Patents

Literature

218 results about "Whipped cream" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Whipped cream powder, preparation method and application

ActiveCN103039631AHigh foaming rateImprove plasticityEdible oils/fats production/working-upSodium CaseinateAnticaking agent

The invention relates to a preparation method of whipped cream powder. The method comprises the following steps that (1) vegetable fat and an emulsifying agent are mixed uniformly to form mixed liquid 5; white granulated sugar, sodium caseinate, whey protein and milk powder are mixed with water to form mixed liquid 1; the mixed liquid 1 is mixed with glucose syrup to form mixed liquid 3; a water retention stabilizer and a thickener are mixed with the water to form mixed liquid 2; the mixed liquid 2 is mixed with the mixed liquid 3 to form mixed liquid 4; the mixed liquid 5 is mixed with the mixed liquid 4 to form oil-water mixed pulp; the oil-water mixed pulp is stirred, sheared and emulsified to form uniform light-milk yellow pulp; (2) the pulps obtained in Step (1) are homogenized to form homogenized pulp; and (3) the homogenized pulp is pasteurized and subjected to spray drying; an anticaking agent is added to powder obtained through the spray drying, and mixed uniformly to form the whipped cream powder. The whipped cream powder can serve as a principal raw material of preparation of decorative cakes, mousse cakes and puffs.

Owner:无锡超科食品有限公司

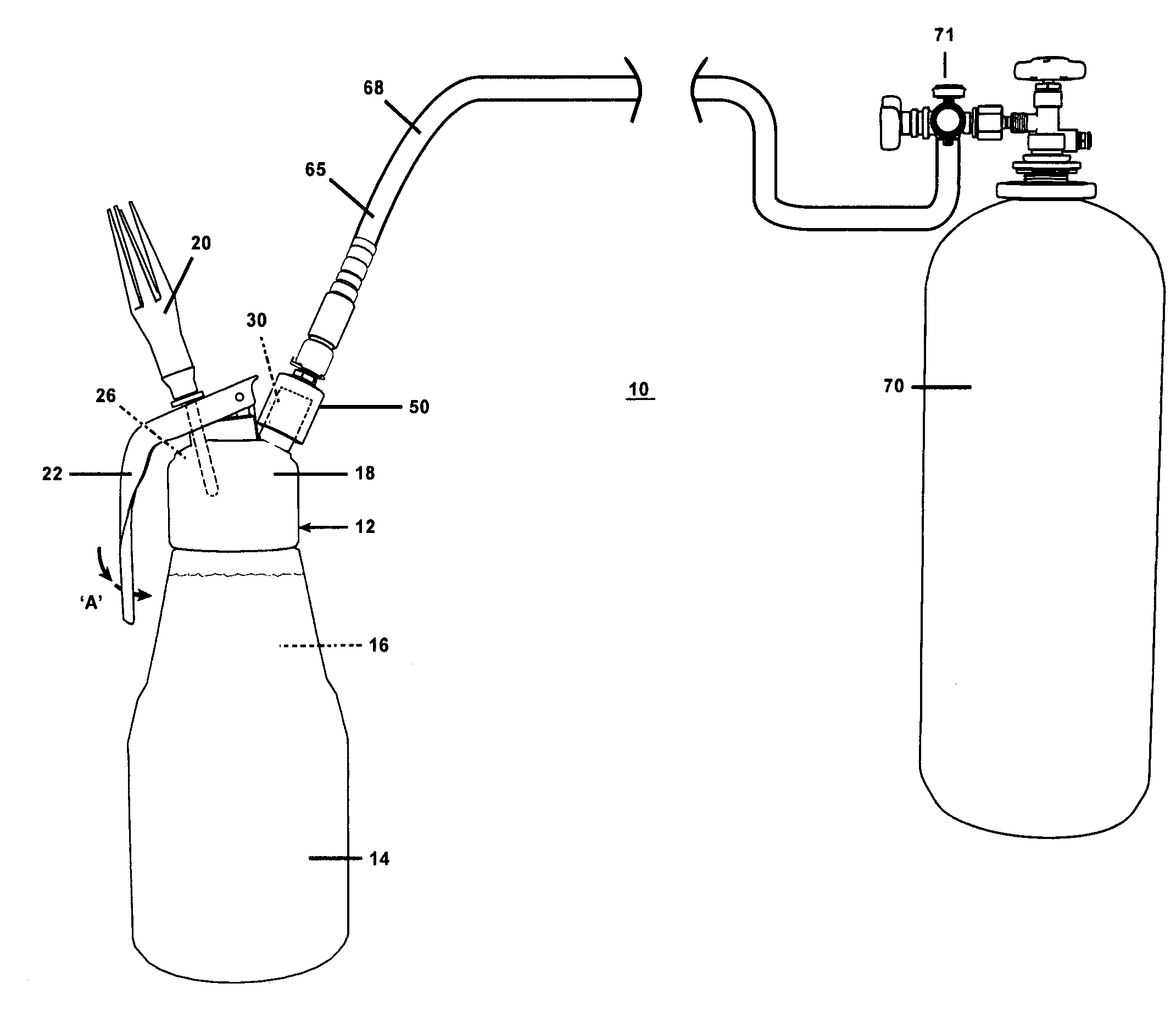

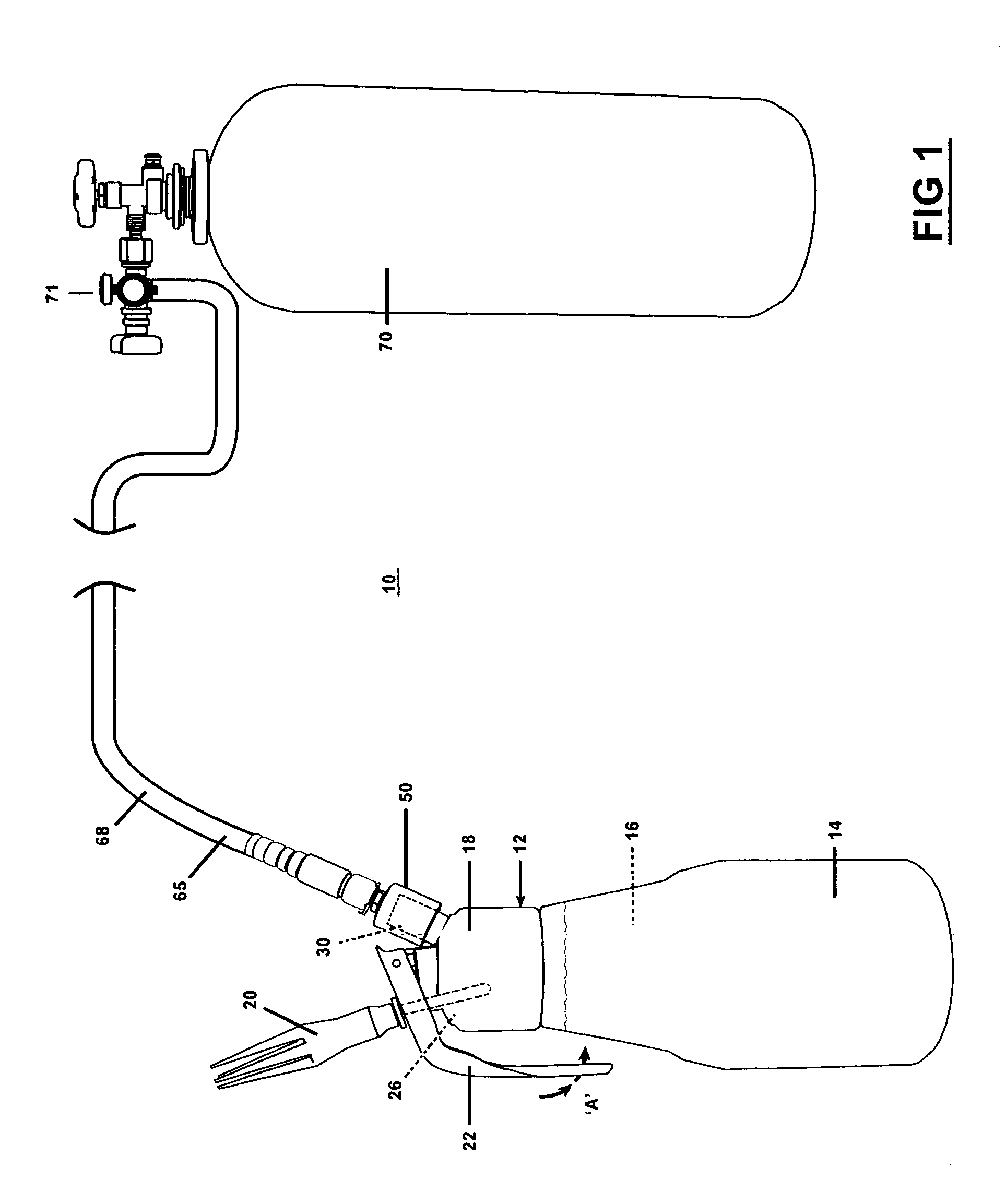

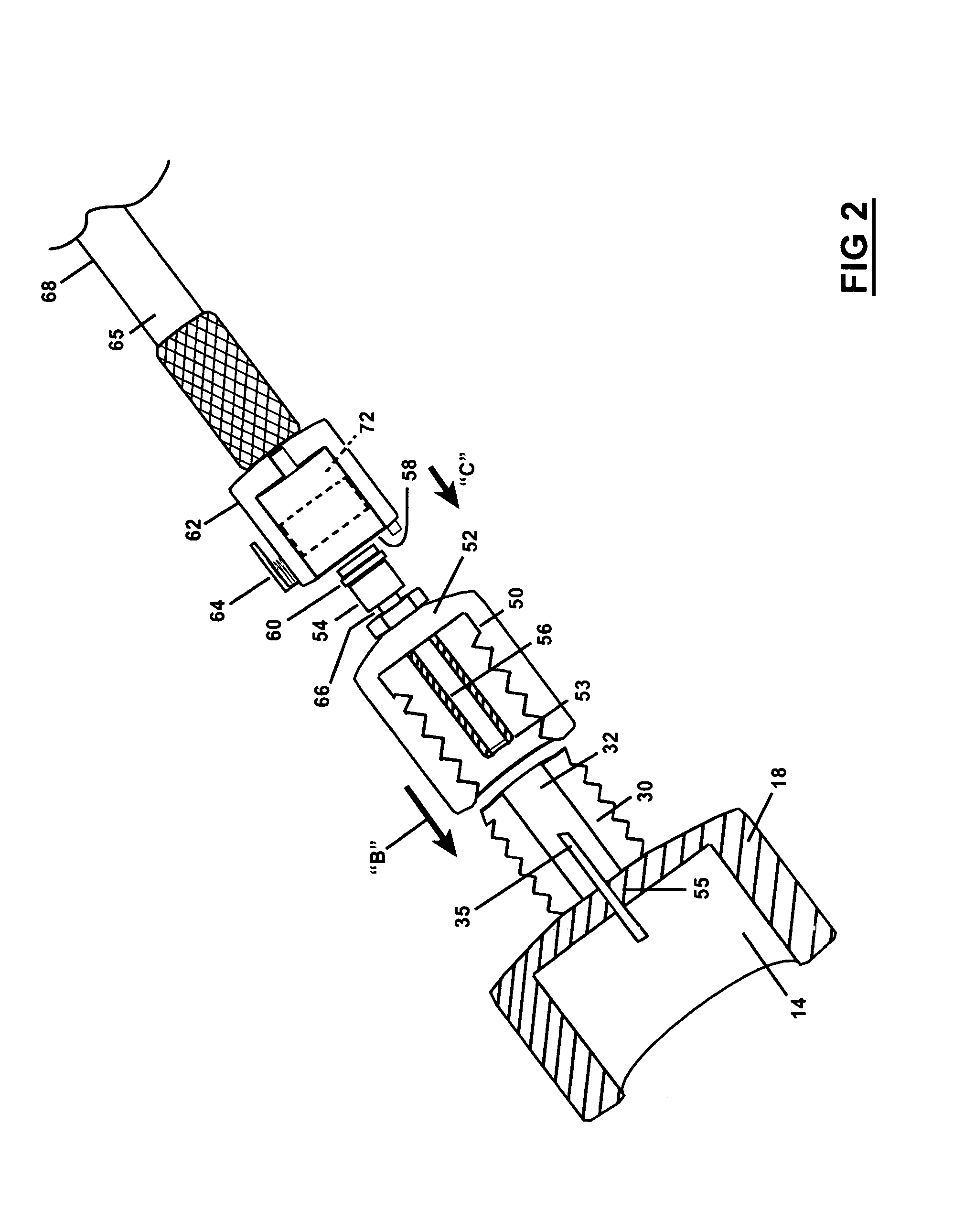

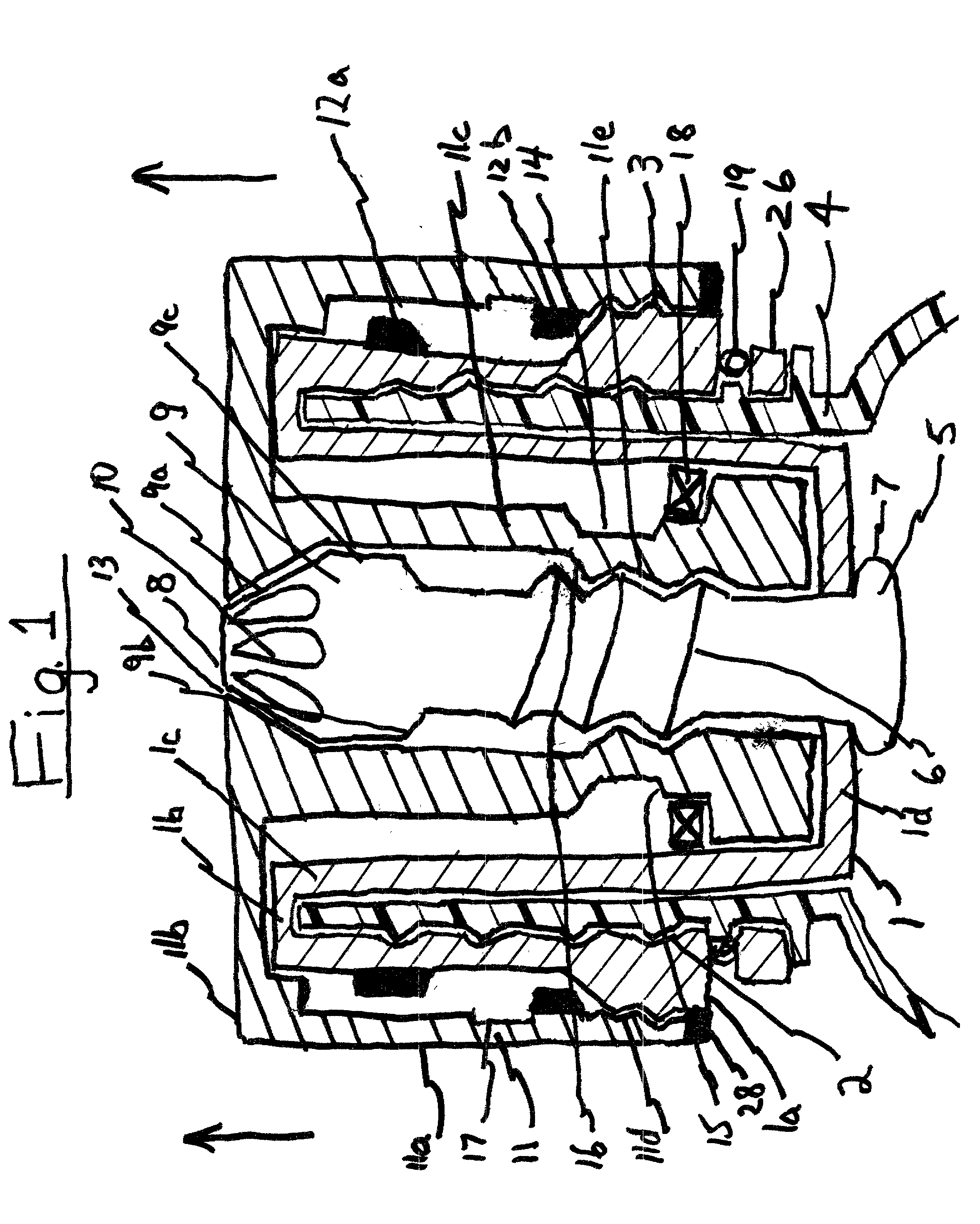

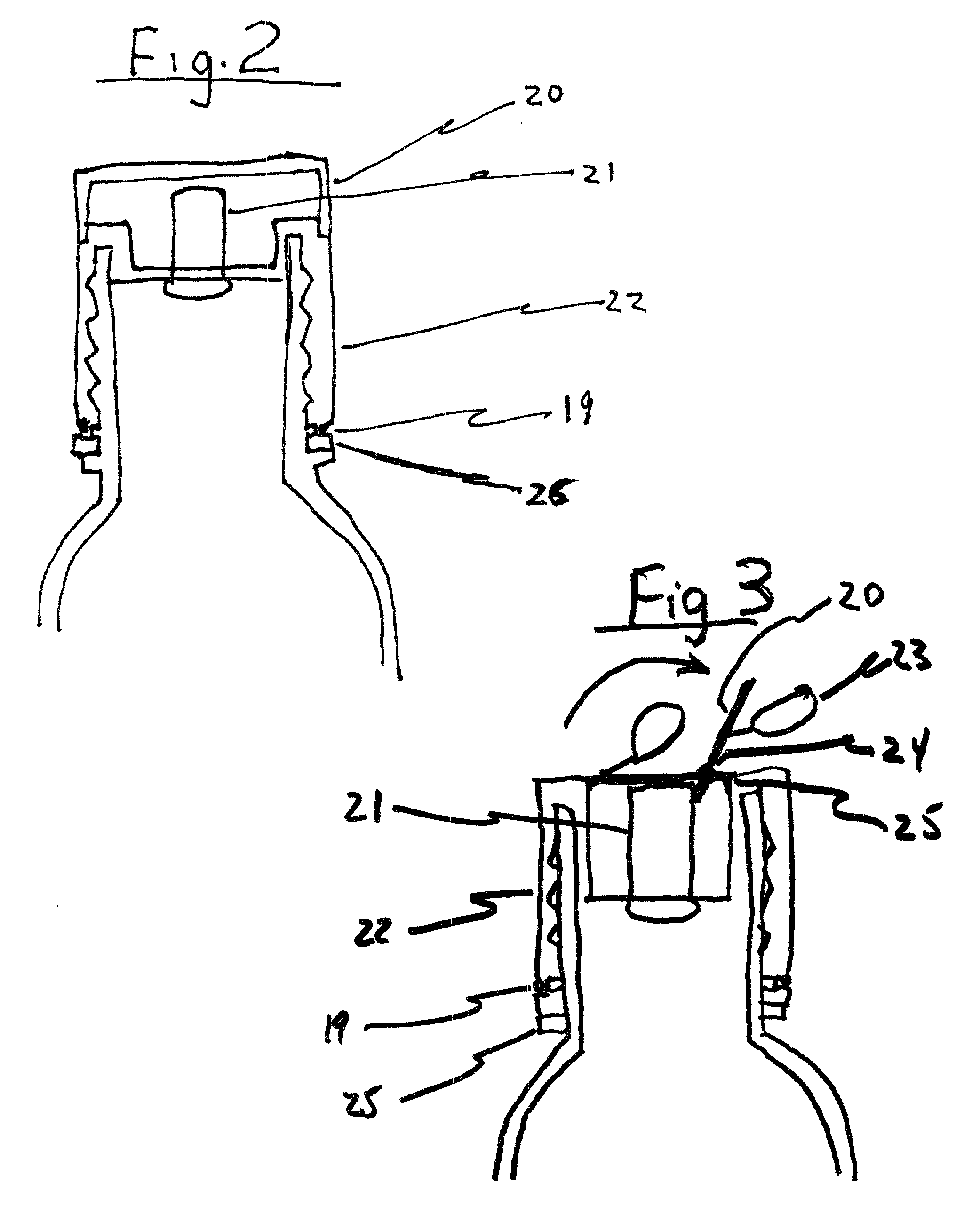

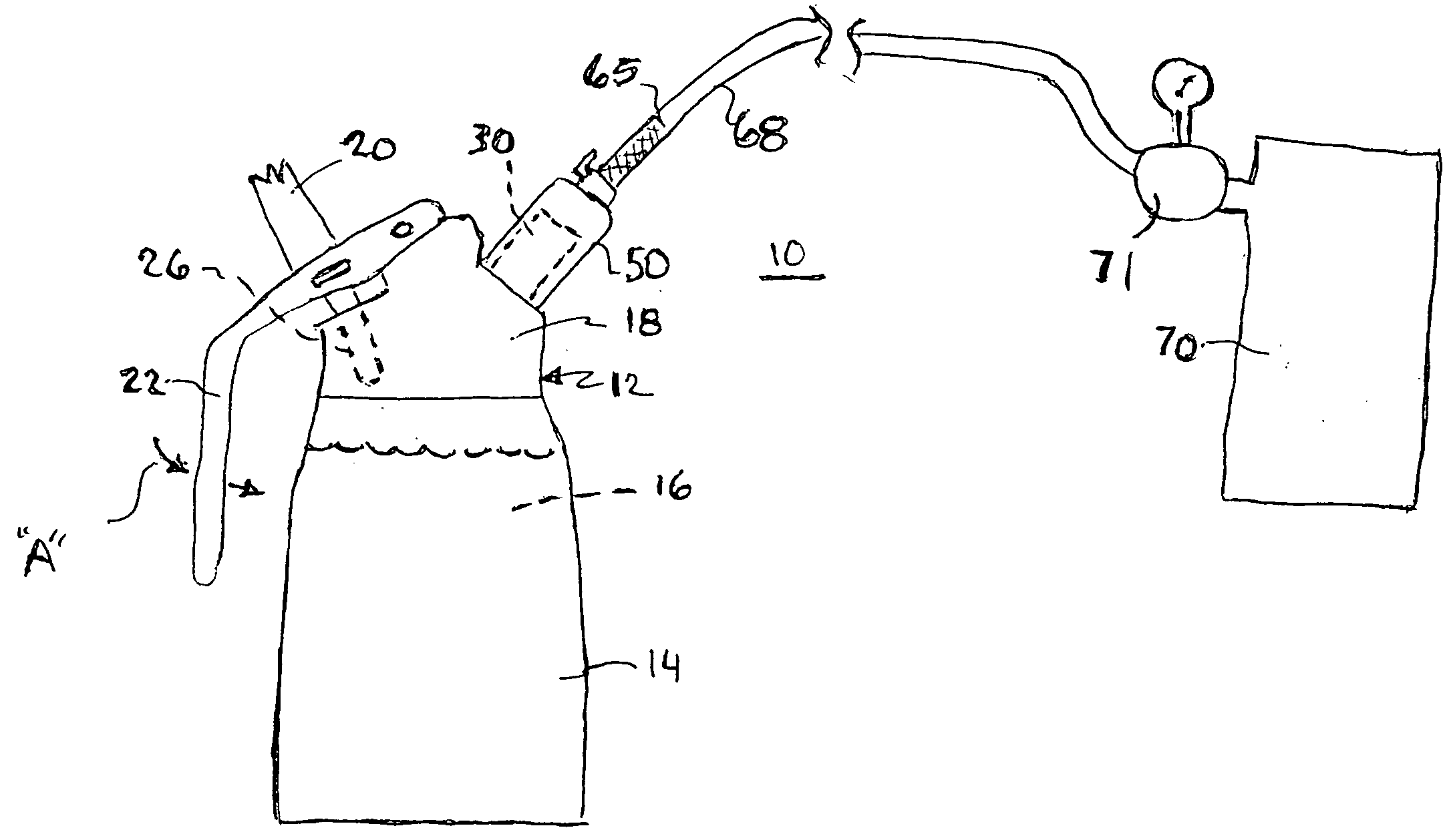

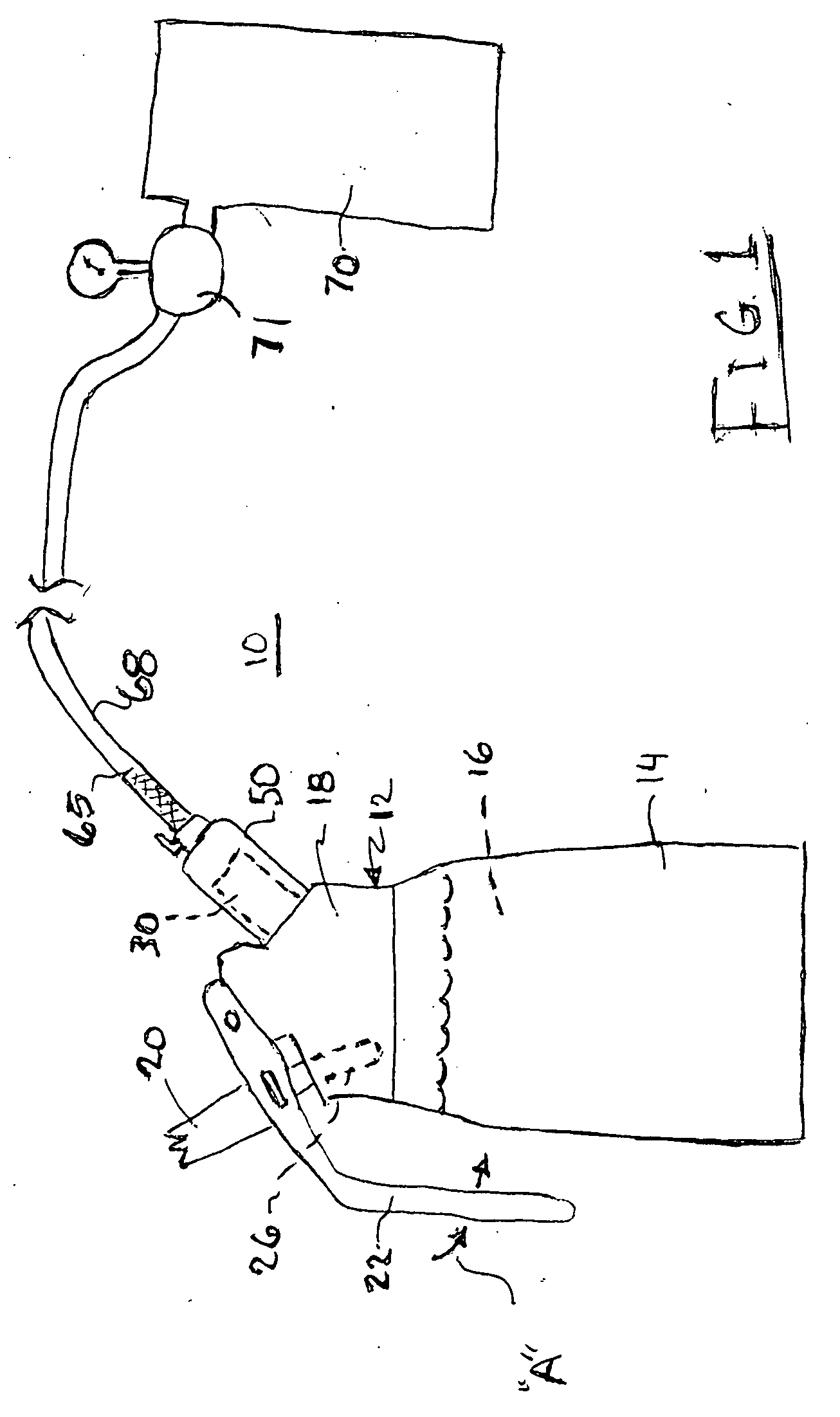

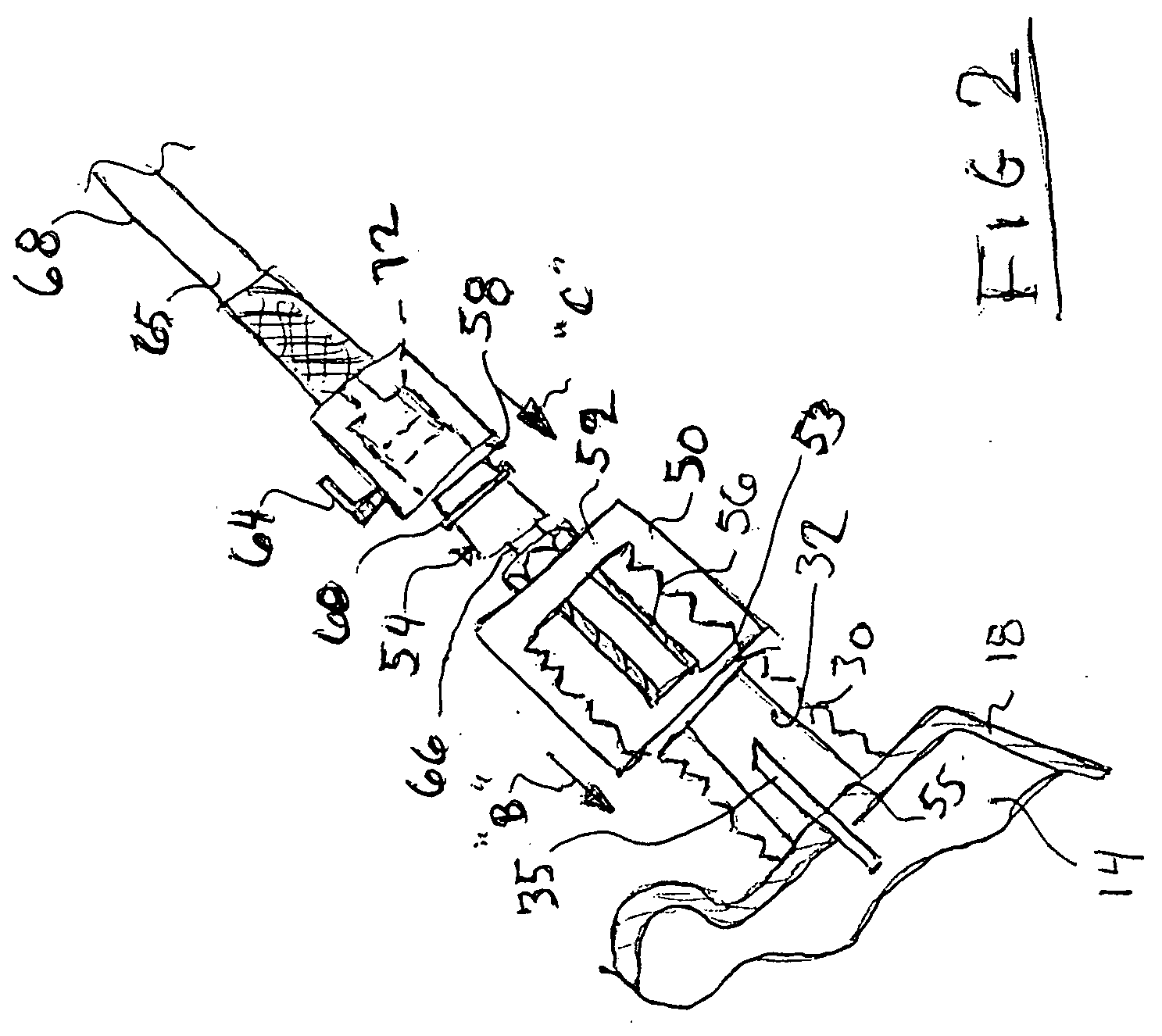

Remote pressure system for portable whipped cream dispensers

ActiveUS7100799B2Remove changeGuaranteed continuous useOpening closed containersBottle/container closurePressure systemFuel tank

A whipped cream dispenser arrangement comprising a portable, hand-held whipped cream dispenser-canister for holding a quantity of cream to be dispensed as whipped cream. The dispenser has a male fitting on the canister with a central bore there-through. The bore encloses a cartridge piercing pin therein, as part of its prior art use. A replacement adapter cap is arranged in fluid communication with a spaced-apart tank of pressurized gas, and the dispenser has a nozzle having a valve therewith for dispensing whipped cream when pressurized gas is introduced through the adapter cap from a large, spaced-apart pressurized gas tank, and into the canister.

Owner:MULDOON TOM

Bottle containment cap

This invention relates to the containment of effervescence in carbonated beverages through the use of a containment cap designed to expel only carbonated liquid and contain the gas within the bottle. The present invention uses an aerosol valve assembly similar to those used to dispense whipped cream from cans.

Owner:SEKENDUR ORAL FATIH

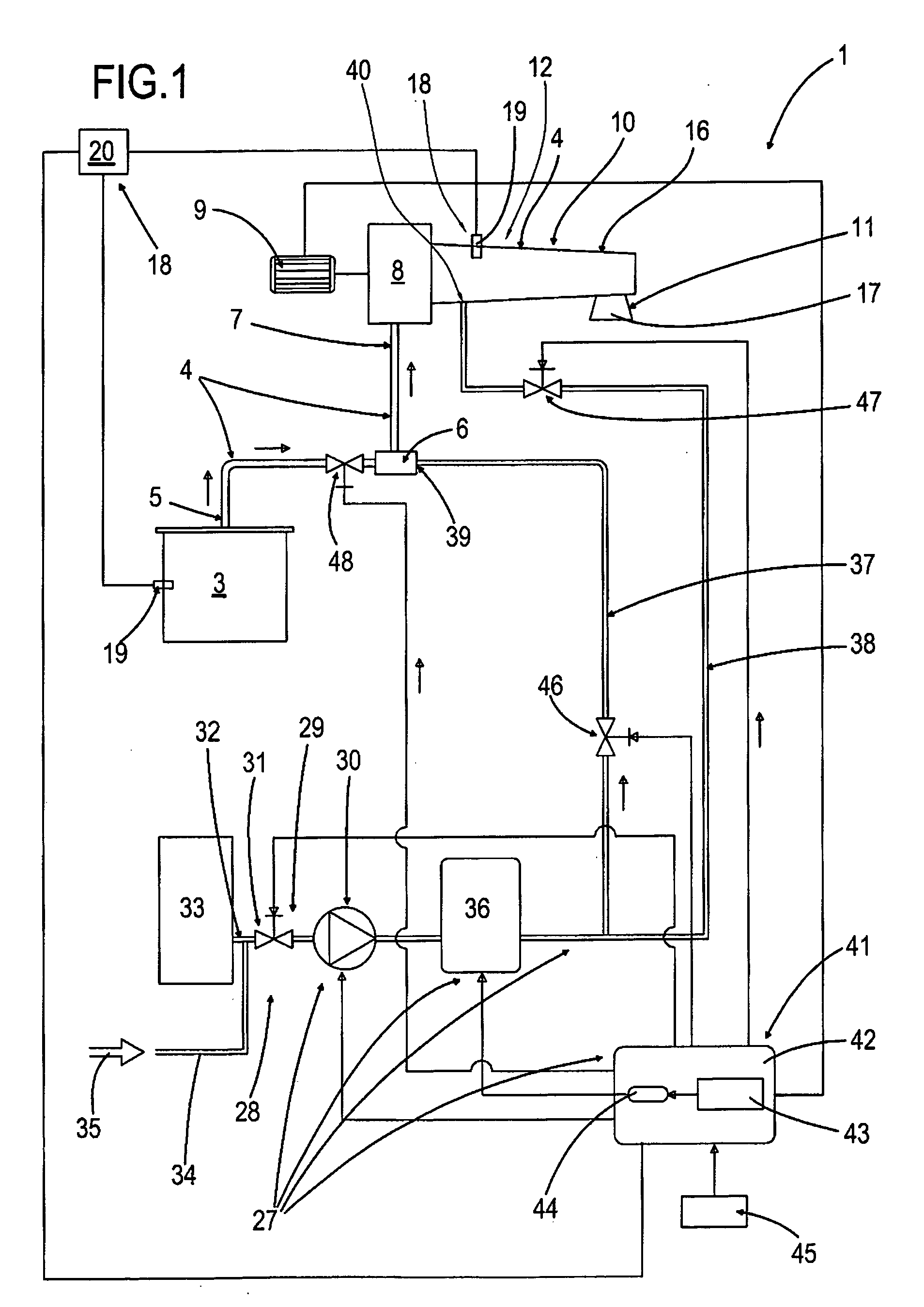

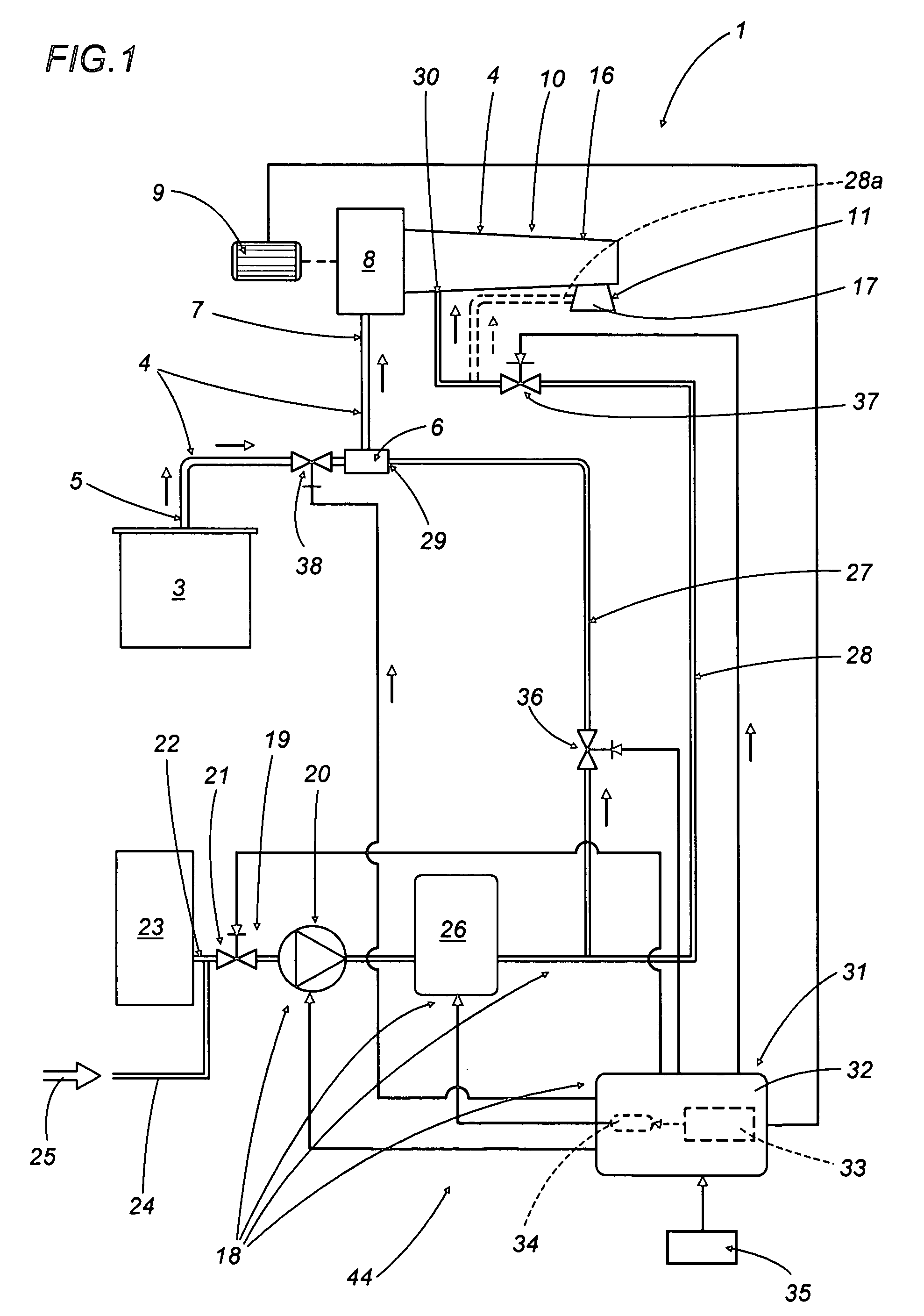

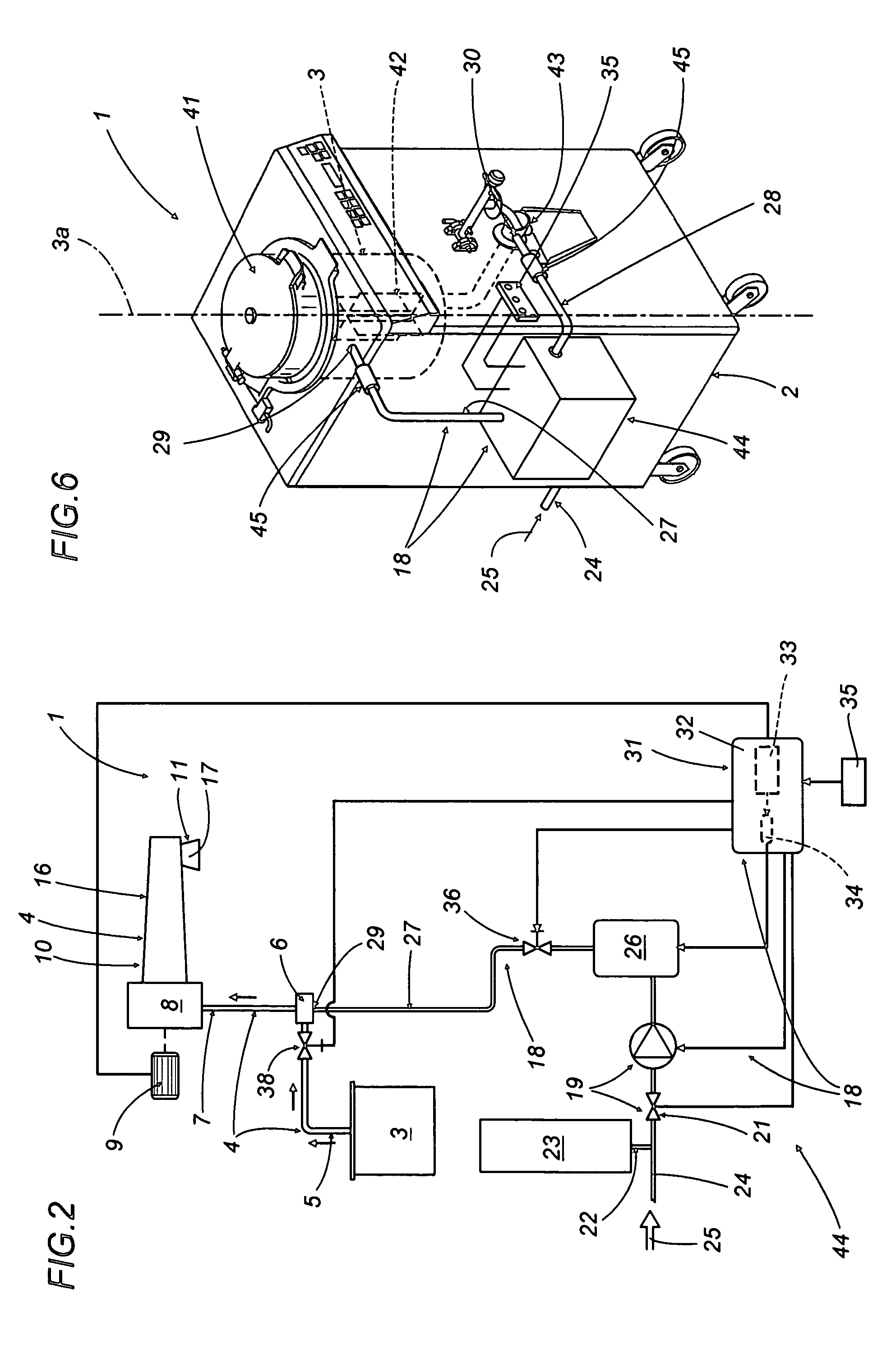

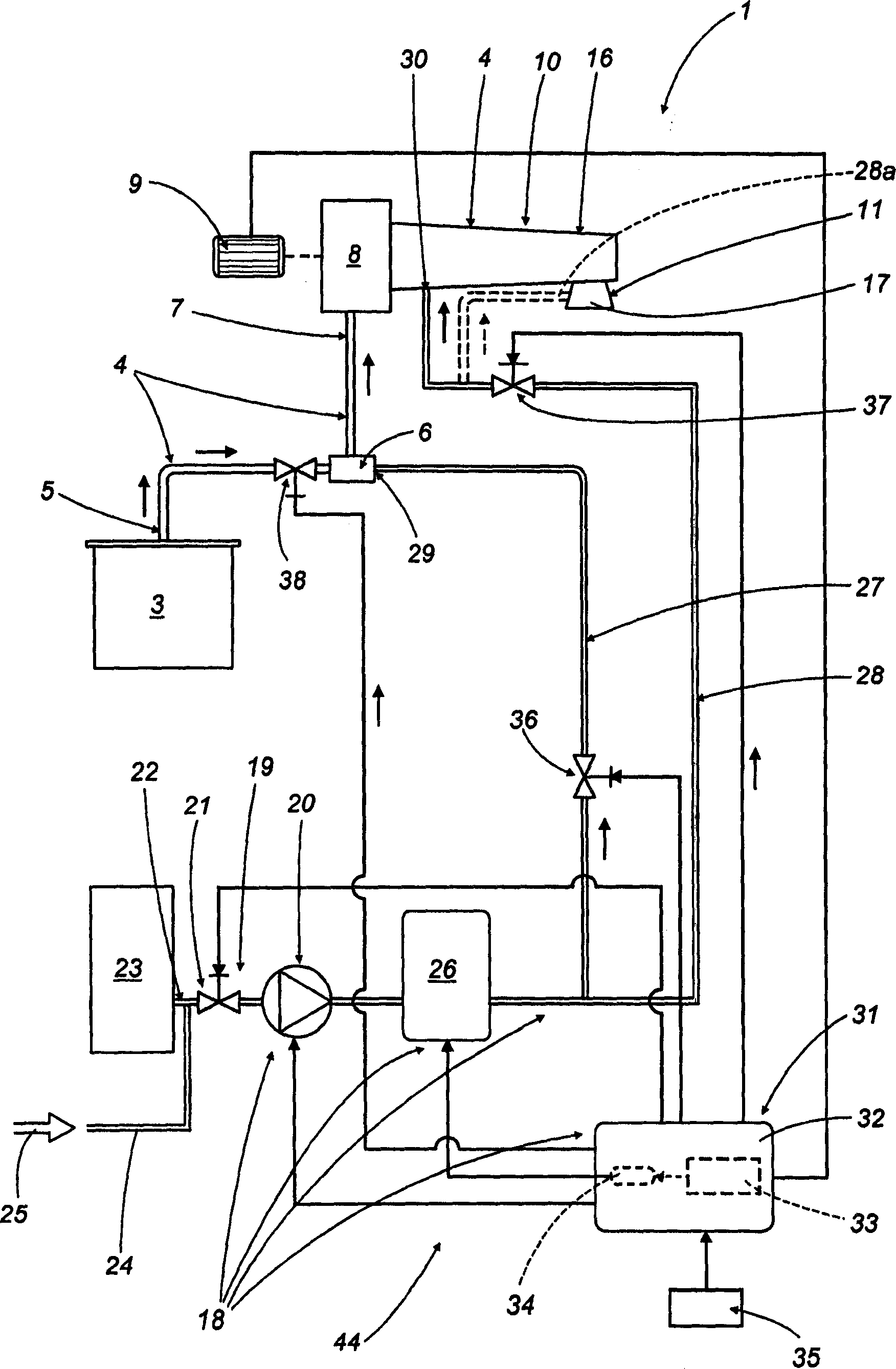

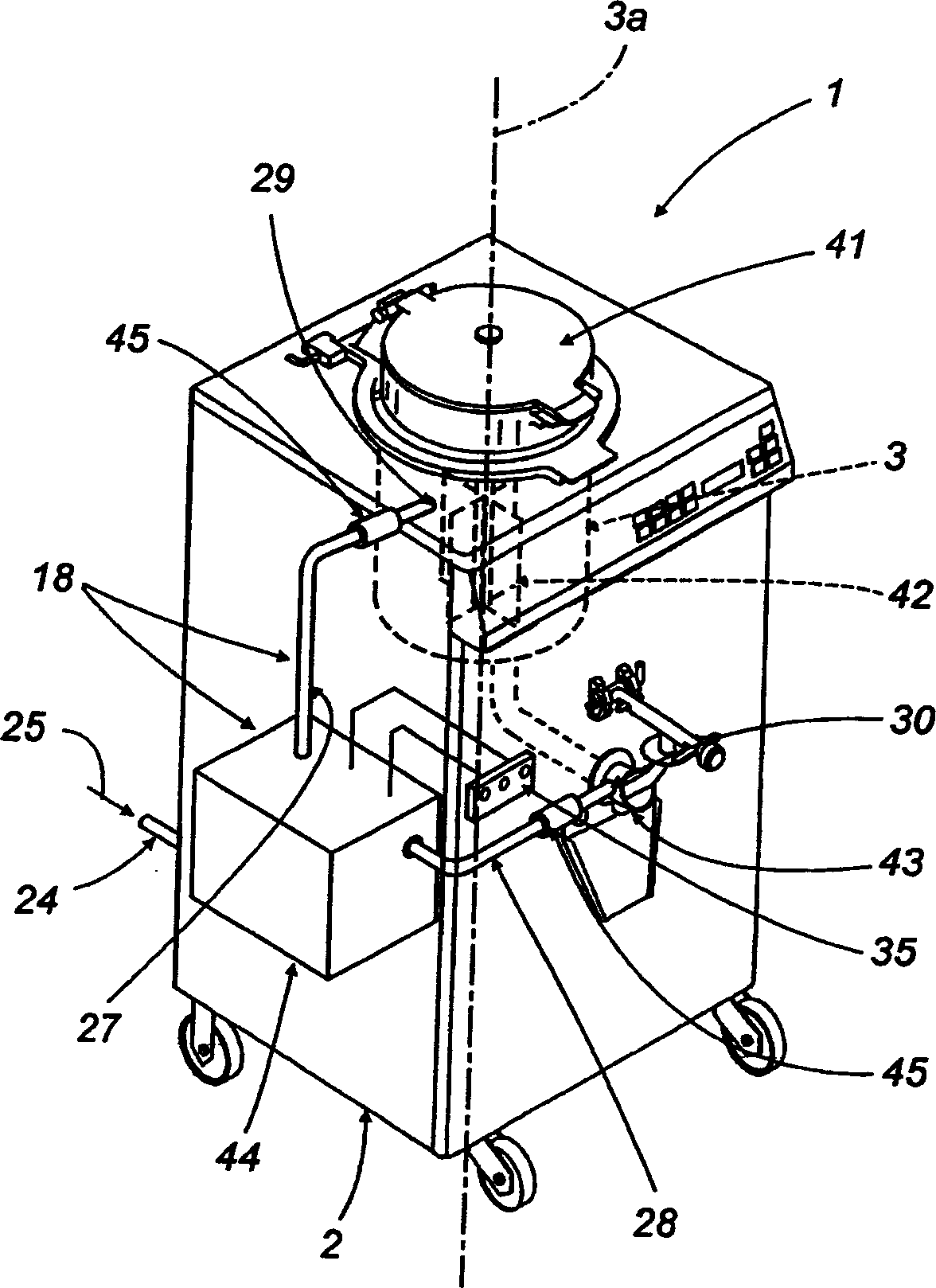

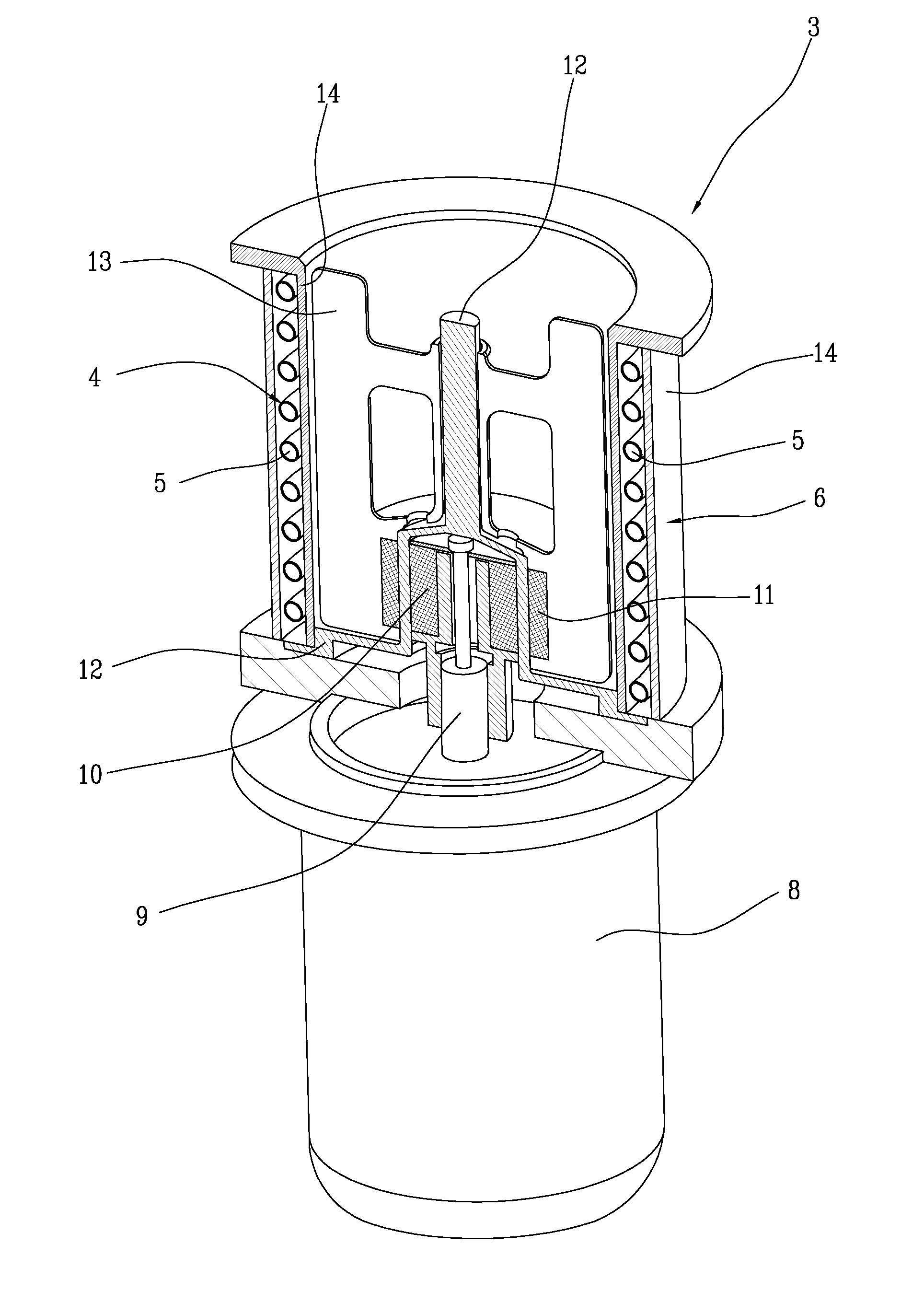

Machine and method for producing and dispensing liquid or semi-liquid consumer food products

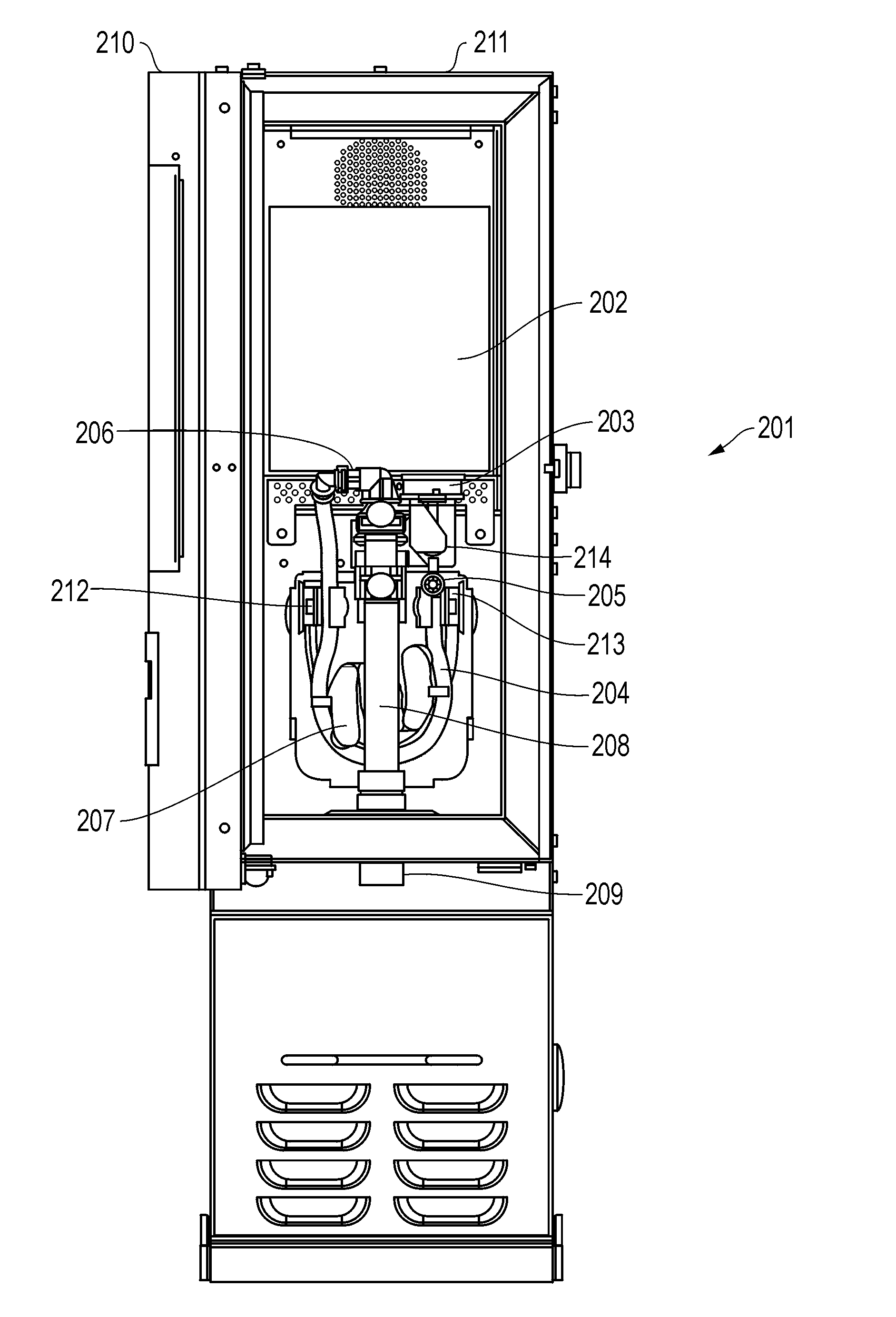

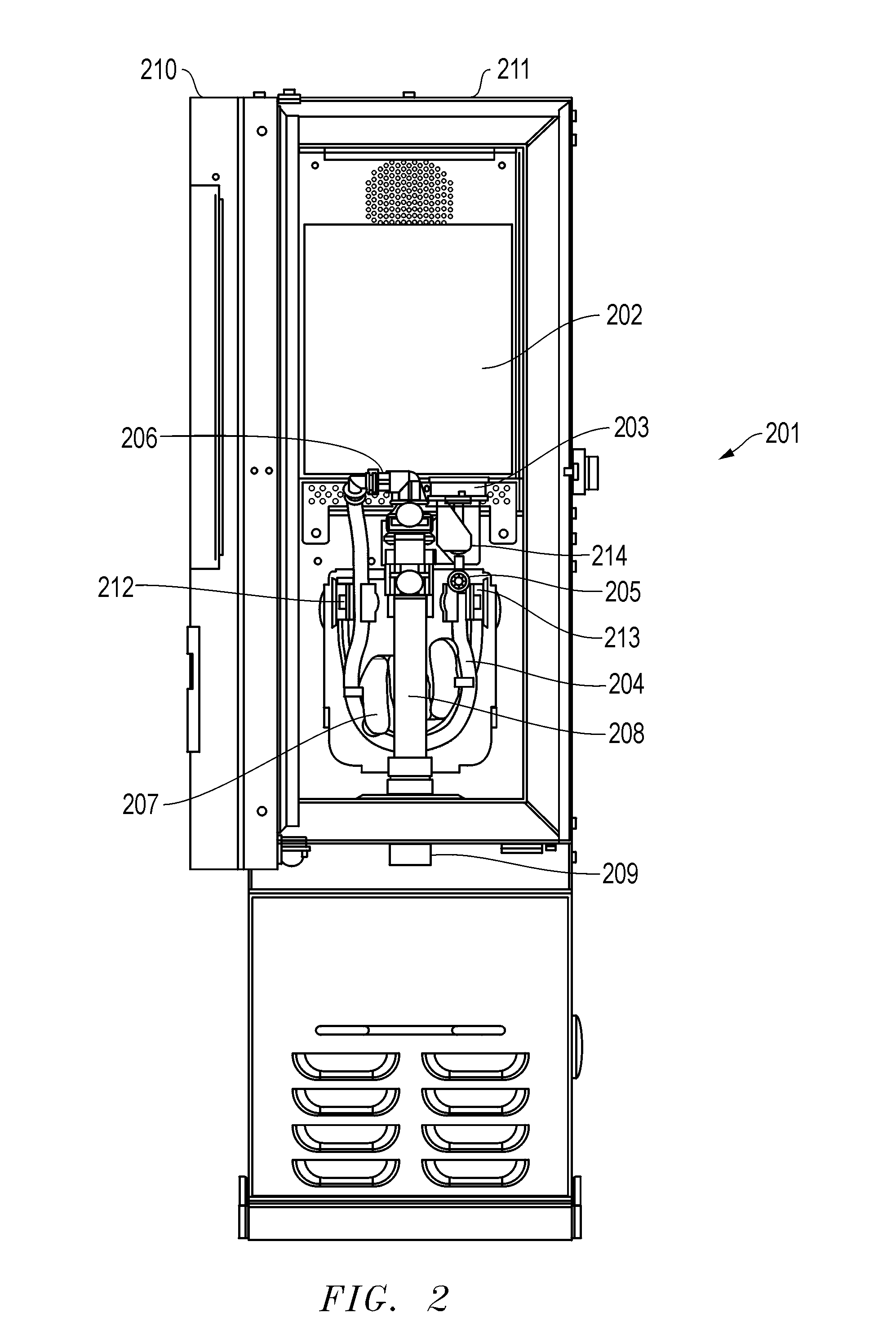

ActiveUS20080226779A1Overcome disadvantagesFrozen sweetsFood preservationEngineeringProcess engineering

A machine for producing and dispensing liquid and semi-liquid consumer food products such as ice creams, whipped cream, yogurt and the like comprises a container for a basic product of the consumer food product, a feed and treatment circuit for the basic product, comprising a feed pump, dispensing means positioned at an outfeed end of the feed and treatment circuit, and a device for checking the bacterial load of the product during production / dispensing; an electronic control unit controlling and regulating the various steps for measuring the bacterial load.

Owner:ALI - CARPIGIANI GROUP

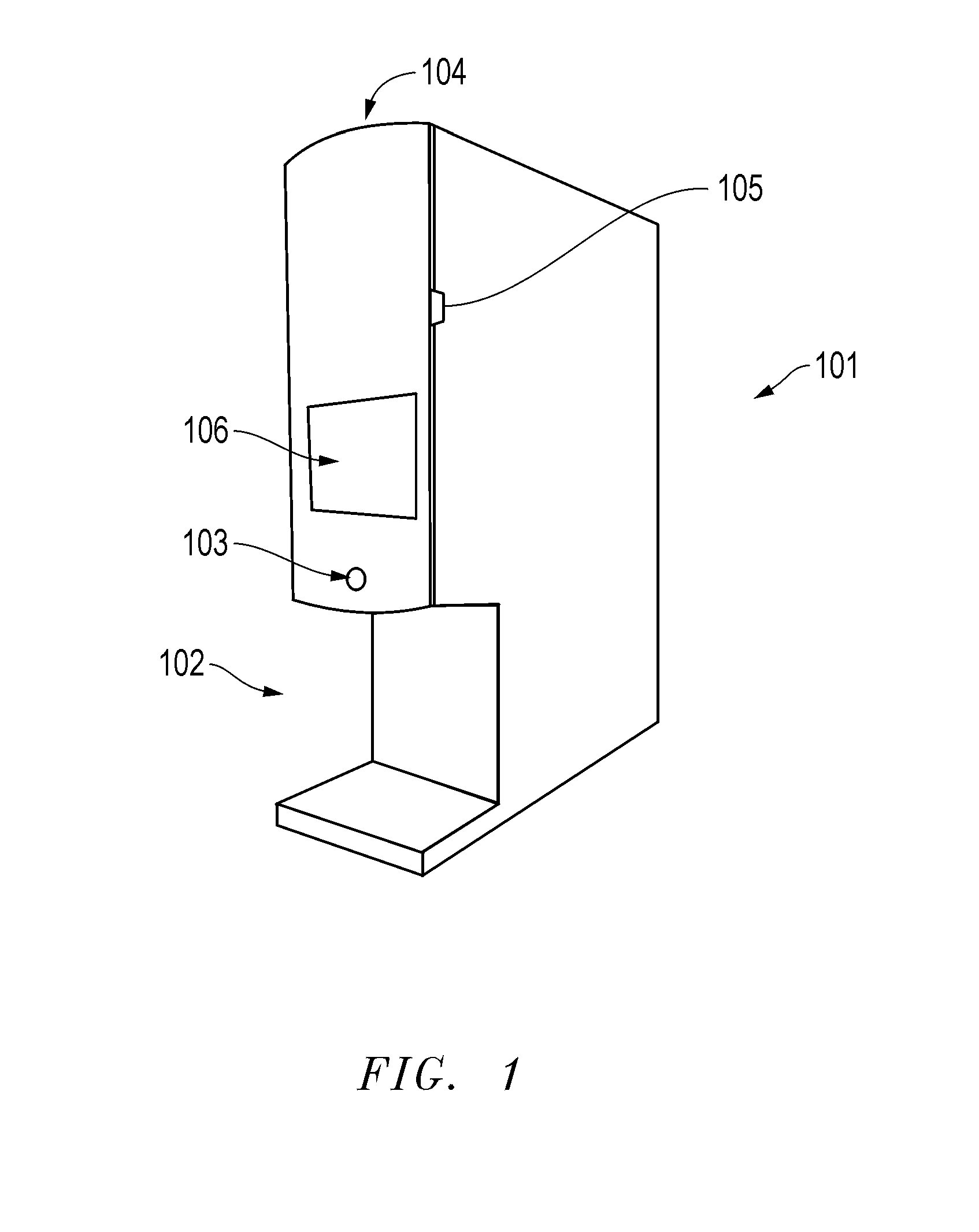

Method and System for Dispensing Whipped Toppings

A method and system for automatically producing and dispensing a whipped product, such as edible whipped cream, is provided. In one embodiment, the system includes a mixture bag containing an input mix, a check valve which allows air to comingle with the input mix, a peristaltic pump which moves the input mix and air into a whipping rod housing, a whipping rod which whips the input mix and air in the whipping rod housing to form a whipped product, and a dispensing mechanism for dispensing the whipped product. Such system components may also be housed within or in close proximity to a refrigeration compartment. In addition, the system may also include a warning function and display device to provide notice of when the system's input mix levels are low or when other maintenance may be required.

Owner:EIEIO

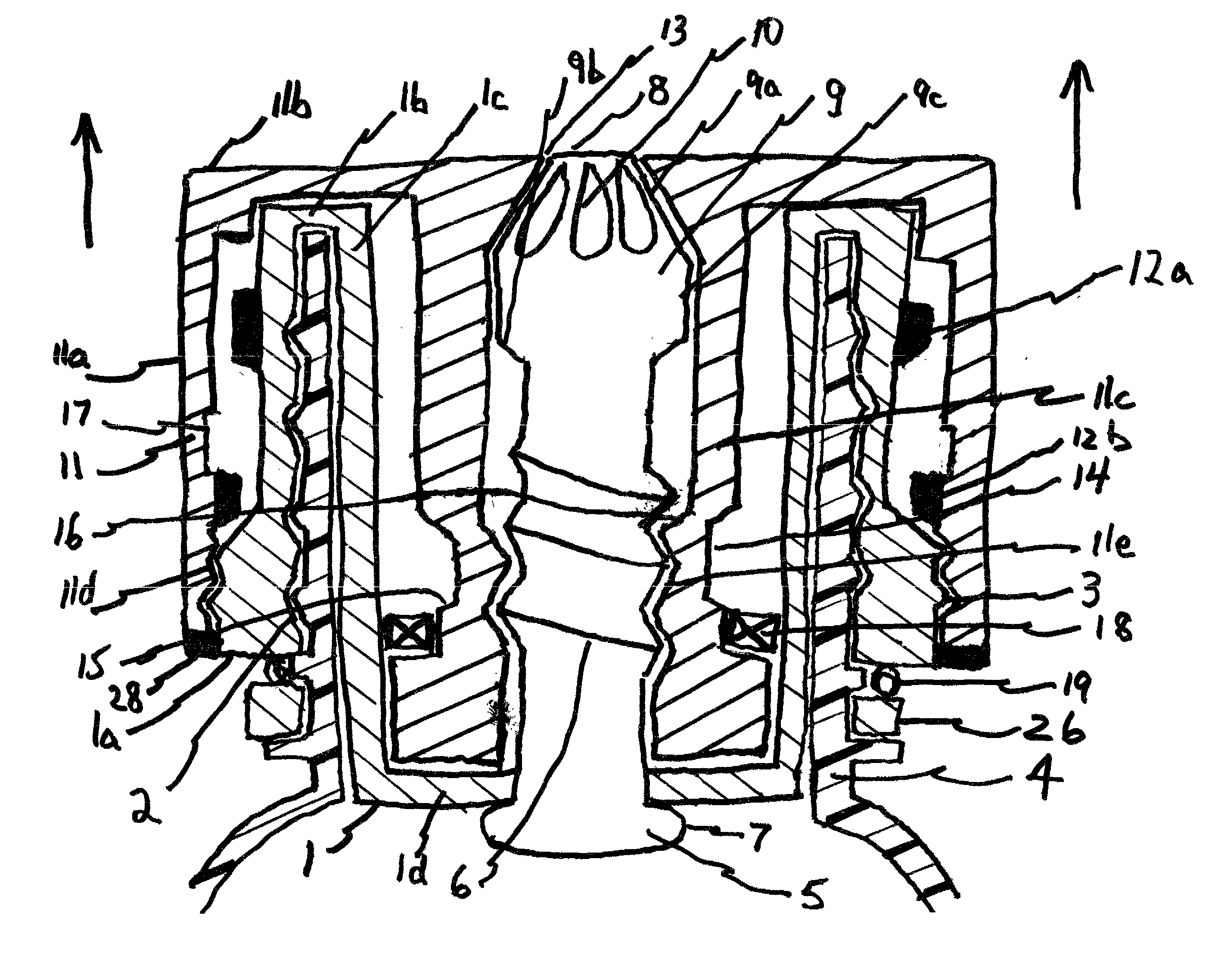

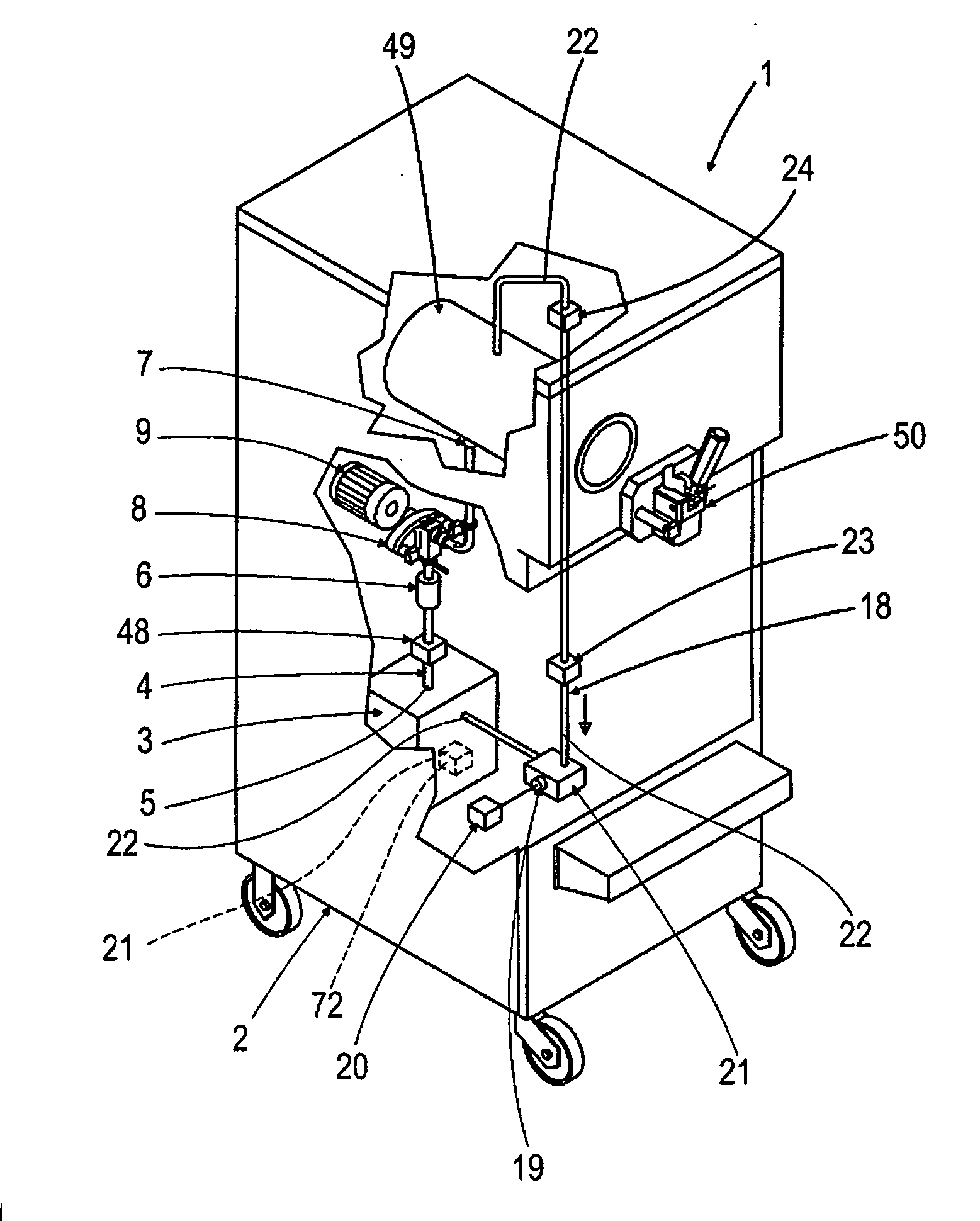

Machine and method for producing and dispensing liquid or semi-liquid consumer food products

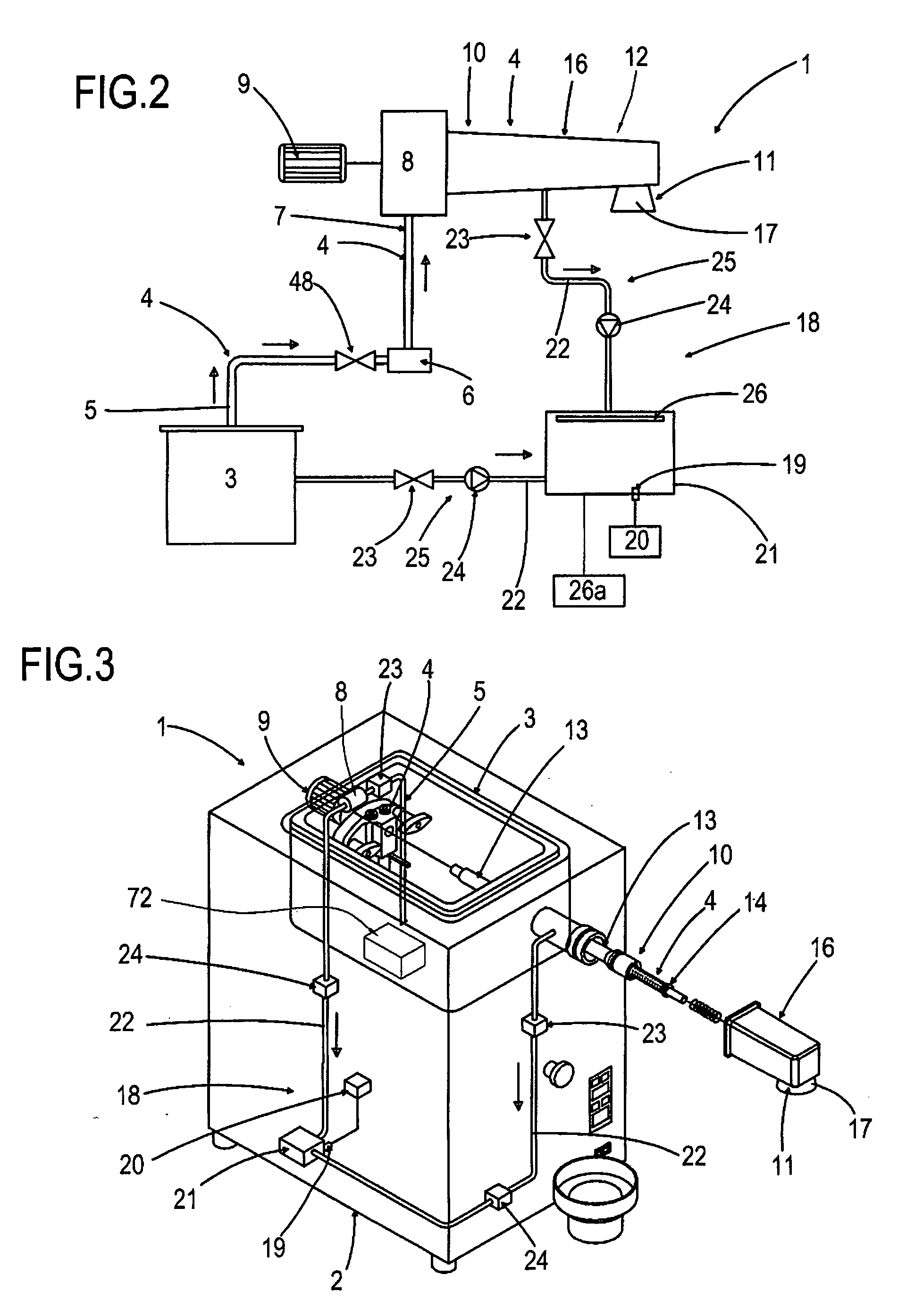

InactiveUS20060243310A1Overcome disadvantagesFrozen sweetsHollow article cleaningLiquid stateProcess engineering

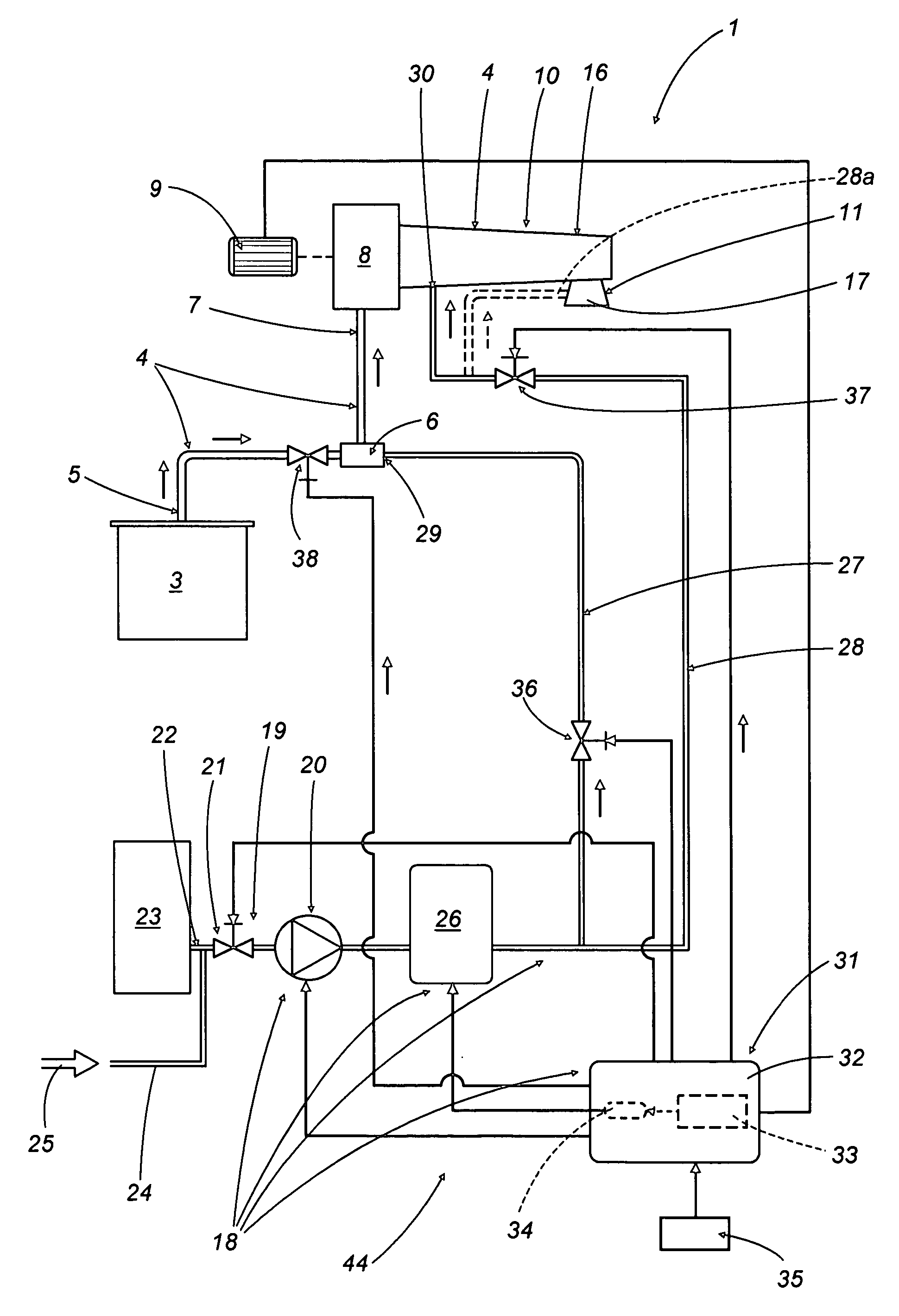

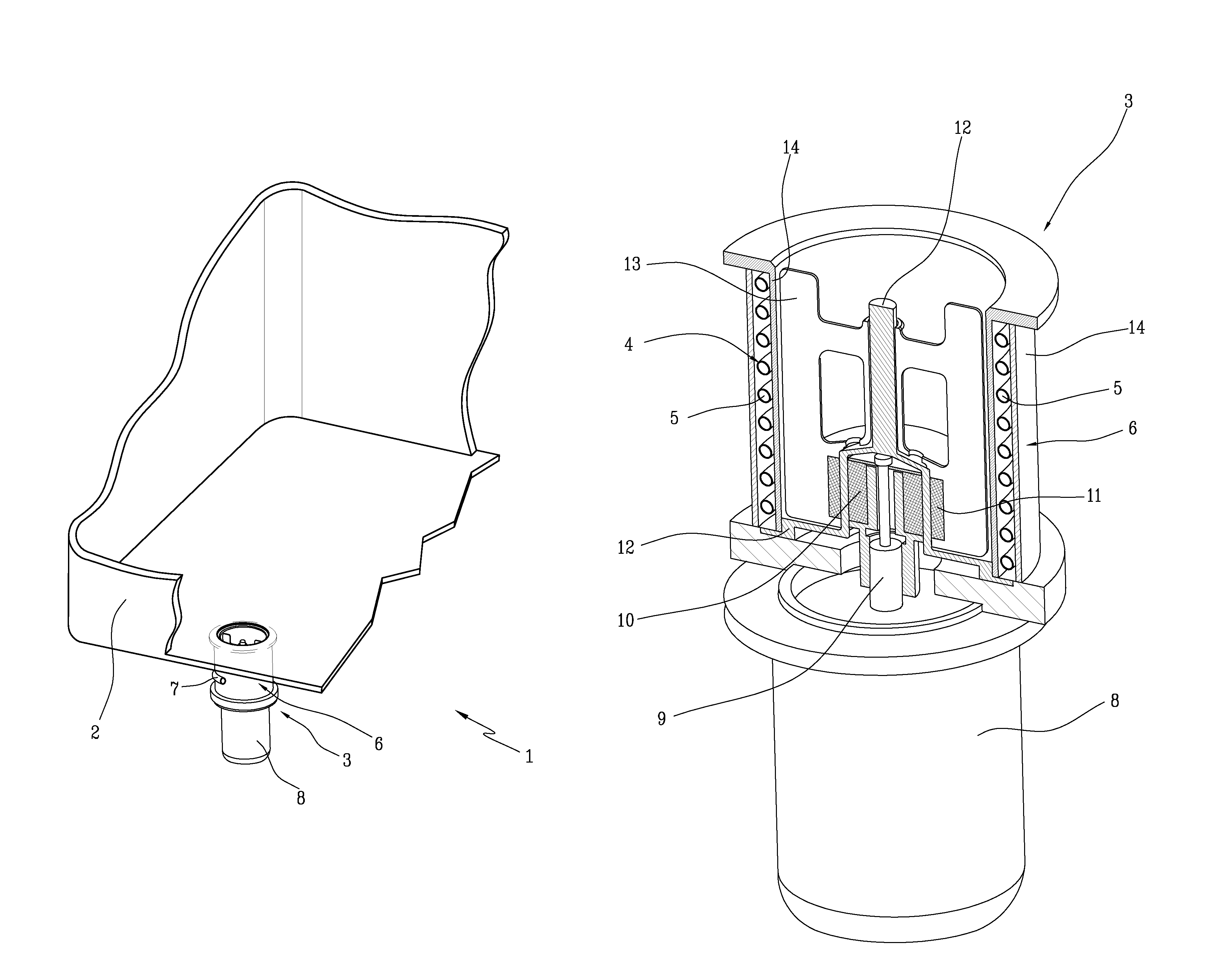

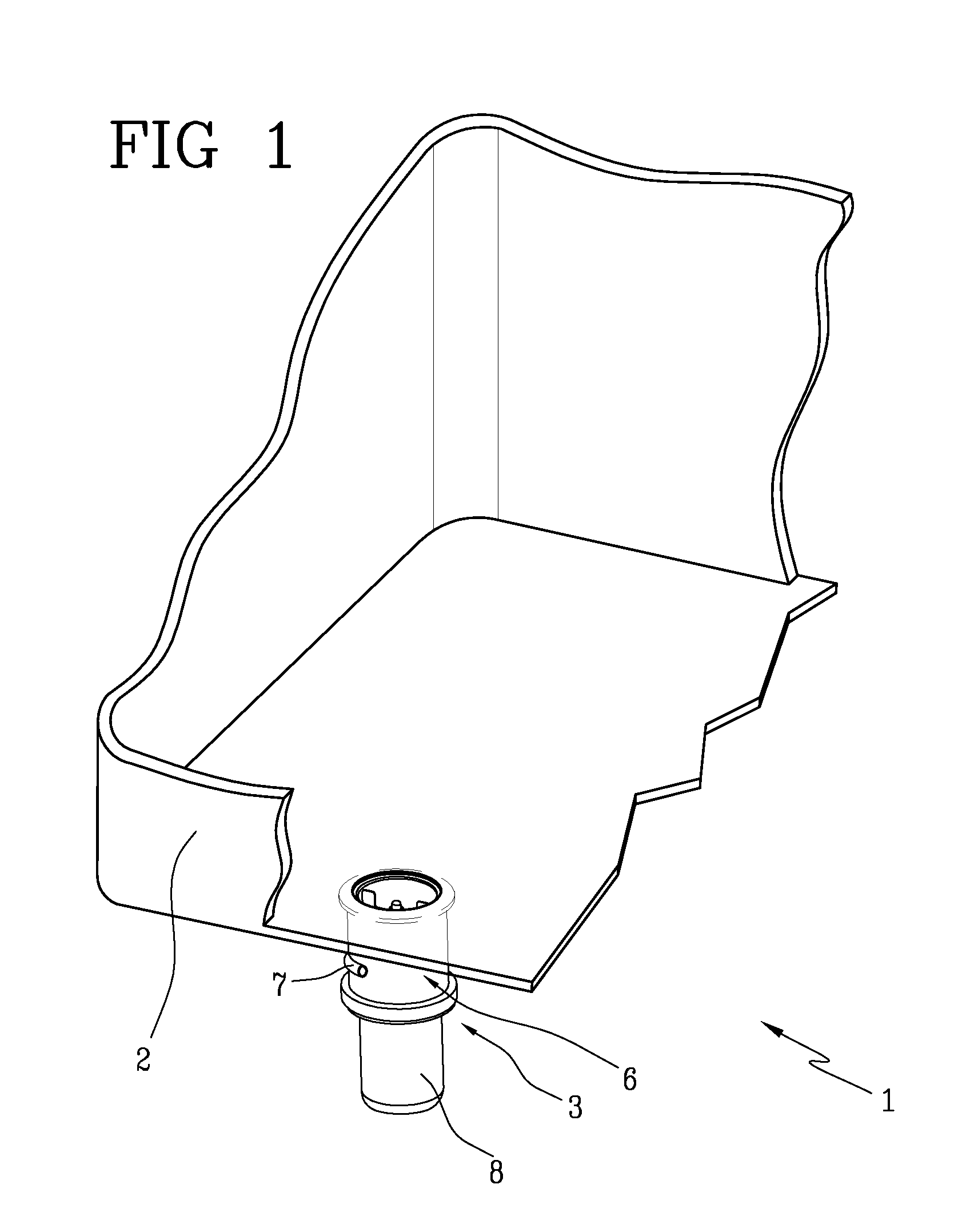

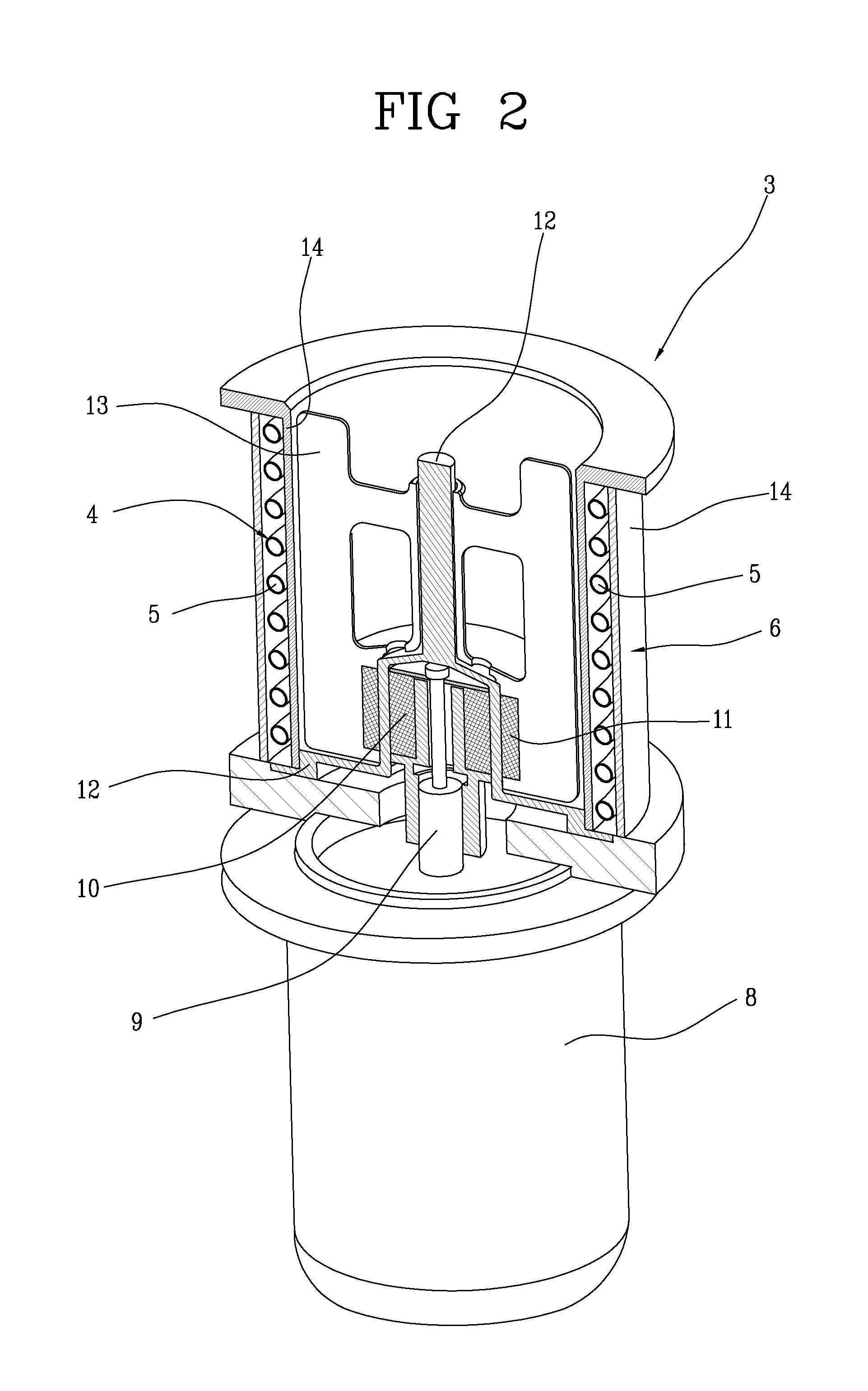

A machine for producing and dispensing liquid and semi-liquid consumer food products such as ice cream, whipped cream, yogurt and the like, comprises a container (3) for a basic product of the consumer food product, a feed and treatment circuit (4) for the basic product comprising a feed pump (8), dispensing means (11) positioned at an outfeed end of the feed and treatment circuit (4), and a washing device (18) used to introduce, in alternate steps, into the circuit (4) a flow of fluid in the liquid state or in the steam state to allow feed and treatment circuit (4) washing and sanitizing. There is a central processing unit (32) which controls and regulates the various washing and sanitizing steps.

Owner:ALI

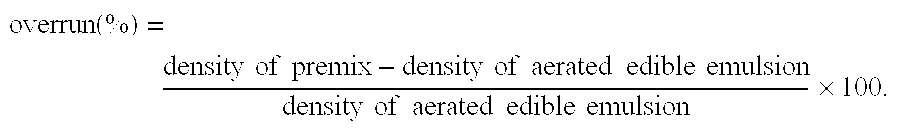

Aerated edible emulsion

InactiveUS20060233933A1Reduce the amount requiredMaximise suitabilityFrozen sweetsAnimal feeding stuffEmulsionIce cream

The present invention provides aerated edible emulsions such as whipped creams, toppings, mousses and ice creams, fortified with calcium and comprising at least 2% fat by weight of the aerated edible emulsion. The fat comprises less than 20% saturated fatty acids by weight of the fat.

Owner:CONOPCO INC D B A UNILEVER

Sucrose-free pastry for diabetics and preparation method thereof

InactiveCN102090440AGreat tasteSolve the pain of not being able to taste sweetnessDough treatmentBakery productsSucroseVegetable oil

The invention relates to a food, in particular relating to a pastry and a preparation method thereof. The pastry comprises the following components in parts by weight: 100 parts of wheat flour, 10-60 parts of vegetable oil, 2-8 parts of sucrose-free whipped cream and 10-80 parts of sucrose-free sweet modifier, wherein the sucrose-free whipped cream comprises the following components in percentageby weight: 18-35% of maltodextrin, 10-40% of whole milk powder, 10-15% of vegetable oil, 3-6% of sodium caseinate, 5-10% of sodium stearoyl lactate, 3-10% of silicon dioxide, 8-12% of glycerin monostearate, 2-6% of guar gum and 3-10% of edible flavorant; and the sucrose-free sweet modifier comprises the following components in percentage by weight: 30-60% of sorbitol, 5-12% of maltodextrin, 8-50%of xylitol, 3-10% of maltitol, 2-5% of disodium hydrogen phosphate, 0.6-0.8% of sucrose fatty acid ester, 0.6-0.8% of glycerin monostearate, 1.5-3.5% of acesulfame potassium, 6-12% of sucralose, 0.05-0.08% of aspartame and 2.8-4.6% of xanthan gum. The pastry is favorable for the diabetics to use and has a good mouthfeel.

Owner:HUZHOU ZHENYUANTONG FOOD

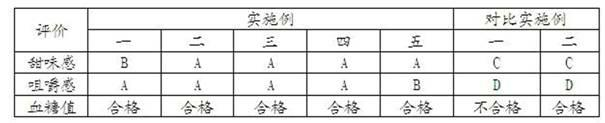

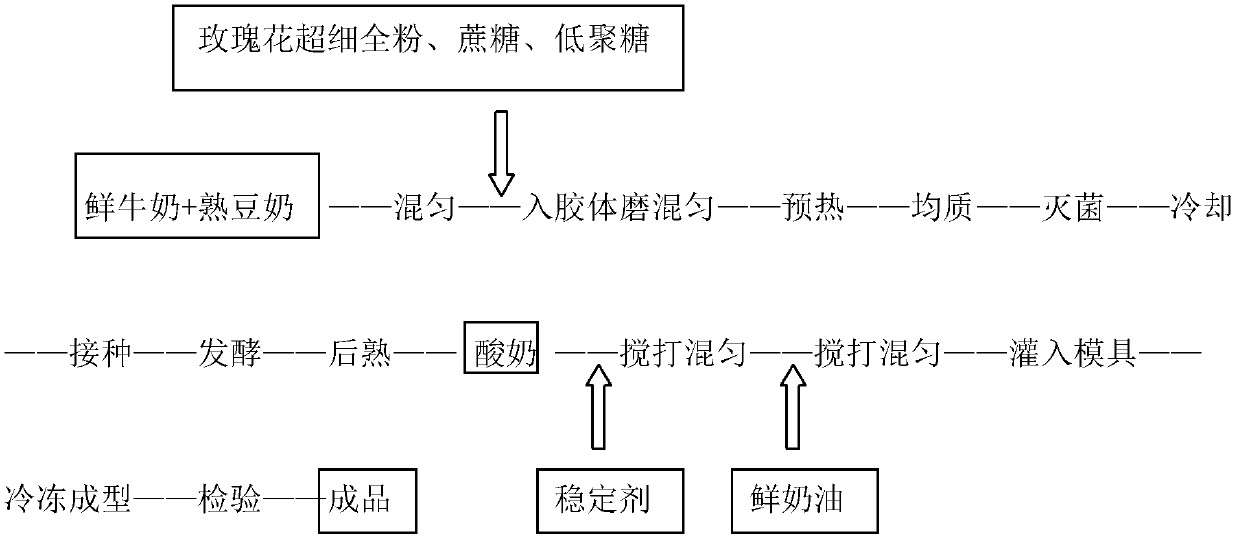

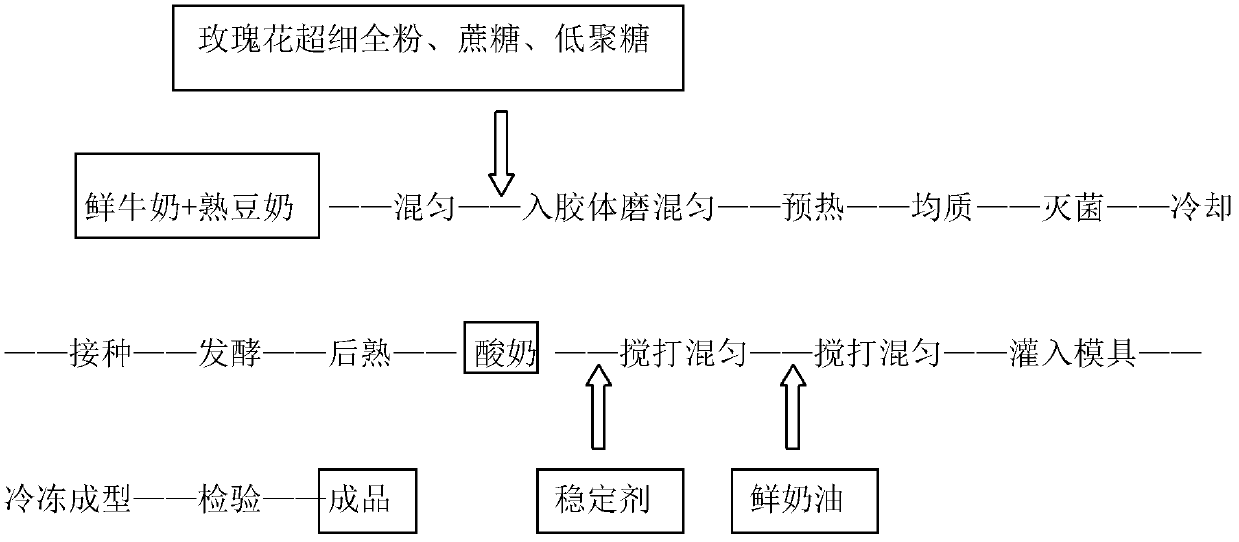

Low-heat-value yoghurt jelly containing superfine full rose powder and preparation method thereof

InactiveCN102177965AHelps proliferateDelicate and soft tasteMilk preparationFrozen sweetsPink colorFlavor

The invention relates to low-heat-value yoghurt jelly containing superfine full rose powder. The low-heat-value yoghurt jelly is prepared from the following components in parts by weight: 70 parts of fresh milk, 30 parts of cooked soymilk, 15-20 parts of the superfine full rose powder, 8-15 parts of sucrose, 5-10 parts of oligosaccharide, 3-5 parts of a mixed strain fermentation agent, 35-45 parts of whipped cream and 7-10 parts of a mixed stabilizer. The invention further discloses a preparation process of the low-heat-value yoghurt jelly. Experiments prove that the product has the advantages of soft, exquisite, refreshing, lubricating, moderately sour and sweet taste, well-balanced and specific flavor and texture of rose, yoghurt and milk jelly, uniformly pink color, no layering phenomenon and richness in components such as prebiotics, dietary fiber and the like which are beneficial to growth of probiotics.

Owner:山东省农业管理干部学院

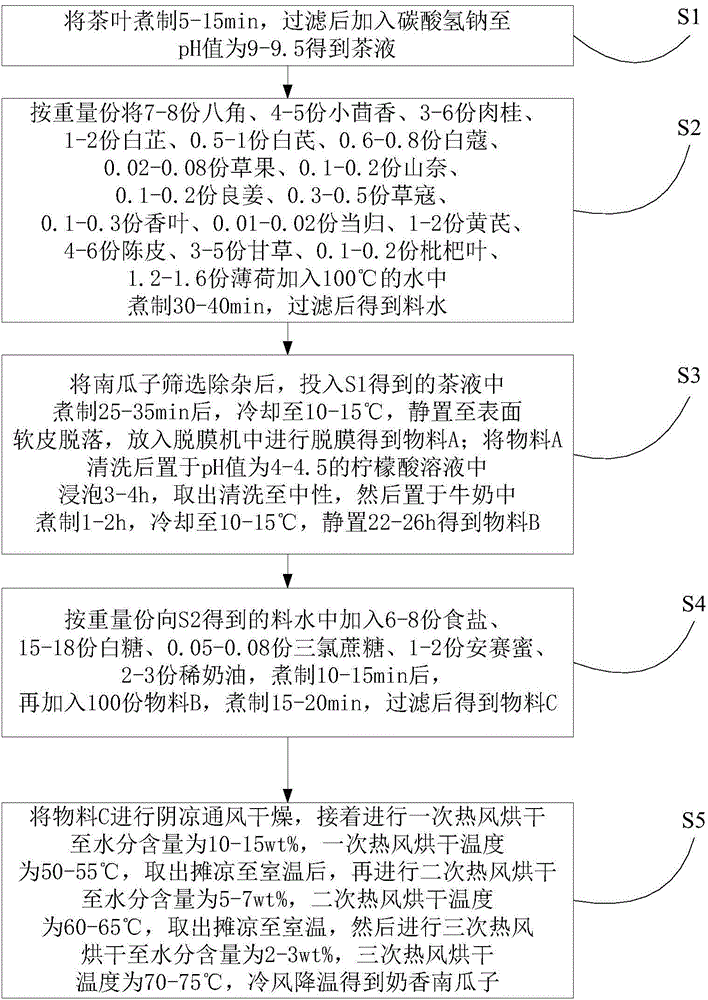

Milk flavored pumpkin seed preparation method

InactiveCN104886666AEasy accessImprove crispnessNatural extract food ingredientsFood dryingSodium bicarbonateAngelica dahurica

The present invention discloses a milk flavored pumpkin seed preparation method which comprises the following steps: boiling tea leaves for 5-15 min, filtering the boiled tea leaves, and adding sodium bicarbonate into the filtrate to obtain the tea liquid; adding star anises, fennel, cinnamomum cassia, angelica dahurica, cynanchum otophyllum, alpinia tonkinensis, amomum tsaoko, rhizoma kaempferiae, alpinia officinarum, alpinia hainanensis, bay leaves, angelica sinensis, astragalus membranaceus, dried tangerine peels, liquorice, eriobotrya japonica leaves, and mentha haplocalyx are added into water to conduct boiling, and filtering the boiled materials to obtain the material filtrate; screening pumpkin seeds and removing impurities of the pumpkin seeds, then putting the impurity removed pumpkin seeds into the tea liquid to conduct boiling, cooling and keeping the boiled pumpkin seeds still until the surface soft skins fall off, then put into a stripping machine for stripping to obtain material A; washing the material A, soaking in a citric acid solution, removing the material A out and washing the material A to be neutral, then placing the material A in milk to conduct boiling and cooling and keeping the boiled material A still for 22-26 h to obtain material B; adding edible salt, white granulated sugar, sucralose, acesulfame and whipping cream into the material filtrate to conduct boiling, then adding the material B to conduct boiling, and filtering the above materials to obtain material C; and air-drying the material C at cool place, and followed by conducting hot air-drying, and cold-air temperature lowering to obtain the flavored pumpkin seeds.

Owner:蚌埠市徽味炒货厂

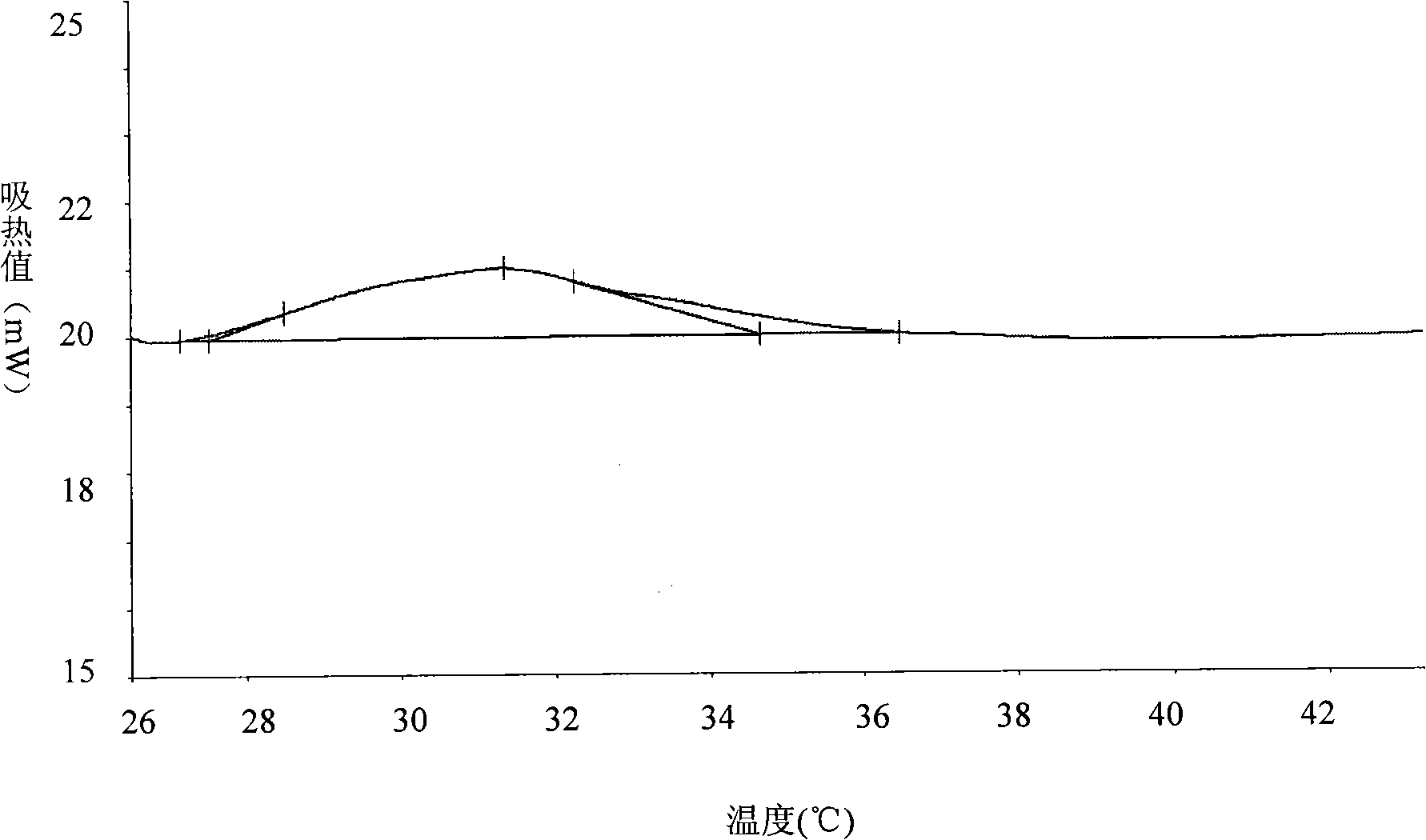

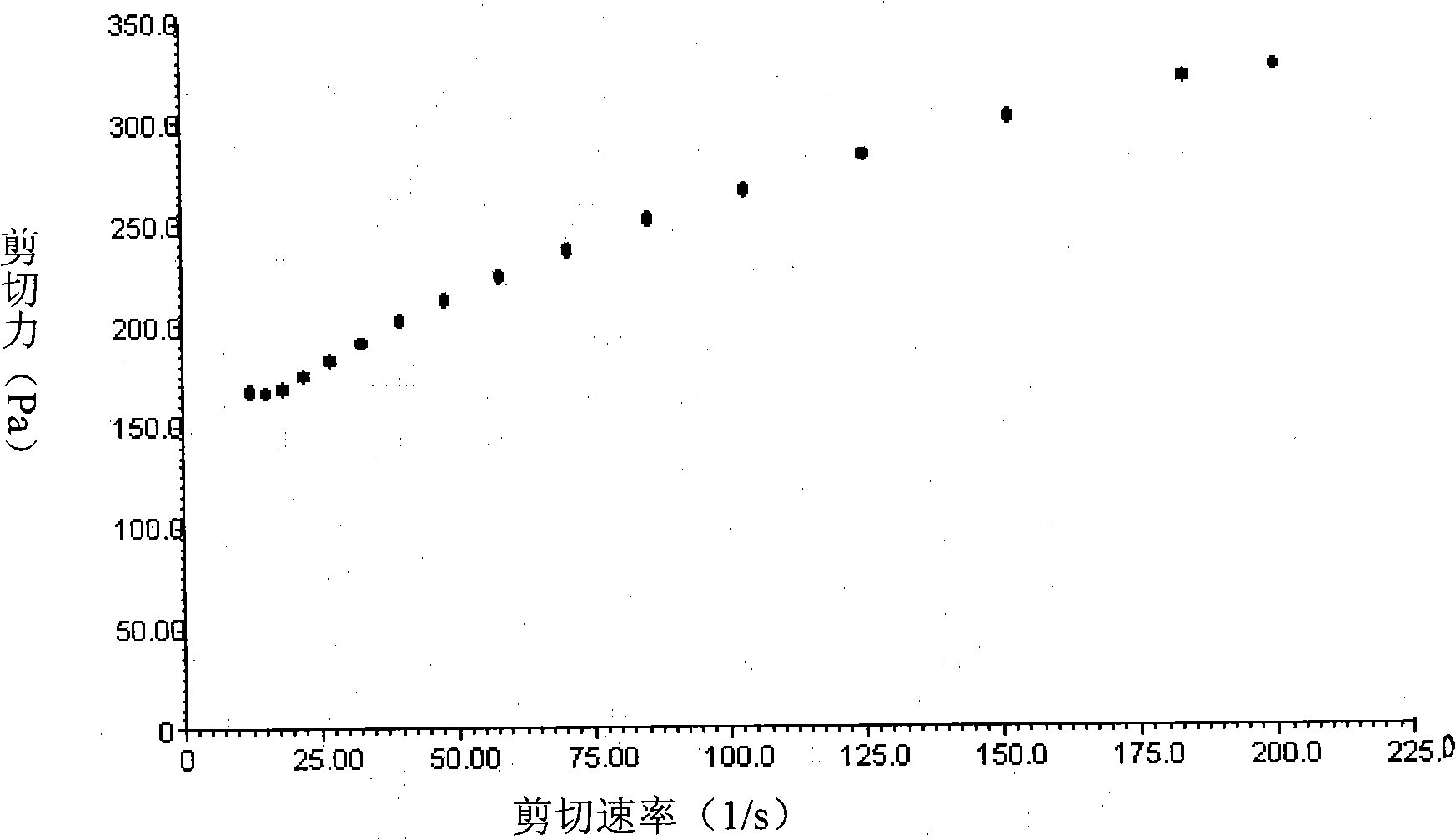

Preparation method for ultrahigh-temperature whipping cream

The invention discloses a preparation method for an ultrahigh-temperature whipping cream, which belongs to the technical field of dairy food processing. Whipping cream with 38 to 42 wt percent of fat content and fresh milk with 3.3 to 3.6 wt percent of fat content are adopted as main materials; auxiliary materials accounting for 0.4 to 1.6 wt percent of the total amount of materials are added; the fresh milk and the whipping cream which are acceptable are rapidly cooled to 0 DEG C to 5 DEG C, respectively stored in material storage tanks, blended, cooled, stored, degasified under vacuum, homogenized, sterilized under ultrahigh temperature, cooled, filled and kept still for storage, and thereby the ultrahigh-temperature whipping cream product is obtained. The emulsifier used in the productis green food emulsifier which is allowed to be added by China; ultrahigh-temperature sterilization is carried out after homogenization; and when the produced ultrahigh-temperature whipping cream is tested after the shelf life reaches six months, the appearance, taste and smell of the product are not changed, the texture of the product is good, the phenomena of floating fat and coagulation do notoccur, and the microbiological indicators of the product fully come up to the regulations.

Owner:北京艾莱发喜食品有限公司

Fresh cheese rich in probiotics and preparation method thereof

The invention provides a fresh cheese rich in probiotics. The fresh cheese comprises the following raw materials in parts by weight: cow milk 60-70, skimmed milk powder 8-15, whipping cream 8-10, white granulated sugar 8-10, stabilizer 0-1, jam 0-15, Lactobacillus casei starter 1-3, and Streptococcus lactis and Streptococcus cremoris mix direct vat set starter dilution 0.3-0.5. The invention also provides a preparation method of the fresh cheese. Proteins are coagulated through mix fermentation of several kinds of Lactobacillus, and chymosin, acidulant and coagulator are not necessary; the generation of sticky matter and the use of the stabilizer make a whey draining step be not necessary after coagulation; the taste of the cheese is improved by a stirring step, seasonings can be added during the stirring process, and the kinds of products are increased; and the fresh cheese can be produced by the existing yoghourt processing equipment. The theoretical production rate of the fresh cheese is 100%. The fresh cheese is rich in probiotics, and the content of the probiotics reaches more than 107 cfu / mL.

Owner:HUNAN AGRICULTURAL UNIV

UHT treated 100 % non-dairy whipping cream

InactiveUS20050048184A1Good surface textureShape stableEdible oils/fats ingredientsEdible oils/fats with fatty acid estersNon dairyFatty acid

The present invention relates to a UHT treated 100% non-dairy whipping cream with high shape stability and / or a very good surface texture and / or an overrun of at least 3.5. Said whipping cream preferably contains less than 2% of trans fatty acids, is free from any dairy product and free from any protein source. The whipping cream according to the present invention can be stored at temperatures up to 20° C. and thereby avoids frozen or cooled transport and / or storage.

Owner:PURATOS NV

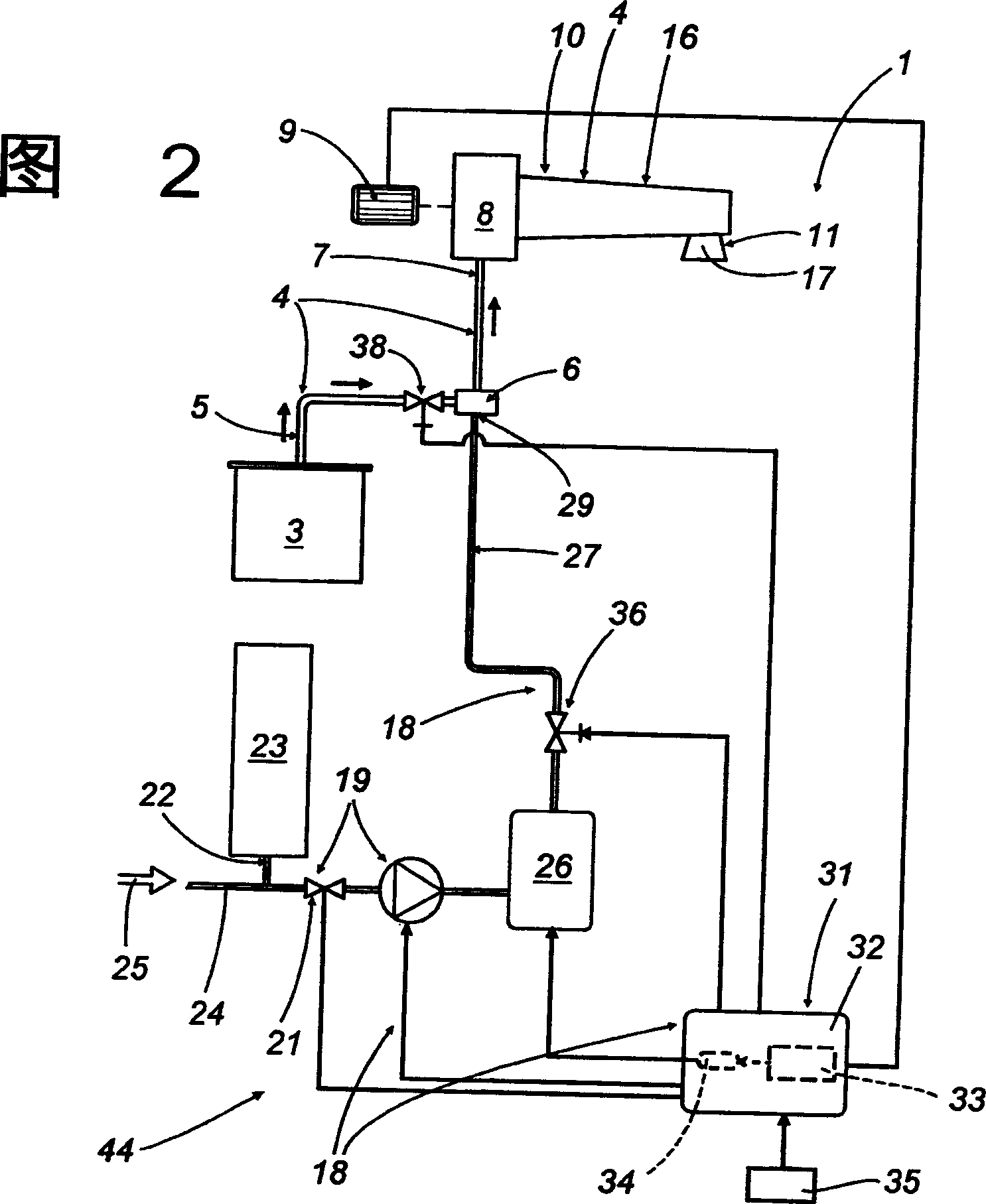

UHT (ultra high temperature treated) whipping cream with butter serving as raw materials and preparation method of UHT whipping cream

InactiveCN104365861ALow production costImprove utilization efficiencyCream preparationOil phaseSkimmed milk powder

The invention discloses a UHT (ultra high temperature treated) whipping cream with butter serving as raw materials and a preparation method of the UHT whipping cream. The whipping cream is mainly prepared from the butter with skimmed milk powder, emulsifiers and compound thickeners being compounded. The whipping cream comprises, by weight, 40%-50% of the butter, 5.5%-6.5% of skimmed milk, 0.45%-0.55% of the compound emulsifiers, 0.18%-0.22% of the thickeners and the balance water. The whipping cream is prepared by weighing the raw materials according to the matching ratio, enabling a water phase to dissolve completely and an oil phase to disperse sufficiently, adding the water phase into the oil phase slowly under stirring, emulsifying mixed liquor by the aid of shearing and homogenizing technologies and subjecting treated emulsion to UHT system sterilization. Whipping bubbling rate of the whipping cream is 150%-200%, creaming rate of the whipping cream within the quality guarantee period is zero, and the quality guarantee period of the whipping cream is eight months at the temperature of 4-8 DEG C.

Owner:CHINA AGRI UNIV

Machine and method for producing and dispensing liquid or semi-liquid consumer food products

A machine for producing and dispensing liquid and semi-liquid consumer food products such as ice cream, whipped cream, yoghurt and the like, comprises a container (3) for a basic product of the consumer food product, a feed and treatment circuit (4) for the basic product comprising a feed pump (8), dispensing means (11) positioned at an outfeed end of the feed and treatment circuit (4), and a washing device (18) used to introduce, in alternate steps, into the circuit (4) a flow of fluid in the liquid state or in the steam state to allow feed and treatment circuit (4) washing and sanitising. There is a central processing unit (32) which controls and regulates the various washing and sanitising steps.

Owner:ALI

Remote pressure system for portable whipped cream dispensers

ActiveUS20050082312A1Remove changeGuaranteed continuous useOpening closed containersBottle/container closurePressure systemFuel tank

A whipped cream dispenser arrangement comprising a portable, hand-held whipped cream dispenser-canister for holding a quantity of cream to be dispensed as whipped cream. The dispenser has a male fitting on the canister with a central bore there-through. The bore encloses a cartridge piercing pin therein, as part of its prior art use. A replacement adapter cap is arranged in fluid communication with a spaced-apart tank of pressurized gas, and the dispenser has a nozzle having a valve therewith for dispensing whipped cream when pressurized gas is introduced through the adapter cap from a large, spaced-apart pressurized gas tank, and into the canister.

Owner:MULDOON TOM

Animal and plant mixed cream for conditioning and application thereof

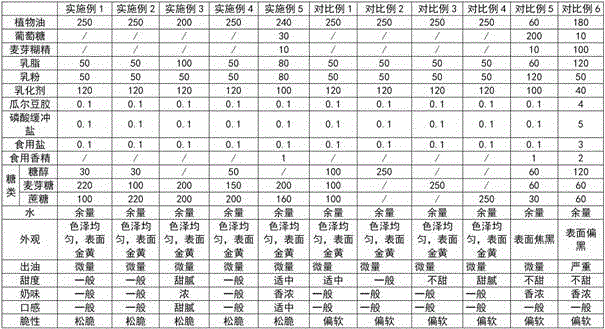

The invention discloses animal and plant mixed cream for conditioning and application thereof. The cream for conditioning is prepared from, by weight, 1-400 parts of vegetable oil, 0-200 parts of glucose, 0-200 parts of maltodextrin, 1-400 parts of milk fat, 1-200 parts of milk powder, 10-150 parts of an emulsifying agent, 0.1-4 parts of guar gum, 0.1-5 parts of phosphate buffer salt, 0.1-3 parts of salt, 0-2 parts of edible essence, 1-200 parts of saccharides and the balance water added until the total part is 100. The animal and plant mixed cream has the aroma of natural butter or margarine, can replace whipping cream or butter or margarine, is applied to a baking product formula or smeared to the surfaces of baking products to harmonize the flavor and increase the aroma and has the advantages of being strong in milk flavor, capable of resisting high-temperature baking and achieving the unique flavor of animal fat, convenient to use, capable of improving the tissue state of the products and good in stability.

Owner:ZENGCHENG LEGO FOODS CO LTD

Machine for the homogenization and thermal treatment of liquid and semi-liquid food products

ActiveUS9016926B2Heating evenlyLimited running costMilk preservationFrozen sweetsEngineeringThermal treatment

A machine for the homogenization and thermal treatment of liquid and semi-liquid food products, for example ice creams, whipped cream, creams, chocolate, yogurt and the like, comprises a containment tank for the mixture and a centrifugal pump put in fluid communication with the bottom of the containment tank for drawing mixture from the tank and putting it back into the tank, heating and cooling means acting at the pump for heating and cooling the mixture in transit in the pump. The heating and cooling means comprise a thermal machine with reversible thermodynamic cycle and using carbon dioxide as refrigerant.

Owner:ALI - CARPIGIANI GROUP

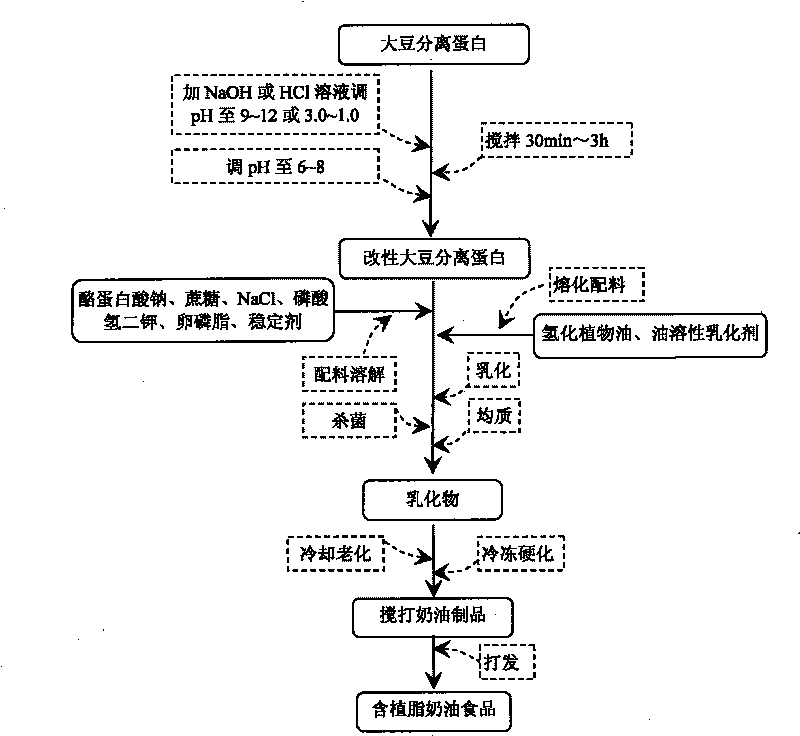

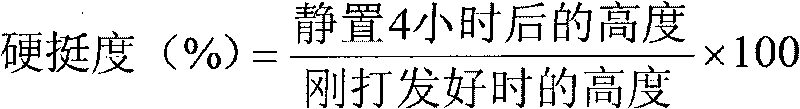

Method for producing whipped cream product

ActiveCN101756106ASimple and fast operationShorten the timeCream substitutesFood preparationEmulsionProcess conditions

The invention provides a method for producing a whipped cream product through pH deviation treatment of soybean protein isolate. The method can be used for producing a cream product with high yield and good stiffness through controlling the pH deviation treatment degree, emulsion formulation and process conditions. The invention has the advantages of simple process and high applicability. The modified soybean protein isolate product has an optimal application performance in the whipped cream, and also has a superior economic performance and great market potential.

Owner:JIANGNAN UNIV

Unsalted butter special for egg tart and preparing method thereof

ActiveCN101313718AIncrease content ratioGuaranteed water retentionCream preparationBiotechnologyCow milking

The invention discloses whipping cream special for an egg tart and a production method thereof. The compositions per 100 grams of raw materials by weight of the whipping cream special for the egg tart provided by the invention are: 80 to 98 grams of the whipping cream, 0.5 to 19 grams of cow milk, 0.1 to 0.8 gram of emulsifiers, 0.1 to 0.8 gram of stabilizers, 0.0 to 0.1 gram of pigment, 0.0 to 0.05 gram of preservative, the balance being water which makes up for 100 grams. Nutrition reinforcer is also preferably added into the raw materials. The production method thereof comprises the following steps of: firstly, acceptance check of the raw material milk; secondly, separation of the whipping cream; thirdly, addition of the compositions; fourthly, pasteurization; fifthly, homogenization; sixthly, UHT sterilization; seventhly, cooling; and eighthly, package. The production of the whipping cream special for the egg tart has smooth mouthfeel and rich nutrition, and meets the roasting stability through addition of the emulsifiers and the stabilizers. Moreover, the quality guarantee period is prolonged by adoption of the UHT sterilization technology, the aseptic package technology and the online addition technology of the nutrition reinforcer.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Low-fat high-fiber nondairy whipping cream and preparation method thereof

InactiveCN105580915ALow fat contentLower levelEdible oils/fats ingredientsEdible oils/fats with reduced calorie/fat contentBiotechnologyFiber

The invention provides low-fat high-fiber nondairy whipping cream. The low-fat high-fiber nondairy whipping cream is prepared from the following components in percentage by mass: 8-12% of part of hydrogenated vegetable oil, 0.01-5.1% of an emulsifying agent, 0.1-1.5% of dietary fibers, 0.05-1.5% of colloid, 1-41% of sugar and the balance being water. The nondairy whipping cream disclosed by the invention is low in fat content, and high in content of dietary fibers, has the characteristics of low cost, good serviceability and good stability, and conforms to development of health and nutrient of the nondairy whipping cream.

Owner:ZENGCHENG LEGO FOODS CO LTD

Formula and method for preparing deer whip cream

The invention discloses a formula and a method for preparing deer whip cream. The formula comprises the following components in percentage by weight: 0.2 to 0.4 percent of velvet antler, 8 to 15 percent of deer sinew, 0.3 to 0.8 percent of deer whip, 20 to 30 percent of deer bone, 7 to 14 percent of deer skin, 0.4 to 0.8 percent of sugar and the balance of water. The method for preparing the deer whip cream comprises the following steps: washing the deer skin and the deer sinew; blanching and washing the deer bone; cutting the deer skin, the deer sinew and the deer bone into blocks; grinding the velvet antler and the deer whip into powder; putting the deer skin into a vessel, adding water into the vessel, and stewing for 5 to 8 hours to obtain gel juice; filtering and cooling the gel juice; putting the deer bone into the vessel, adding water into the vessel and stewing for 3 to 5 hours; adding the deer sinew and stewing for 4 to 6 hours; adding the velvet antler and the deer whip ground into the powder and the prepared gel juice; stewing the mixture for 3 to 4 hours; filtering the gel juice; adding the sugar into the filtered gel juice; and continuing to stew for 1 to 2 hours to obtain the deer whip cream. The deer whip cream obtained by the preparation process disclosed by the invention has significant effects of strengthening body and nourishing kidney yang, is convenient to eat, and does not have side effects.

Owner:SNTO TECH GRP

Method for producing whipped cream using purified inulin as fat substitute

A manufacturing method of non-dairy whipped topping which takes purified inulin as a substitute of fat belongs to the fat substitute technical field. The invention takes the inulin which is extracted from jerusalem artichoke and purified as a substrate material to obtain an inulin microgel particle system by stirring; fatty oil is substituted partially; and a non-dairy whipped topping product, the fat substitute, which takes the purified inulin as the substrate is obtained by stirring, homogenizing, refrigerating and going off like hot cakes. The invention substitutes the fat in the non-dairy whipped topping by proper prescription and proportion as well as appropriate processing technique and processing method. The method of the invention takes the inulin to substitute the fat in the non-dairy whipped topping partially, when the inulin substitute rate is not more than 50 percent, every physical and chemical character of a substitute sample is similar as a full cream sample, which is easy for the consumer to accept.

Owner:JIANGNAN UNIV

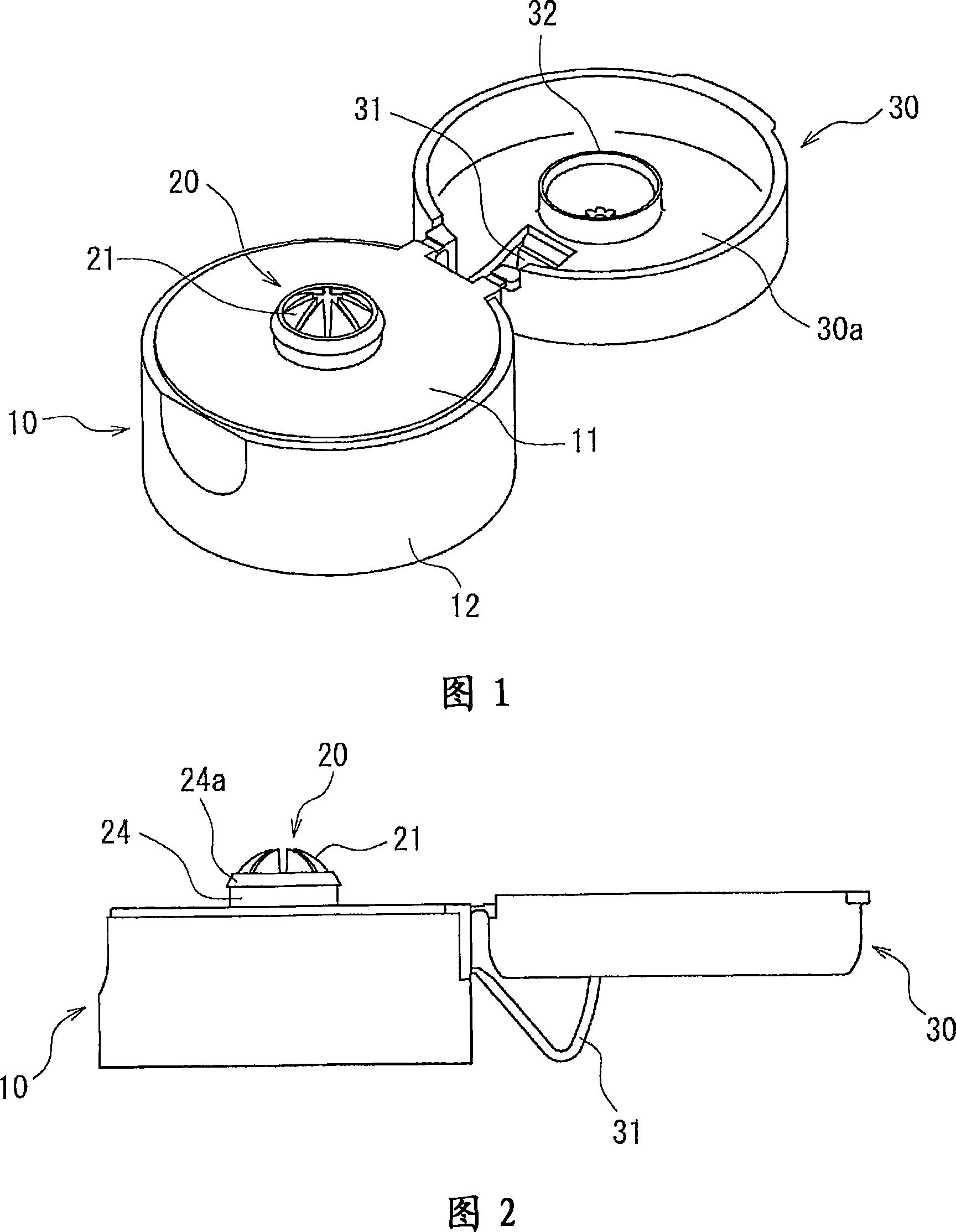

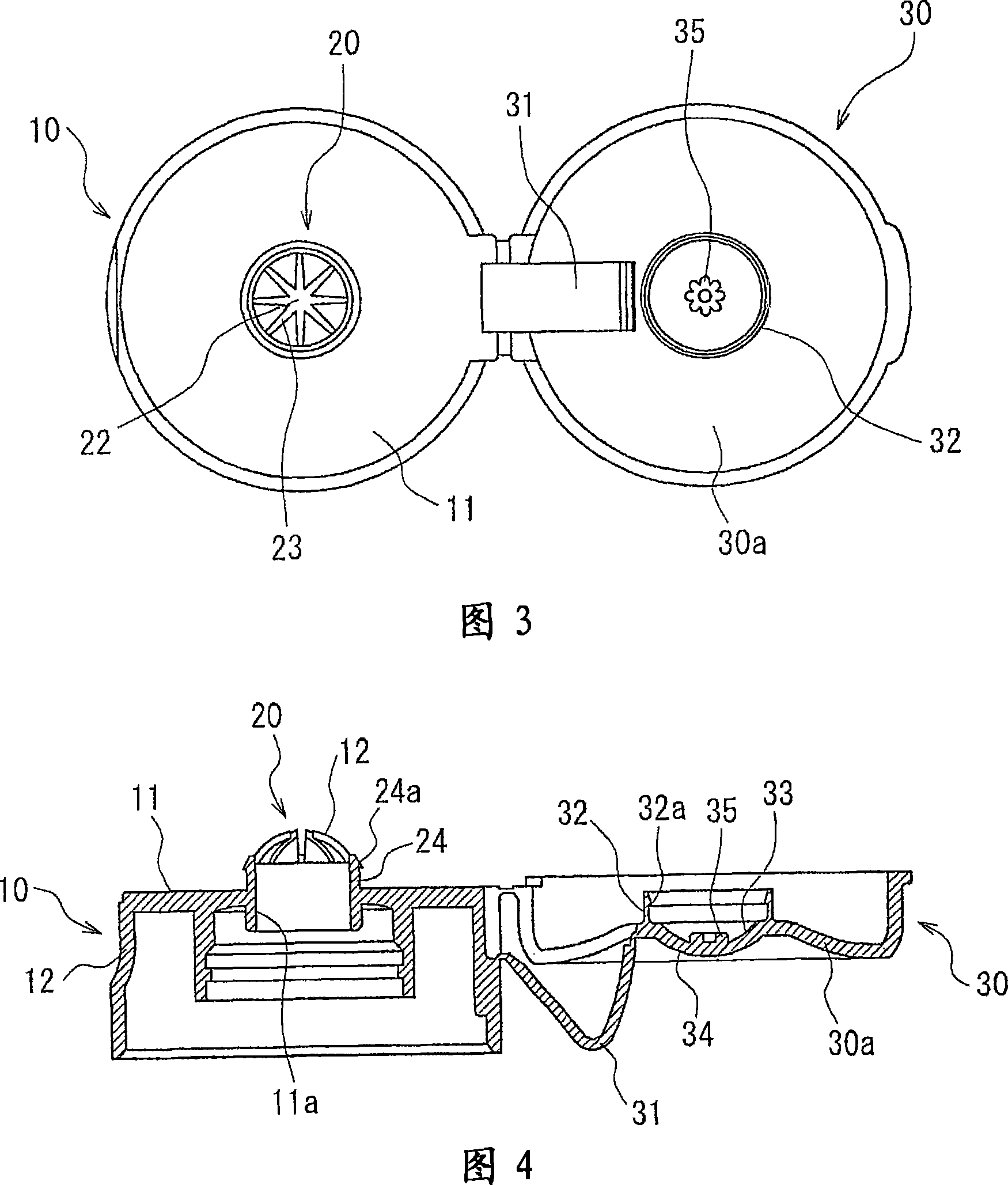

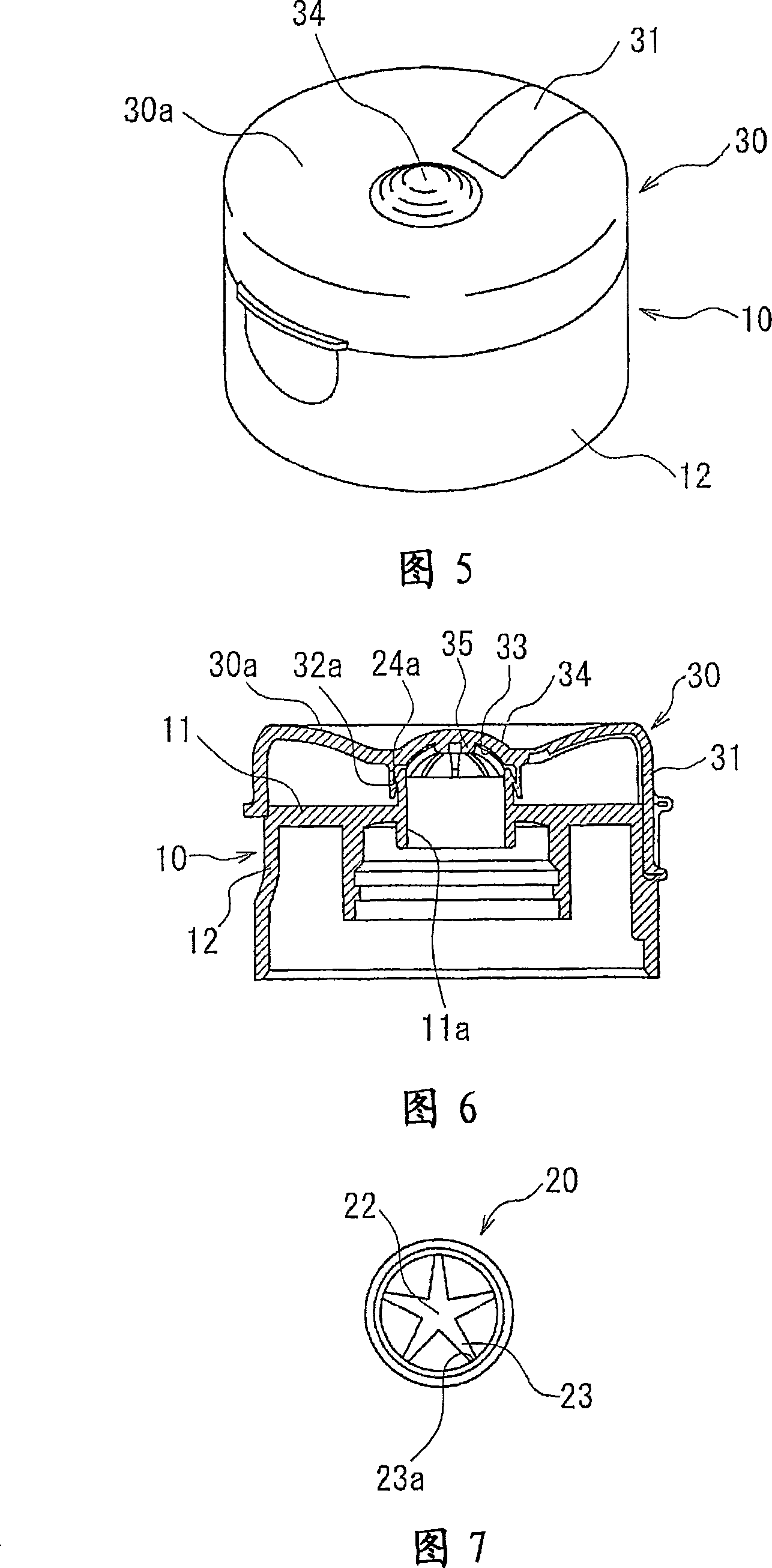

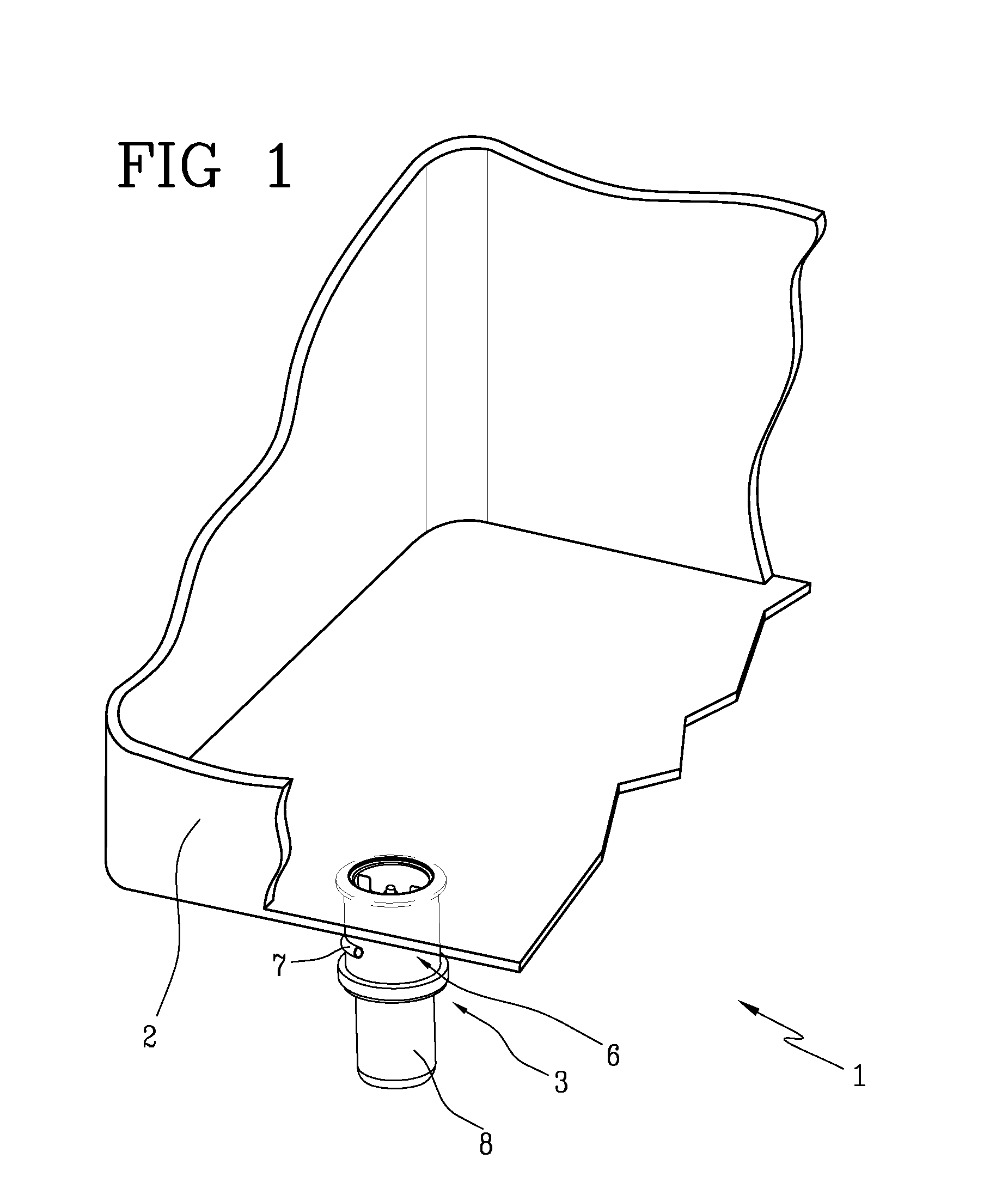

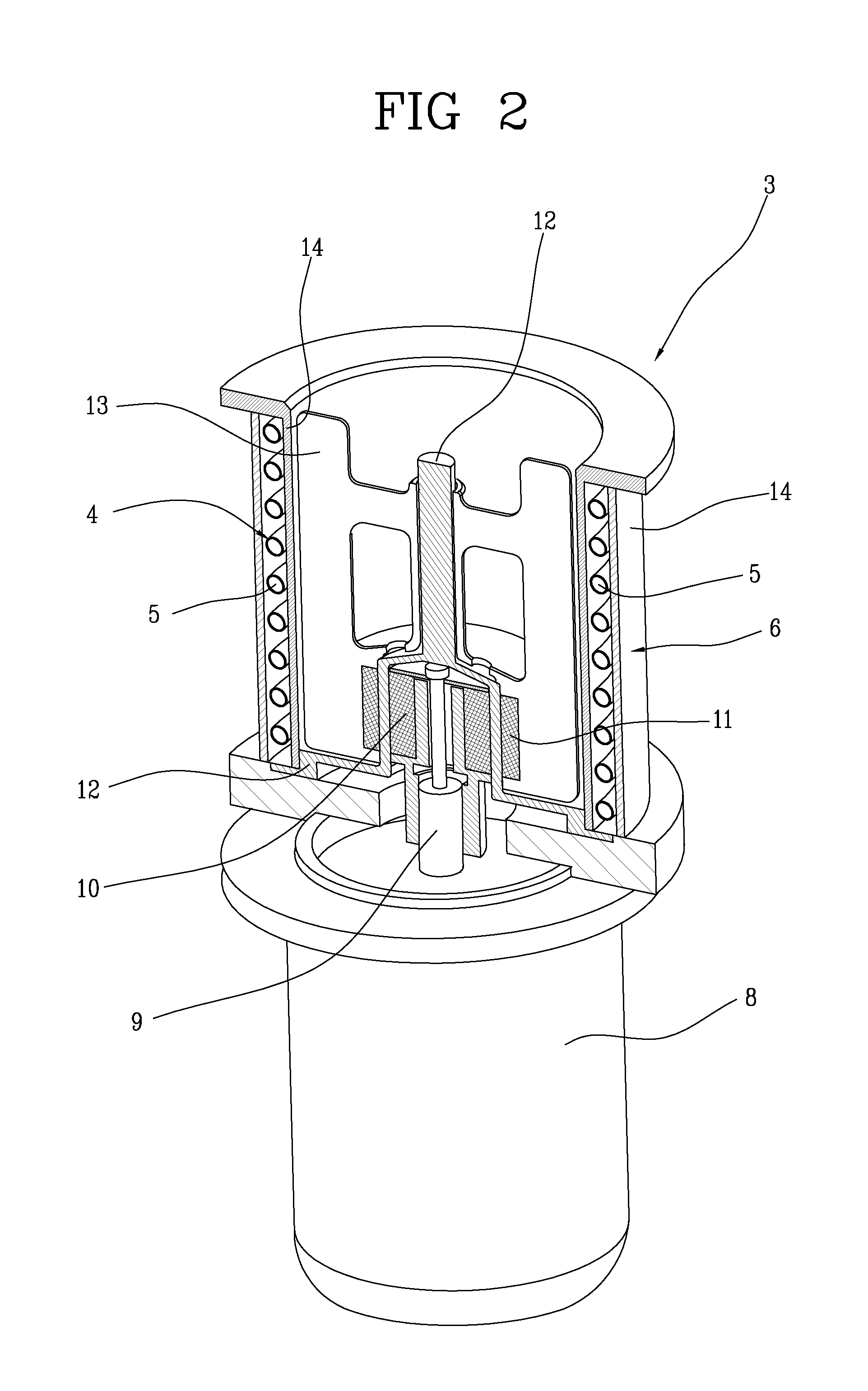

Ejection cap

ActiveCN101189169AEmphasize the effect of adjustment, etc.ClosuresDispensing apparatusEngineeringViscosity

An ejector cap which can impart a whipped cream-like appearance to a body care composition at the time of ejection. In order to find the arrangement of an ejection opening, a main means comprises a cap body fixed to a container and having an ejection opening formed in the top wall, and a lid movable freely between an open position and a close position. In the ejection cap for ejecting a body care composition, contained in the container and having viscosity of 10,000-50,000 Pas, from the ejection opening, the cap body has a dome-like portion formed on the top wall, and the ejection opening is formed of a central opening formed in the center of the dome-like portion and at least three leg-like openings extending radially outward from the central opening. The lid has an enclosing function for preventing leakage of the body care composition from the ejection opening at the close position.

Owner:THE PROCTER & GAMBLE COMPANY +1

Nondairy whipping cream and ultrahigh-temperature instant sterilization preparation method thereof

ActiveCN107027898AReduce shipping costsReduce storage costsEdible oils/fats ingredientsFinished edible oils/fats preservationVegetable oilOil phase

The invention provides nondairy whipping cream and an ultrahigh-temperature instant sterilization preparation method thereof, and relates to the field of foods. The raw materials of the sterilized nondairy whipping cream comprise the following components in percentage by weight: 10-20% of vegetable oil, 5%-20% of syrup, 8%-15% of sugar, 1%-10% of fat-containing dairy products, 0.2-2% of a stabilizing agent, 0.2-2% of an emulsifying agent, 0.2-2% of a thickening agent and 30%-60% of water. The preparation method comprises the following steps of warming the fat to 60-65 DEG C, adding the stabilizing agent, the emulsifying agent and the thickening agent, and performing uniform stirring and dispersing, so as to obtain an oil-phase mixture; the dissolving the sugar, the syrup, and the fat-containing dairy products in water of 60-70 DEG C so as to prepare an aqueous phase mixture; and adding the aqueous phase mixture to the oil-phase mixture, performing uniform stirring, then performing homogenizing, then performing ultrahigh temperature instant sterilization, performing rapid cooling, performing filling and performing package.

Owner:SHANGHAI HI ROAD FOOD TECHNOLOGY CO LTD

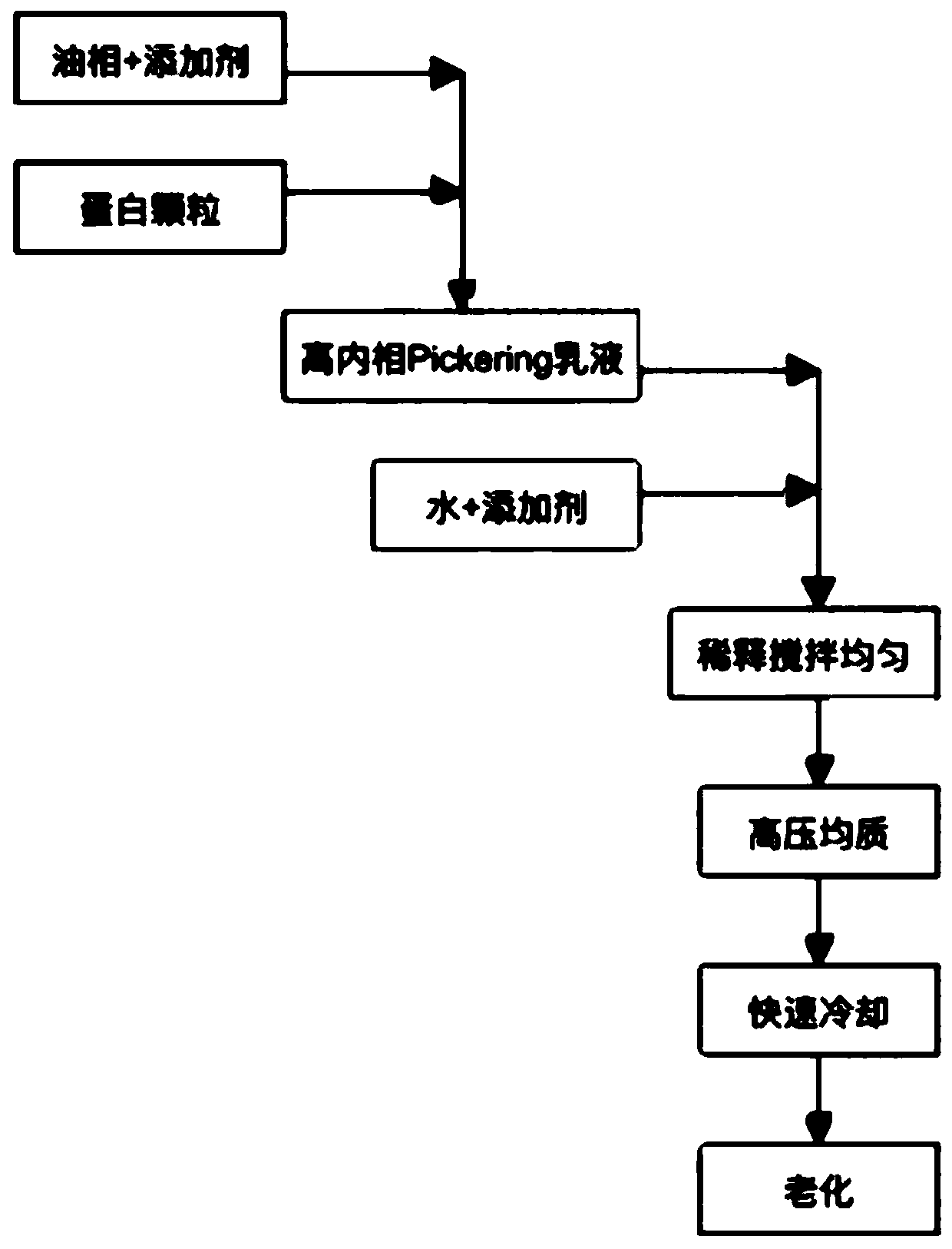

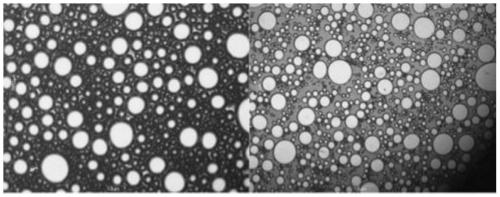

Whipped cream based on high-internal-phase Pickering emulsion and preparation method of whipped cream

PendingCN111296586AMeet needsGood foaming effectEdible oils/fats production/working-upCoconut oilPickering emulsion

The invention relates to whipped cream based on high-internal-phase Pickering emulsion and a preparation method of the whipped cream. The preparation method comprises the following steps: 1) carryingout thermal crosslinking and enzyme crosslinking on a plant protein isolate solution, and carrying out high-speed shearing and high-pressure homogenization in sequence to obtain protein microgel particles; 2) mixing an oil phase and an additive, performing heating and stirring, performing mixing with the protein microgel particles, and carrying out high-speed shearing to obtain a high-internal-phase Pickering emulsion, wherein the oil phase comprises palm oil and coconut oil; and 3) diluting the high-internal-phase Pickering emulsion by stirring, and carrying out high-pressure homogenization,rapid cooling and aging. The whipped cream based on the high-internal-phase Pickering emulsion does not contain trans-fatty acids, has a milder milk white color, and has no peculiar smell. The whippedcream is in a state similar to whipped cream sold on the market, has better foaming property and plasticity, and meets the requirement of consumers on whipped cream products with zero trans-fatty acid.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Machine for the homogenization and thermal treatment of liquid and semi-liquid food products

ActiveUS20120103201A1Heating evenlyLimited running costMilk preservationConfectioneryEngineeringThermal treatment

A machine for the homogenization and thermal treatment of liquid and semi-liquid food products, for example ice creams, whipped cream, creams, chocolate, yogurt and the like, comprises a containment tank for the mixture and a centrifugal pump put in fluid communication with the bottom of the containment tank for drawing mixture from the tank and putting it back into the tank, heating and cooling means acting at the pump for heating and cooling the mixture in transit in the pump. The heating and cooling means comprise a thermal machine with reversible thermodynamic cycle and using carbon dioxide as refrigerant.

Owner:ALI - CARPIGIANI GROUP

Milk cover powder and preparation method thereof

The present invention provides milk cover powder and a preparation method thereof. The milk cover powder is prepared from the following accessory materials: non-dairy creamers, milk powder, white granulated sugar, refined edible salt, a compound stabilizer, and food essences. The milk cover consists of the following components in weight based on 1,000 g of the weight of a main agent: 150-200 g of non-dairy creamers, 250-300 g of milk powder, 50-55 g of edible salt, 40-60 g of compound stabilizer, 0.5-2 g of food essences, and the balanced being white granulated sugar. The products prepared by applying the preparation method are easy to eat and the delicious and smooth milk cover can be enjoyed by beating the products with pure milk and whipping cream according to a certain proportion. The milk cover can be added into various drinks at will and has relatively good consumption channels.

Owner:HANGZHOU EVER MAPLE FLAVOR & FRAGRANCE

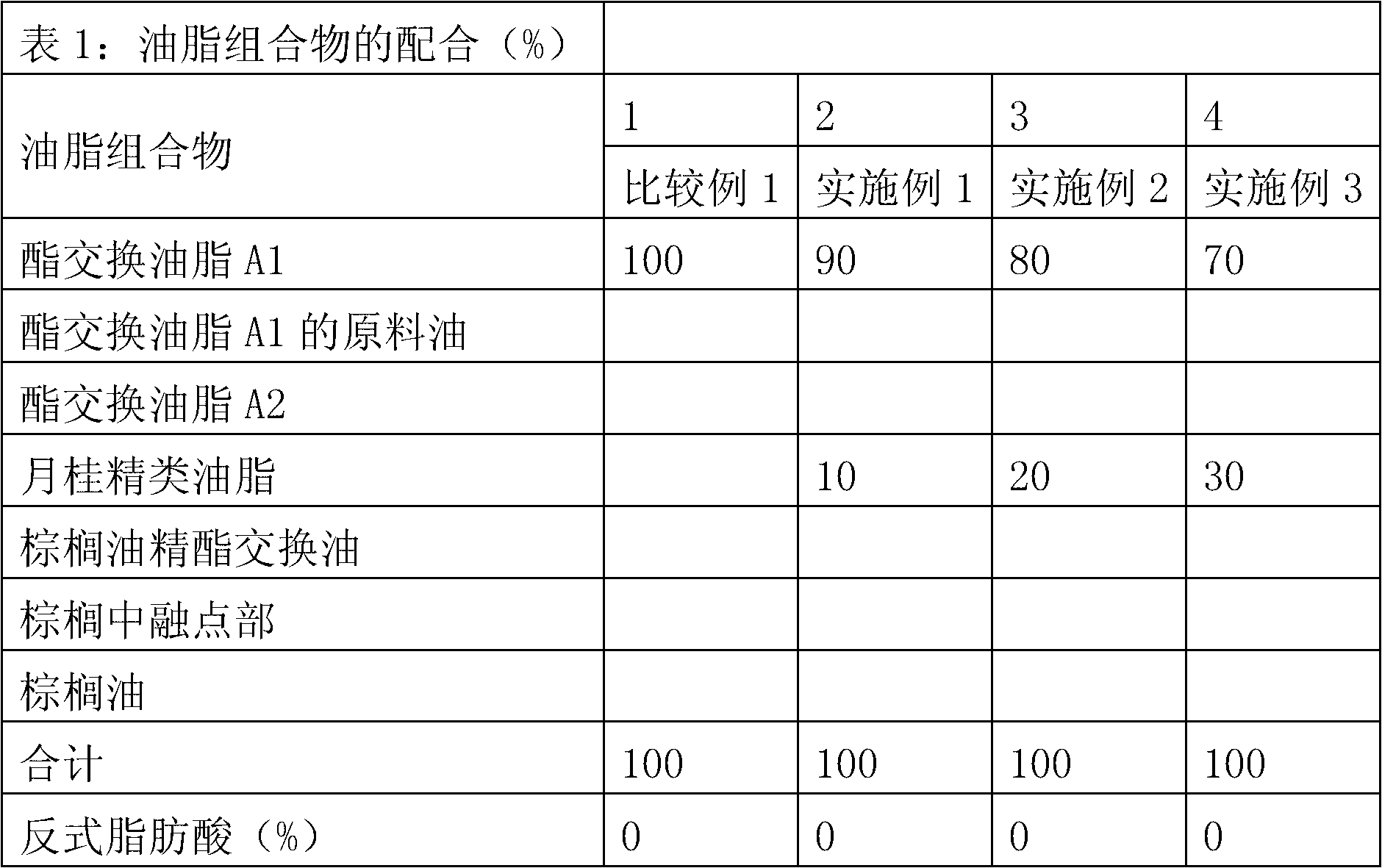

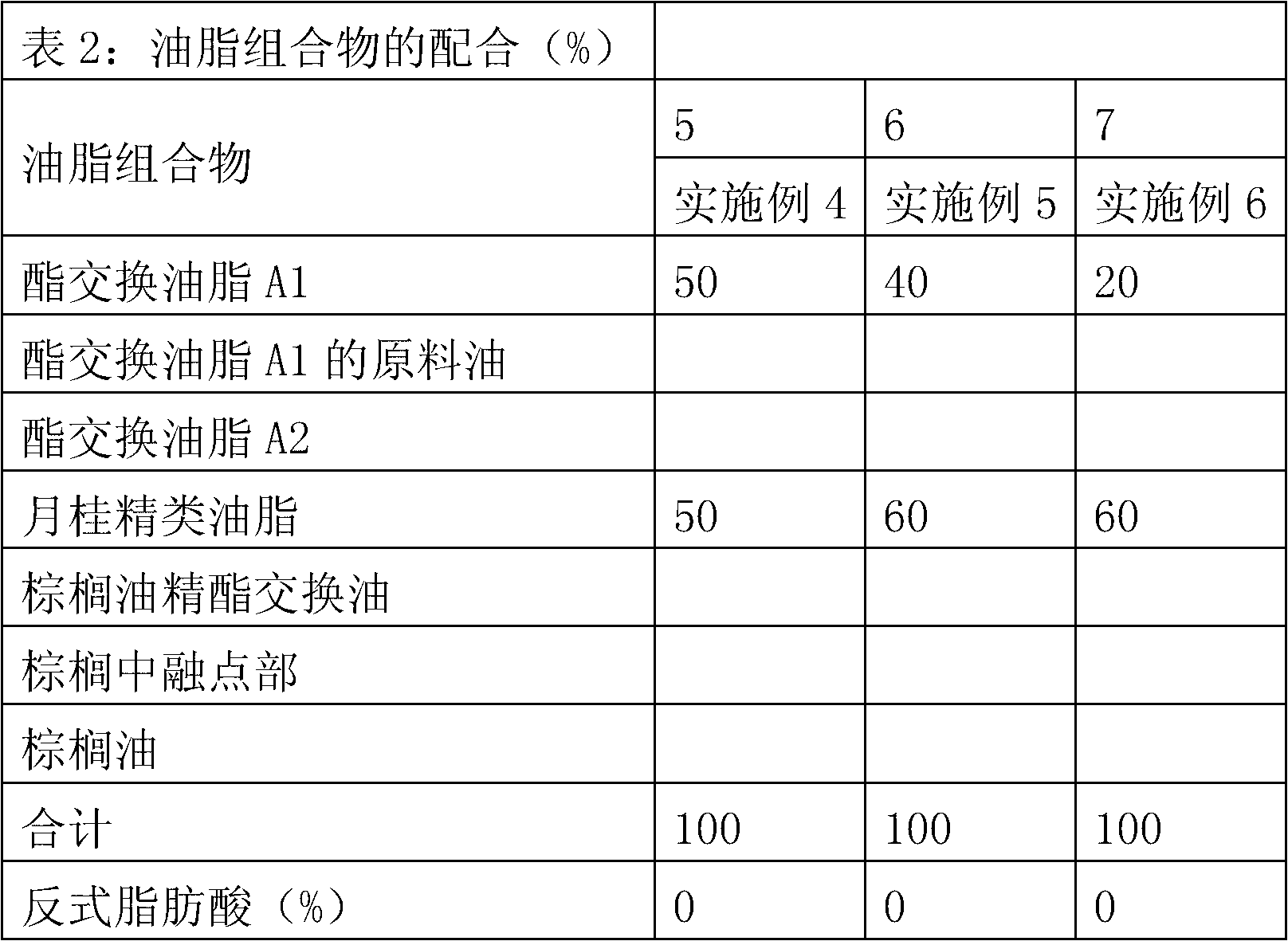

Oleaginous composition and oil-in-water type emulsifier containing oleaginous composition

ActiveCN102811625AGood melt in the mouthInhibition of changes in physical propertiesCream substitutesFood preparationCarbon numberInteresterified fat

Disclosed is a preferred oleaginous composition in an oil-in-water type emulsifier used as whipped cream mainly in confectionary and bread manufacturing. Use of the oleaginous composition suppresses whipped cream property changes that occur because of temperature changes, substantially without containing trans-fatty acid thereby providing an oil-in-water emulsifier with an excellent melt-in-the-mouth property. Disclosed is the manufacturing of an oil-in-water type emulsifier using an oleaginous composition containing a lauric acid content of 10 - 30% by weight and a triglyceride content of 30 - 55% by weight whose total carbon number is 44 - 48 of fatty-acid residue that composes the triglyceride, and containing a lauric-type oleo that contains interesterified fat with an iodine value of 30 - 50 and a lauric acid content of 40% by weight.

Owner:THE NISSHIN OILLIO GRP LTD

Foaming skincare formulations

ActiveUS20140120039A1Efficient use ofImprove textureCosmetic preparationsAerosol deliveryActive agentEngineering

In one aspect, the present invention is directed to formulations comprising at least one pressure generating vehicle along with at least one skincare active agent in a container such that the pressure generating vehicle would eject the formulation as foam, whipped cream or a similar form upon application of external pressure on the container.

Owner:BEIERSDORF AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com