Patents

Literature

104results about How to "Curb production cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Whole-nutrition biological flushing and spreading fertilizer and preparation method thereof

InactiveCN101037369ASolve the single nutrientSolve solubilityClimate change adaptationAlkali orthophosphate fertiliserMicroorganismNicotiana tabacum

A full nutrition fertilizer of biology type and its producing method belongs to organic complex fertilizer field in biology type. The components of the full nutrition fertilizer is 20-50% of organic waste liquid, 10-30% of urea, 8-15% of diammomium phosphate, 10-25% of potassium sulfate, 5-20% of medium trace element, 1-5% of microbial inoculum, 0-0.2% of root-promoting agent; 0-2% of solutizer, effective viable count content of the microbial inoculum of more than 1010 / g. The fertilizer is produced by adding the urea, diammomium phosphate, potassium sulfate, medium trace element, root-promoting agent, solutizer into organic waste liquid and blending uniformly, then adding microbial inoculum. The invention uses the wastes to produce fertilizer with a low cost a high availability and a good prospect in the fertilizer industry. The fertilizer can be widely applied to the vegetables, melon and fruits, food, tobacco, forests and different commercial crops.

Owner:INST OF SOIL & FERTILIZER SHANDONG ACAD OF AGRI SCI

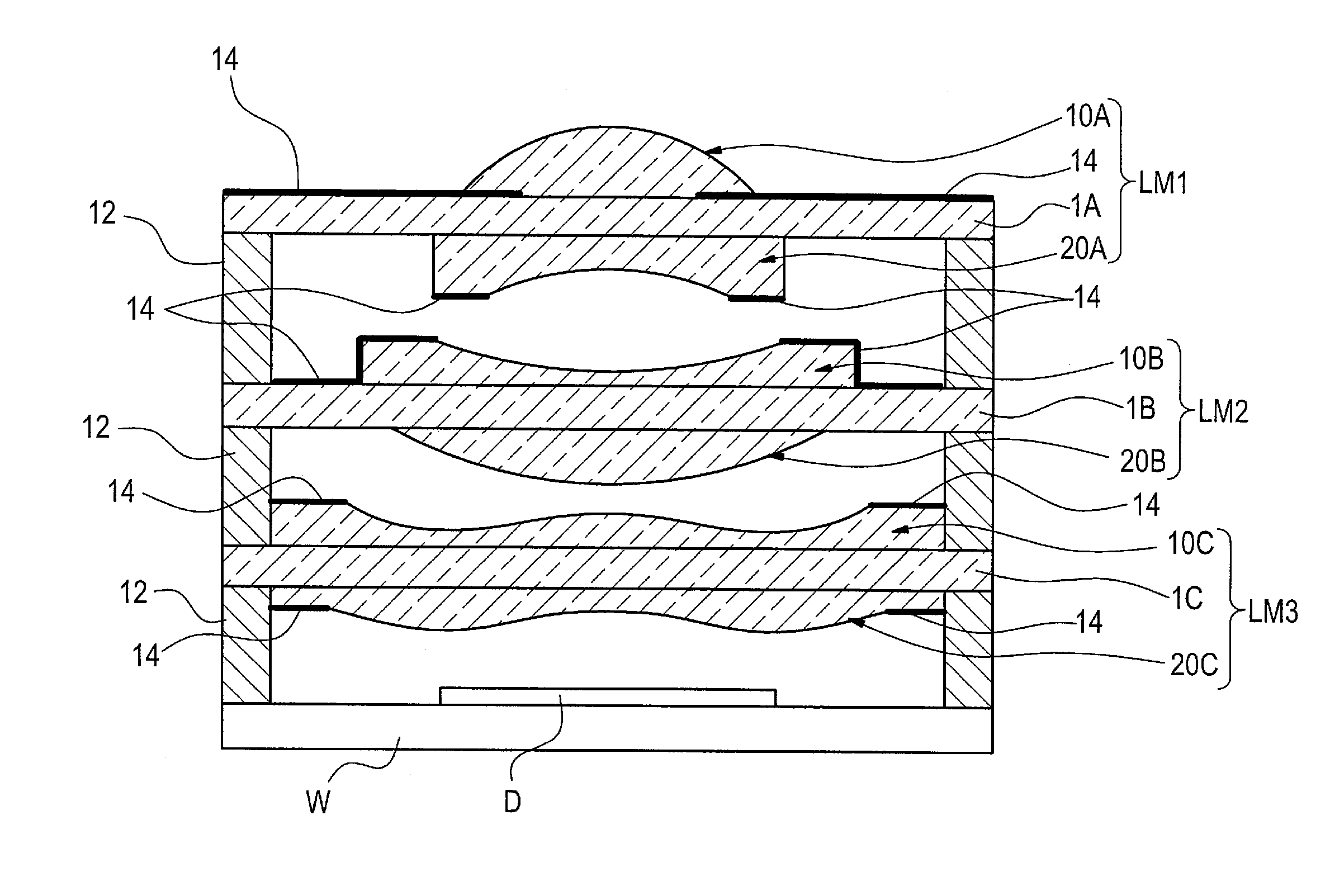

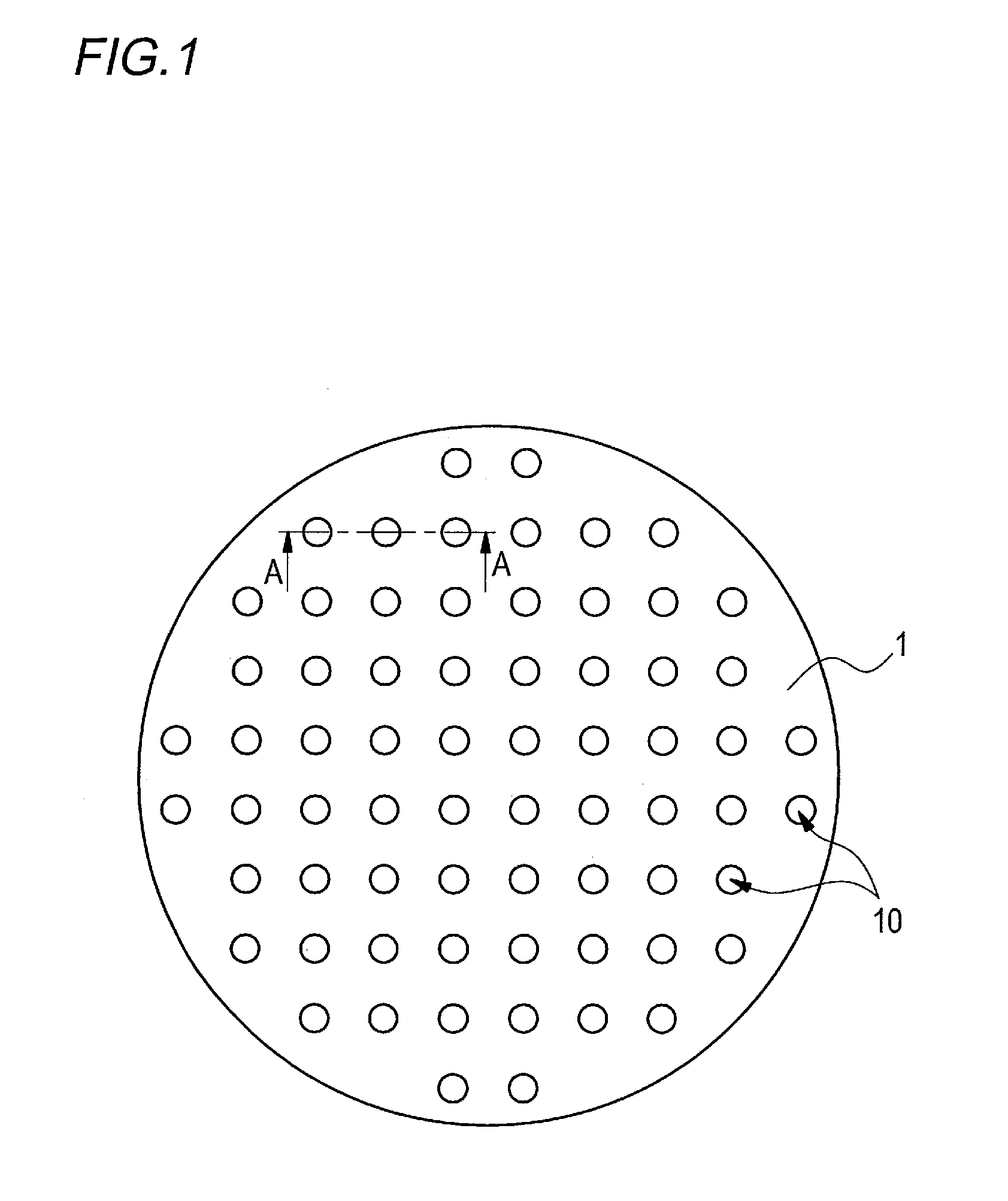

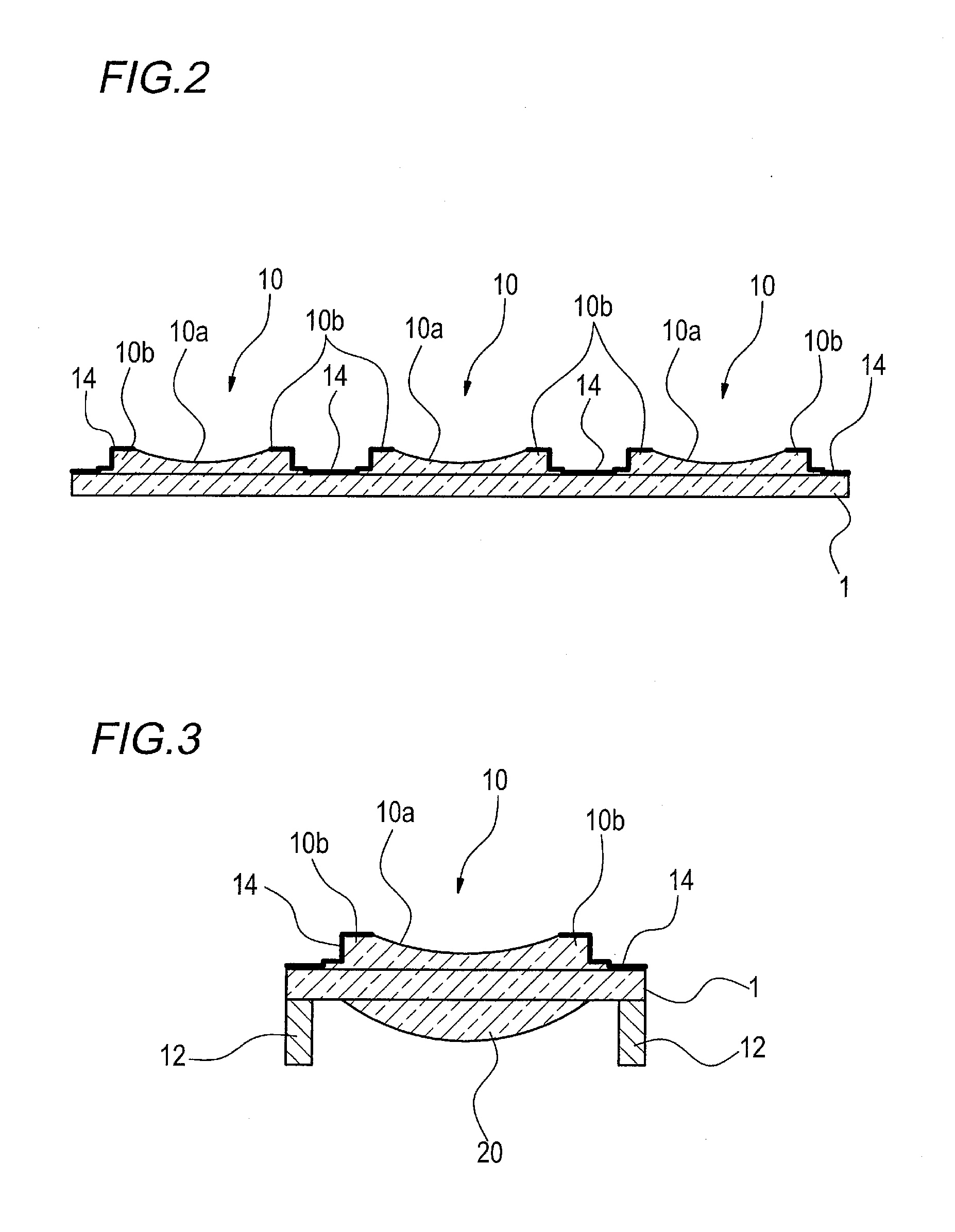

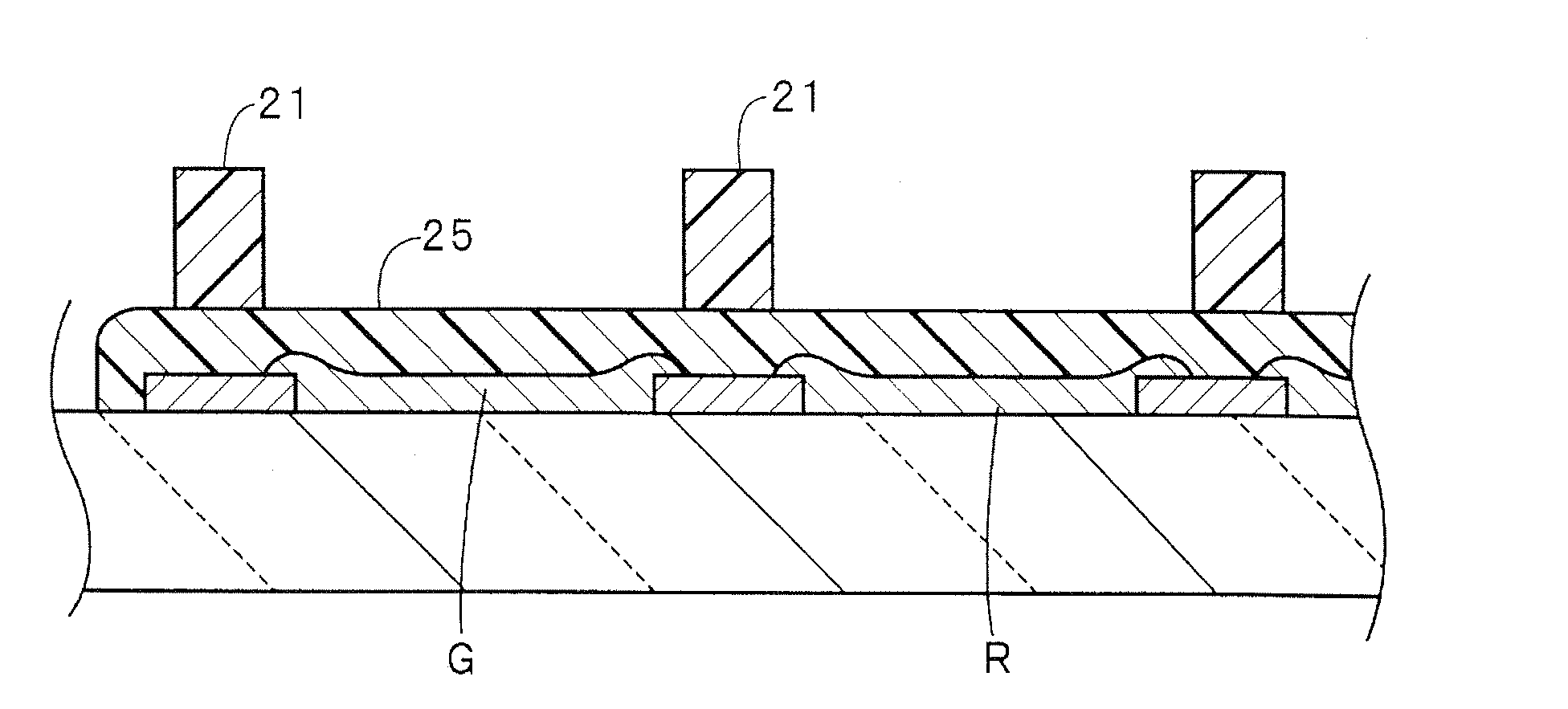

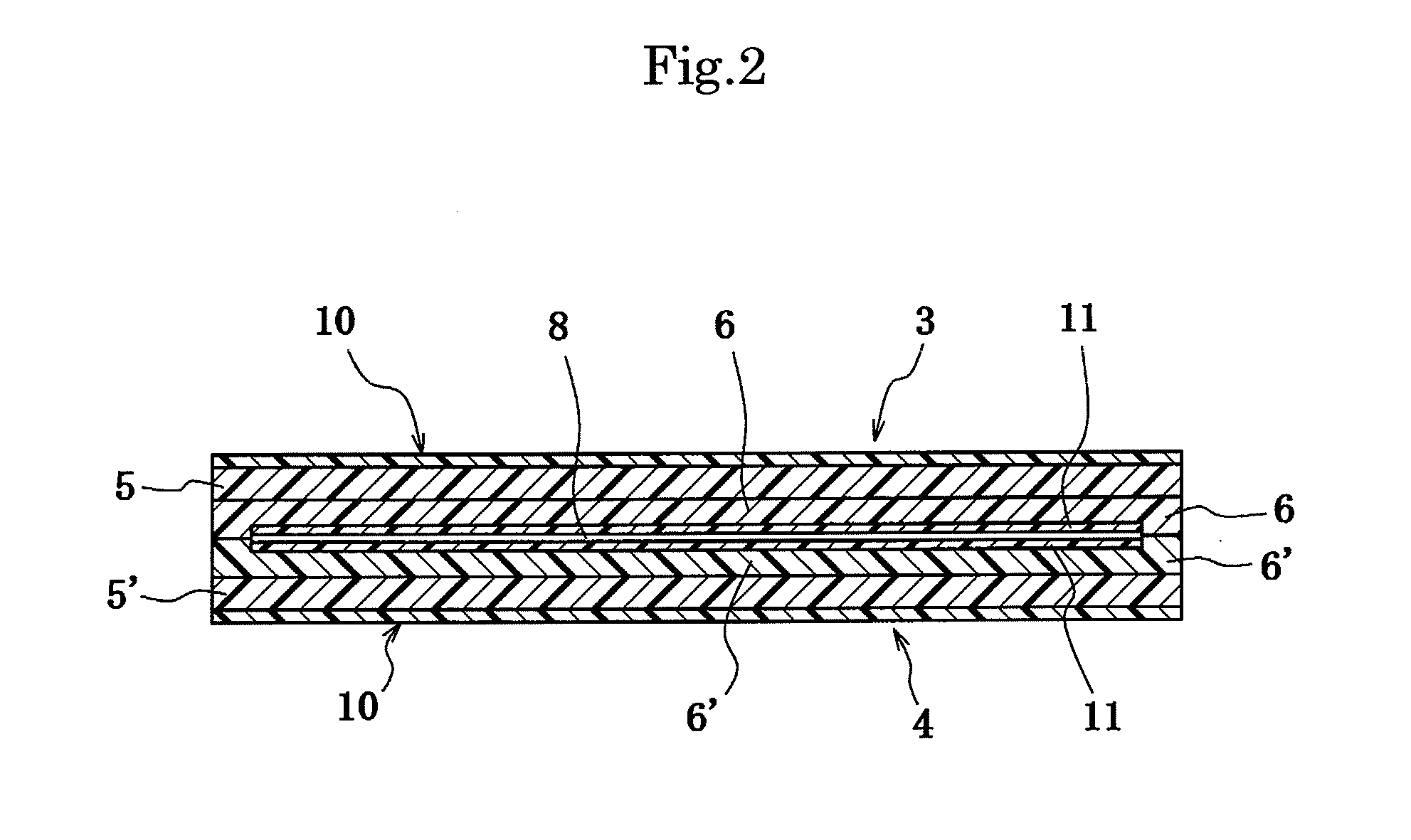

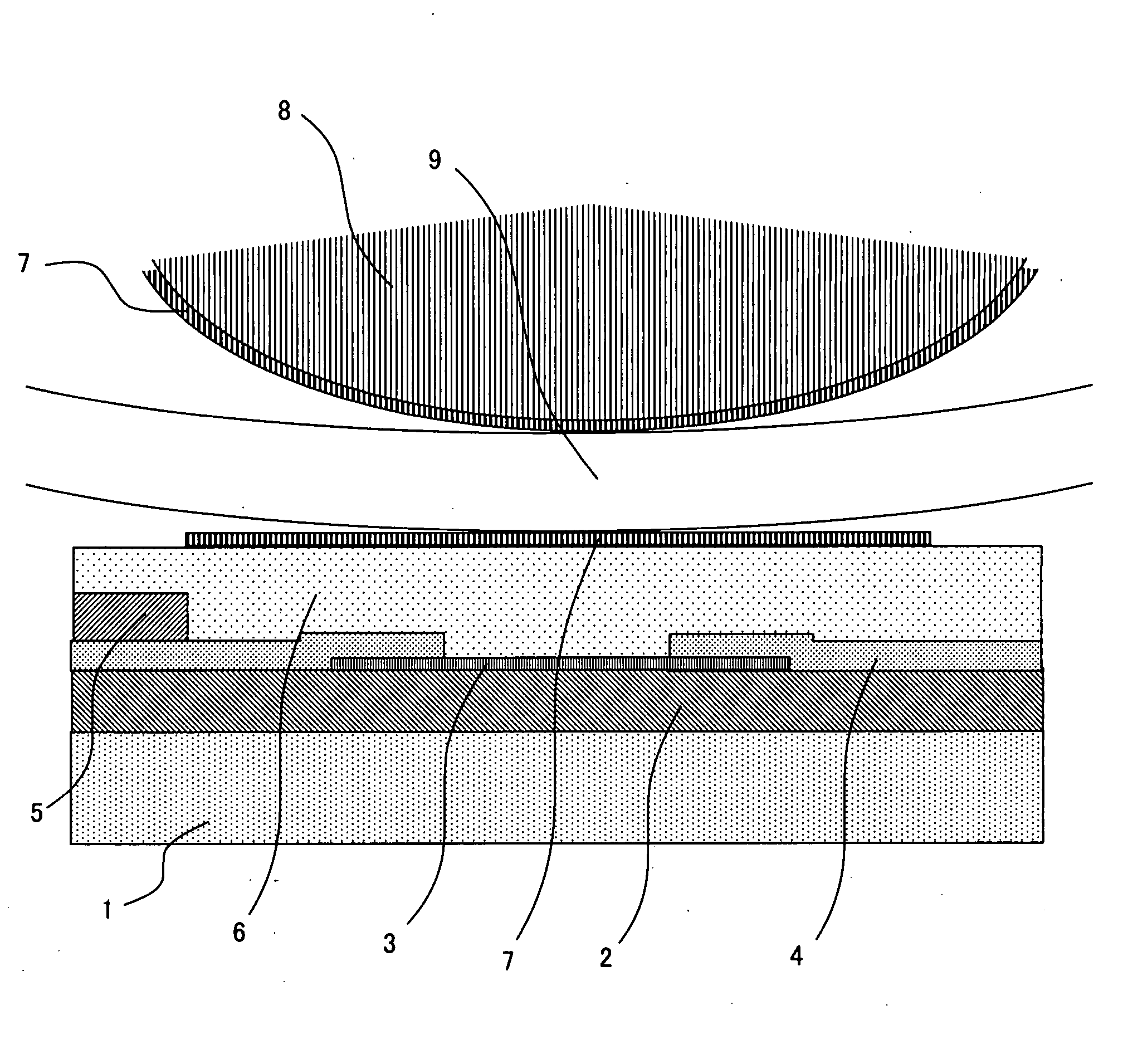

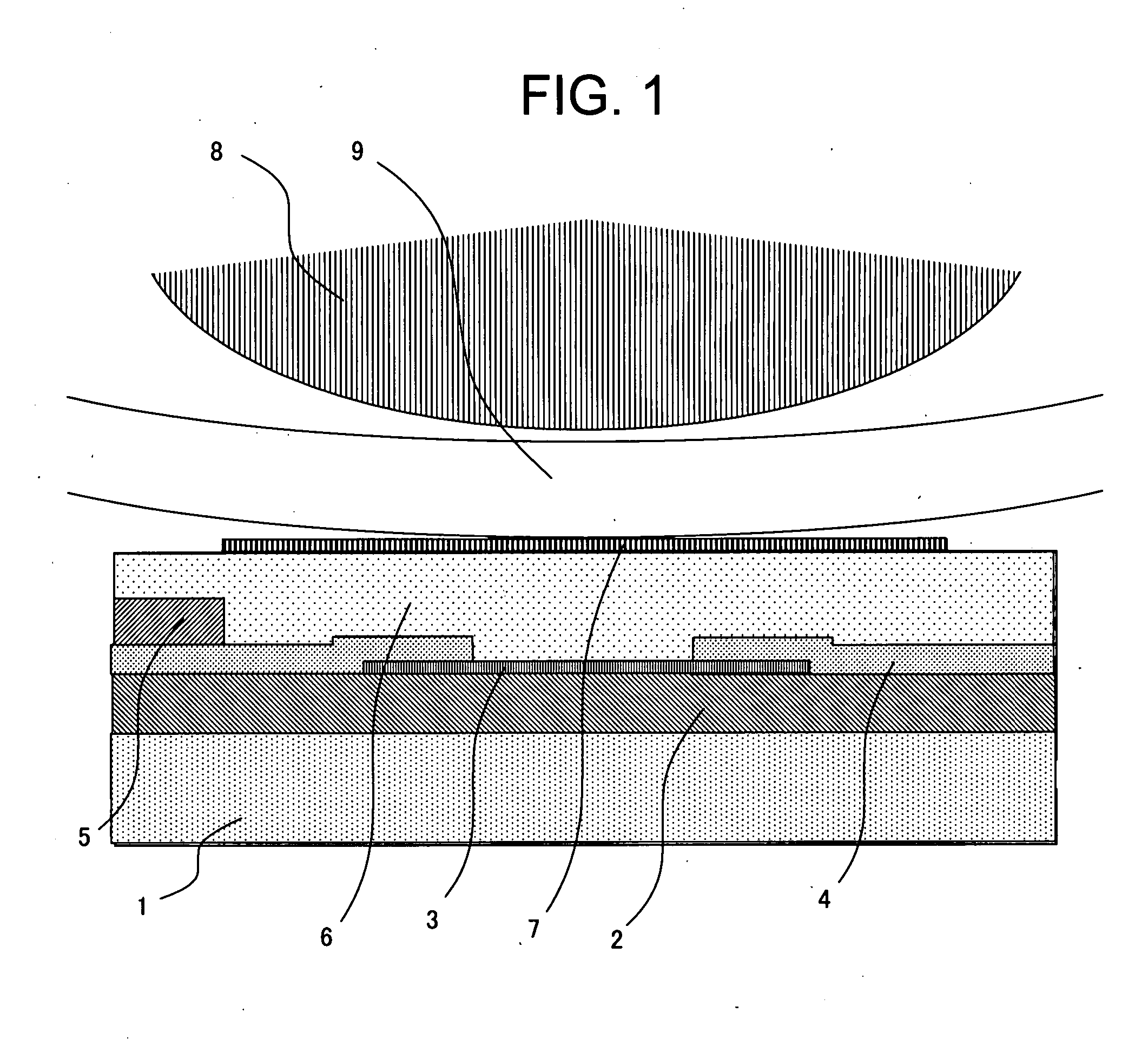

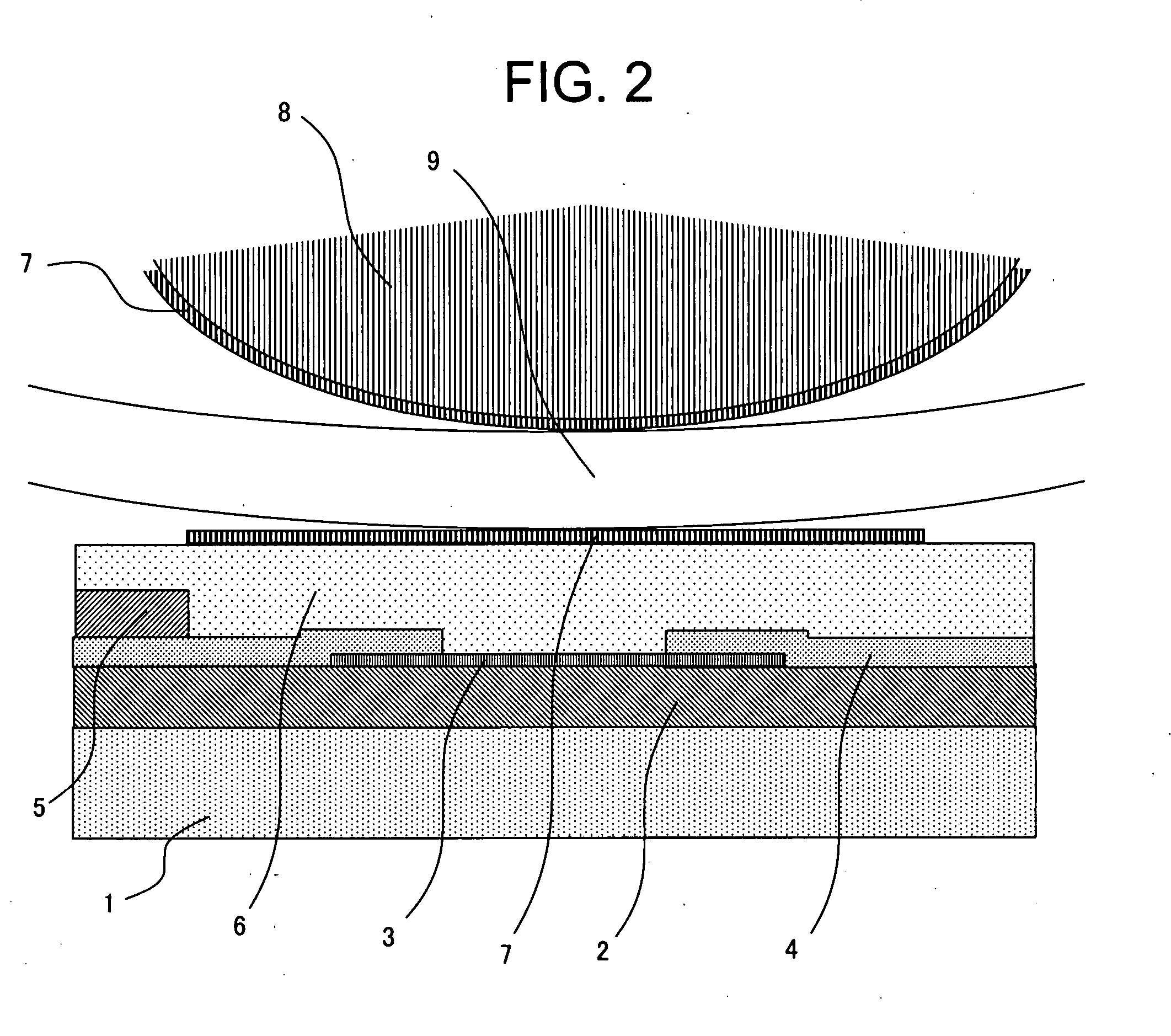

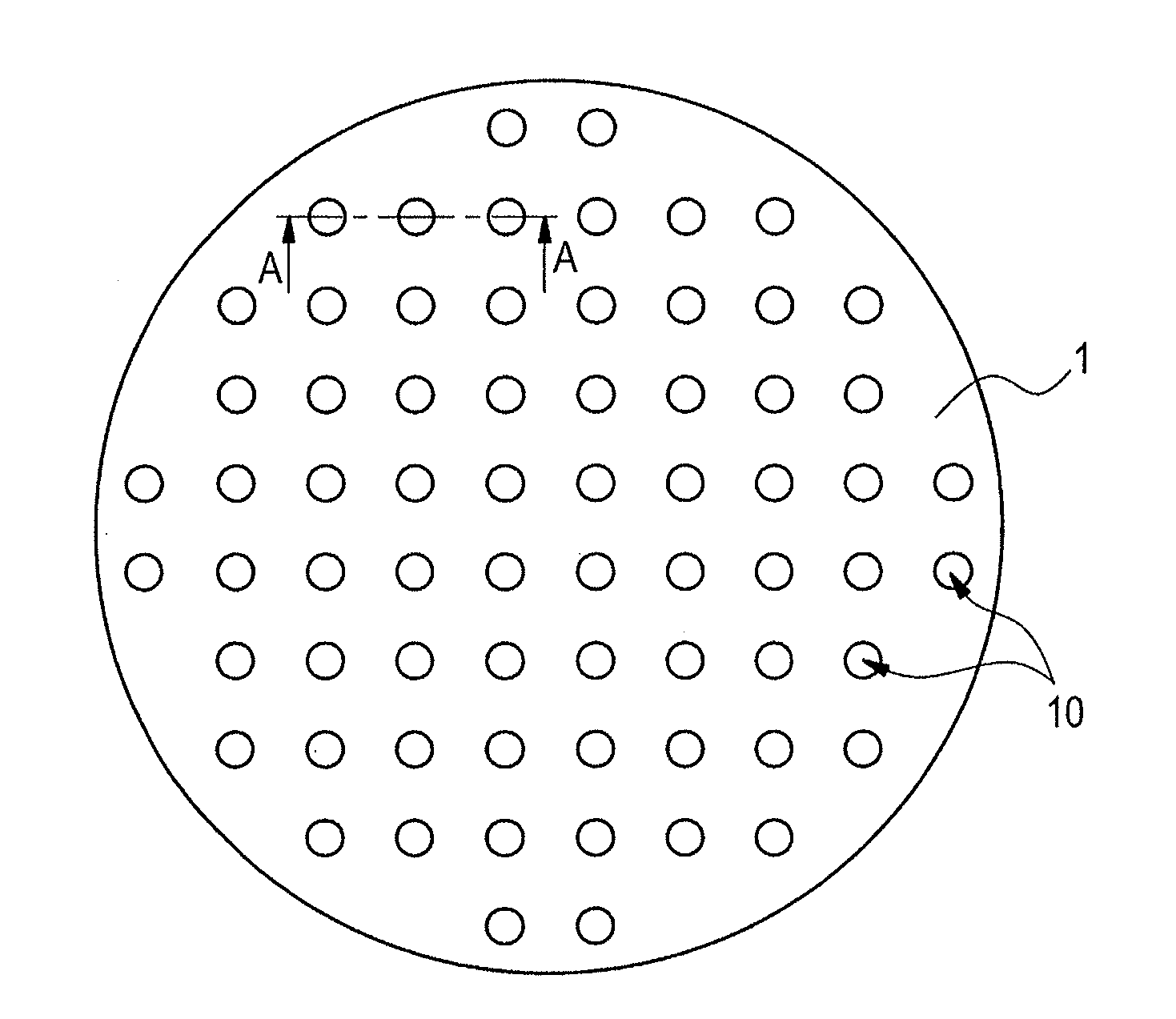

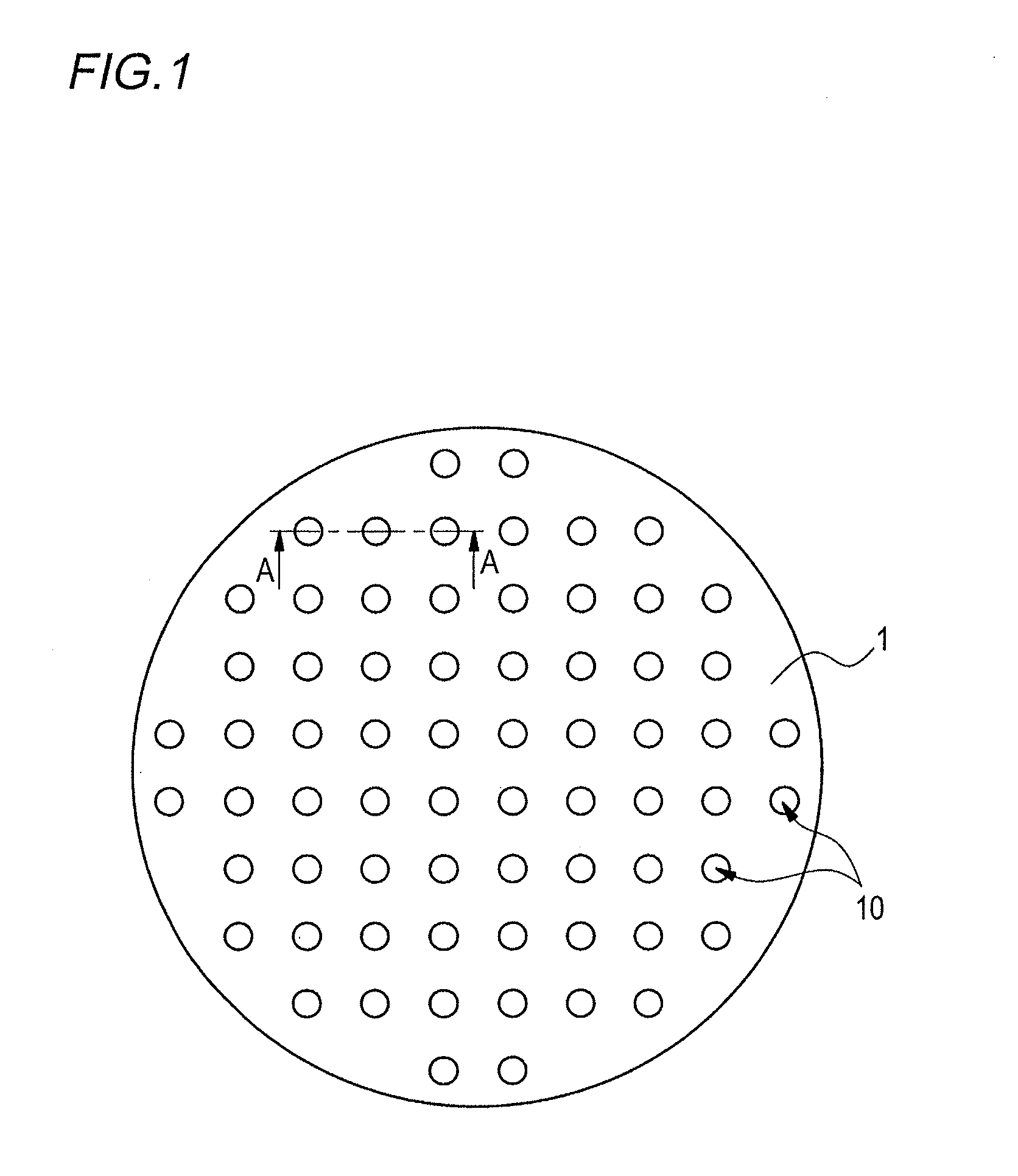

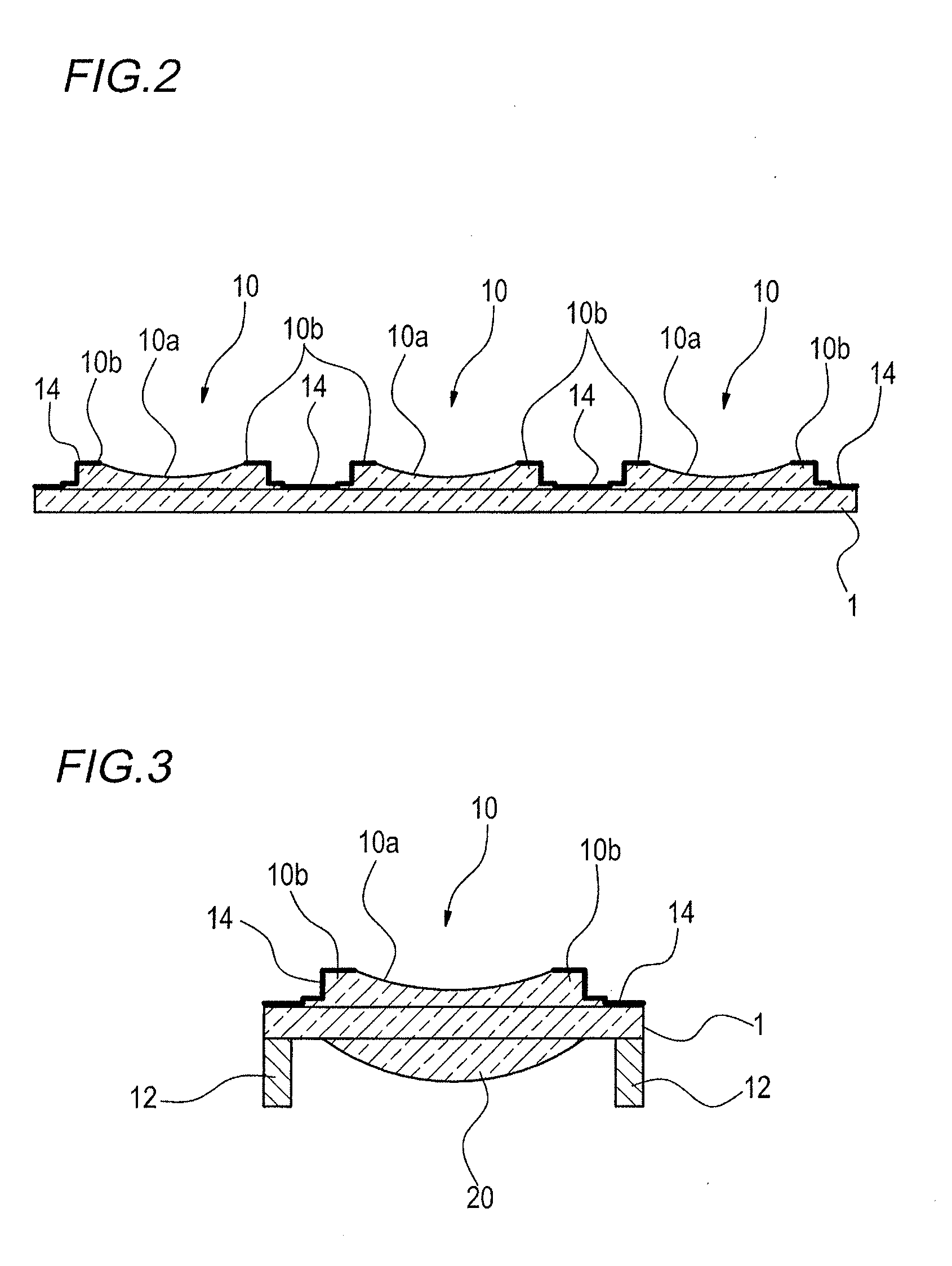

Wafer level lens, production method of wafer level lens, and imaging unit

InactiveUS20120134028A1Avoid light transmissionPrevent penetrationSolid-state devicesOptical articlesResistOptical axis

A sufficient light-shielding property is obtained by a wafer level lens having at least one lens module having a substrate and a plurality of lenses formed on the substrate in which the wafer level lens has a black resist layer formed on the surface of the lens module or on the surface of the substrate and the black resist layer is formed with a pattern having an opening at a part intersecting the optical axis of the lens, and generation of defects such as ghosts, flares and the like due to a reflected light can be prevented and an increase in the production cost can be suppressed.

Owner:FUJIFILM CORP

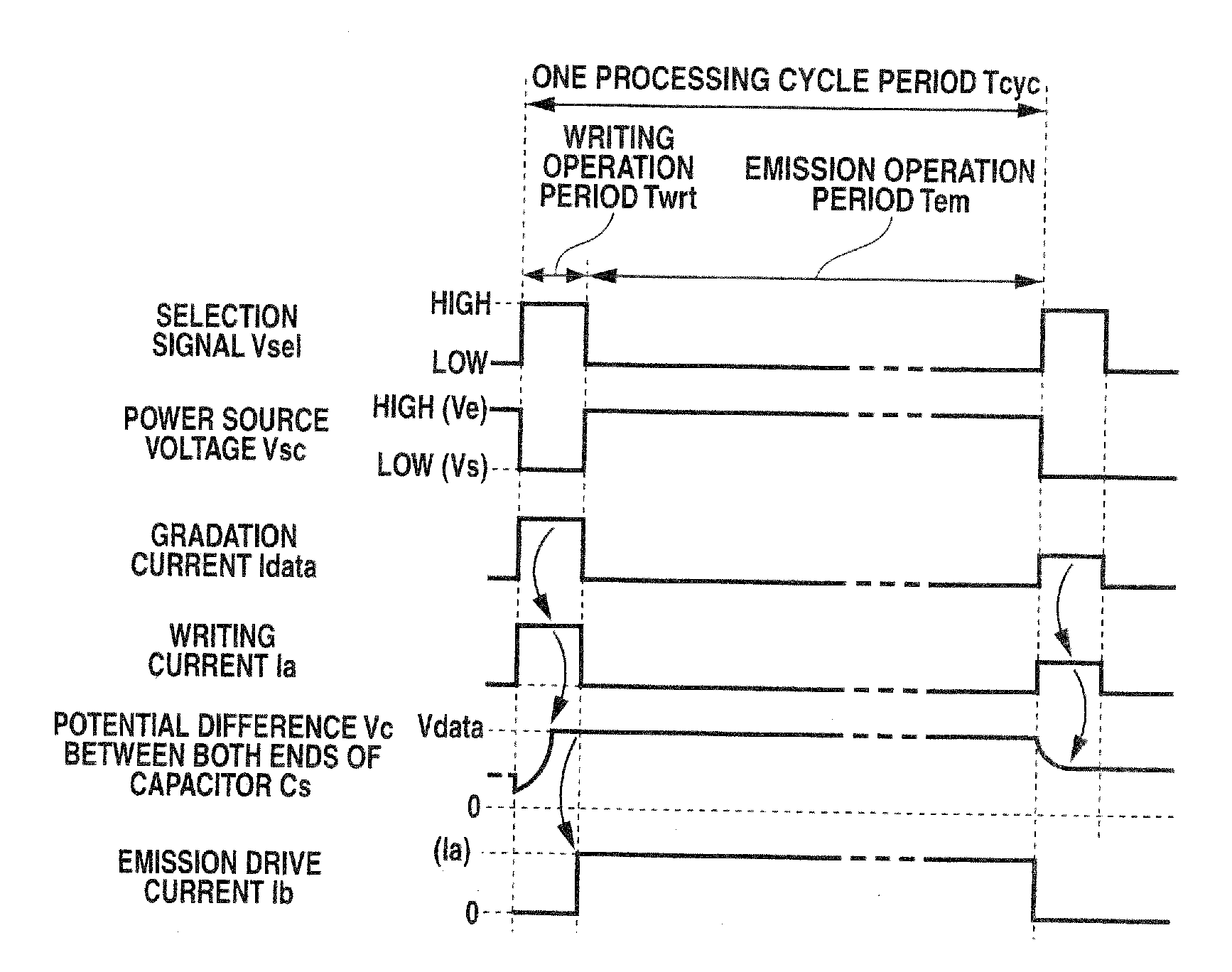

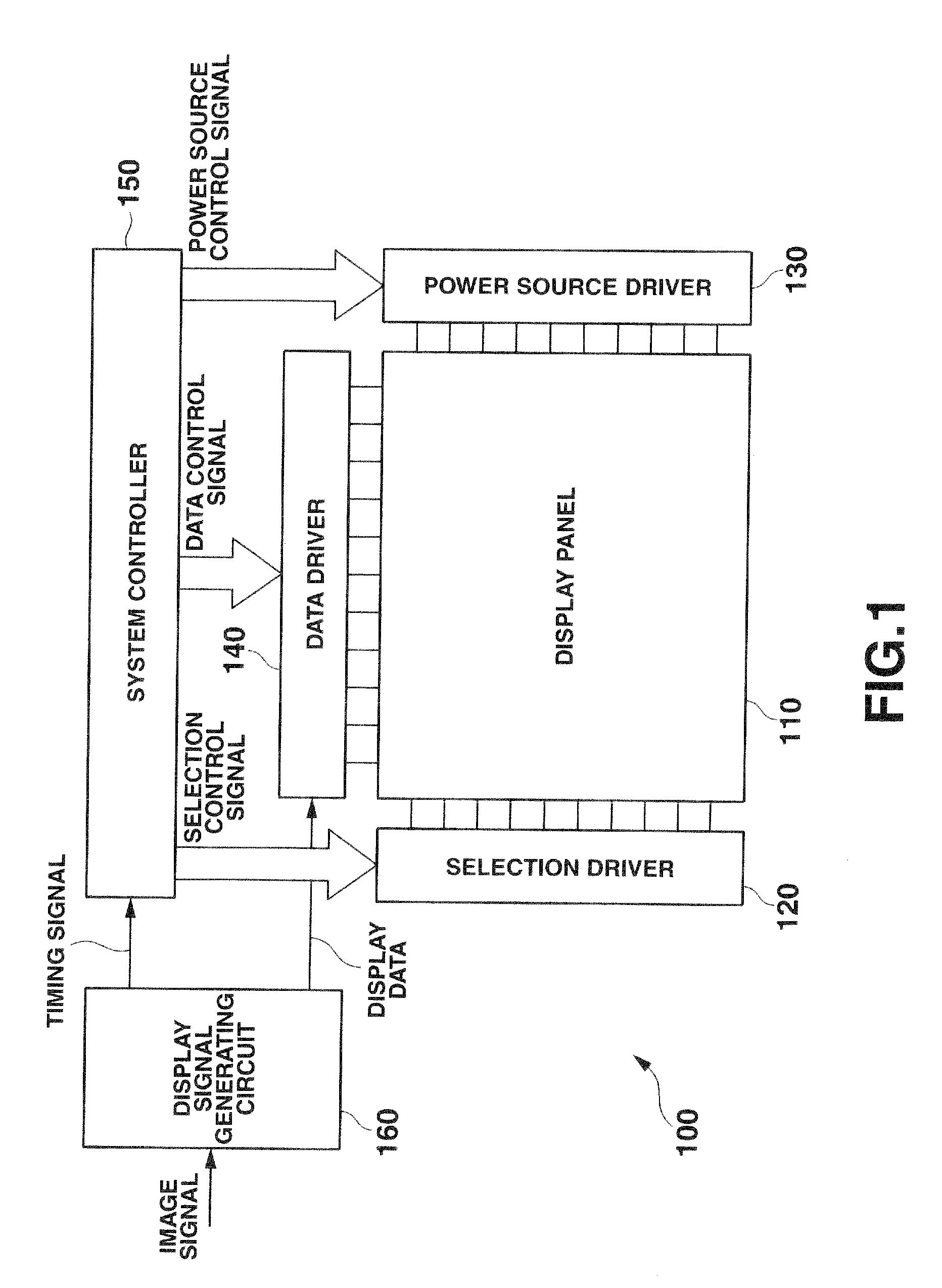

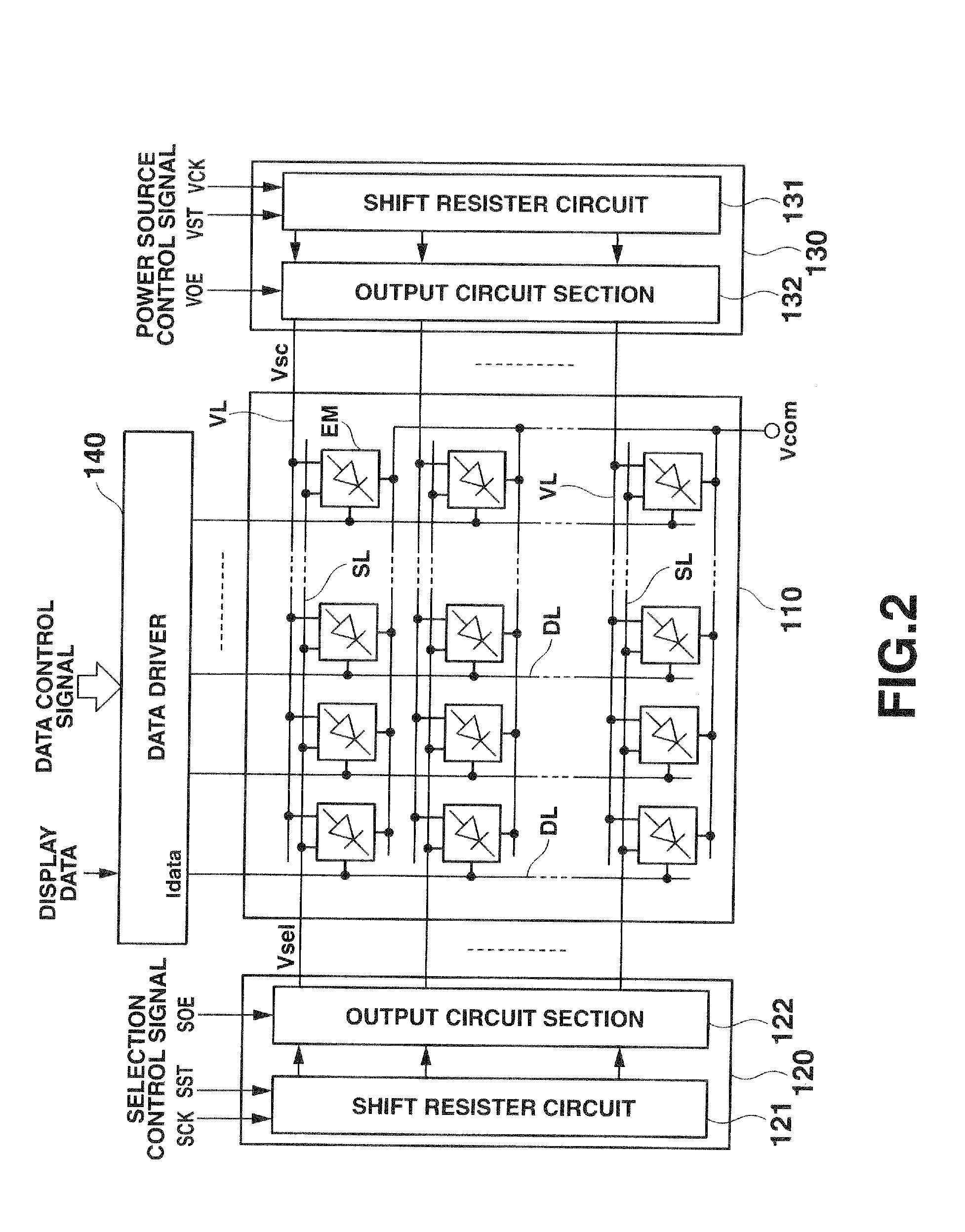

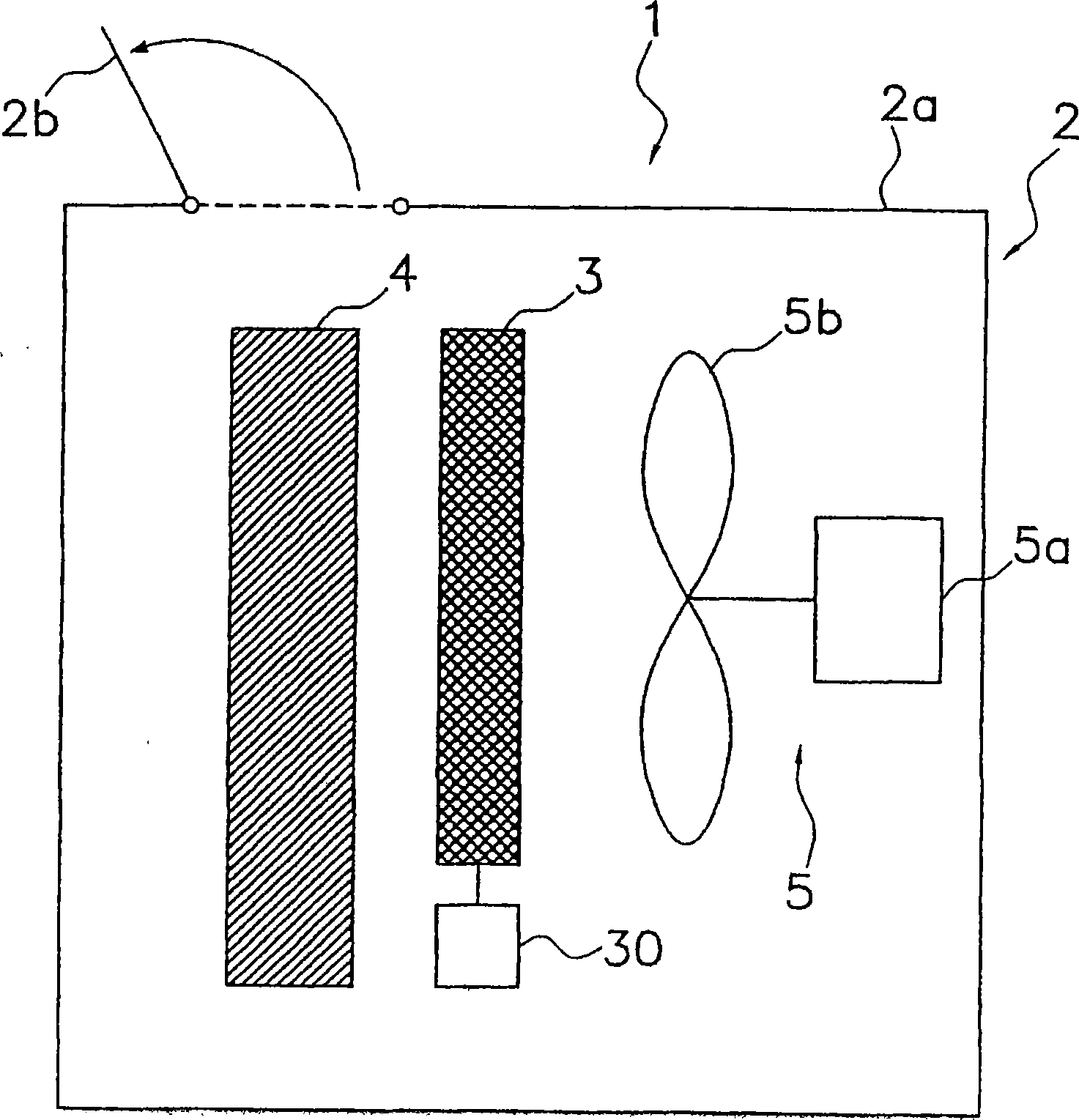

Display drive apparatus, and display apparatus and display drive method thereof

InactiveUS20090195530A1Curb production costDifficult to recognizeCathode-ray tube indicatorsInput/output processes for data processingComputer engineeringVoltage

A display drive apparatus performs a display drive of a display panel on the basis of display data and comprises a selection drive section for applying a selection signal to each of display pixels arranged in each row of the display panel, a data drive section for generating a drive signal based on the display data, and a power source drive section for setting at least a row as a writing region and at least a region as a designated region separated from the writing region by the number of one or more rows and sequentially moving correspondingly to moving of the writing region, and the power source drive section supplies a power source voltage for operating each display pixel to make each display pixel corresponding to the row of the writing region and each display pixel corresponding to the row of the designated region perform non-display operation.

Owner:SOLAS OLED LTD

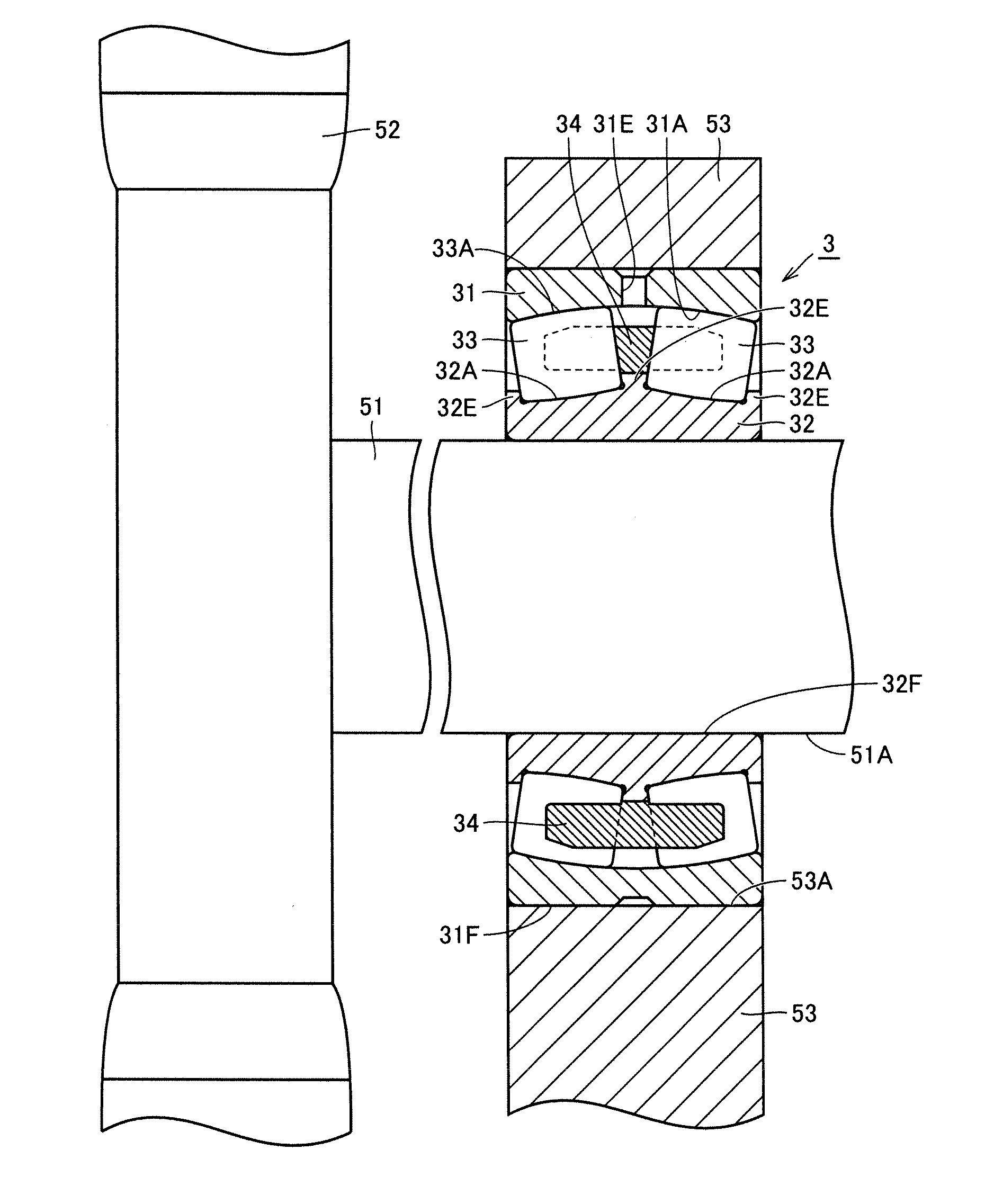

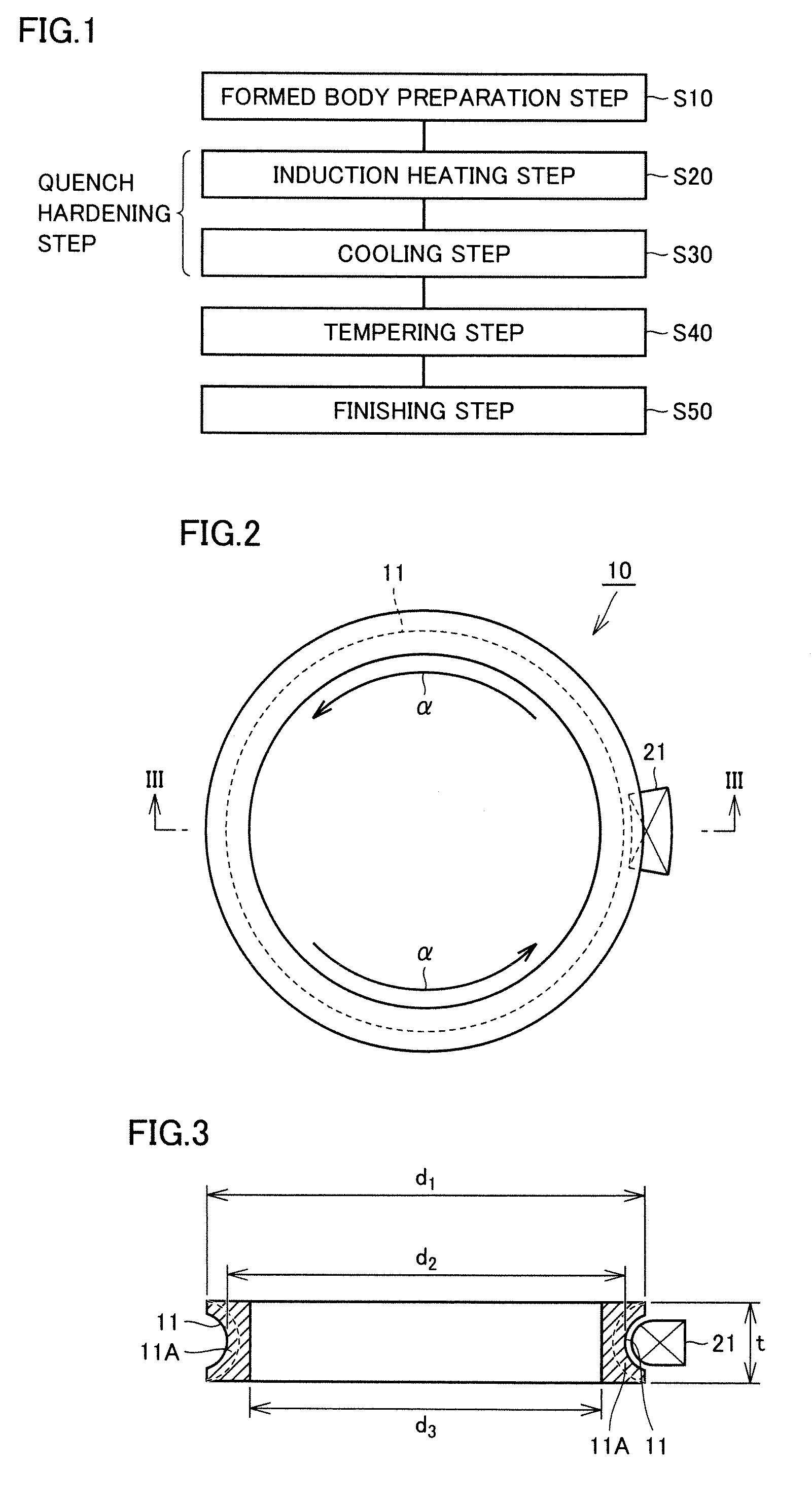

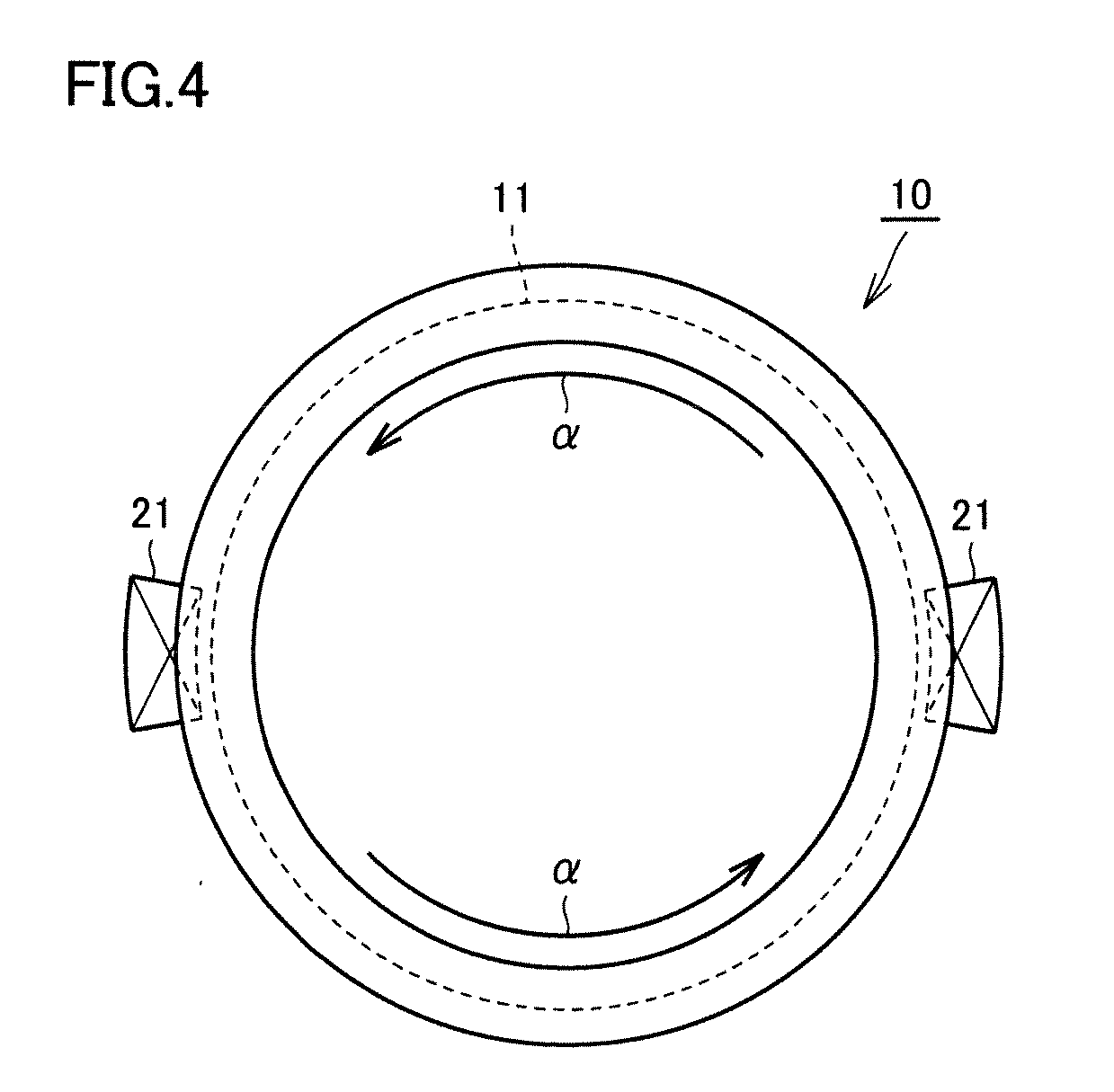

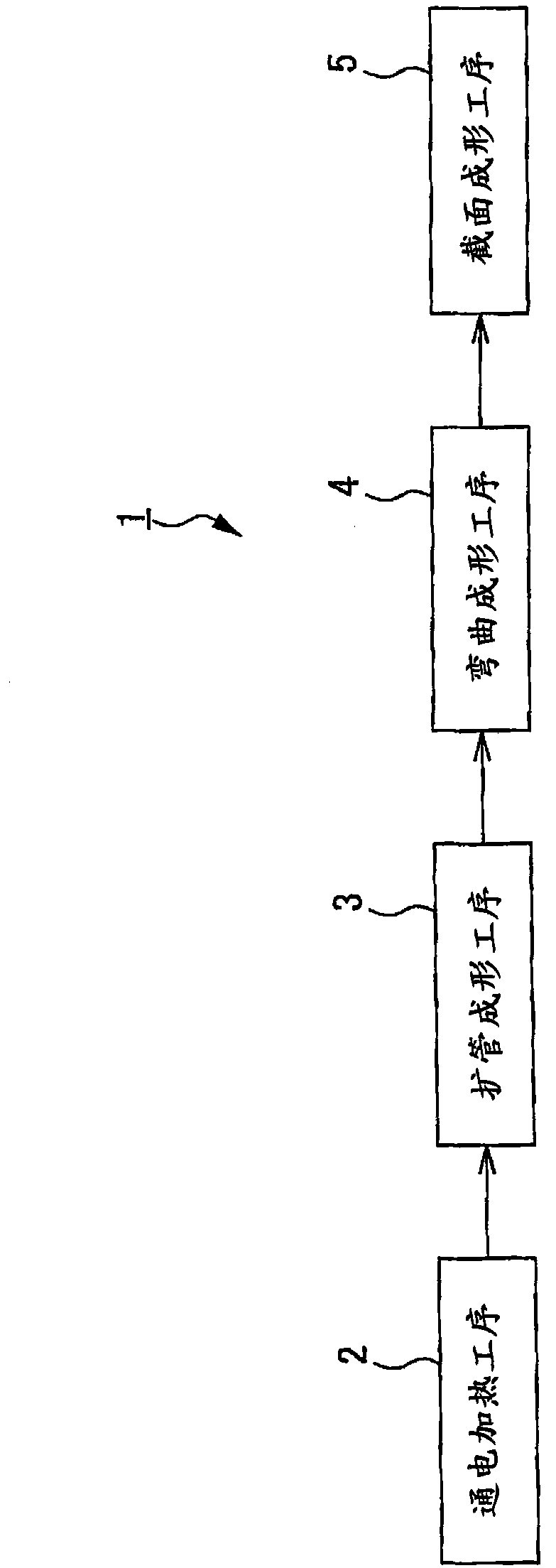

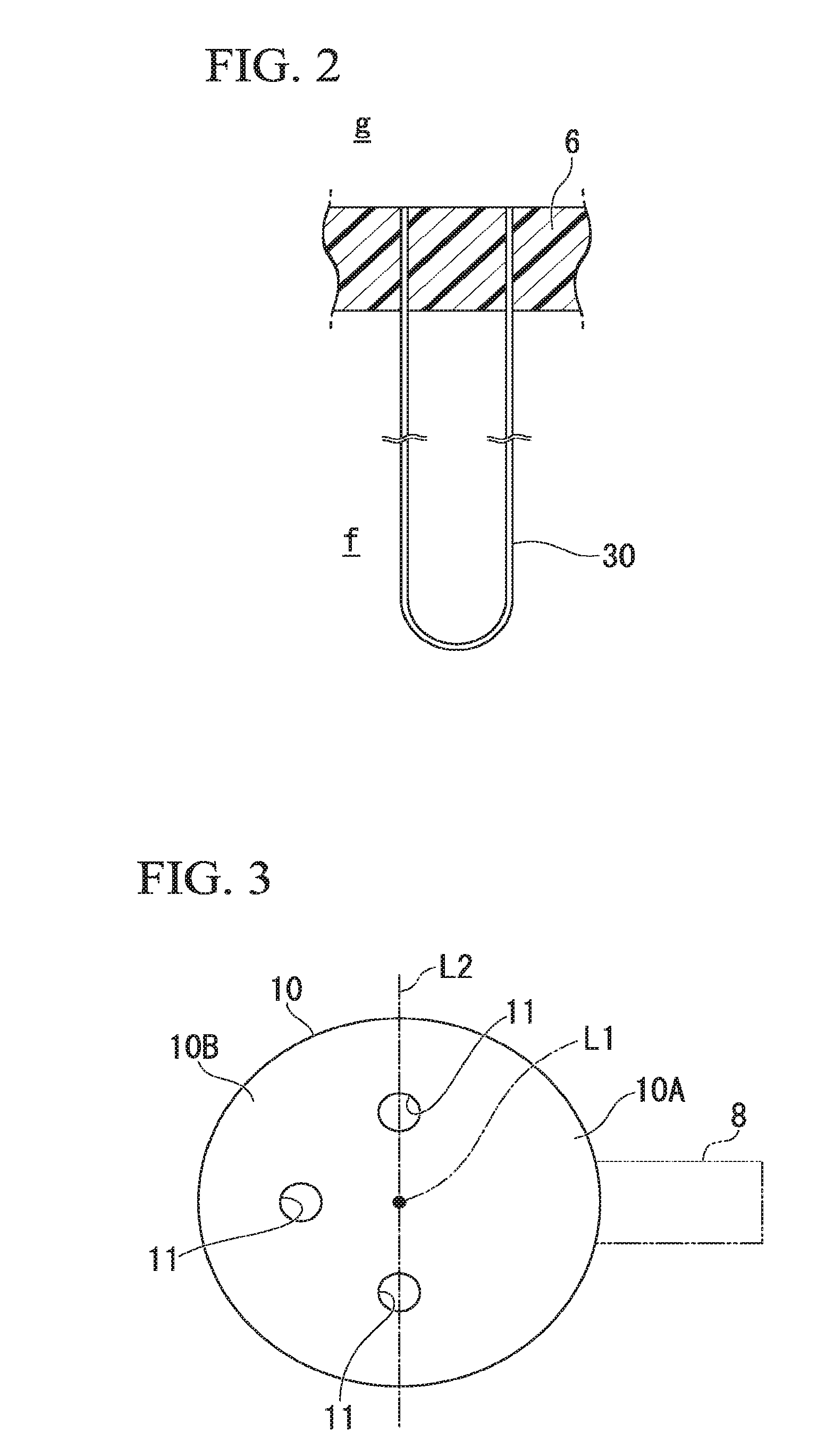

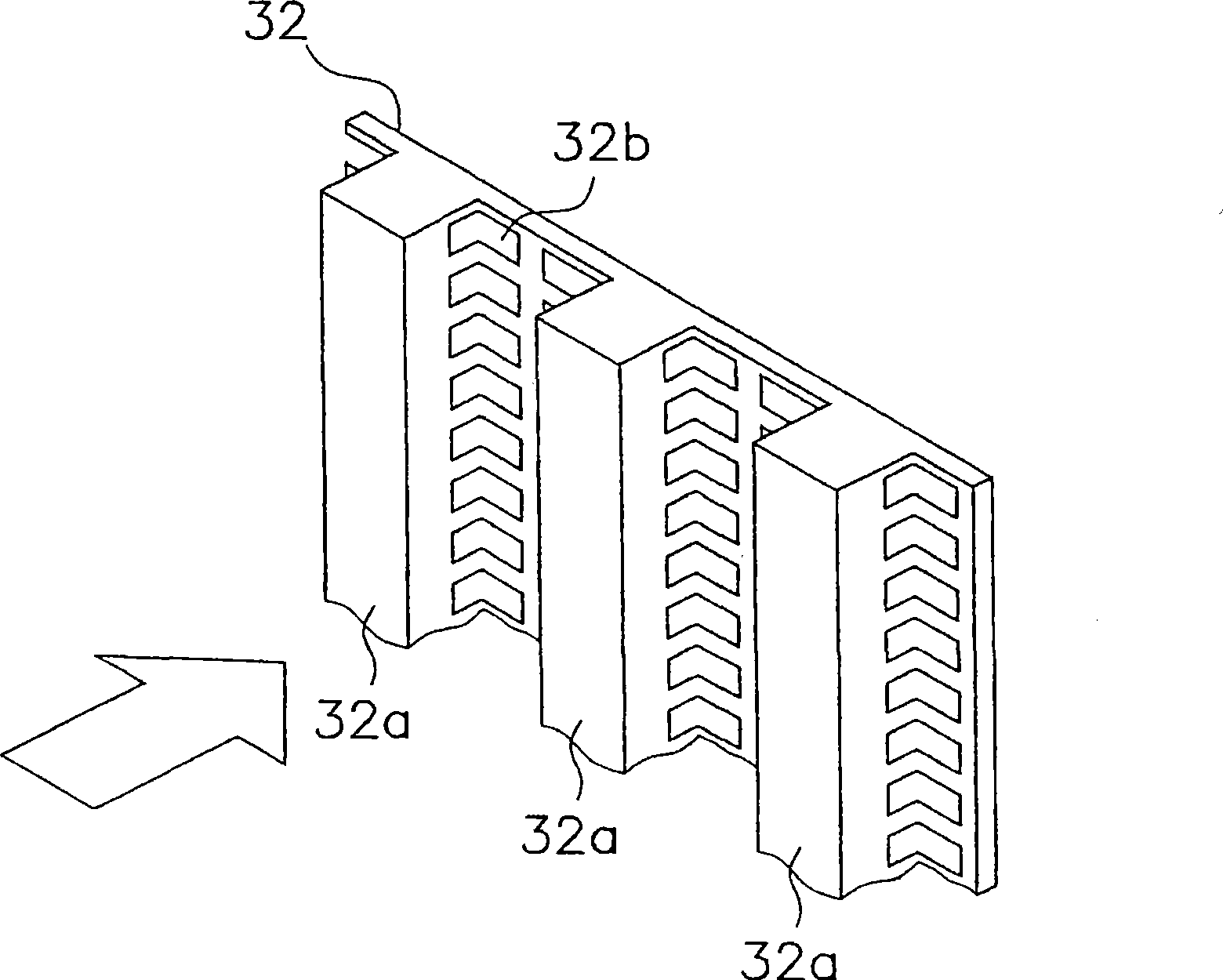

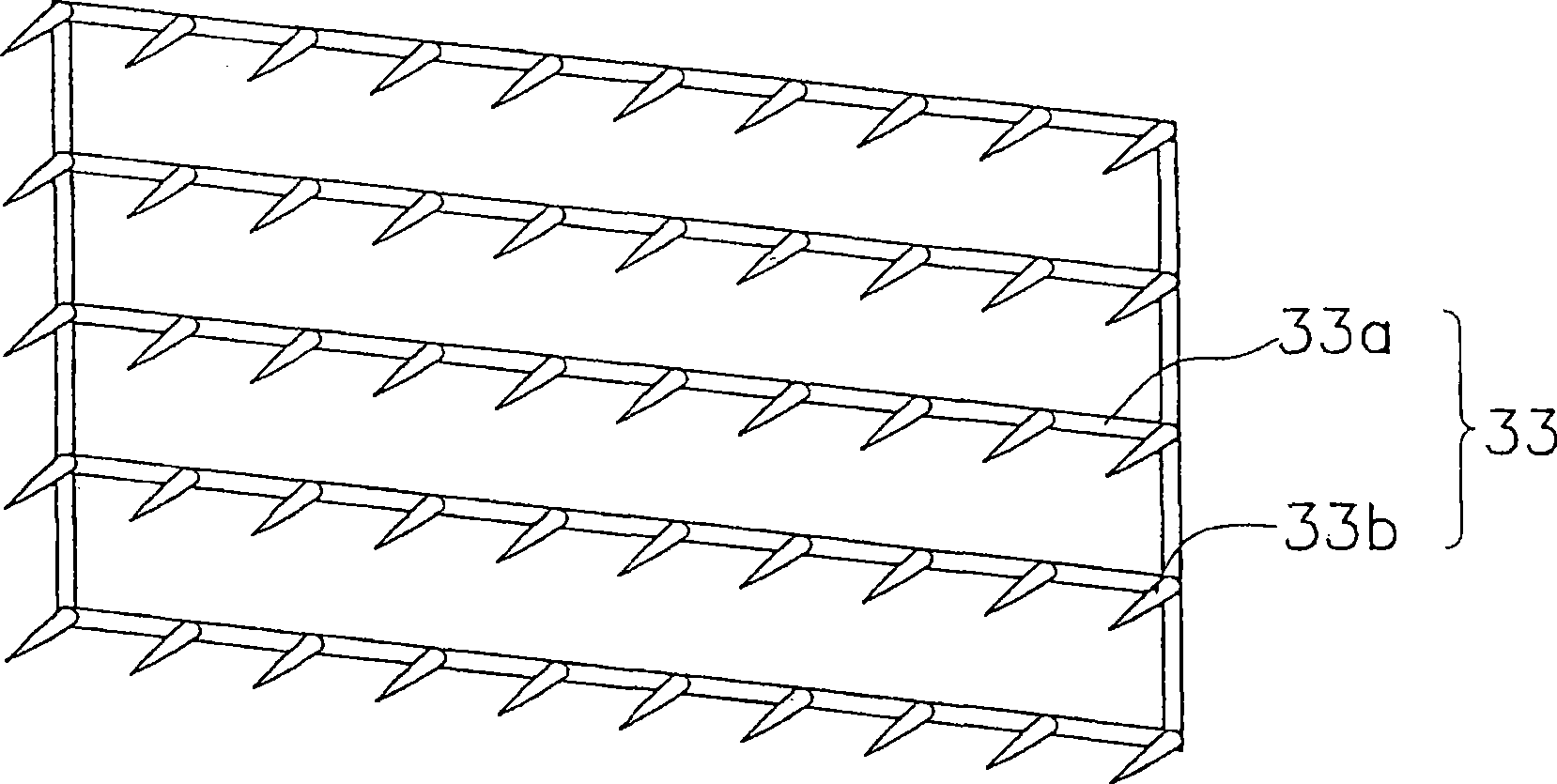

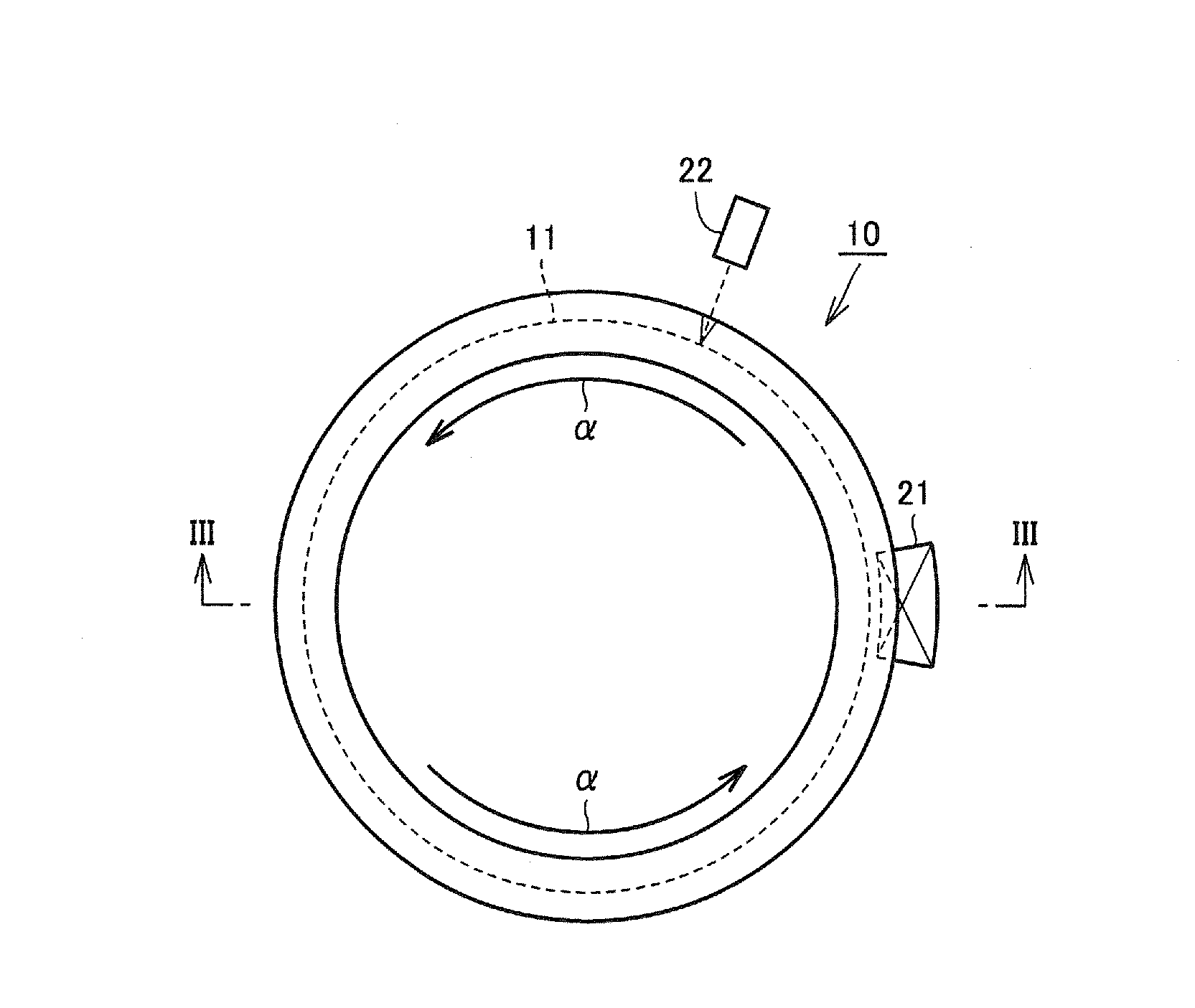

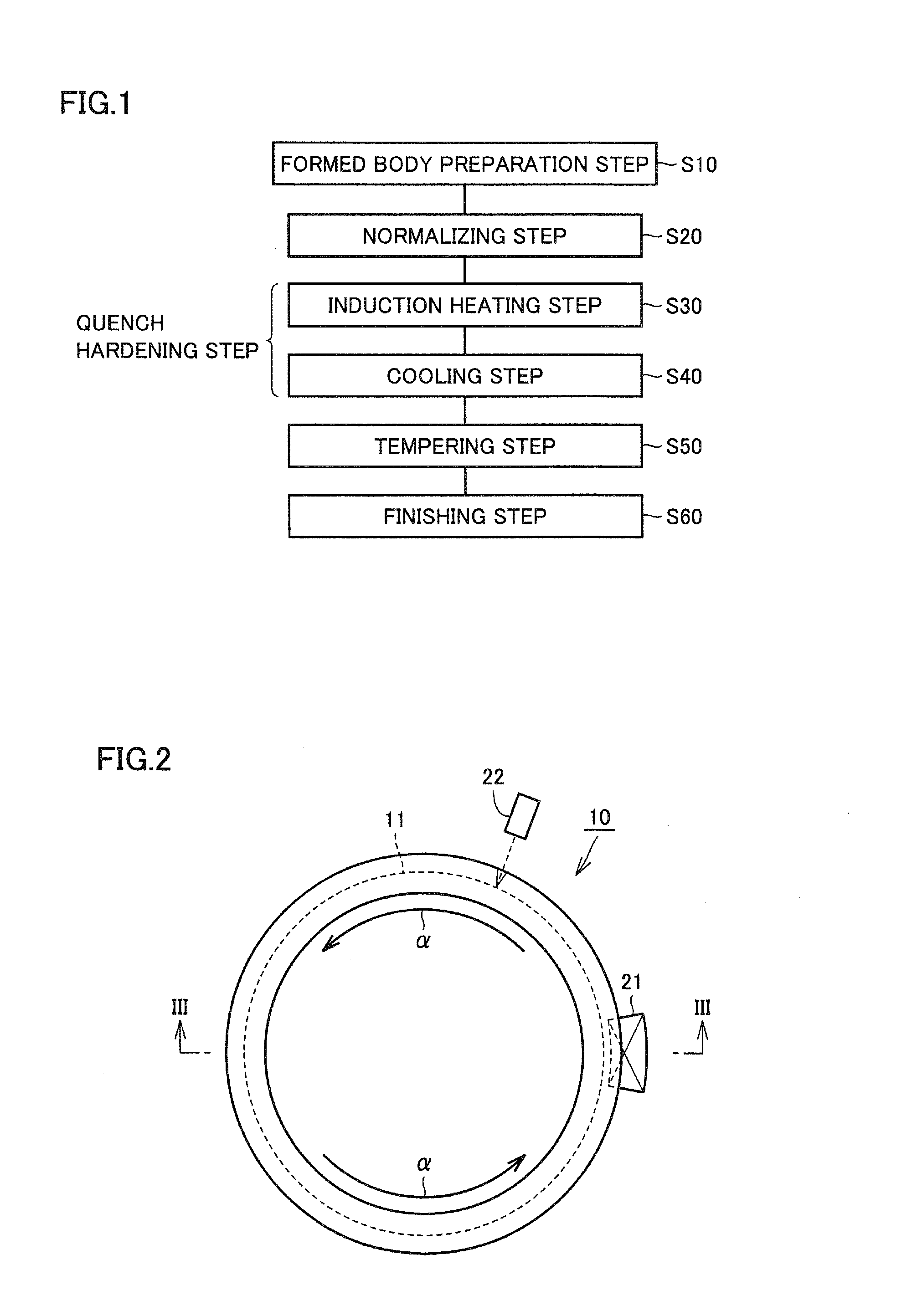

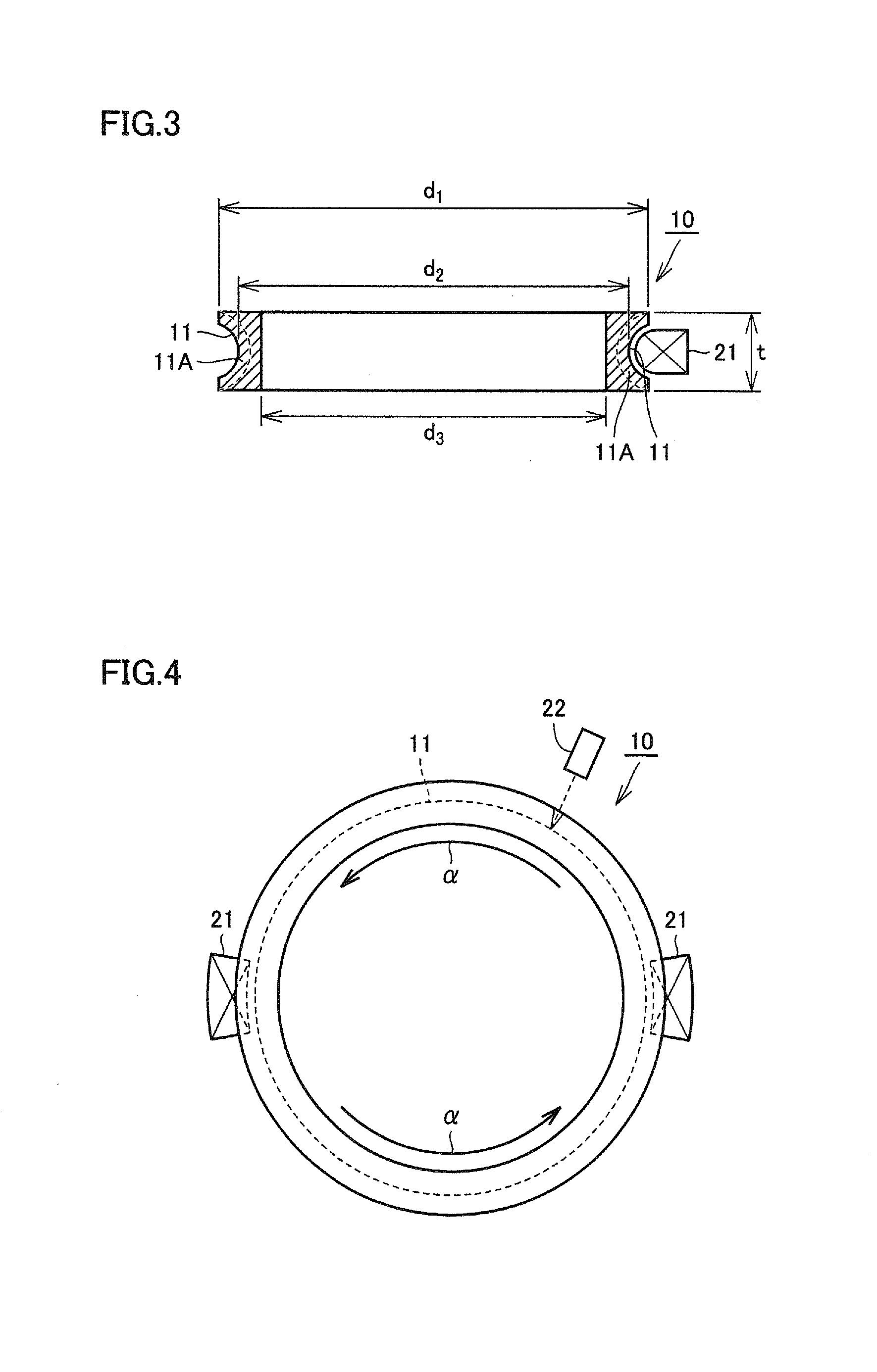

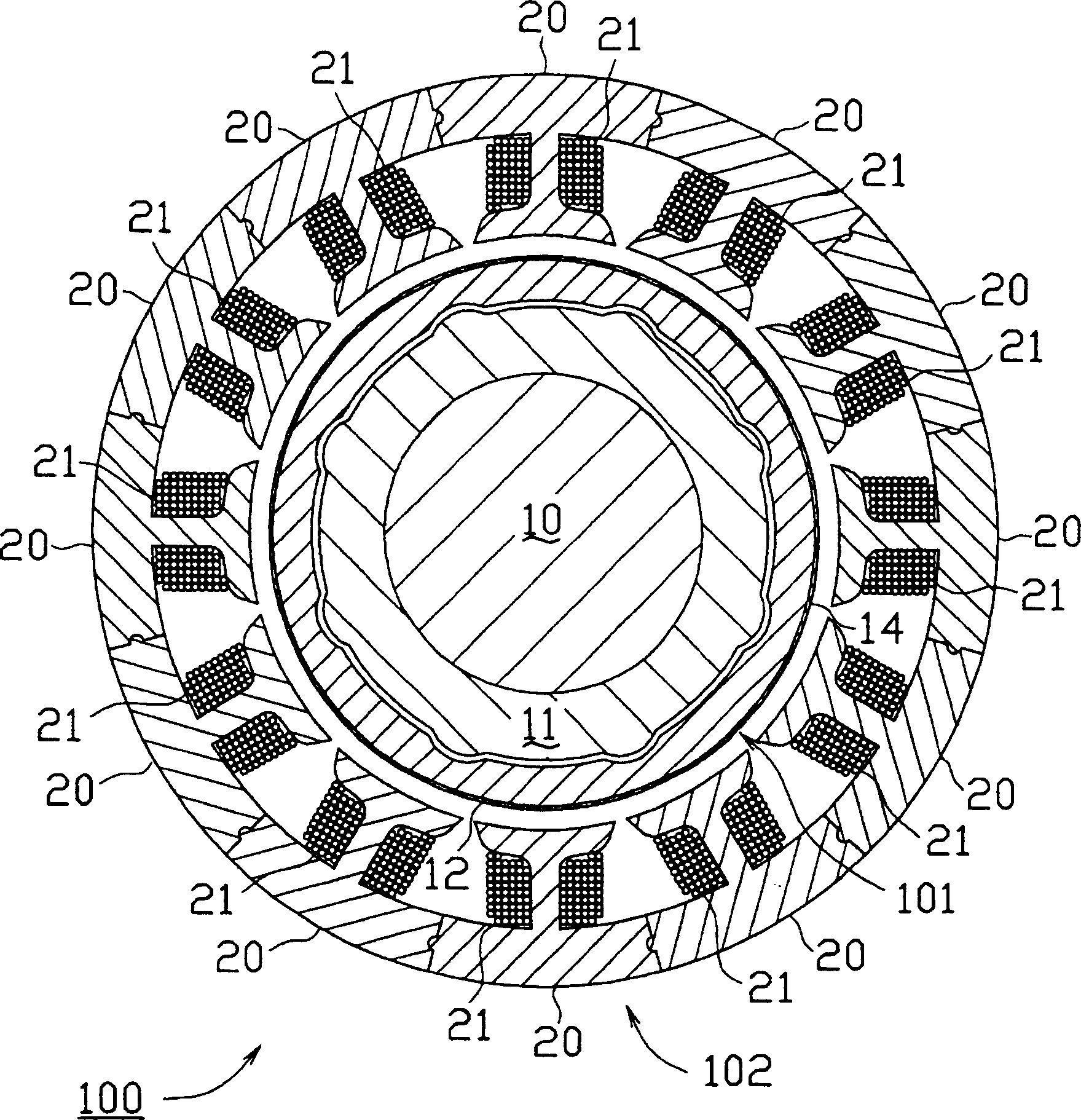

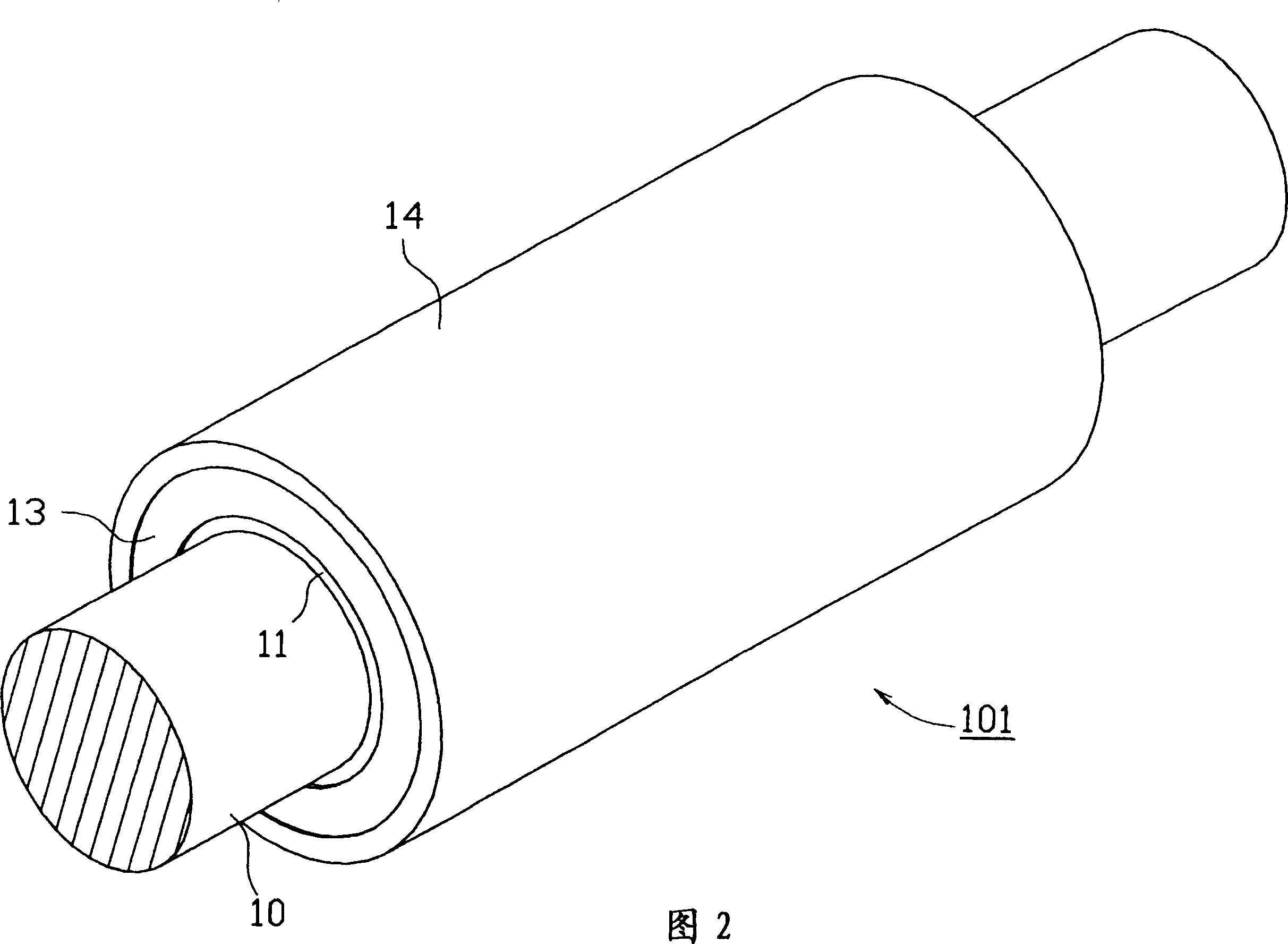

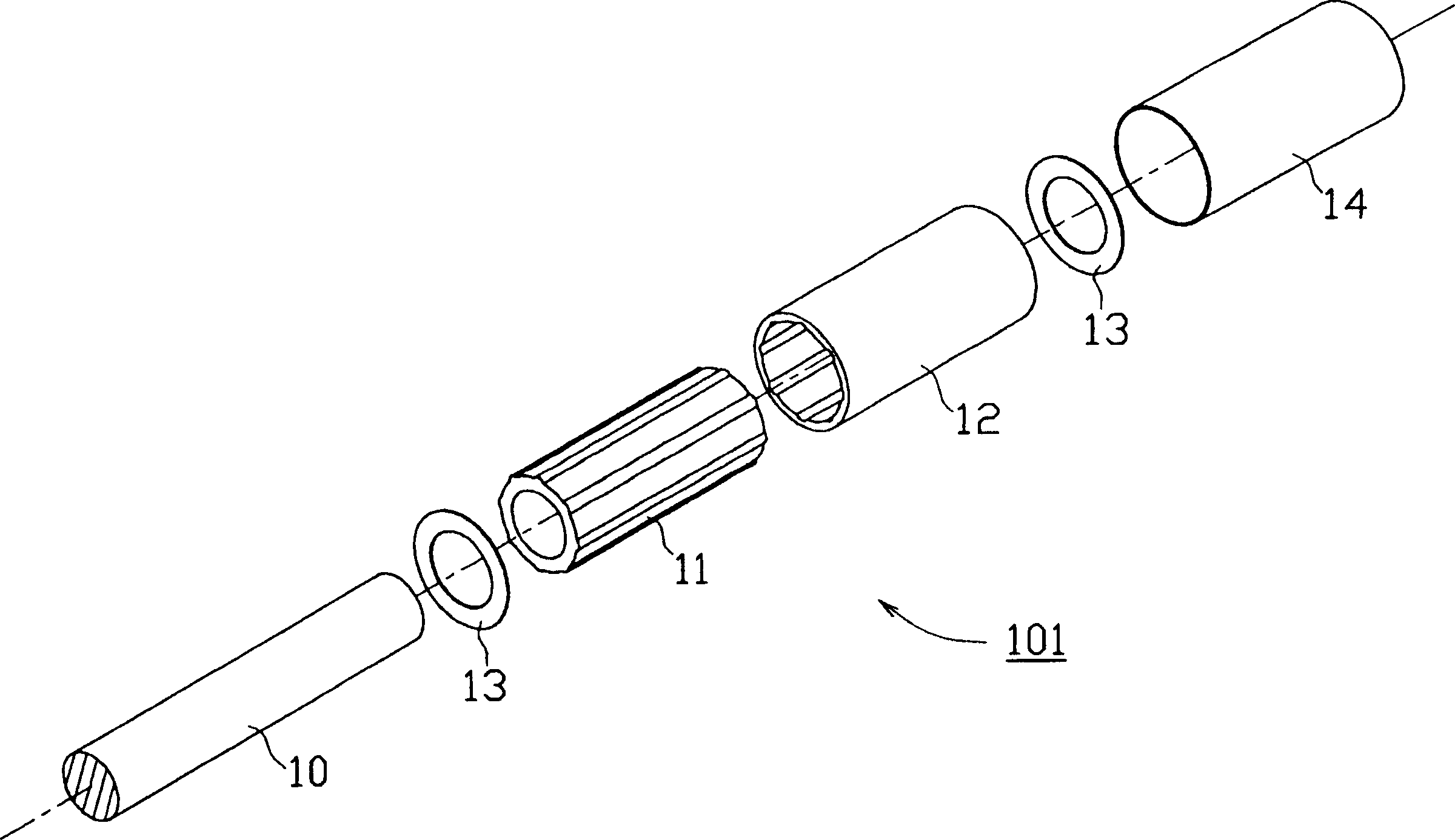

Method for heat-treating a ring-shaped member, method for producing a ring-shaped member, ring-shaped member, bearing ring, rolling bearing, and method for producing a bearing ring

Disclosed is a method for heat-treating a ring-shaped member, which makes it possible to form a quench-hardened region having a uniform annular shape in the circumferential direction, while the production costs in terms of the quenching apparatus are kept down. The method includes the following steps: a step in which a coil which is disposed in such a way as to face a rolling contact surface of a ring-shaped formed body made of steel and which performs induction heating of the formed body is rotated relative to the formed body in the circumferential direction thereof, whereby an annular heating region which is heated to a temperature at or above an A1 point is formed on the formed body; and a step in which the whole of the heating region is simultaneously cooled to a temperature at or below an MS point.

Owner:NTN CORP

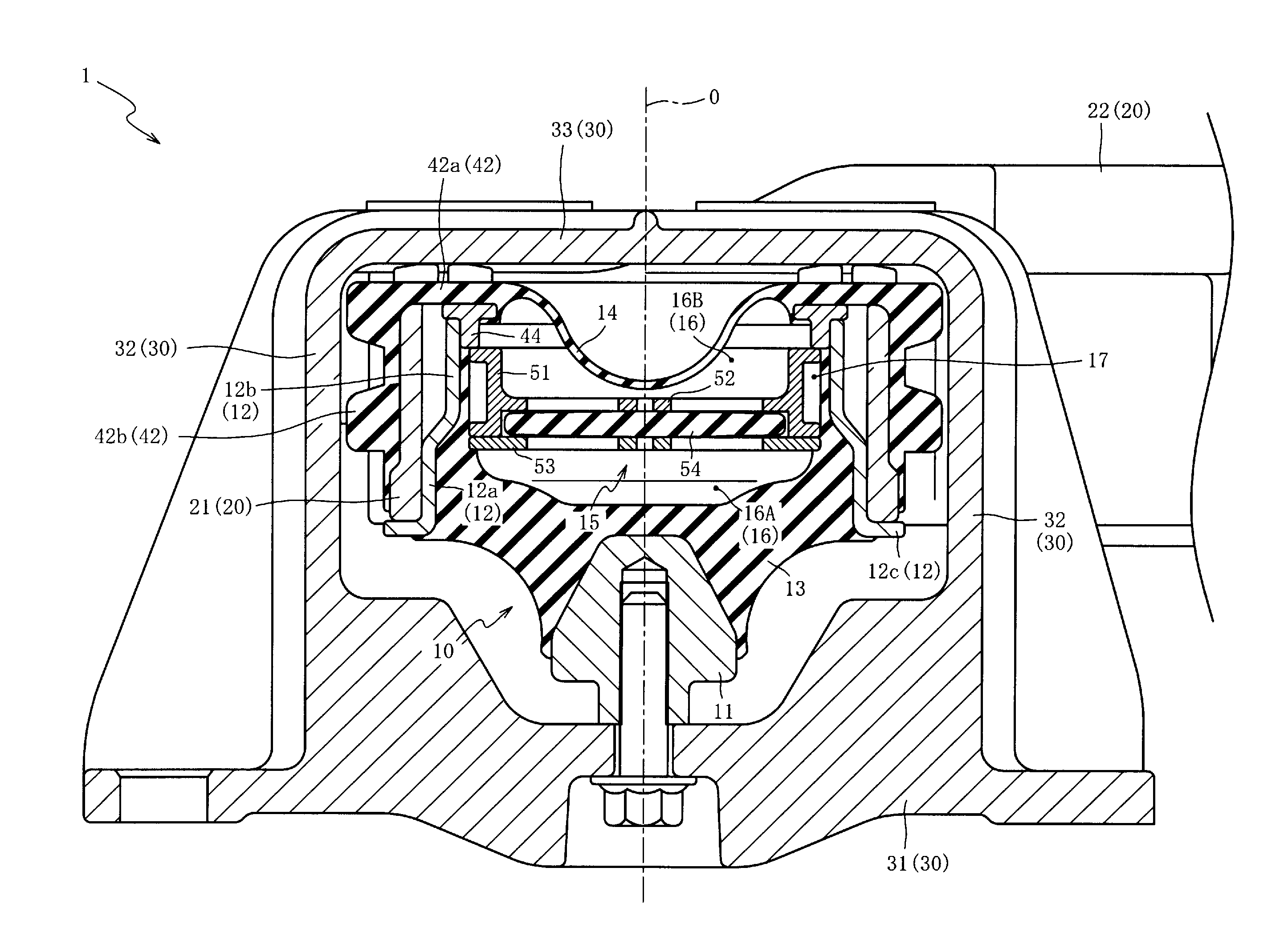

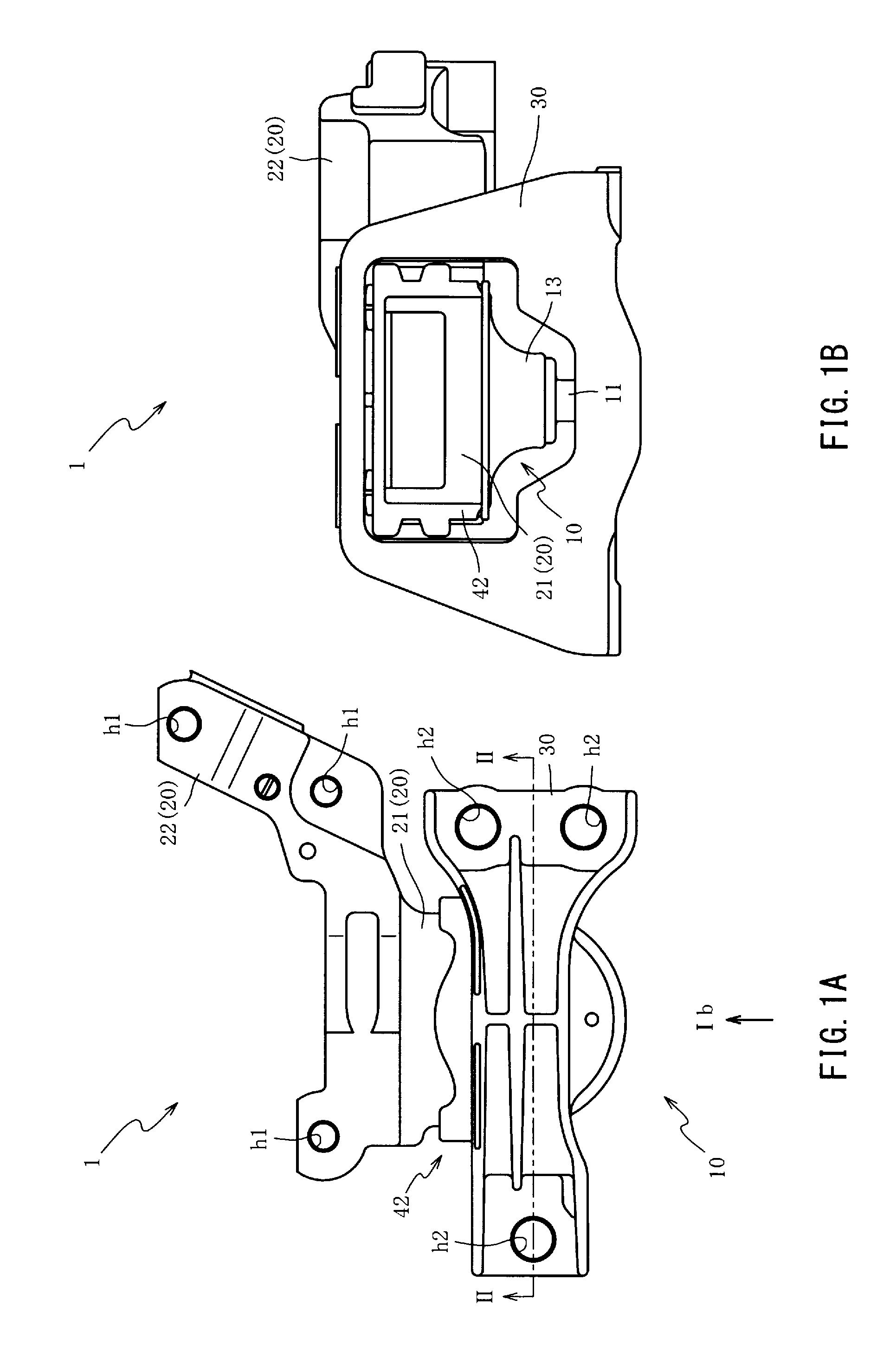

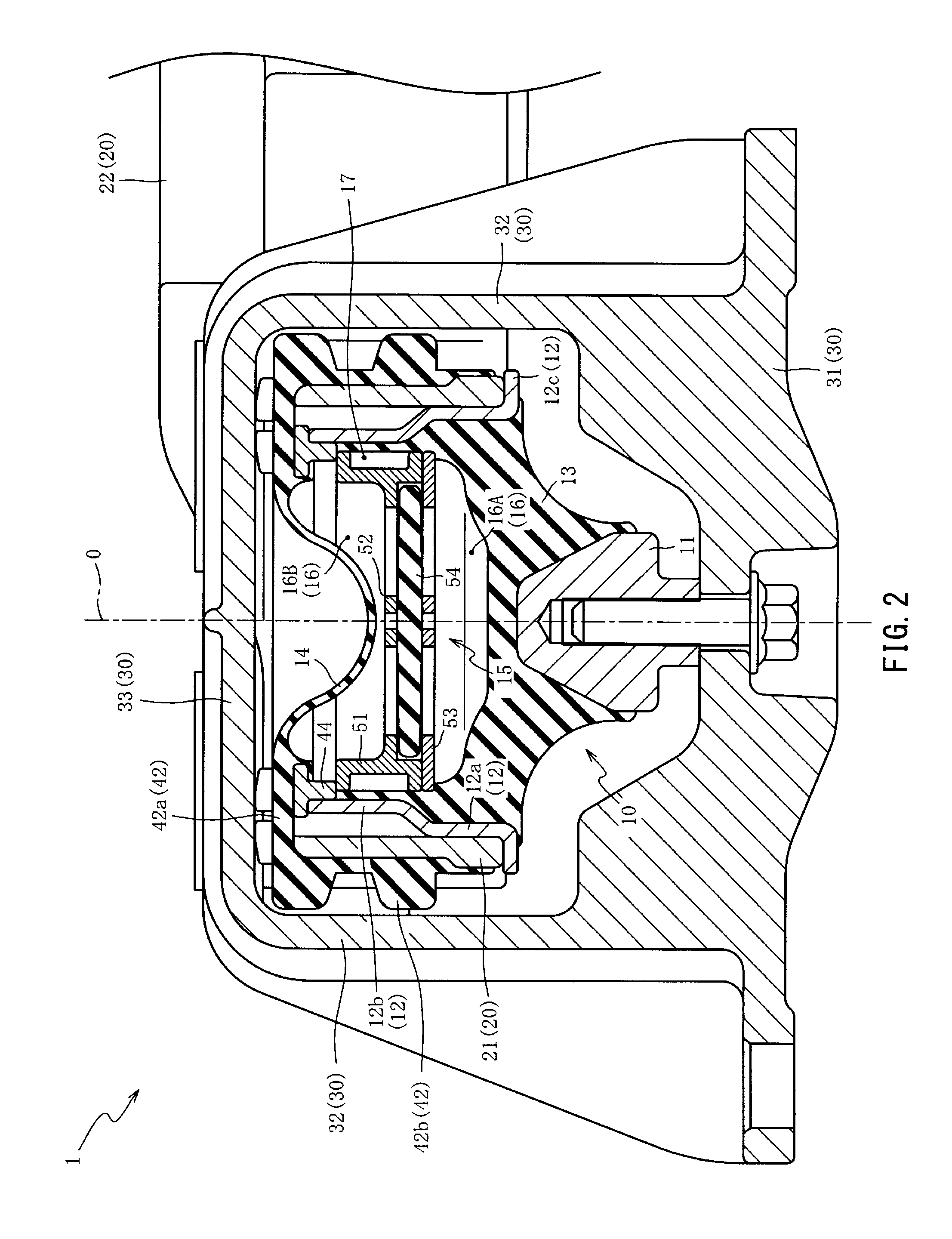

Vibration isolation unit

InactiveUS20130112839A1Compact equipmentCompact efficiency of manufacturing processSpringsStands/trestlesRubber materialMan-hour

To provide a vibration isolation unit capable of reducing the number of parts, man-hour and material cost, and suppressing the product cost. One side of a stopper rubber member continues to the outer edge of a diaphragm. Accordingly, because they can be vulcanizingly molded simultaneously, the number of parts can be reduced. Also, because the diaphragm is attached to an outer tube member, the stopper rubber member also can be fixed simultaneously, and therefore the man-hour can be reduced. Further, because one side of the stopper rubber member continues to the outer edge of the diaphragm, overlapping of them in an axial view can be avoided, and a rubber material can be used efficiently. Thus, the number of parts, man-hour and material cost can be reduced and the product cost of the overall vibration isolation unit can be suppressed.

Owner:TOYO TIRE & RUBBER CO LTD

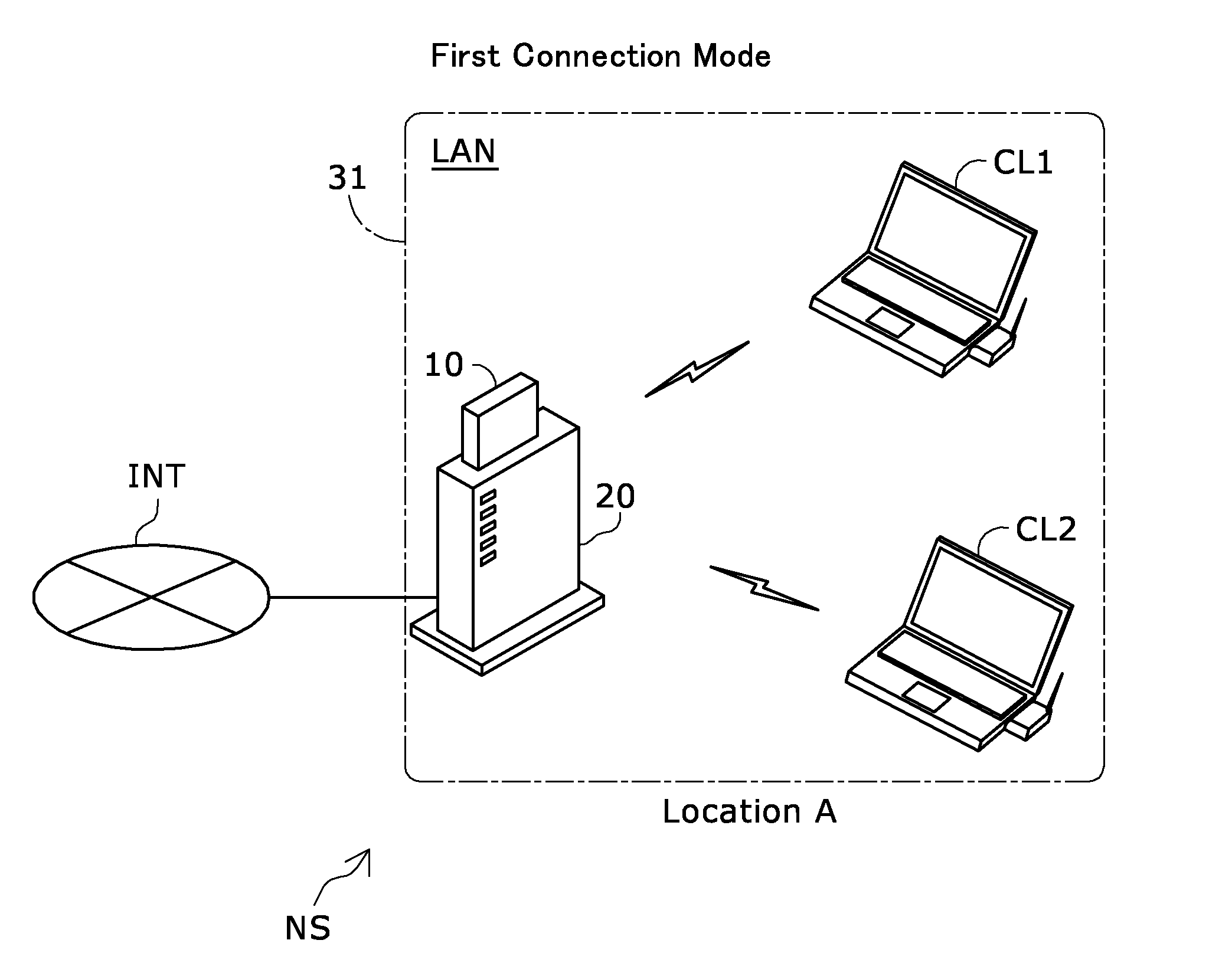

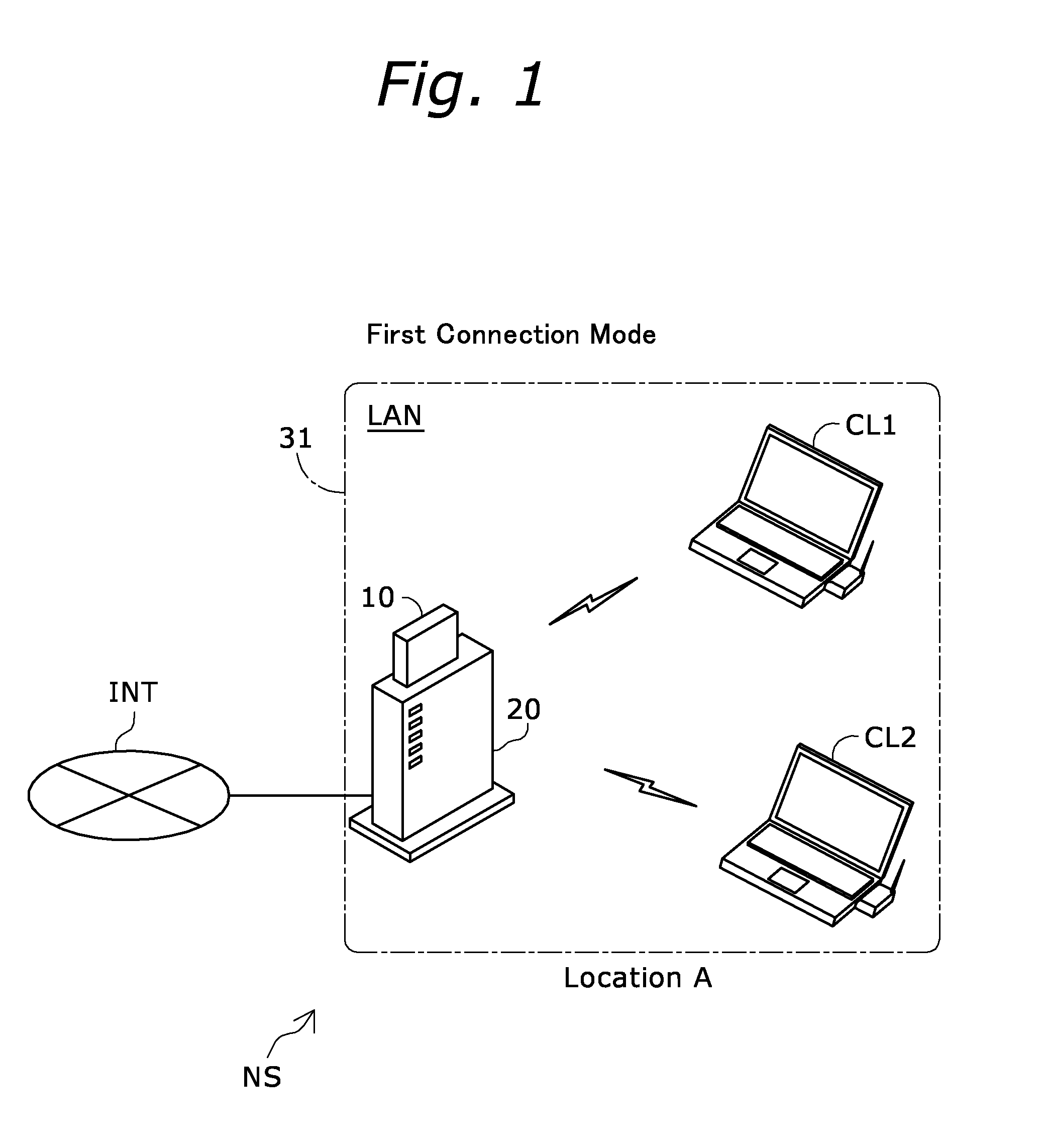

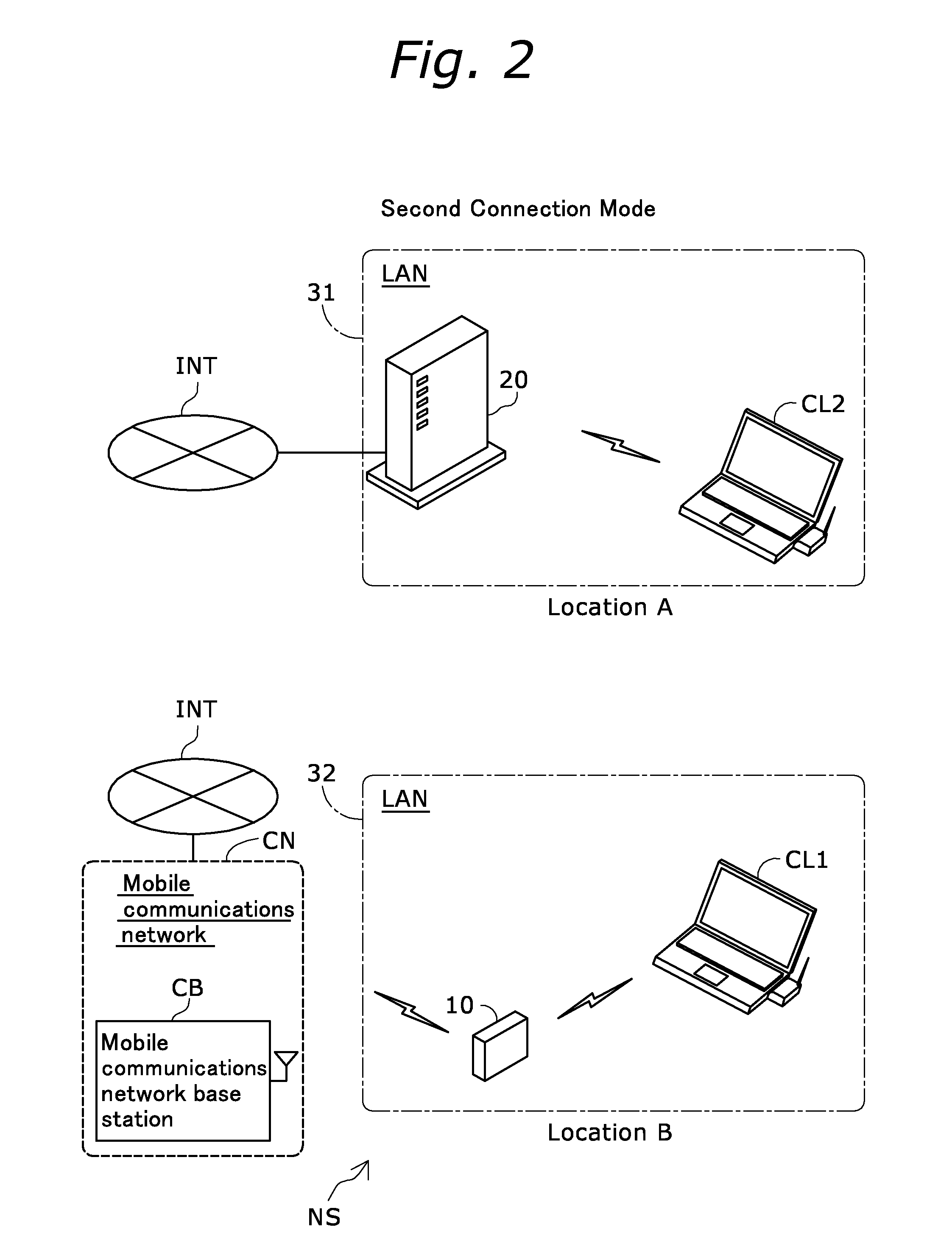

Wireless Network System, Method of Controlling the System, and Wireless Network Relay Device

InactiveUS20130016708A1Reduce workloadCurb production costAssess restrictionNetwork topologiesTelecommunicationsInformation transmission

A wireless network system includes first and second network relay devices, with the first relay device having first wireless communication setup information pre-set thereto and including a first communication I / F part and a first wireless communication setup information transmission part for sending first wireless communication setup information to the second wireless relay device if the first and second relay devices are enabled to communicate with each other, and with the second relay device including: a second communication I / F part; a first wireless communication setup information reception part for receiving the first wireless communication setup information via the second communication I / F part; and a first wireless communication part for performing wireless communication with a client by using the received first wireless communication setup information.

Owner:BUFFALO CORP LTD

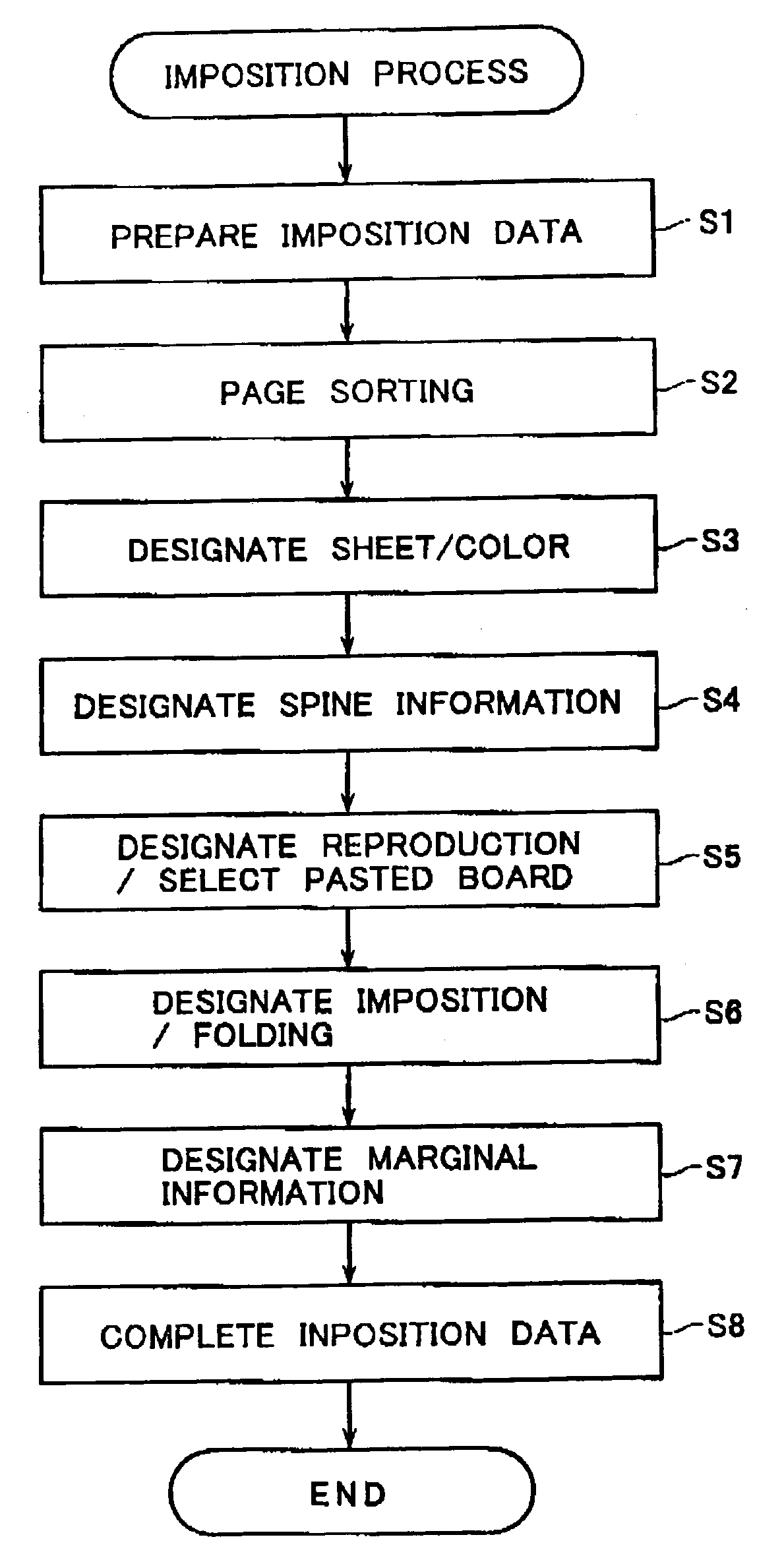

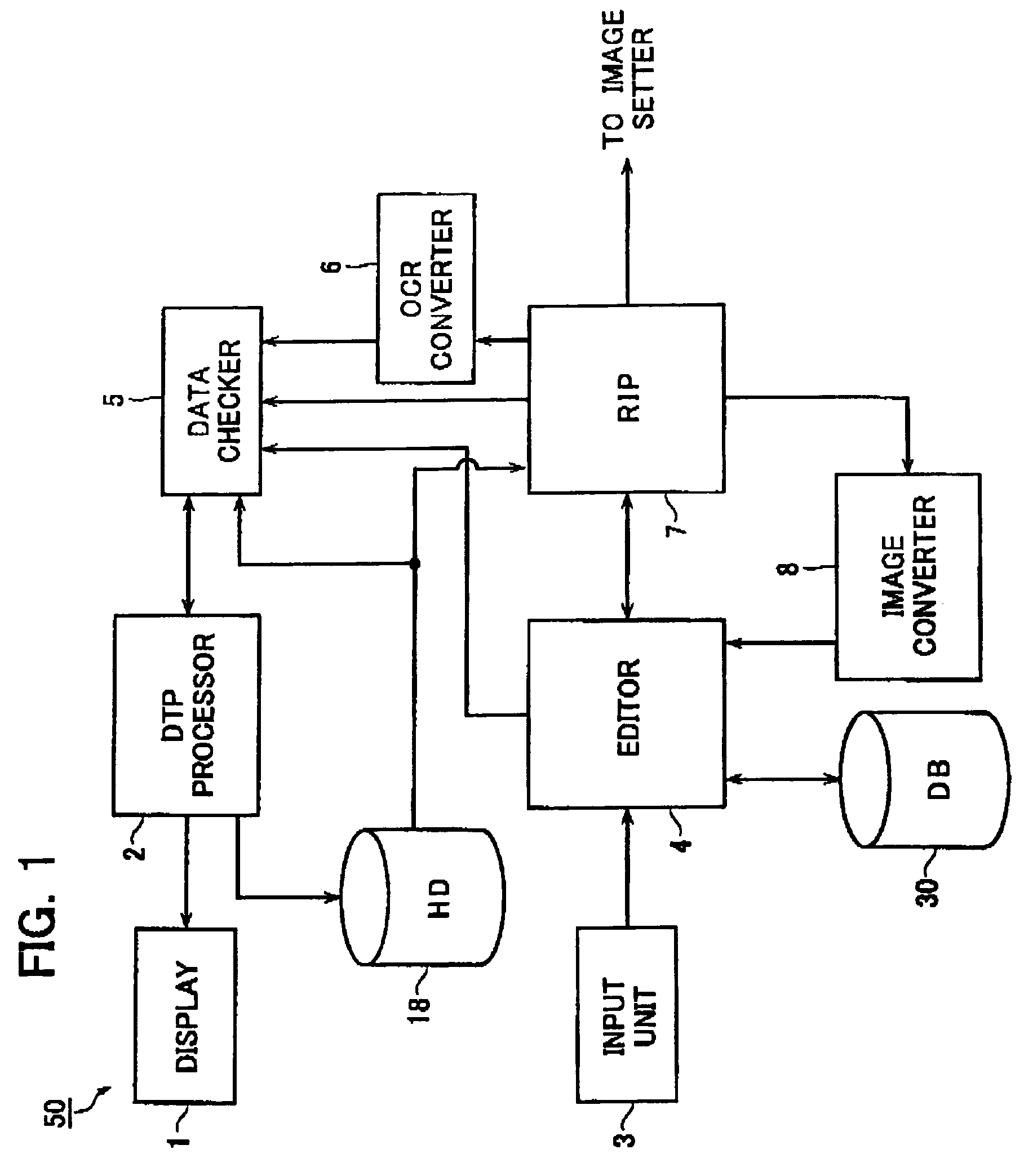

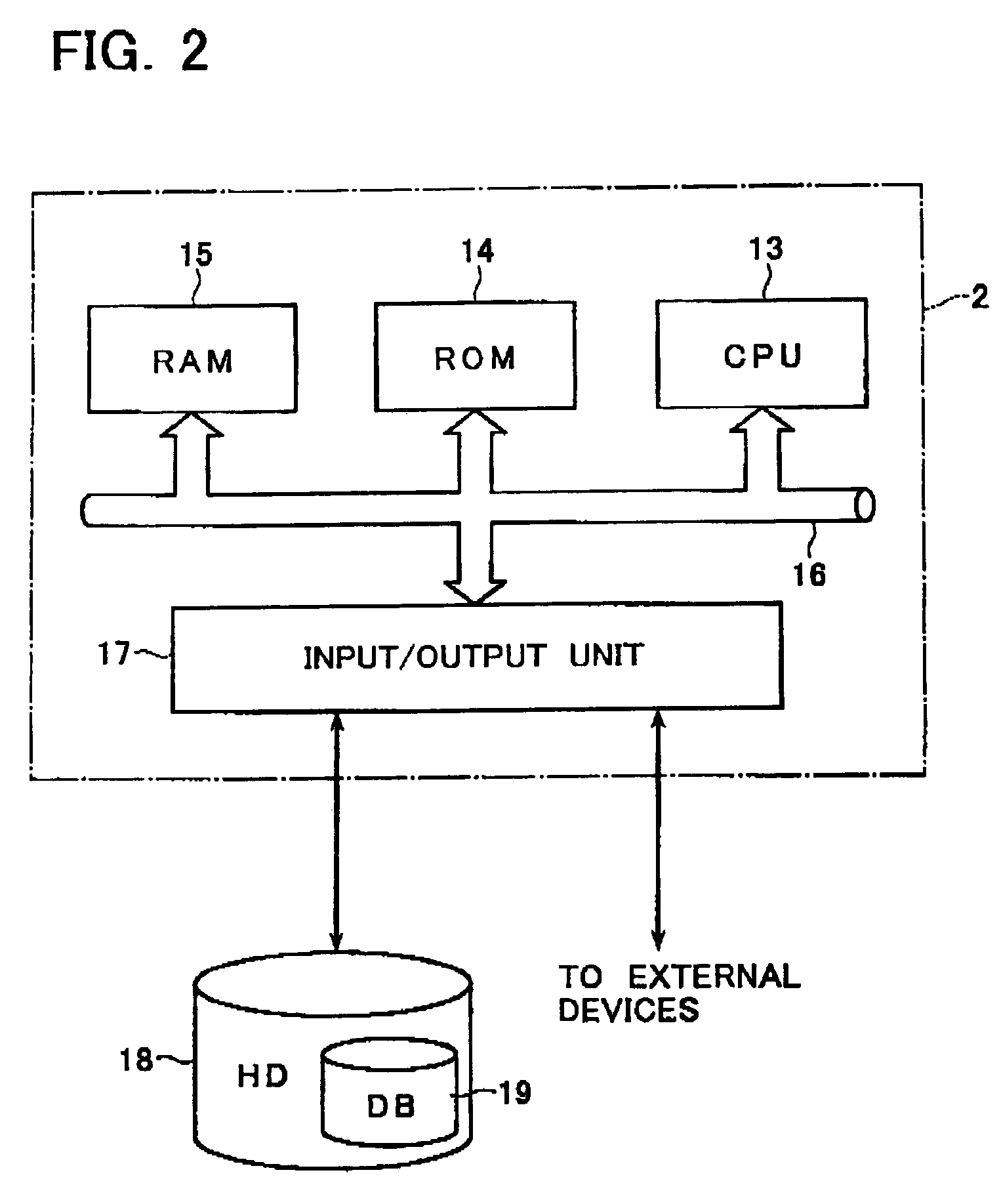

Method of producing publications, electronic publication produced by the method, and method and network system for displaying the electronic publication

InactiveUS7447992B2Simple processSimplify the linkText processingCharacter and pattern recognitionImage transformationWeb system

Methods for producing publications are described that may include displaying an image of a publication, reading raster image data by page to be linked on the publication, superimposing raster image data selected on the basis of link information on an image of a page in the publication selected, varying the image of the publication through an image transformation process on the basis of screen transit operation information, and producing a publication by associating the selected page with raster image data for the selected page.

Owner:E MEDIA

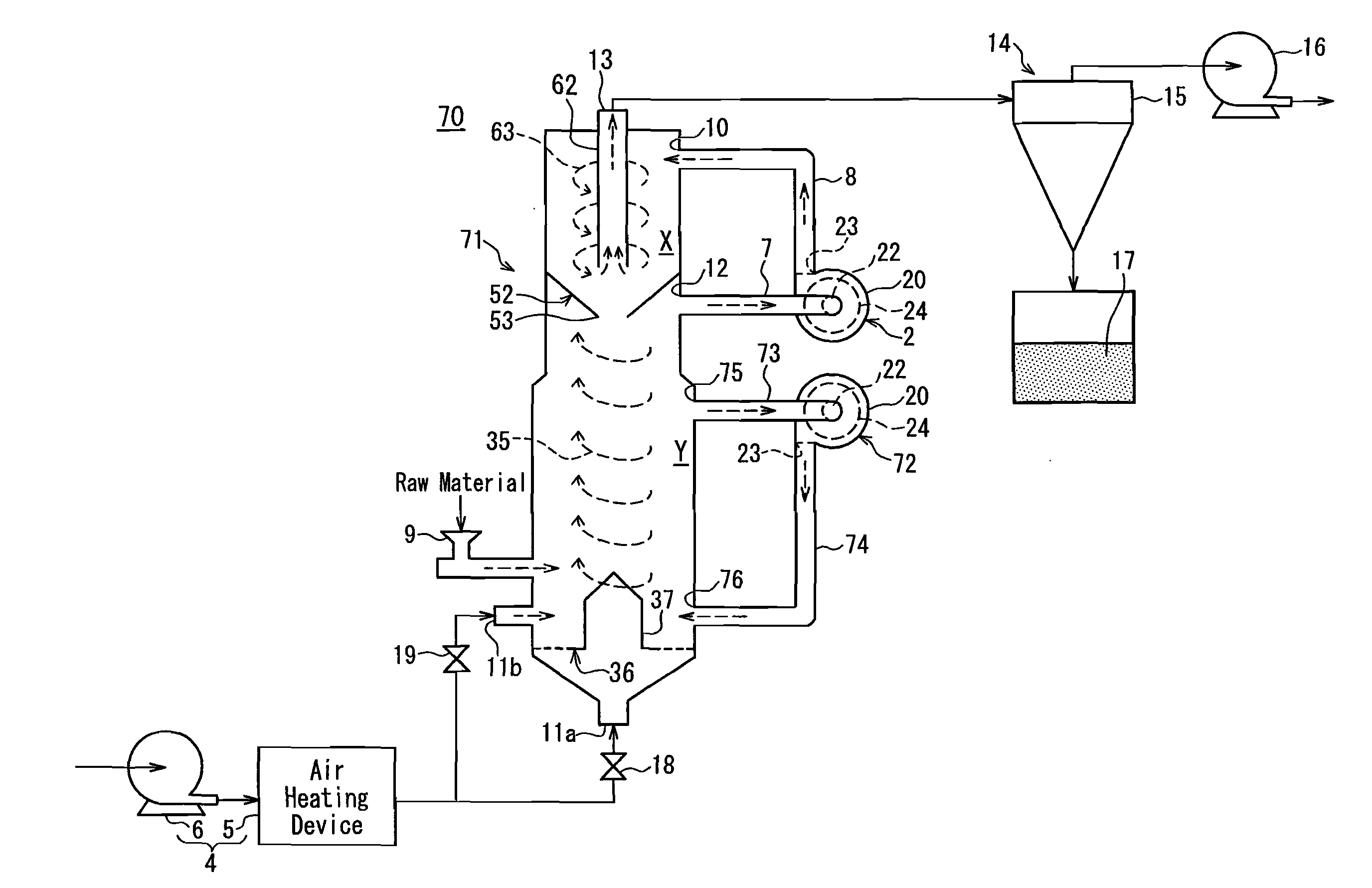

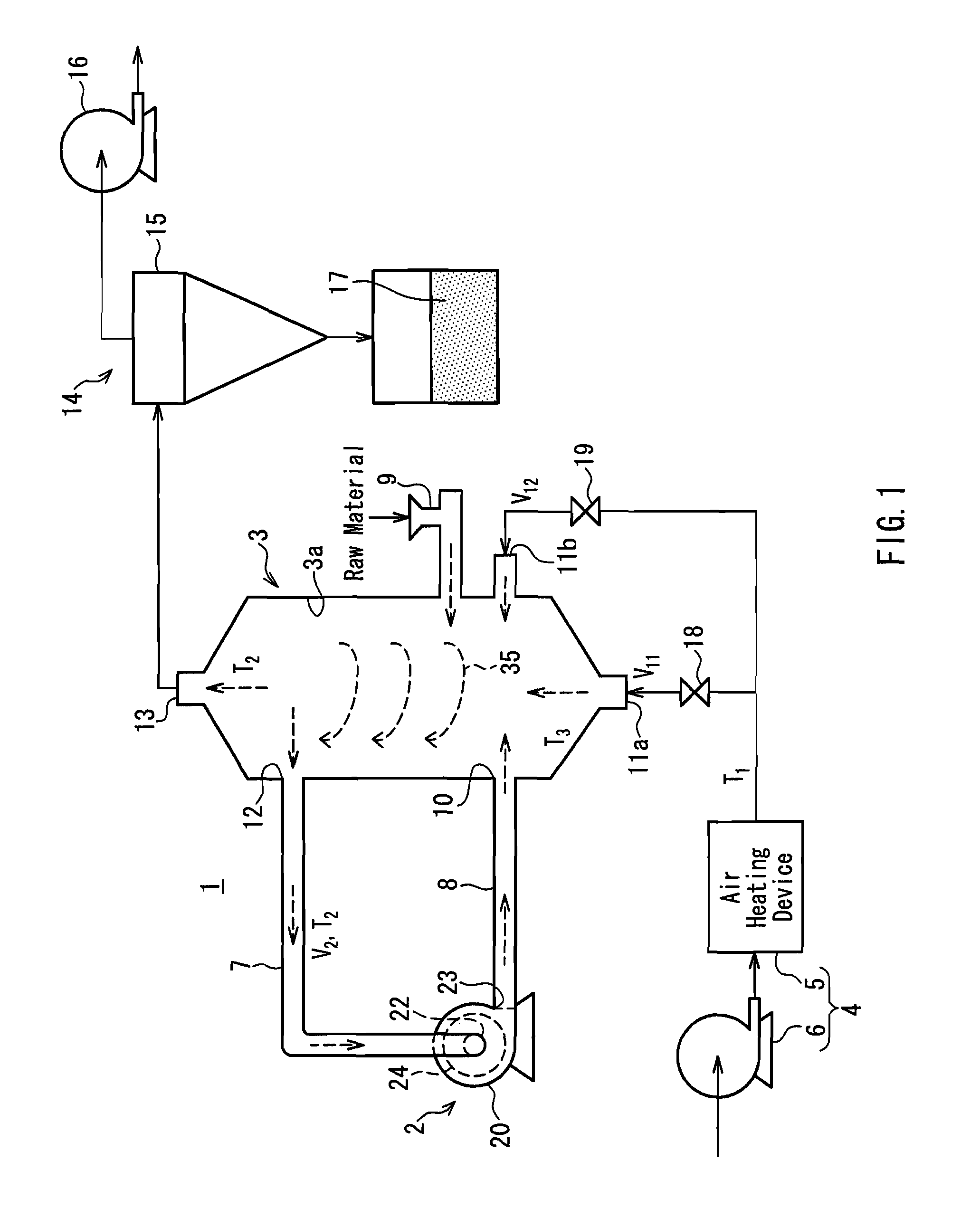

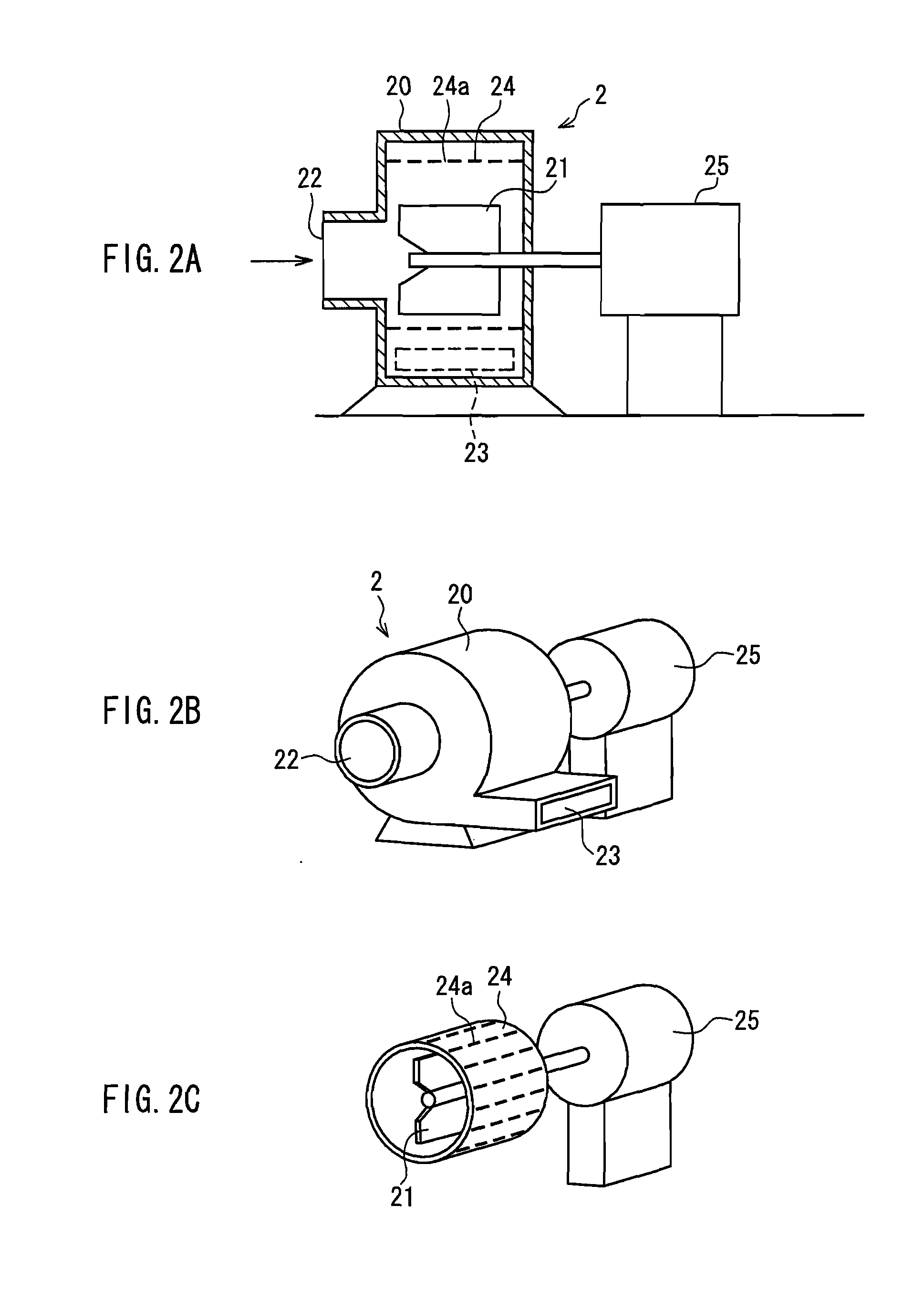

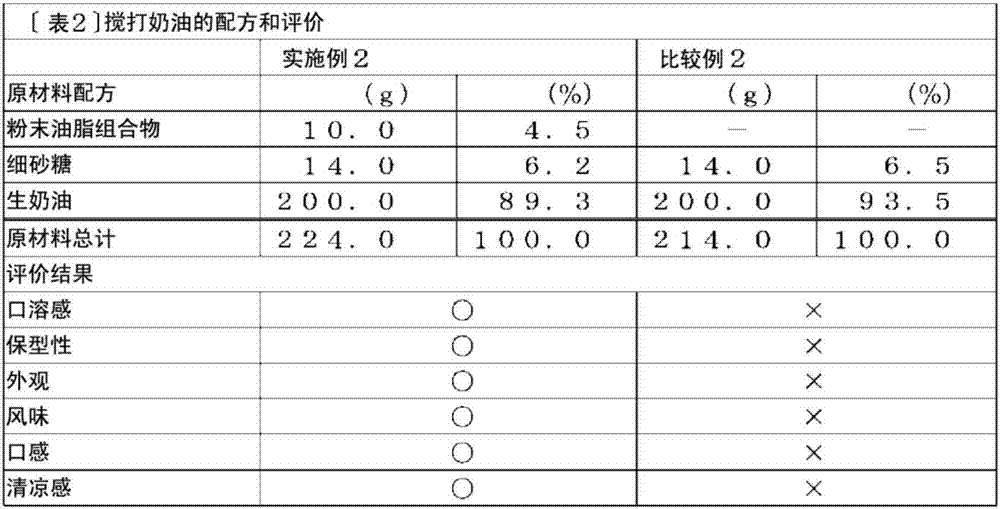

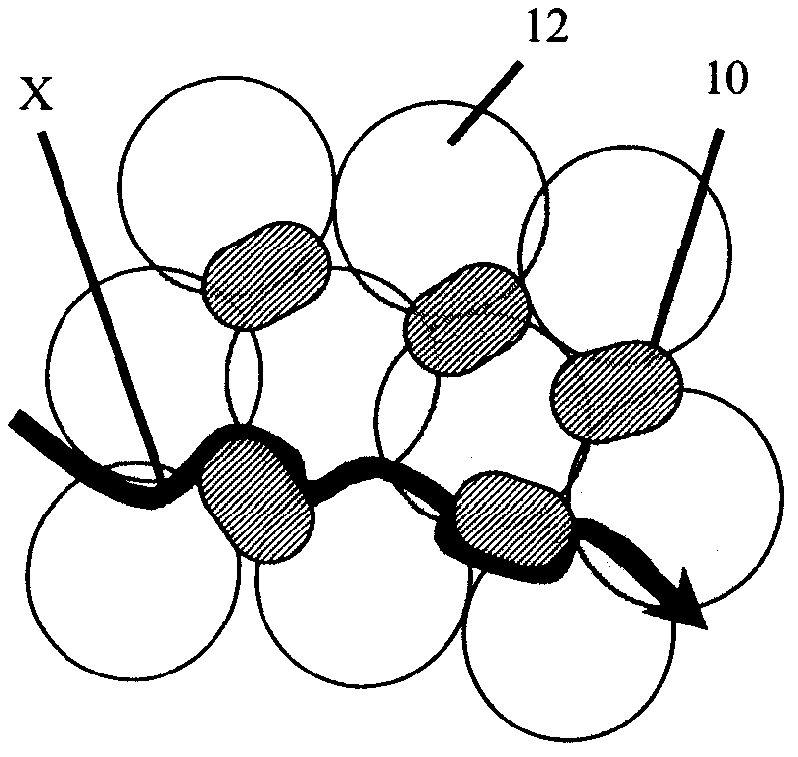

Pulverized material producing system

InactiveUS20100102150A1Increase in sizeIncrease moisture contentGas current separationGrain millingImpellerEngineering

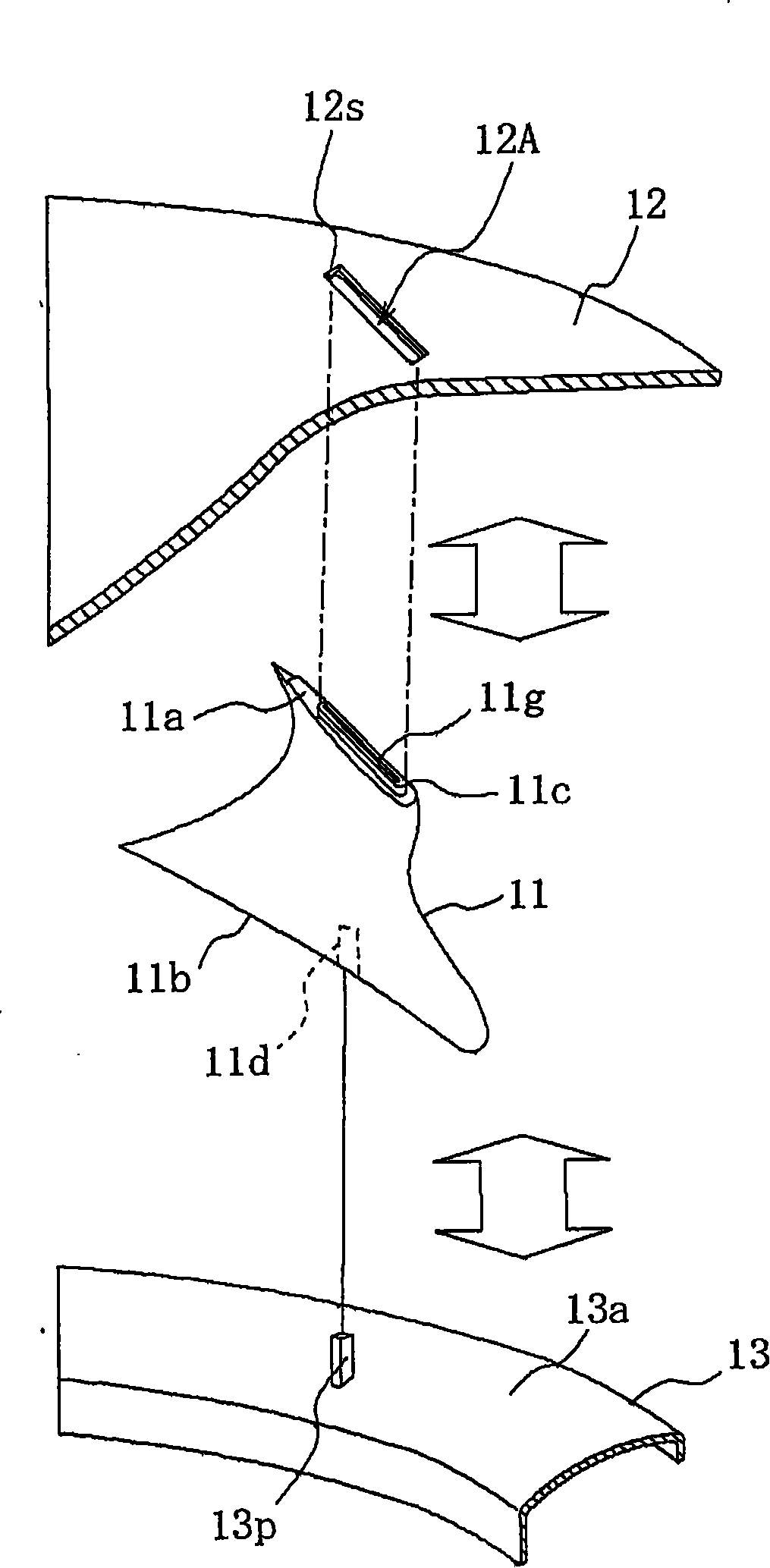

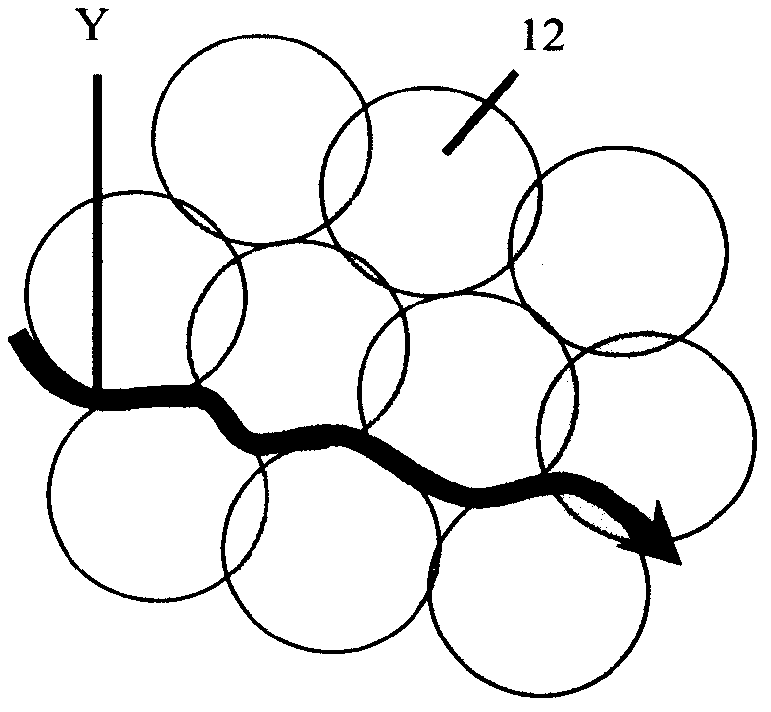

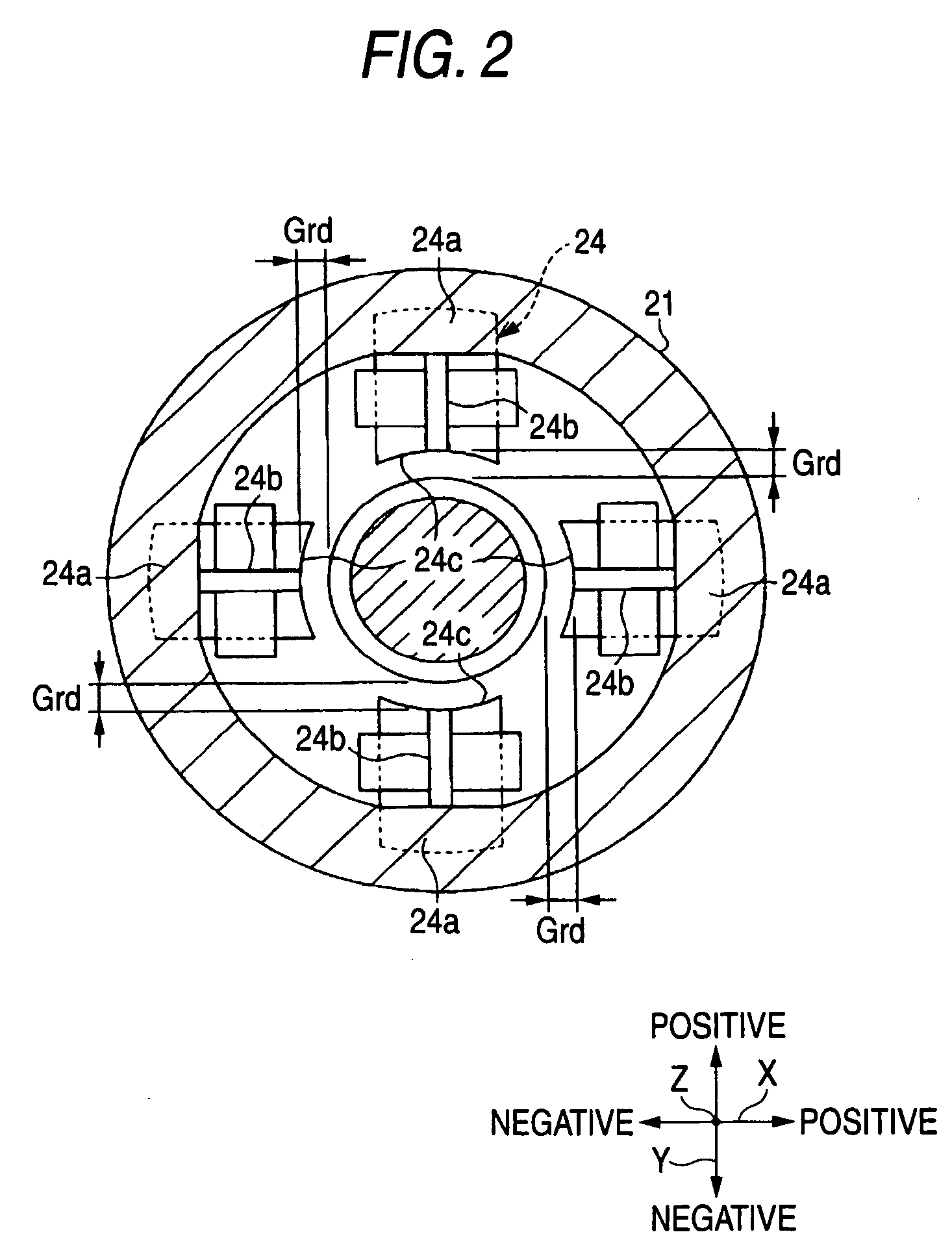

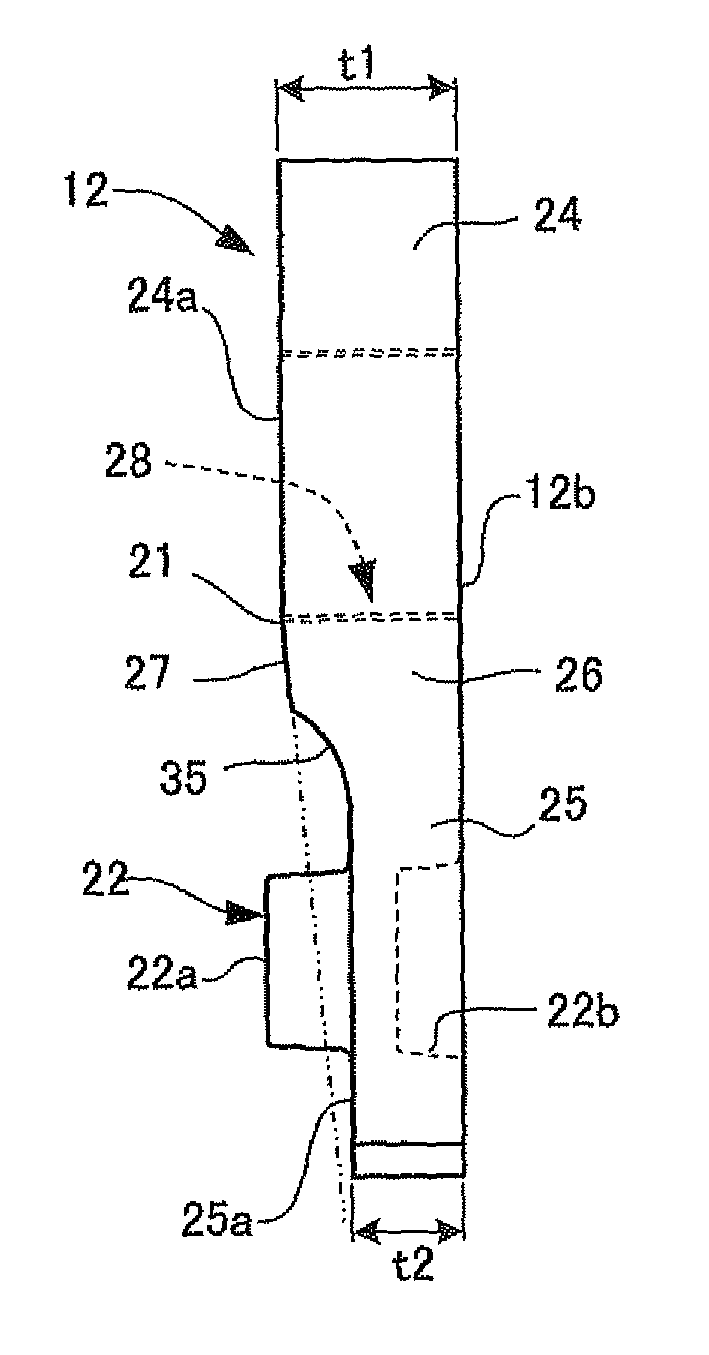

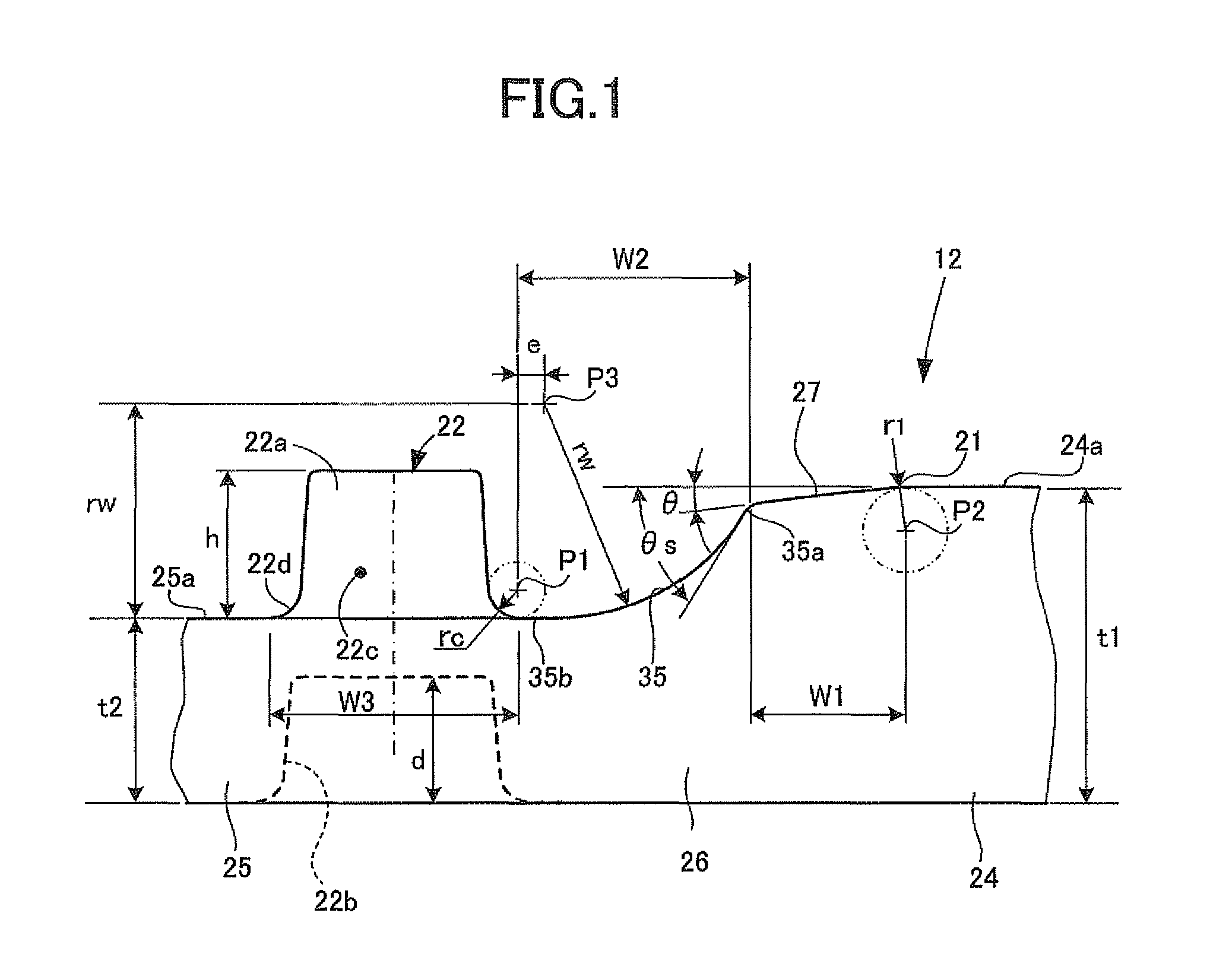

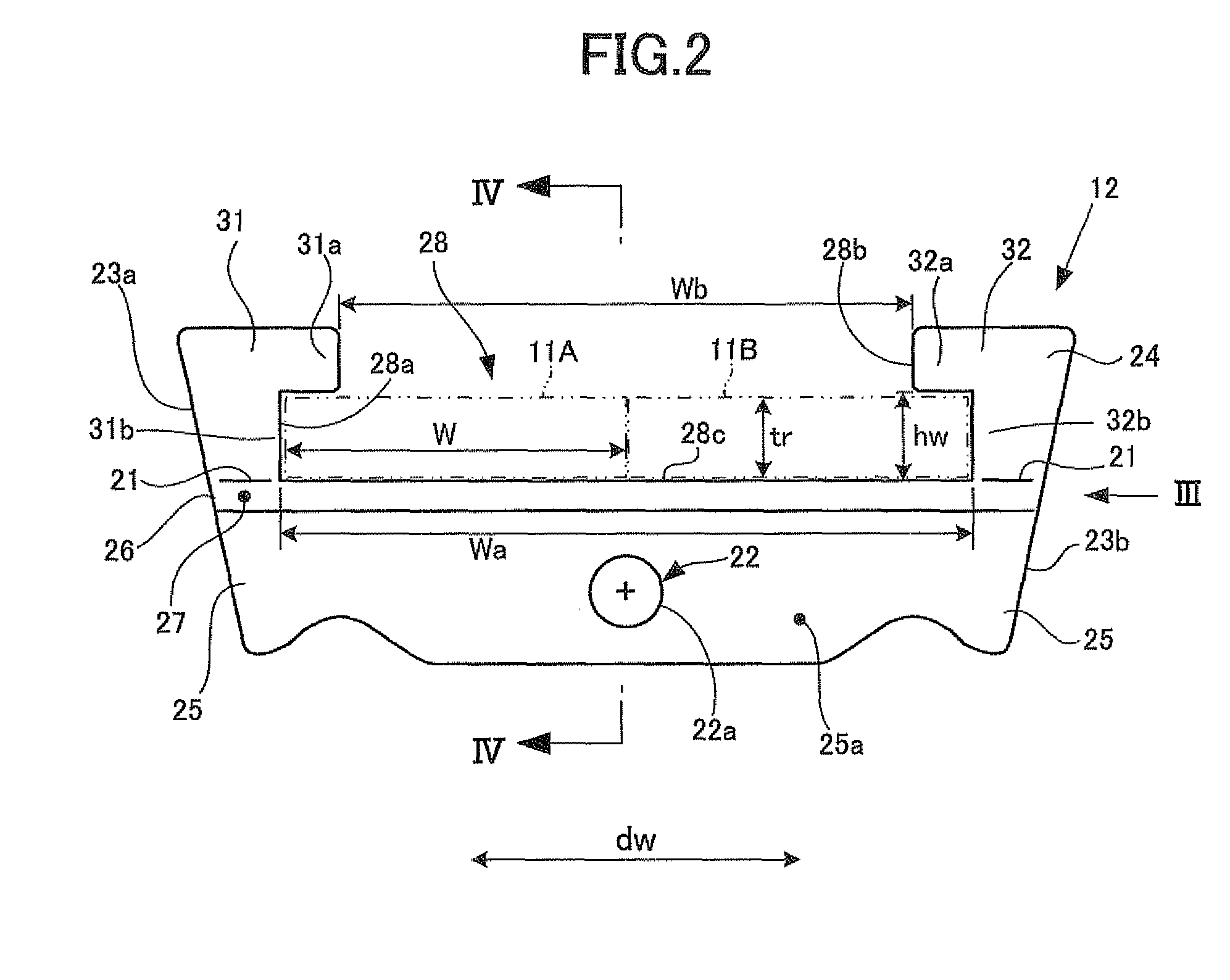

A pulverized material producing system capable of producing a pulverized material dried sufficiently from a raw material, while at the same time suppressing production costs, even in the case where the raw material has a high moisture content and viscosity, is provided. A pulverized material producing system that includes a pulverizer 2, a container 3, and a heated air supplier 4 that supplies heated air is used. The container 3 includes a first inlet 10, second inlets 11a and 11b, a first outlet 12, and a second outlet 13, and is configured so that a swirl flow 35 is created within the container. The heated air is supplied by the heated air supplier 4 to the interior of the container 3 via the second inlets 11a and 11b. The pulverizer 2 includes a casing 20 provided with a suction port 22 and a discharge port 23, an impeller, and a screen 24 that has many pores, and has blower functionality. The first inlet 10 is connected to the discharge port 23 of the casing via a pipeline 7, and the first outlet 12 is connected to the suction port 22 of the casing via a pipeline 8.

Owner:EARTHLINK

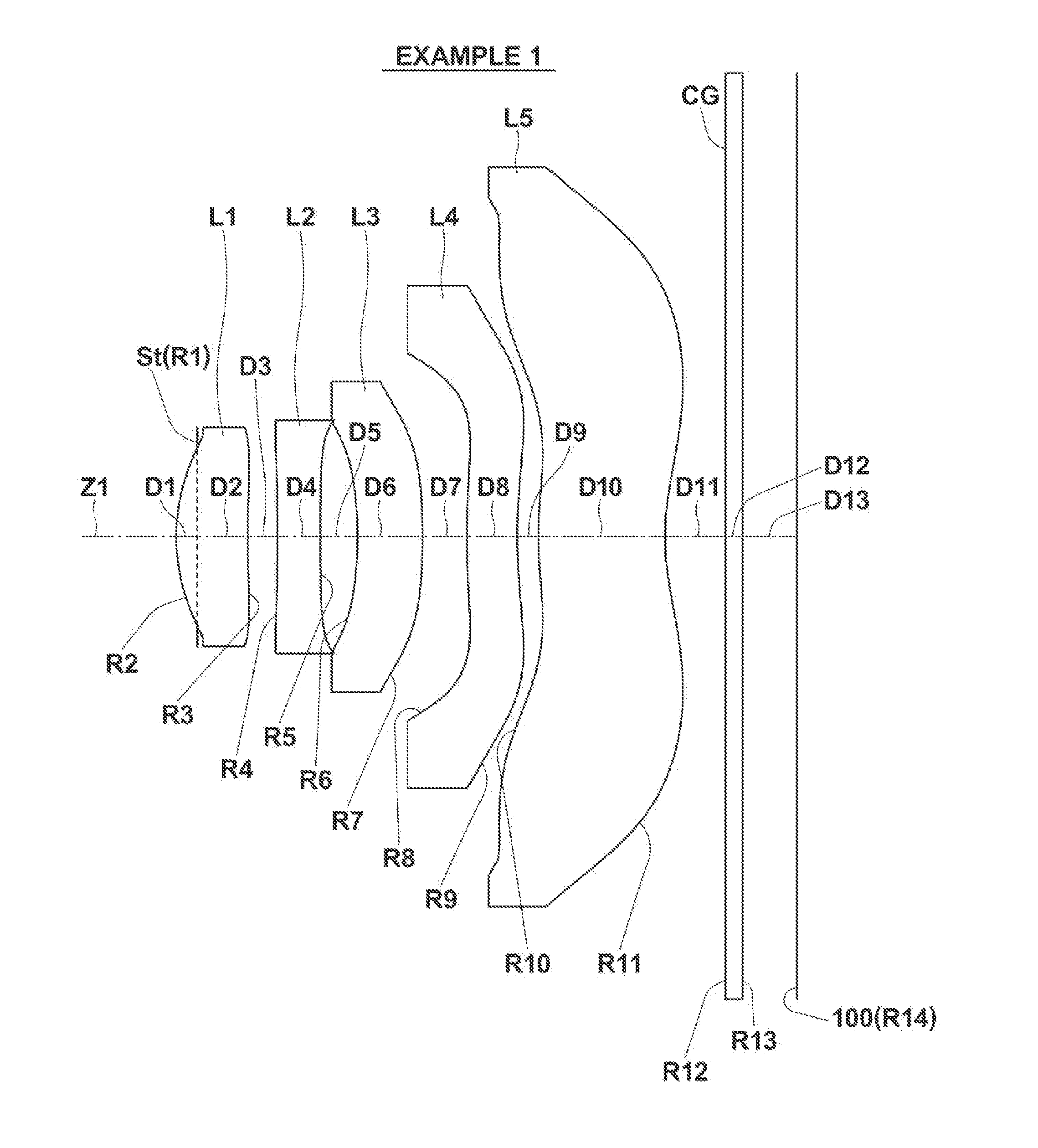

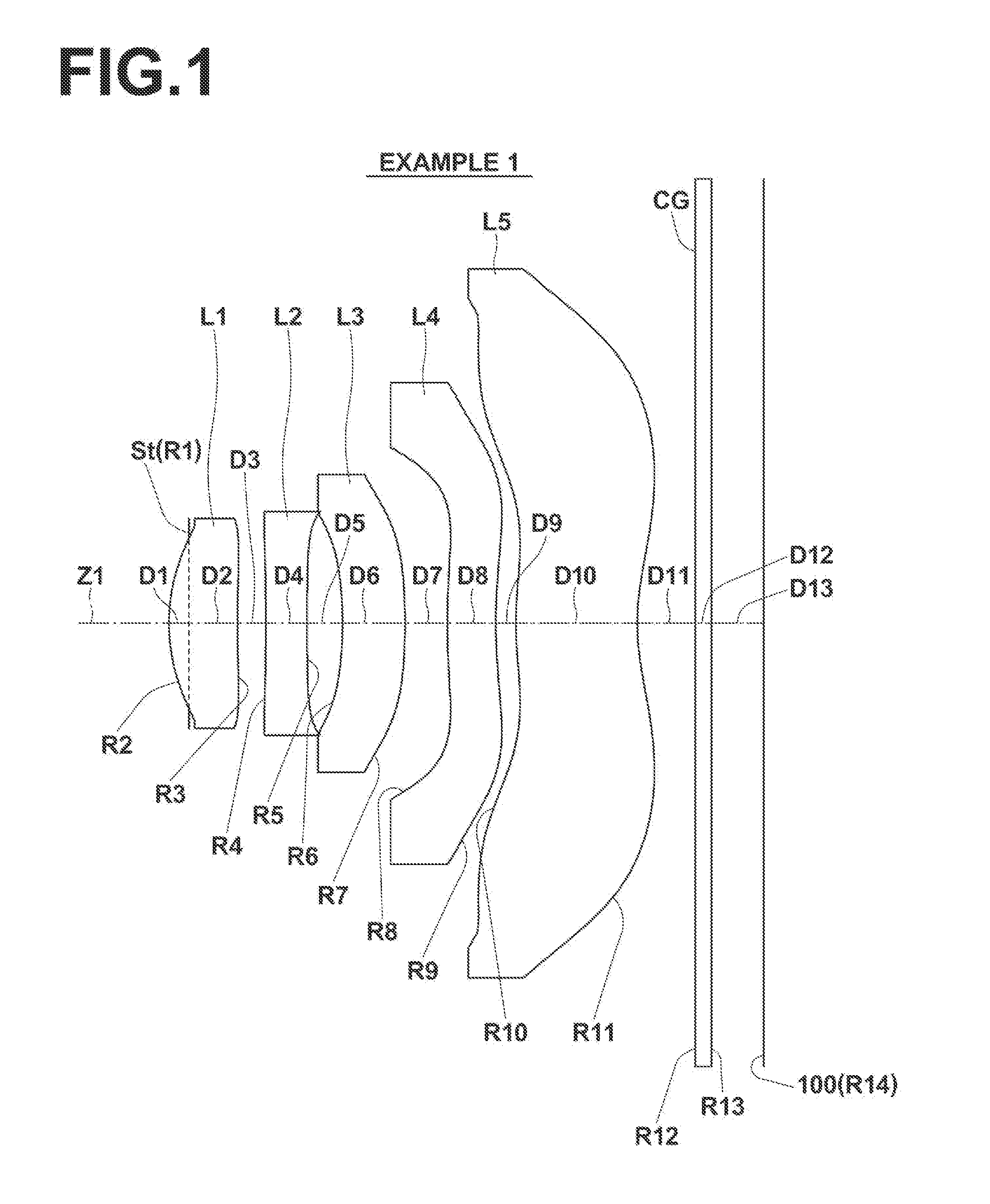

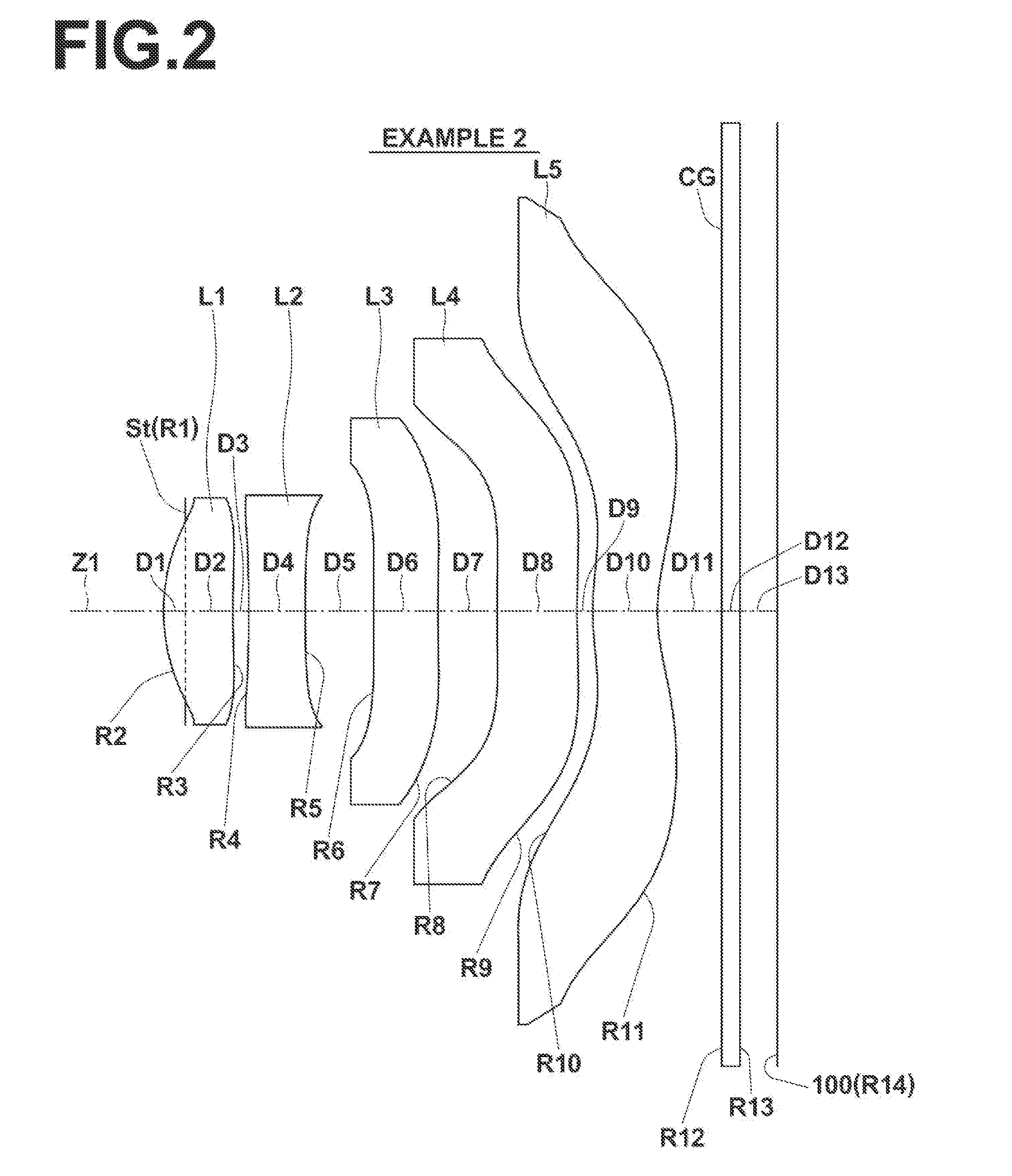

Imaging lens and imaging apparatus equipped with the imaging lens

An imaging lens is substantially constituted by five lenses, including: a first lens having a positive refractive power; a second lens having a negative refractive power; a third lens having a negative refractive power; a fourth lens having a negative refractive power; a fifth lens having a negative refractive power and an inflection point on the surface thereof toward the image side. All of the first lens through the fifth lens are single lenses, and the imaging lens satisfies predetermined conditional formulae.

Owner:JIANGXI OFILM OPTICAL CO LTD

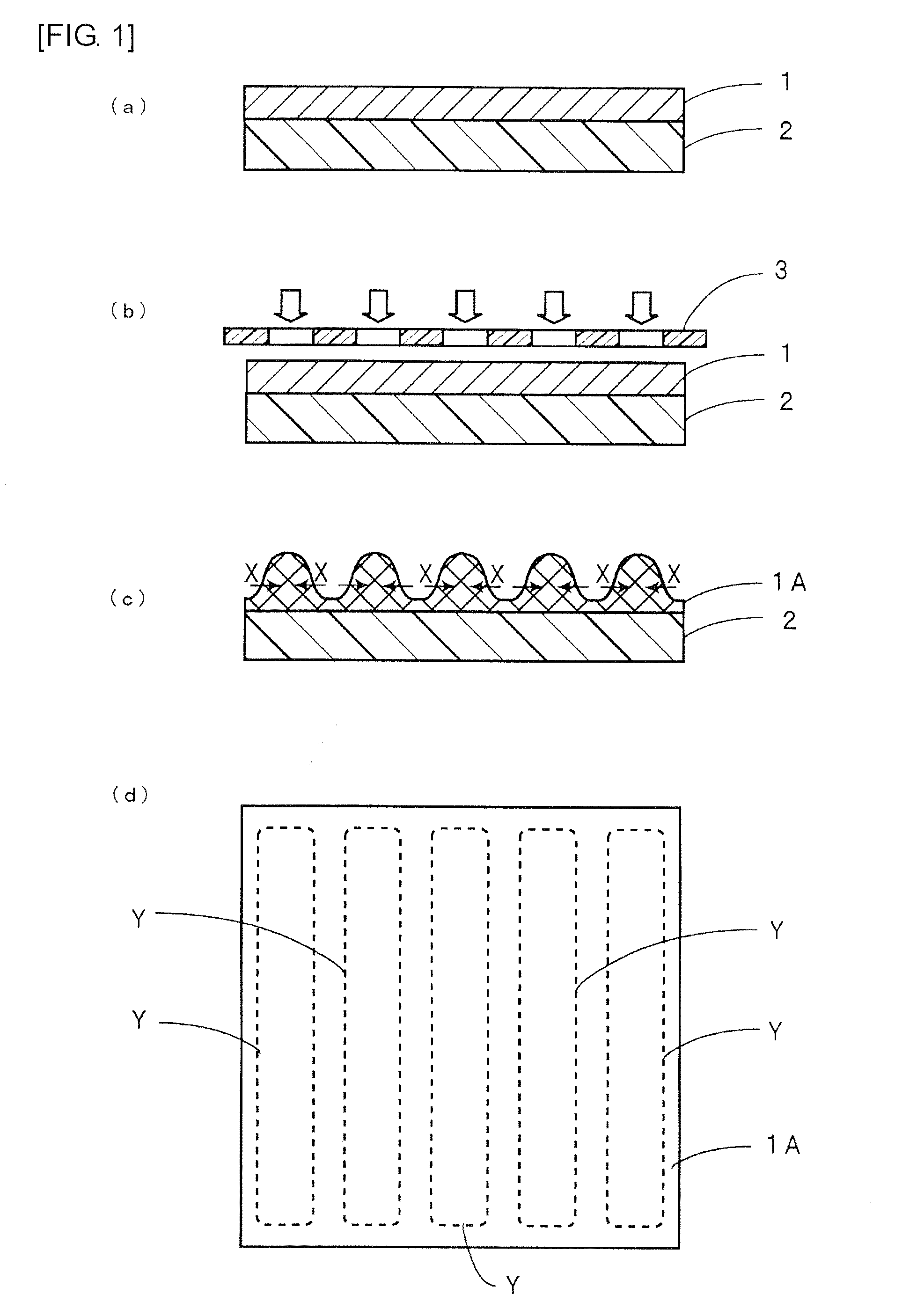

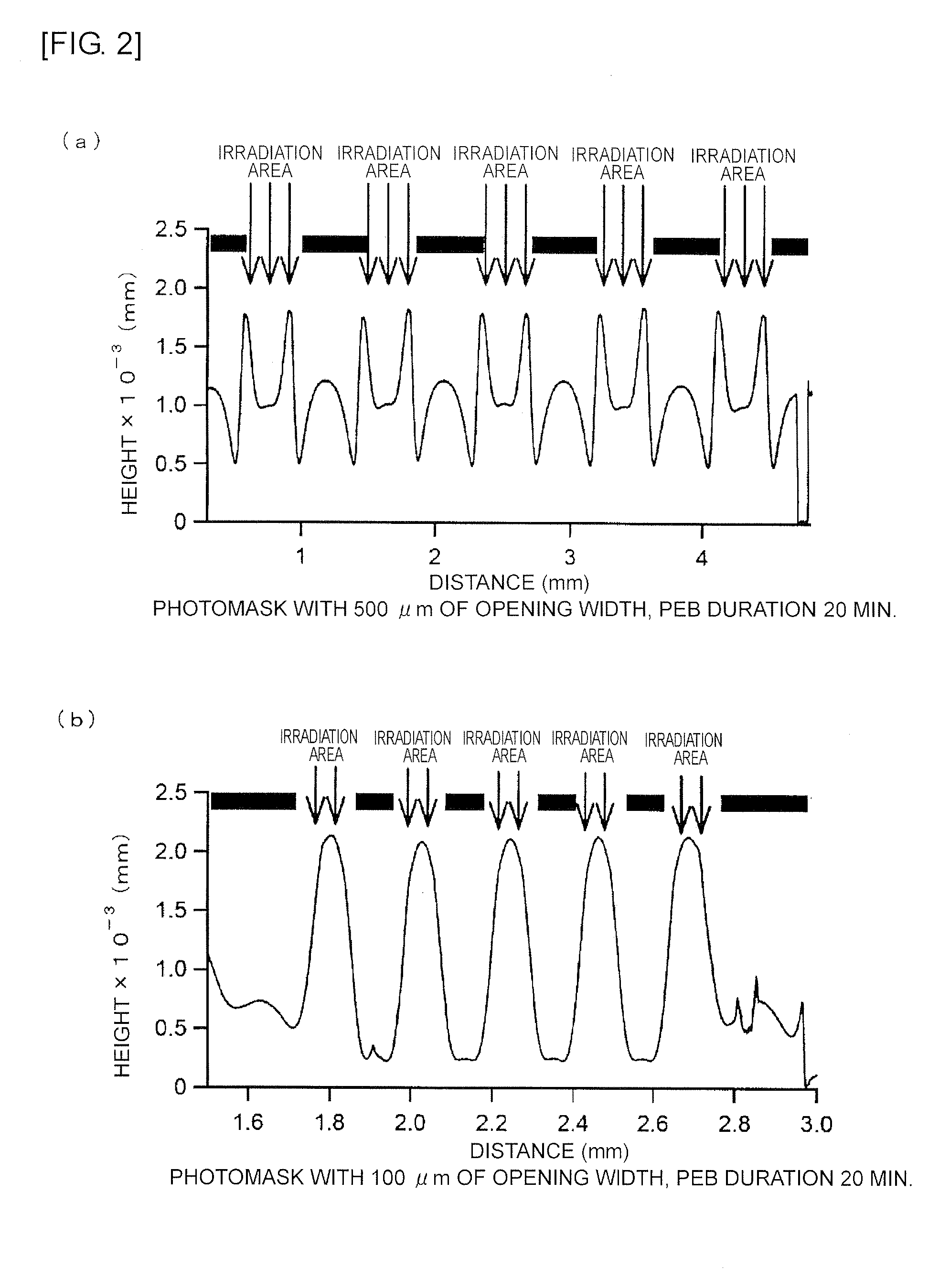

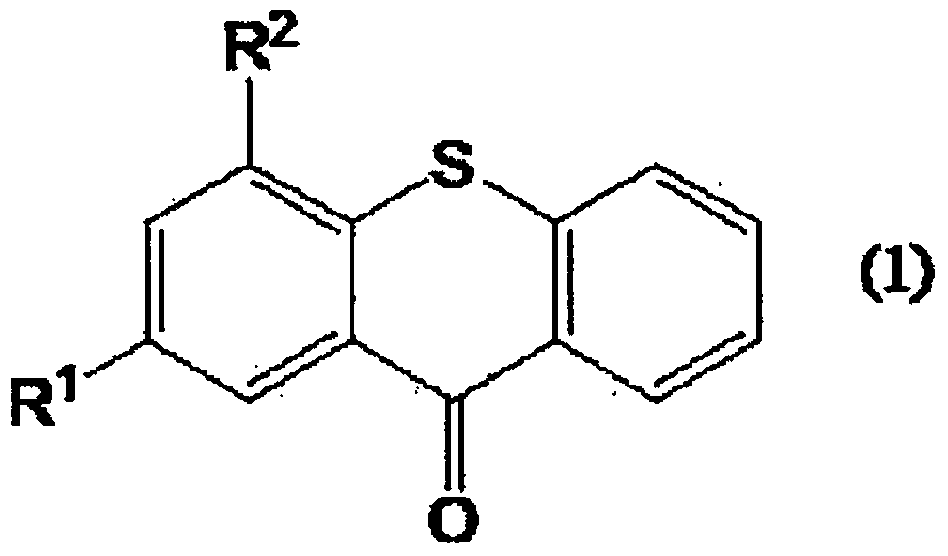

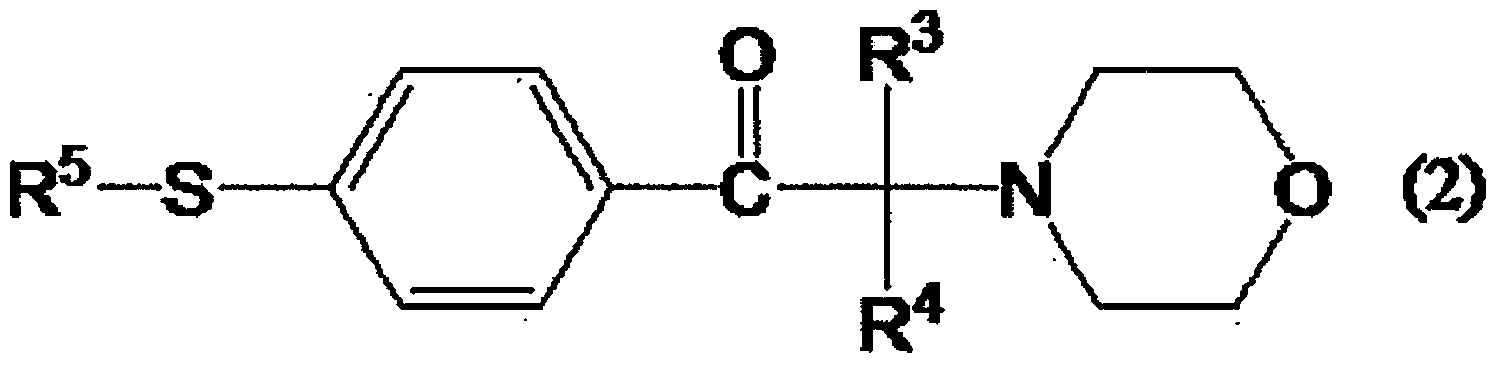

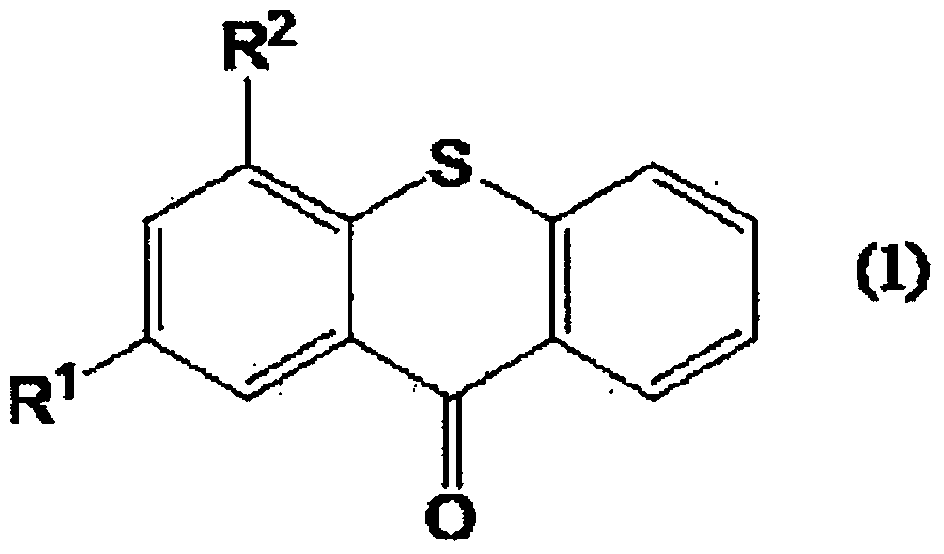

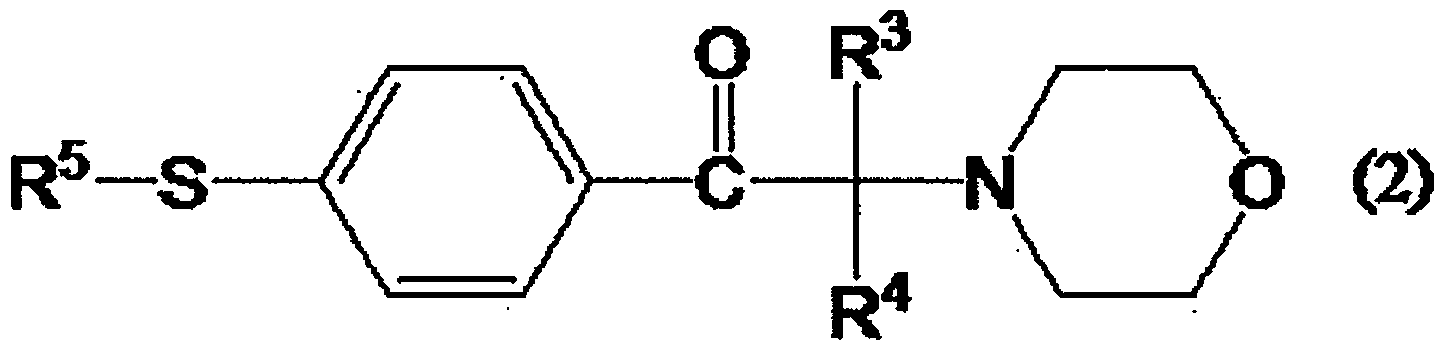

Process for producing patterned film and photosensitive resin composition

ActiveUS20090202942A1Reduce environmental loadEliminates preparationPhotosensitive materialsSemiconductor/solid-state device manufacturingLight irradiationPolymer chemistry

A process for producing a film pattern, in which a layer of photosensitive resin composition is formed on a substrate and exposed selectively through a mask to light to thereby obtain a film pattern provided on its surface with protrusions and depressions without the need to remove the layer of photosensitive resin composition at unexposed regions or exposed regions by, for example, development; and a photosensitive resin composition for use in the above process for producing a film pattern. There is provided a process for producing a patterned film, comprising the steps of preparing a photosensitive resin composition that upon light irradiation, generates an acid or a base and is hardened; coating substrate (2) with the photosensitive resin composition to thereby form photosensitive resin composition layer (1) of given thickness; and exposing the photosensitive resin composition layer (1) selectively through mask (3) to light so as to travel at least portion of the photosensitive resin composition at unexposed regions toward the exposed regions and further effect hardening thereof, thereby obtaining patterned film (1A) furnished on its surface with protrusion / depression pattern.

Owner:SEKISUI CHEM CO LTD

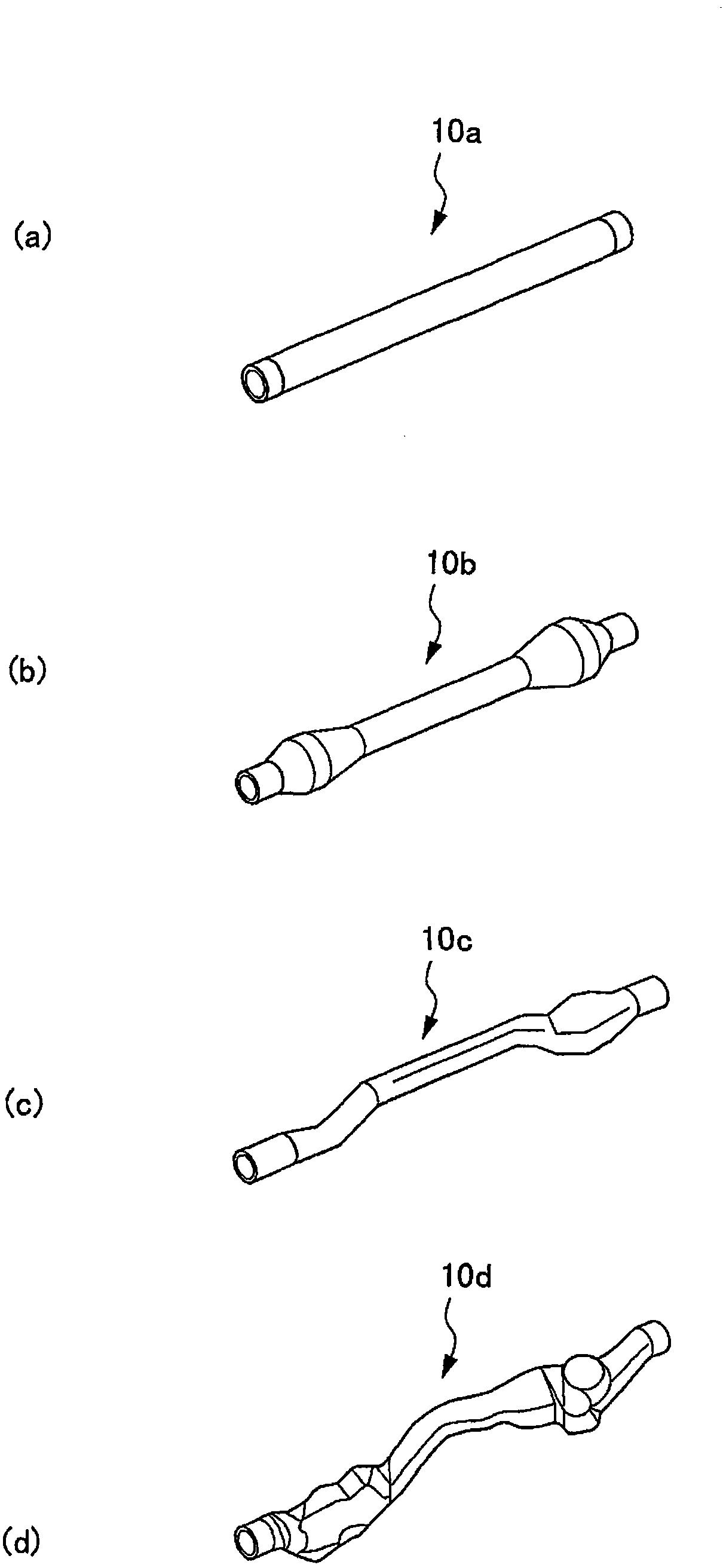

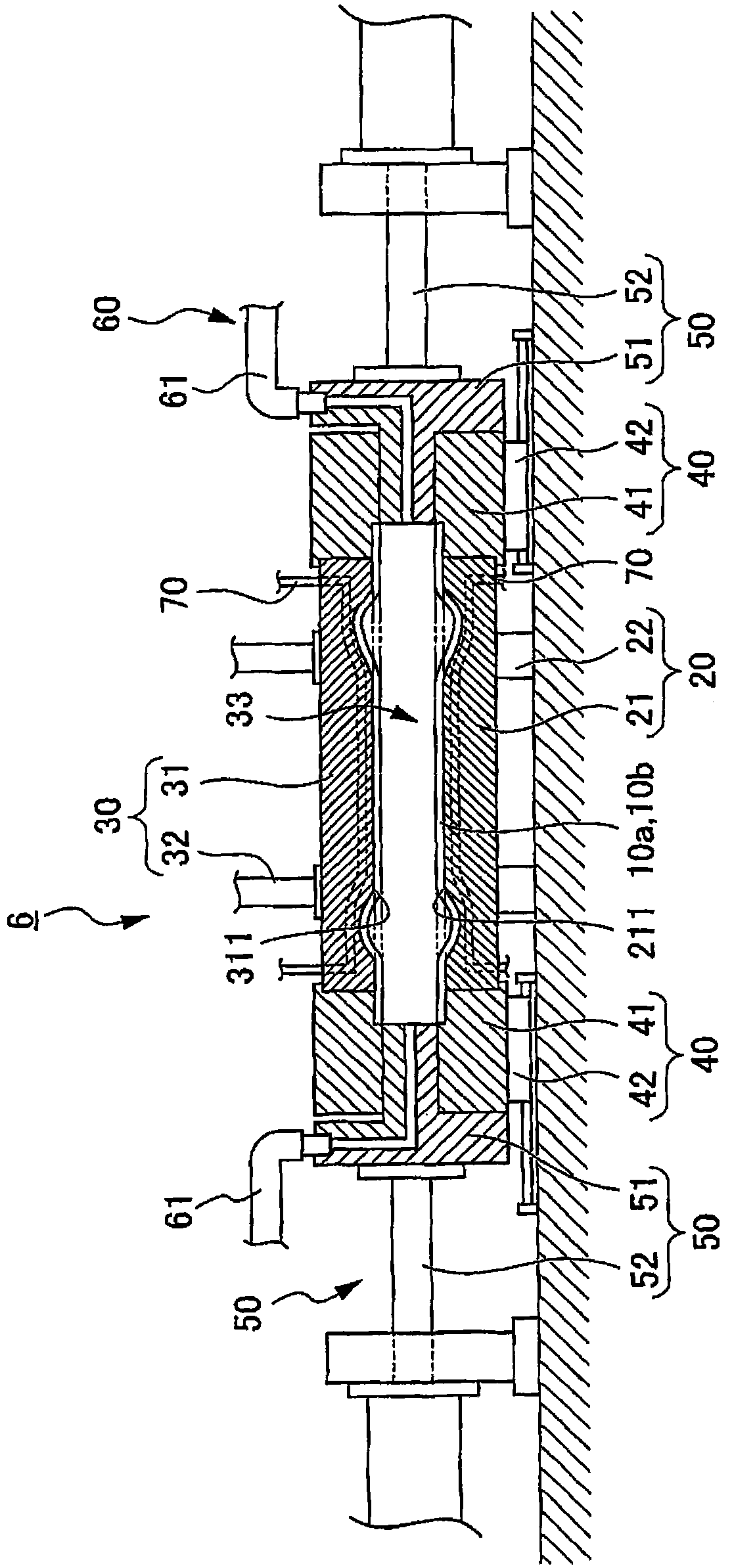

Hot bulge forming die apparatus

Owner:HONDA MOTOR CO LTD

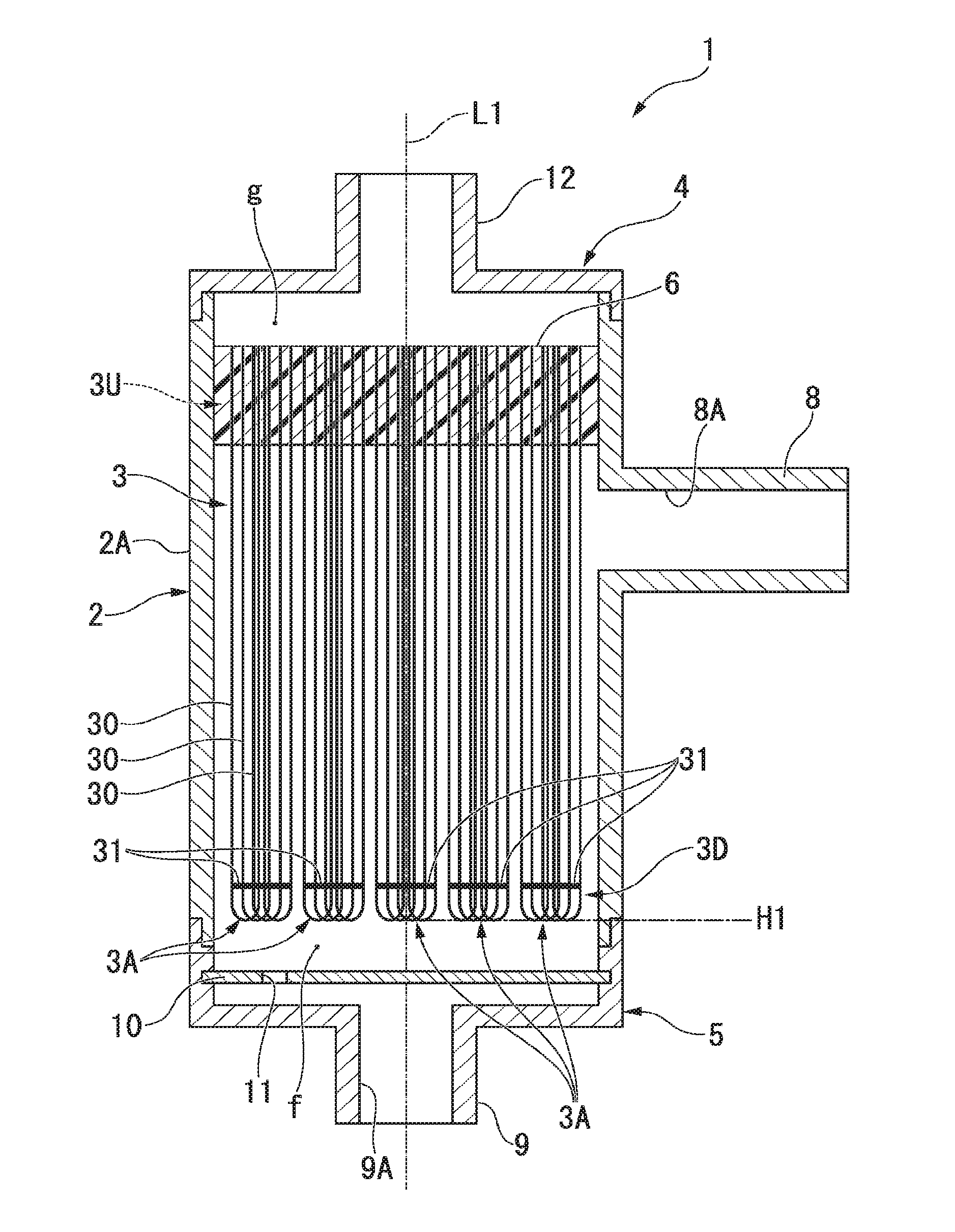

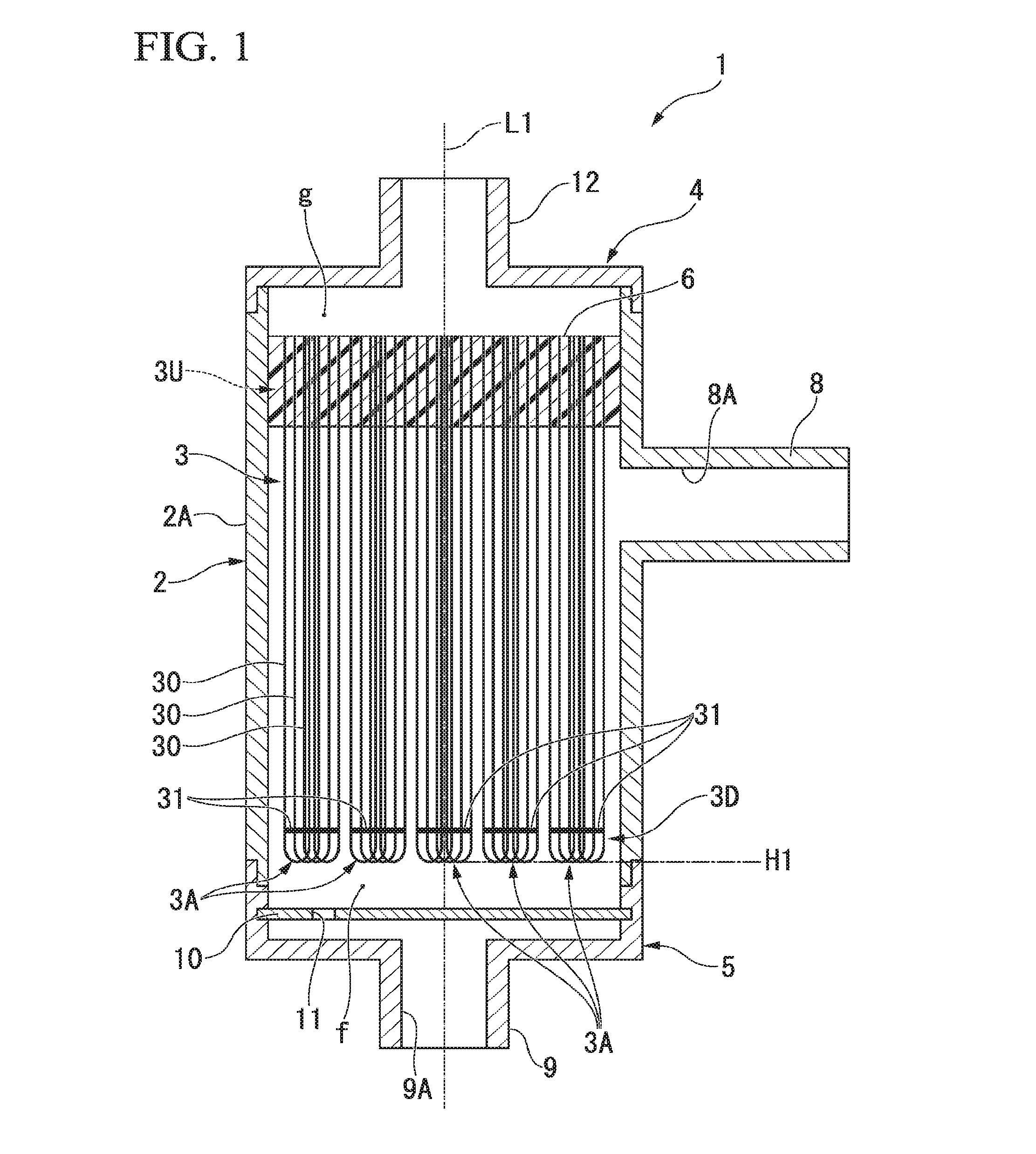

External-perfusion hollow-fiber membrade module and inkjet printer having said module

ActiveUS20160158670A1Curb production costEfficient executionMembranesSemi-permeable membranesPerfusionHollow fiber membrane

The present invention relates to a external-perfusion hollow-fiber membrane module containing a hollow-fiber membrane bundle including a plurality of hollow-fiber membranes; and a casing that houses the hollow-fiber membrane bundle, wherein the hollow-fiber membrane bundle has one end that is fixed to an inside of the casing by a potting portion in an open state, and the external-perfusion hollow-fiber membrane module is configured to perform degassing on a gas contained in a liquid inside the casing, the gas being introduced into an inside from an outer surface of the hollow-fiber membrane.

Owner:MITSUBISHI CHEM CORP

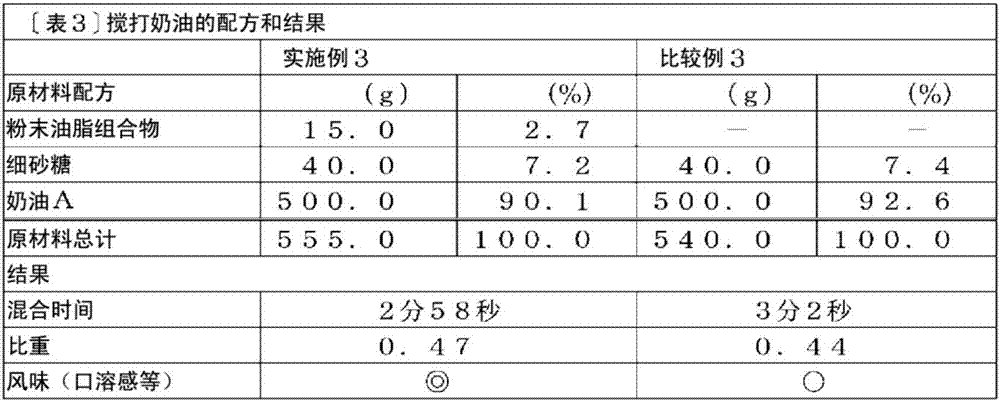

Powdered fat composition for creams

InactiveCN107249344AMeeting the needs of the unmetEasy to manufactureFatty acid esterificationCream substitutesCarbon numberFood flavor

The present invention addresses the problem of providing a powdered fat composition for creams, said composition dissolving in the mouth in a satisfactory manner and having sufficient shape retention, and being used to produce creams with good appearance, mouthfeel and flavor. The present invention is a powdered fat composition for creams, said composition containing a powdered fat composition that satisfies condition (a) below. (a) A fat composition that contains, with respect to 100 mass% of the total triglyceride content, 65-99 mass% of an XXX triglyceride having fatty acid residues X having a carbon number x at positions 1-3, and 35-1 mass% of at least one type of X2Y triglyceride in which one fatty acid residue X of the XXX triglyceride has been replaced with a fatty acid residue Y having a carbon number y, the carbon number x being an integer selected from 8-20, and each carbon number y being independent, being an integer selected from x+2 to x+12, and satisfying y<=22.

Owner:THE NISSHIN OILLIO GRP LTD

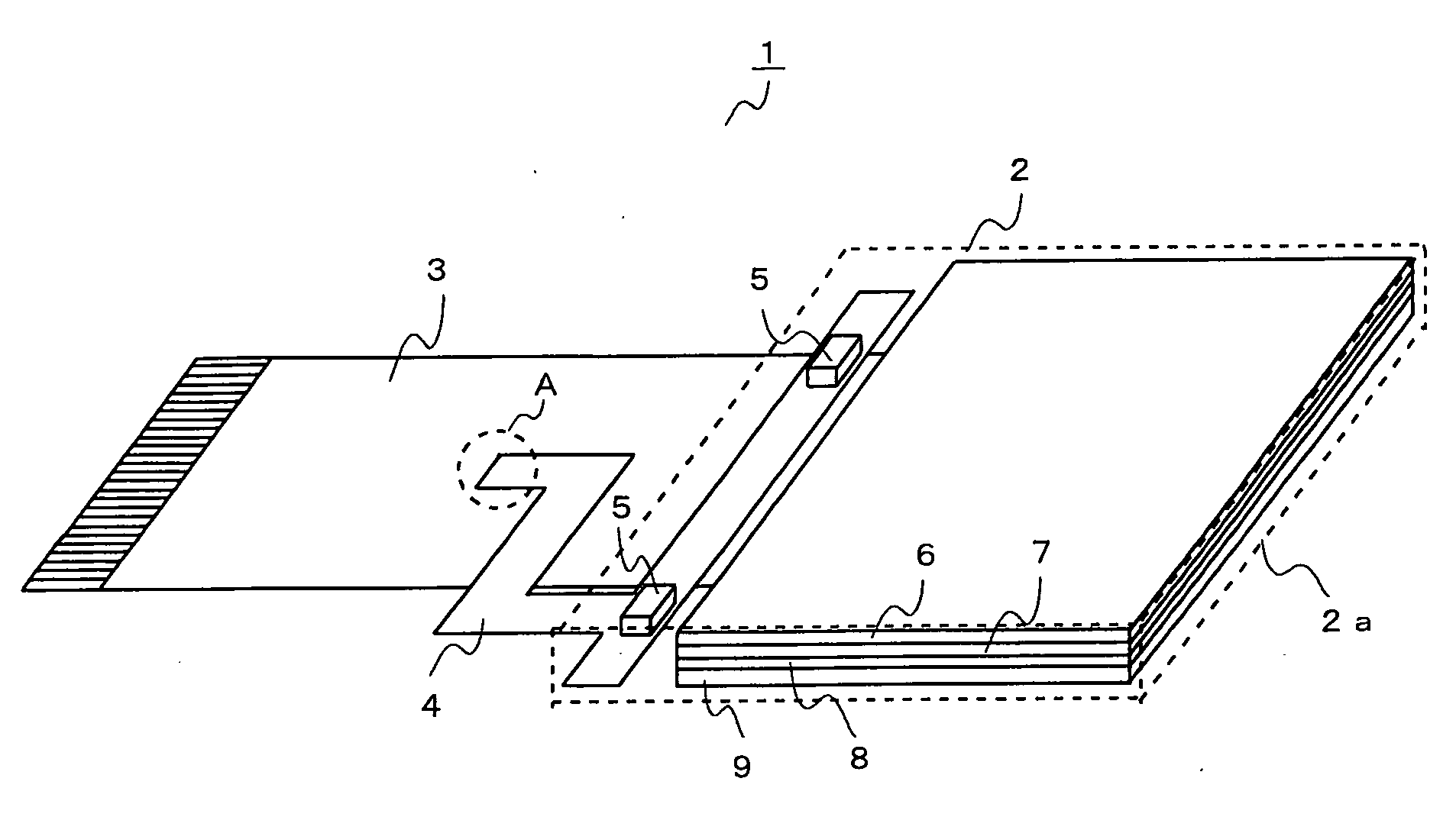

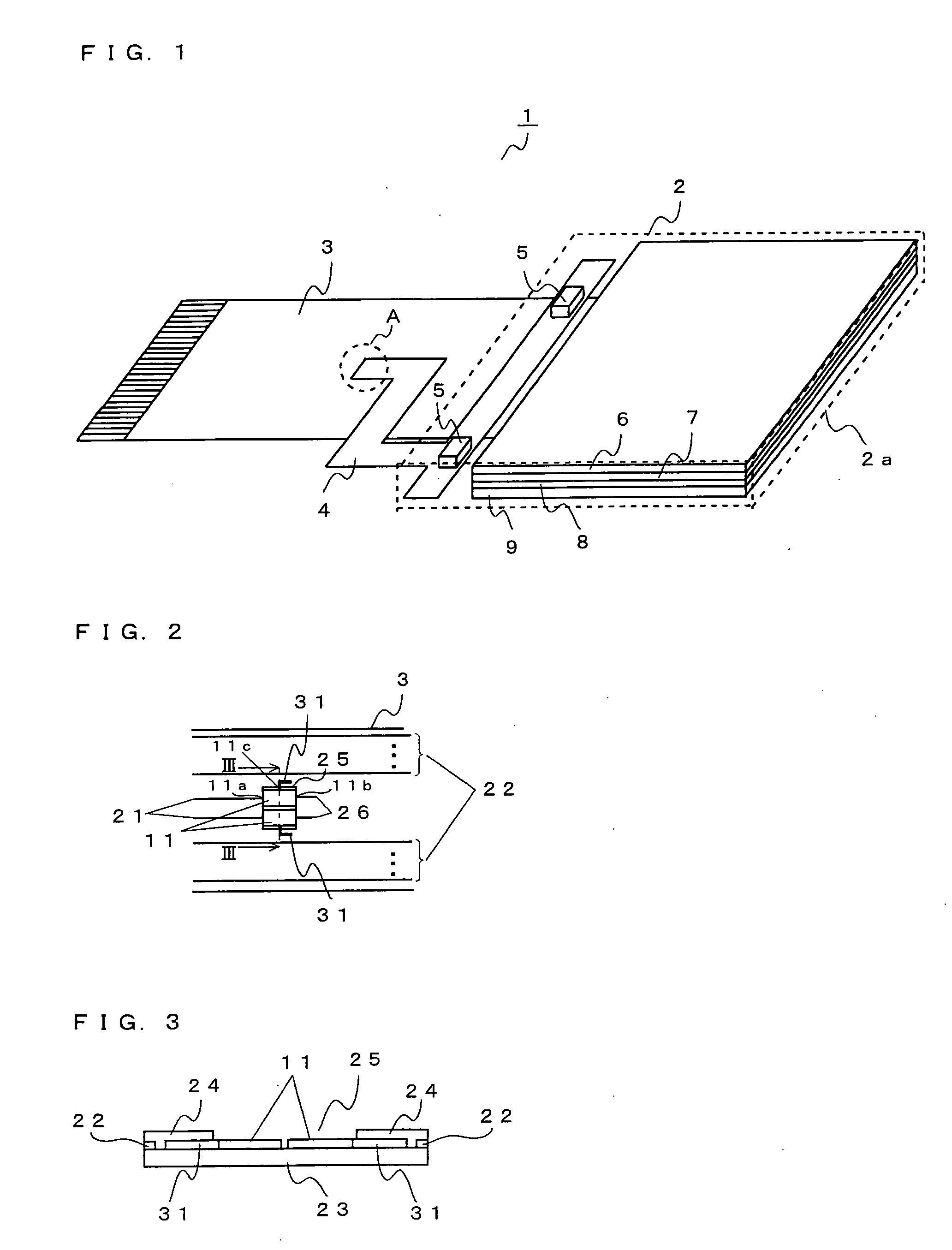

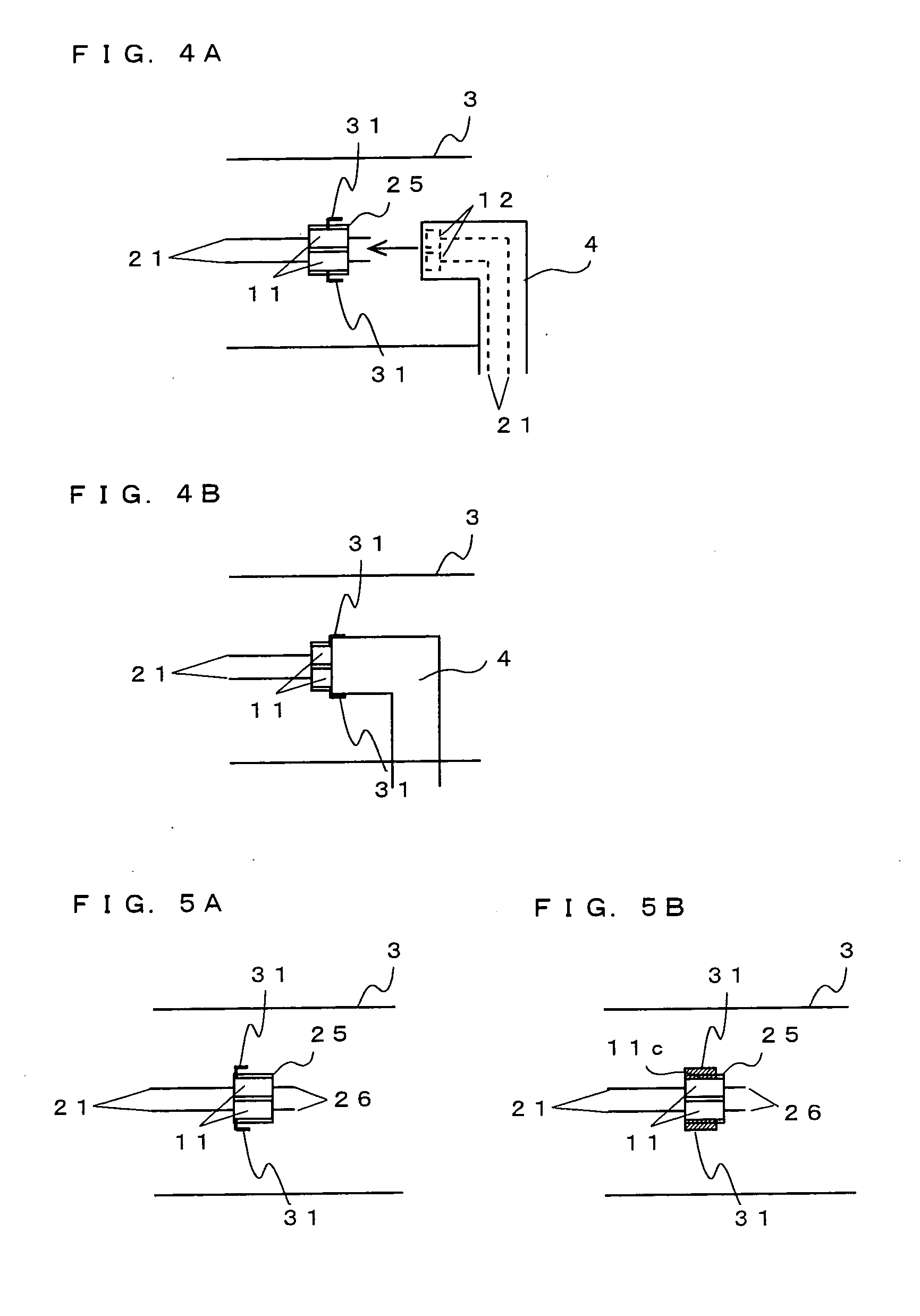

Flexible print circuit and liquid crystal display device

InactiveUS20080291380A1Easy to implementReduce loadStatic indicating devicesPrinted circuit aspectsLiquid-crystal displayEngineering

A first electrode pad which is connected to a prescribed wiring and is exposed without being covered with a protection film, is formed in a flexible print circuit (FPC). The first electrode pad is set up to be bonded with a second electrode pad which is included in the other FPC. A positioning pattern which is made of the same material as the first electrode pad, and which is used as a marker to position the other flexible print circuit when the first electrode pad and the second electrode pad are bonded together, is extended from the first electrode pad.

Owner:FUNAI ELECTRIC CO LTD

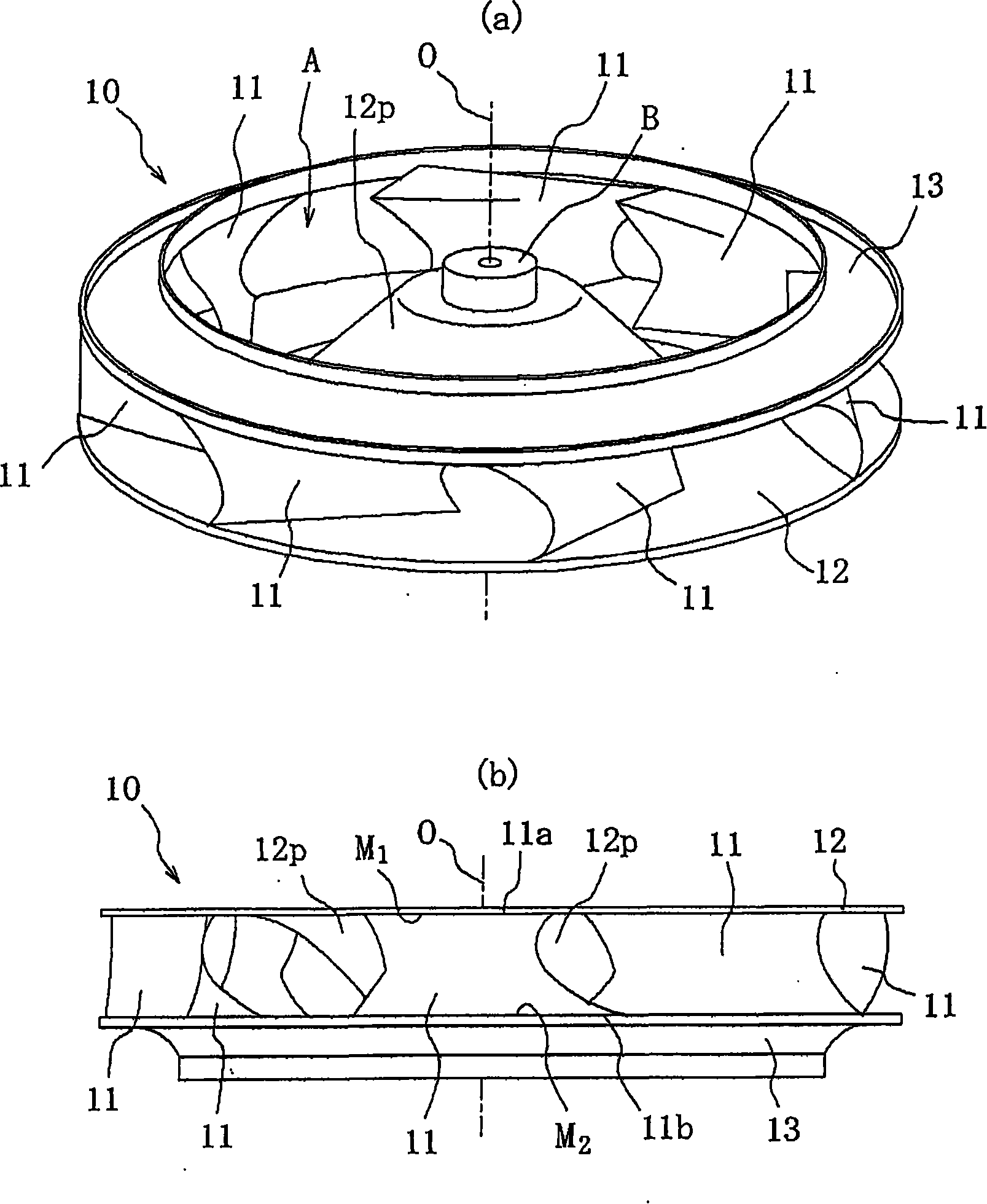

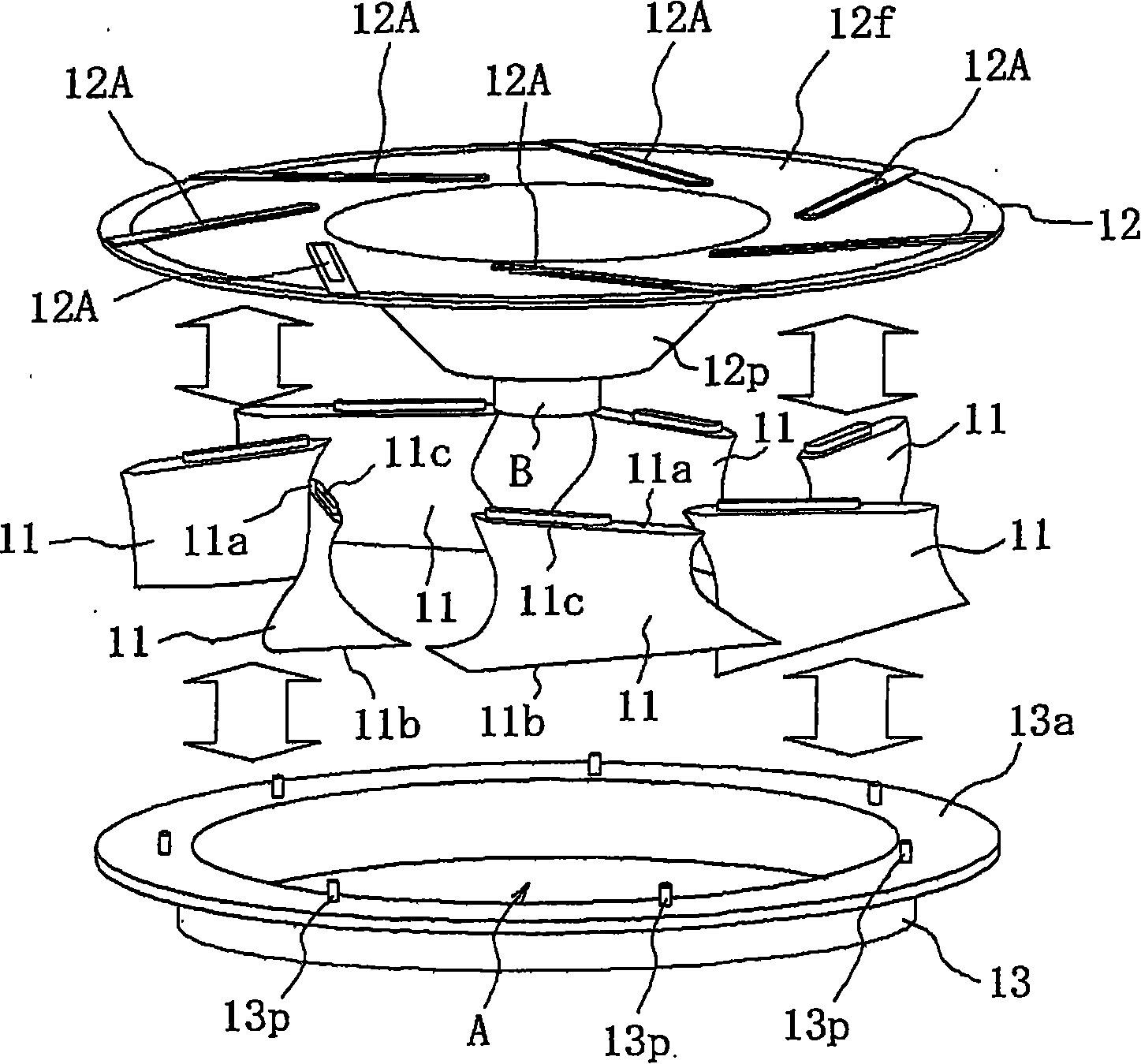

Centrifugal fan and production method thereof

ActiveCN101173671AReduce operating proceduresIncrease production capacityPump componentsPumpsEngineeringUltimate tensile strength

The invention provides a centrifugal blower and the production method. The centrifugal blower can reduce the operating procedure in the assemble joint and improve the intensity and size precision when jointing three components namely a blade component and two support boards respectively connected with the end of the blade component. The production method of the centrifugal blower ensures a protuberance forming at the end communicating a through hole forming at a main board and ensures the front end of the protuberance expose from the main board when having trail installation to the three components. Secondly, when the main board and the protecting cover are jointed at a plurality of blade components, the front end of the protuberance is supplied with vibration energy using a welding head and the pressure is applied. At the same time of jointing the protecting cover and the end or after the jointing, the front end of the protuberance is supplied with vibration energy and the pressure is applied, to ensure the front end of the protuberance is jointed at the shoulder of the through hole of the main board after the protuberance is fused, thereby supplying vibration energy to the main board as well as applying pressure to joint the main board and the end.

Owner:日本高分子株式会社

Vehicular interior trim

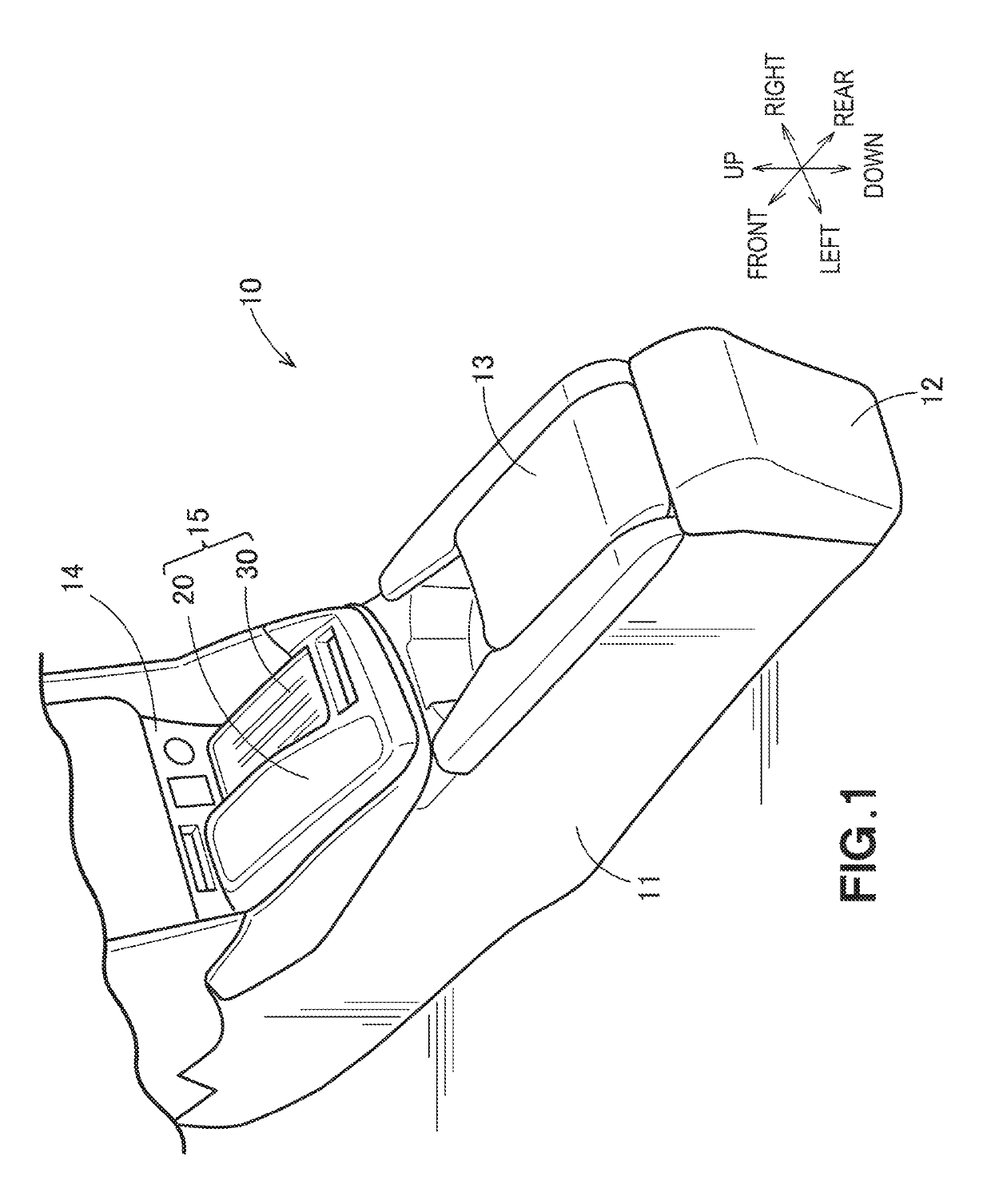

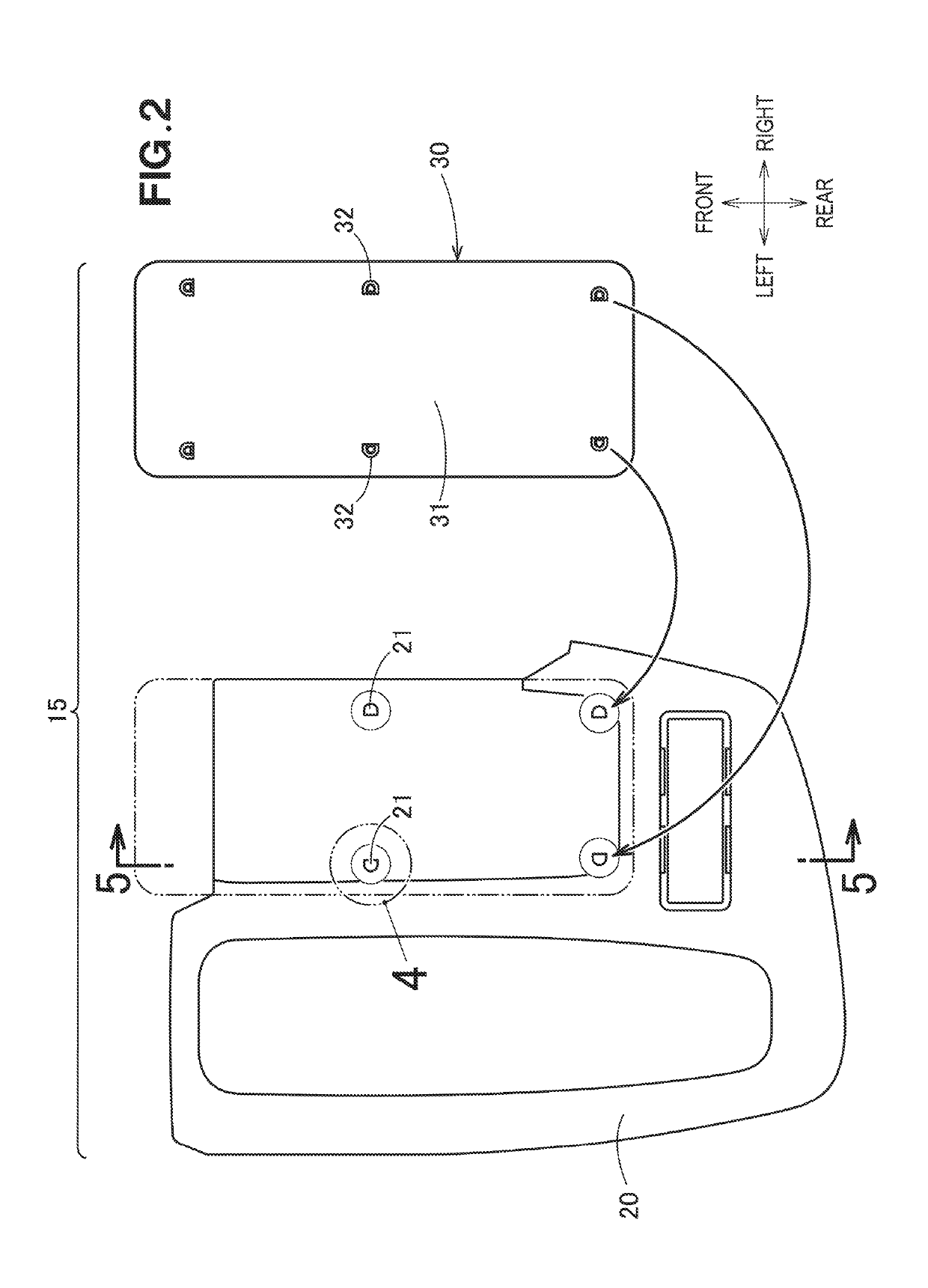

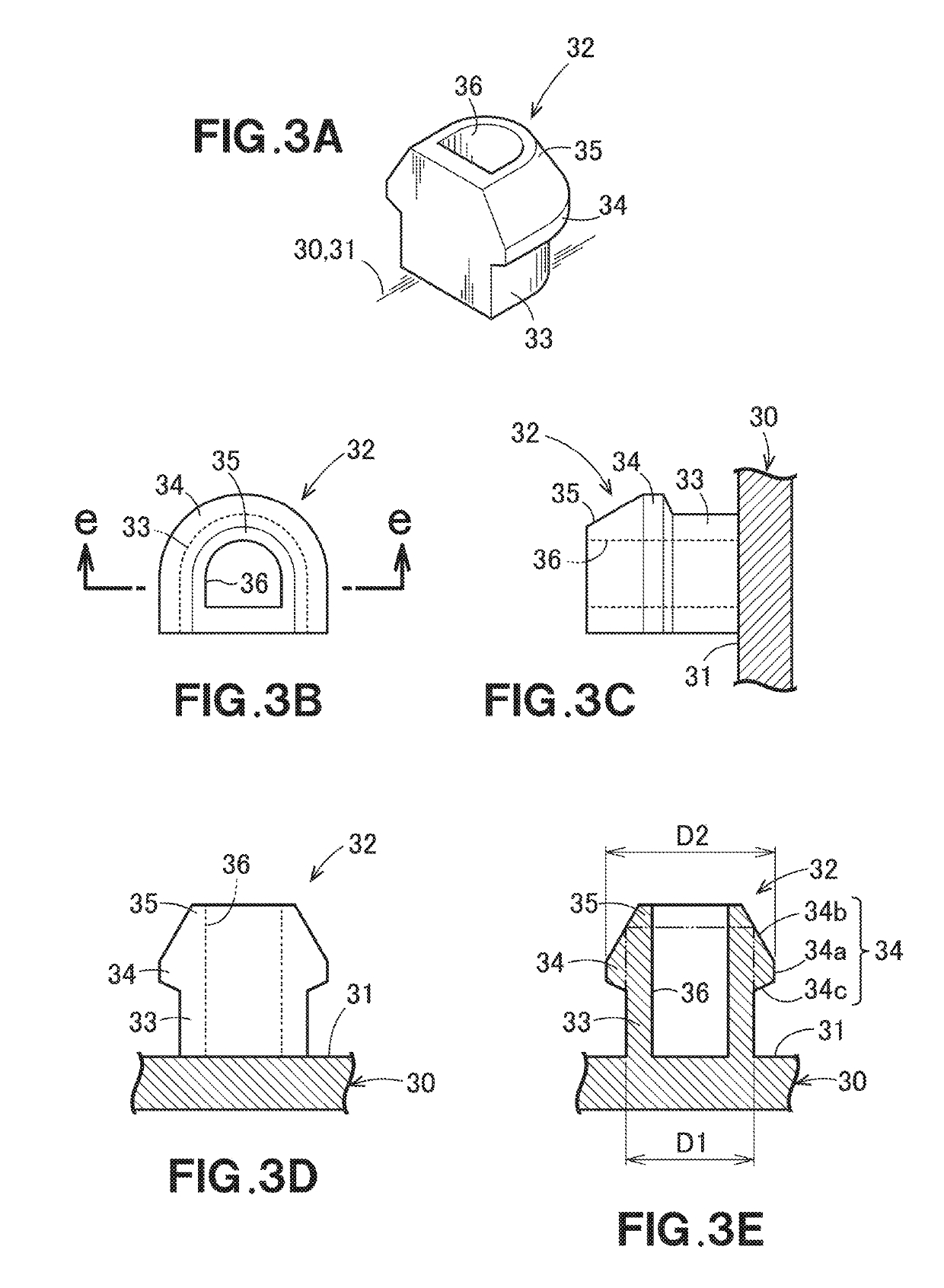

ActiveUS20190315290A1Decreasing circumferential lengthDesigning can be facilitatedSnap-action fastenersPassenger spaceEngineeringMechanical engineering

Owner:MORIROKU TECH

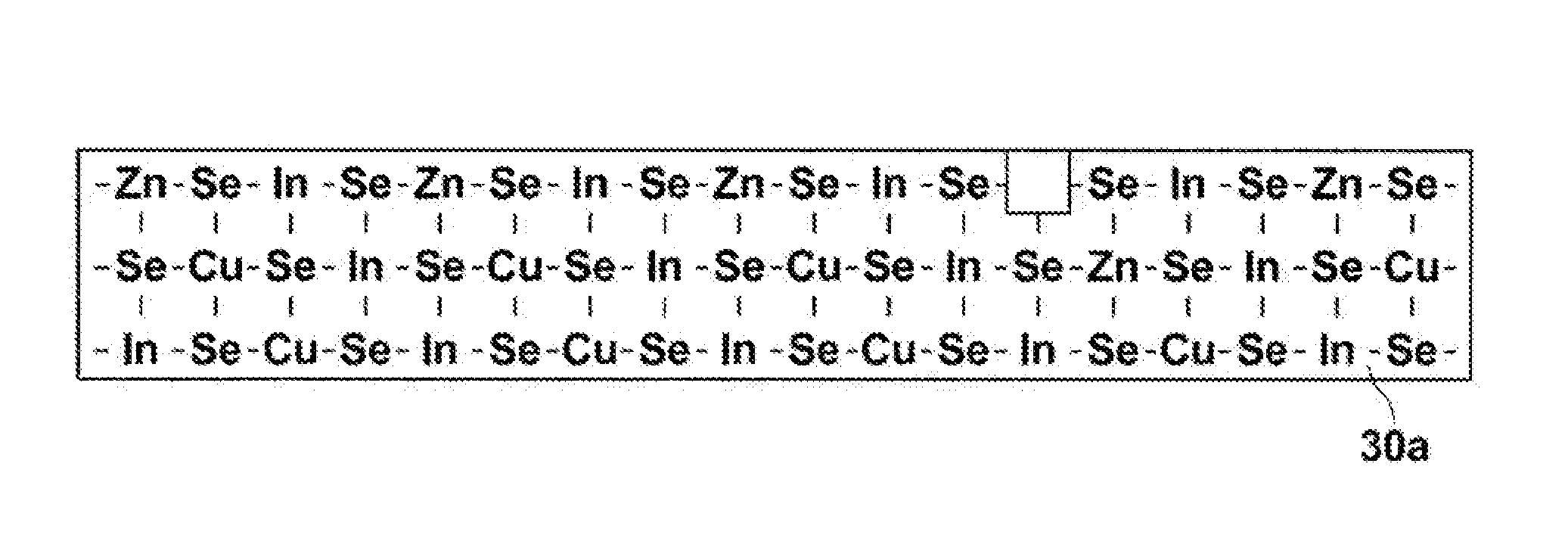

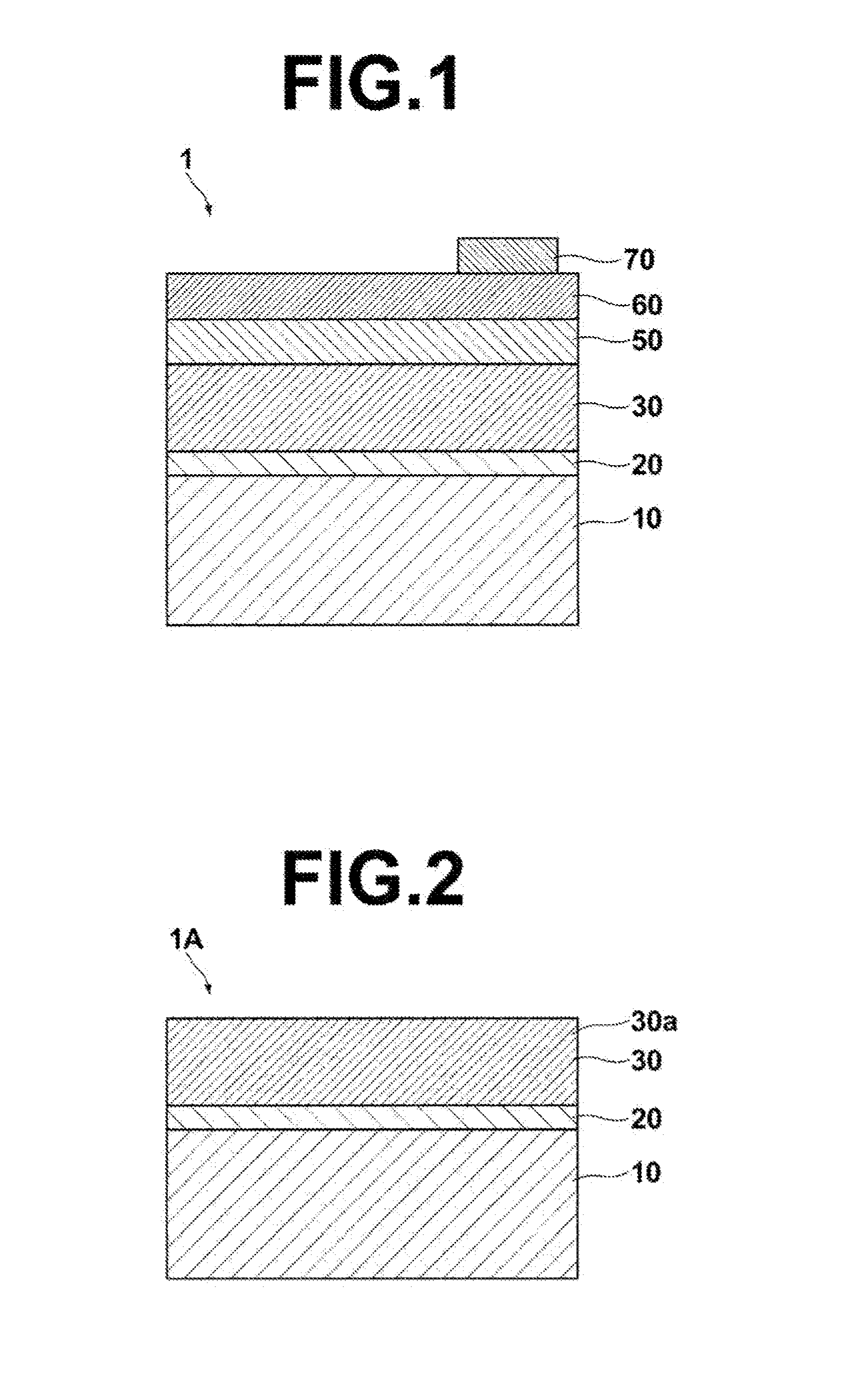

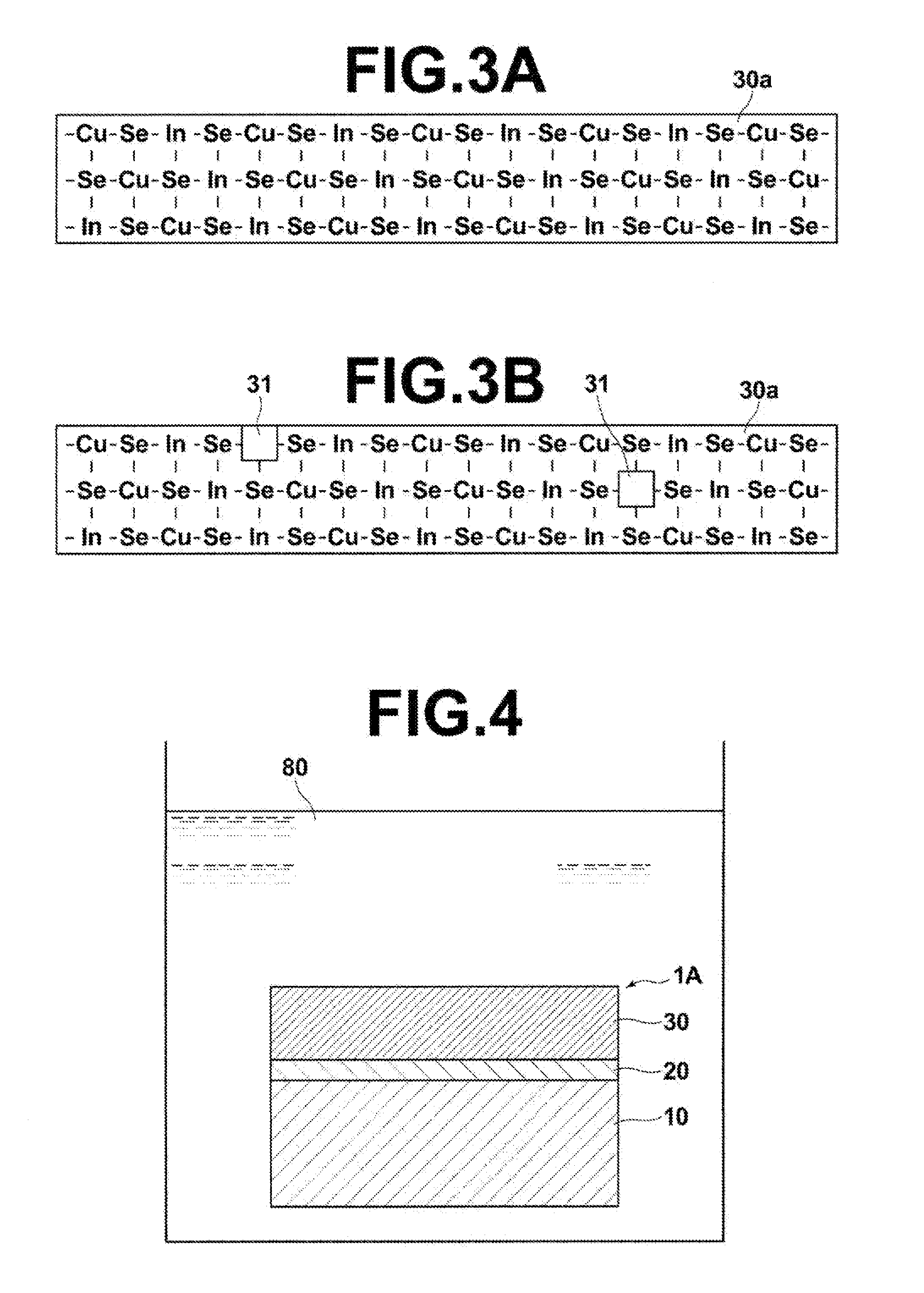

Method for producing photoelectric conversion device

InactiveUS20130244370A1Easily and evenly diffuseHigh densityFinal product manufactureSemiconductor/solid-state device manufacturingSurface layerPhotoelectric conversion

In a method for producing a photoelectric conversion device including a light absorption layer made of a CIGS-based compound semiconductor, a vacancy formation process for forming Cu vacancies in a surface layer of the light absorption layer in a layered member that is composed of a lower electrode and the light absorption layer deposited on a substrate is performed, and after then, a pn junction is formed in the surface layer of the light absorption layer.

Owner:FUJIFILM CORP

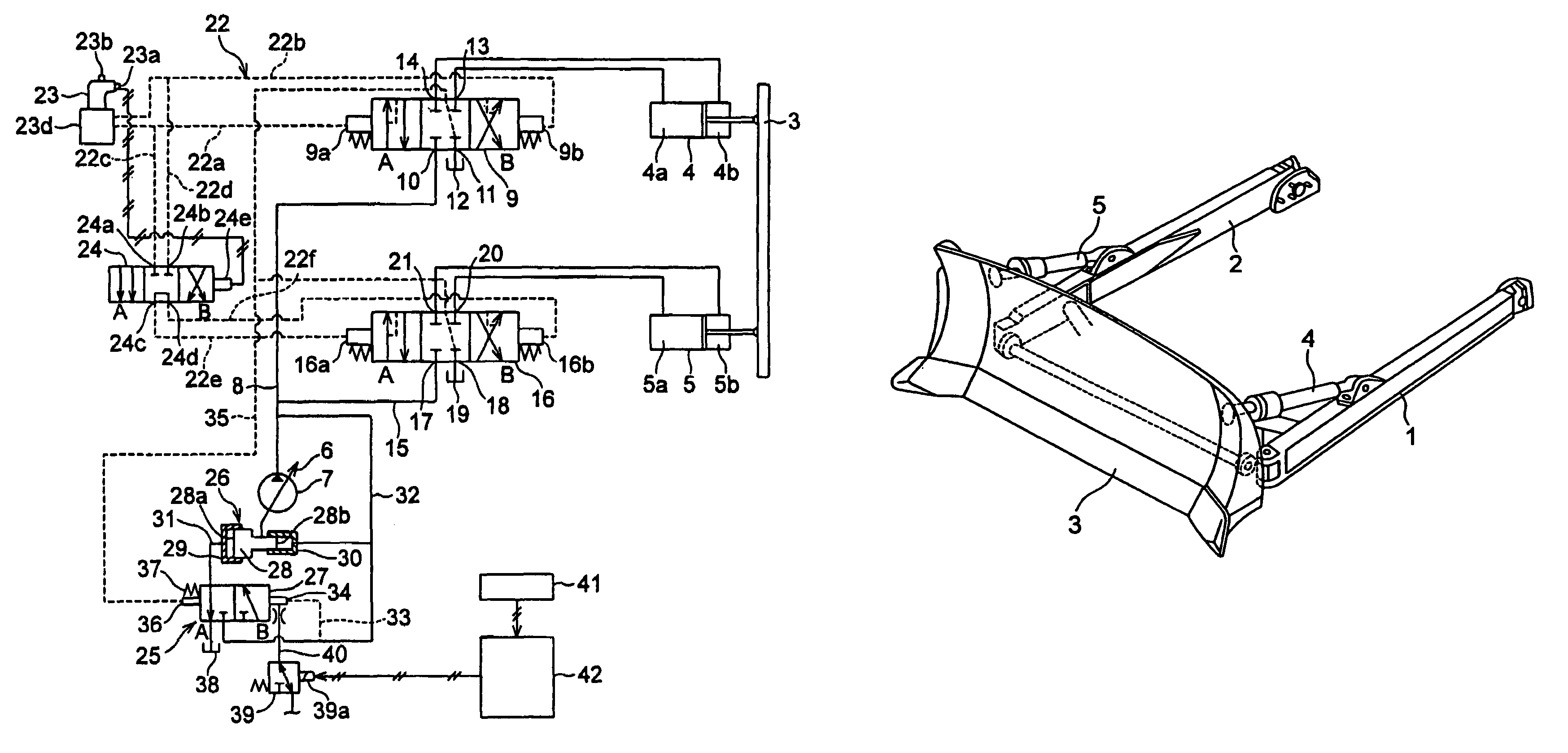

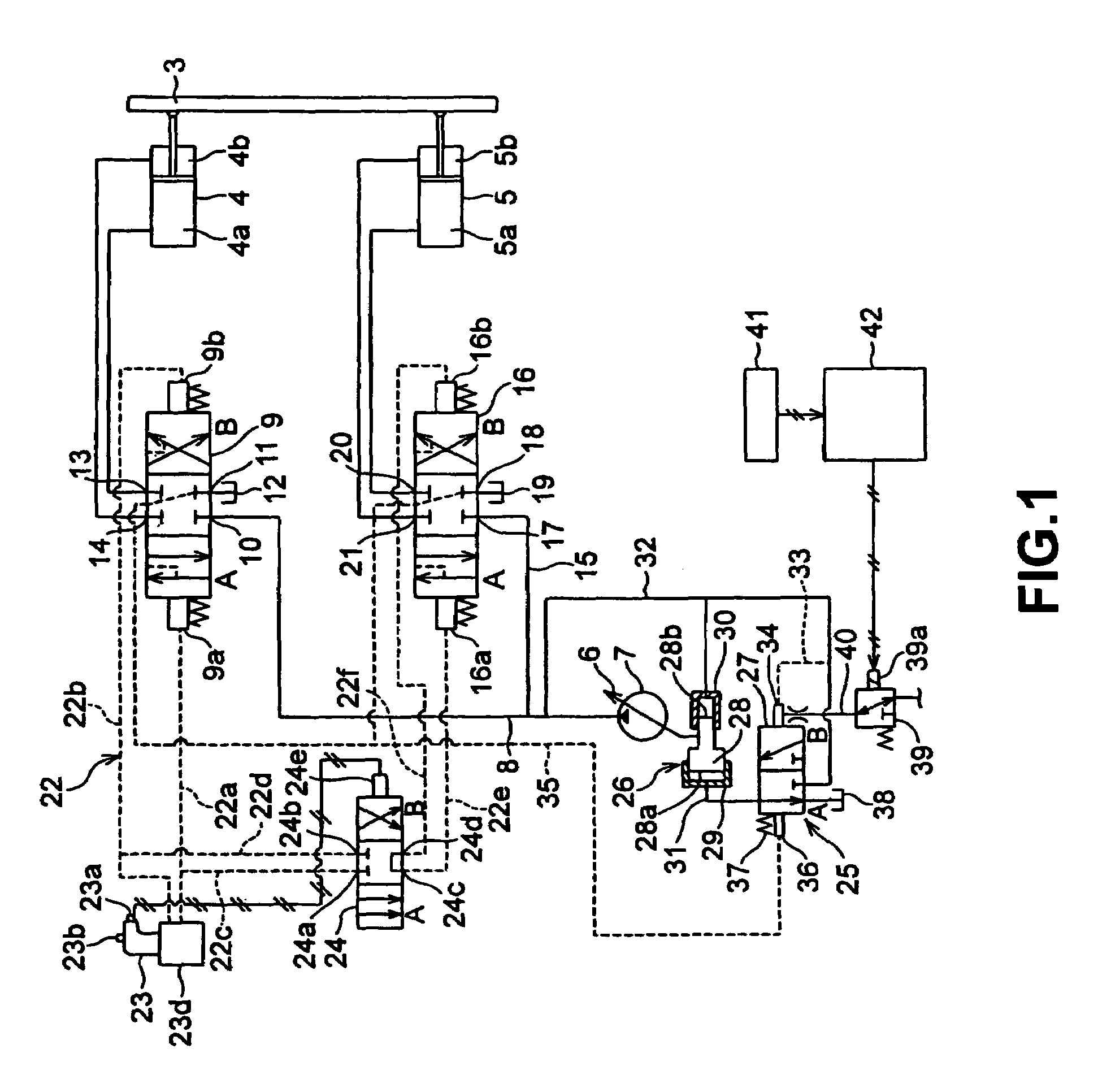

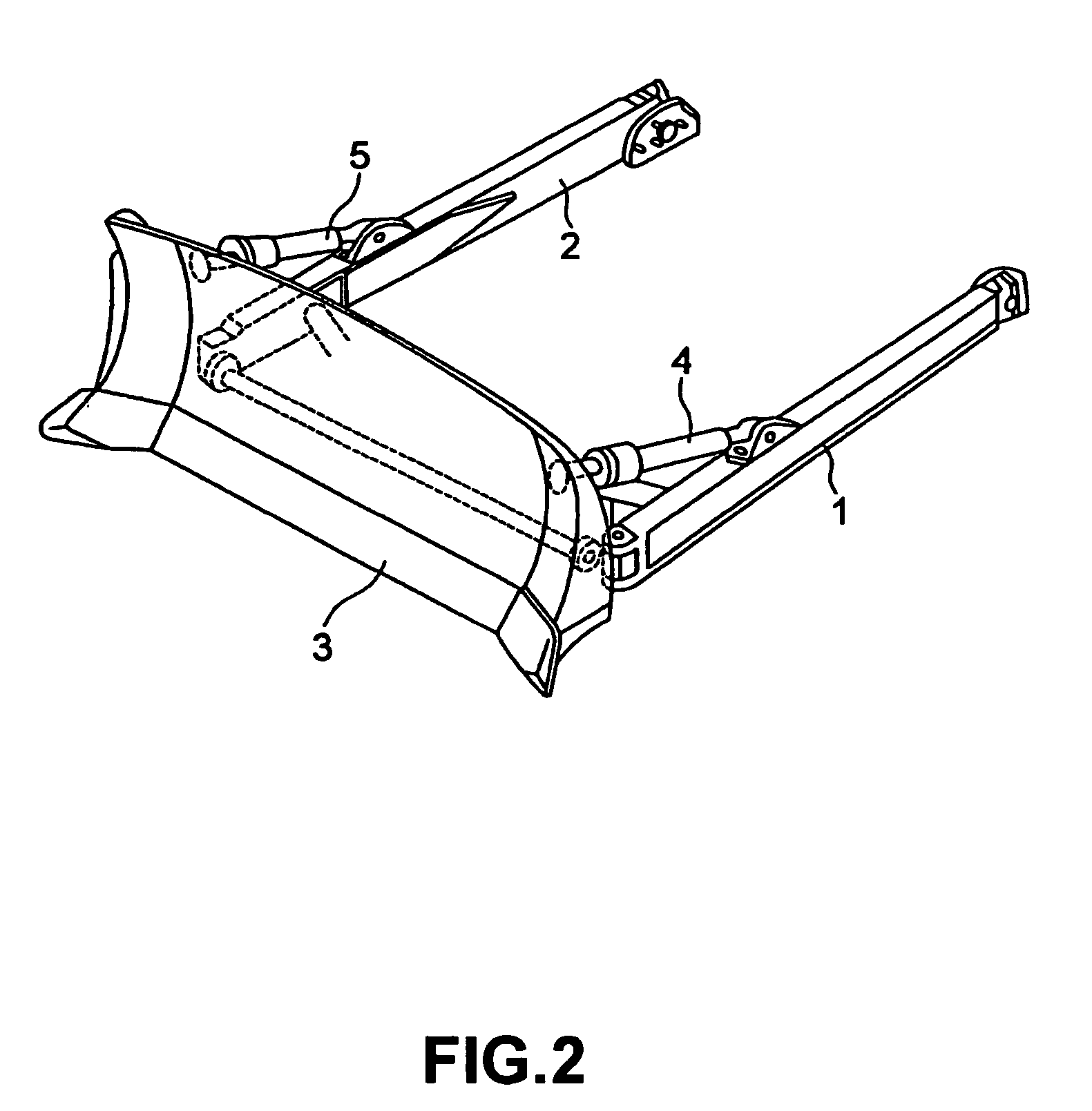

Oil-pressure controlling device for earthmoving machine

ActiveUS6945335B2Without complexityLow costServomotor componentsMechanical machines/dredgersDifferential pressureHydraulic pump

An optimal pump flow for both dual tilt operations and single tilt operations is obtained at low cost without increasing the complexity of the device constitution. Where there is a wish to implement a dual tilt operation, a switch is selectively operated and, in accordance with this selection result, the differential pressure set value decreases and a comparatively small flow is supplied from the hydraulic pump to the left and right tilt cylinders. Accordingly, the extension / retraction speed of the left and right tilt cylinders decreases. Where there is a wish to implement a single tilt operation, a switch is selectively operated and, in accordance with this selection result, the differential pressure set value increases and a comparatively large flow is supplied from the hydraulic pump to the left cylinder. Accordingly, the extension / retraction speed of the left tilt cylinder increases. In this way, the tilt operating speed of the blade in dual tilt operations is made to be the same as the tilt operating speed of the blade in single tilt operations. By virtue of this, when a changeover is implemented from a dual tilt operation to a single tilt operation (or when the reverse changeover thereto is implemented), the operating speed of the blade 3 is unaltered and the discomfort associated with the alteration of the operating speed when this changeover is implemented can be alleviated. Accordingly, the operability throughout the working of the bulldozer is markedly improved.

Owner:KOMATSU LTD

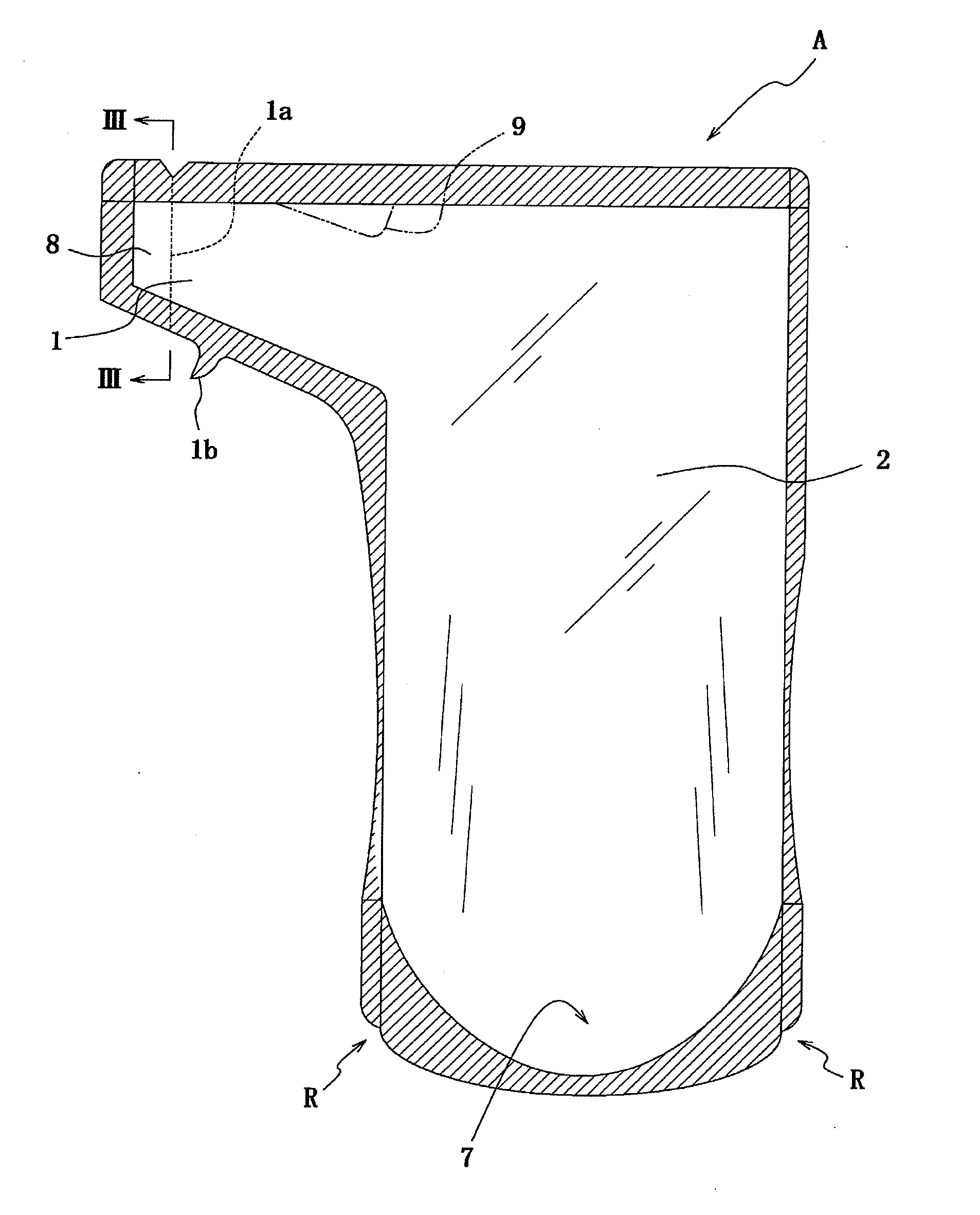

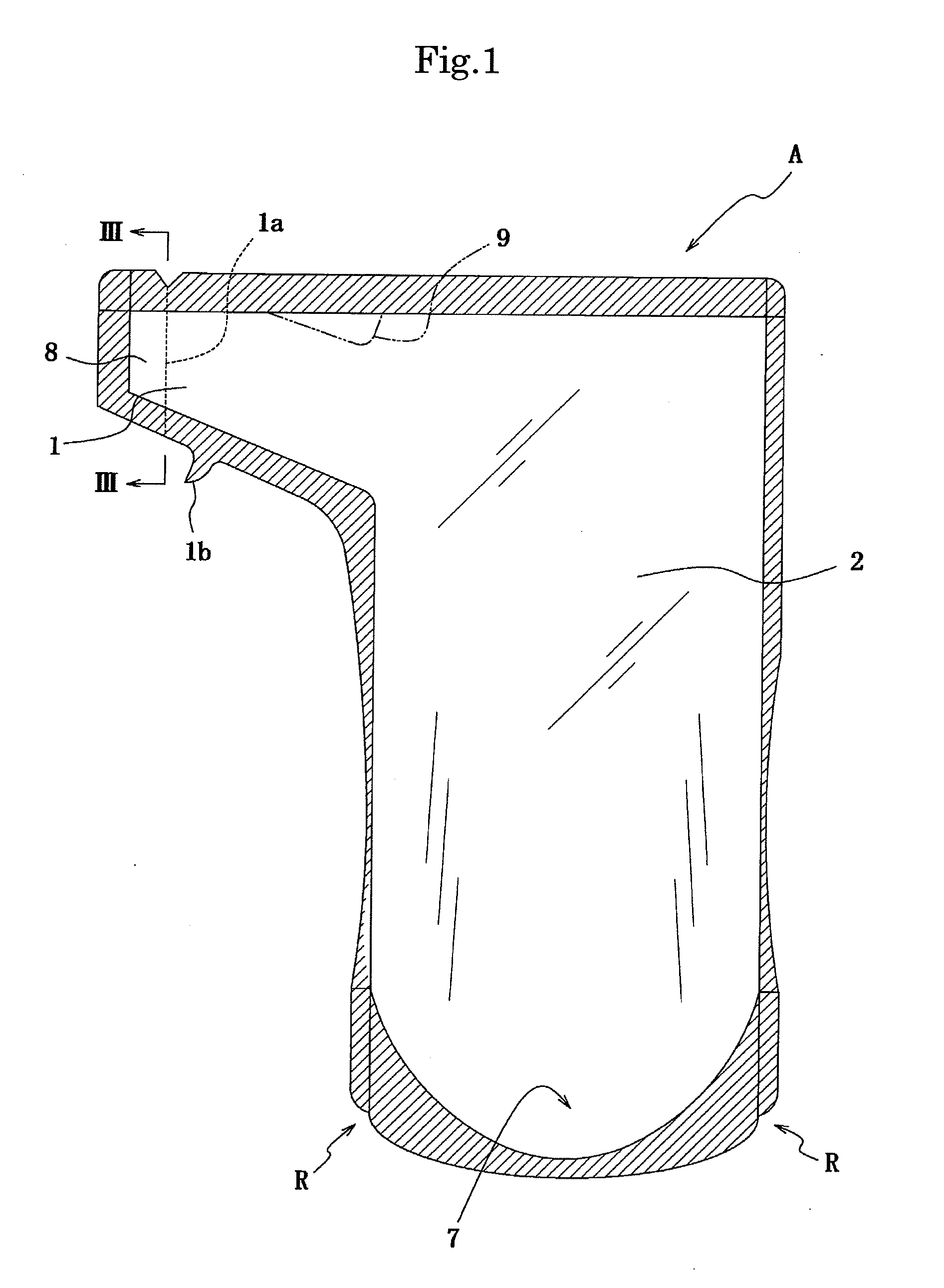

Self-standing liquid package bag with a flat film valve

A self-standing liquid package bag provided with flat film valve is provided at a single use form by self-standing a liquid package bag with a film valve having a one-way function without being required to house and fix in another outer package vessel and obstructing the one-way function of the film valve. The self-standing liquid package bag of the invention is formed by protrudingly disposing a flat film valve having a one-way function, which is subjected to a wetting treatment at full inner faces in a pouring path and a portion adjacent to a fused part near to the pouring path, on an upper part or top part of at least one side edge of a bag body portion and disposing a self-standable bottom portion at bottom thereof.

Owner:YUSHIN

Device for regaining deodoration function and air conditioner equipped with the device

InactiveCN101370579AInhibitionReduce the burden onPhysical/chemical process catalystsLighting and heating apparatusDeodorantWastewater

The invention aims at regaining the deodorization performance of a deodorant by decomposing the components of bad smells and harmful gas adsorbed on the deodorant completely in a short time with less labor without generating wastewater. A device (1) for regaining the deodorization function of a deodorant (4) on which at least one of the bad-smelling components and harmful gas components suspended in the air is adsorbed, which is provided with a casing (2) and an active species formation section (3), wherein the casing (2) can hold a deodorant and active species capable of decomposing or deactivating at least one of the bad-smelling components and harmful gas components are formed in the section (3).

Owner:DAIKIN IND LTD

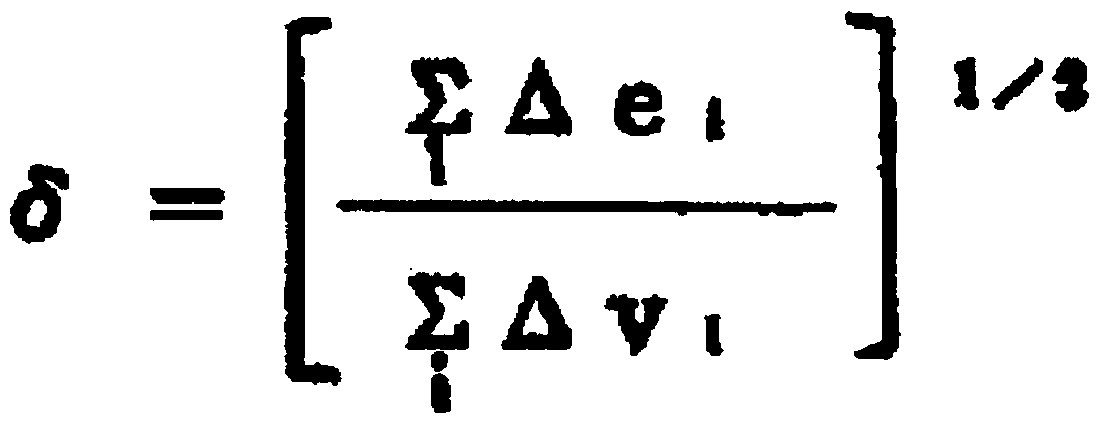

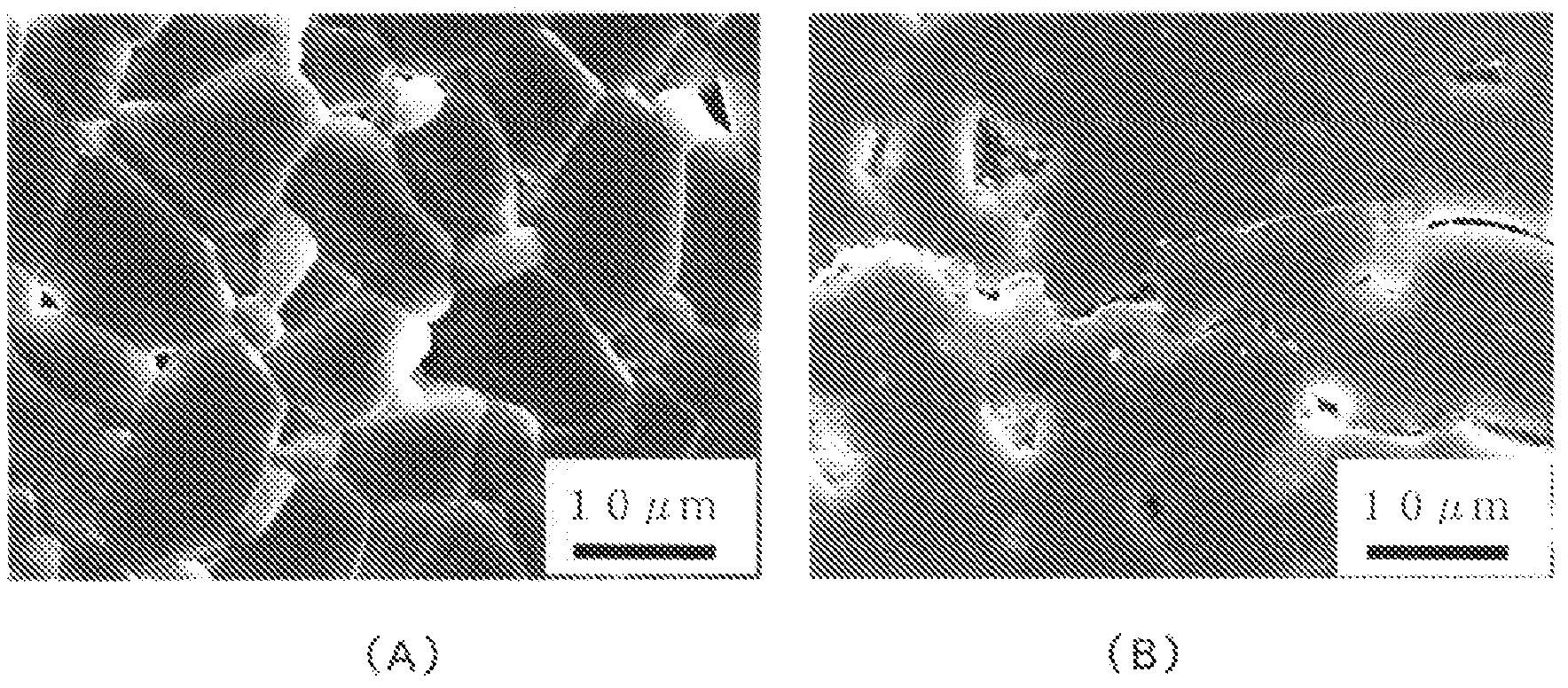

Method for producing bearing ring, bearing ring, and rolling bearing

ActiveUS20130301969A1Production cost be suppressCurb production costRoller bearingsShaftsMaterials scienceRolling-element bearing

A method for producing a bearing ring of a rolling bearing includes the steps of: preparing a formed body constituted of hypereutectoid steel; forming an annular heated region heated to a temperature of at least an A1 point on the formed body by relatively rotating an induction heating member arranged to face part of an annular region for becoming a rolling contact surface of the bearing ring in the formed body to induction-heat the formed body along the circumferential direction of the annular region; and simultaneously cooling the whole of the heated region to a temperature of not more than an Ms point.

Owner:NTN CORP

Active energy ray curable adhesive composition, polarizing film and method for producing same, optical film and image display device

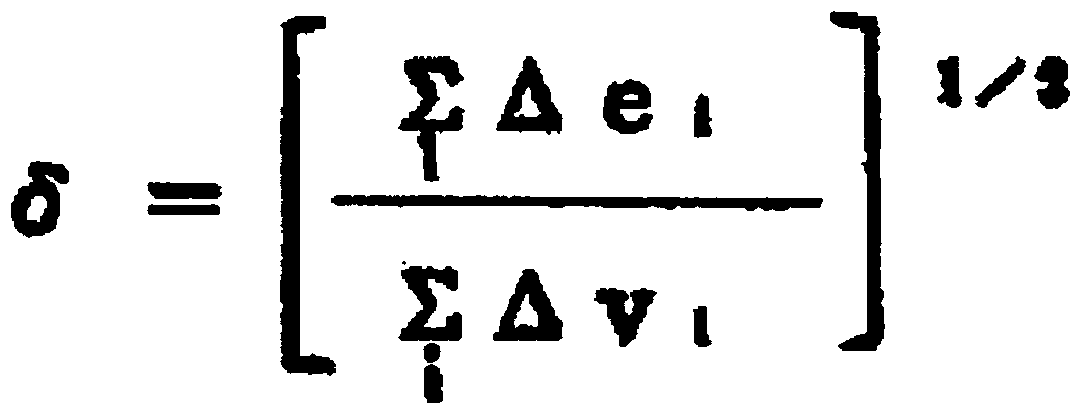

ActiveCN104395420AIncreased durabilityImprove water resistanceAdhesive processesNon-macromolecular adhesive additivesOrganic chemistryChemistry

An active energy ray curable adhesive composition comprises radical polymerizable compounds (A), (B) and (C), as curable components, the composition being characterized by containing, when the total amount of the composition is 100 weight%, the radical polymerizable compound (A) having an SP value of 29.0 (kJ / m3)1 / 2 to 32.0 (kJ / m3)1 / 2 in an amount of 1.0 to 30.0 weight%, the radical polymerizable compound (B) having an SP value of 18.0 (kJ / m3)1 / 2 or more and less than 21.0 (kJ / m3)1 / 2 in an amount of 35.0 to 98.0 weight%, and the radical polymerizable compound (C) having an SP value of 21.0 (kJ / m3)1 / 2 to 23.0 (kJ / m3)1 / 2 in an amount of 1.0 to 30.0 weight%.

Owner:NITTO DENKO CORP

Method for producing alumina sintered body, alumina sintered body, abrasive grains, and grindstone

ActiveCN103189331AHigh hardnessImprove fracture toughnessMaterial nanotechnologyOther chemical processesTitaniumGrinding wheel

The present invention is a method for producing an alumina sintered body that satisfies (1) and (2) below, which is characterized by mixing and sintering ilmenite powder and alumina powder, and an alumina sintered body, abrasive grains and a grindstone obtained by said production method. (1) The total amount of the content of a titanium compound converted to TiO2, the content of an iron compound converted to Fe2O3 and the content of alumina is not less than 98 mass %. (2) The total amount of the content of the titanium compound converted to TiO2 and the content of the iron compound converted to Fe2O3 is 5 to 13 mass %.

Owner:RESONAC CORP

Active energy ray curable adhesive composition, polarizing film and method for producing same, optical film and image display device

ActiveCN104395419AIncreased durabilityImprove water resistanceAdhesive processesNon-macromolecular adhesive additivesOligomerAcrylic monomers

An active energy ray curable adhesive composition comprising a radical polymerizable compound (A) having an SP value of 29.0 (kJ / m3)1 / 2 to 32.0 (kJ / m3)1 / 2, a radical polymerizable compound (B) having an SP value of 18.0 (kJ / m3)1 / 2 or more and less than 21.0 (kJ / m3)1 / 2, and a radical polymerizable compound (C) having an SP value of 21.0 (kJ / m3)1 / 2 to 23.0 (kJ / m3)1 / 2, as curable components, and an acrylic oligomer (D) obtained by polymerizing a (meth)acrylic monomer, wherein when the total amount of the composition is 100 weight%, the radical polymerizable compound (B) is contained in an amount of 25 to 80 weight%.

Owner:NITTO DENKO CORP

Rotor for brushless motor and brushless motor

InactiveCN1684340ACurb production costAvoid idlingMagnetic circuit rotating partsMechanical energy handlingBrushless motorsMagnetic poles

Owner:ICHINOMIYA ELECTRIC

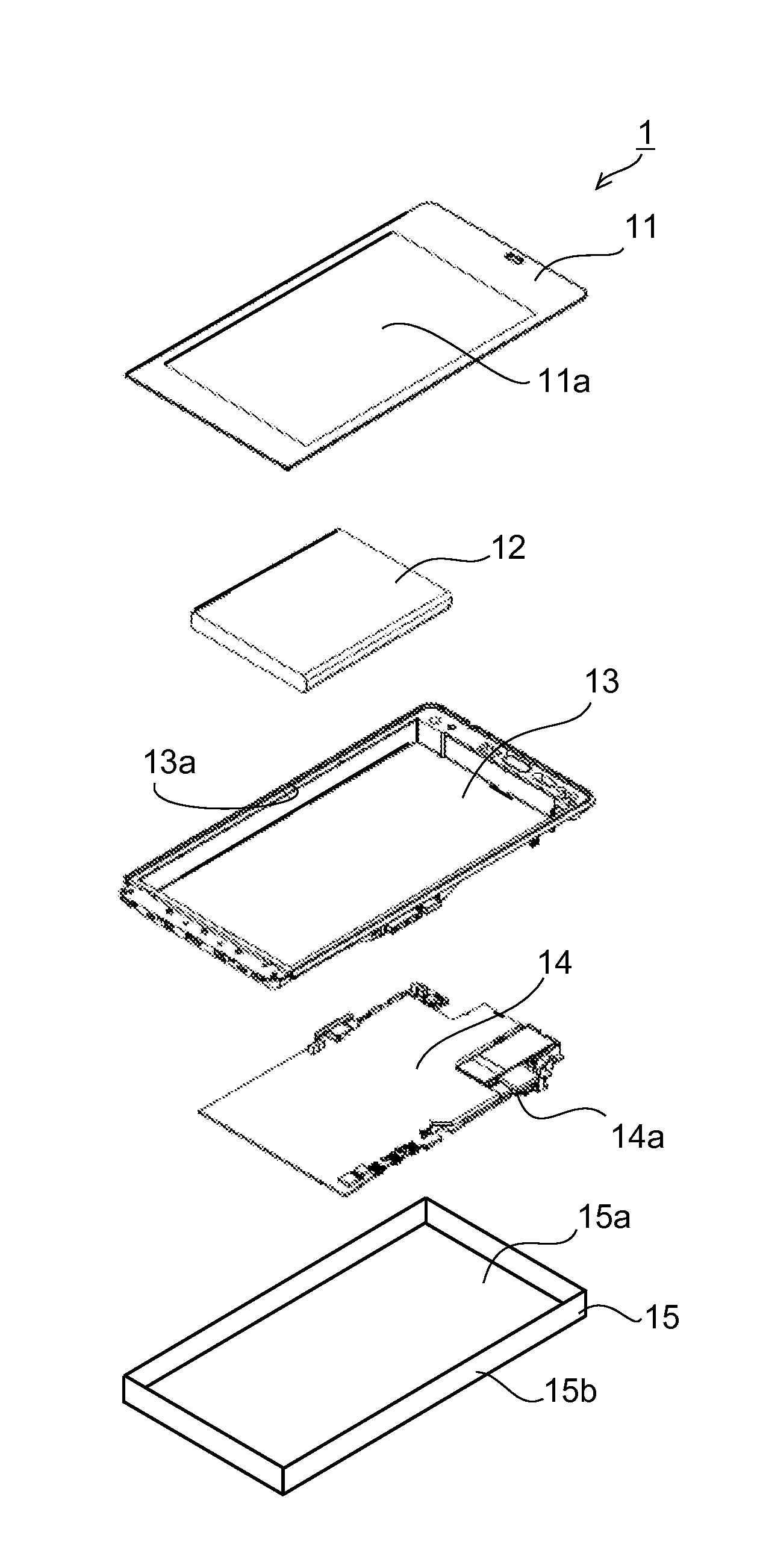

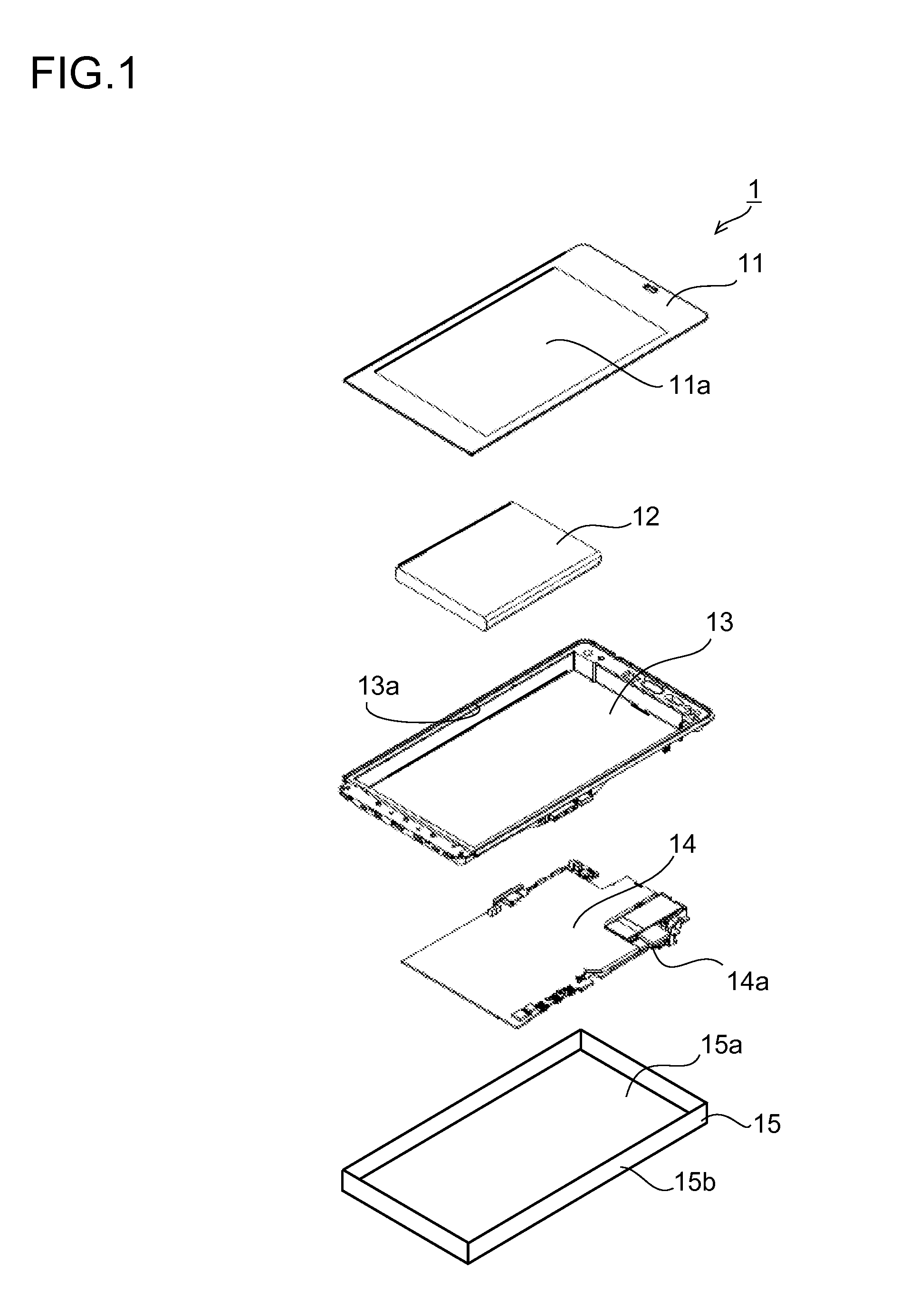

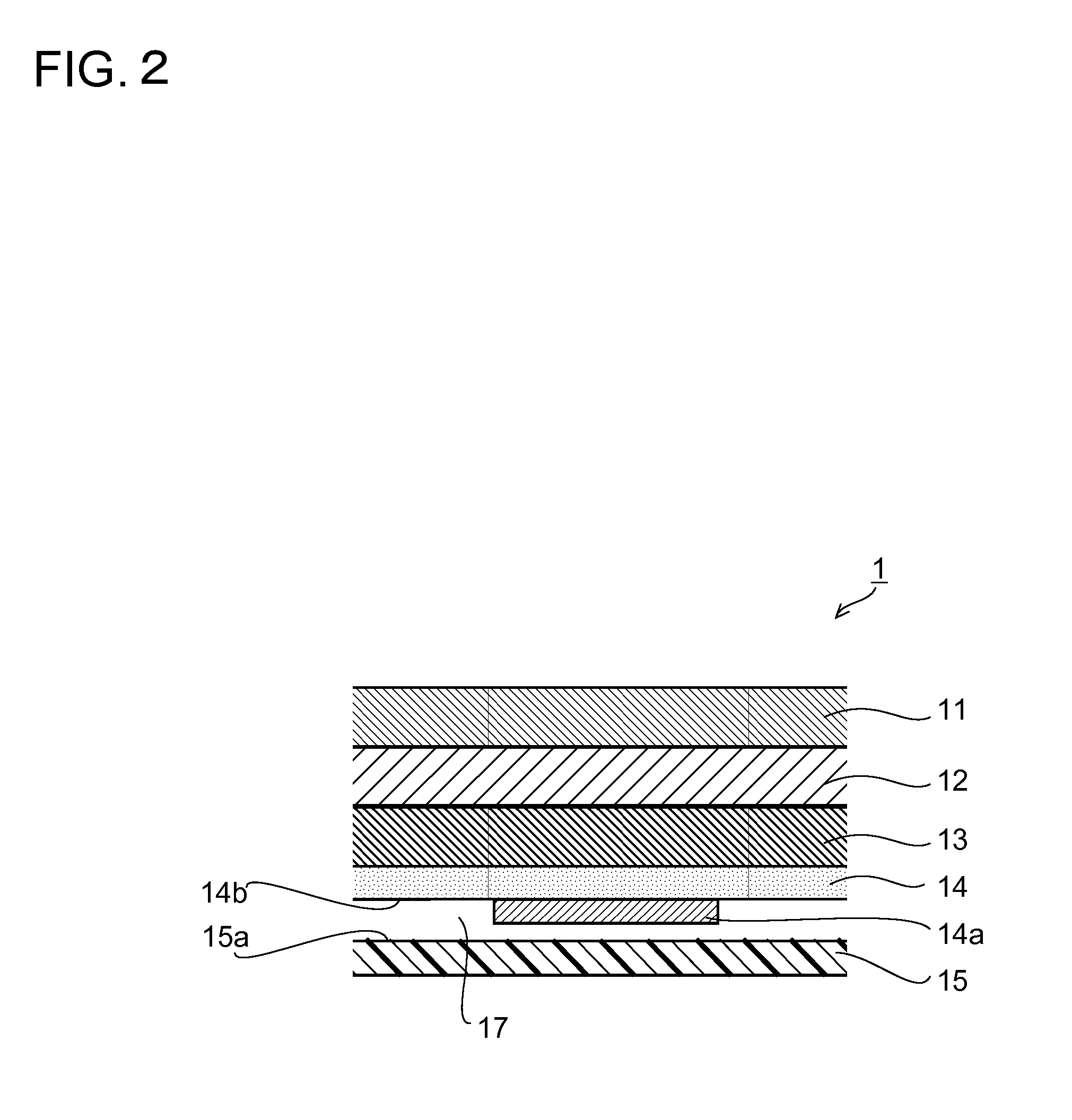

Portable terminal

ActiveUS20150173247A1Large heat capacityEffective radiationDigital data processing detailsPrinted circuit board receptaclesRechargeable cellEngineering

This portable terminal has disposed therein: a circuit board (14), which is disposed in a cabinet (15), and which has an electronic component (14a) mounted thereon; a display panel (11) disposed on the open plane of the cabinet (15); and a rechargeable battery (12) disposed between the display panel (11) and the circuit board (14).

Owner:SHARP KK

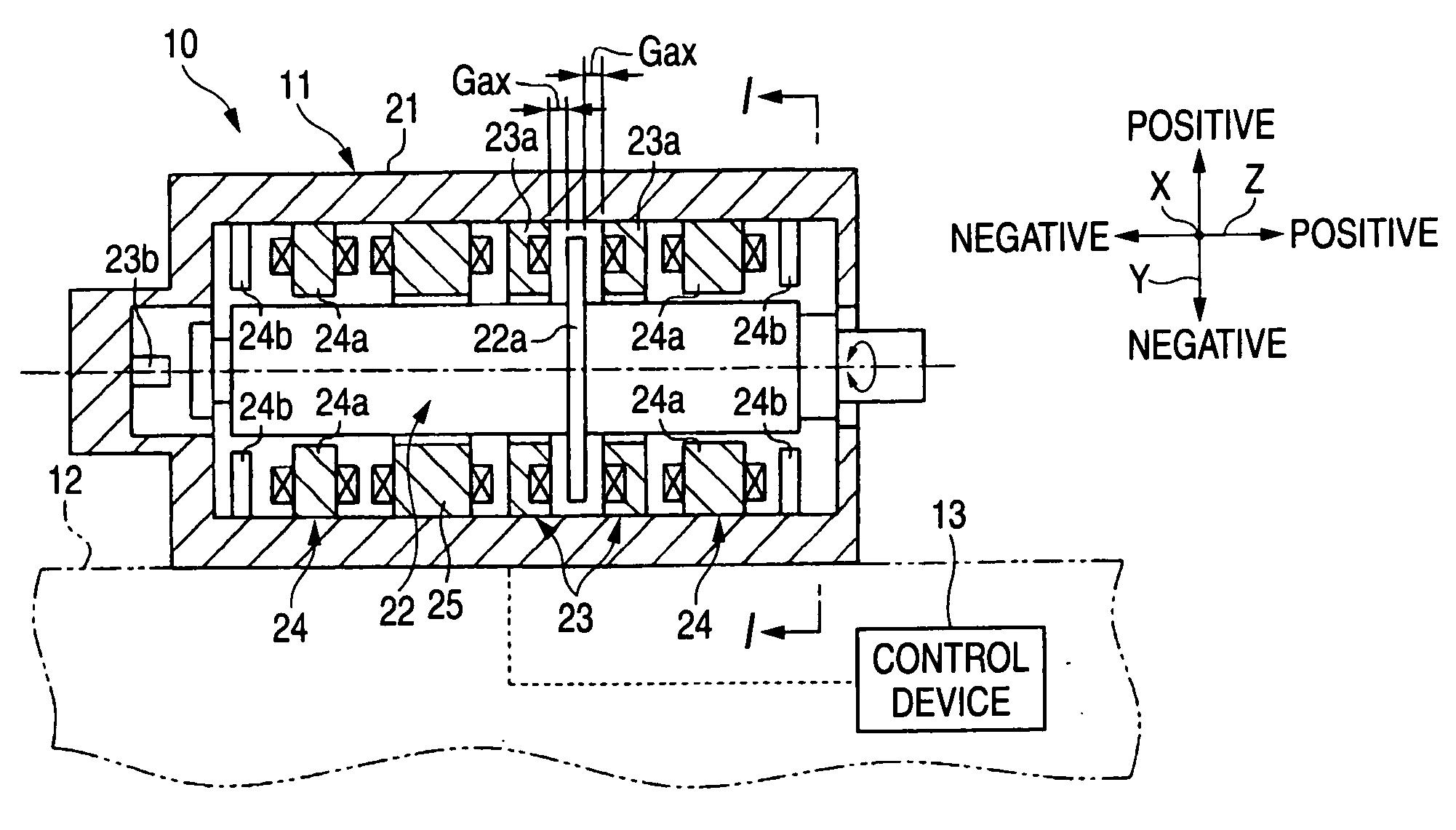

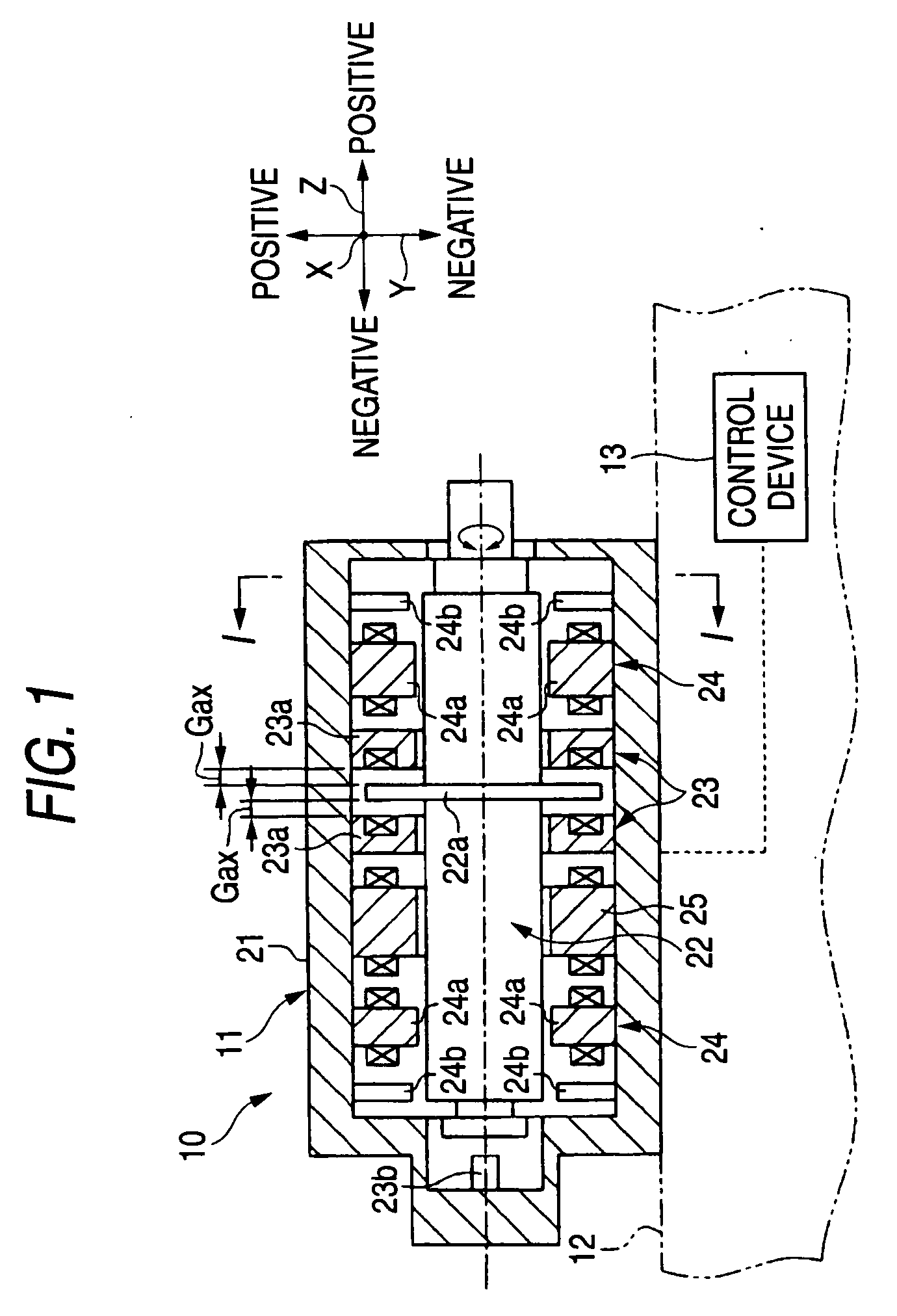

Magnetic bearing device and magnetic bearing spindle device

InactiveUS20080252161A1Production cost be reduceSimple calculationShaftsLarge fixed membersNon linearityMagnetic bearing

A control device includes a differential amplifying circuit for obtaining a difference between values of exciting currents (exciting voltage values) supplied to a pair of axial electromagnets and a pair of radial electromagnets, multiplying the obtained difference by coefficient times, and outputting it as the bearing load in an axial direction and a radial direction. The exciting current includes steady current supplied to the axial electromagnets and the radial electromagnets and control current which varies by the displacement of a main shaft. By supplying the steady current to the axial electromagnets and the radial electromagnets, the magnetic attraction force of the axial electromagnets and the radial electromagnets having non-linearity is linearly approximated. Accordingly, the difference between the values of the exciting currents (exciting voltages) supplied to a pair of electromagnets is obtained and is multiplied by coefficient times, thereby obtaining a value corresponding to the bearing load.

Owner:JTEKT CORP

Power transmission belt and method of producing the same

A power transmission belt low in cost and preventing work precision from being lowered and life expectancy of a metal press working mold from being decreased and a method of producing such a power transmission belt are provided. The power transmission belt includes endless band-like rings, and a plurality of elements bonded into an annular shape by the endless band-like rings. Each of the elements has both side end surface portions pressed between pulleys in the belt width direction, a rocking edge portion serving as a fulcrum when rocked in the state that the elements are partly wound around the pulleys, and a concave-convex portion engageable in concave-convex engagement with the concave-convex portions of a pair of neighboring elements. Each of the elements is formed with a curved inclination surface between the rocking edge portion and the concave-convex portion to have an inclination angle reduced toward the concave-convex portion.

Owner:TOYOTA JIDOSHA KK

Thermal head and thermal printer using the same

InactiveUS20080225104A1Curb production costEasy to implementPrintingEngineeringElectrical and Electronics engineering

A thermal head has a heat storage layer provided on an insulating substrate and a heat generating resistance layer provided on the heat storage layer. An individual electrode and a common electrode are formed on the heat generating resistance layer, and a protective film layer covers the electrodes and the heat generating resistance layer. A resin covering layer is formed on the surface of the protective film layer by applying and drying fluorine-based resin particles dissolved in a solvent on the surface.

Owner:SEIKO INSTR INC

Wafer level lens, production method of wafer level lens, and imaging unit

ActiveUS20140246566A1Big pCurb production costSolid-state devicesMaterial analysis by optical meansResistOptical axis

A sufficient light-shielding property is obtained by a wafer level lens having at least one lens module having a substrate and a plurality of lenses formed on the substrate in which the wafer level lens has a black resist layer formed on the surface of the lens module or on the surface of the substrate and the black resist layer is formed with a pattern having an opening at a part intersecting the optical axis of the lens, and generation of defects such as ghosts, flares and the like due to a reflected light can be prevented and an increase in the production cost can be suppressed.

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com