UHT (ultra high temperature treated) whipping cream with butter serving as raw materials and preparation method of UHT whipping cream

A cream and butter technology, applied in cream preparations, dairy products, applications, etc., can solve the problems of differences, difficulty in direct sales, low market recognition, etc., and achieve the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

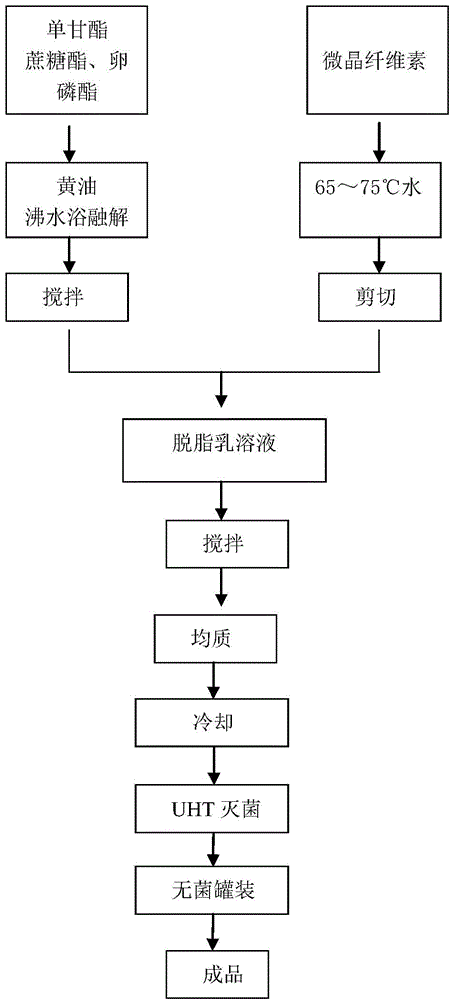

[0021] The following is based on figure 1 The production process of the present invention is to prepare UHT whipping cream with butter as raw material of the present invention, wherein the percentages are all mass percentages.

[0022] Weigh the following materials according to the amount to prepare 2kg of whipped cream: butter 800-1000g, skimmed milk powder 110-130g, compound emulsifier 8-12g (monoglyceride: sucrose ester 1:1-2:1, egg The amount of phospholipid added is 0.7‰-0.8‰), the thickener microcrystalline cellulose is 3-5g, and the water is 853-1079g.

[0023] Place the above-mentioned weighed butter in a boiling water bath and heat it to melt. After the oil is melted, add the above-mentioned compound emulsifier into the melted butter, and stir for 10 minutes under the condition of 400-450r / min; Under the condition of shearing for 10 minutes; the above-mentioned skim milk powder was weighed, dispersed in hot water at 40-60°C, and stirred at 400-500r / min for 10 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com