Vehicle front body structure

A technology for the front part of the body and the tower part, which is applied to the superstructure, superstructure sub-assemblies, vehicle parts, etc., can solve the problem that the collision energy cannot be fully dispersed and transmitted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

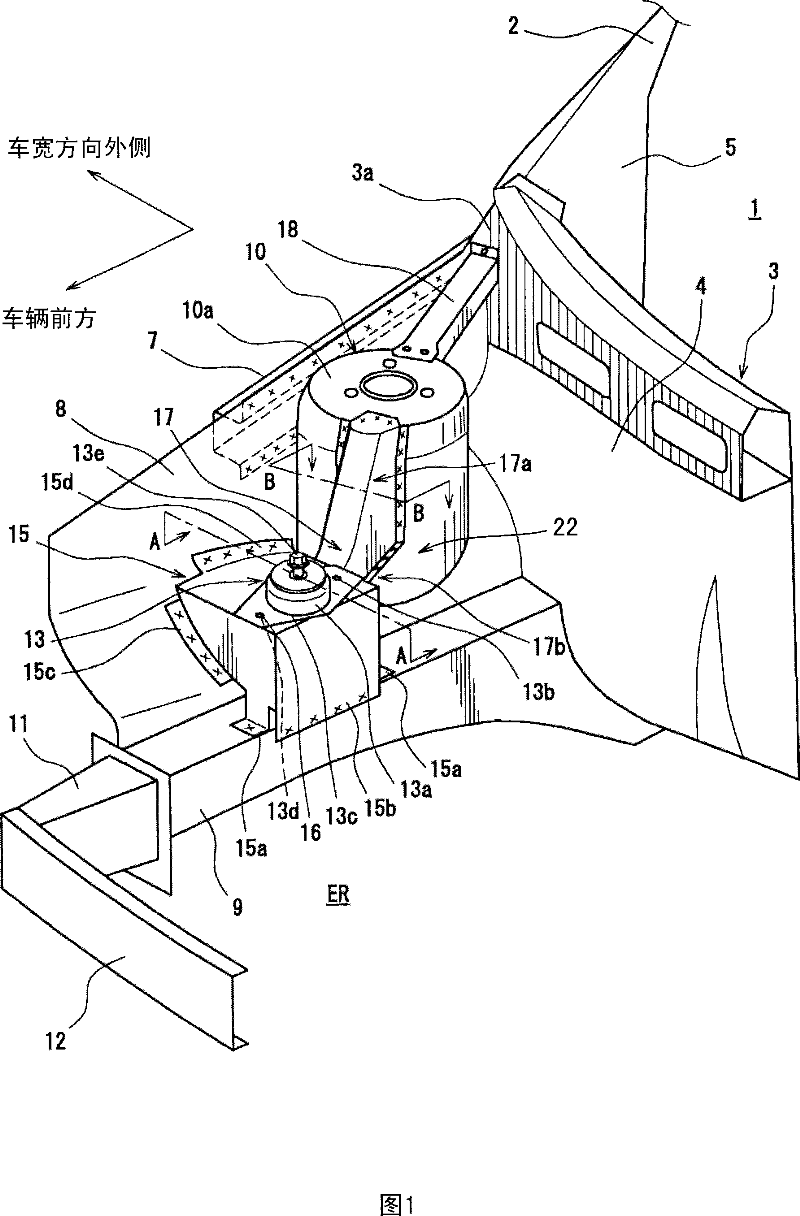

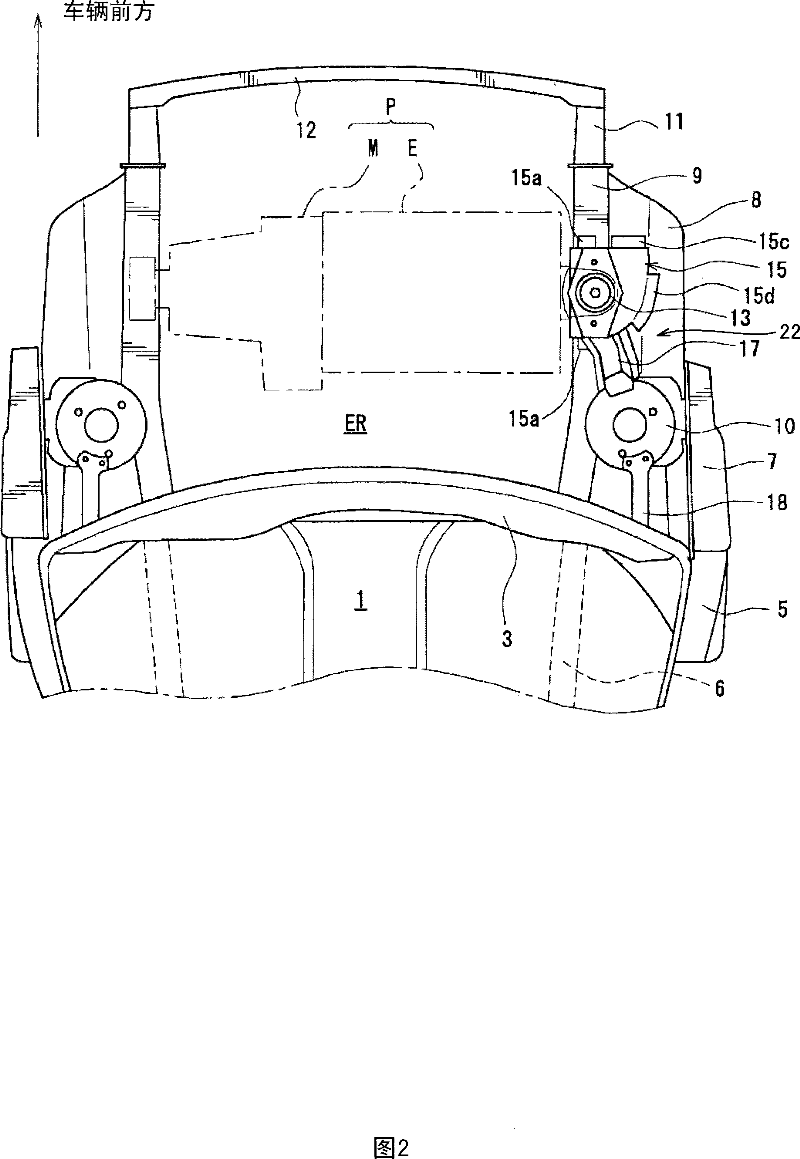

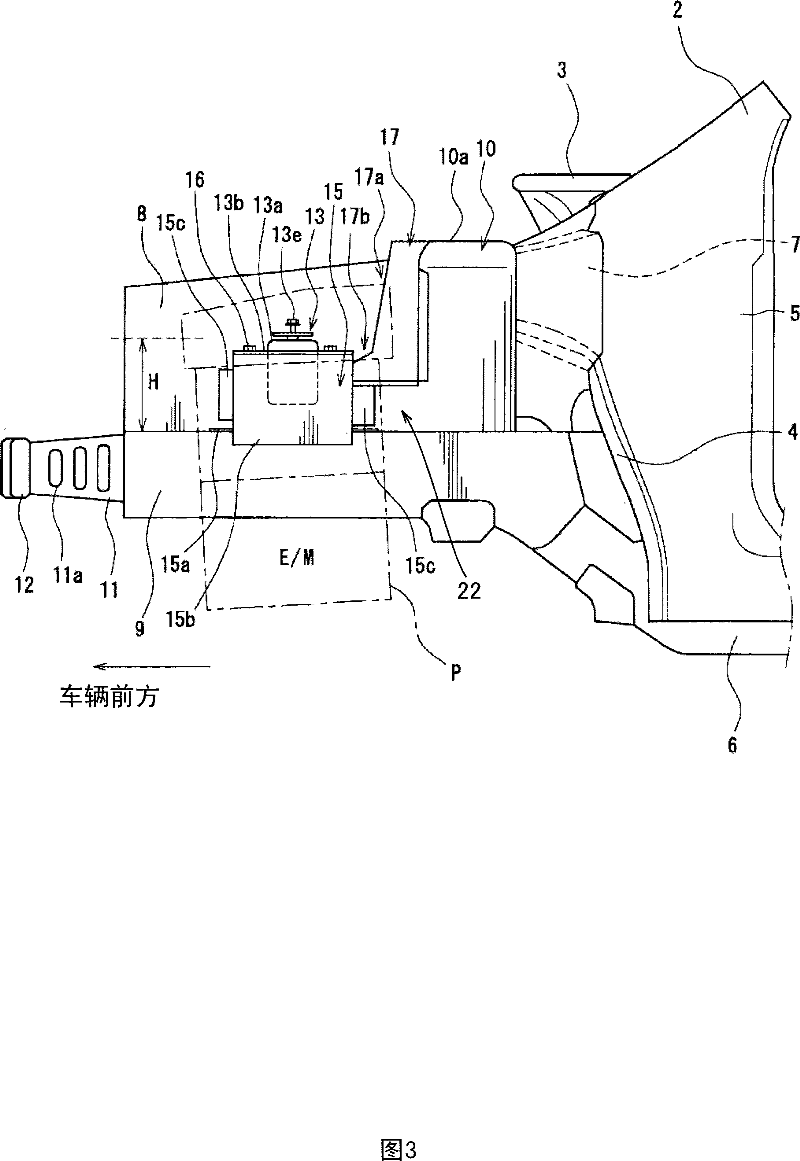

[0052] 1 and 3 are a perspective view and a side view, respectively, showing a main part (right side portion) of a vehicle body front structure according to a first embodiment of the present invention, and FIG. 2 is a plan view of the vehicle body front structure. In FIGS. 1 to 3 , the front part of the compartment 1 mainly includes a pair of A-pillars (also known as A-pillars) located at the lower edge of the front glass (not shown) and connecting the left and right pairs in the vehicle width direction. A neck portion 3 of a window pillar or front pillar 2; a dash panel 4 as a partition separating the vehicle compartment 1 and the engine room ER; a hinge support tower extending downward from the A-pillar 2 (hinge tower) 5.

[0053] The dash panel 4 is arranged at the lower part of the vehicle neck 3 , and its left and right side edges are respectively connected to a pair of left and right hinge support towers 5 . The hinge support tower 5 is provided with door hinges for fre...

no. 2 approach

[0099] In the above-mentioned first embodiment, the installation part 15 and the gusset member 17 are provided, and the retreat energy of the power plant P is distributed and transmitted to the upper part 10a of the suspension support tower 10 through them, but it is not necessarily limited thereto. For example, in the present invention, it is also possible to replace the mounting part 15 and the gusset part 17 of the engine assembly part, and set a single part (gusset part 117) having both functions as shown in Figure 9, and use the gusset part 117 constitutes the frame member 22 .

[0100]Fig. 9 is a perspective view showing the main parts of the vehicle body front structure related to the second embodiment, Fig. 10 is an exploded perspective view showing the main parts of the car body front structure related to the second embodiment, Fig. 11(a), 11 (b) are respectively the sectional view in the direction of the arrow of line C-C and the sectional view in the direction of th...

no. 3 approach

[0117] Next, the configuration of the third embodiment will be described with reference to FIGS. 12 to 18 . 12 is a right side perspective view showing a left side portion of a vehicle body front structure according to the third embodiment, FIG. 13 is a left side perspective view showing a right side portion of the vehicle body front structure, and FIG. 14 is a vehicle body front structure. Figure 15 is a top view of the front structure of the vehicle body, Figure 16 is a front view of the left part of the front structure of the vehicle body, and Figure 17 is a view of the front structure of the vehicle body viewed from the inside of the engine room The side view of the left part, Fig. 18 (a) is a sectional view of the E-E line arrow direction in Fig. 16, and Fig. 18 (b) is a sectional view of the F-F line arrow direction in Fig. 16 . In each figure, the left side of the driver is referred to as the left side of the vehicle, and the right side of the driver is referred to as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com