Installation metal tool and using method of tangent suspension tower changing single hanging point to double hanging points

A single hanging point, double hanging point technology, applied to towers, building types, buildings, etc., can solve the problems of affecting the air gap between the wire and the tower, and the height reduction of the hanging point, so as to achieve simple structure, easy installation, and strong versatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

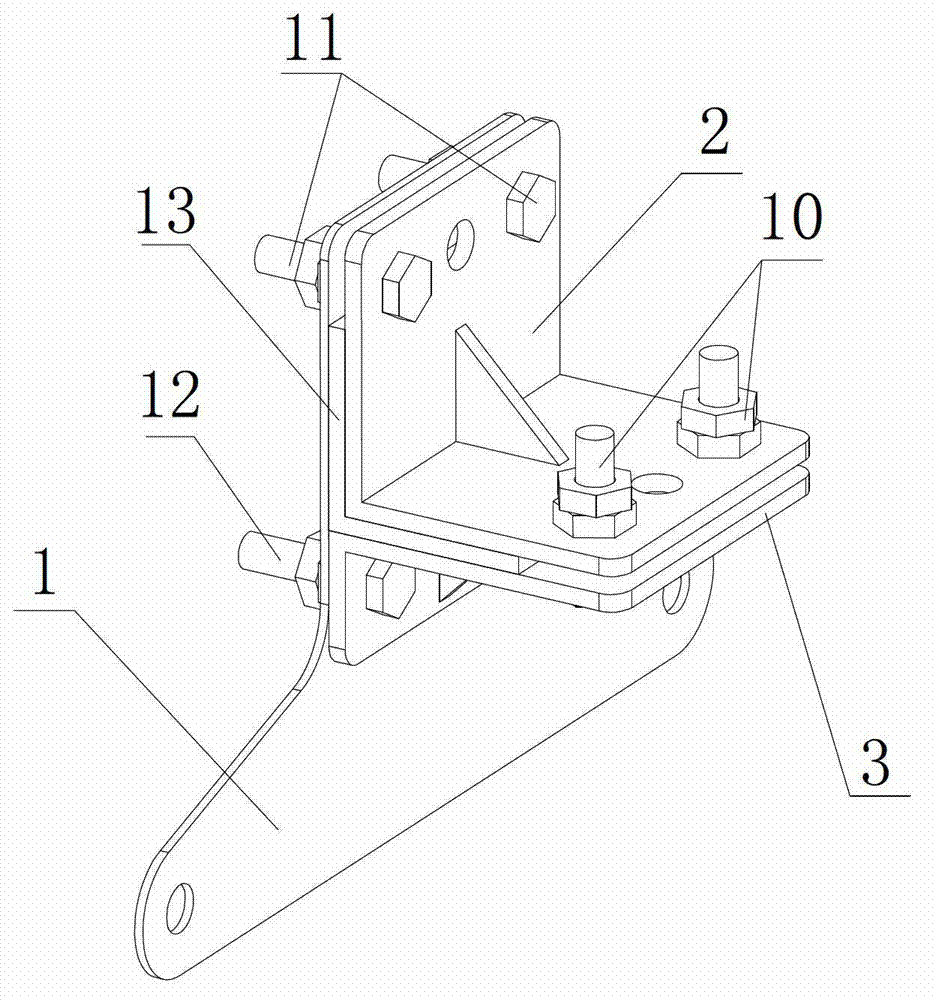

[0040] See Figure 1-Figure 4 , The hanging plate 1 is made of a steel plate with a thickness of 16mm, and the upper and lower splints 2 and 3 are made of a steel plate with a thickness of 8mm. All connecting bolts are locked with double nuts, all metal parts are hot-dip galvanized and anti-corrosion, and the grade of bolts is 6.8 for iron towers.

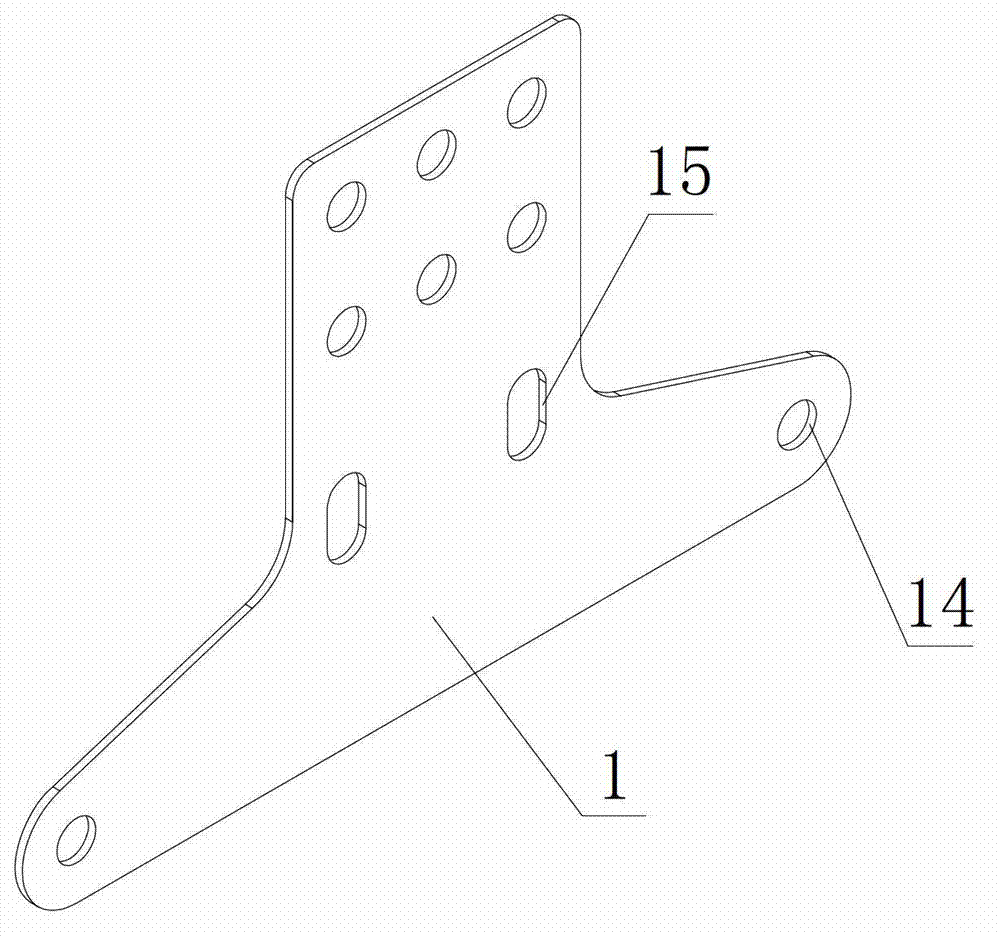

[0041] See figure 2 , the top of the hanger plate is connected with the upper splint 2 and the lower splint 3 respectively, and the connection hole 15 with the lower splint 3 is made as an oblong hole, so as to adapt to the original pole tower hanging point angle steel 13 of different thicknesses. The bottom is provided with two independent wire hanging holes 14 with a spacing of 400mm. The size design of the hanging plate 1 minimizes the downward movement of the hanging point position, so as not to affect the safe distance of the lead wire to the pole tower member after the transformation.

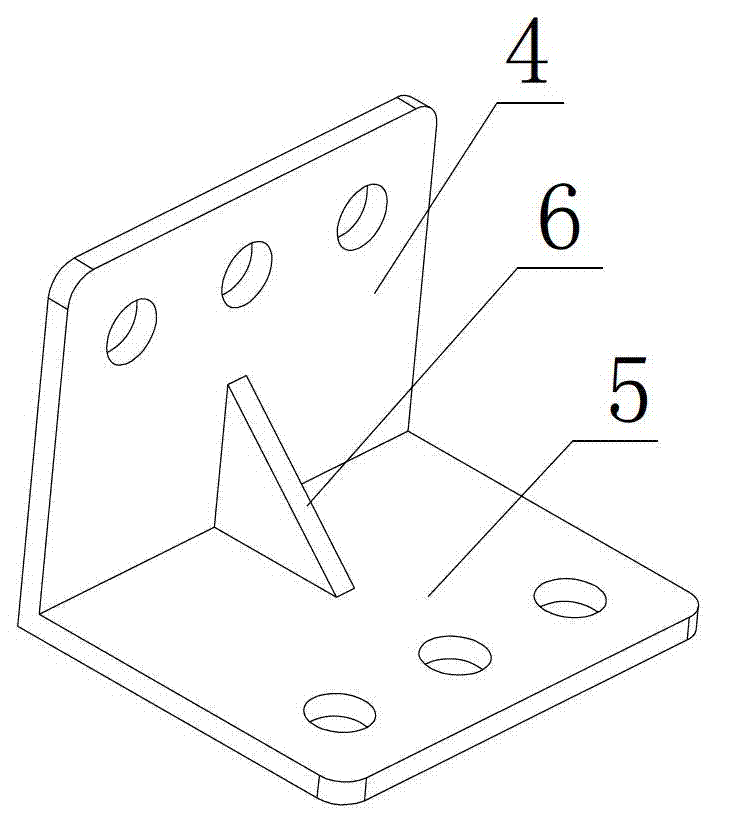

[0042] See image 3 , the upper sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com