Suspension tower overhead line take-up device

A technology for overhead lines and linear towers, applied to overhead lines/cable equipment, etc., can solve the problems of burnt wires or lightning protection lines, difficulty in line repair, poor construction safety, etc., to reduce labor intensity, easy to popularize and implement, and easy to operate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

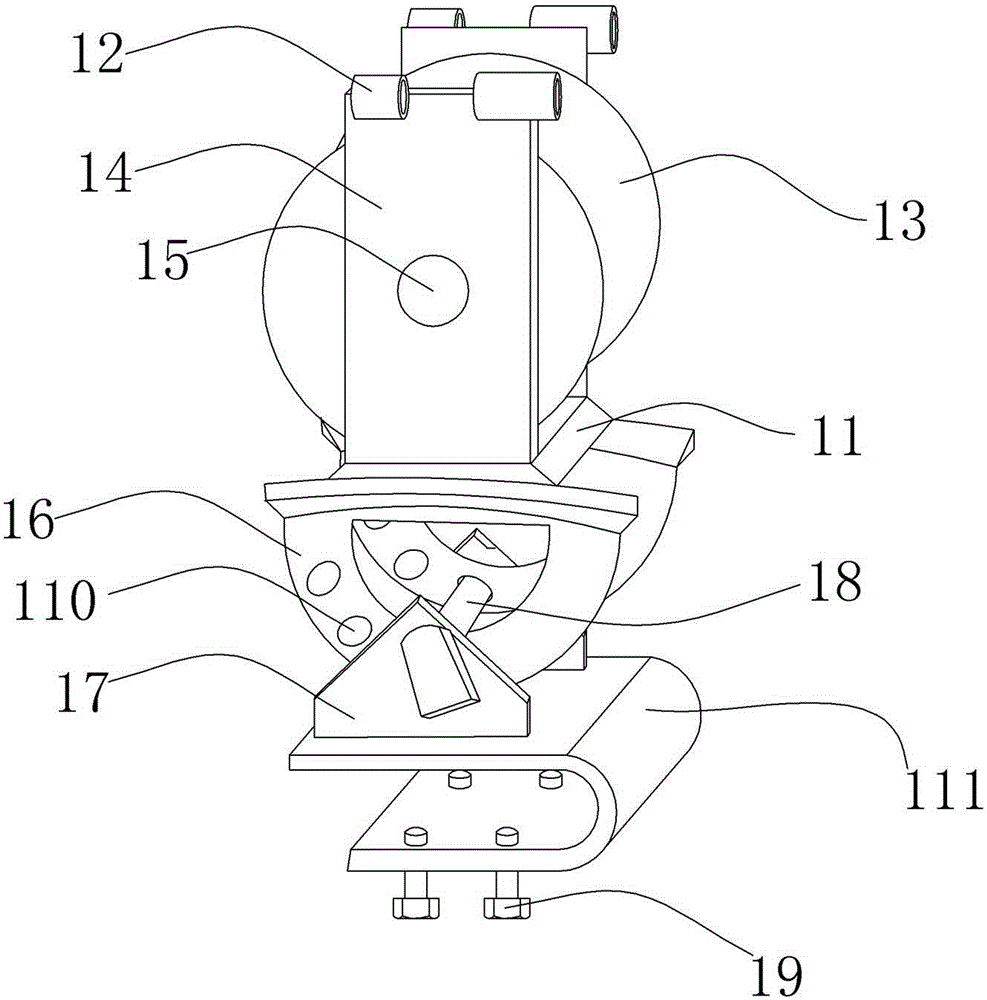

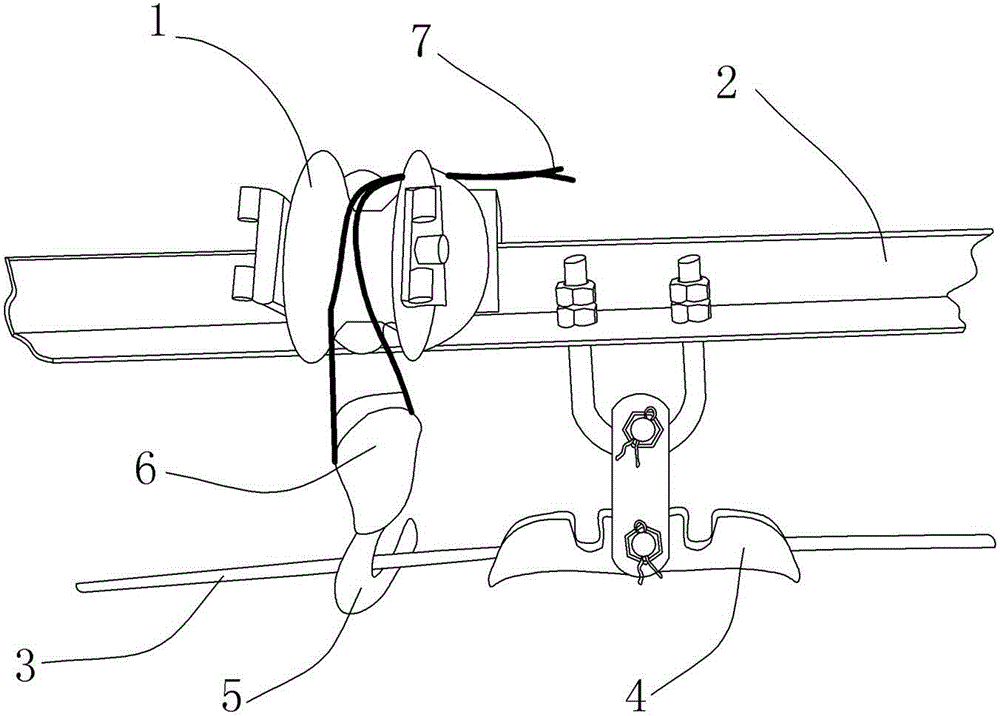

[0021] Embodiment 1, a wire take-up device for a linear tower overhead line, including a pulley, a support mechanism, a support, a hook, a hook pulley and a control hinge, the support mechanism and the support are hinged and fixed, and the support mechanism includes a support body, two vertical The board and the angle adjustment unit, the two vertical boards are fixed vertically on the support body, the pulley is fixed between the two vertical boards through the pulley shaft, and the angle adjustment unit includes a hinged board body 1 and a hinged board body 2 respectively fixed to the support body. A number of hinged holes are arranged on the first hinged plate body and the second hinged plate body, and the support is fixed to the support mechanism through the hinged holes, and the support is fixed to the linear pole tower.

Embodiment 2

[0022] Embodiment two, see Figure 1~2 As shown, it is basically the same as Embodiment 1, the difference is that the first hinged plate and the second hinged plate are arranged parallel to each other, and several hinged holes are respectively arranged in a circular arrangement on the first hinged plate body and the second hinged plate body, and the adjustment of the tension angle is more convenient. Convenient, reliable, practical, see figure 2 As shown, with the cooperation of the hook and the hook pulley, the replacement of the suspension clamp can be completed under the adjustment and control of one operator. The pulley can choose U-shaped groove pulley or V-shaped groove pulley to adjust and control according to the use requirements. Due to the friction between the hinge and the pulley, the operator can adjust the tension and angle of the suspension line by controlling the hinge. The operation is more convenient and reliable. The tension of each suspension line is differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com