Rotor for brushless motor and brushless motor

一种无刷电机、转子的技术,应用在带有静止电枢和旋转磁体的同步电动机、电动组件、电气元件等方向,能够解决研磨工序复杂、制造成本增加等问题,达到防止空转和飞散、防止飞散的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments according to the present invention will be described in detail below with reference to the accompanying drawings.

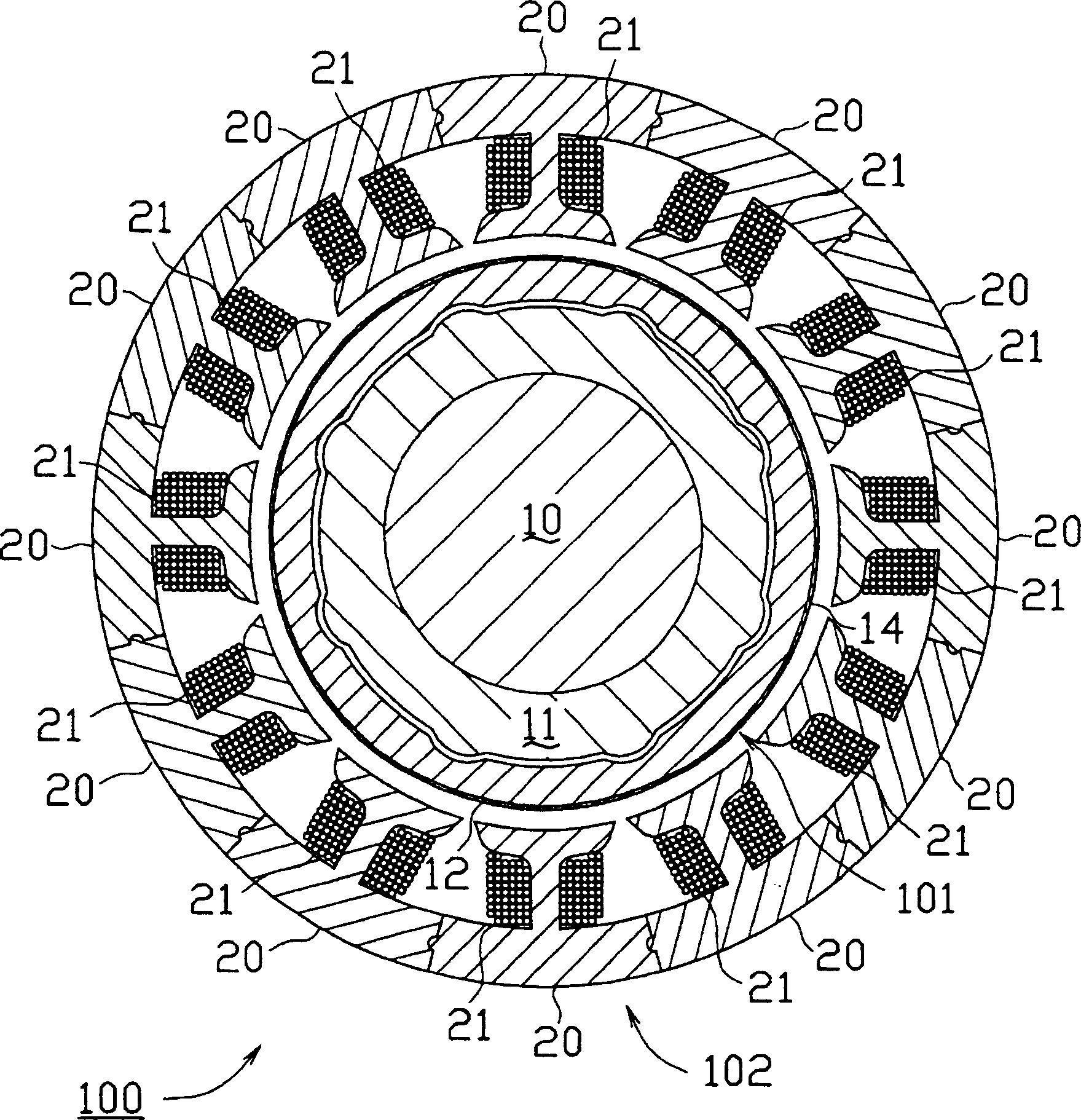

[0024] The brushless motor 100 according to an embodiment of the present invention is an inner rotor type motor having an inner rotor and an outer stator structure. Such as figure 1 As shown in , the inner rotor is composed of a rotor (rotor for a brushless motor) 101, and the outer stator is composed of a stator 102, in which a predetermined number of magnetic cores 20 divided into each tooth are ring-connected together. In the example this number is 12 and a coil 21 is wound on each tooth. The rotor 101 is rotatably provided by forming a fixed gap in the stator 102 .

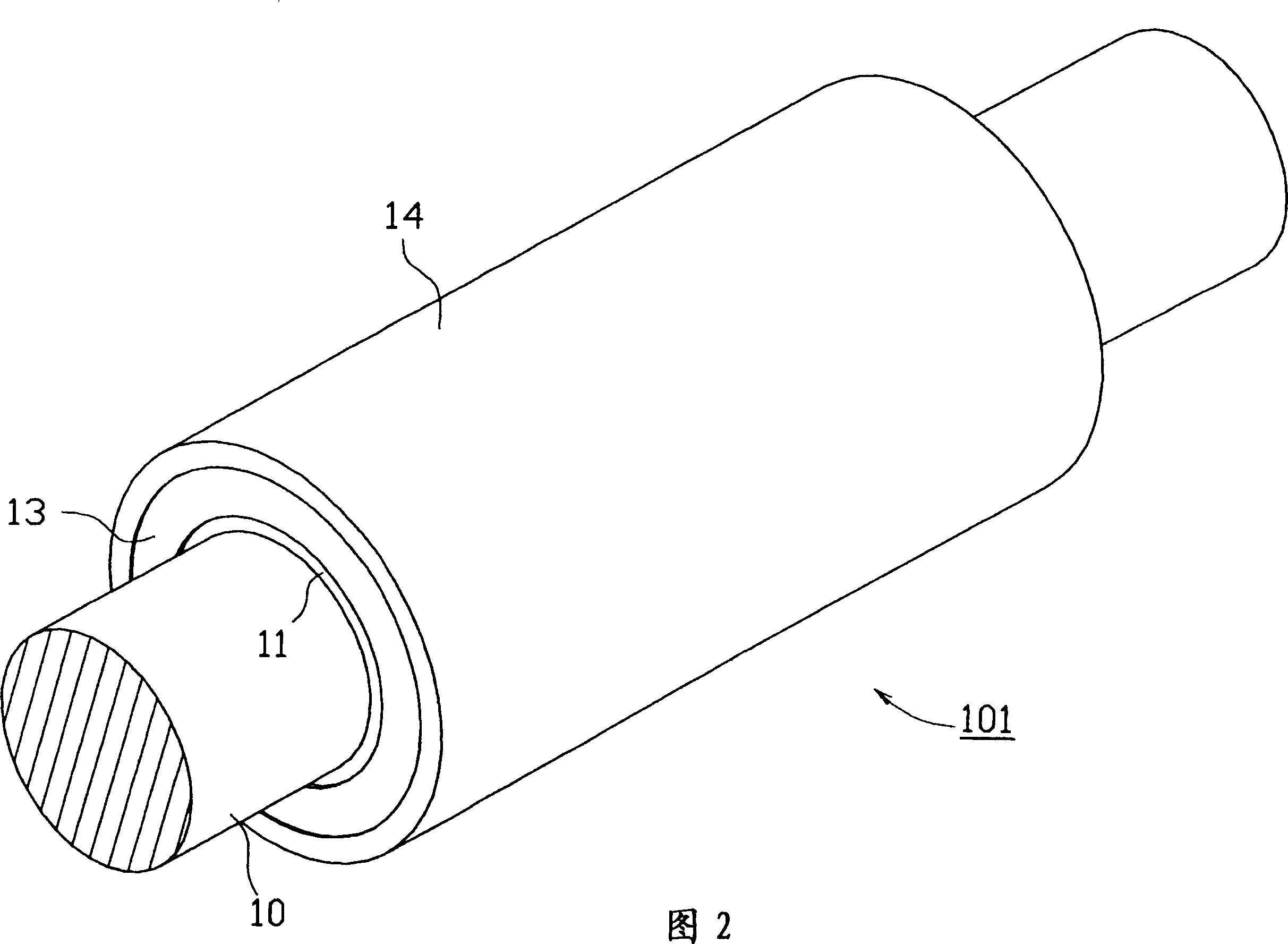

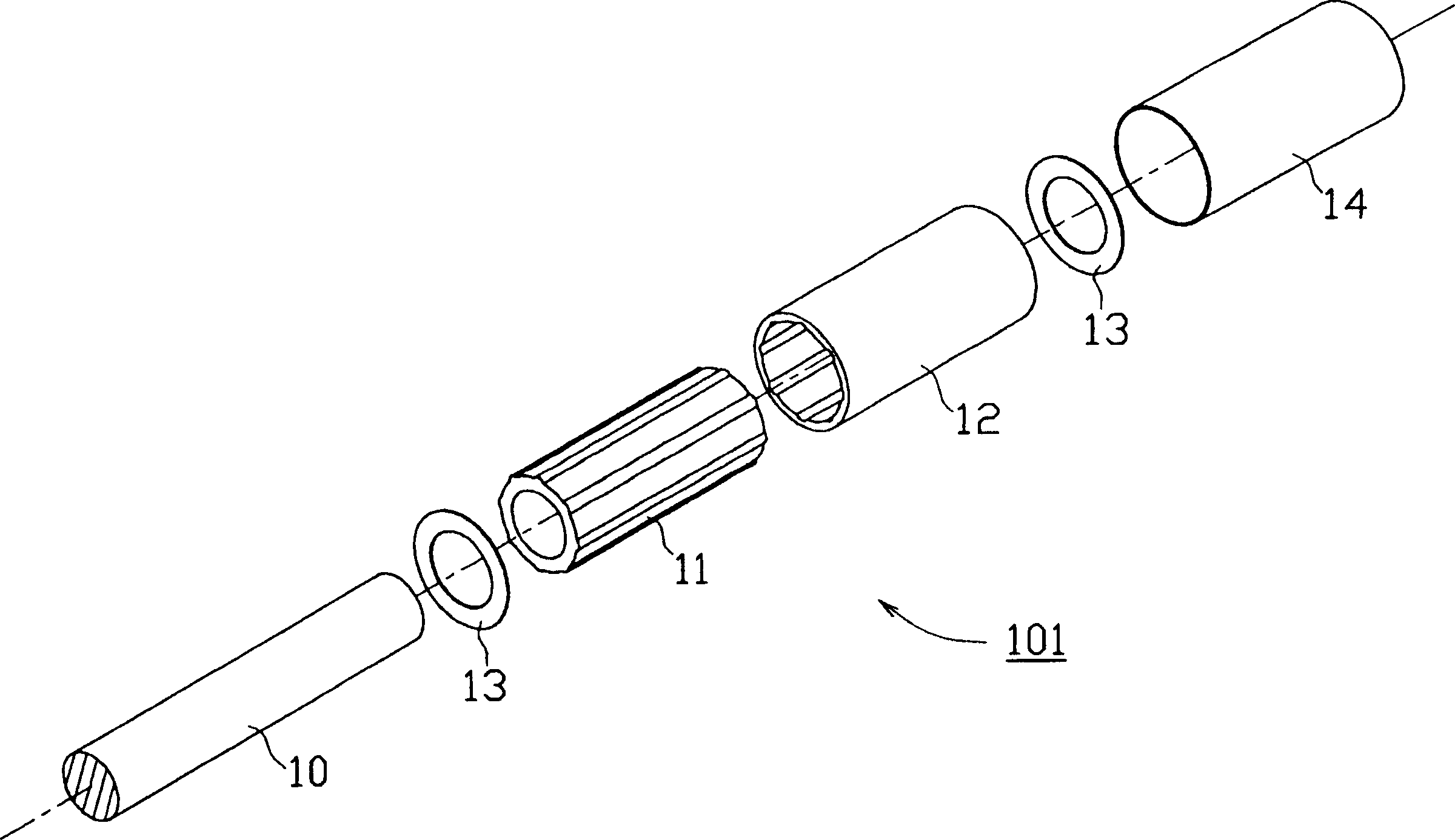

[0025] As shown in FIGS. 2 and 3, the rotor 101 has a shaft 10 forming the shaft of the motor, a rotor yoke 11 provided concentrically on the shaft 10, a sintered ring magnet 12 provided on the outer periphery of the rotor yoke 11, a A protective plate 13 covering two axial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com