Active and passive coordinated regulated magnetic levitation wind yawing system

A yaw system and magnetic levitation technology, applied in engine control, wind engine, engine control parameters and other directions, can solve the problems of large yaw power consumption of wind turbines, the suspension air gap is easily affected by external interference, and the suspension power consumption is increased. Achieve the effect of reducing equipment cost and equipment failure rate, reducing yaw power consumption and suspension power consumption, and improving suspension stiffness and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

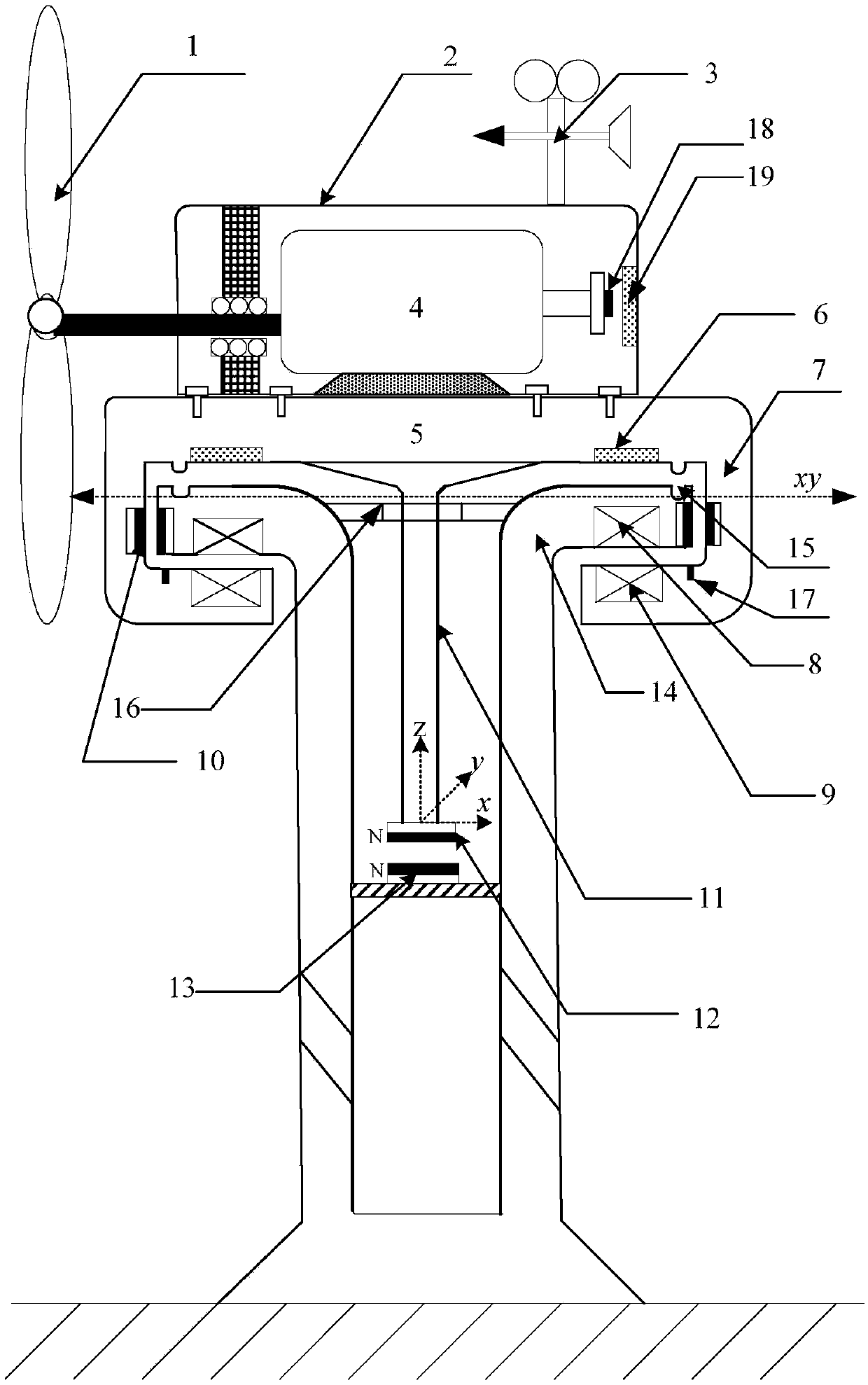

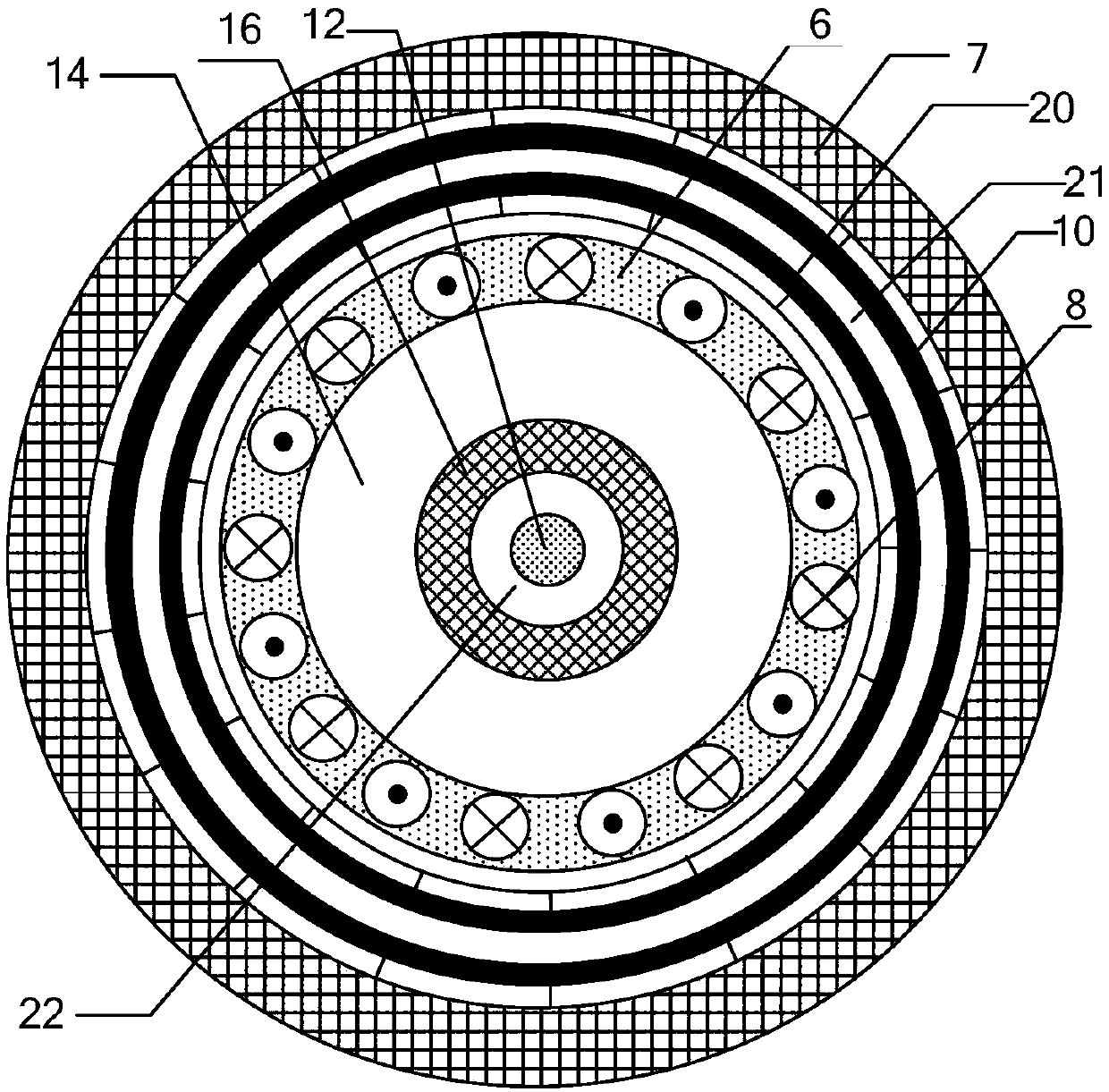

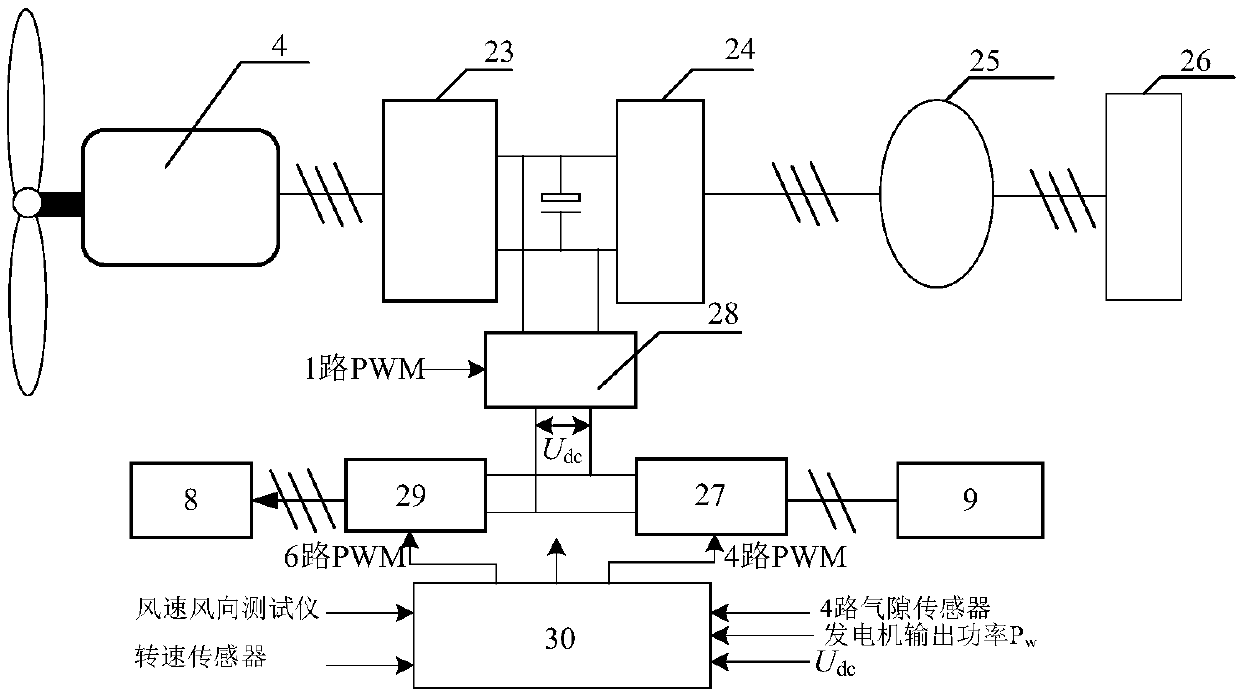

[0018] The active-passive coordinated control maglev wind yaw system disclosed in the present invention includes a nacelle 2 , a yaw support body 7 , a pitch adjustment suspension 11 and a suspension tower 14 . Wherein the nacelle includes a blade 1, a generator 4, an anemometer 3, a shock-absorbing tail shaft 18, a shock-absorbing aluminum plate 19, and a nacelle base 5, an annular aluminum plate 6, a yaw winding 9, and a yaw support body 7 are installed. The vertical permanent magnet 10 of the yaw support body, the suspension tower 14 includes the suspension winding 8, the vertical permanent magnet 20 of the suspension tower, and the inner support of the tower. The converter 28 is completed under the action of the DSP28035 main control unit 30 , and the active yaw is completed by the yaw winding 9 , the three-phase inverter 29 and the BUCK converter 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com