Vehicle body structure

A body and body panel technology, applied in the direction of the superstructure, the superstructure sub-assembly, the connection between the superstructure sub-assemblies, etc., can solve the problems of low fatigue strength, fracture, etc. The effect of suppressing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] [First exemplary embodiment]

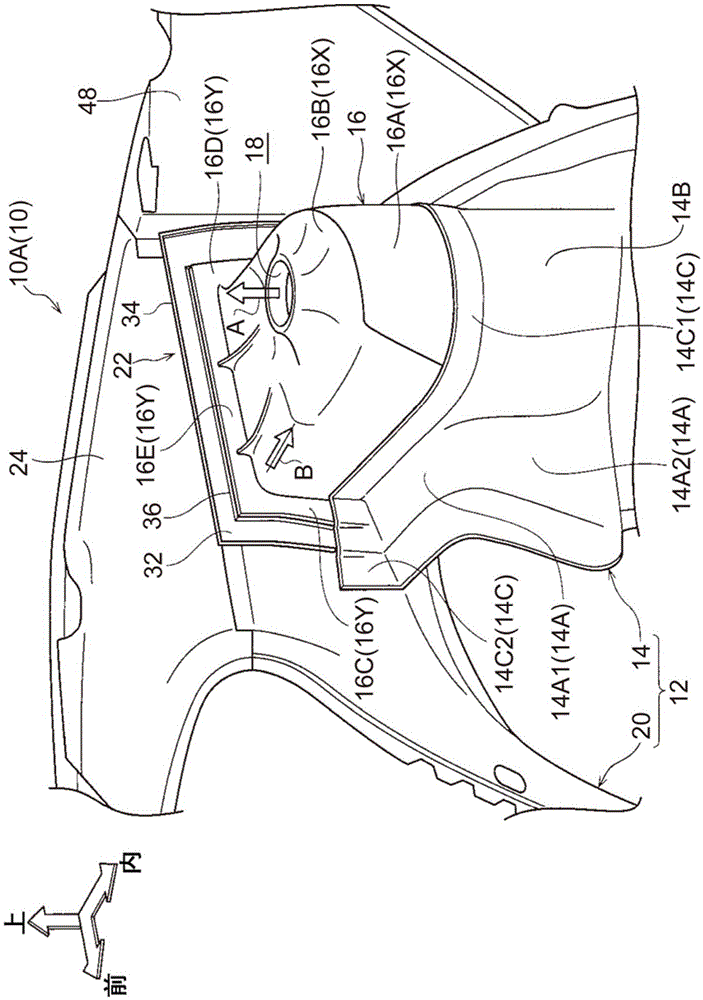

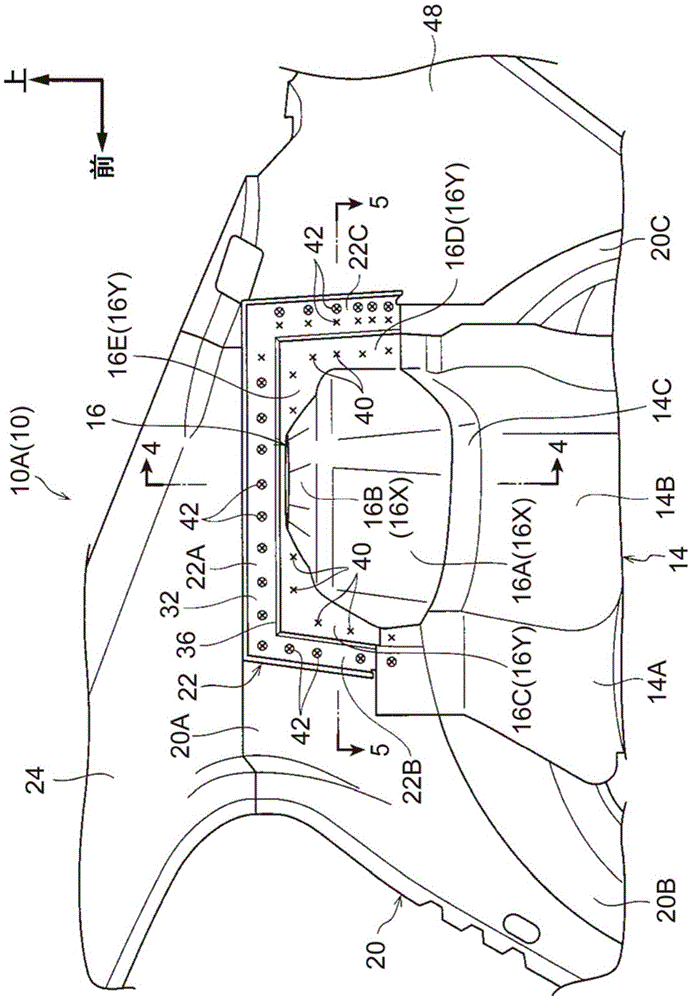

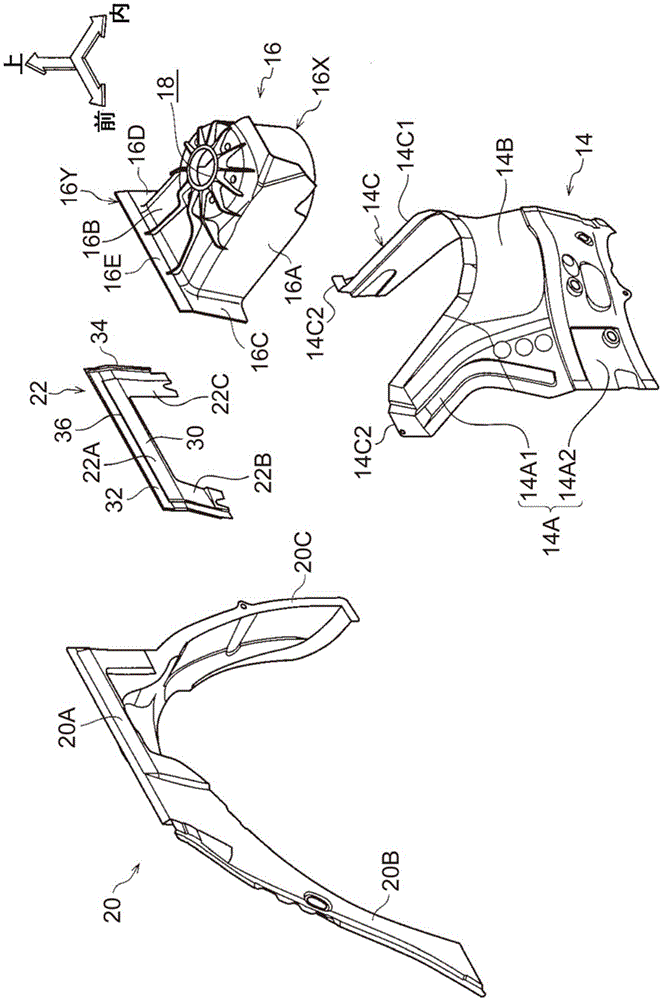

[0048] will now refer to Figures 1 to 8B A vehicle rear structure according to a first example embodiment of a vehicle body structure to which the present invention is applied is described. In the drawings, an arrow "front" (FR) indicates the vehicle front side, an arrow "up" (UP) indicates the vehicle upper side, and an arrow "in" (IN) indicates the vehicle width direction inner side.

[0049]

[0050] as in Figure 1 to Figure 3 As shown in , the wheel house inner panel 14 forming the inner panel of the rear wheel house 12 and opening its upper end in a substantially U-shape, the rear suspension support cover 16 engaged and fitted around the upper end of the wheel house inner panel 14 , and the rear suspension support cover 16 are arranged on A wheel house outer panel 20 forming an outer panel of the rear wheel house 12 on the vehicle width direction outer side of the wheel house inner panel 14 and an extension panel 22 interposed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com