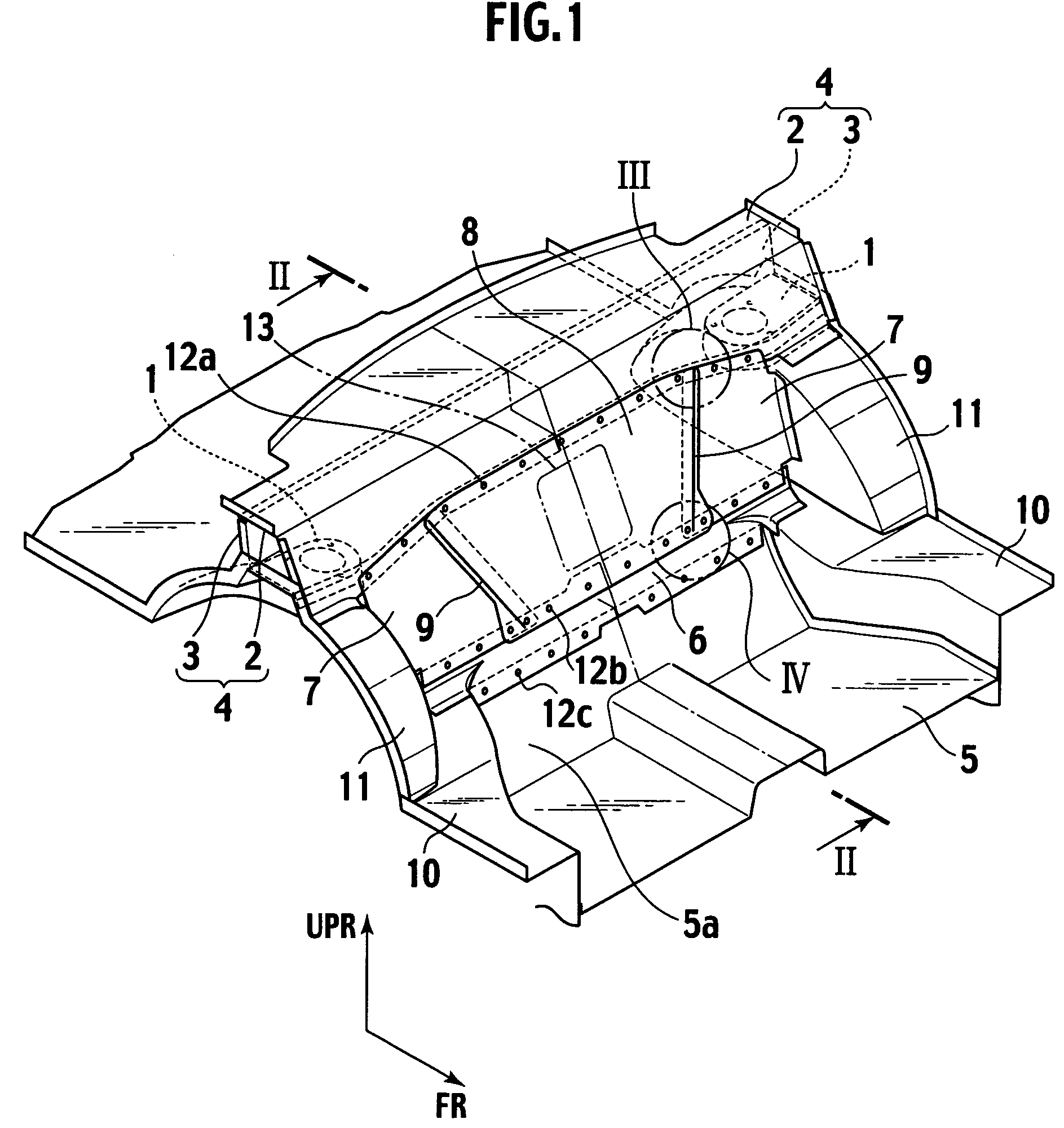

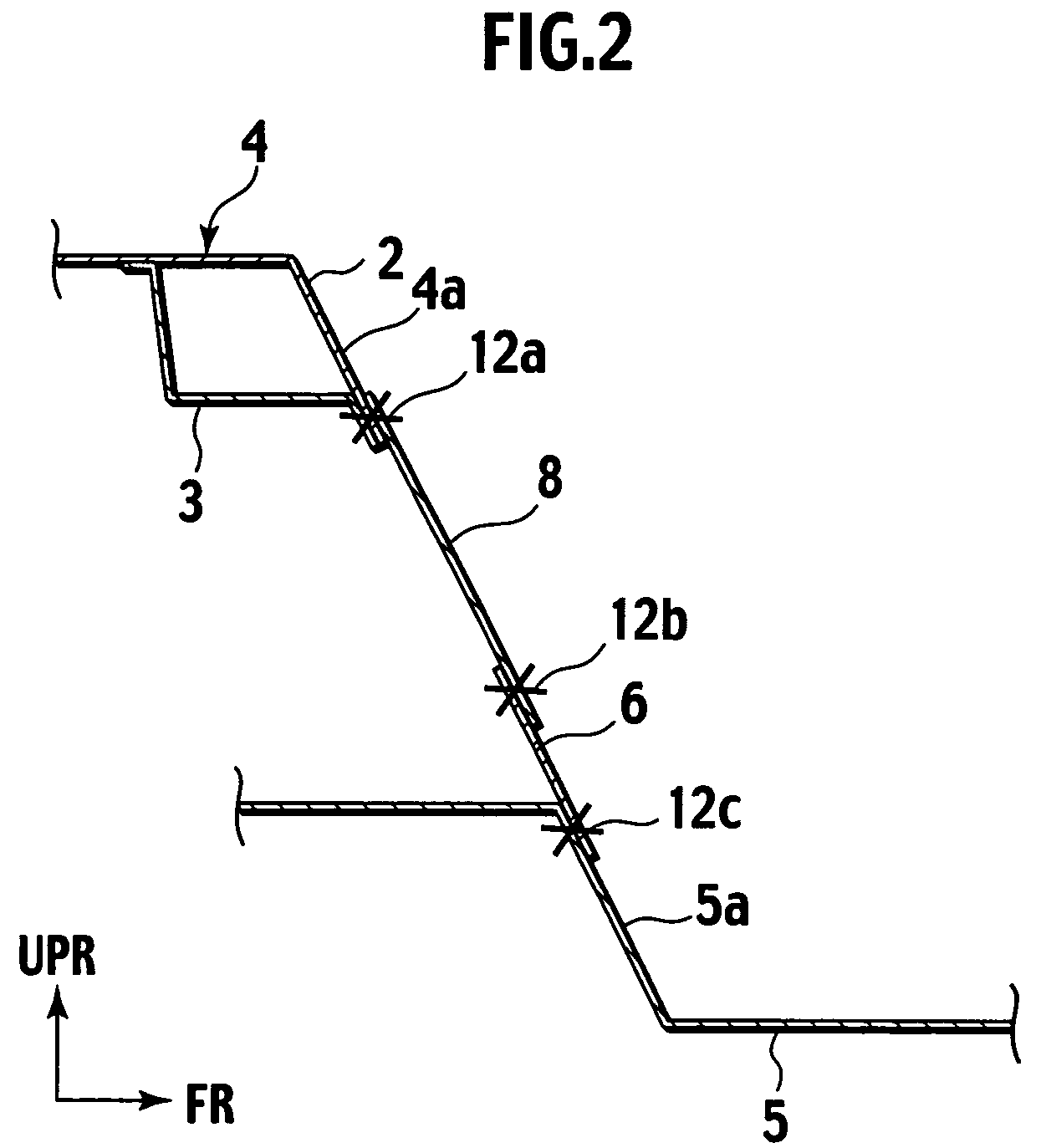

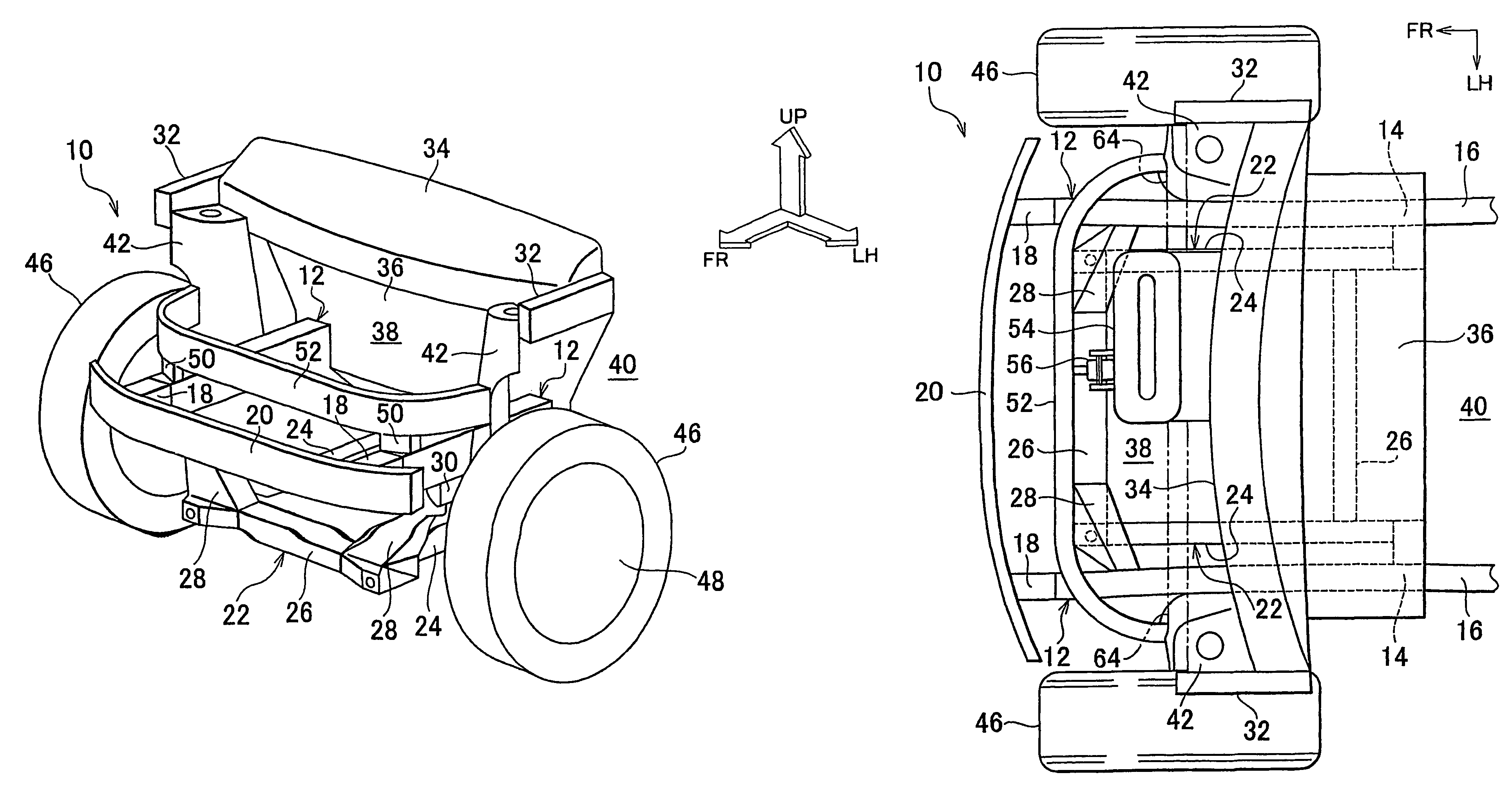

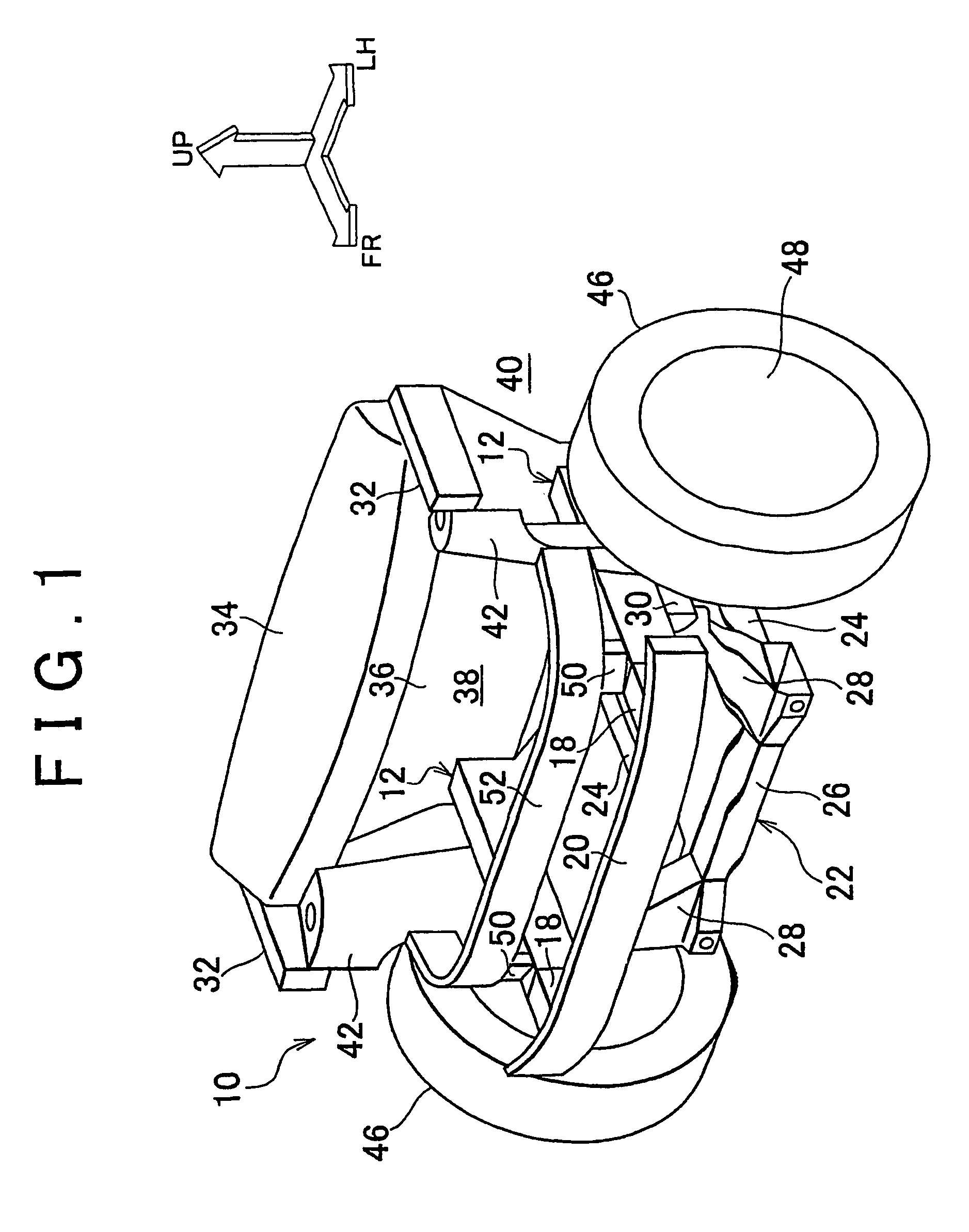

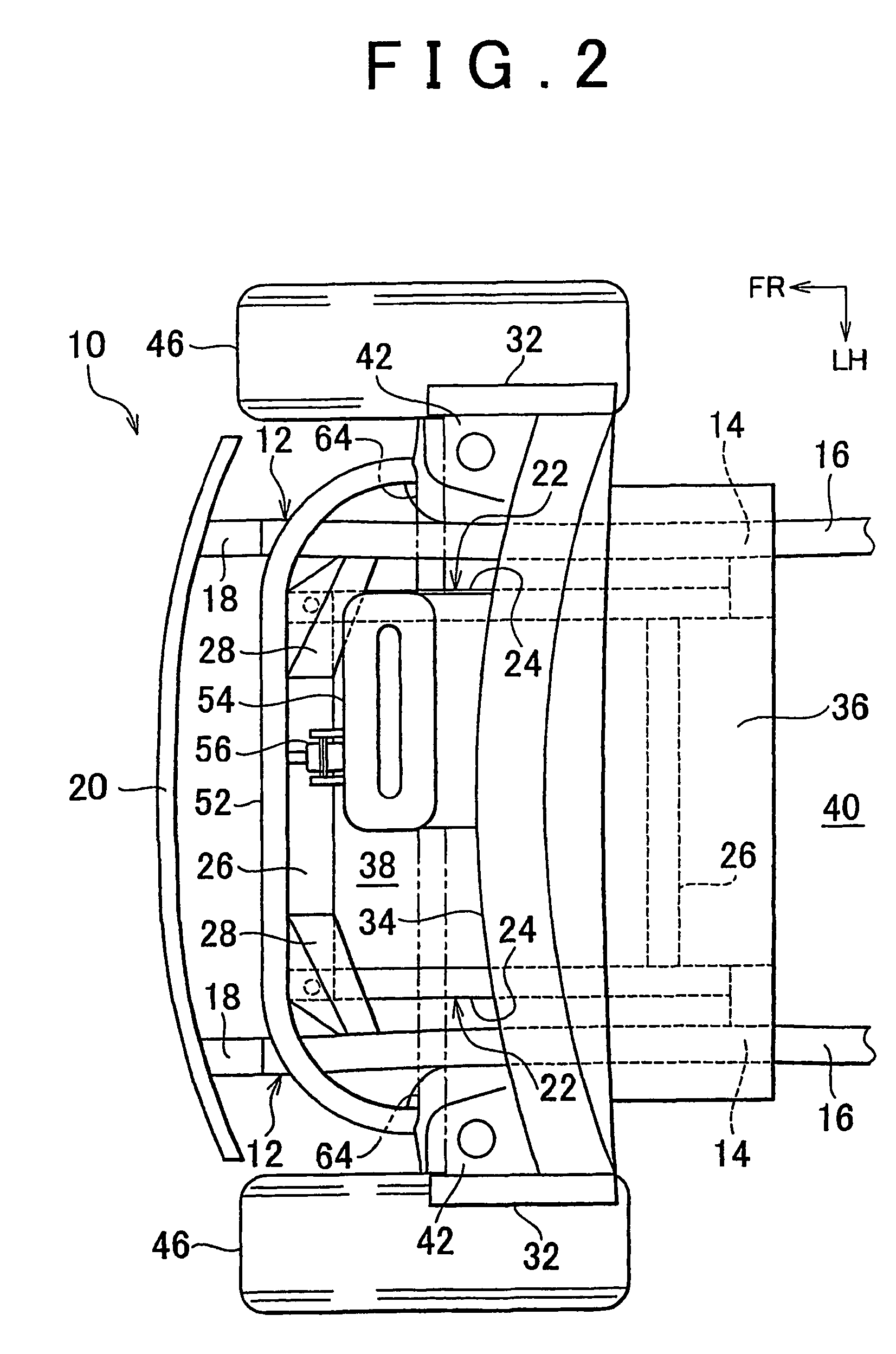

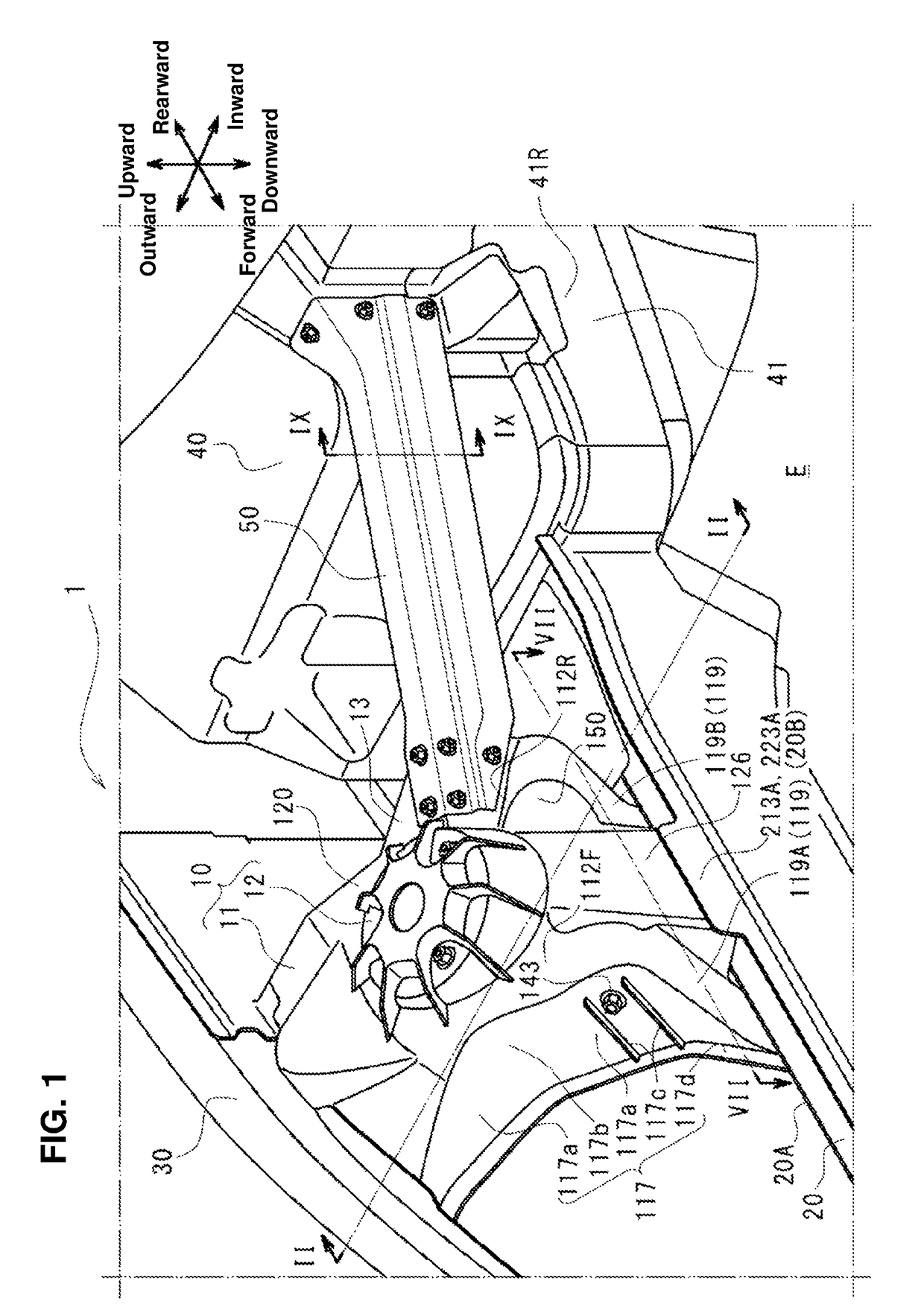

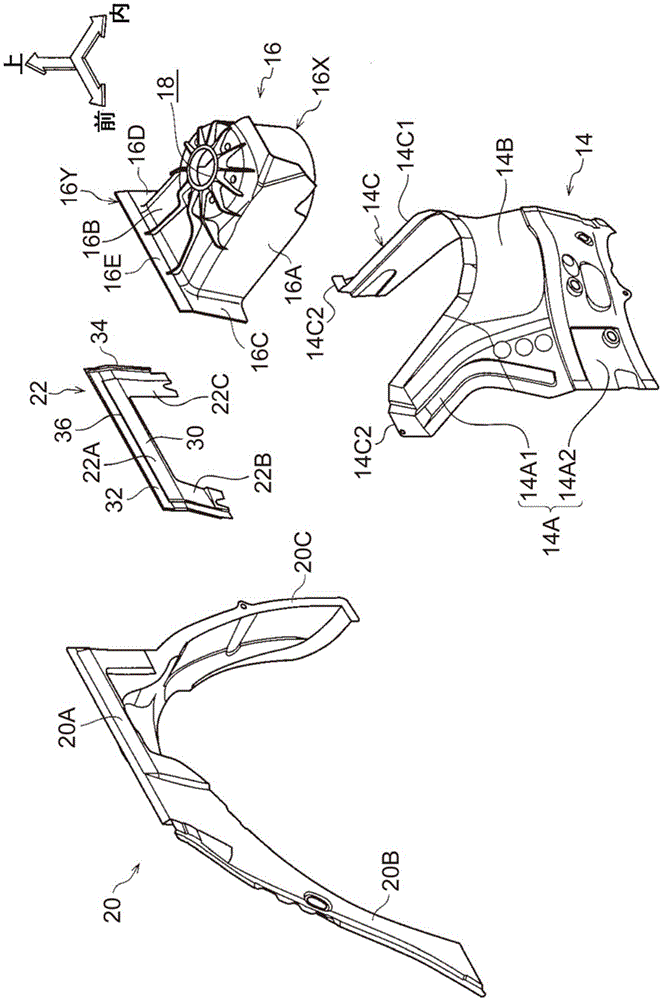

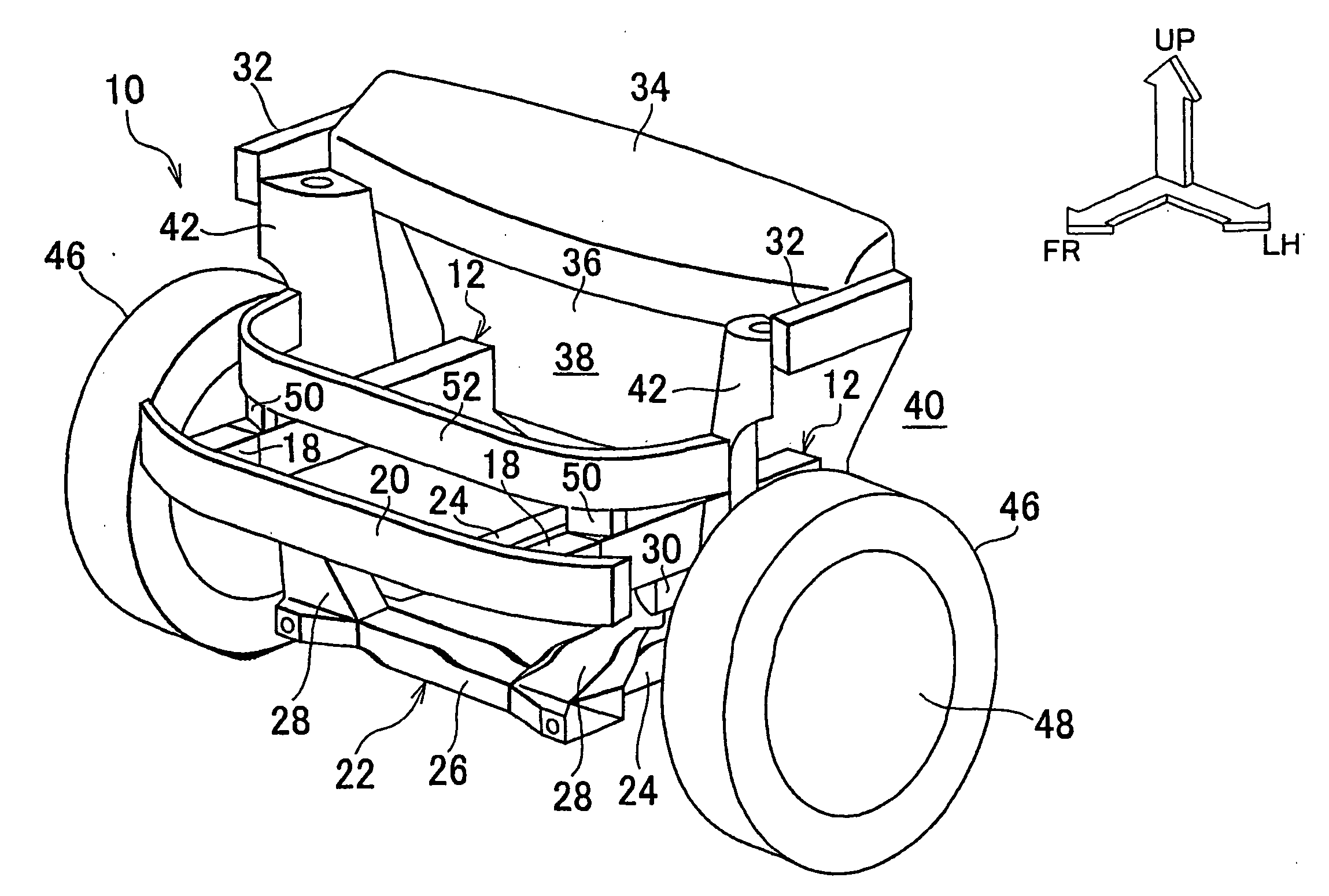

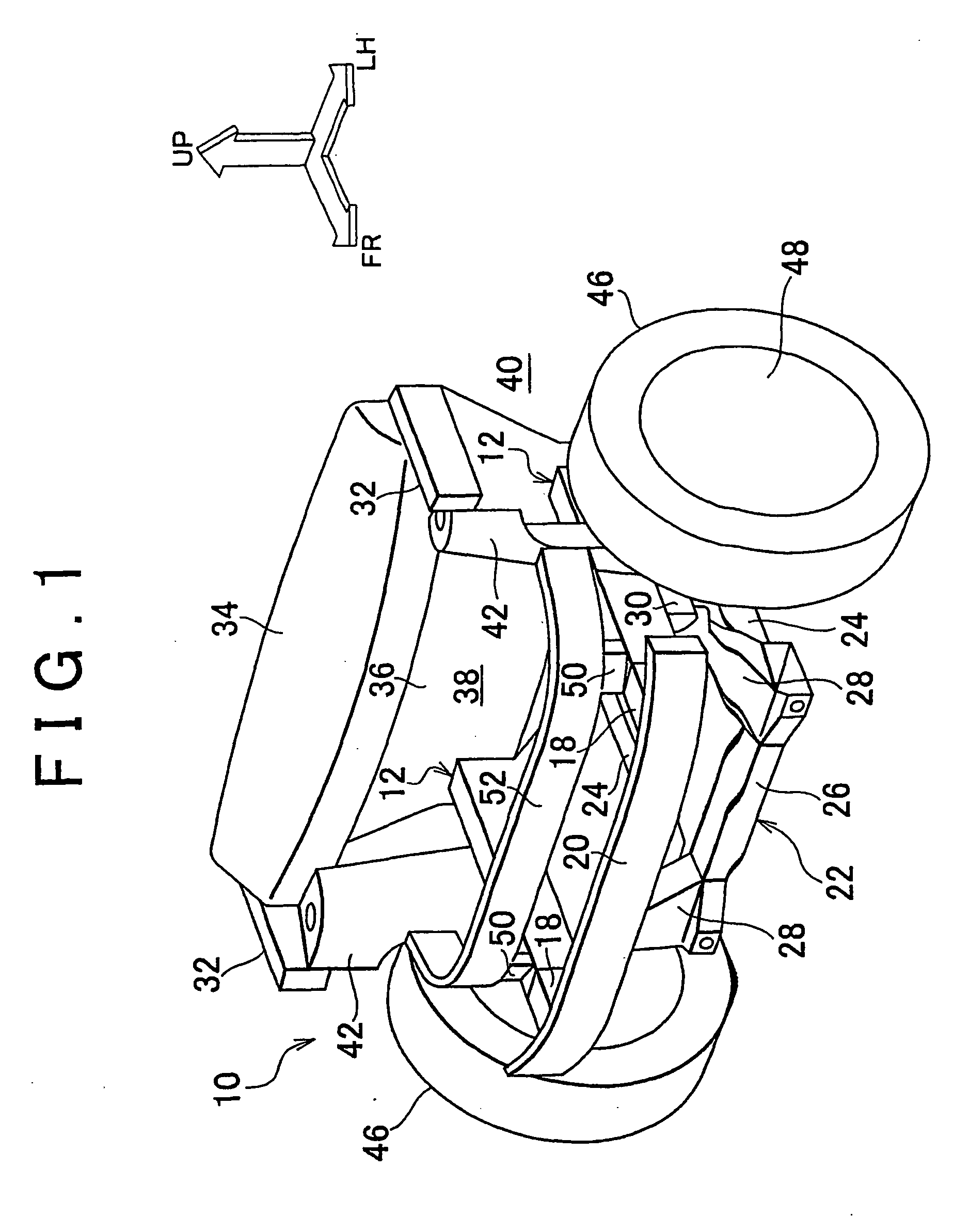

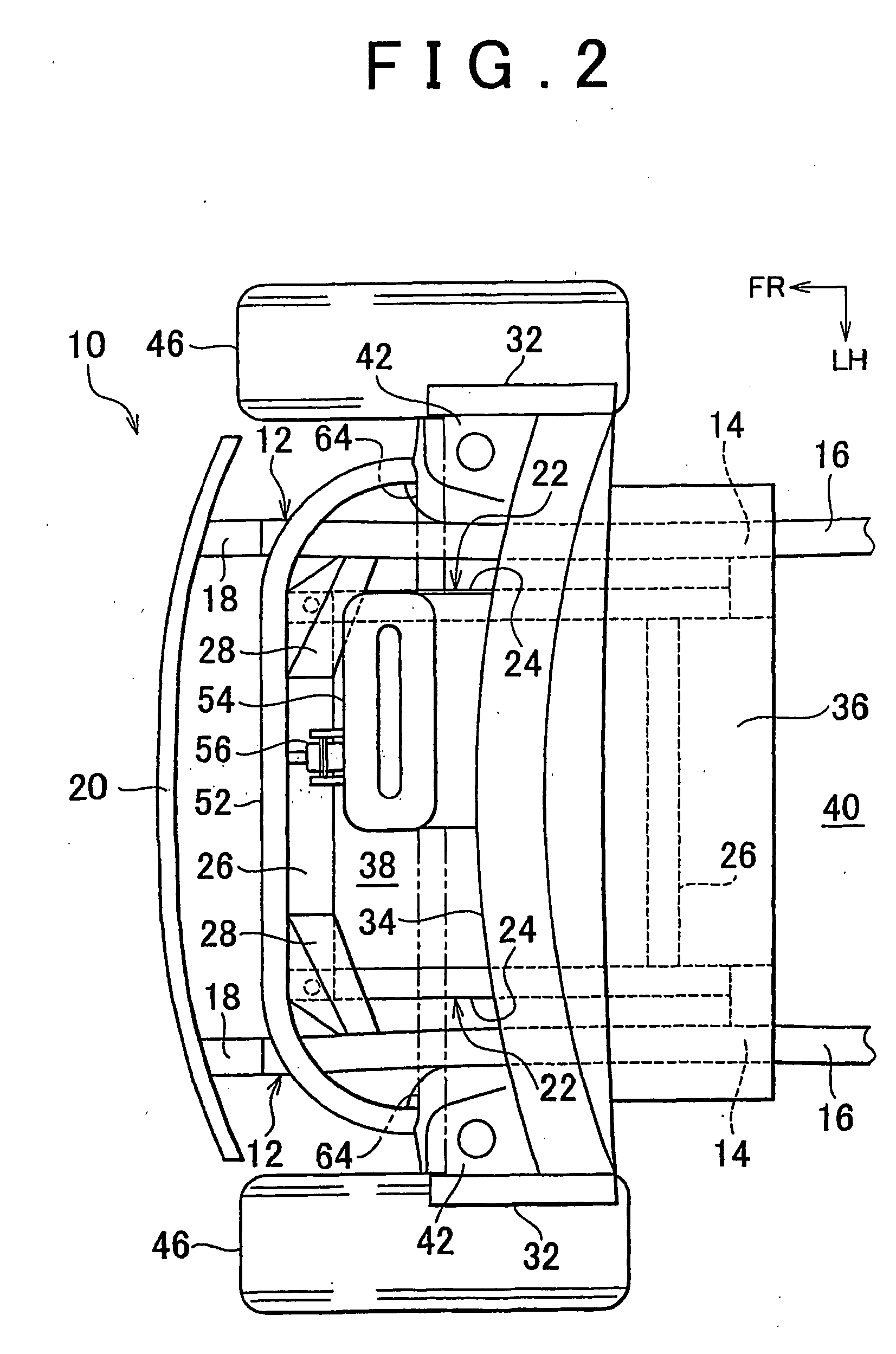

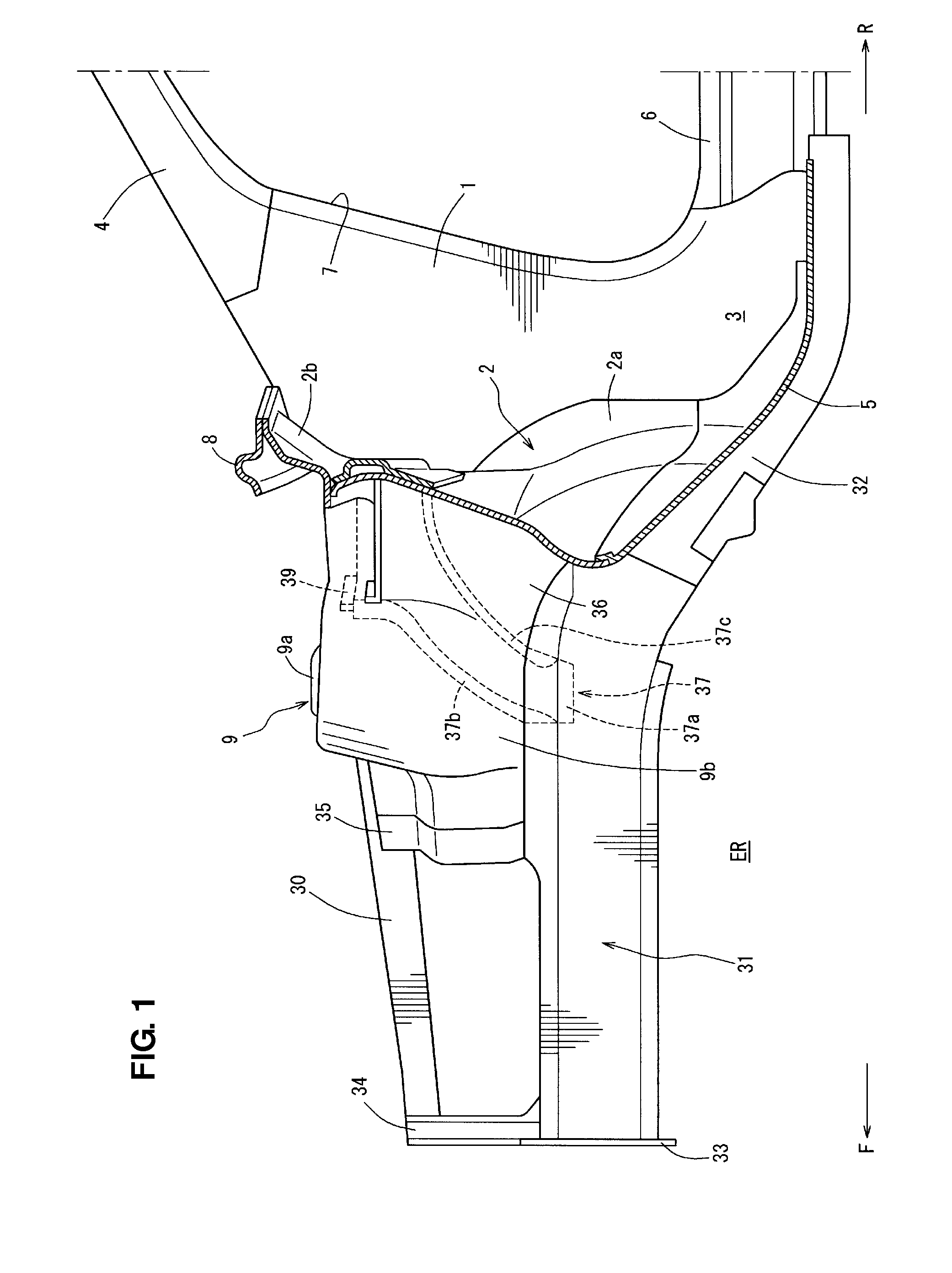

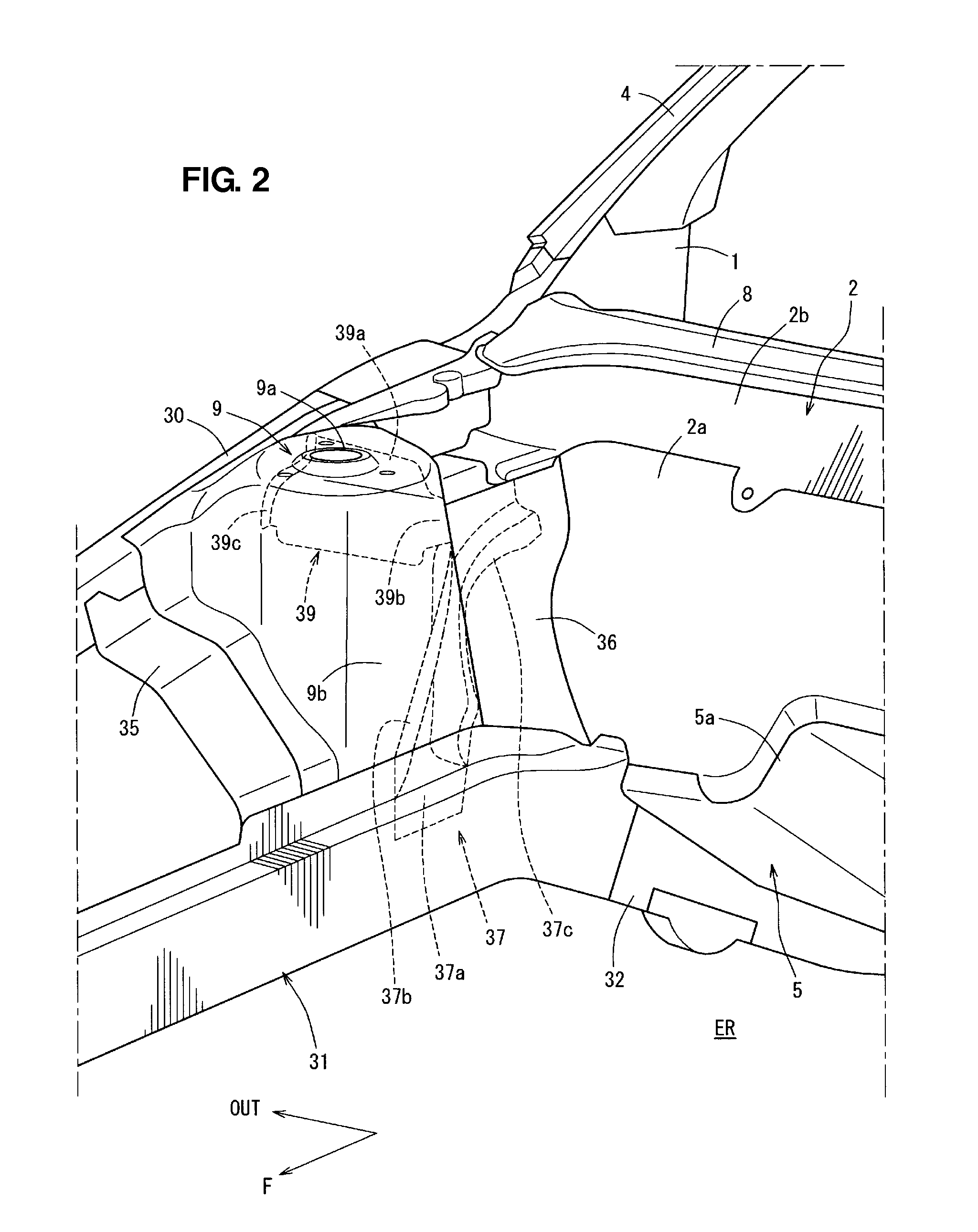

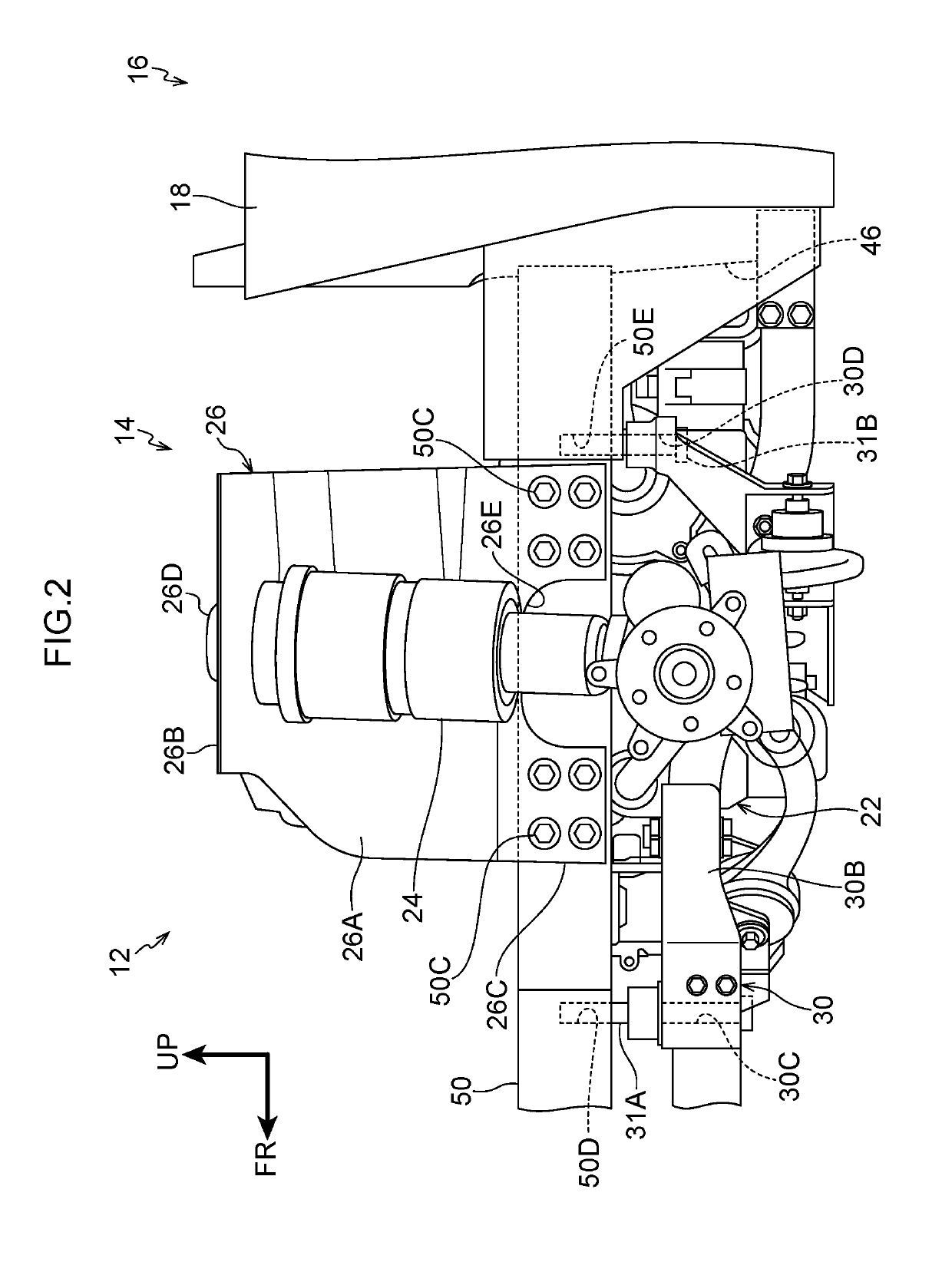

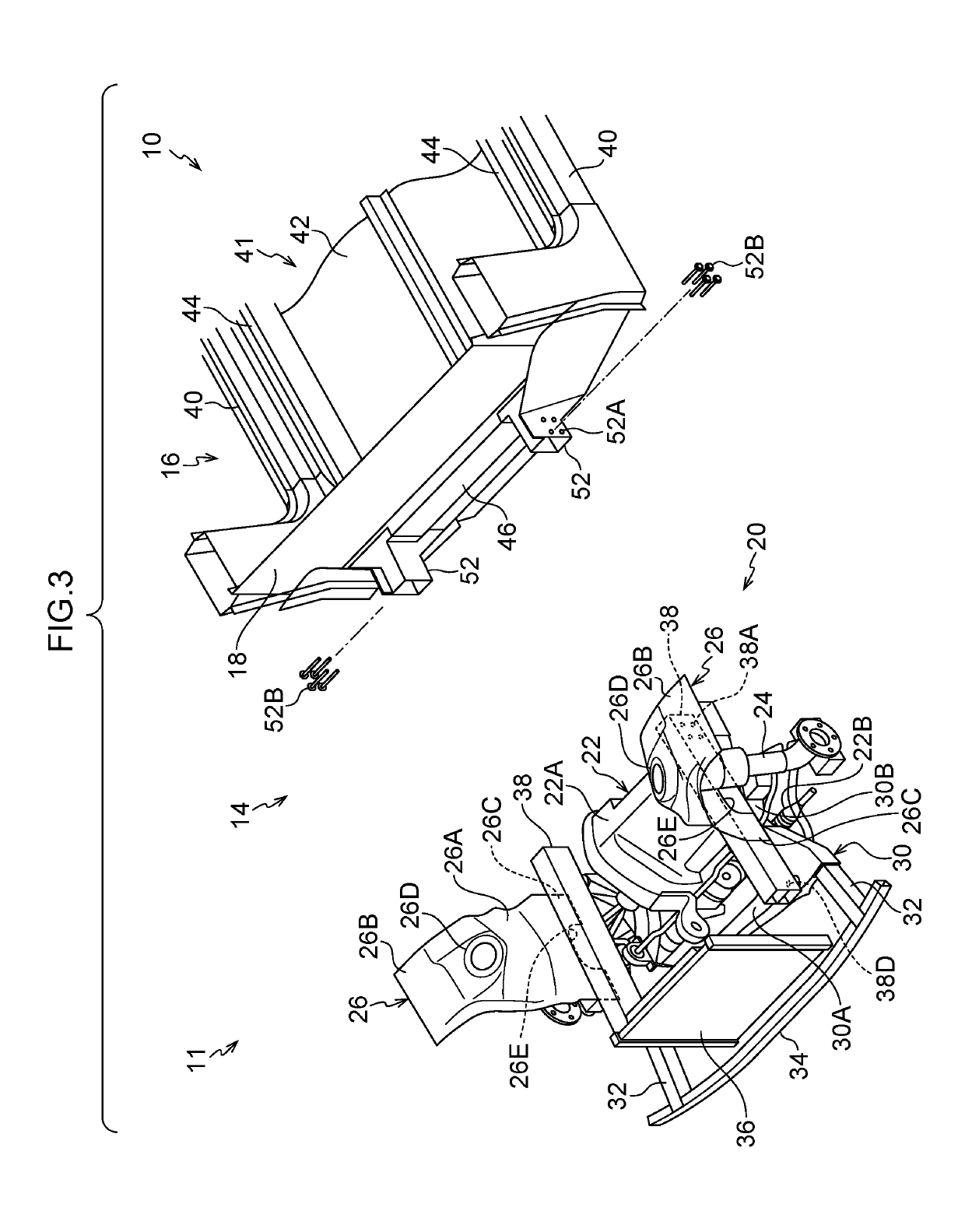

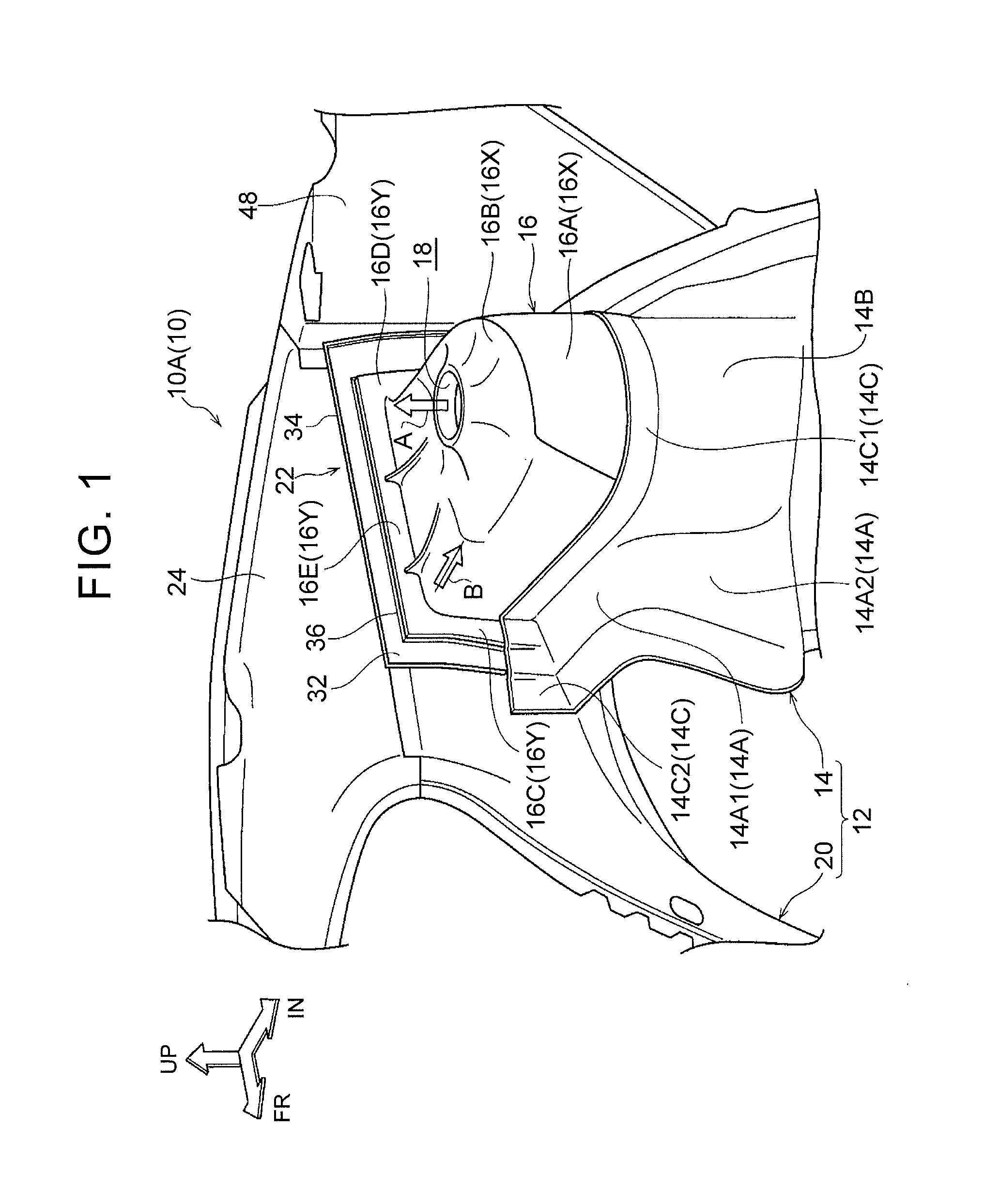

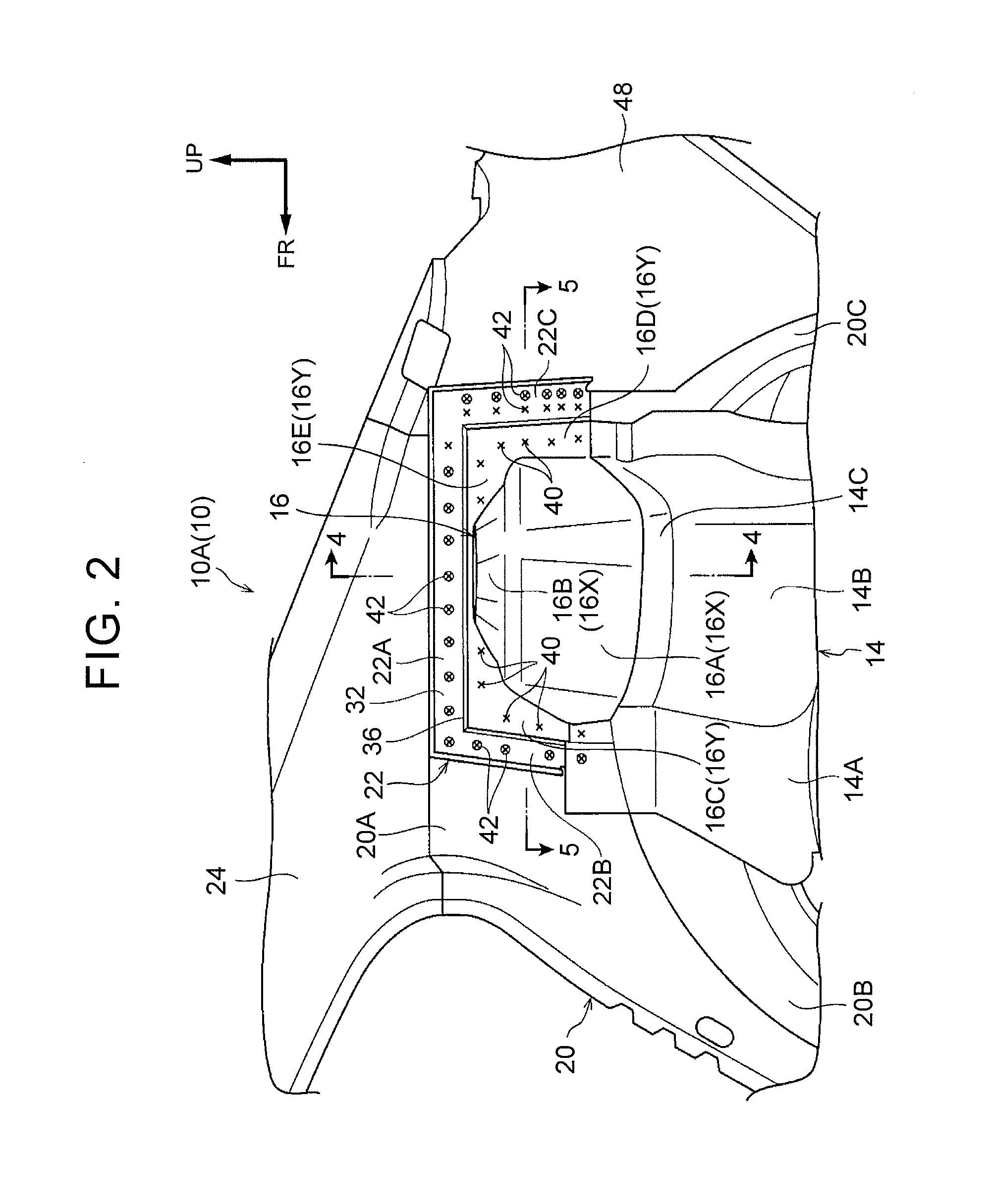

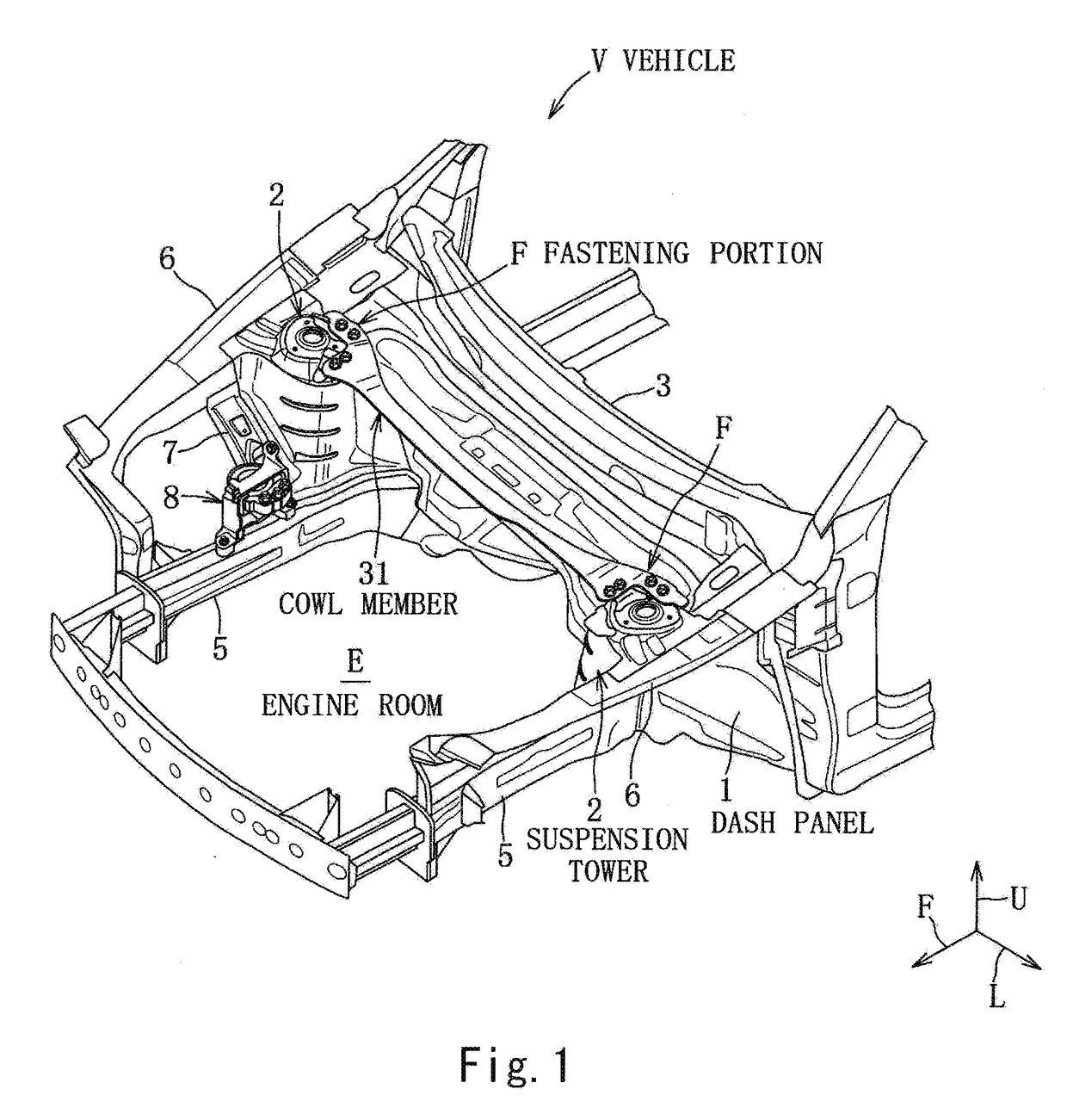

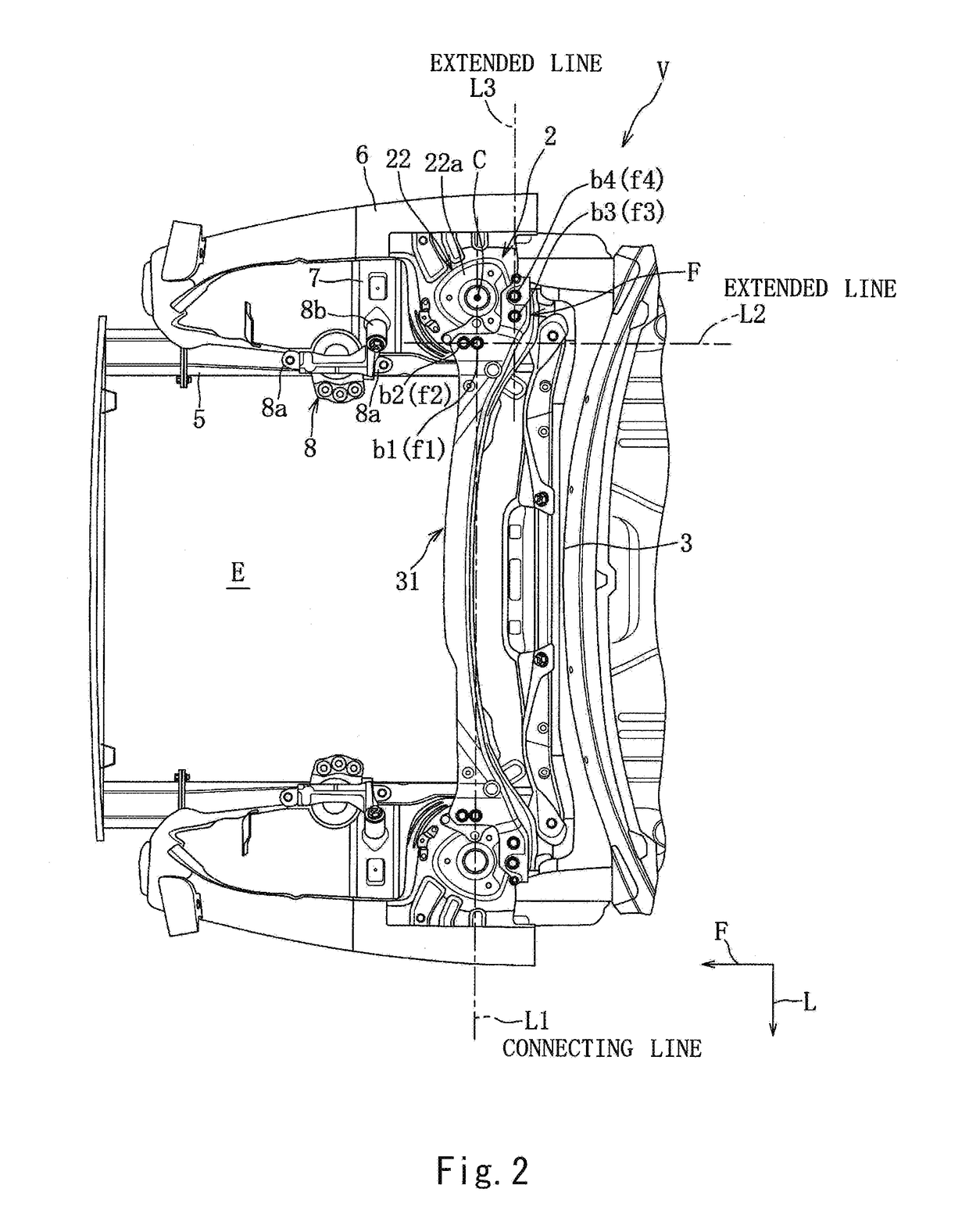

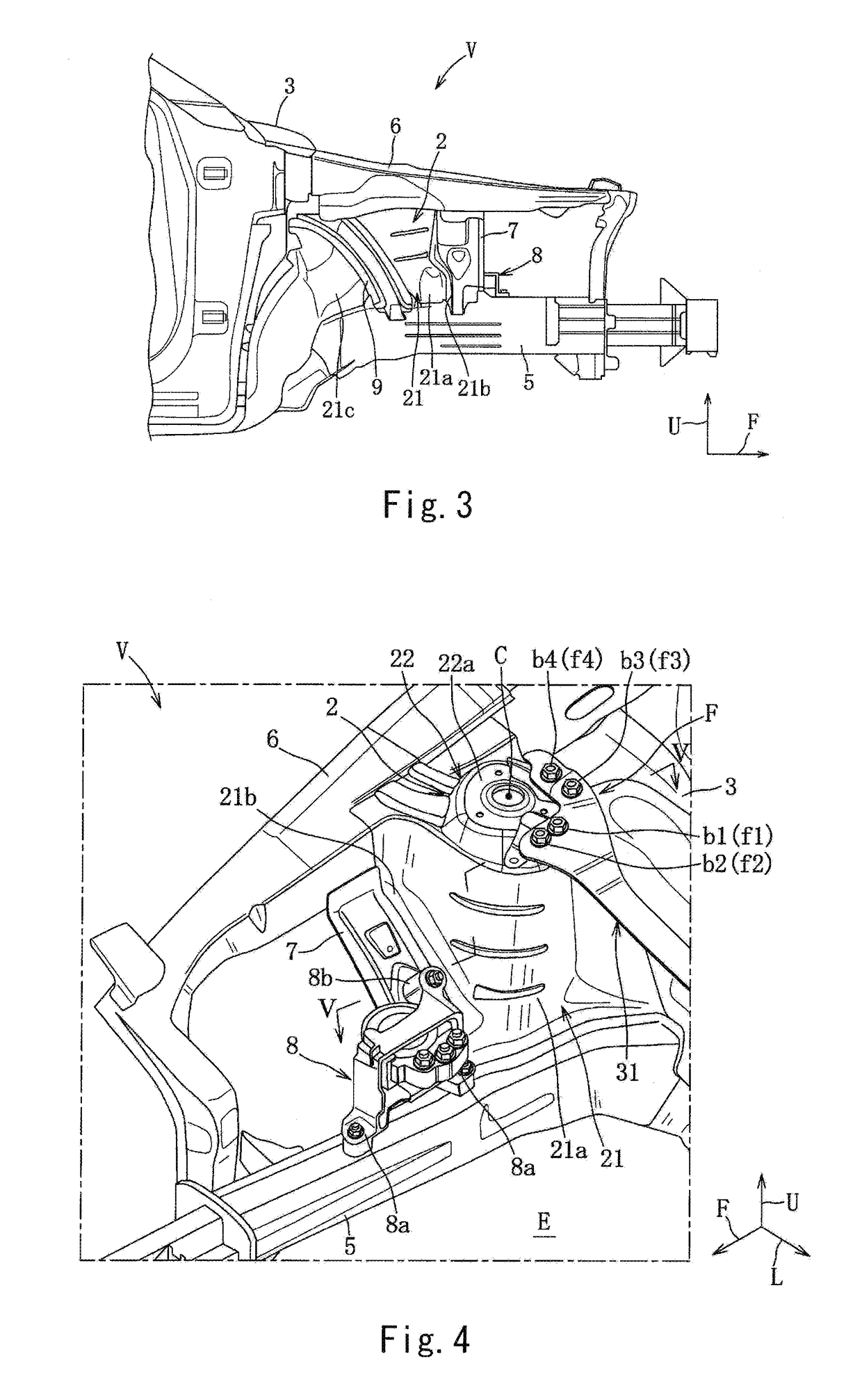

The present inventive vehicle front body structure, comprises a front side frame provided so as to project forward from a dash panel; an apron member provided so as to project substantially forward at a location that is outside the vehicle width direction of the front side frame; a suspension tower portion provided so as to at least partly protrude in an engine room for at least partly accommodating a front suspension vibration damper therein, the suspension tower portion being engaged with the apron member and the front side frame; an engine mount provided at the front side frame in front of the suspension tower portion so as to support a side portion of a power plant; and a first connecting member provided so as to straightly interconnect an upper portion of the suspension tower portion and a portion of the front side frame that is located in front of the engine mount, the member being disposed so as to overlap with the engine mount in a top view. The present invention provide a front structure of vehicle body for transmitting a collision load working on a front side frame to an upper portion of a vehicle body which is capable of absorbing the energy caused by the axial compression of the front side frame by suppressing any upward bend of the front side frame by reliably dispersing the collision load to the upper portion of the vehicle body while arranging an engine mount on the front side frame.

Owner:MAZDA MOTOR CORP

Vehicle front body structure

A bridge-shaped frame member is disposed on a front side frame in front of a suspension tower so as to extend vertically and stride over a No. 4 mount. Accordingly, there can be provided a vehicle front body structure that can attain a proper energy absorption of the front side frame with its axial compression can be attained at a vehicle crash.

Owner:MAZDA MOTOR CORP

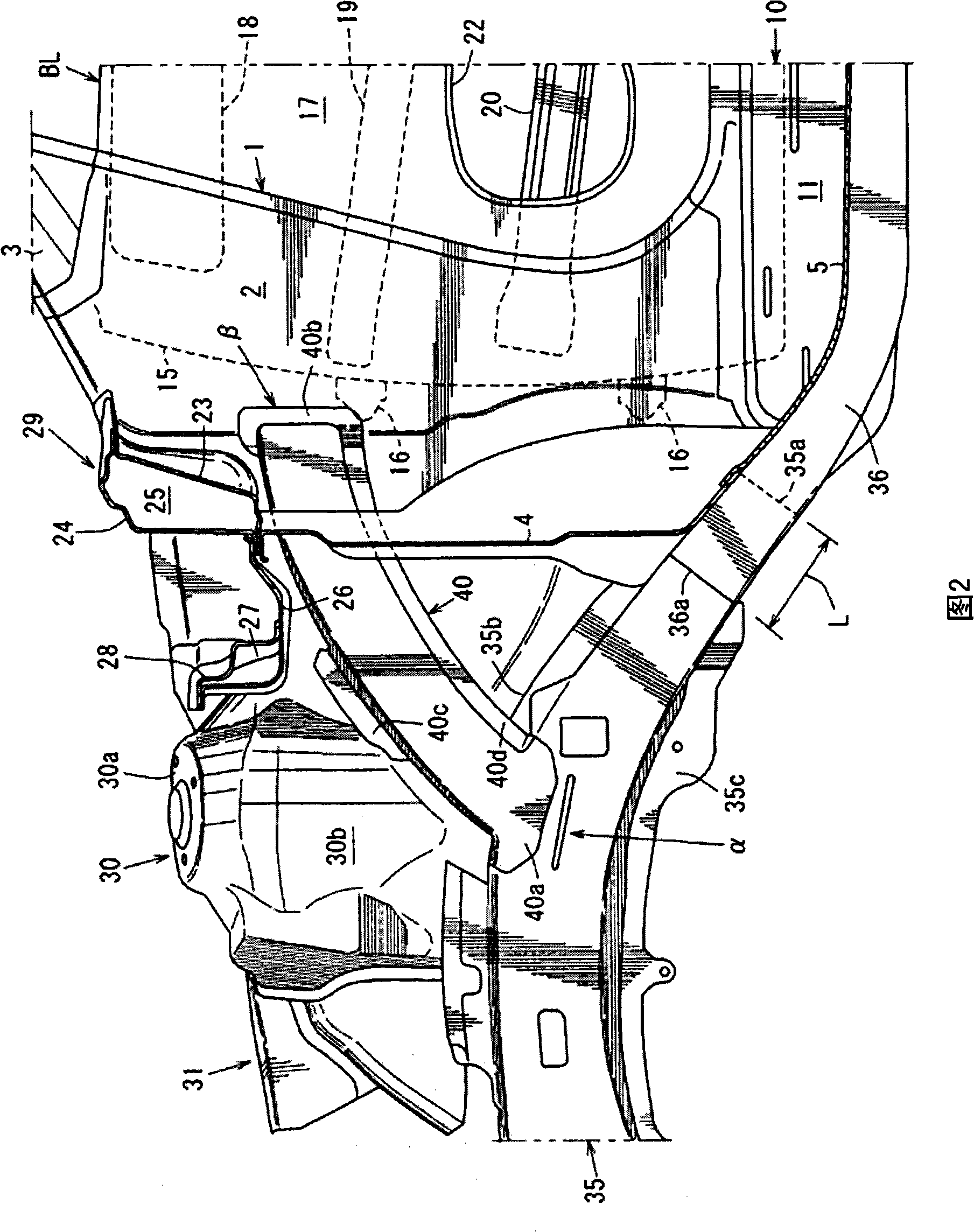

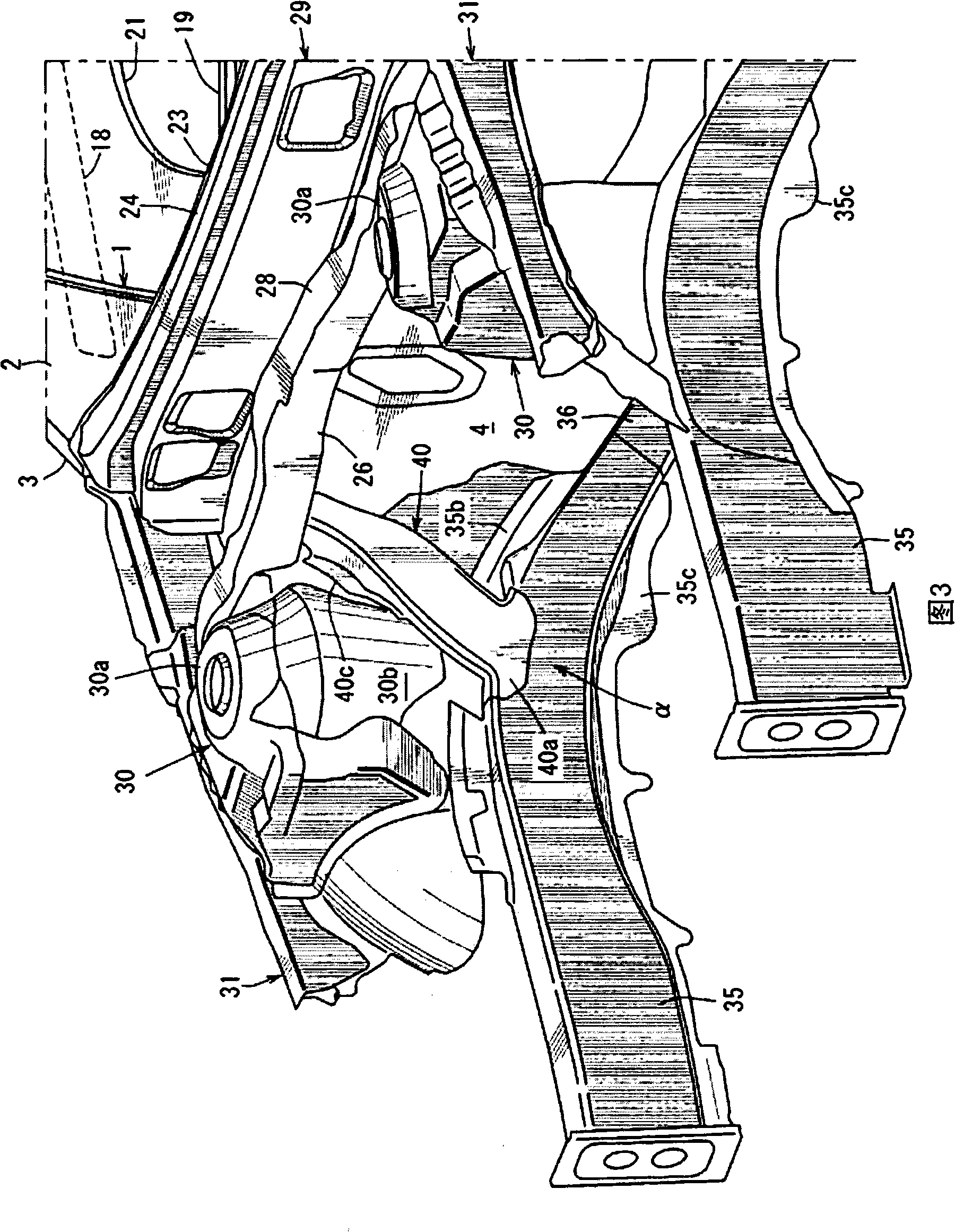

Front structure of automotive vehicle

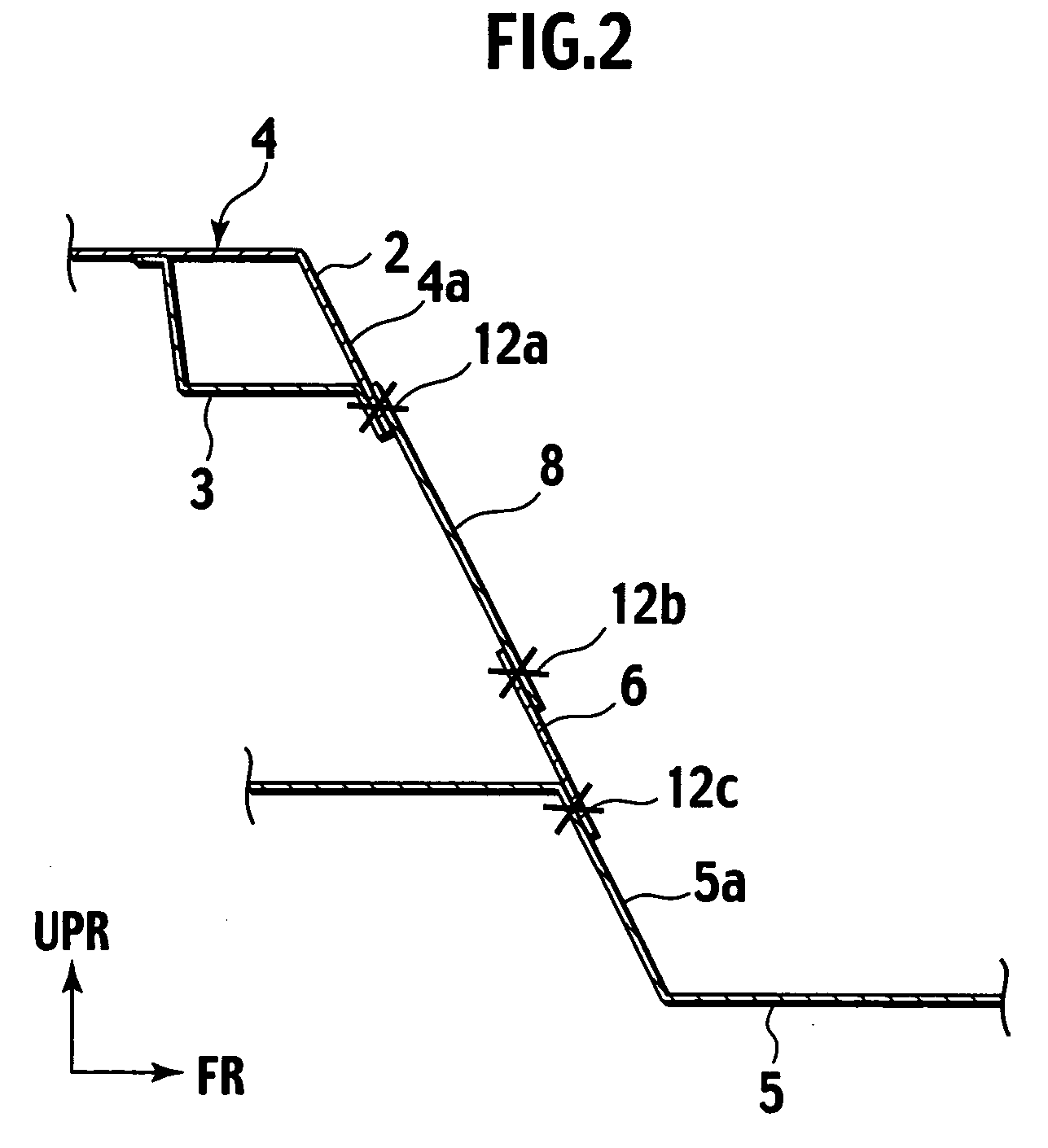

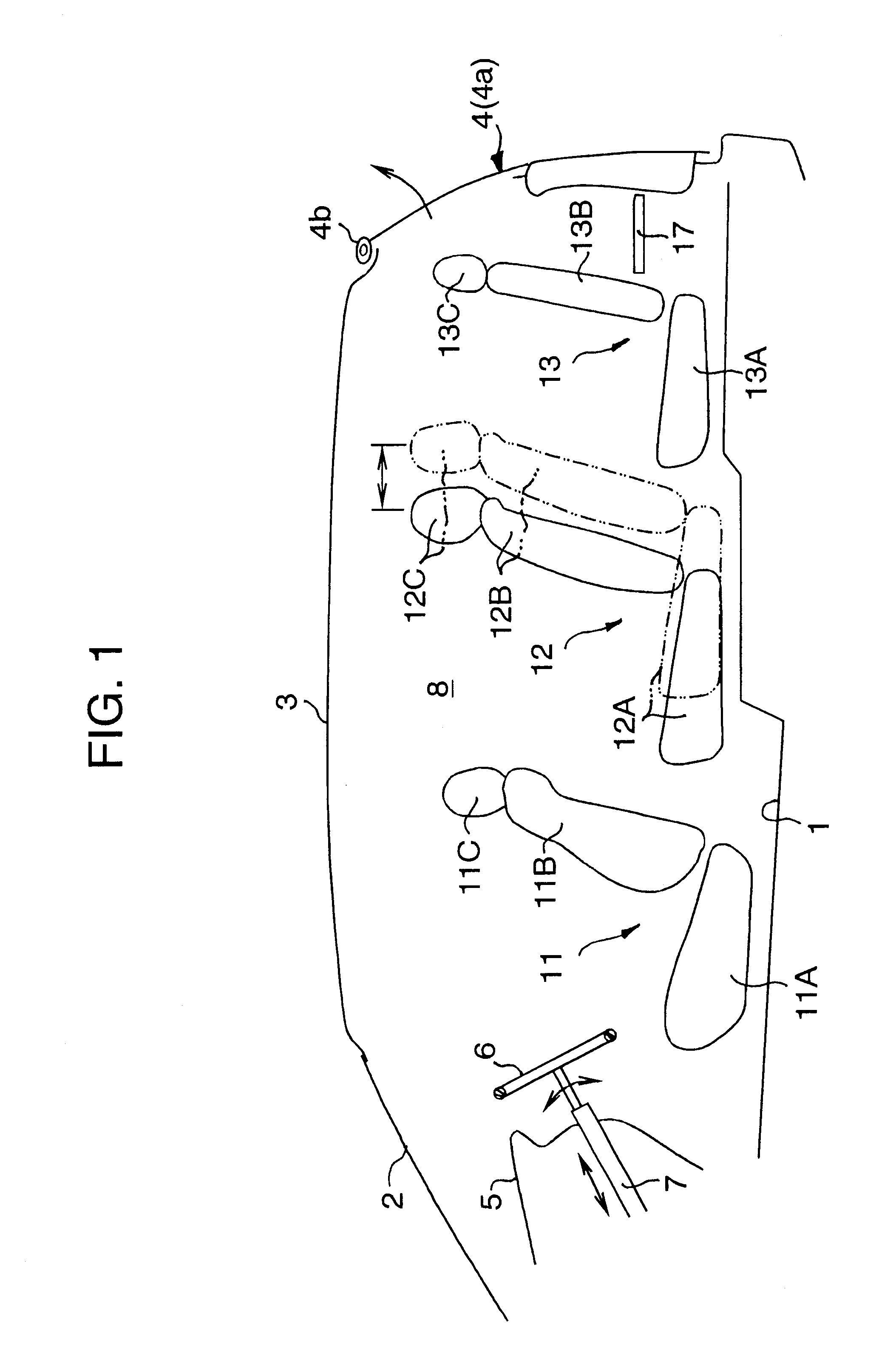

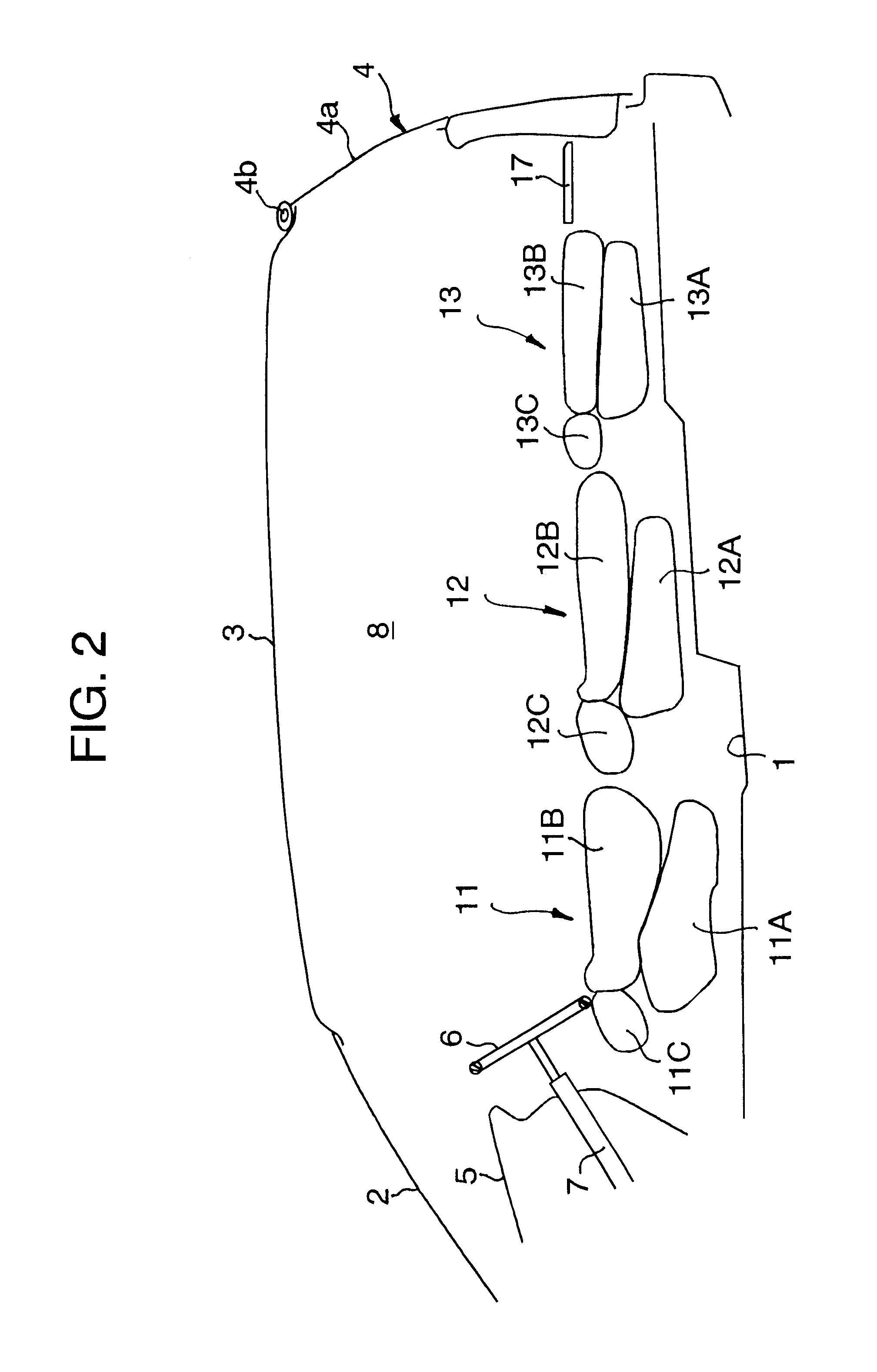

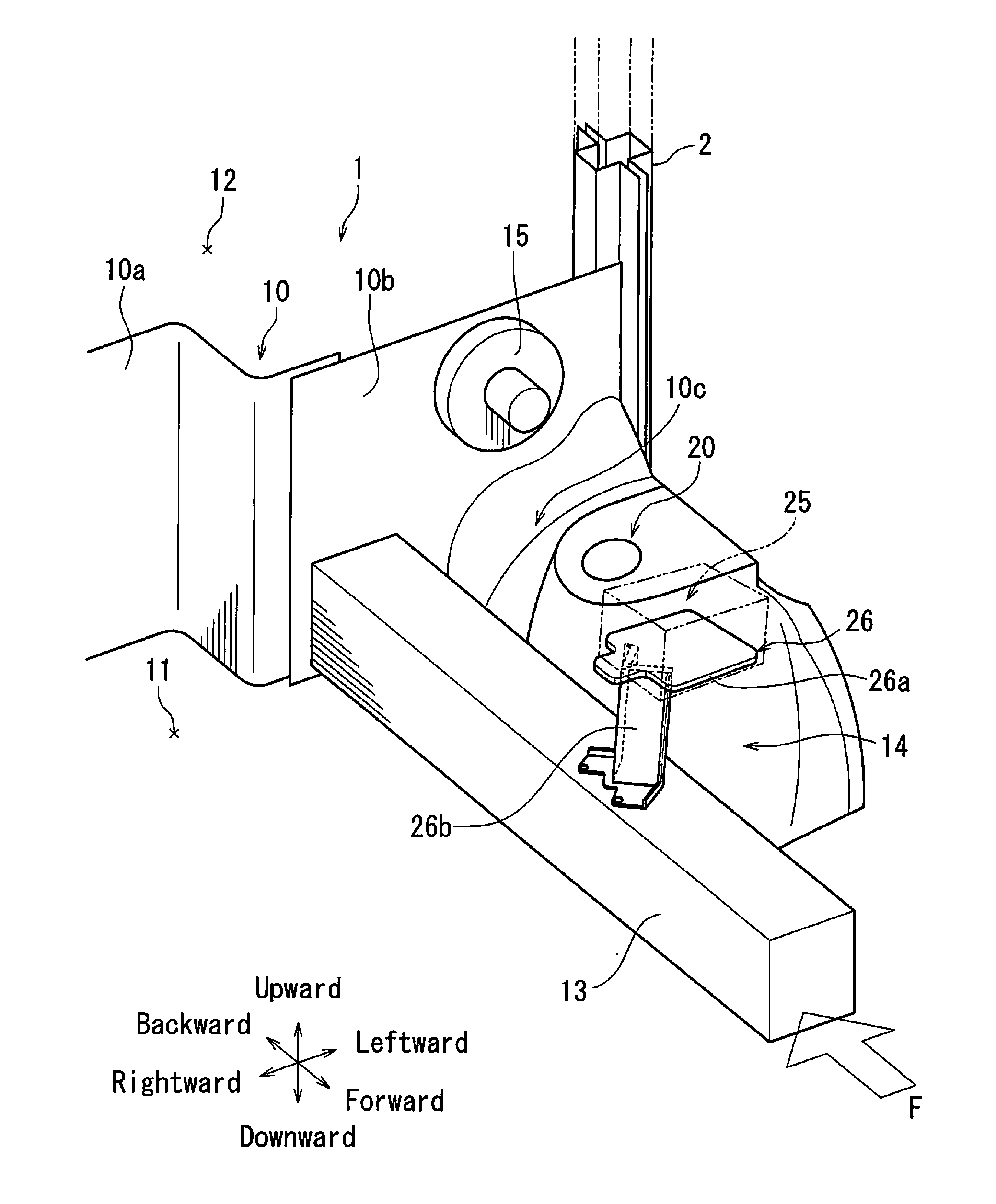

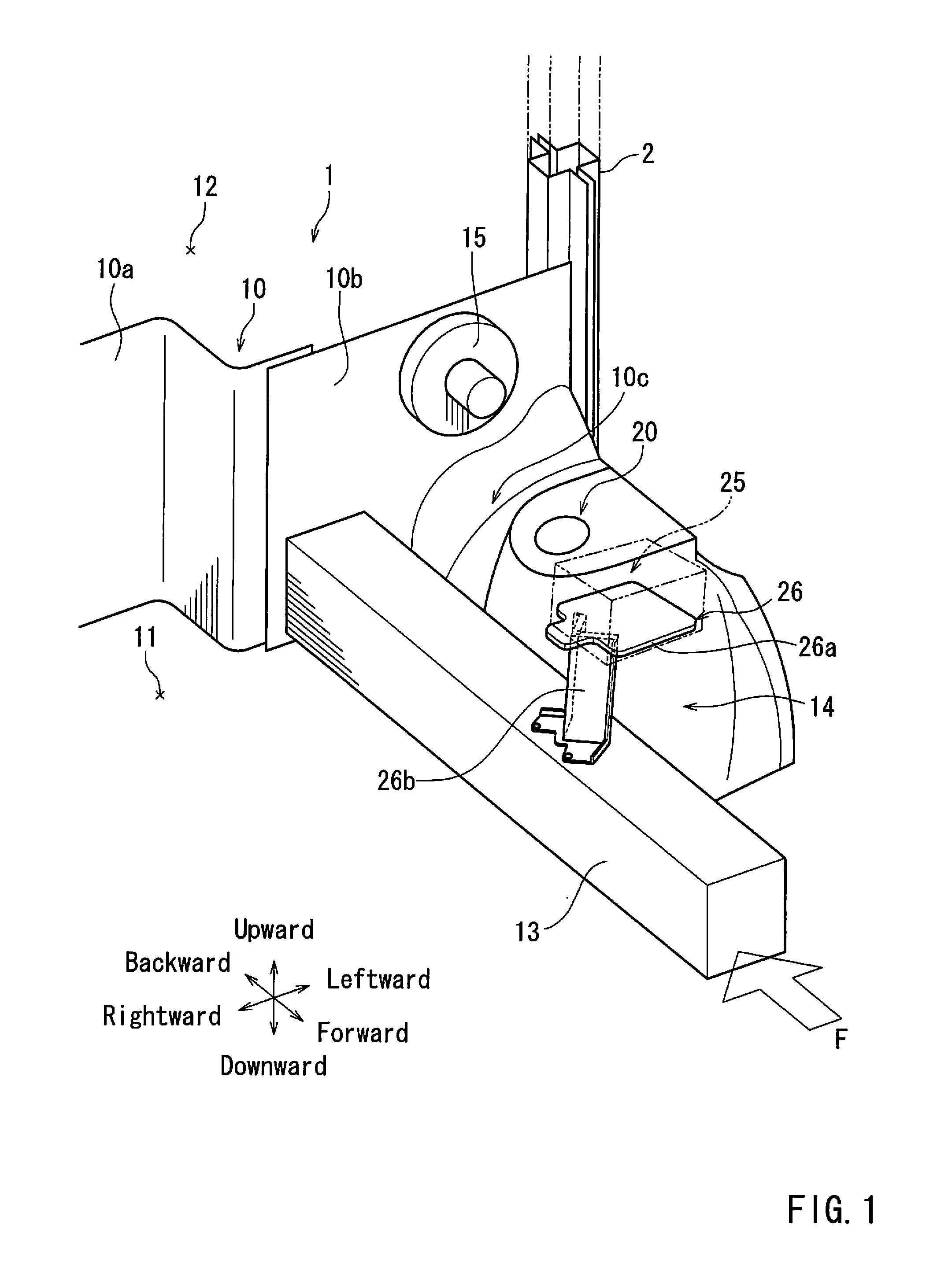

A support frame is provided to extend upward and rearward from a portion of a front side frame near a suspension tower substantially straight and connect to an upper portion of a hinge pillar. Accordingly, there can be provided a front structure of an automotive vehicle that can properly restrain a forward deformation of a cabin by transmitting an impact load at a vehicle frontal crash to the hinge pillar efficiently.

Owner:MAZDA MOTOR CORP

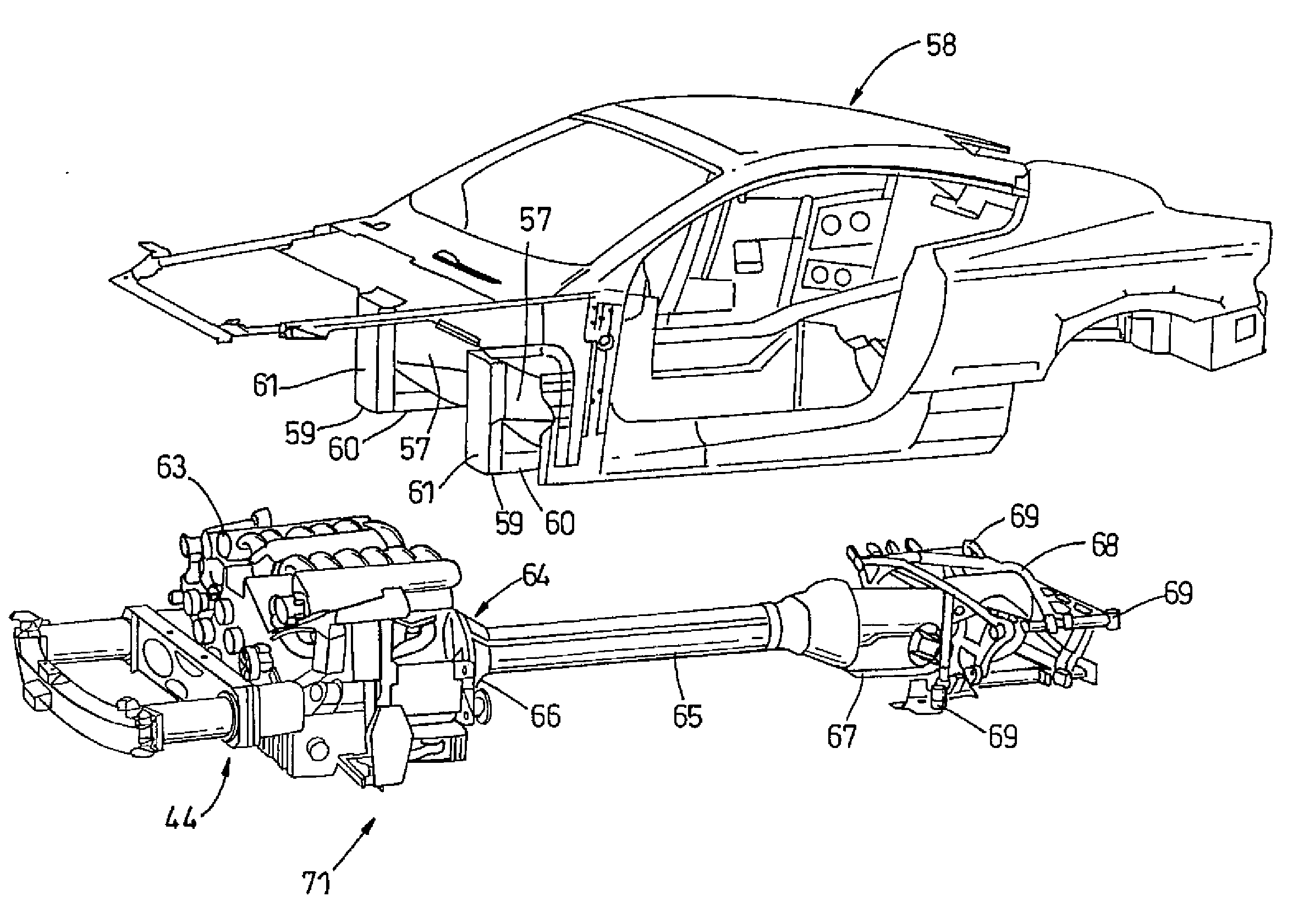

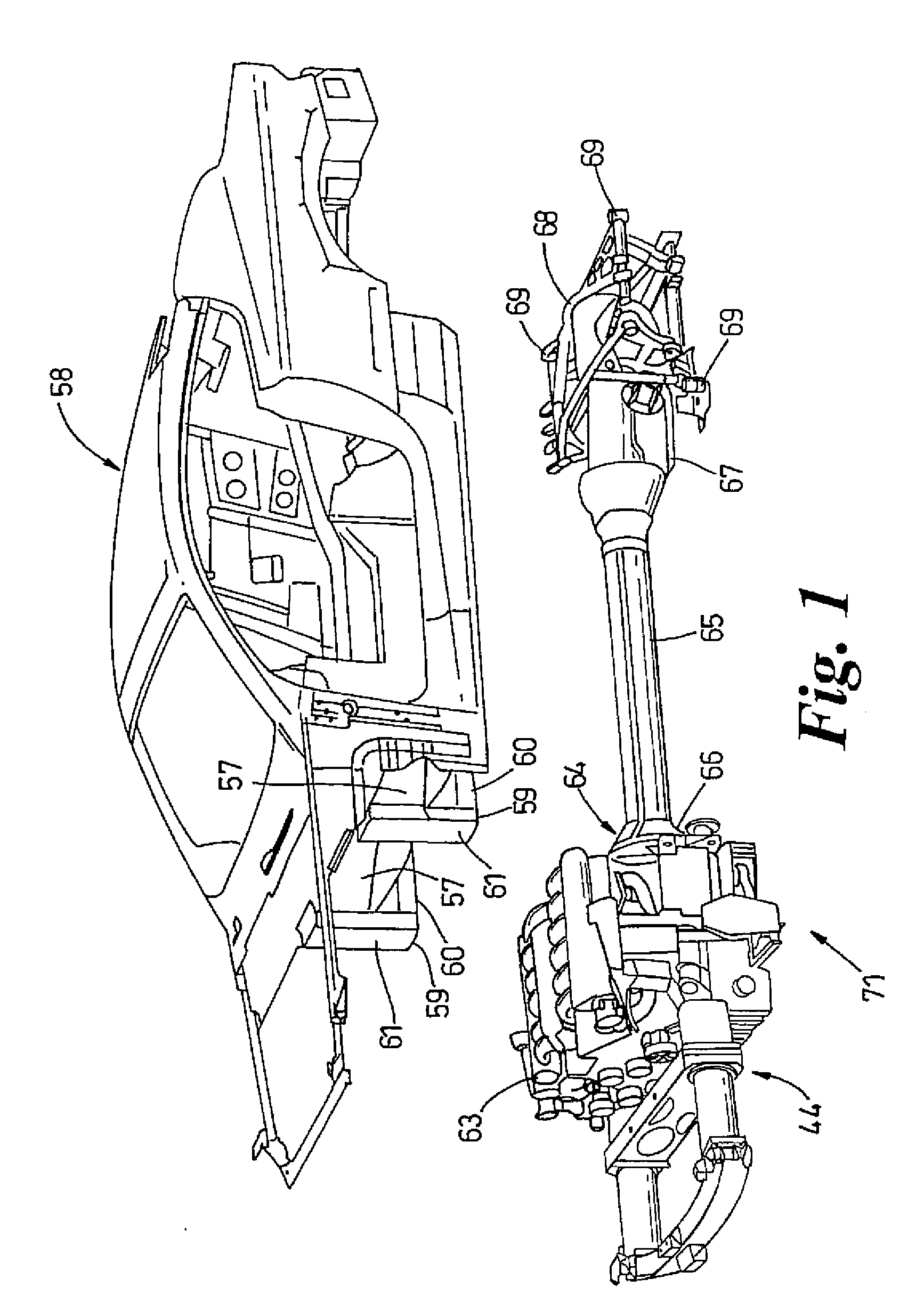

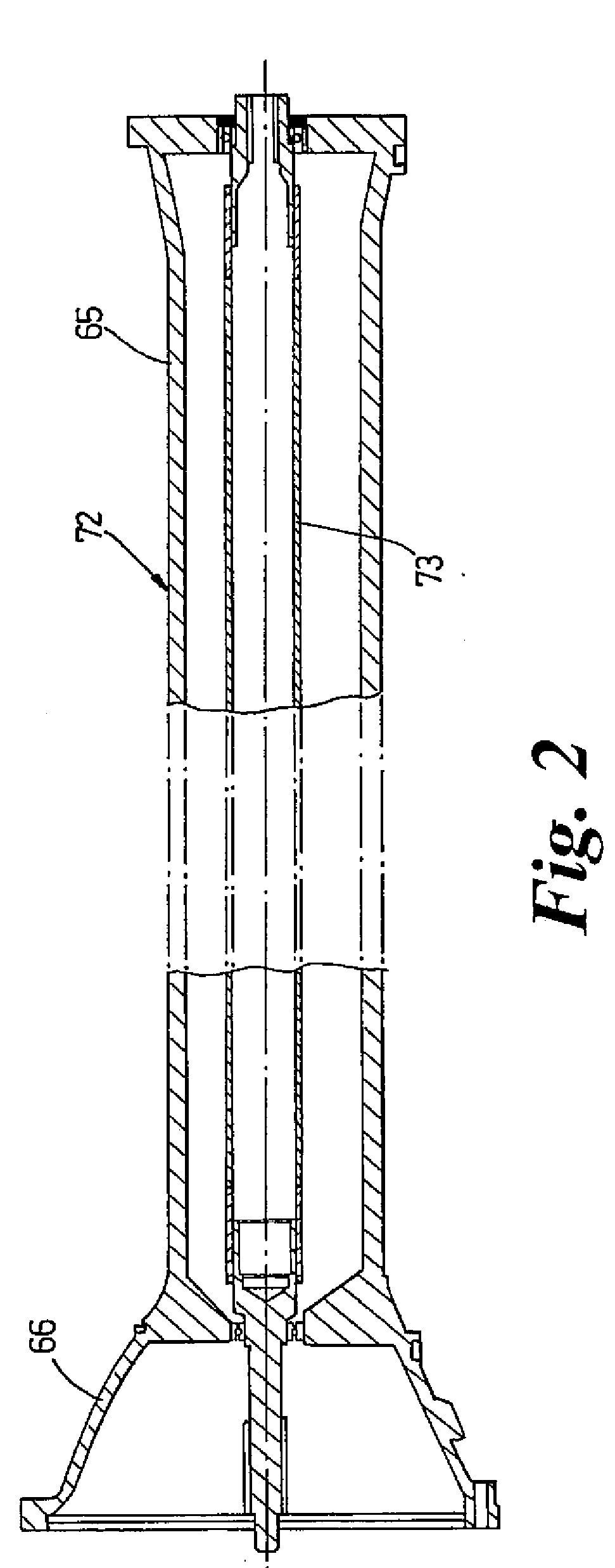

Assembly of a motor vehicle body and a power train and chassis module

ActiveUS20070137919A1Easy to assembleVehicle body-frame connectionsUnderstructuresSuspension towerSet screw

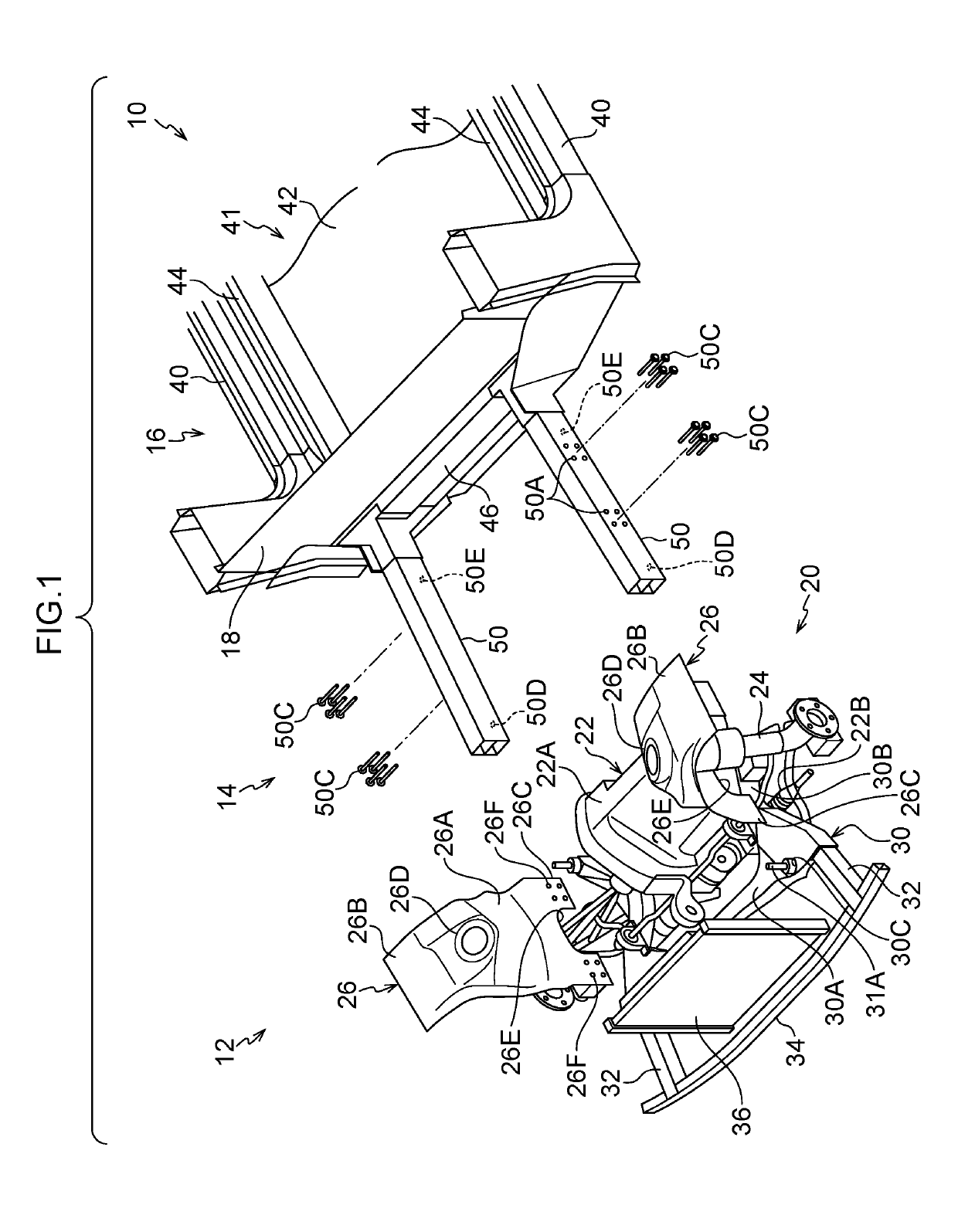

A motor vehicle front subframe includes a pair of main longitudinal beams each formed from an extrusion with a flange casting at the rear end and a suspension tower at the other end. Two lower longitudinal beams extend parallel to the main longitudinal beams and are connected by a cross member. Each lower longitudinal beam has a vertical rear flange and a generally horizontal front flange where it is attached to a corresponding flange face at the lower end of the adjacent suspension tower. Two intermediate longitudinal beams are attached to the suspension towers and to a main cross-member and forward of this are two crush cans to which is attached a bumper armature. The front subframe is part of a power train and chassis module which includes an engine, a longitudinally extending torque tube attached to the rear of the engine by a bell housing, a rear transmission and final drive assembly attached to a rearward end of the torque tube and a rear subframe mounted on the rear transmission and final drive assembly. The vehicle has a body with a passenger compartment and vertical pillars just forward of the passenger compartment. The body is assembled to the power train and chassis module by lowering the body with the of the vertical pillars just clear of the rear faces of the flanges and until various fixing holes in the flanges and align with those in the pillars. The body is then moved forward to close the gap between the flanges and the pillars. Suitable bolts or set screws are then inserted to secure the front subframe to the body and the rear subframe is attached to the body.

Owner:ASTON MARTIN LAGONDA LIMITED

Vehicle-body front structure

InactiveUS20120205944A1Avoid deformationImprove rigidityVehicle seatsSuperstructure subunitsSuspension towerEngineering

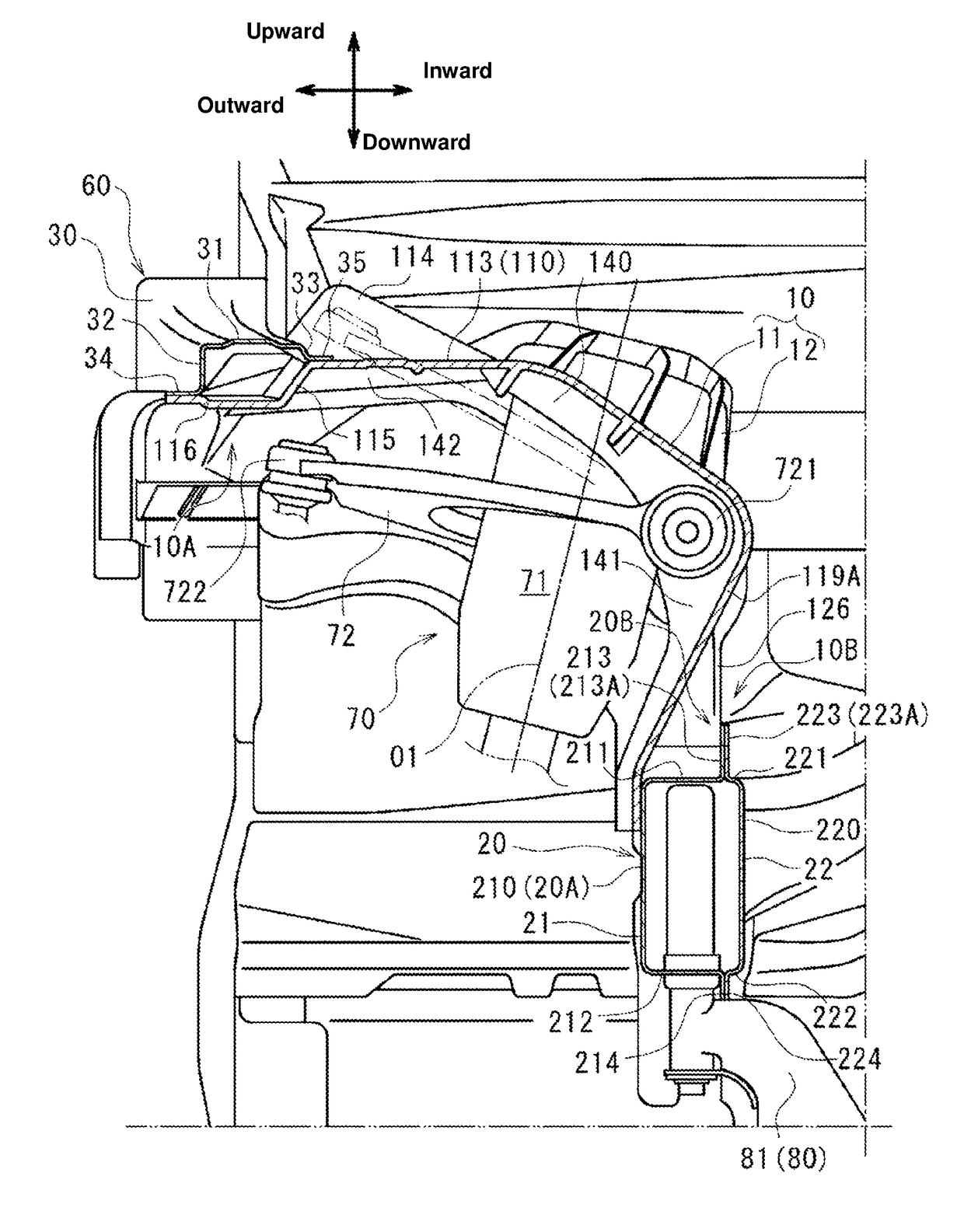

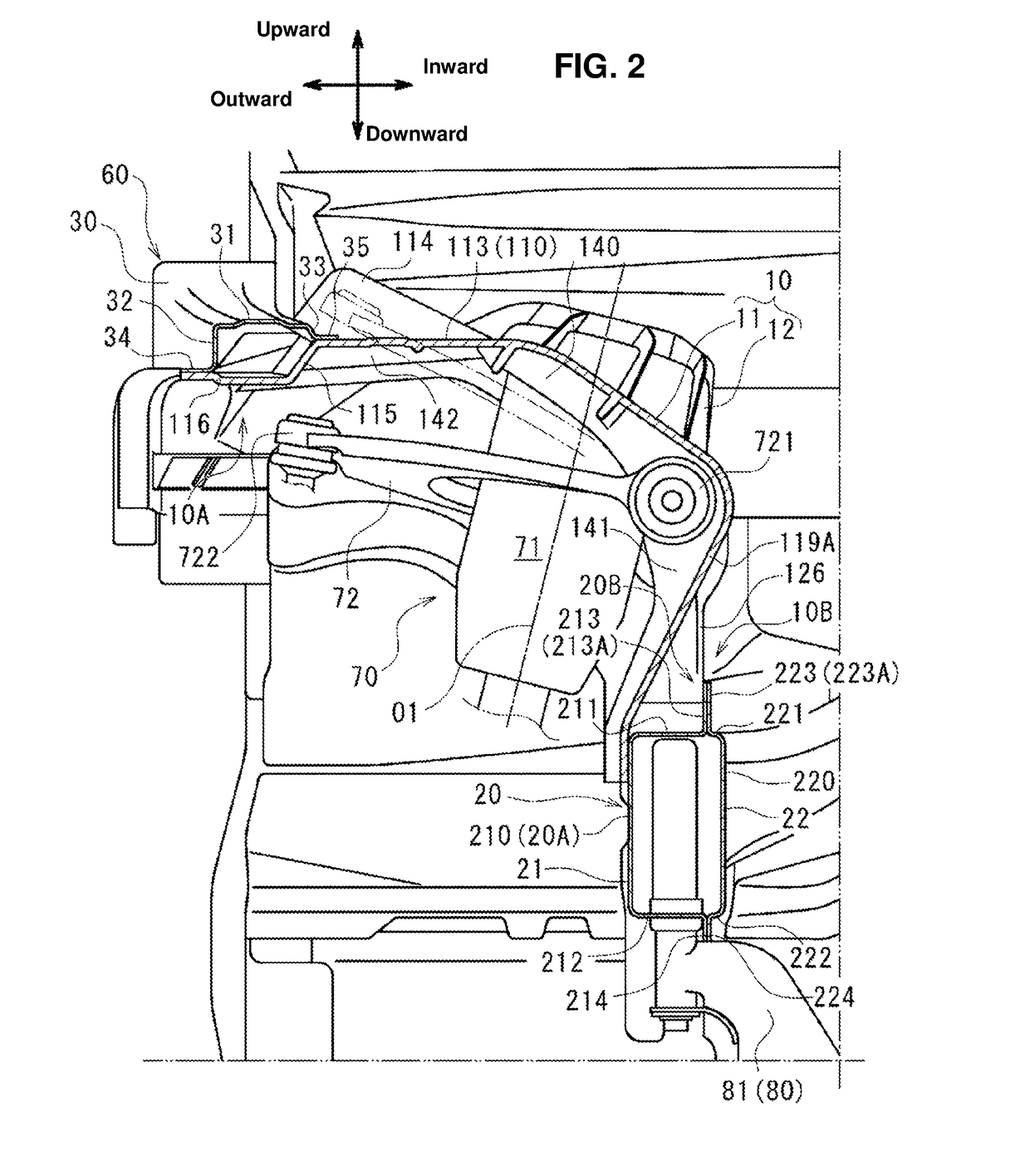

A rear apron panel is provided between a suspension tower and a dash panel. A vertical branch brace is provided to extend upwardly from a front side frame along an inner face of a suspension tower to form a closed cross section with a rear portion of the suspension tower. A deformation restraint member interconnects the apron frame and the vertical branch brace. Accordingly, there is provided a vehicle-body front structure which can restrain the apron frame from deforming outwardly in the vehicle width direction in the vehicle frontal collision to prevent the dash panel from moving back into the vehicle compartment too much.

Owner:MAZDA MOTOR CORP

Vehicle rear body structure

A vehicle rear body structure including: a cross member provided beneath a rear parcel shelf to connect upper ends of rear suspension towers; a strip member provided along a rear edge of a floor panel; and panel members provided between the cross member and the strip member to connect the cross member and the strip member. The panel members include a center panel and a pair of side panels arranged on outer sides in a vehicle transverse direction of the center panel, respectively. Each of the side panels is joined along an inner edge in the vehicle transverse direction thereof to the center panel by a continuous welding.

Owner:NISSAN MOTOR CO LTD

Front structure of automotive vehicle

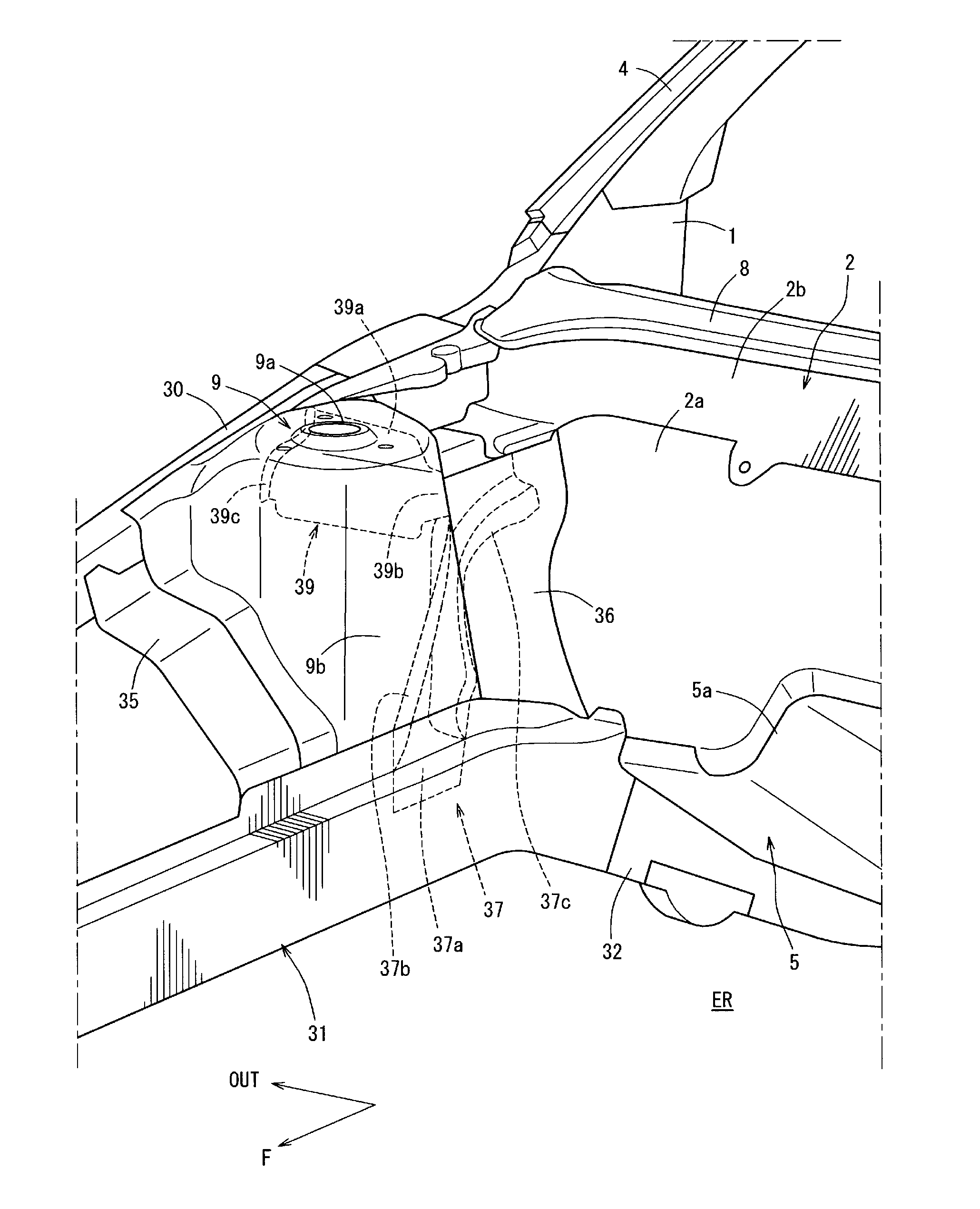

A support frame is provided to extend upward and rearward from a portion of a front side frame near a suspension tower substantially straight and connect to an upper portion of a hinge pillar. Accordingly, there can be provided a front structure of an automotive vehicle that can properly restrain a forward deformation of a cabin by transmitting an impact load at a vehicle frontal crash to the hinge pillar efficiently.

Owner:MAZDA MOTOR CORP

Vehicle rear body structure

ActiveUS7325865B2Increase workforceDifficult to maintainVehicle seatsUnderstructuresSuspension towerRear quarter

Owner:NISSAN MOTOR CO LTD

Inverter mounting structure for vehicle

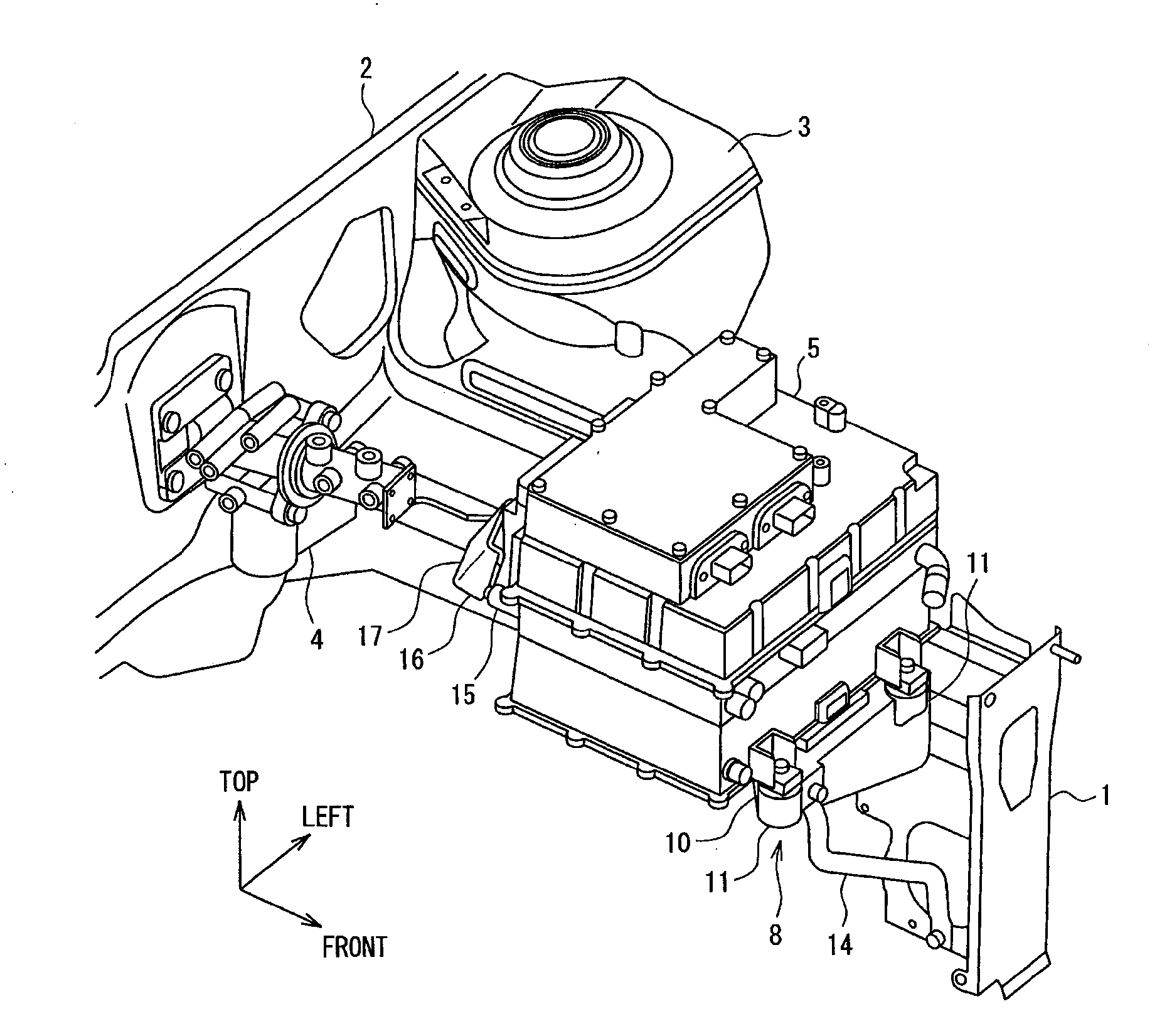

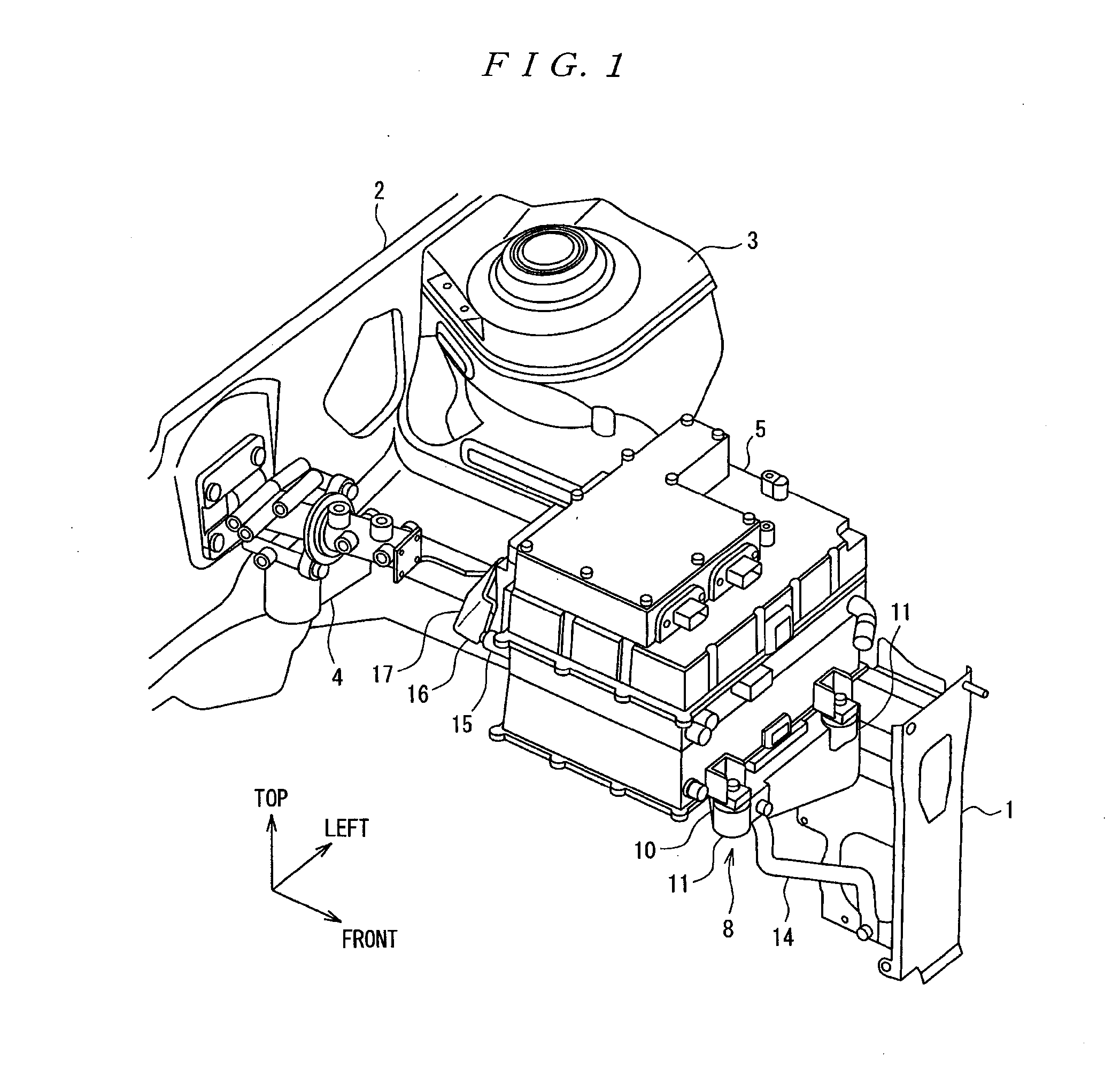

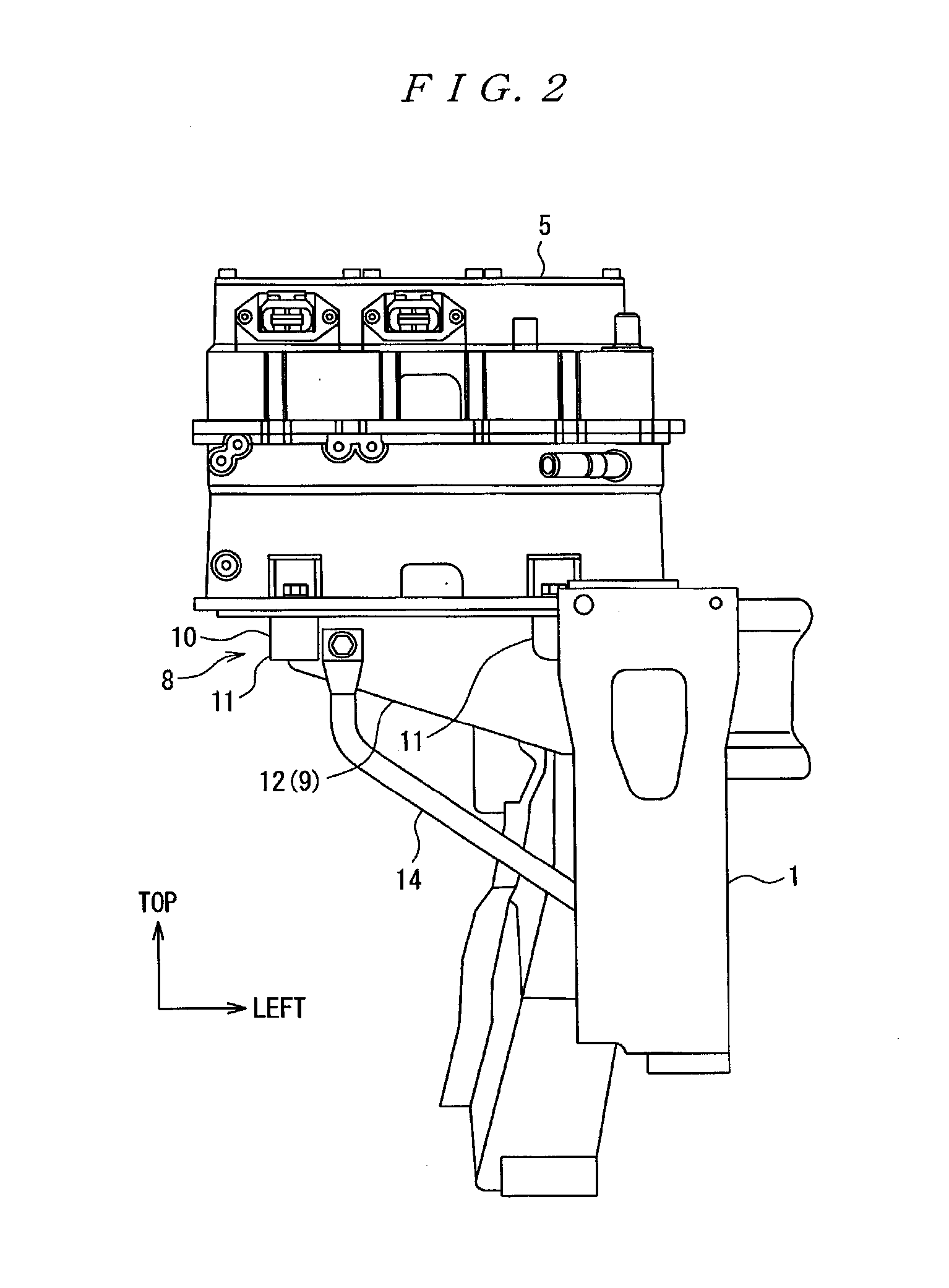

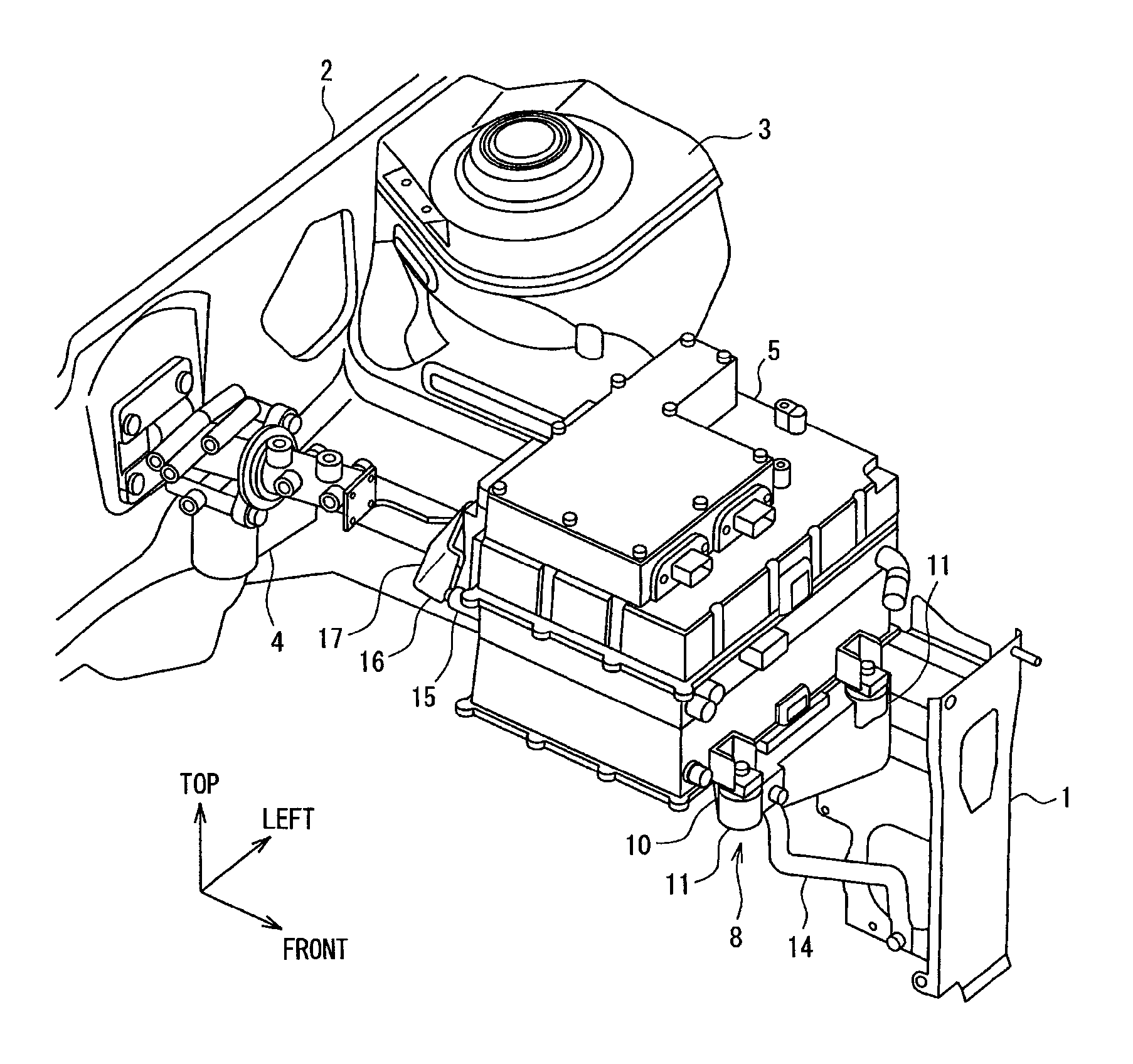

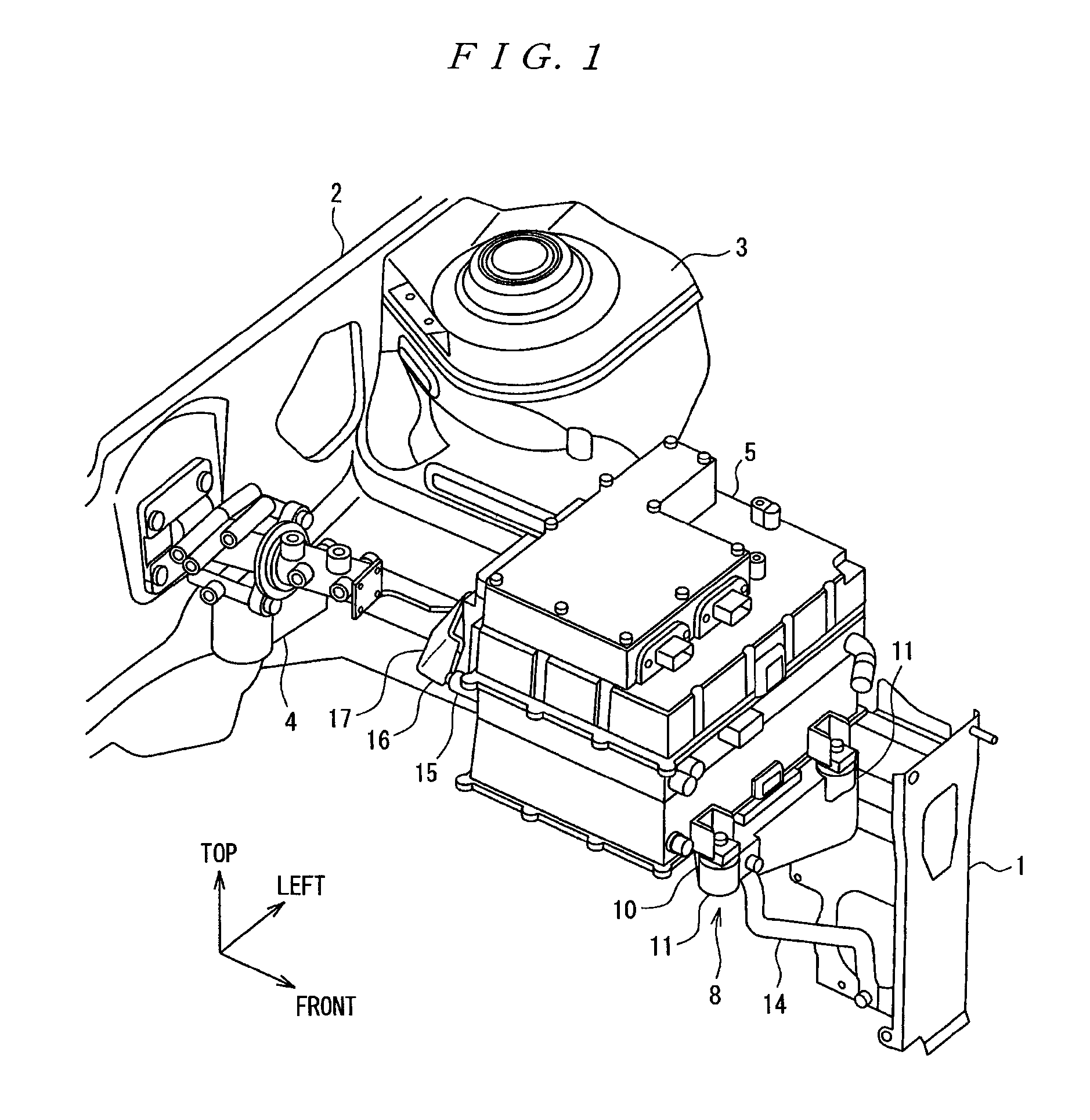

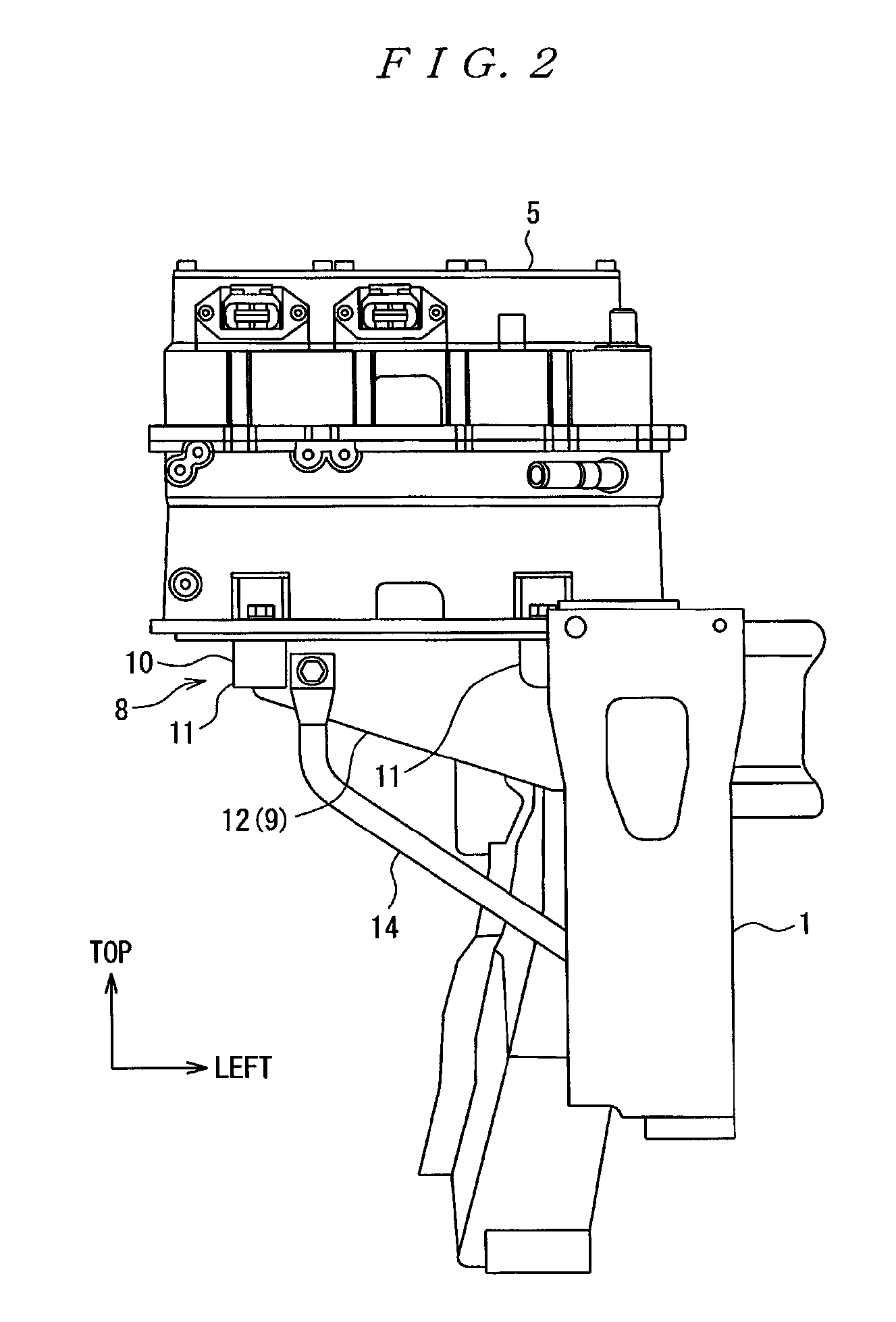

ActiveUS20130037335A1Avoid deformationSuppression problemElectric propulsion mountingPrinted circuit board receptaclesSuspension towerMaster cylinder

A supporting portion of an inverter bracket is made of cast, and the inverter bracket is attached onto the side member to locate a vehicle rear end portion of the attachment portion to be on the front side in the vehicle, by a prescribed distance from a vehicle front surface portion of the suspension tower. When a force F is exerted from the front side of the vehicle, the side member curves outward in the vehicle width direction between one part to which the suspension tower is coupled and another part to which the inverter bracket is attached. The inverter bracket and inverter are pushed obliquely outward in the vehicle width direction, so that the contact with the master cylinder can be suppressed.

Owner:SUZUKI MOTOR CORP

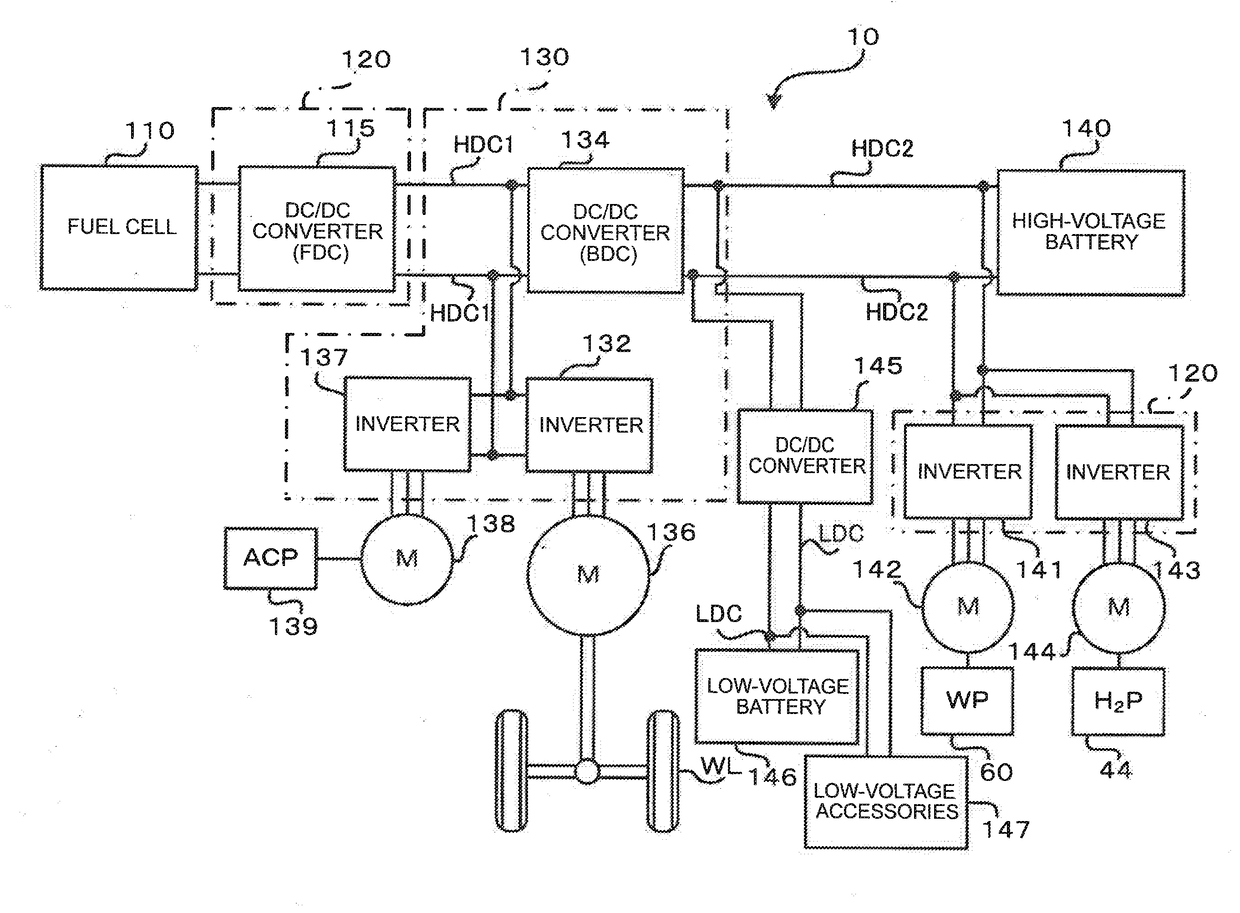

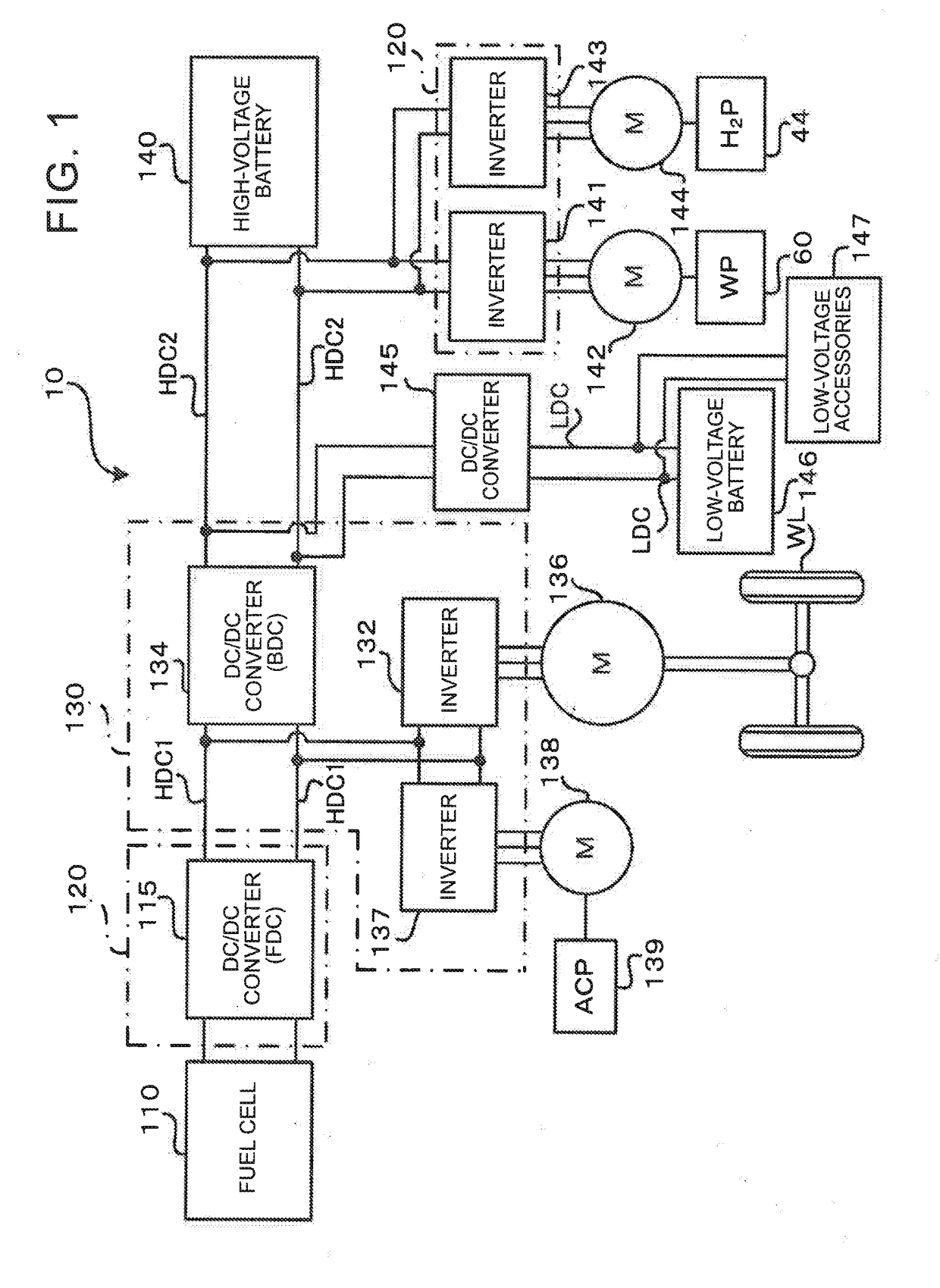

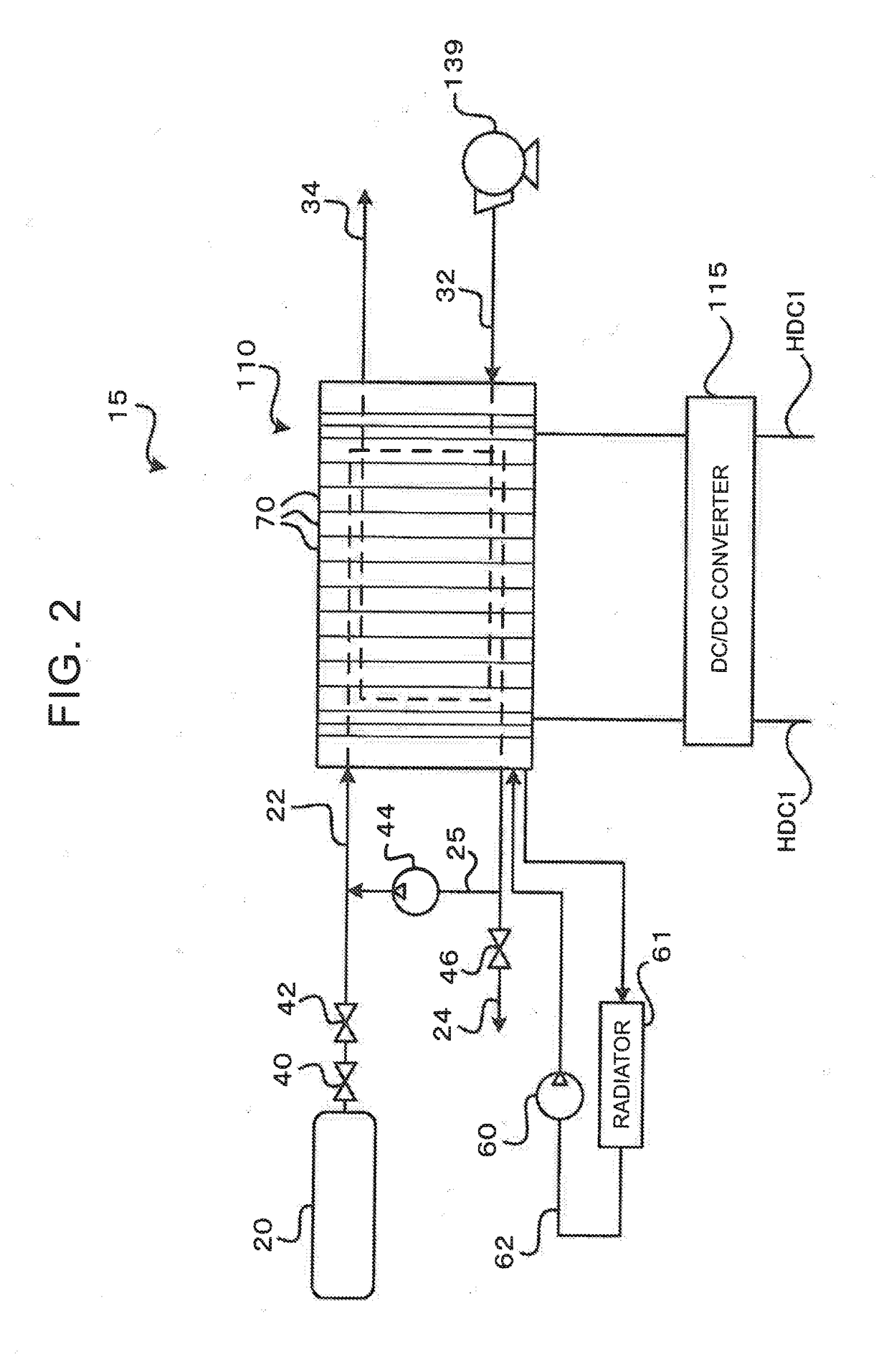

Fuel cell vehicle

ActiveUS20180229771A1Solve the lack of rigidityHigh strengthElectric devicesFuel cell auxillariesDashboardSuspension tower

Owner:TOYOTA JIDOSHA KK

Front structure of automotive vehicle

InactiveCN101293537AInhibition of forward movementSuperstructure subunitsSuspension towerEngineering

A support frame is provided to extend upward and rearward from a portion of a front side frame near a suspension tower substantially straight and connect to an upper portion of a hinge pillar. Accordingly, there can be provided a front structure of an automotive vehicle that can properly restrain a forward deformation of a cabin by transmitting an impact load at a vehicle frontal crash to the hinge pillar efficiently.

Owner:MAZDA MOTOR CORP

Vehicle front structure

Owner:TOYOTA JIDOSHA KK

Front vehicle-body structure of vehicle

ActiveUS20180029643A1Improve rigidityAvoid interferenceUnderstructuresSuperstructure subunitsSuspension towerMechanical engineering

A front vehicle-body structure of a vehicle comprises a front frame which extends in a longitudinal direction, an apron reinforcement which is positioned above and on an outward side, in a vehicle width direction, of the front frame and extends in the longitudinal direction, and a suspension housing which is provided to be laid between the front frame and the apron reinforcement and accommodating a suspension therein, wherein the suspension housing includes a narrow-width portion which has the narrowest width in the longitudinal direction in an upper view, and a suspension tower portion where a damper member of the suspension is attached is formed at a portion of the suspension housing which includes the narrow-width portion.

Owner:MAZDA MOTOR CORP

Vehicle body structure

ActiveUS9616937B2Increased durabilityImprove fatigue strengthSuperstructure subunitsSuperstructure connectionsSuspension towerDie casting

Owner:TOYOTA JIDOSHA KK

Rear body structure for vehicle

InactiveUS6338516B1Improve structural strengthReduce distortionPedestrian/occupant safety arrangementSuperstructure subunitsSuspension towerRear-end collision

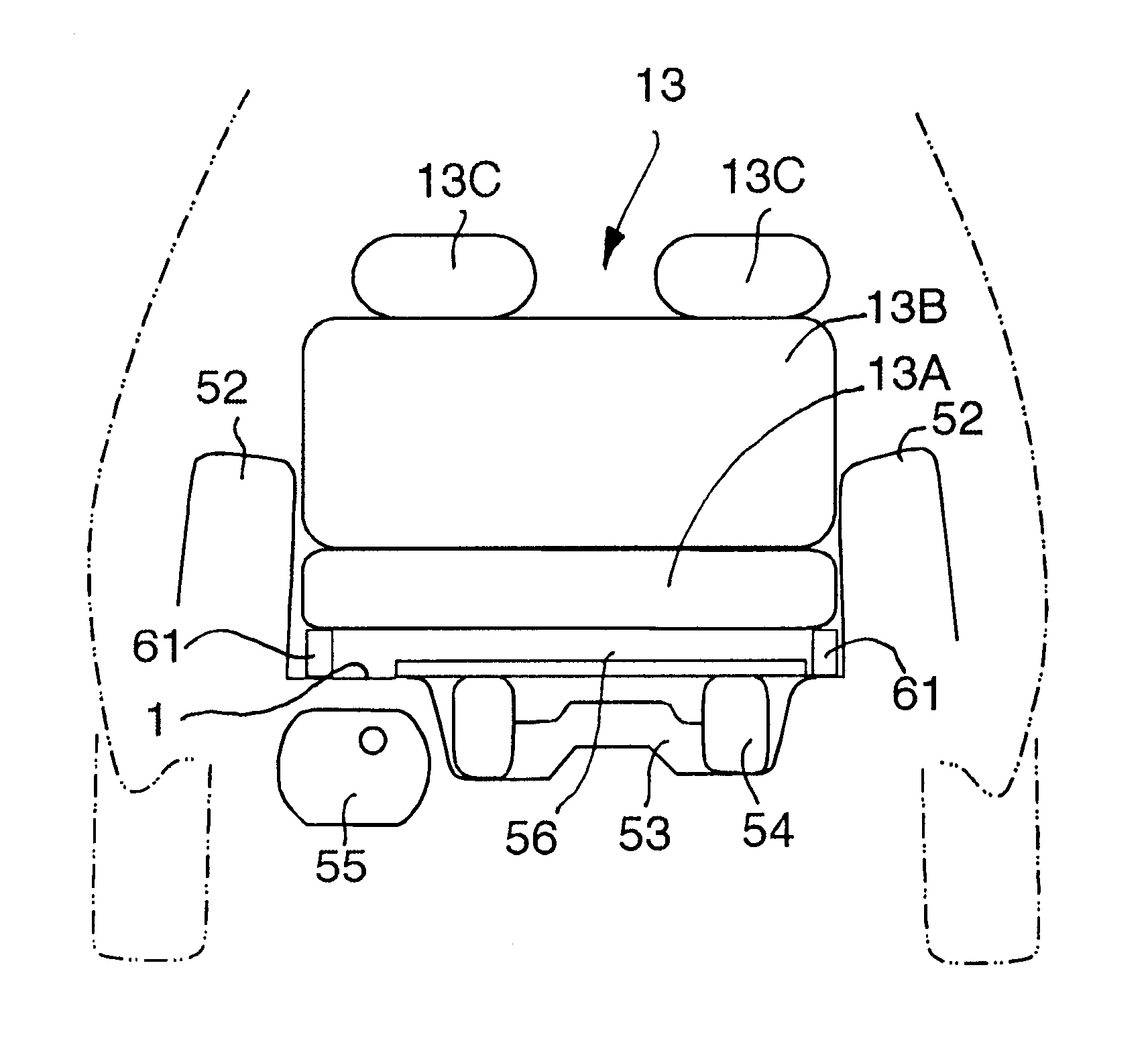

Disclosed herein is a vehicle rear body structure to reduce the amount of the transformation of the vehicle rear body portion for the back row seat in the event of the rear end collision. A pair of the rear wheel houses (51) are formed at the back part of a floor panel. A suspension tower (52) is formed to the rear wheel house (51). The pan (53) is formed nearly in the center part in the traverse direction of the floor panel 1 behind the suspension tower (52). The pan (53) is formed like the plate so as to being opened upward. The bottom of the pan (53) is substantially horizontal. The spare tire (54) is kept substantially horizontal in the pan (53).

Owner:MAZDA MOTOR CORP

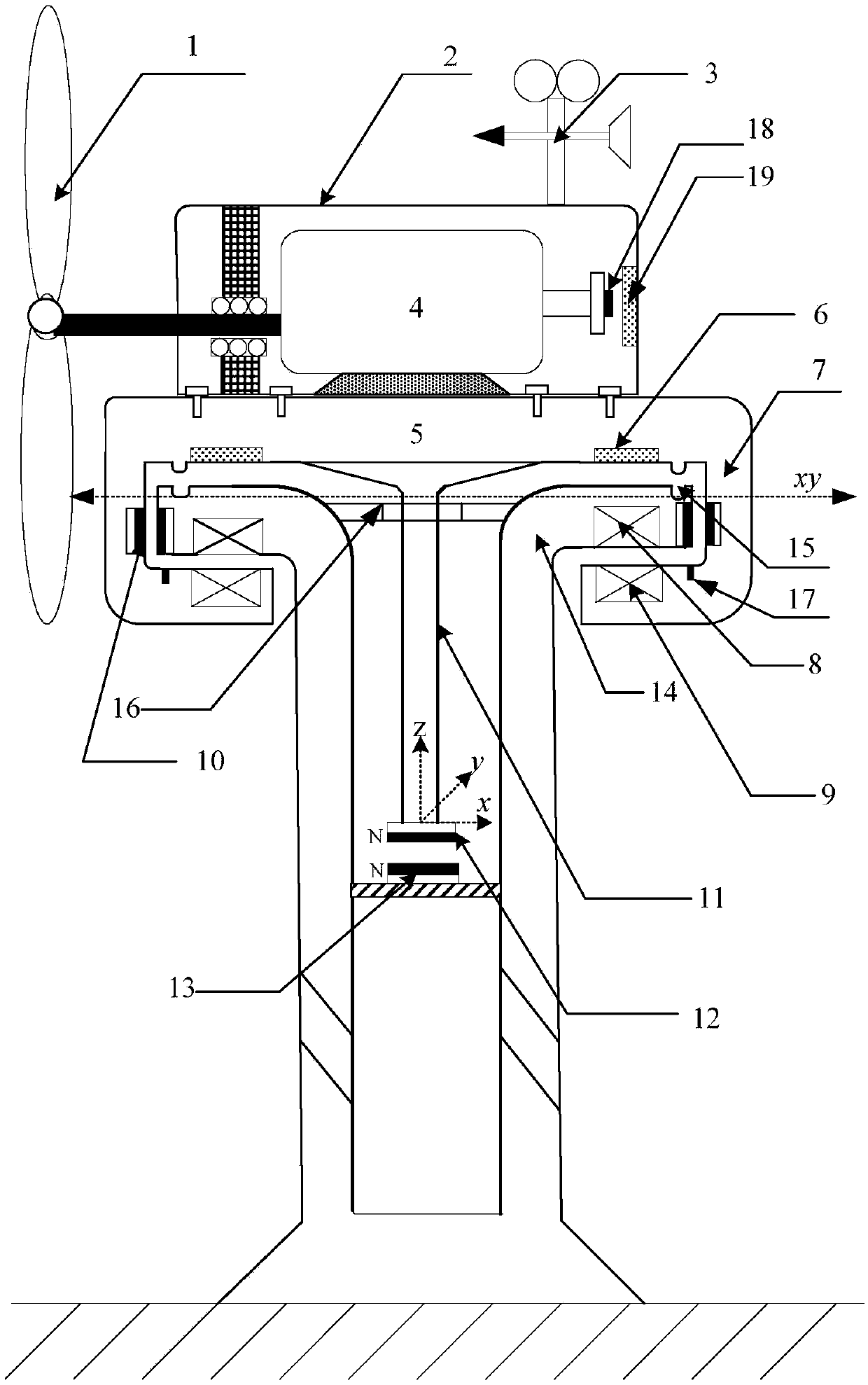

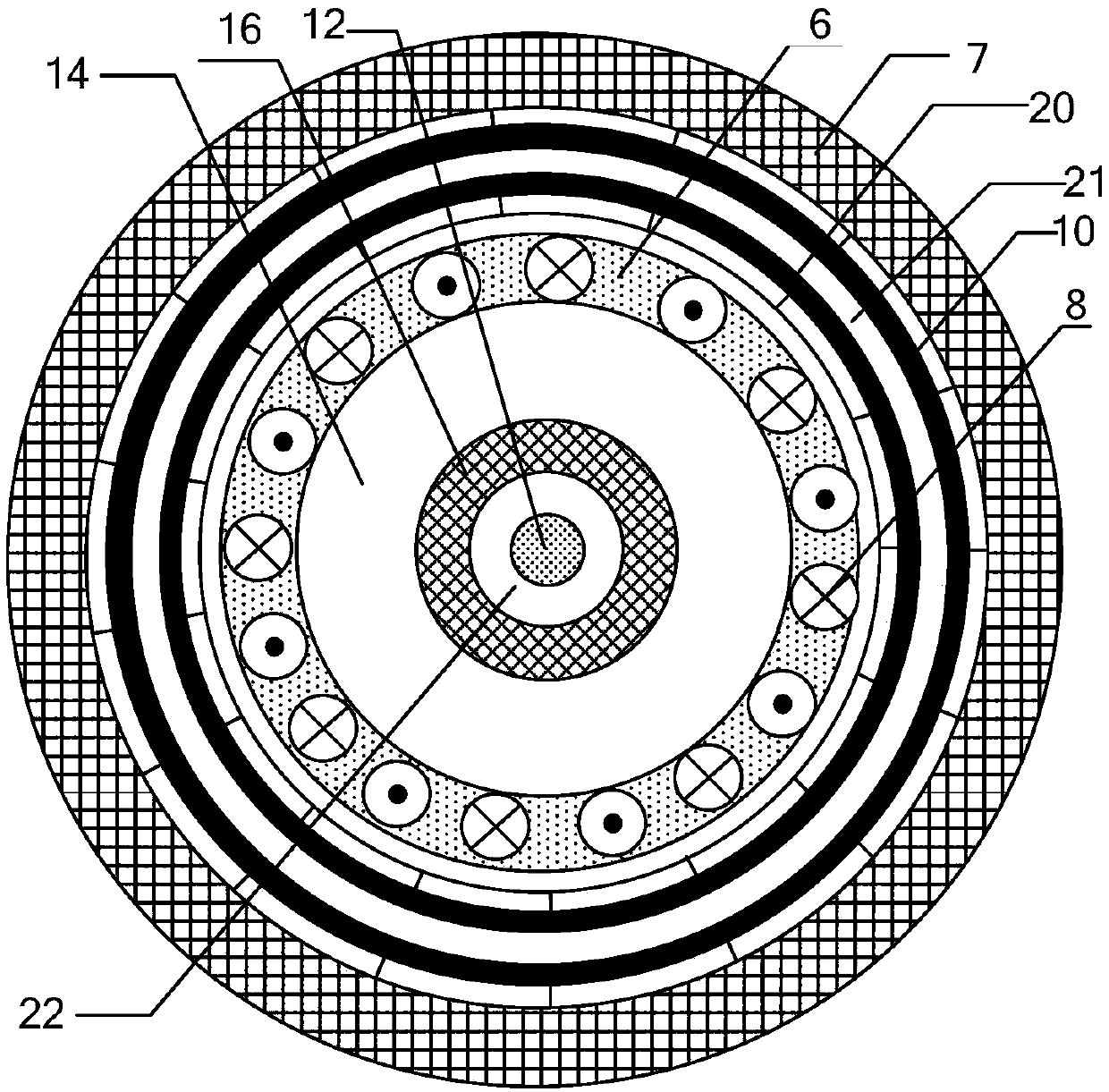

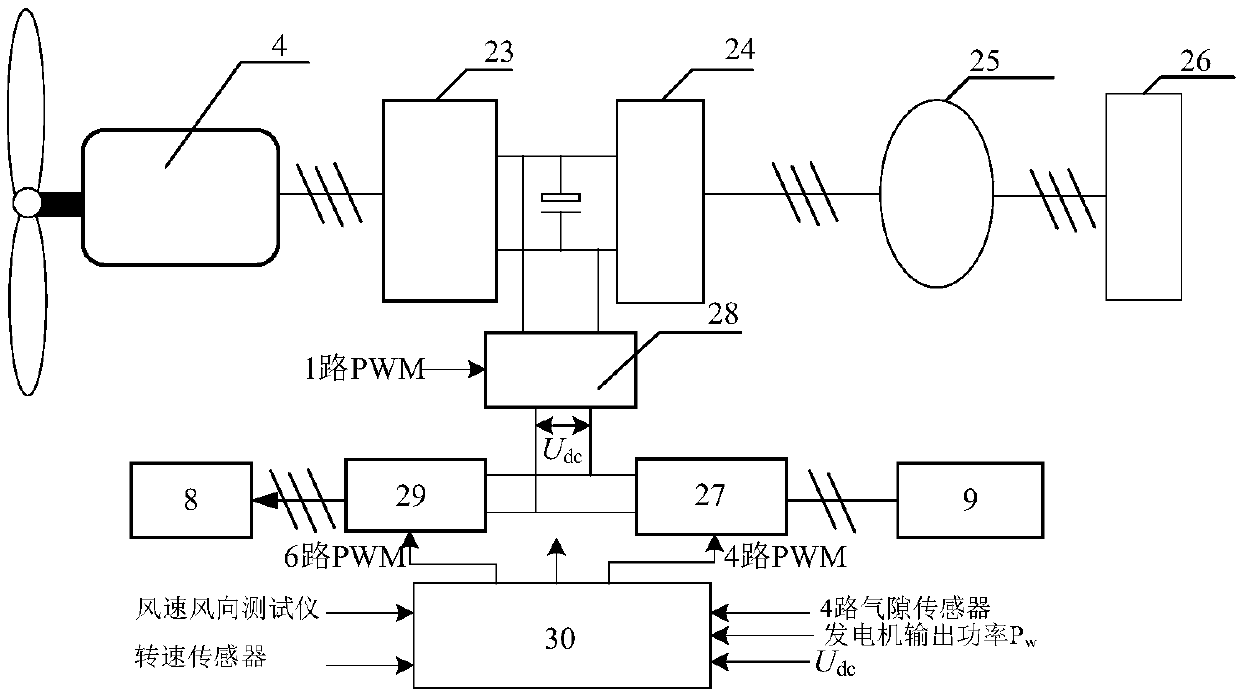

Active and passive coordinated regulated magnetic levitation wind yawing system

ActiveCN108019316AIncrease pitch angle stiffnessResolve swingWind motor controlMachines/enginesNacelleYaw system

The invention discloses an active and passive coordinated regulated magnetic levitation wind yawing system applied to large- and medium-sized wind turbine generators. The system comprises a cabin, a yawing supporting body, a pitch adjusting suspension rack and a suspension tower to finish enhancement of pitch rigidity of the yawing supporting body, high frequency air gap fluctuation inhibition, horizontal displacement passive adjustment, active suspension control and cabin yawing control in a coordinated manner; a 6mm thick aluminum plate is arranged in a cabin base of the yawing supporting body to generate an eddy-current damping force to passively inhibit high frequency fluctuation of an axial suspension air gap. The pitch rigidity of the cabin is enhanced by means of the pitch adjustingsuspension rack, permanent magnets and a suspension tower-based support, and the active suspension degree of freedom, the horizontal repulsive force between the permanent magnet on the inner side ofthe yawing supporting body and the permanent magnet on the outer side of the suspension tower and the passive balanced water level displacement are reduced; windward and crosswind protection of passive yawing when the cabin is suspended stably is achieved under control of a master control unit DSP28035 of a BUCK converter, an H bridge converter and a three phase inverter by active suspension and yawing separately.

Owner:QUFU NORMAL UNIV

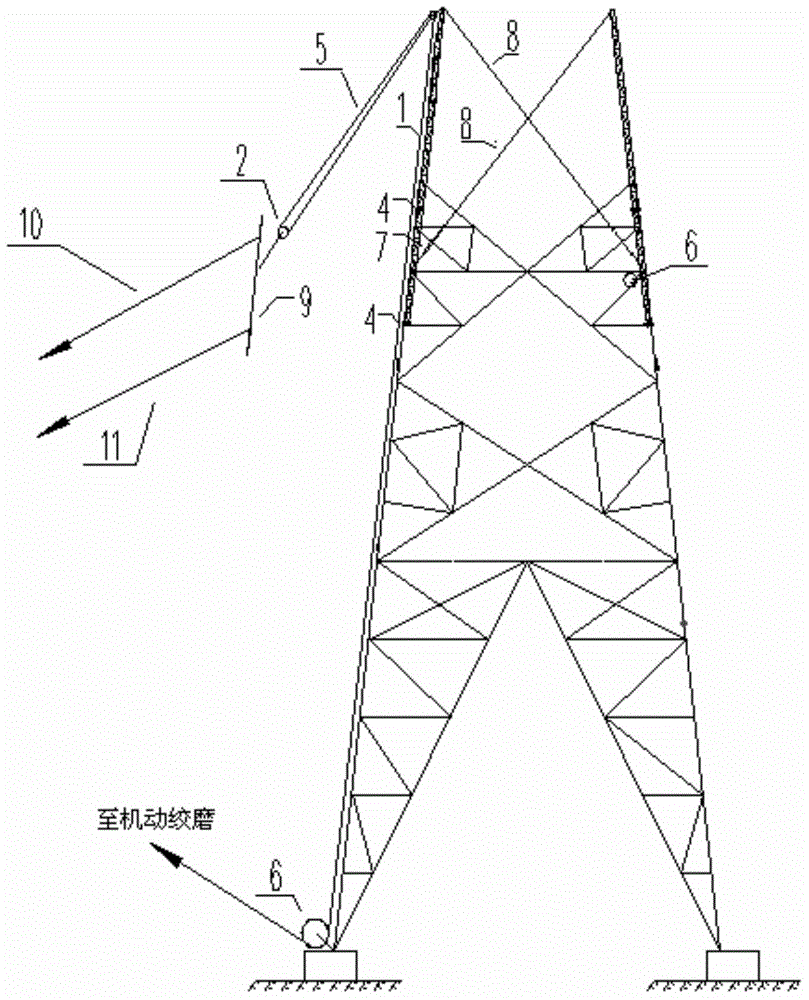

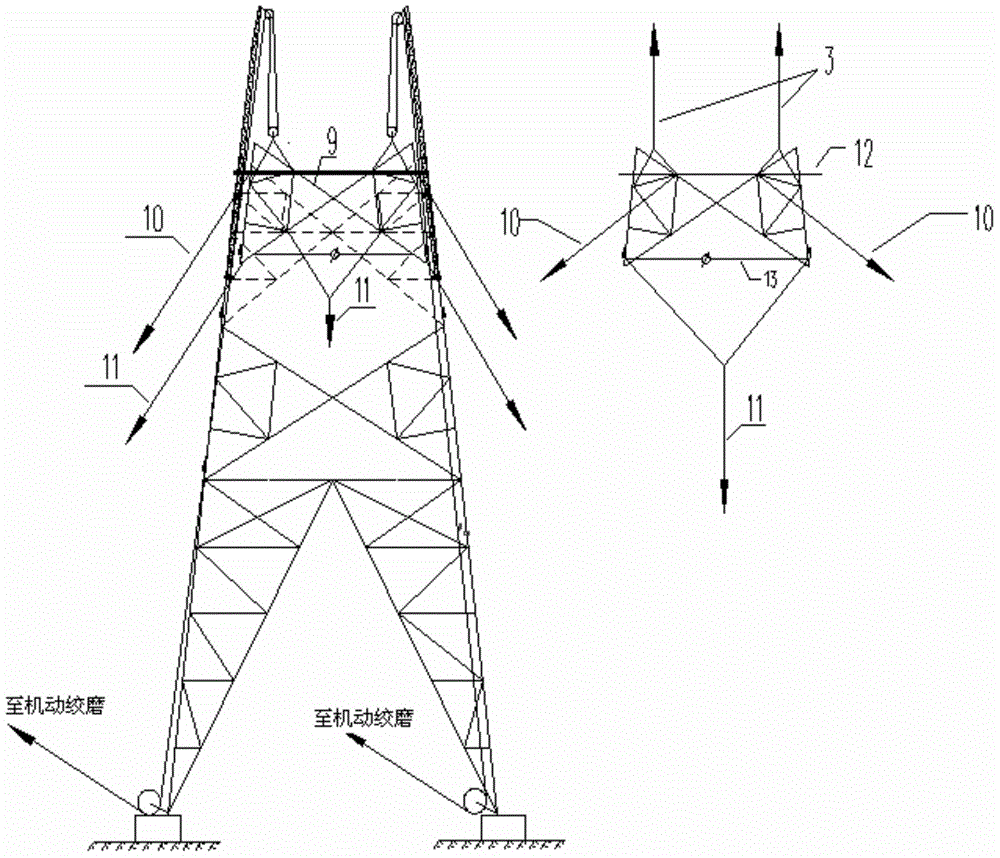

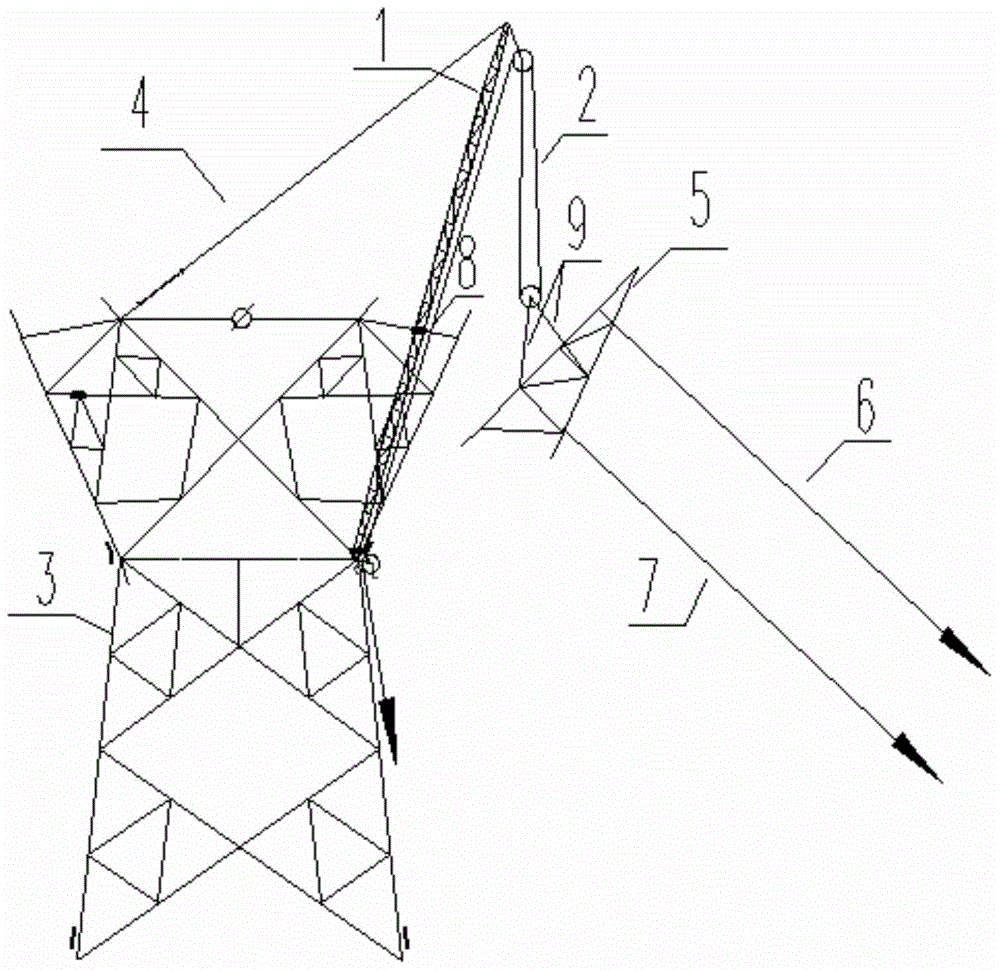

Construction method for assembling 1000 kV tangent suspension tower through double holding poles

ActiveCN104594696AEasy to transportImprove construction efficiencyTowersBuilding material handlingSuspension towerUltra high voltage

The invention relates to a construction method for assembling a 1000 kV tangent suspension tower through double holding poles. Through the construction method for assembling the 1000 kV tangent suspension tower through the double holding poles, the heavy tower with long cross arms and high crank arms in a 1000 kV ultra high voltage power transmission line is assembled through the double holding poles; when cup-type tangent towers are hoisted, a construction method that outer stay wires are suspended internally and single holding poles are used is adopted frequently, unsafe factors of large dip angles of the holding poles, large included angles between the outer stay wires and the ground, positioning difficulty and the like are caused by the adoption of assembling conducted by internally suspending the outer stay wires and adopting the single holding poles due to the facts that weight is large, crank arms are high and cross arms are large, and no guarantee can be provided for construction safety production. The cup-type tangent tower is hoisted through the double holding poles, so that construction safety risks are greatly reduced, tool transportation in mountainous terrain is facilitated, safety guarantees are provided for tower assembling, and construction efficiency and economic effects of tower assembling are improved.

Owner:STATE GRID CORP OF CHINA +2

Vehicle body structure

InactiveCN105730512AIncreased durabilityAvoid deformationSuperstructure subunitsSuperstructure connectionsSuspension towerMetallic materials

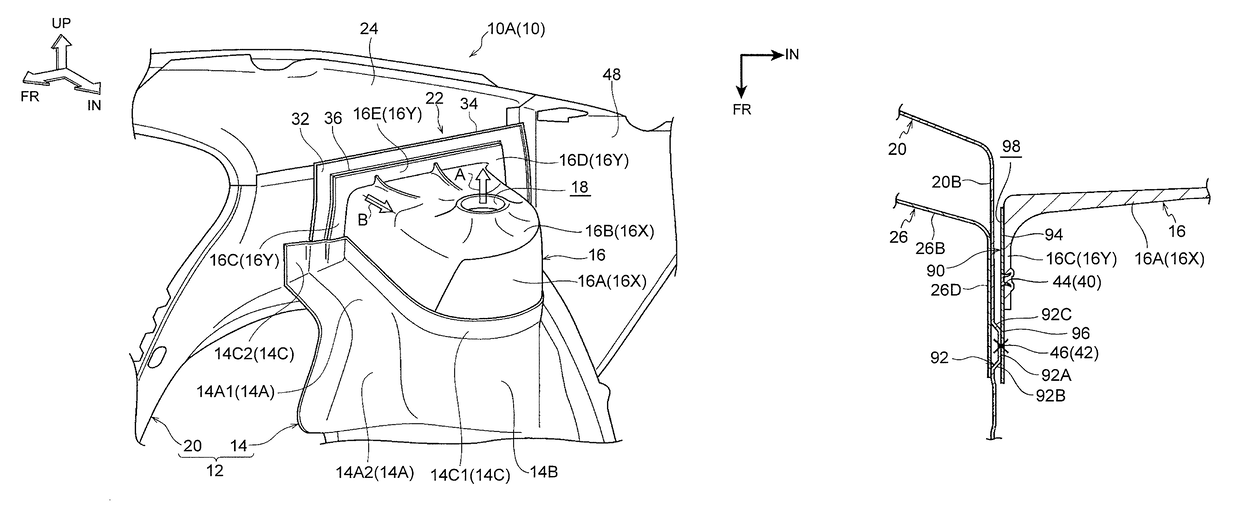

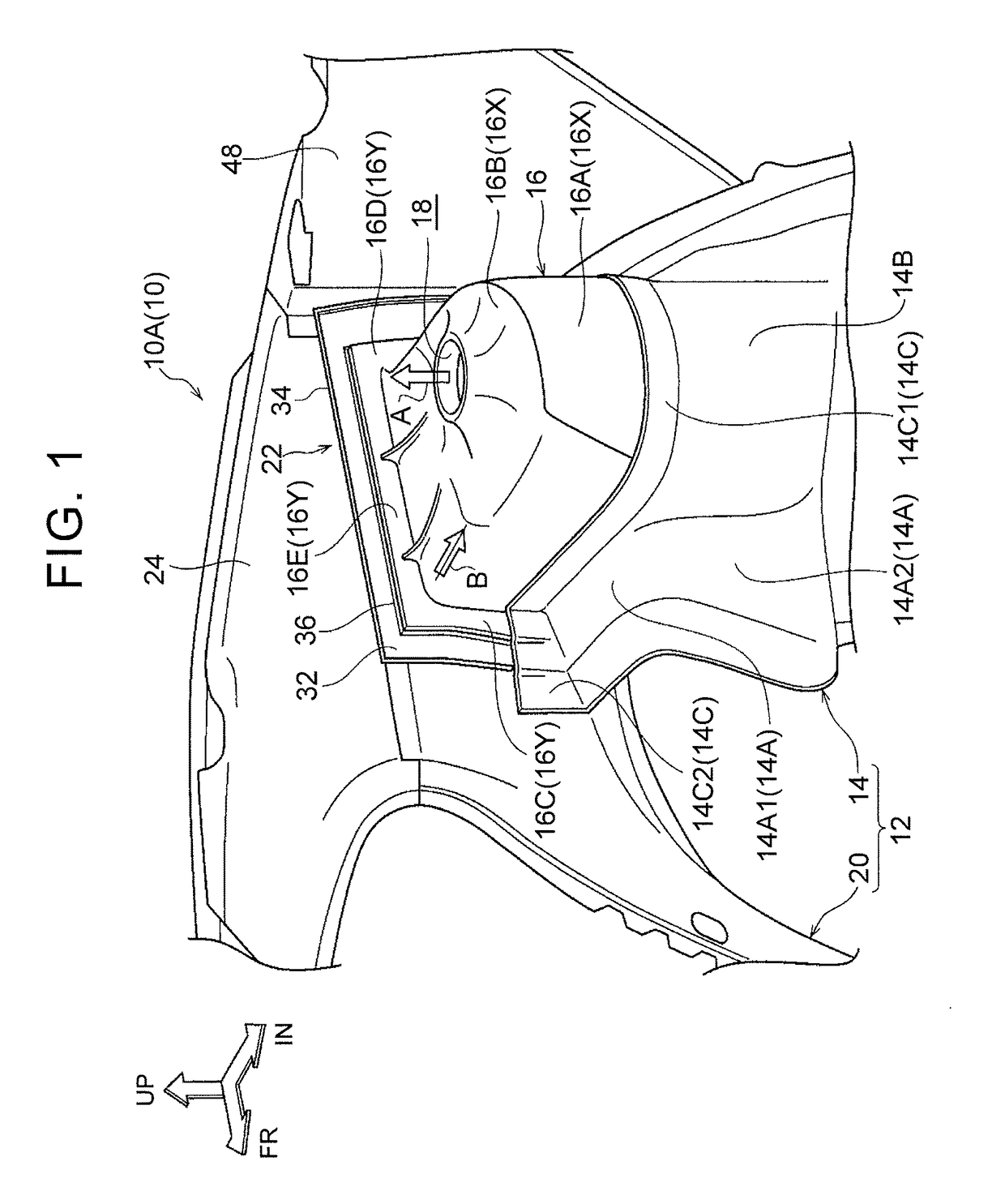

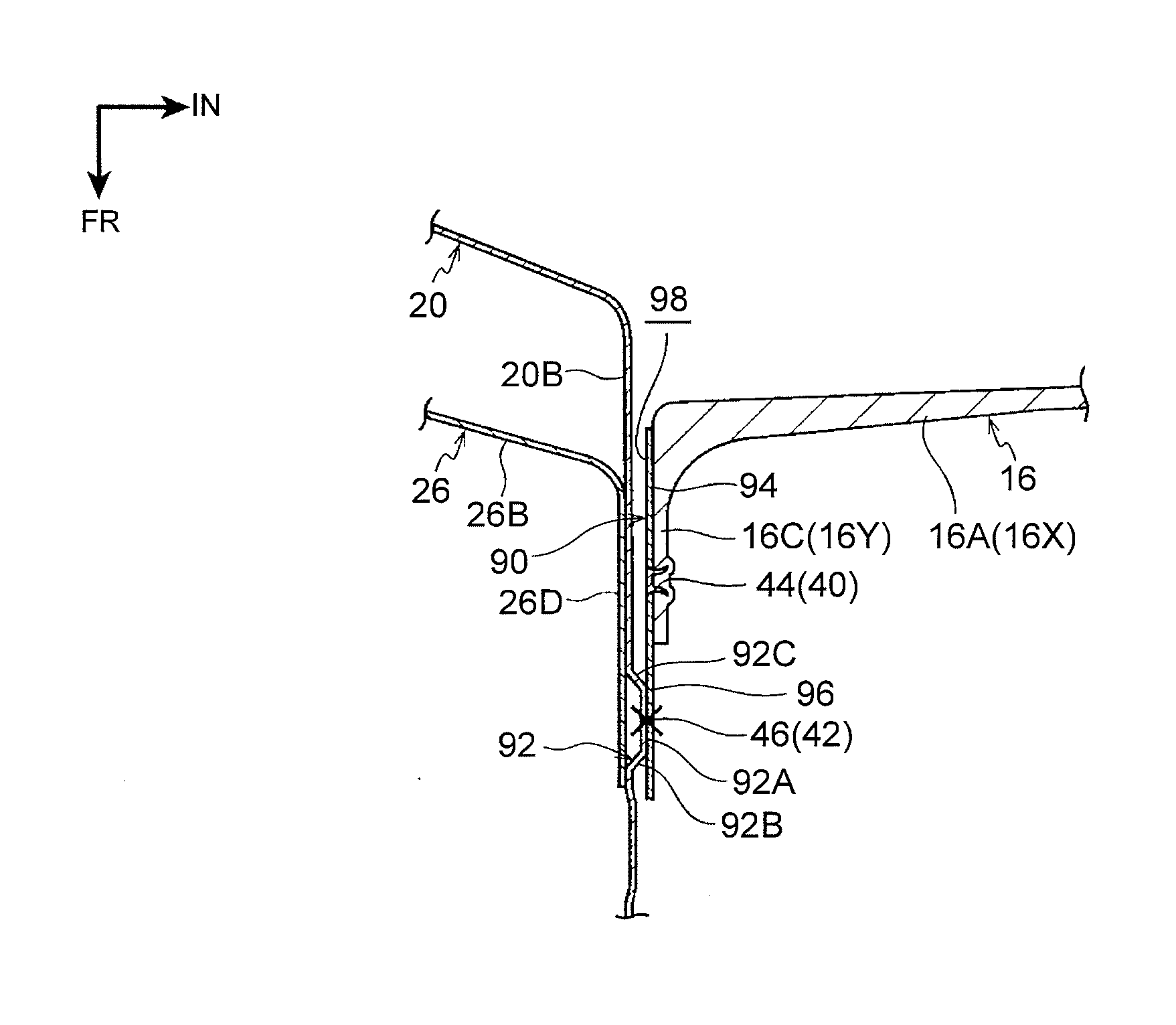

In a vehicle rear structure that is one example of a vehicle body structure, a rear suspension tower (16) that is made of aluminum die-cast and a wheel house outer (20) that is made of metal material having higher fatigue strength than the rear suspension tower (16), are joined together via an extension panel (22) that is made of metal material having higher fatigue strength than the rear suspension tower (16). Further, a step portion (36) is formed between an inner peripheral portion (30) and an outer peripheral portion (32) of the extension panel (22).

Owner:TOYOTA JIDOSHA KK

Inverter mounting structure for vehicle

ActiveUS8596397B2Avoid deformationSuppression problemElectric propulsion mountingPrinted circuit board receptaclesSuspension towerMaster cylinder

Owner:SUZUKI MOTOR CORP

Vehicle Front Structure

Owner:TOYOTA JIDOSHA KK

Vehicle-body front structure

InactiveUS8899662B2Avoid deformationImprove rigidityVehicle seatsUnderstructuresSuspension towerEngineering

A rear apron panel is provided between a suspension tower and a dash panel. A vertical branch brace is provided to extend upwardly from a front side frame along an inner face of a suspension tower to form a closed cross section with a rear portion of the suspension tower. A deformation restraint member interconnects the apron frame and the vertical branch brace. Accordingly, there is provided a vehicle-body front structure which can restrain the apron frame from deforming outwardly in the vehicle width direction in the vehicle frontal collision to prevent the dash panel from moving back into the vehicle compartment too much.

Owner:MAZDA MOTOR CORP

Body structure of vehicle

InactiveUS20130169003A1Easy to transformSufficient support stiffnessVehicle seatsUnderstructuresSuspension towerMechanical engineering

A dash panel has an impact absorption portion formed therein. A suspension tower is connected to the impact absorption portion, so that support stiffness thereof can be ensured. In addition, the suspension tower can be rotated around the front pillar due to an impact, so that an amount of backward movement of the dash panel toward a vehicle interior can be reduced.

Owner:TOYOTA SHATAI KK

Vehicle front section structure and vehicle front section coupling method

InactiveUS20190152548A1Easy to operateElectric propulsion mountingUnderstructuresSuspension towerCoupling

A vehicle front section structure includes: a chassis module configured to be disposed at a vehicle front section, and including a drive unit, a suspension, and a suspension tower disposed upright at a vehicle width direction inner side of the suspension with the suspension being attached to the suspension tower; a rear-side coupling member configured to be disposed at a vehicle front side of a vehicle body-side member that is disposed further toward a vehicle rear than the chassis module, overlapping with the chassis module along a vehicle front-rear direction, and being coupled to the chassis module; and a fastener that fastens the chassis module and the rear-side coupling member together from a vehicle width direction outer side.

Owner:TOYOTA JIDOSHA KK

Vehicle body structure

ActiveUS20160185394A1Improve performanceGood jointSuperstructure subunitsSuperstructure connectionsSuspension towerMetallic materials

In a vehicle rear structure that is one example of a vehicle body structure, a rear suspension tower that is made of die-cast aluminum and a wheel housing outer that is made of a metal material having a higher fatigue strength than the die-cast aluminum of the rear suspension tower, are joined together via an extension panel that is made of a metal material having a higher fatigue strength than the die-cast aluminum of the rear suspension tower. Further, a step portion is formed between an inner peripheral portion and an outer peripheral portion of the extension panel to form a deformable portion.

Owner:TOYOTA JIDOSHA KK

Front vehicle-body structure of vehicle

ActiveUS20160031485A1Increase body rigidityImprove rigidityVehicle seatsSuperstructure subunitsSuspension towerFlange

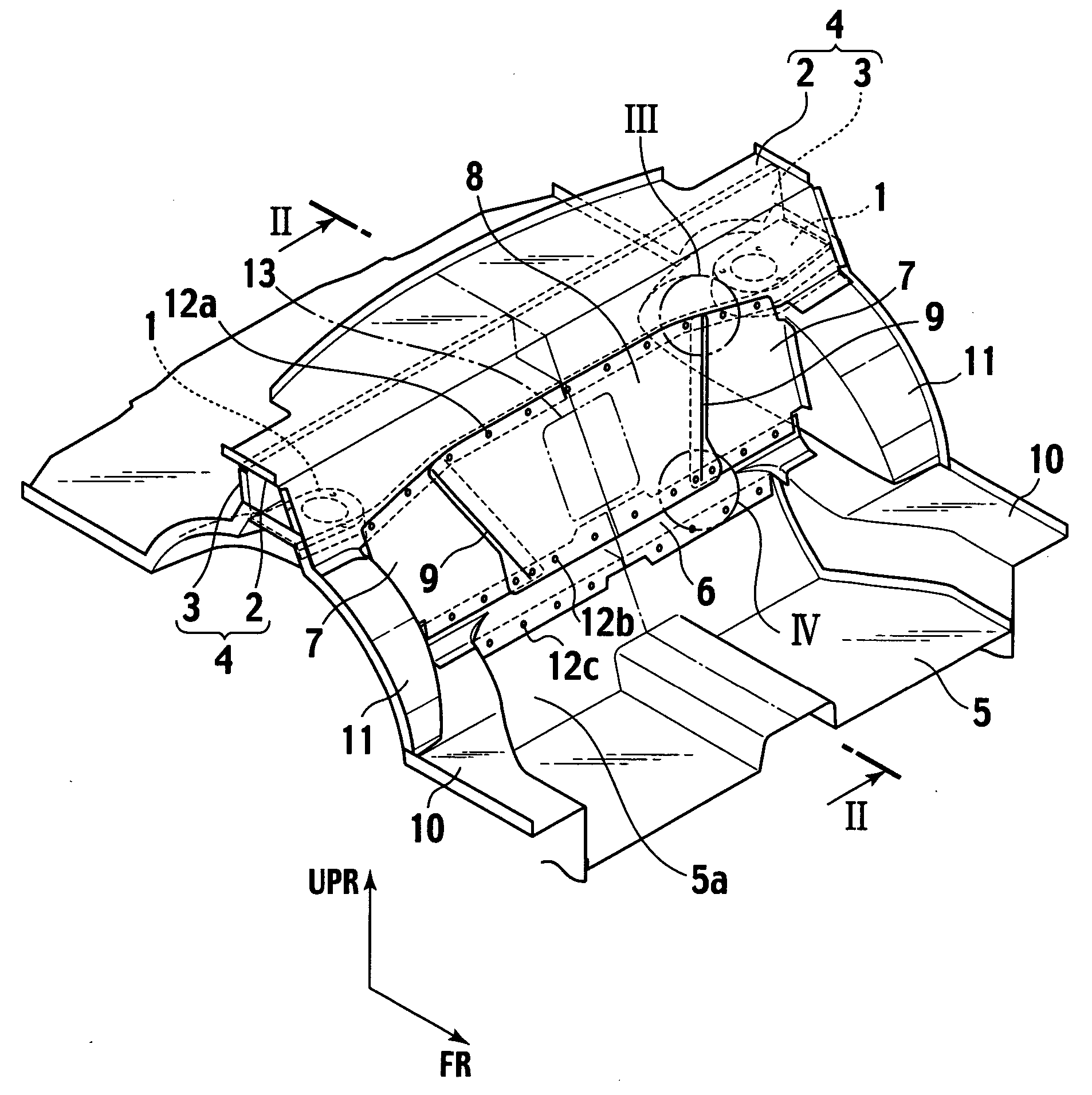

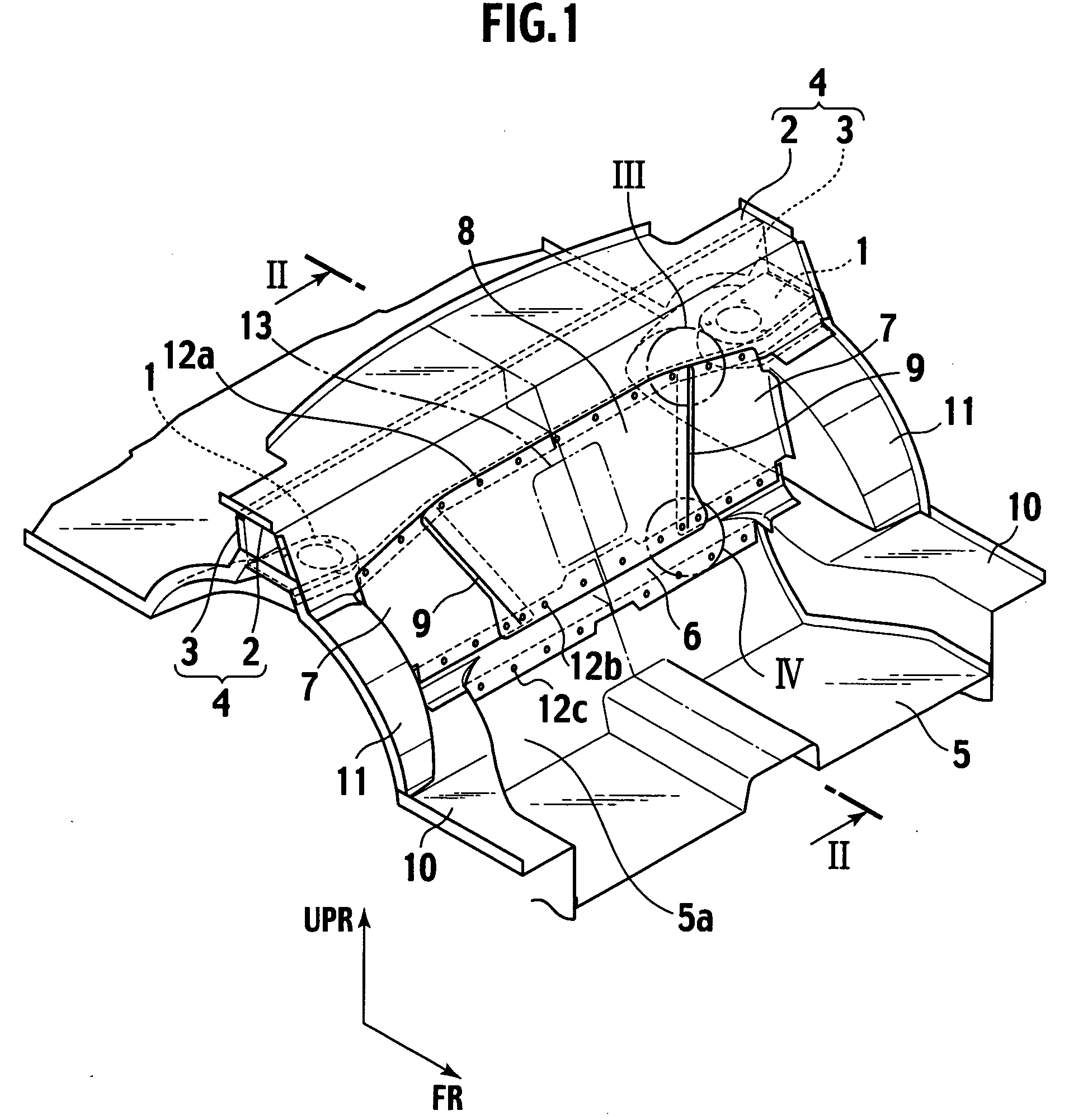

There are provided a cowl panel provided above a dash panel partitioning an engine room from a vehicle compartment and extending in a vehicle width direction, a suspension tower protruding toward an inside of the engine room and supporting a front suspension, and a connecting bracket connecting the suspension tower and the cowl panel and configured to slant rearward and upward, wherein the connecting bracket comprises a front-end flange portion and a rear-end flange portion, the front-end flange portion is joined to a slant portion formed at a rear portion of a top of the suspension tower which is configured to slant rearward and downward, and the rear-end flange portion is configured to rise upward via a bending portion and joined to a vertical wall portion of the cowl panel.

Owner:MAZDA MOTOR CORP

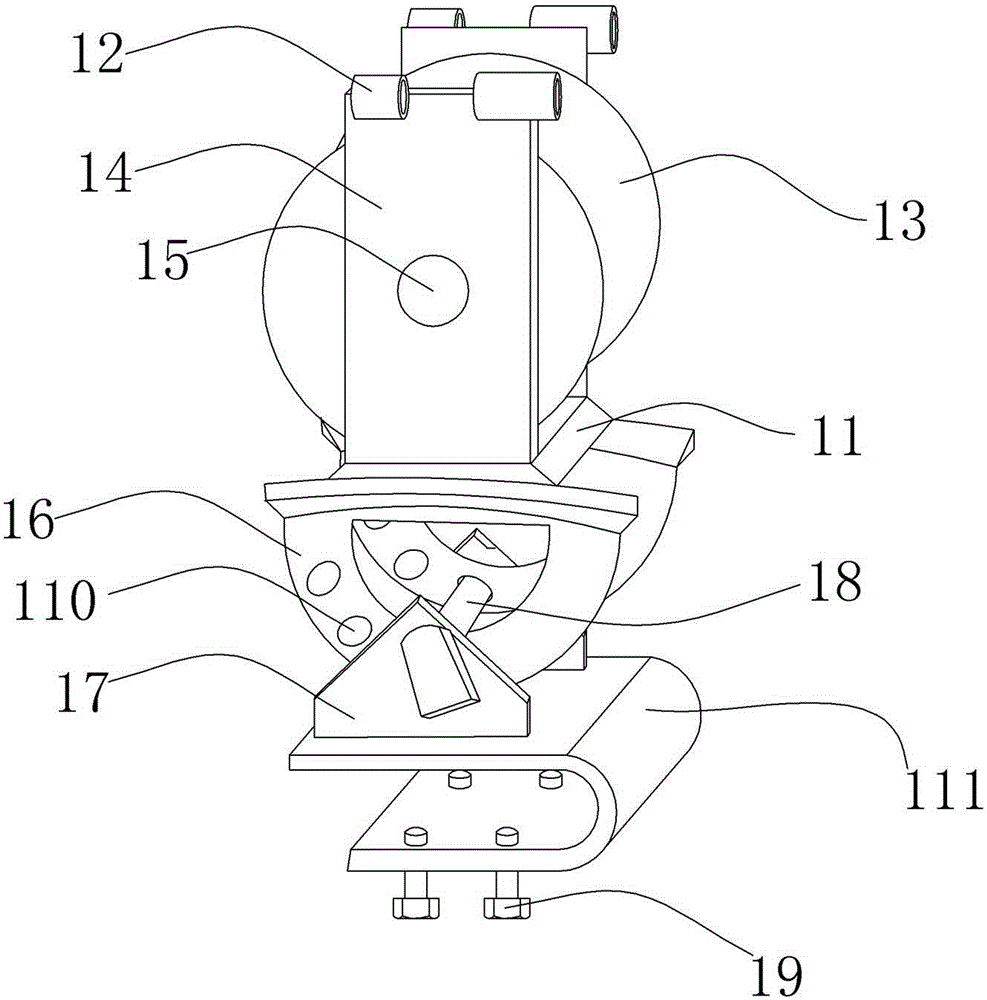

Suspension tower overhead line take-up device

ActiveCN105186370AReduce labor intensityImprove securityApparatus for overhead lines/cablesSuspension towerControl engineering

The present invention relates to a suspension tower overhead line take-up device. The suspension tower overhead line take-up device comprises a pulley, a supporting mechanism, a support, a hook, a hook pulley and a control hinge, the supporting mechanism is hinged and fixed to the support and comprises a supporting body, two vertical plates and an angle adjusting unit, and the two vertical plates are fixed on the supporting body vertically. The pulley is fixed between the two vertical plates via a pulley shaft, and the angle adjusting unit comprises a hinging plate body 1 and a hinging plate body 2 which are fixed to the supporting body separately. The hinging plate body 1 and the hinging plate body 2 are both equipped with a plurality of hinging holes, and the support is fixed to the supporting mechanism via the hinging holes. The suspension tower overhead line take-up device of the present invention is simple in structure and reasonable in design, and enables the suspension clamps to be replaced under the cooperation of the hook and the hook pulley, namely under the regulation and control of a worker. The tension force of each suspension line is different and can be controlled by the angle adjusting unit, thereby being convenient to operate, relieving the labor intensity of the working personnel substantially, improving the safety of the construction working personnel, and being easy to popularize and implement.

Owner:GONGYI CITY POWER SUPPLY

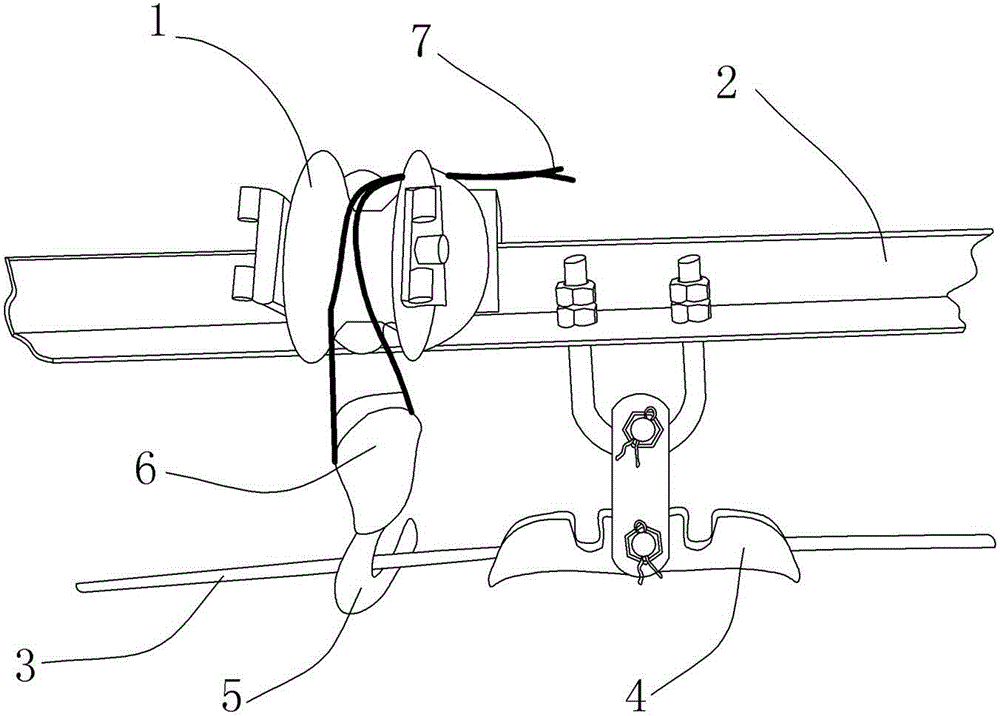

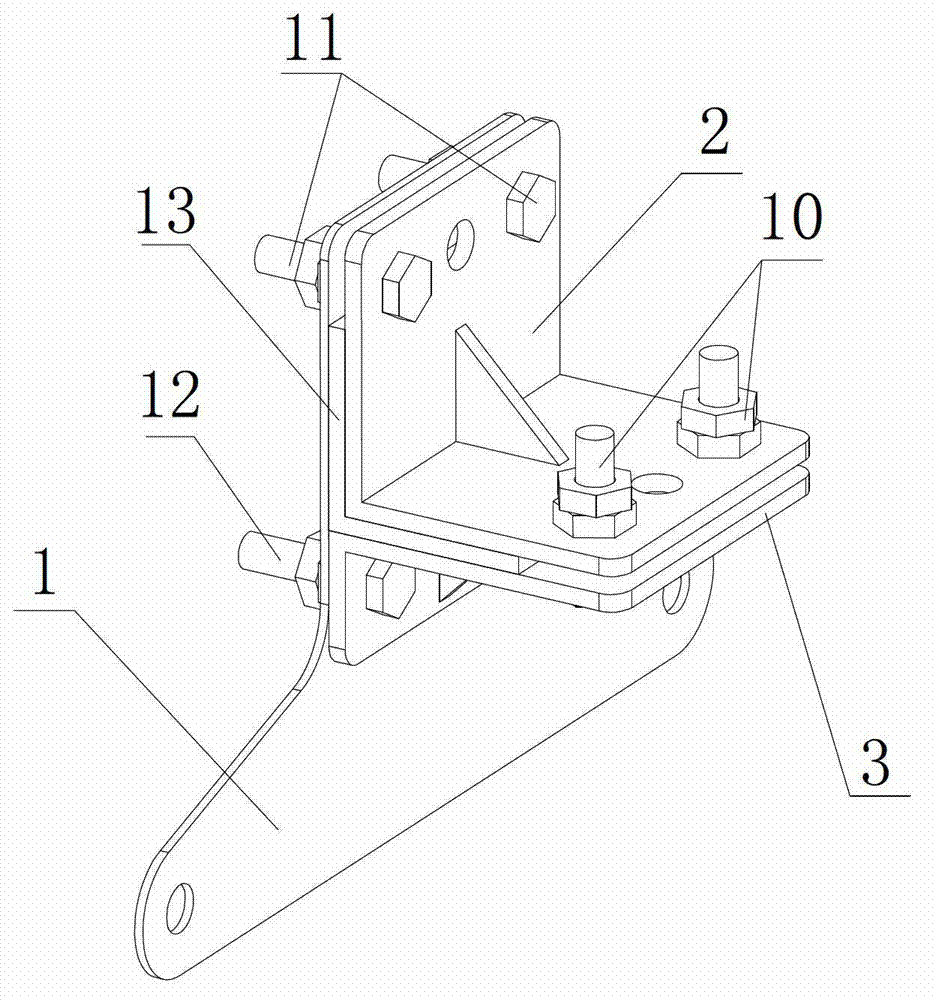

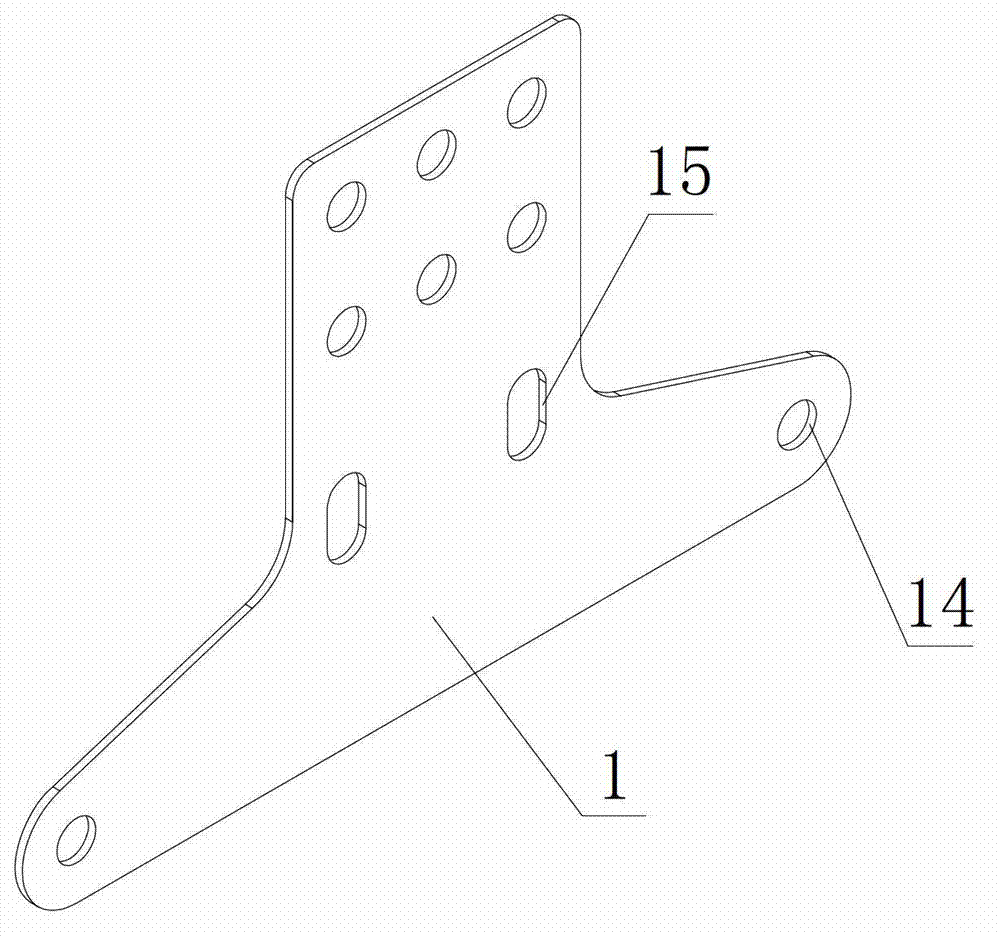

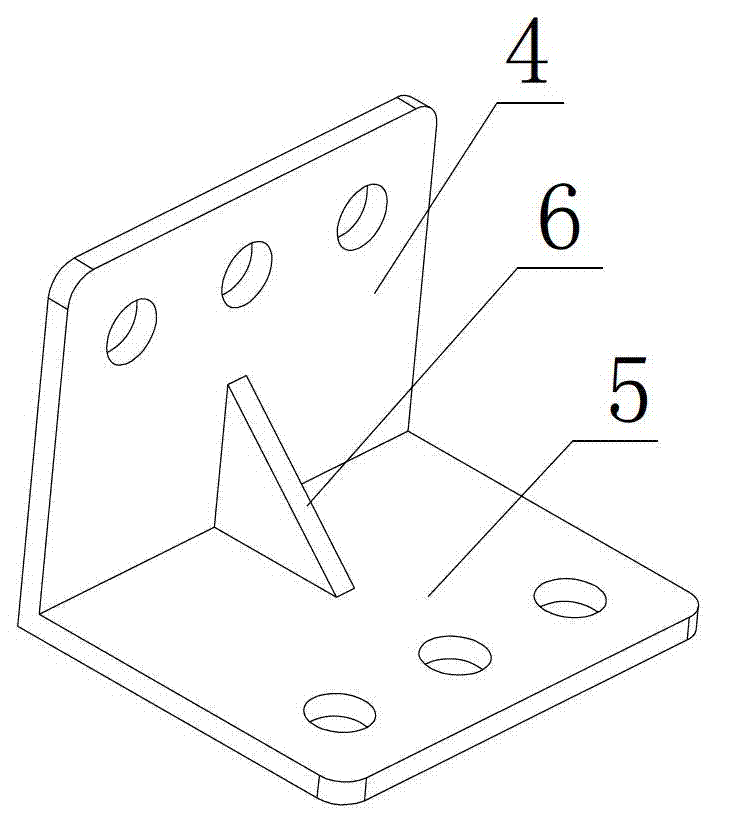

Installation metal tool and using method of tangent suspension tower changing single hanging point to double hanging points

The invention relates to an installation metal tool and a using method of a tangent suspension tower changing a single hanging point to double hanging points, wherein the installation metal tool comprises a hanging wire plate, an upper clamp plate, and a lower clamp plate, the upper clamp plate is connected with the lower clamp plate through a first fastening piece, the upper clamp plate is connected with the upper portion of the hanging wire plate through a second fastening piece, the lower clamp plate is connected with the middle portion of the hanging wire plate through a third fastening piece, an original tangent suspension tower hanging wire angle iron is clamped among the hanging wire plate, the upper clamping plate and the lower clamping plate, two hanging wire holes are formed in the lower portion of the hanging wire plate. The installation metal tool and the using method of the tangent suspension tower changing the single hanging point to double hanging points have the advantages of being applicable to zone marker (ZM) type and GUZ type tangent suspension tower hanging points, applicable to 90 degrees and below angle irons and hanging wire angle irons with different thickness, being strong in generality, simple in structure, and convenient to install. Moreover, an iron tower pole and tower structure is not changed and the pole and tower structure is not detached; the metal tool is fixed on the original hanging wire angle irons, thereby achieving the double fixing hanging points and satisfying requirement of rules.

Owner:ANSHAN POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER COMPANY +1

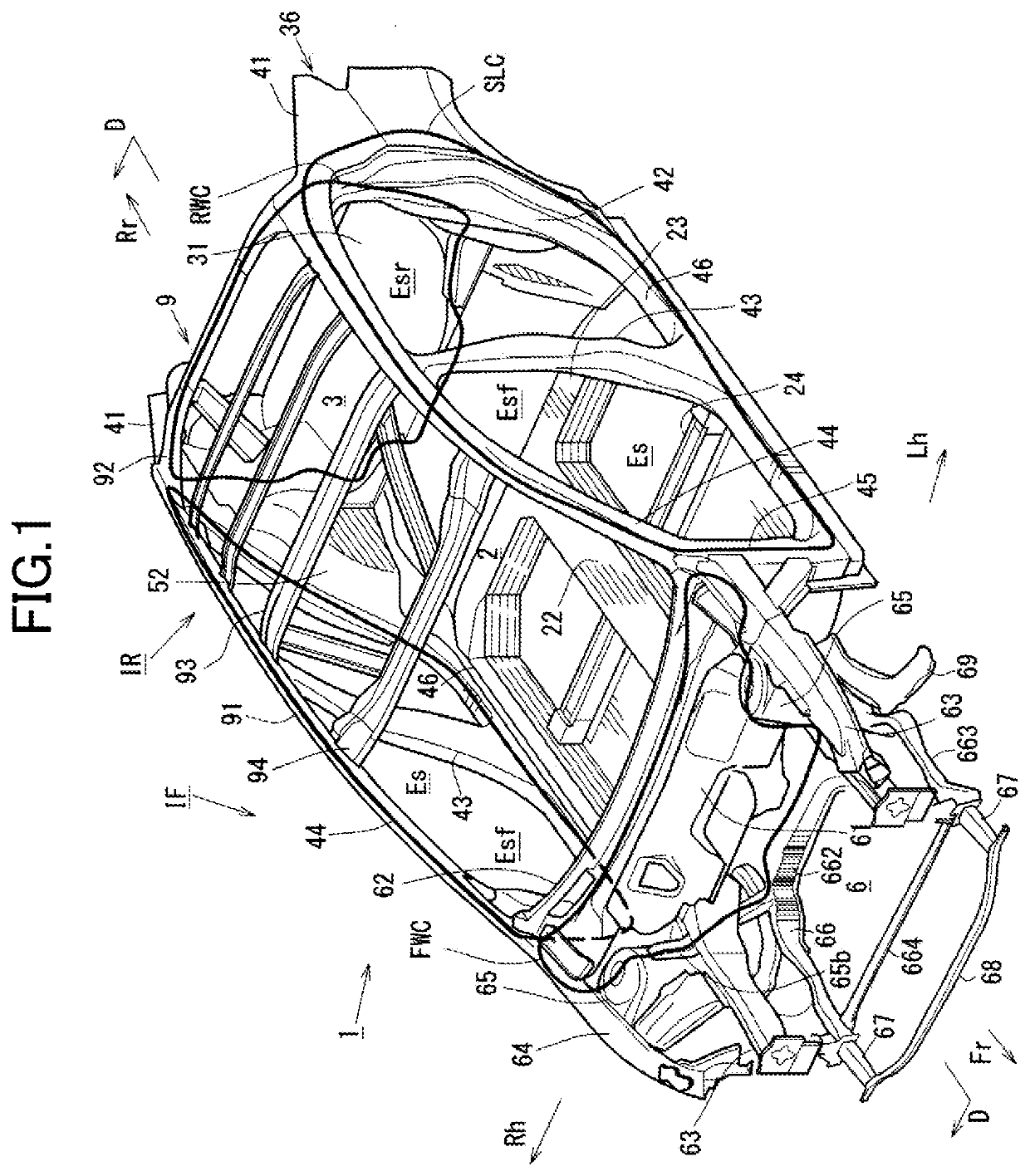

Vehicle body structure of vehicle

ActiveUS20200307695A1Add supportImprove support stiffnessUnderstructuresSuperstructure subunitsSuspension towerVehicle frame

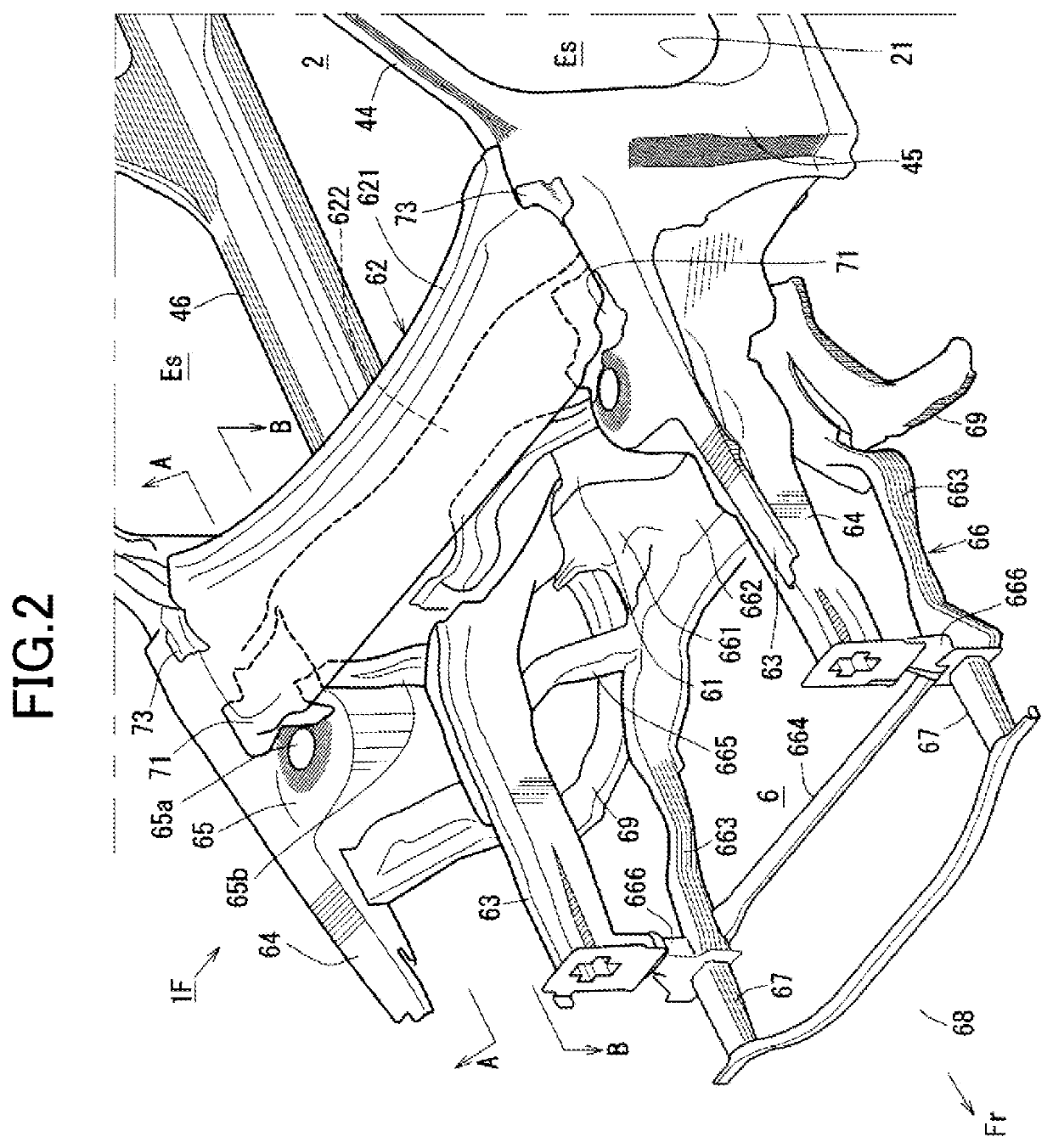

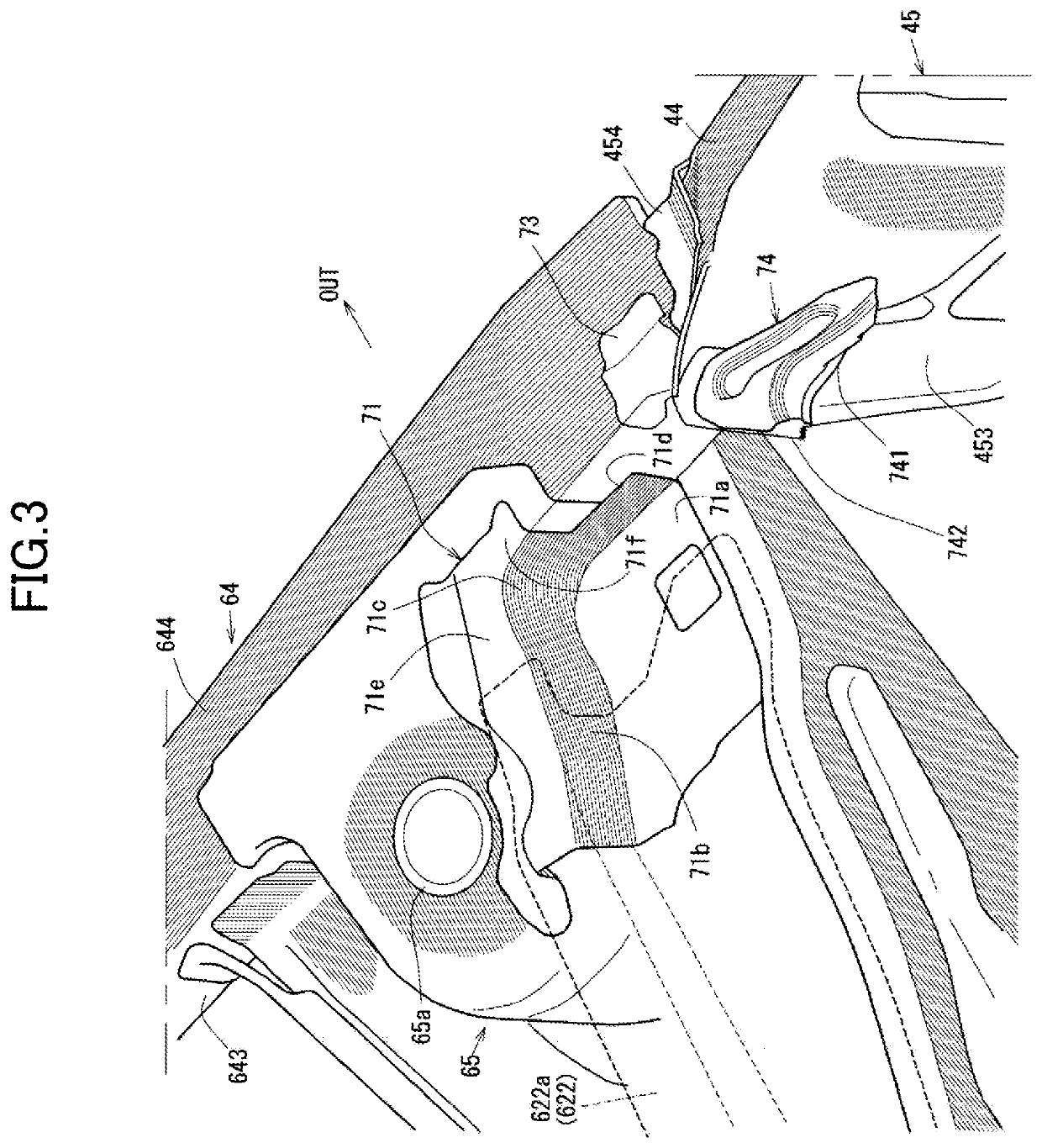

A vehicle body structure includes: a front lateral ring-shaped vehicle body framework (FWC) having a substantially ring shape in a vehicle lateral direction, disposed near suspension towers (65), and constituted by front subframes (66), suspension tower reinforcing members (65b), and a cowl box (62); and longitudinal ring-shaped vehicle body frameworks (SLC) disposed along side door openings (Es). The vehicle body structure includes: cowl side frames (64) coupling upper ends of hinge pillars (45) constituting the longitudinal ring-shaped vehicle body frameworks (SLC) to the suspension towers (65) in a vehicle longitudinal direction; and side part panels (71) connected to the cowl box (62) and coupled to the suspension towers (65).

Owner:MAZDA MOTOR CORP

Side vehicle body structure of vehicle

A side vehicle body structure prevents a fastening bolt of a cowl member from being loosened while suppressing production cost. The structure includes a pair of left and right suspension towers each formed so as to expand into an engine room and supporting a buffer device of a front suspension, and a cowl member extending forward from an upper end portion of a dash panel separating the engine room from a vehicle interior. Left and right end portions of the cowl member are coupled to respective top portions of the suspension towers by a pair of fastening portions using bolts, and each fastening portion includes a first bolt fastening portion arranged inward of a corresponding center of the top portion and at least partially overlapping a line connecting the centers, and a second bolt fastening portion arranged at a front side of the first bolt fastening portion.

Owner:MAZDA MOTOR CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com