Whipped cream based on high-internal-phase Pickering emulsion and preparation method of whipped cream

A technology of high internal phase and cream, applied in the field of whipping cream and its preparation, can solve the problems of increasing people suffering from cardiovascular diseases, diabetes and cancer, and achieve the effects of low cost, good foamability and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

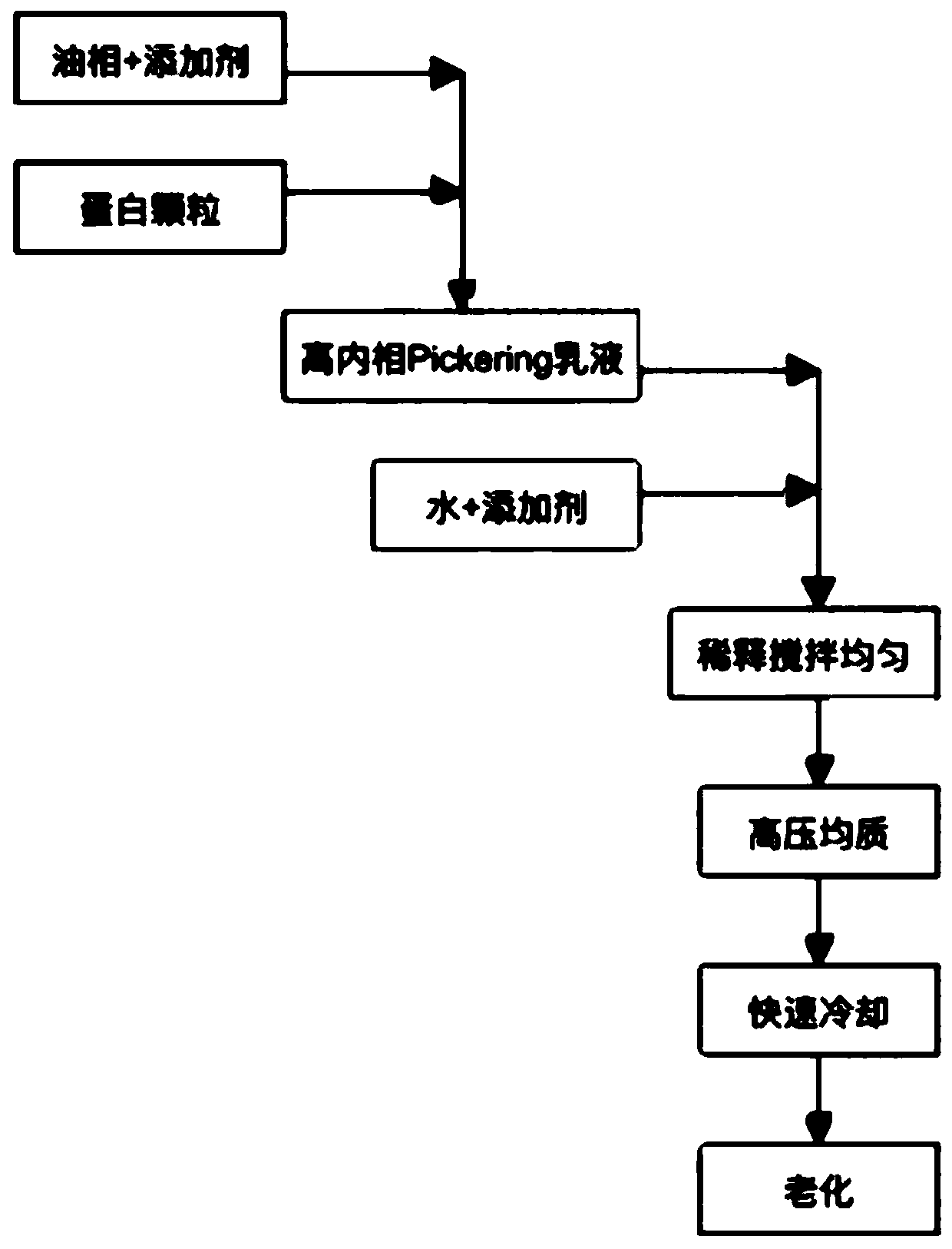

[0028] This example is a preparation method of whipped cream based on high internal phase Pickering emulsion, see the process flow chart figure 1 , Including the following steps:

[0029] (1) Heat cross-link the soy protein isolate solution at 80°C for 20 minutes, and then use 1000 U / g of transglutaminase to perform enzyme cross-linking at 45°C for 4 hours after cooling to room temperature;

[0030] (2) Dilute the cross-linked soy protein isolate and perform high-speed shearing at 12000 rpm and high-pressure homogenization at 1000 mp to obtain protein microgel particles;

[0031] (3) Combine the oil phase (35%) (palm oil: coconut oil=3:7) with emulsifiers, foaming agents and stabilizers (mono- and di-fatty acid glycerides 1%, lecithin 1%, sodium caseinate 0.5 %, sucrose fatty acid ester 0.5%, Tween 80 0.5%, xanthan gum 0.025%, carrageenan 0.025%, white granulated sugar 16%) heat at 70℃ and stir evenly, then mix with granules (0.8%) at high speed at 5000rpm Shear to obtain high inter...

Embodiment 2

[0035] This example is a preparation method of whipped cream based on high internal phase Pickering emulsion, see the process flow chart figure 1 , Including the following steps:

[0036] (1) Heat cross-link the soy protein isolate solution at 80°C for 20 minutes, and then use 1000 U / g of transglutaminase to perform enzyme cross-linking at 45°C for 4 hours;

[0037] (2) Dilute the cross-linked soy protein isolate and perform high-speed shearing at 12000 rpm and high-pressure homogenization at 1000 mp to obtain protein microgel particles;

[0038] (3) Combine the oil phase (35%) (palm oil: coconut oil = 5:5) with emulsifiers, foaming agents and stabilizers (mono- and di-fatty acid glycerides 1%, lecithin 1%, sodium caseinate 0.5 %, sucrose fatty acid ester 0.5%, Tween 80 0.5%, xanthan gum 0.025%, carrageenan 0.025%, white granulated sugar 16%) heat at 70℃ and stir evenly, then mix with granules (0.8%) at high speed at 5000rpm Shear to obtain high internal phase Pickering emulsion;

[...

Embodiment 3

[0042] This example is a preparation method of whipped cream based on high internal phase Pickering emulsion, see the process flow chart figure 1 , Including the following steps:

[0043] (1) Heat cross-link the soy protein isolate solution at 80°C for 20 minutes, and then use 1000 U / g of transglutaminase to perform enzyme cross-linking at 45°C for 4 hours;

[0044] (2) Dilute the cross-linked soy protein isolate and perform high-speed shearing at 12000 rpm and high-pressure homogenization at 1000 mp to obtain protein microgel particles;

[0045] (3) Combine the oil phase (35%) (palm oil: coconut oil = 7:3) with emulsifiers, foaming agents and stabilizers (mono- and di-fatty acid glycerides 1%, lecithin 1%, sodium caseinate 0.5 %, sucrose fatty acid ester 0.5%, Tween 80 0.5%, xanthan gum 0.025%, carrageenan 0.025%, white granulated sugar 16%) heat at 70℃ and stir evenly, then mix with granules (0.8%) at high speed at 5000rpm Shear to obtain high internal phase Pickering emulsion;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com