Front structure of automotive vehicle

A front body and automobile technology, applied to the upper structure, upper structure sub-assembly, vehicle parts, etc., can solve the problem of low collision load transmission efficiency, inability to fully restrain the cab, and low collision load transmission efficiency, which cannot fully suppress the rollover Issues such as movement ahead

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

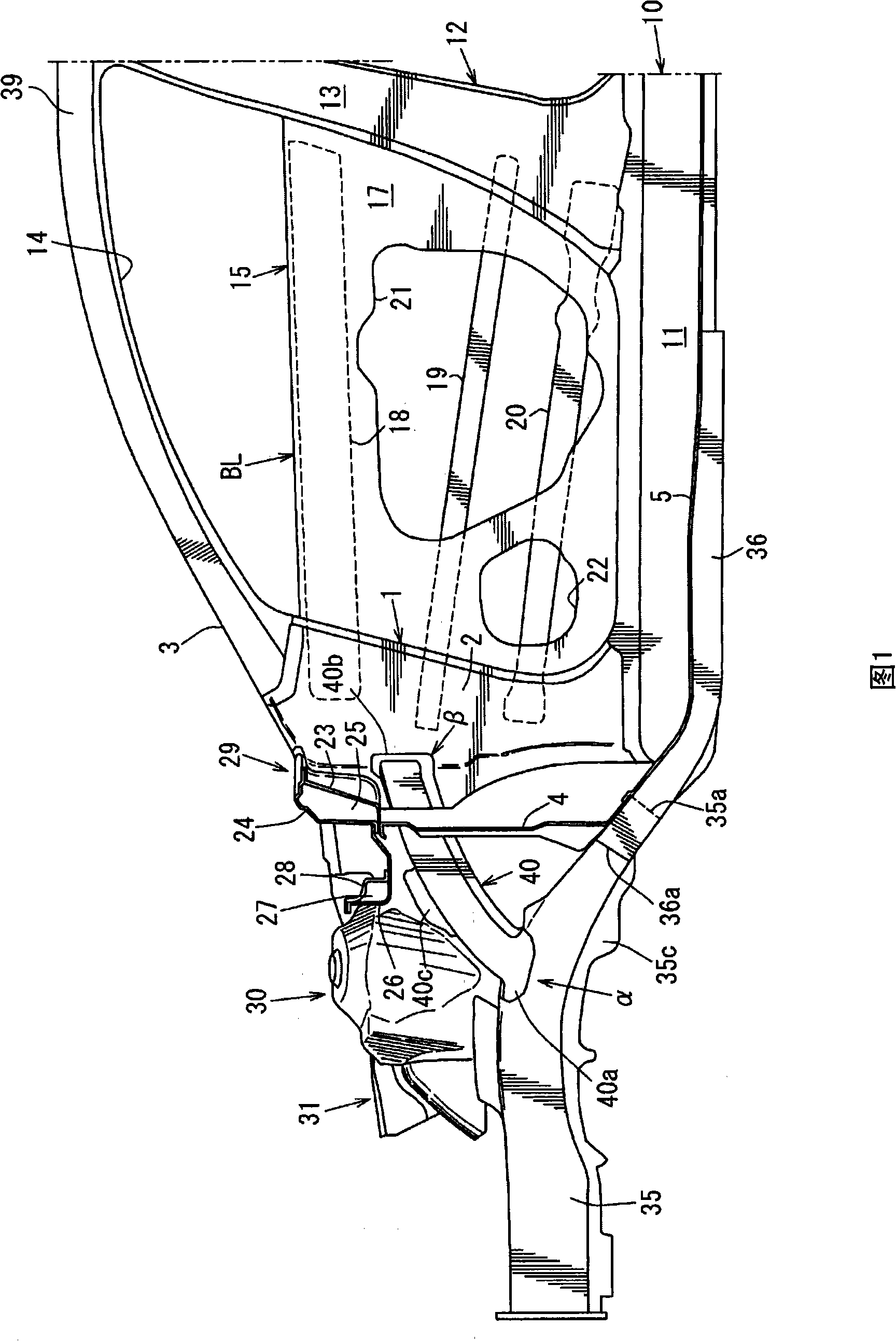

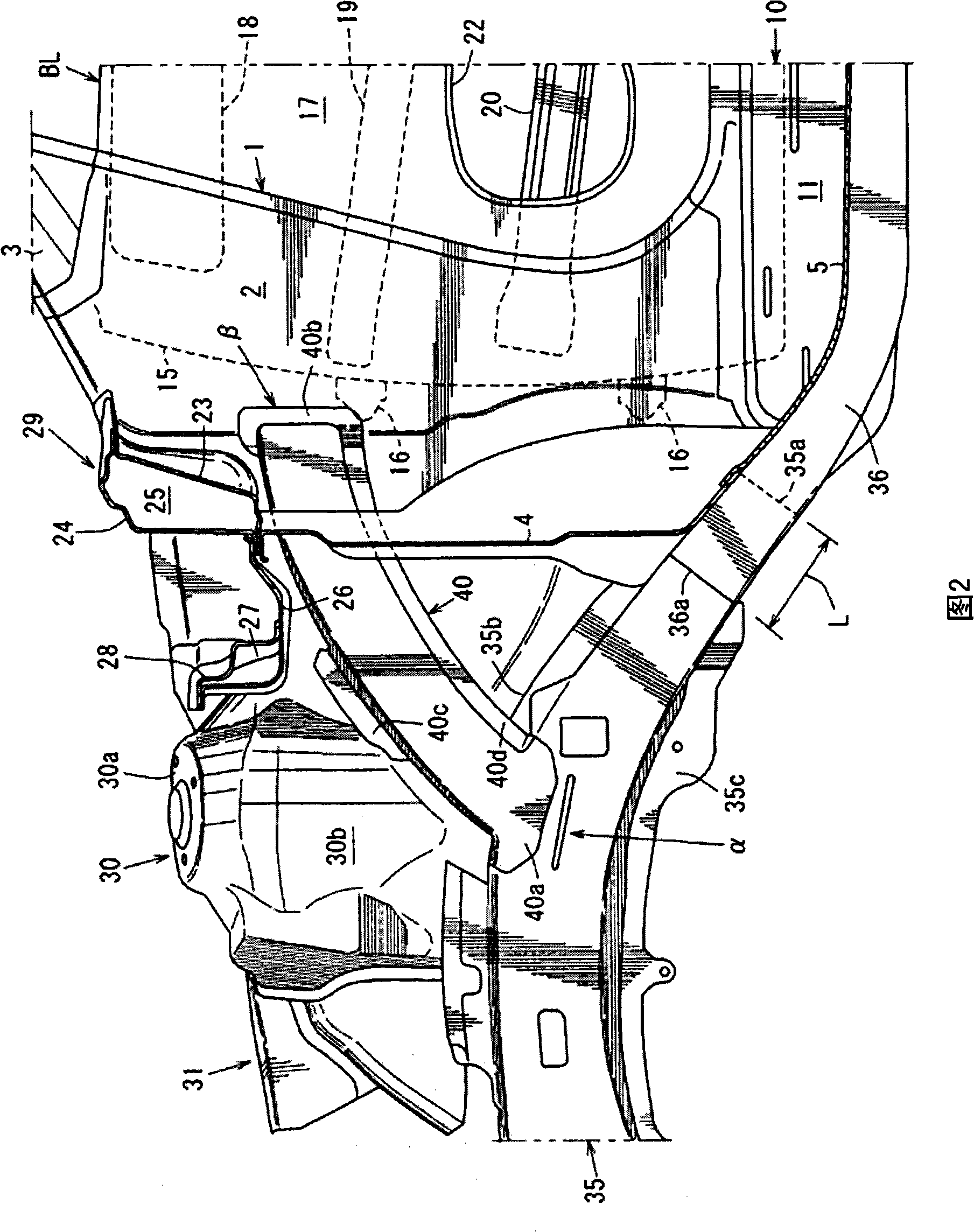

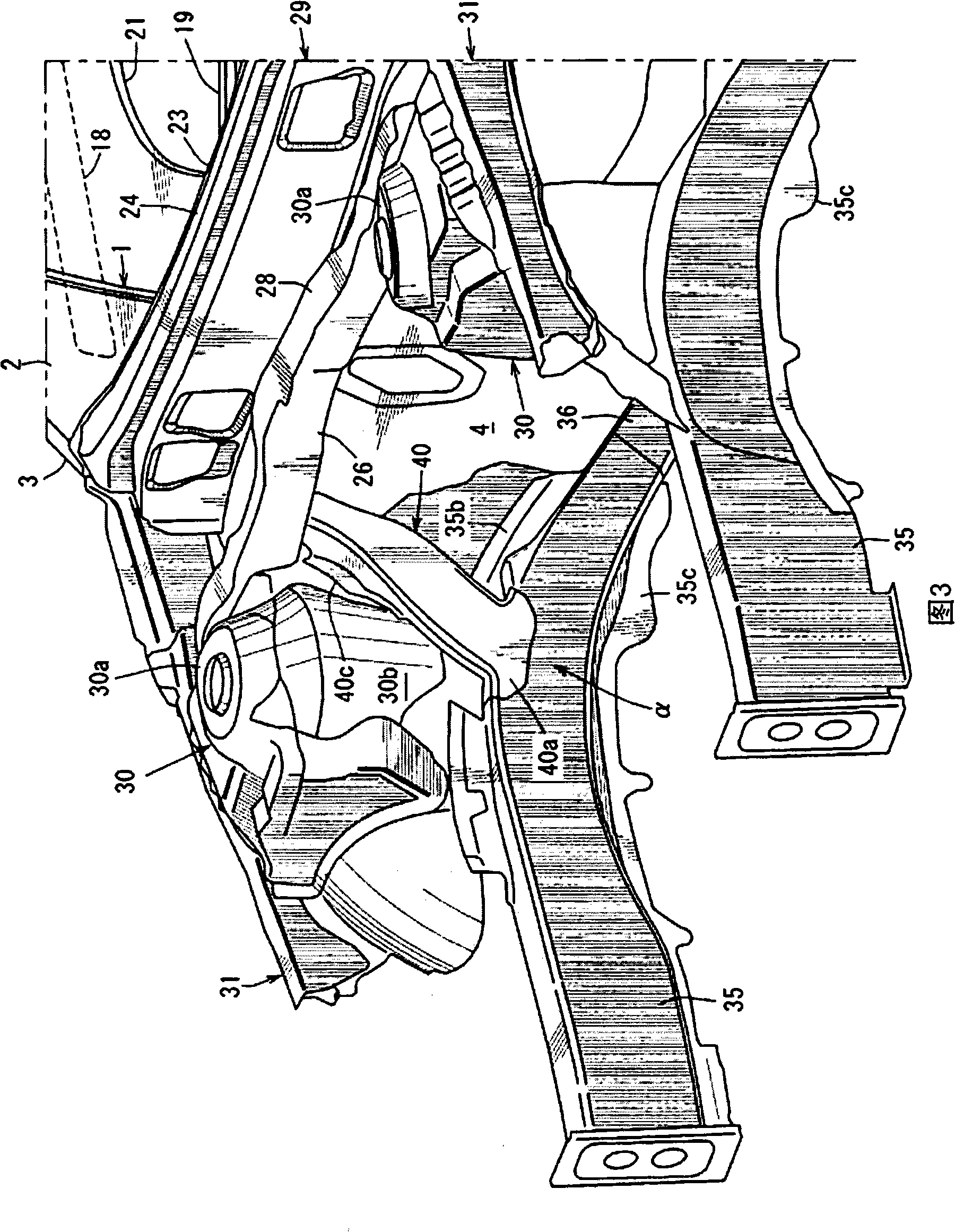

[0050] 1 is a side sectional view showing the front body structure of an automobile according to the first embodiment (a view of the front part of the vehicle body seen from the middle part in the vehicle width direction toward the outside in the vehicle width direction), and FIG. 2 is a main part of FIG. 1 Enlarged view, Fig. 3 is a perspective view of the main part of Fig. 1, and Fig. 4 is a state in which the cowl front panel 26 and the cowfront cross member 28 are removed, the structure of Fig. In the perspective view seen from above, Fig. 5 is a perspective view of the front body structure seen from the rear with the lower part 4 of the dash panel removed. Figure 6It is a sectional view along the arrow direction of the A-A line in Fig. 4, Fig. 7 is a sectional view along the arrow direction of the B-B line in Fig. 4, and Fig. 8 is a sectional view along the arrow direction of the C-C line in Fig. 4 .

[0051] The front body structure of the present embodiment includes a p...

no. 2 Embodiment approach

[0116] Hereinafter, the front body structure of the automobile according to the second embodiment of the present invention will be described with reference to FIGS. Figure 17 Be explained.

[0117] As shown in Fig. 12, in the automobile of this embodiment, the left and right ends of the dash panel 102 are respectively provided with hinge struts 103 (only one side is shown in the figure) extending in the vertical direction, and the hinge struts 103 are supported on the upper shaft. There are front doors.

[0118] The fender reinforcements 104 , 104 extend forward from the upper end sides of the left and right hinge struts 103 , respectively.

[0119] Front side members 105 , 105 extending substantially parallel to the apron reinforcements 104 , 104 in the front-rear direction of the vehicle body are provided at positions a certain distance inside of the apron reinforcements 104 , 104 in the vehicle width direction. Each front side member 105 is composed of an outer member an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com