Wafer level lens, production method of wafer level lens, and imaging unit

a production method and technology applied in the field of wafer level lens, can solve the problems of increasing the production cost corresponding to this process, affecting the quality of the lens, so as to prevent the generation of light transmission and reflection at a region other than the lens surface, and prevent the transmission of light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]First, the constitutions of a wafer level lens and an imaging unit will be explained.

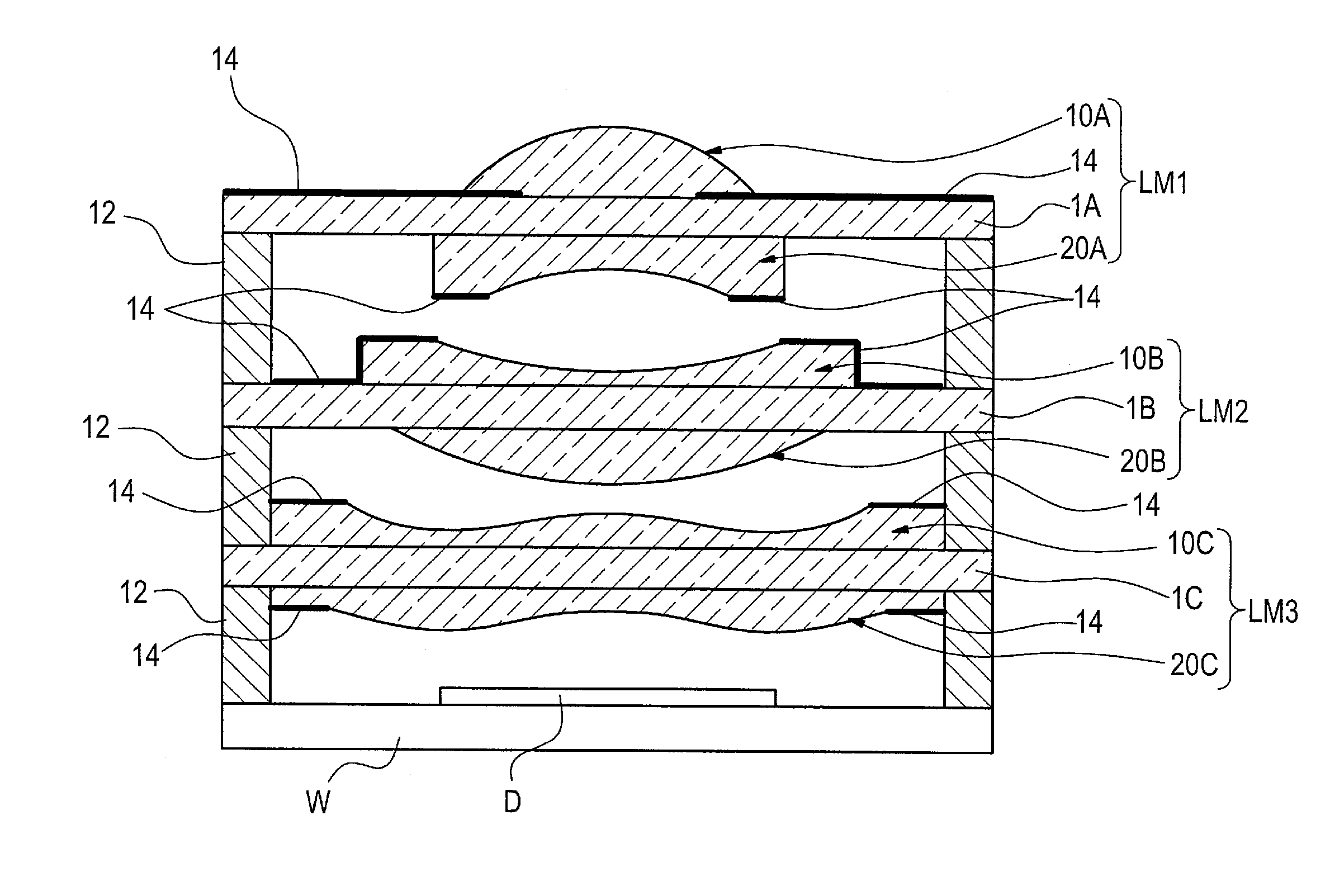

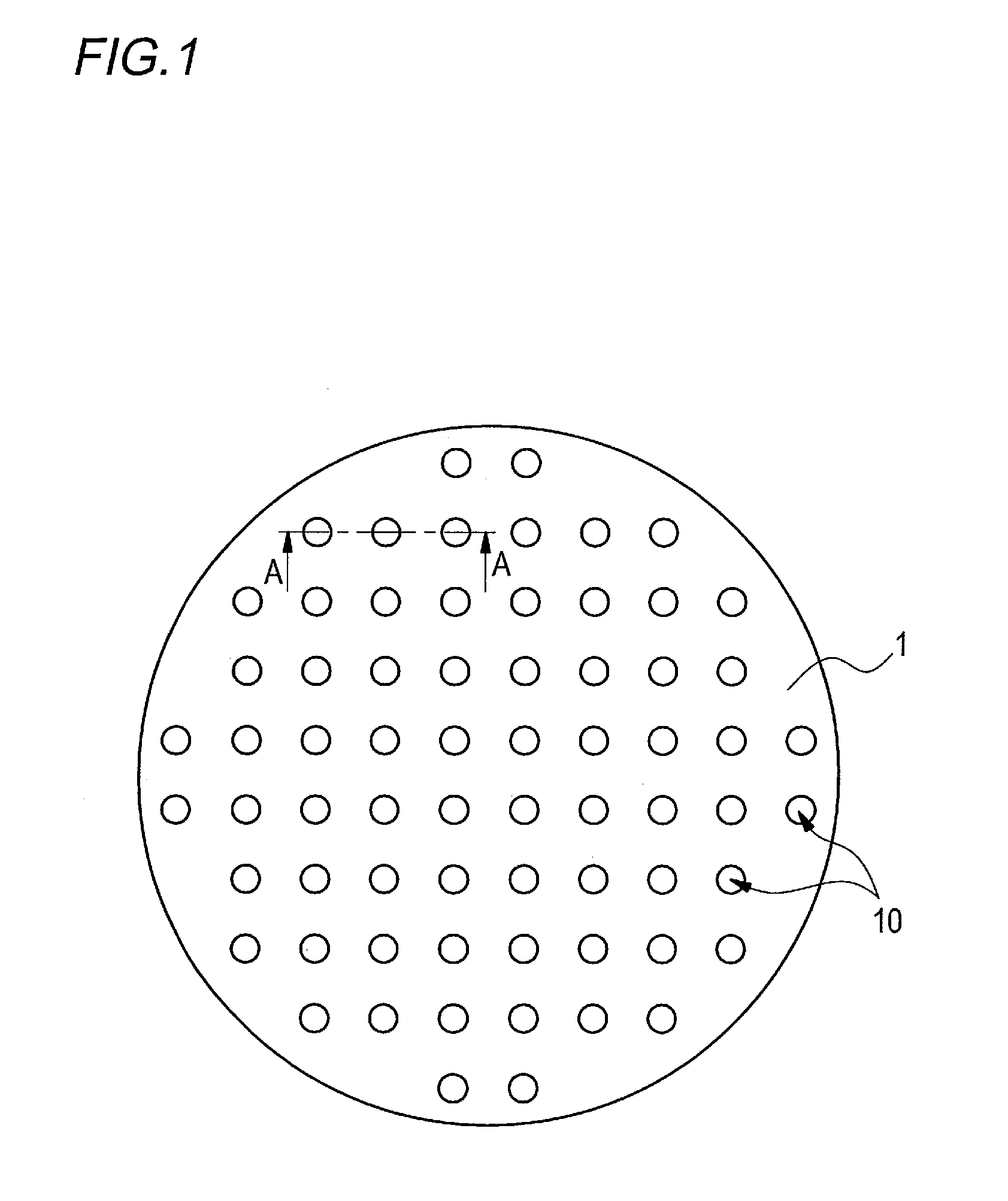

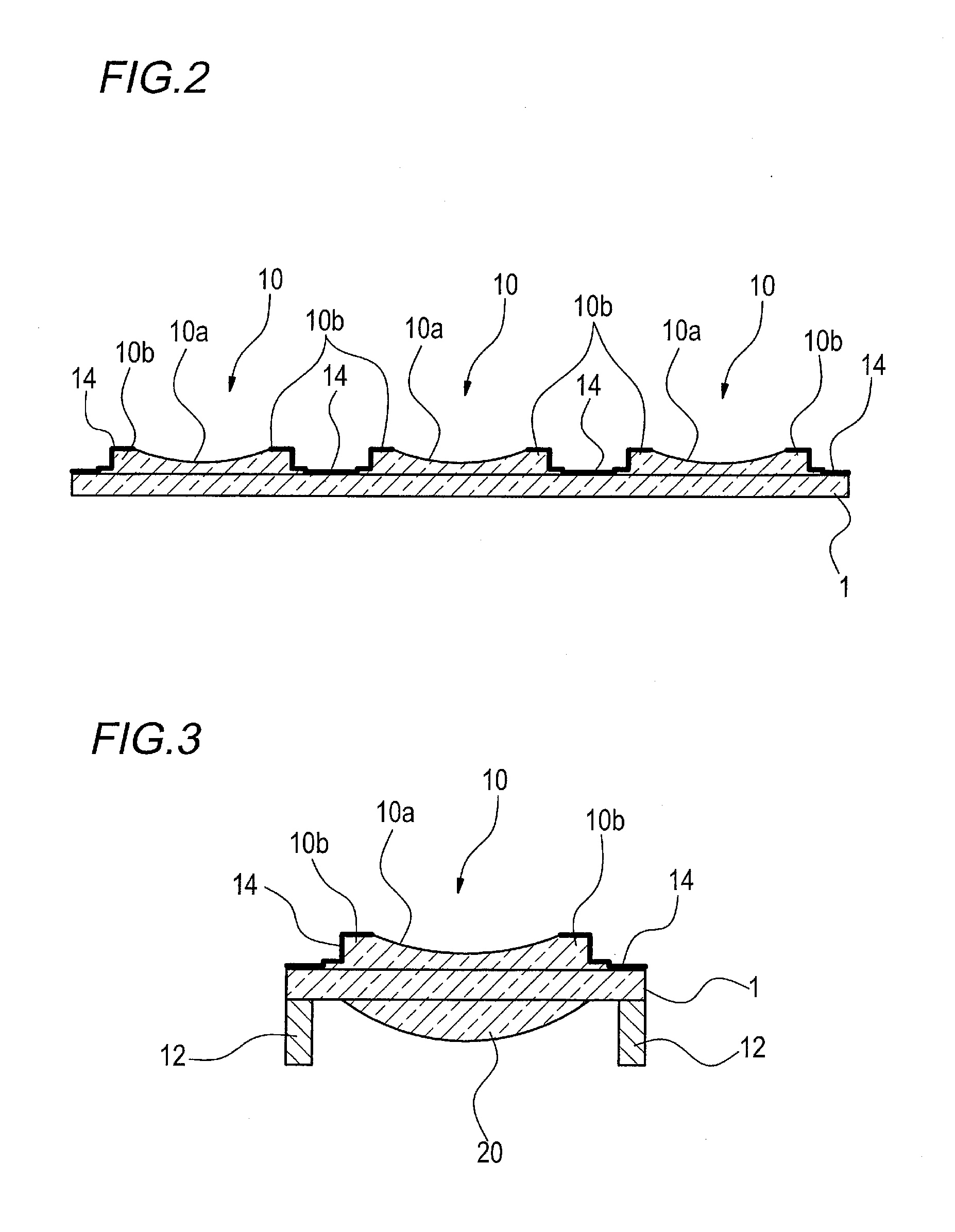

[0042]FIG. 1 is a plane view showing one example of the constitution of a wafer level lens. FIG. 2 is a cross-sectional view taken in a line A-A of the constitution of the wafer level lens shown in FIG. 1.

[0043]The wafer level lens has a lens module having a substrate 1 and a plurality of lenses 10 formed on the substrate 1. The plurality of lenses 10 are arranged on the substrate 1 in one-dimensional mode or two-dimensional mode. In this constitution example, an example of a constitution in which the plurality of lenses 10 are arranged on the substrate 1 in two-dimensional mode as in FIG. 1 will be explained. The lens 10 is constituted of the same material as for the substrate 1, and molded on the substrate 1.

[0044]As shown in FIG. 2, the lens 10 has a concave-shaped lens surface 10a and a lens marginal part 10b around the lens surface 10a. Here, the lens surface 10a has an optical property o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittance | aaaaa | aaaaa |

| transmittance | aaaaa | aaaaa |

| transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com