Under-actuated hoisting equipment control system and method thereof

A hoisting equipment and control system technology, applied in the field of under-actuated hoisting equipment control systems, can solve problems affecting work efficiency, swinging heavy objects, and reducing production efficiency, so as to improve target detection speed, classification accuracy, and work efficiency and high controllability, the effect of improving work productivity

Active Publication Date: 2022-01-07

ROCKET FORCE UNIV OF ENG

View PDF9 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] An underactuated system refers to a system in which the number of independent control quantities is less than the degree of freedom of the system; traditional portal bridge cranes, because they use wire ropes for operations, belong to a type of typical underactuated equipment. Therefore, during the lifting process, Due to the effect of acceleration, deceleration or wind load, heavy objects will inevitably have swing problems, which may affect work efficiency and reduce production efficiency, or bring safety hazards and affect personal safety; in addition, before lifting heavy objects, due to the hook and heavy There is a centering error in the center of gravity of the object, which will cause the phenomenon of crooked pulling and slanting, and also cause the swing after lifting; at the same time, the heavy object may collide with surrounding people or objects during transportation, causing safety accidents;

[0004] Therefore, the design of intelligent and efficient safety control systems for underactuated cranes has received more and more attention. However, in the current control methods for portal bridge cranes, there is no control system and control method that can be used for underactuated cranes. Portal bridge crane anti-skewing, anti-swing, anti-collision "three prevention" functions, so as to improve the stability, safety, work efficiency and controllability of production and transportation operations

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

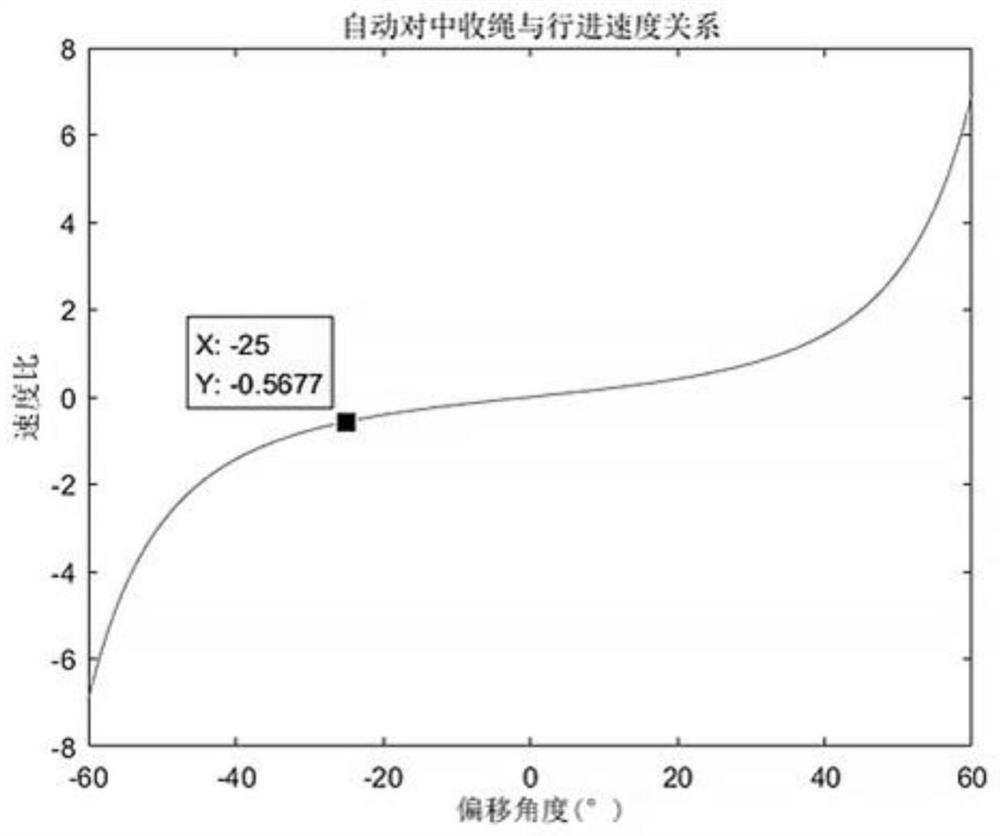

[0143] (1) Verification of anti-slant lifting function (automatic centering function)

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

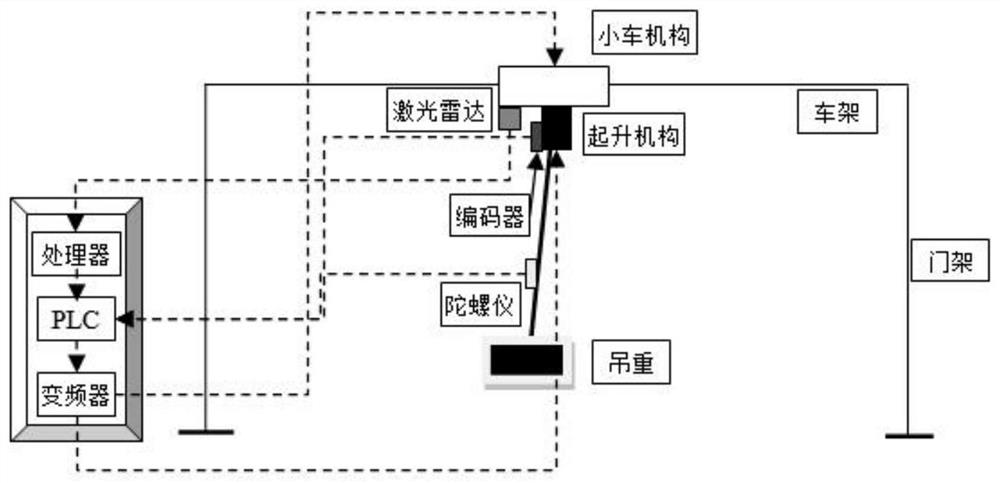

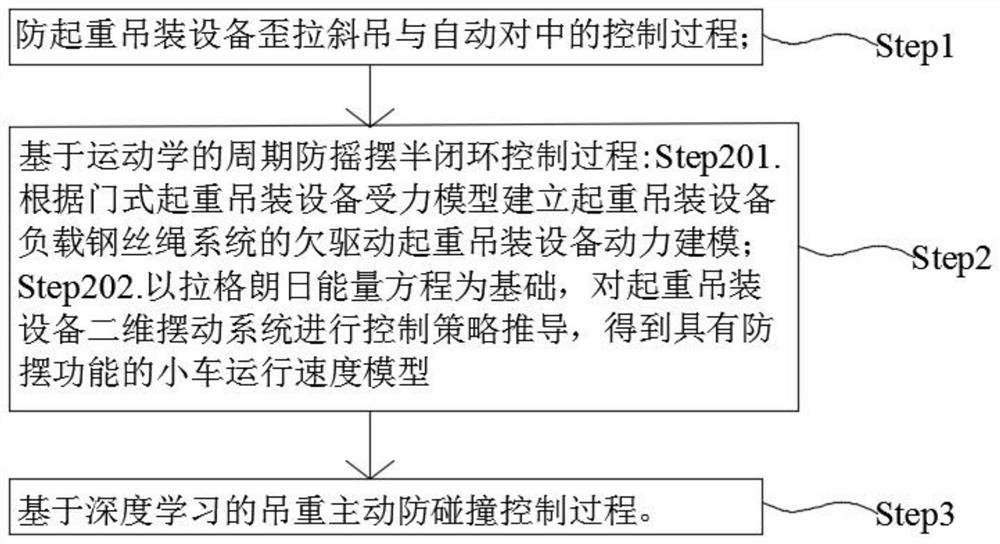

The invention discloses an under-actuated hoisting equipment control system and a method thereof. The system comprises a hoisting scene information obtaining module, a swing angle obtaining module, a height obtaining module and a control module, and the hoisting scene information obtaining module, the swing angle obtaining module and the height obtaining module are all connected with the control module; and the control module controls a hoisting mechanism of hoisting equipment to act. When the system and the method are used, the three-prevention functions of inclined pulling and hoisting prevention, swinging prevention and collision prevention of the gantry crane hoisting equipment in the hoisting process can be achieved, so that the stability, the safety, the working efficiency and the controllability of production and transportation operation are improved, and the system and the method have the characteristics of being high in stability, safety, working efficiency and controllability.

Description

technical field [0001] The invention relates to the technical field of hoisting and hoisting, in particular to an underactuated hoisting and hoisting equipment control system and method thereof. Background technique [0002] Portal bridge cranes have been widely used in lifting and hoisting, industrial production, logistics turnover, port terminals, and railway transportation and other departments and places, and are indispensable large-scale equipment in modern industrial production and lifting transportation; [0003] An underactuated system refers to a system in which the number of independent control quantities is less than the degree of freedom of the system; traditional portal bridge cranes, because they use wire ropes for operations, belong to a type of typical underactuated equipment. Therefore, during the lifting process, Due to the effect of acceleration, deceleration or wind load, heavy objects will inevitably have swing problems, which may affect work efficiency ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B66C13/48B66C13/22B66C13/06B66C13/08B66C13/16B66C15/04G06F30/27G06F17/10

CPCB66C13/48B66C13/22B66C13/063B66C13/085B66C15/045B66C13/16G06F30/27G06F17/10G06F2119/02

Inventor 何祯鑫于传强王欣冯永保李良曹大志杜文正郭杨王俊提

Owner ROCKET FORCE UNIV OF ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com