Powdered fat composition for creams

A technology of oil composition and powder oil, which is applied in the direction of cream substitutes, cream preparations, edible oil/fat, etc., can solve the problems that the mouth melting and shape retention of whipped cream cannot be improved, and achieve the balance of flavor Good, excellent taste, sufficient shape retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] (a) Preparation Step I of Grease Composition

[0058] The oil and fat composition prepared in the step (a) contains the above-mentioned XXX type triglycerides (one or more types) and X2Y type triglycerides (one or more types) in the above mass %. Specifically, for example, XXX-type triglycerides (one or more types) having a fatty acid residue X having a carbon number x at positions 1 to 3, and triglycerides having a carbon number y at positions 1 to 3 are respectively obtained. YYY-type triglycerides (one or more types) of fatty acid residue Y are mixed at a mass ratio of XXX-type triglycerides / YYY-type triglycerides at 90 / 10 to 99 / 1 to obtain a reaction substrate ( Here, the aforementioned carbon number x is an integer selected from 8 to 20, the aforementioned carbon number y is an integer selected from x+2 to x+12, and y≤22), after heating the aforementioned reaction substrate, in the catalyst In the presence of transesterification reaction process obtained.

[0059...

Embodiment 1

[0111]

[0112] According to the formulation in the following Table 1, the cream creams of Example 1 and Comparative Example 1 were manufactured according to a conventional method. More specifically, the powdered oil and fat composition of the present invention was added to shortening and mixed lightly, and then, Merupia base was added and mixed well (specific gravity 0.5). Further add other materials that have been put together in advance and mix well to adjust the specific gravity to 0.6.

[0113] [Table 1]

[0114]

[0115]

[0116] The creams of Example 1 and Comparative Example 1 manufactured above were evaluated in accordance with the following evaluation methods.

[0117]

[0118] (1) Evaluation method for melting in the mouth

[0119] Based on the following criteria, five skilled panelists comprehensively evaluated. In addition, after manufacture, it ate and evaluated after storing at 20 degreeC for 1 day.

[0120] ○: Good melting in the mouth, no residual...

Embodiment 2

[0150]

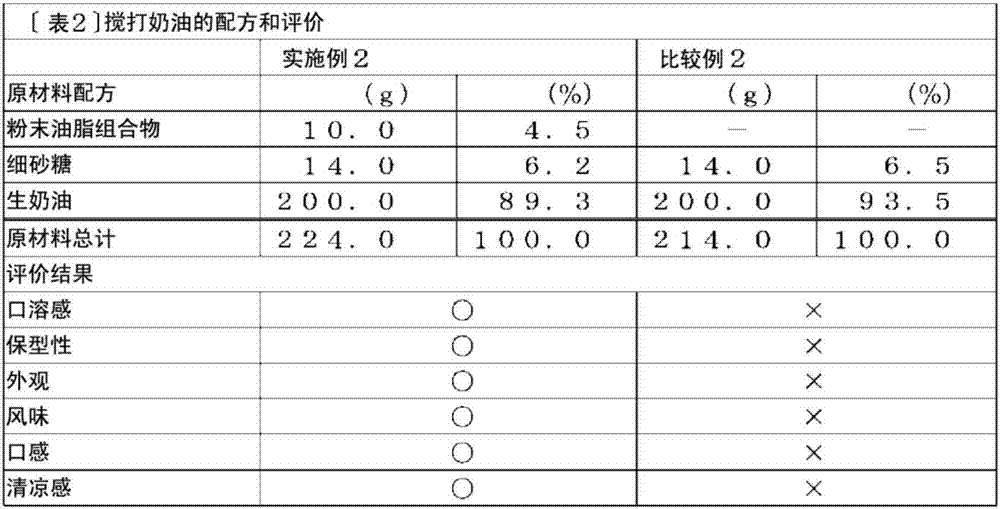

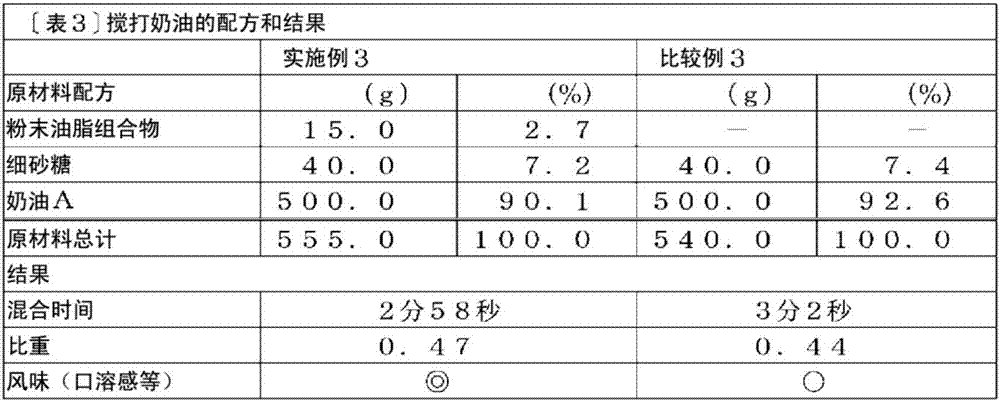

[0151] According to the formulation of following Table 2, the whipped cream of Example 2 and the comparative example 2 were manufactured according to the conventional method. More specifically, granulated sugar was blended with the powdery fat composition of the present invention, whipped cream was added thereto, and the specific gravity was adjusted to 0.4 by mixing well while contacting ice water. In addition, in the comparative example 2, the said powder oil-fat composition was not used.

[0152] [Table 2]

[0153]

[0154]

[0155] About the whipped cream of Example 2 and the comparative example 2 manufactured above, it evaluated according to the evaluation method of the said creams.

[0156] As can be seen from the results in Table 2, the whipped cream (Example 2) produced using the powdered fat composition of the present invention had a good melt-in-the-mouth feeling, sufficient shape retention, and excellent appearance, flavor, and texture. On the othe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com