Method for producing whipped cream product

A technology for whipped cream and production methods, which is applied in the direction of cream substitutes, dairy products, food preparation, etc., and can solve problems that are not involved in product application research, modification methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

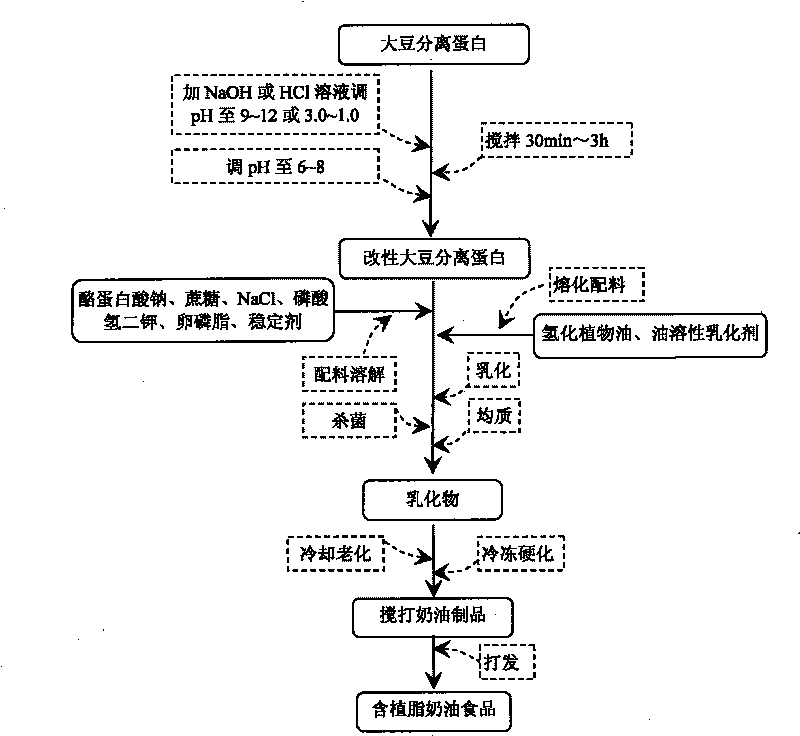

Method used

Image

Examples

Embodiment 1

[0075] Use commercially available soybean protein isolate (Daqing Riyuexing Protein Co., Ltd. product) to be formulated with a solution of soybean protein isolate concentration of 2.0% by weight, and add 6mol / L NaOH solution to the soybean protein isolate solution to make the final concentration of the solution When the pH reaches 12, stir for 30 minutes, and then add 6mol / L HCl solution to the solution to adjust the pH to 8.0. At this time, based on 0.5 parts by weight of soybean protein isolate in the solution, 0.5 parts by weight of sodium caseinate, 25 parts by weight of sucrose, 0.5 parts by weight of NaCl, and 0.2 parts by weight of phosphoric acid were added to the modified soybean protein isolate solution. Dipotassium hydrogen and 0.5 parts by weight of octenyl succinic esterified starch were stirred at a stirring speed of 200 rpm while heating to a temperature of 80° C. and kept at this temperature for 30 minutes to obtain an aqueous phase.

[0076] In addition, based...

Embodiment 2

[0079] Soybean protein isolate (self-extracted in the laboratory, protein content 95%, nitrogen solubility index 90%) is formulated into a solution with a protein concentration of 5.0%, and 4mol / L of HCl solution is added to the obtained soybean protein isolate solution to make its final pH reach 1.5, then stirred for 60min, then added 3mol / L KOH solution to it, and adjusted its pH back to 7.0. The soybean protein isolate added in the above-mentioned solution is 0.8 parts by weight, and 0.2 parts by weight of sodium caseinate, 15 parts by weight of sucrose, 0.8 parts by weight of NaCl, 0.05 parts by weight of dipotassium hydrogen phosphate are added to the modified soybean protein isolate solution, 0.1 part by weight of octenyl succinic esterified starch, stirred quickly, heated to 70°C, and kept at a constant temperature for 30 minutes; separately took 30 parts by weight of hydrogenated oil, 0.1 part by weight of lecithin, 0.05 part by weight of monoglyceride, and 0.05 part by...

Embodiment 3

[0081] Soybean protein isolate (self-extracted in the laboratory, protein content 95%, nitrogen solubility index 90%) is formulated into a solution with a protein concentration of 3.0%, and the soybean protein isolate added in the above-mentioned solution is 0.7 parts by weight. Add 0.3 parts by weight of sodium caseinate, 20 parts by weight of sucrose, 1.5 parts by weight of NaCl, 0.1 part by weight of dipotassium hydrogen phosphate, and 0.1 part by weight of octenyl succinic esterified starch into the protein solution, stir rapidly, and heat to 75°C. Constant temperature for 30min; another 25 parts by weight of hydrogenated oil, 0.1 part by weight of lecithin, 0.05 part by weight of monoglyceride, 0.05 part by weight of monoglyceride diacetyl tartrate, 0.01 part by weight of sodium stearoyl lactylate and 0.01 part by weight of polysorbate, After thorough mixing, stir in a water bath at 85°C for 10 minutes. Pour the oil phase obtained above into the obtained water phase, stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com