Patents

Literature

37results about How to "Solve the increase in production costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

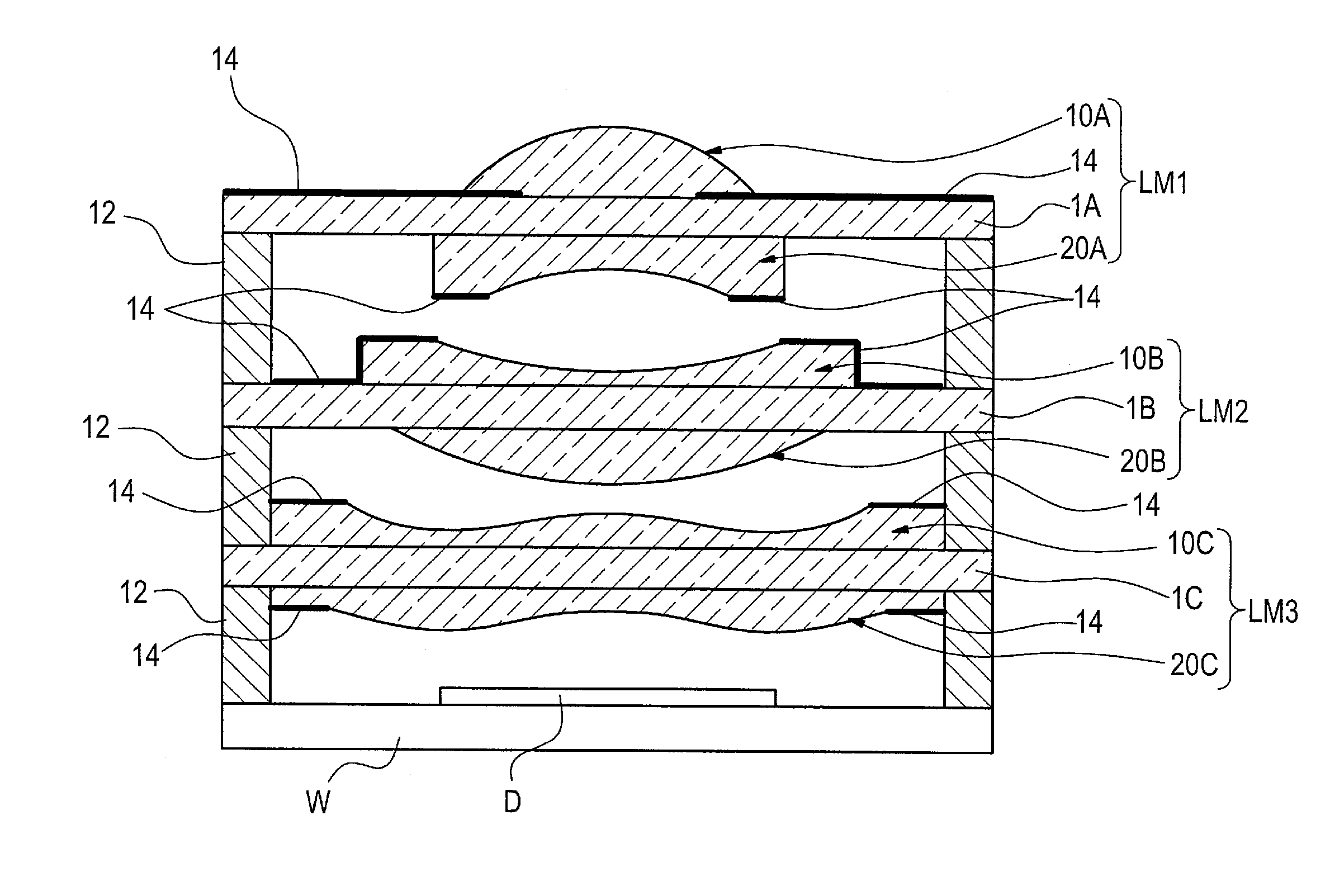

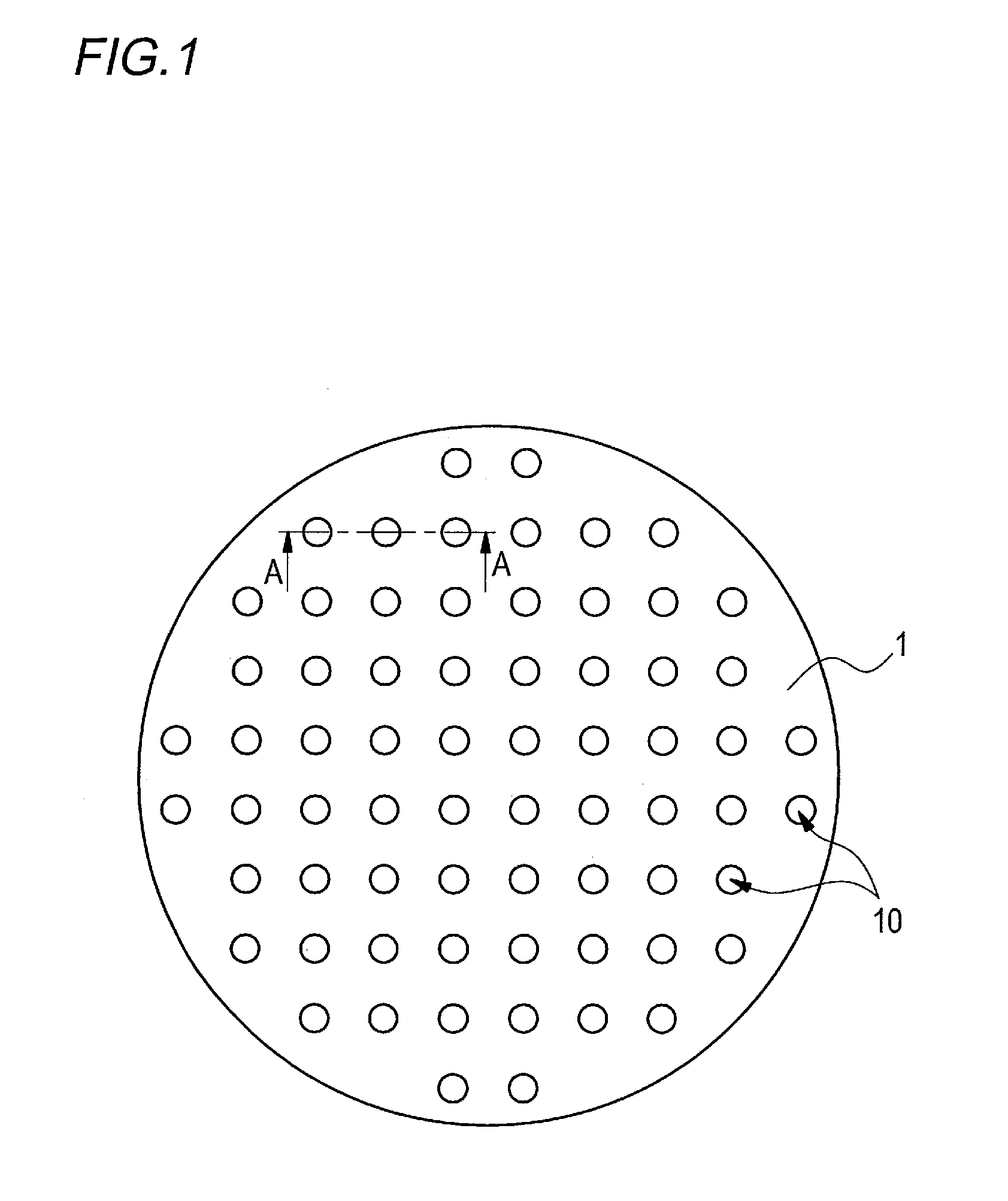

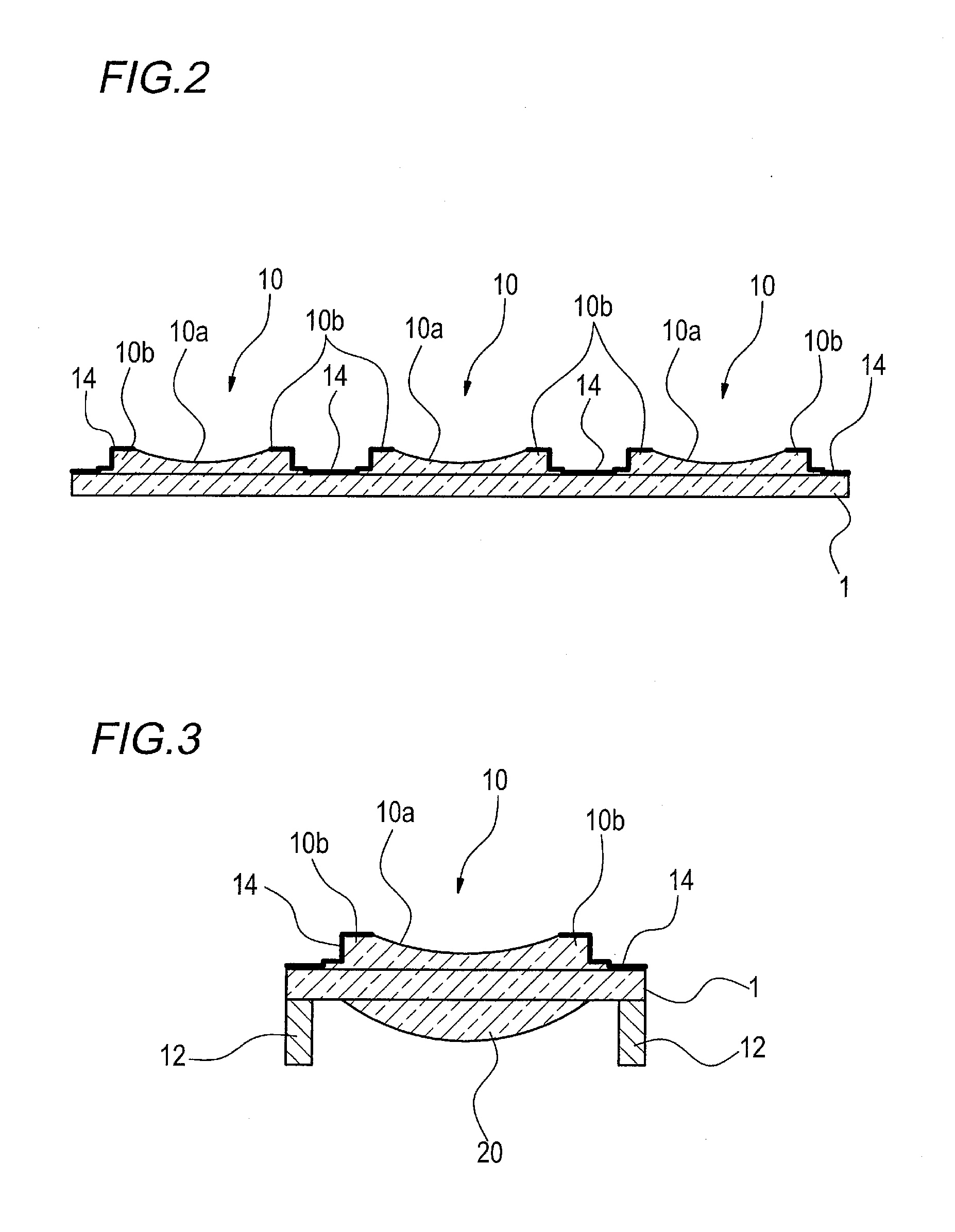

Wafer level lens, production method of wafer level lens, and imaging unit

InactiveUS20120134028A1Avoid light transmissionPrevent penetrationSolid-state devicesOptical articlesResistOptical axis

A sufficient light-shielding property is obtained by a wafer level lens having at least one lens module having a substrate and a plurality of lenses formed on the substrate in which the wafer level lens has a black resist layer formed on the surface of the lens module or on the surface of the substrate and the black resist layer is formed with a pattern having an opening at a part intersecting the optical axis of the lens, and generation of defects such as ghosts, flares and the like due to a reflected light can be prevented and an increase in the production cost can be suppressed.

Owner:FUJIFILM CORP

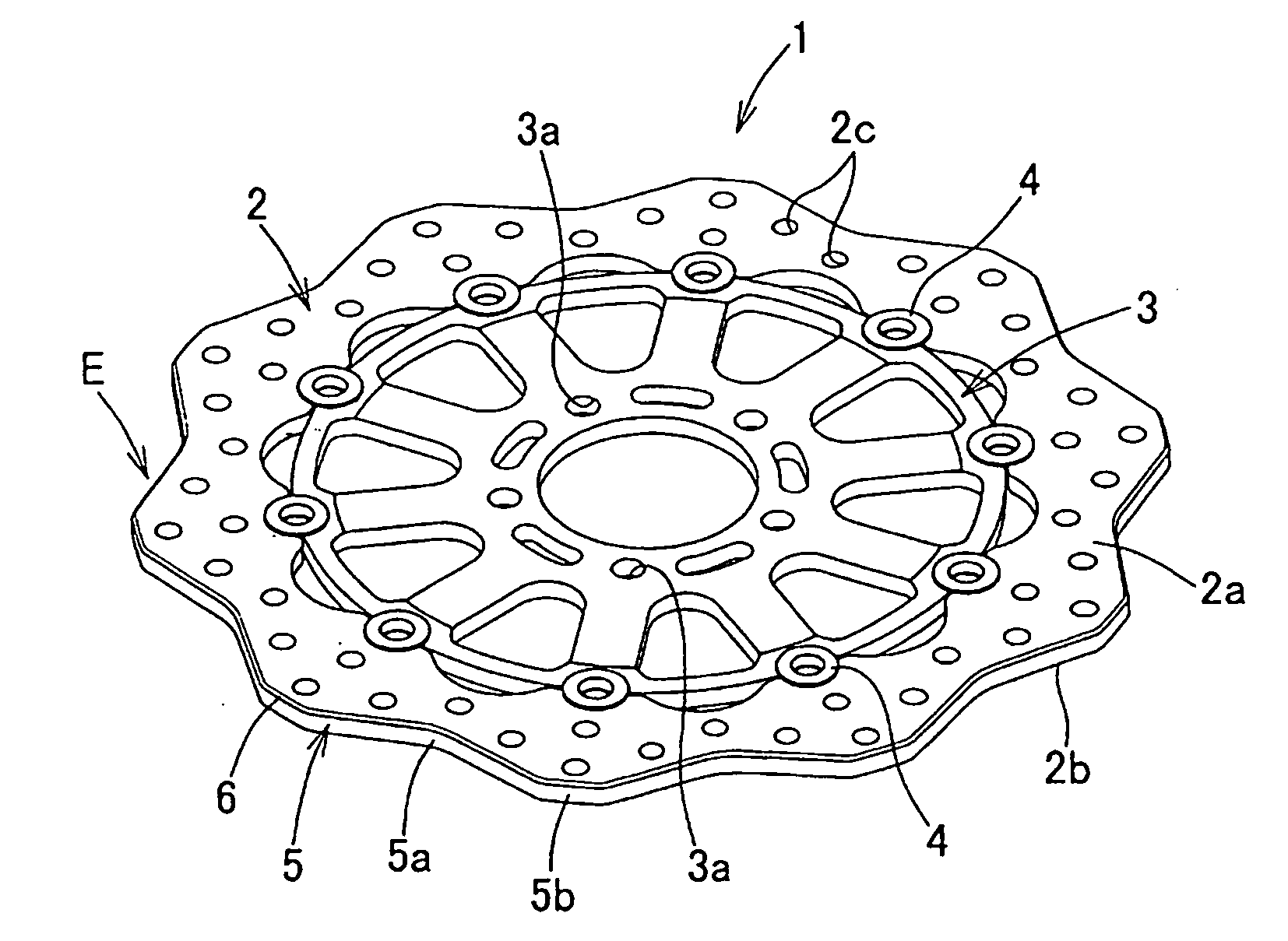

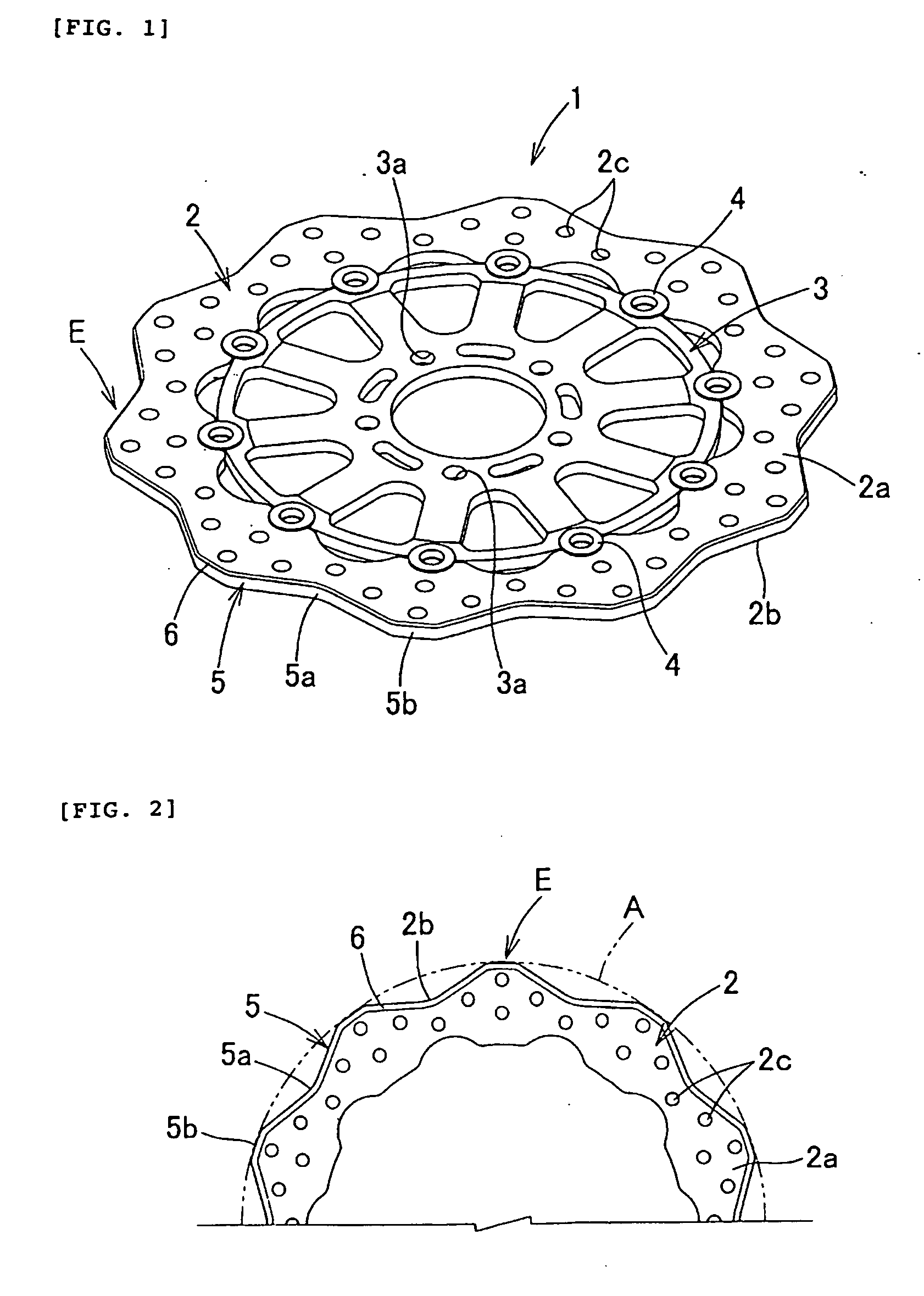

Brake disk producing method and brake disk

InactiveUS20070102247A1Avoid uneven wearReduce wearBraking discsFriction liningMoment of inertiaEngineering

A brake disk producing method, comprising a periphery pressing step for forming an outer peripheral shape (5) of a rotor plate (2) into a peripheral shape having recesses and ridges (5a, 5b) repeated in a radial direction, and a chamfering step for forming a chamfered surface (6) by pressing, against a corner portion (2d) on an outer peripheral edge of the rotor plate (2), a die (7), and a brake disk made by the method. Accordingly, it is possible to improve heat radiation capability, reduce the weight and moment of inertia, improve safety in handling, and suppress increase in production costs. Furthermore, by forming the chamfered surface (6), the amount of wear of a brake pad pressed by the brake disk (1) can be reduced, and durability of braking performance can be maintained or improved.

Owner:SUNSTAR GIKEN KK

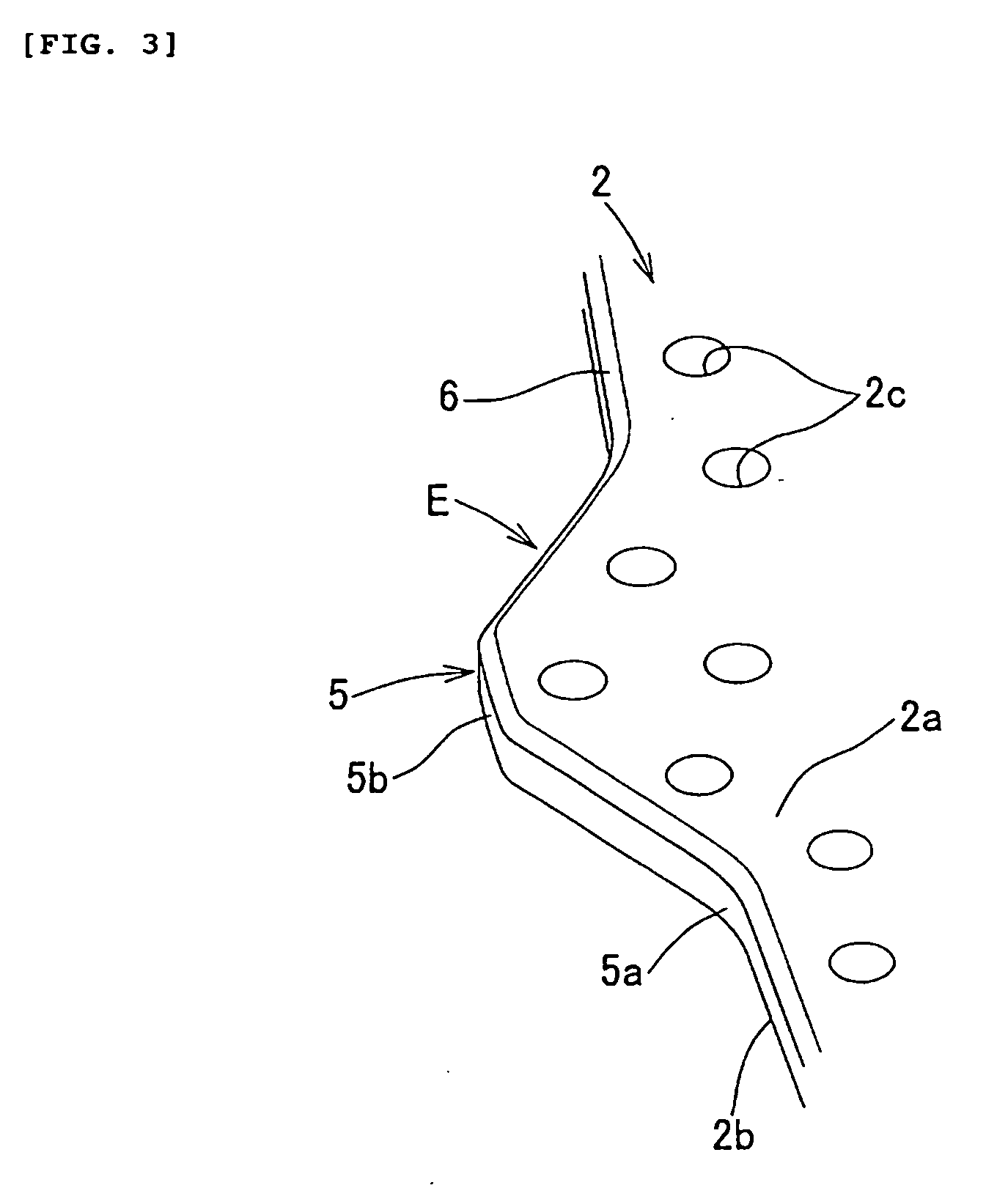

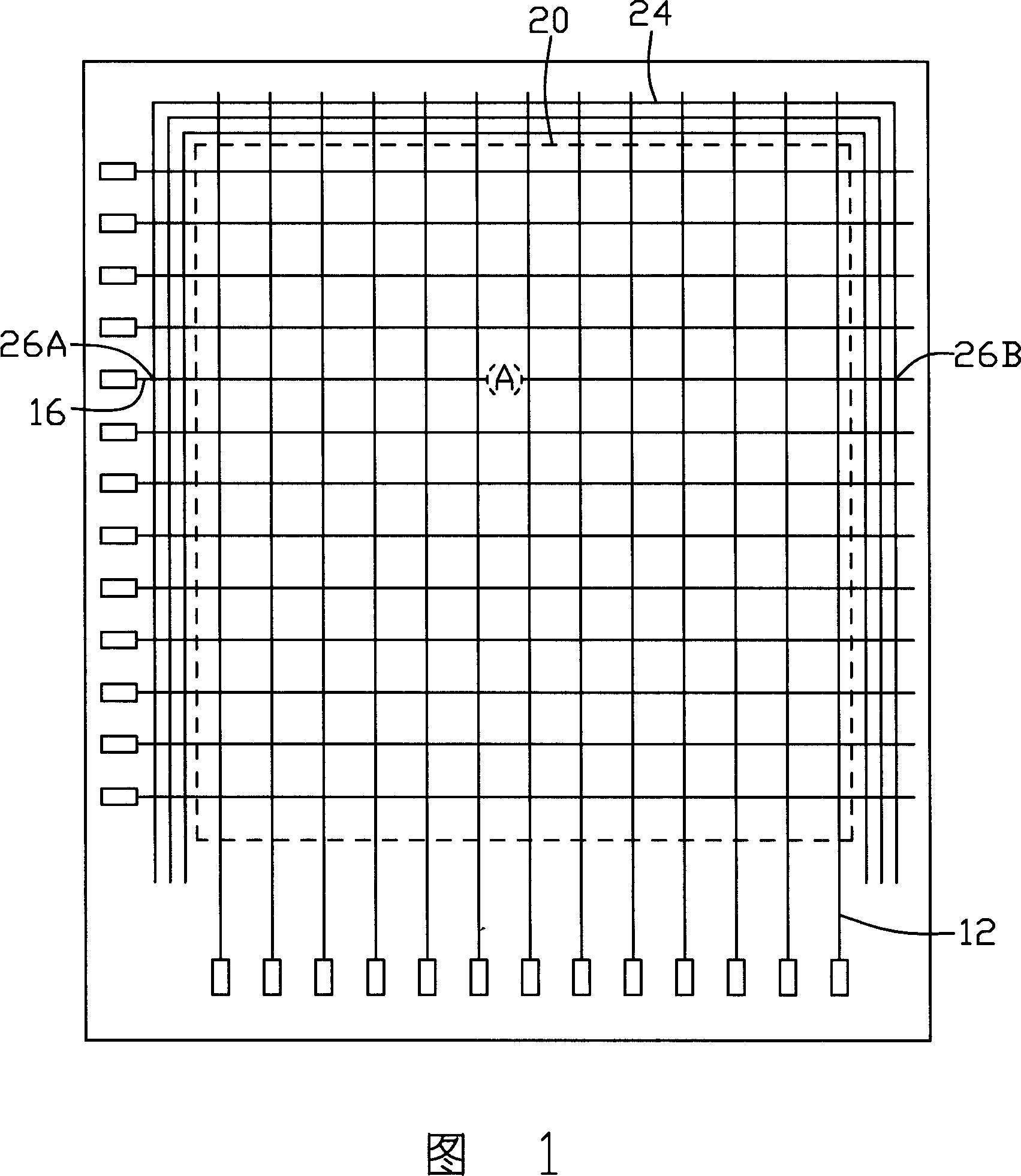

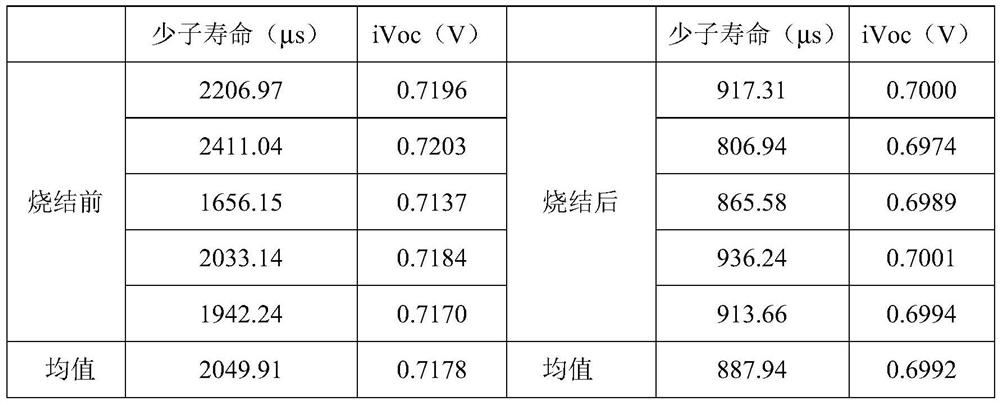

Method for repairing base plate of thin film transistor

InactiveCN1959961ALow costSolve the increase in production costsSemiconductor/solid-state device manufacturingNon-linear opticsElectrical connectionData lines

The invention is related to method for repairing base plate of thin film transistor (TFT). The base plate of TFT includes grid lines, data lines crossed to grid lines, pixel electrodes, and multiple TFT. Grid, source, and drain electrodes of TFT are connected to grid lines, data lines, and pixel electrodes electrically. A defect of electrical connection exists in a grid line. The repairing method includes following steps: cutting off electrical connection between source electrodes of two pieces of TFT located at two ends of the defect point and data line; connecting two pixel electrodes corresponding to the two pieces of TFT to the grid line electrically; connecting the two pixel electrodes electrically. The method can save cost.

Owner:INNOCOM TECH SHENZHEN +1

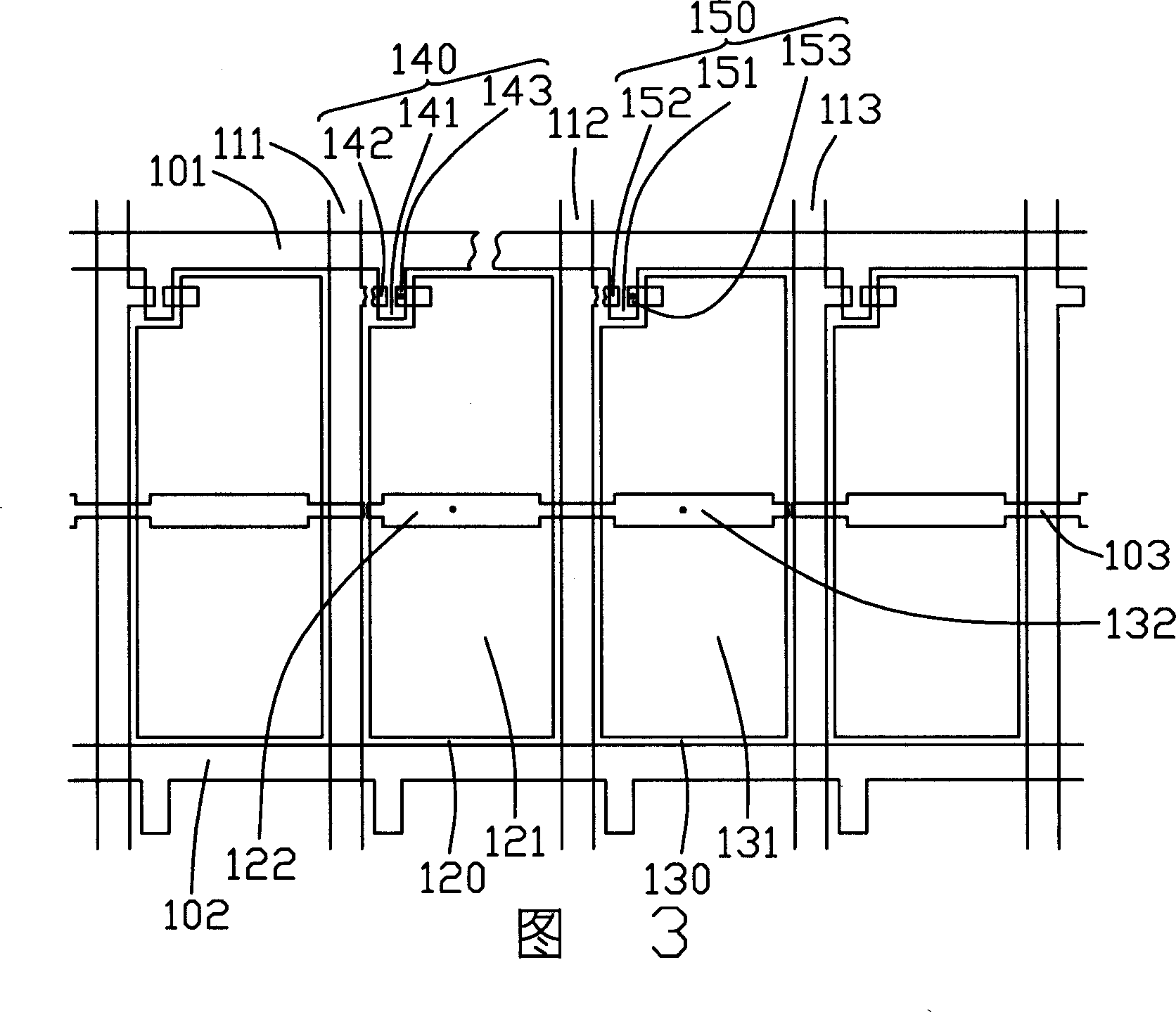

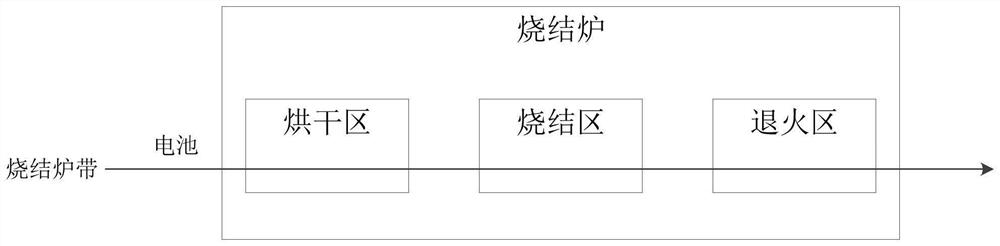

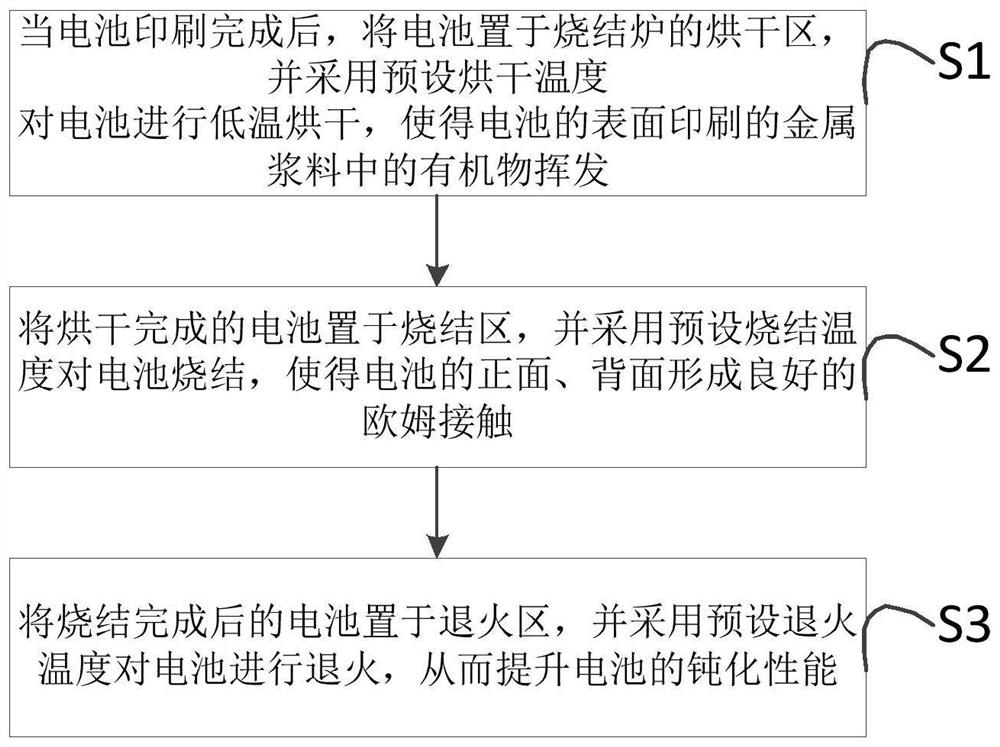

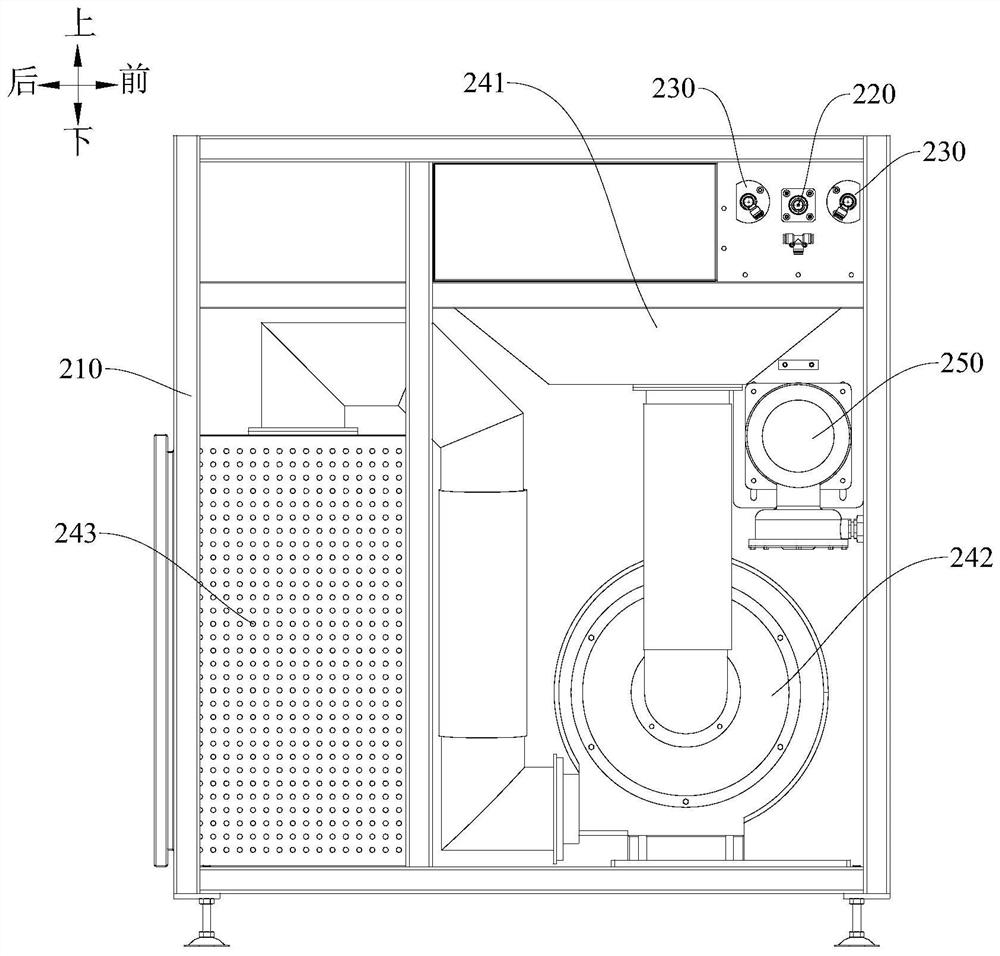

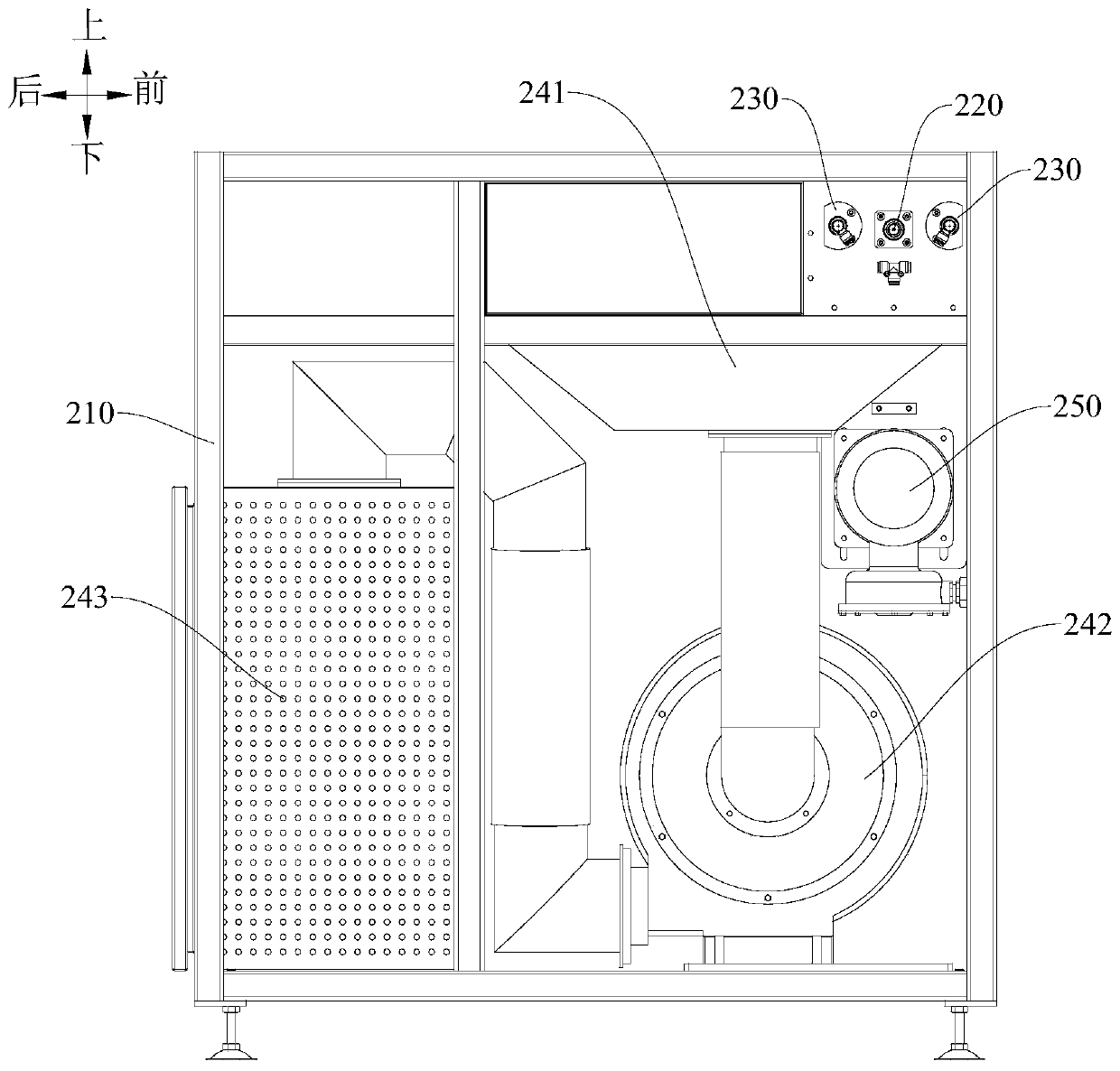

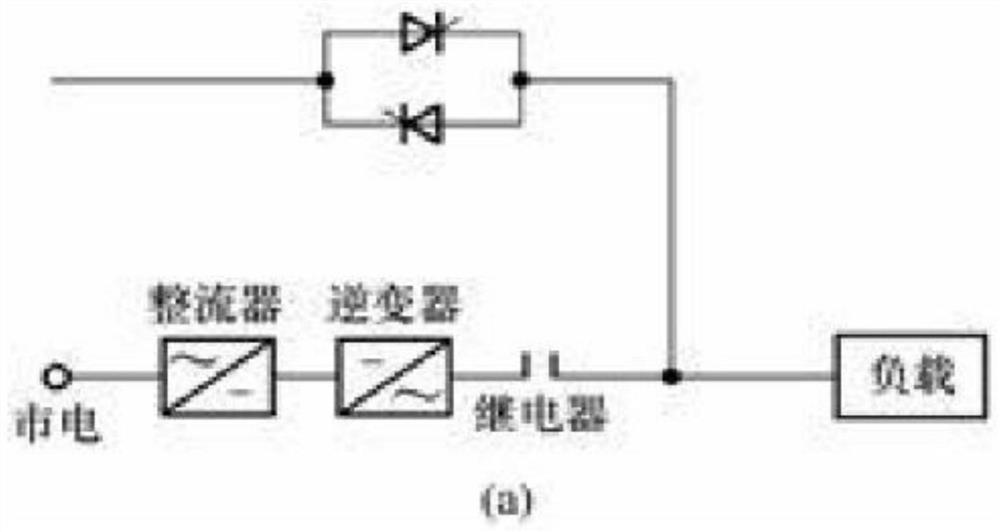

Sintering equipment, sintering annealing method of battery and battery

PendingCN111863661AImprove passivation effectImprove conversion efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingScreen printingOhmic contact

The invention discloses sintering equipment which is used for preparing a battery, and the battery is an N-type TOPCon battery. A drying area, a sintering area and an annealing area are arranged in the sintering equipment; the drying area is used for drying a battery subjected to silk-screen printing, so that organic matters in slurry printed on the surface of the battery are volatilized; the sintering area is used for sintering the dried battery, so that good ohmic contact is formed on the surface of the battery; and the annealing area is used for annealing the sintered battery, so that the passivation performance of the battery is improved. According to the invention, the passivation performance of the battery can be improved on the basis of not increasing extra annealing equipment. Theinvention also provides a sintering annealing method of the battery and the battery.

Owner:RISEN ENERGY (CHANGZHOU) CO LTD

Welding structure of lithium battery and circuit board and welding method

InactiveCN103187552ASolve the increase in production costsTo achieve the purpose of heavy industryCell component detailsEngineeringElectrical and Electronics engineering

The invention provides a welding structure of a lithium battery and a circuit board and a welding method. The welding method includes the lithium battery provided with a positive plate and the negative plate; a first positive electrode welding part is arranged on the positive board and a second positive electrode welding part connected to the first positive electrode welding part; a first negative electrode welding part arranged on the negative plate and a second negative electrode welding part connected to the first negative electrode welding part; the circuit board including a positive electrode pad and a negative electrode pad; a first positive electrode welding area arranged on the positive electrode pad and a second positive electrode welding area connected to the first positive electrode welding area; a first negative electrode welding area arranged on the negative electrode pad and a second negative electrode welding area connected to the first negative electrode welding area. The first positive electrode welding part is welded on the first positive electrode welding area and a first negative electrode welding area is welded on the first negative electrode welding area.

Owner:UER TECH CORP

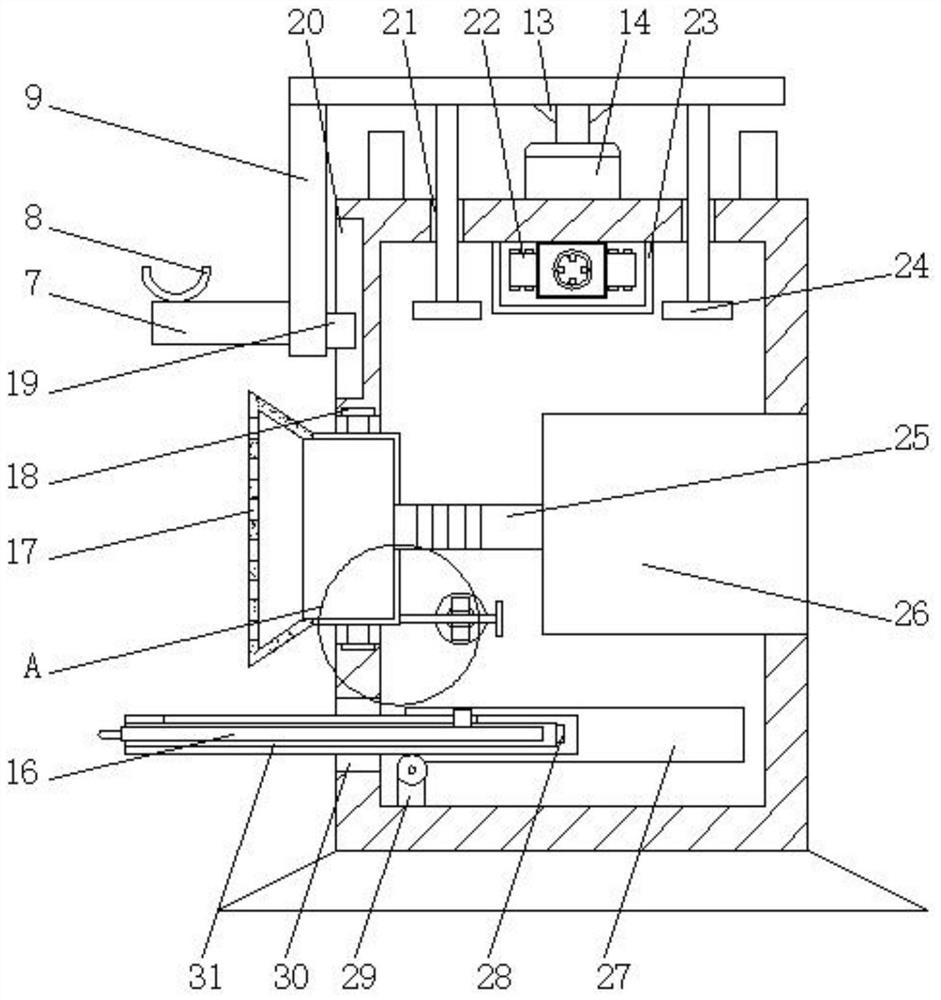

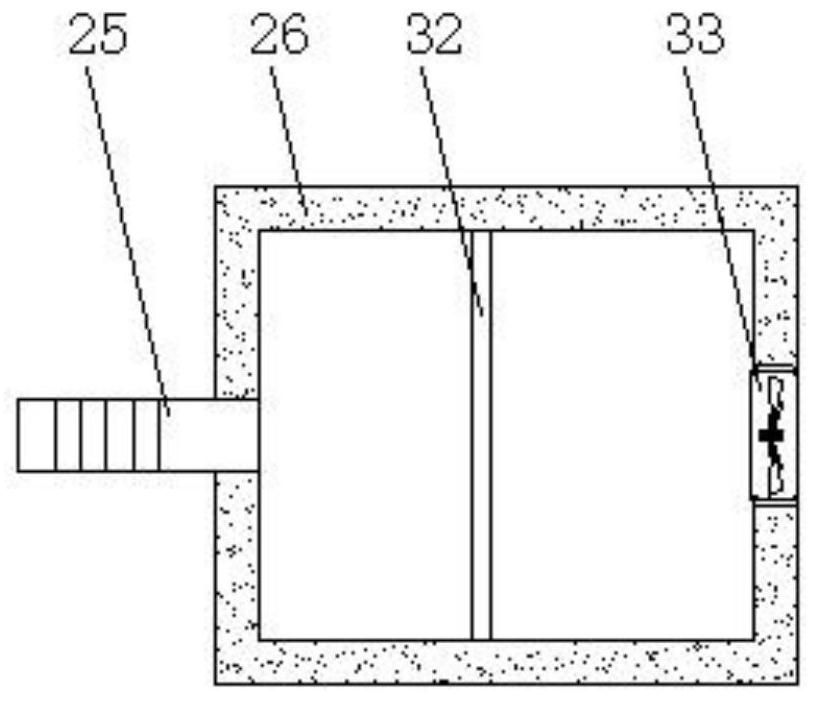

Recycling device used in concrete block cutting process

The invention relates to the technical field of concrete block machining, in particular to a recycling device used in the concrete block cutting process. Compared with the prior art, in the scheme, a waste elevator and a water suction pump are electrically connected with a power source through a slide rheostat, and the sliding end of the slide rheostat is fixedly connected with a waste collecting tank and further electrically connected with the fixed end, away from the power source, of the slide rheostat. The waste collecting tank is further provided with a crushing device electrically connected with the power source. The waste collecting tank is connected to the outer portion of the crushing device in a sleeving manner and is in sliding connection with the crushing device. A self-reset switch is arranged at the bottom of the crushing device. An operation panel corresponding to the self-reset switch is fixedly connected to the side wall of the waste collecting tank. A stirrer is arranged in the waste collecting tank, a liquid storage pond in which a solution is injected is arranged below the waste collecting tank, and the waste collecting tank is located in the liquid storage pond. The recycling device can solve the problems that an existing recycling device cannot automatically clean a blocked inlet of a waste storage tank, the workload is increased, and the device cost is high.

Owner:重庆市泰日建材有限公司

Direct drinking water purification and supply system with self-cleaning function

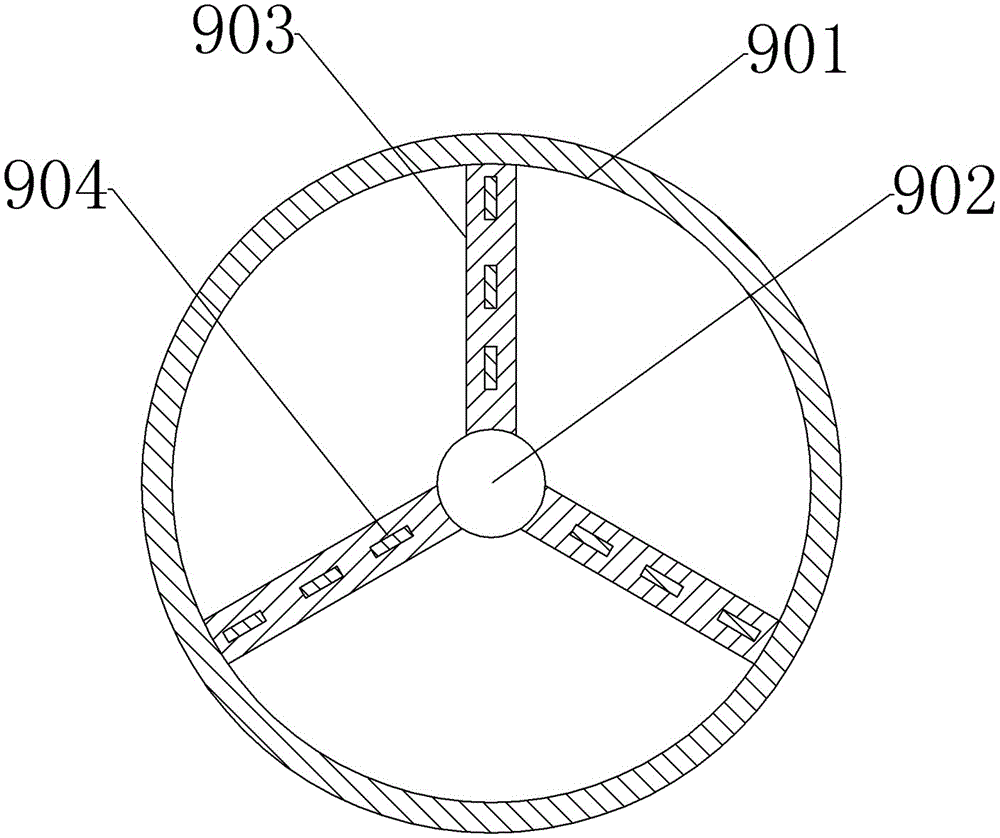

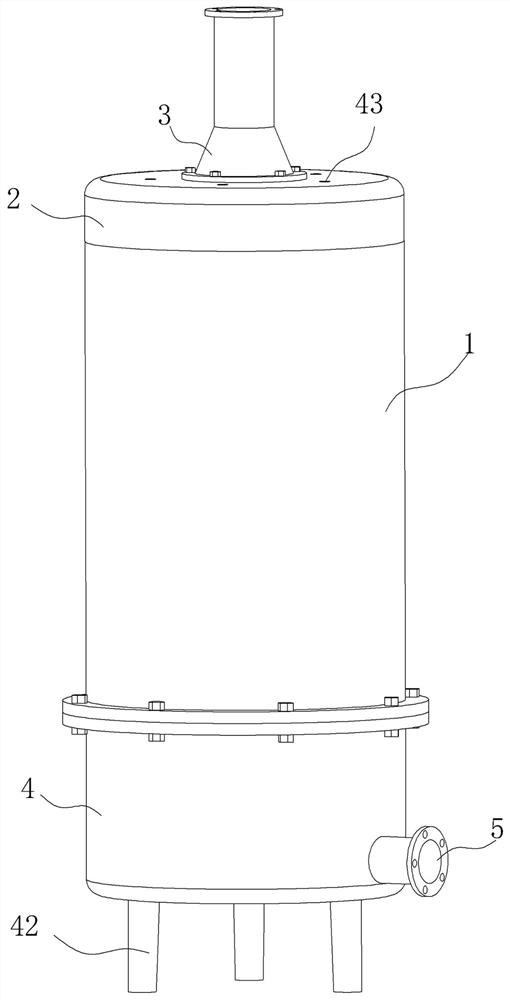

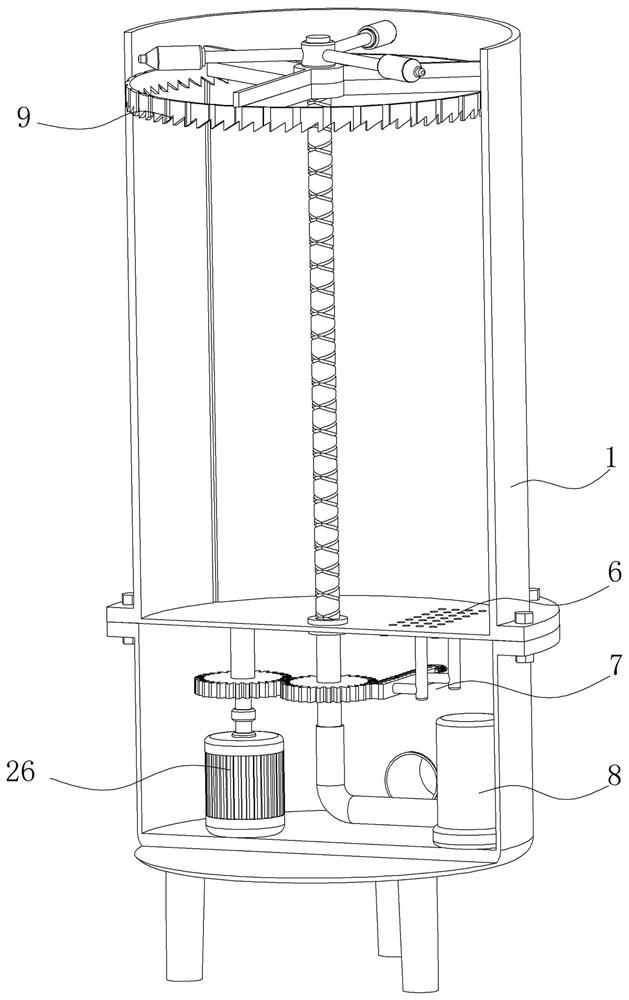

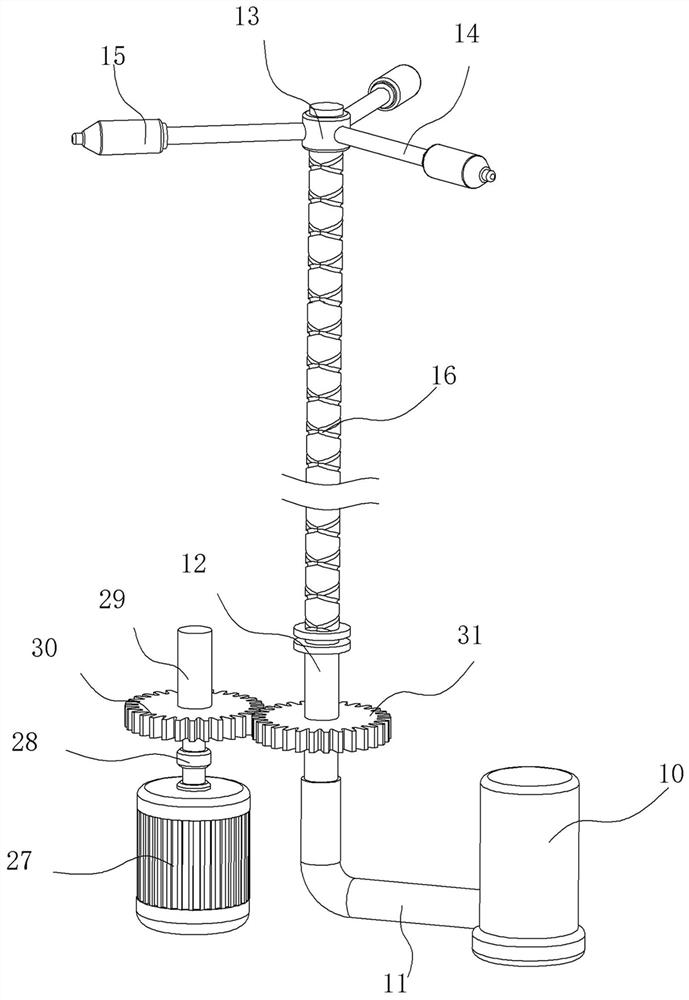

PendingCN113582272ASolve the increase in production costsSpray evenlyHollow article cleaningWater/sewage treatment by heatingTreatments waterLiquid storage tank

The invention discloses a direct drinking water purification and supply system with a self-cleaning function, which comprises a reaction kettle, the top end of the reaction kettle is connected with a top cover, the top end of the top cover is communicated with a feeding pipe, the bottom end of the reaction kettle is fixedly connected with a liquid storage tank, the liquid storage tank is communicated with a conducting pipe, and the bottom end of the reaction kettle is provided with a through hole communicated with the liquid storage tank, the bottom end of the through hole is provided with a sealing assembly. According to the direct drinking water purification and supply system with the self-cleaning function, the liquid storage tank is arranged, and a spraying assembly is arranged in the liquid storage tank, so that a solution in the liquid storage tank is conveyed to a spray head through a pump body in the spraying assembly, the side wall of the reaction kettle is sprayed through the spray head, and an arranged driving part drives the spray head to rotate, so that the spray head can uniformly spray on the side wall of the reaction kettle, the problem that a large amount of solution needs to be treated for treating scale is solved by spraying the solution on the side wall of the reaction kettle, and the problem that the preparation cost of direct drinking water is high is further solved.

Owner:王 伟华

Preparation method for pollination pollen

InactiveCN111527884AQuality improvementEasy to collectDrying solid materials without heatHarvestersFreeze-dryingPollination

The invention discloses a preparation method of pollen for pollination, and belongs to the technical field of pollen collection and preservation. Collected flower buds are crushed and screened to remove impurities to obtain pure anthers, the anthers are fed into a quick-freezing bin to be quickly frozen, the frozen anthers are fed into a drying bin to be sublimated, dehydrated and dried, the driedanthers are cracked to release pollen wrapped in the anthers, and the pollen is separated from the mixture of the pollen and the anthers by using an anther-pollen separator to obtain the pure pollen.The low-temperature freeze drying technology is adopted for the anther, the influence on the biological activity of pollen is small, the activity of the prepared pollen is high, the moisture contentof the prepared pollen is low, the dryness is high, long-time storage is facilitated, and the high activity of the pollen is maintained; the drying speed is high, time is saved, and large-scale industrial production is facilitated.

Owner:四川和泽农业有限公司

Preparation method of natural chicken essence seasoning

PendingCN112385813ATake advantage ofSolve the increase in production costsFood thermal treatmentFood ingredientsEconomic benefitsProcess engineering

The invention discloses a preparation method of a natural chicken essence seasoning. The method comprises the following steps: preparing raw materials: firstly, selecting a raw material chicken, slaughtering the raw material chicken, then performing soaking in hot water for a period of time, then performing cleaning and feather picking, cutting the raw material chicken into blocks after cleaning is completed to obtain raw material chicken blocks to be treated, putting the raw material chicken blocks to be treated into a high-pressure cooking pot, and carrying out sealed cooking. Through the preparation of the chicken essence seasoning, leftovers in broiler chicken processing can be fully utilized, economic benefits of enterprises are improved, an advanced process can be applied to the actual production of broiler chicken processing, a development direction is provided for the further development of meat deep processing, and problems that in the prior art, the main raw material for producing the chicken essence seasoning is chicken, and leftovers such as chicken bones and meat in broiler chicken processing are discarded, so that the fragrance, taste and nutritional ingredients of natural chicken are lost, and therefore the production cost of enterprises is increased are solved.

Owner:江苏帮厨佳食品科技有限公司

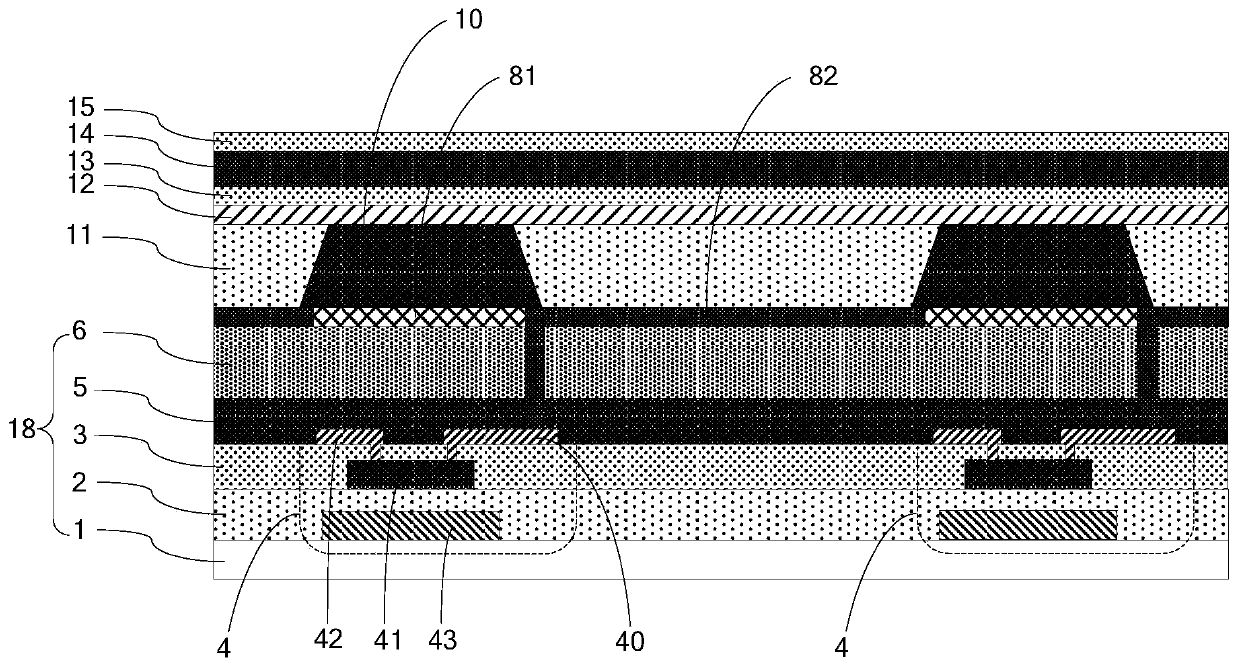

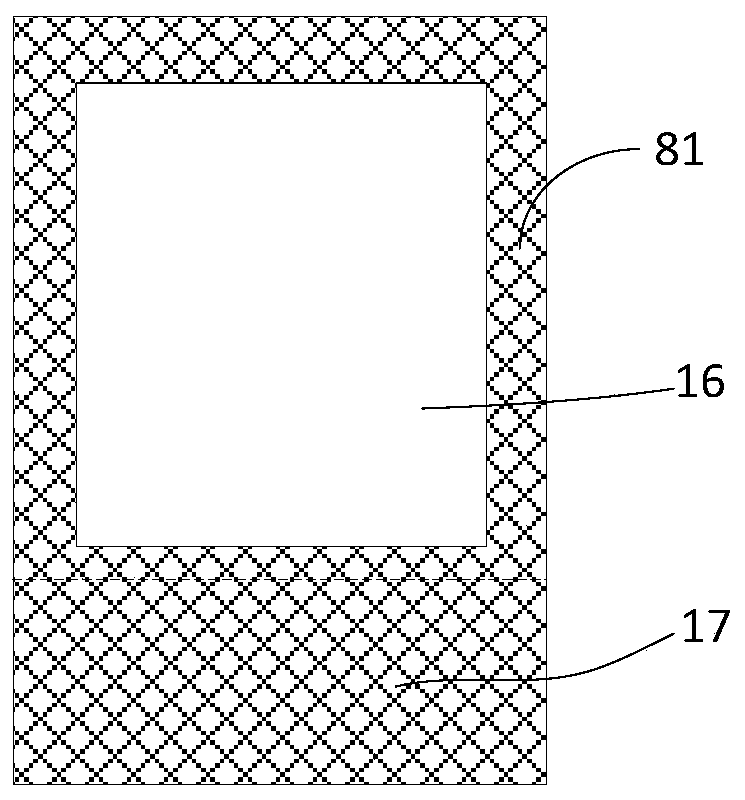

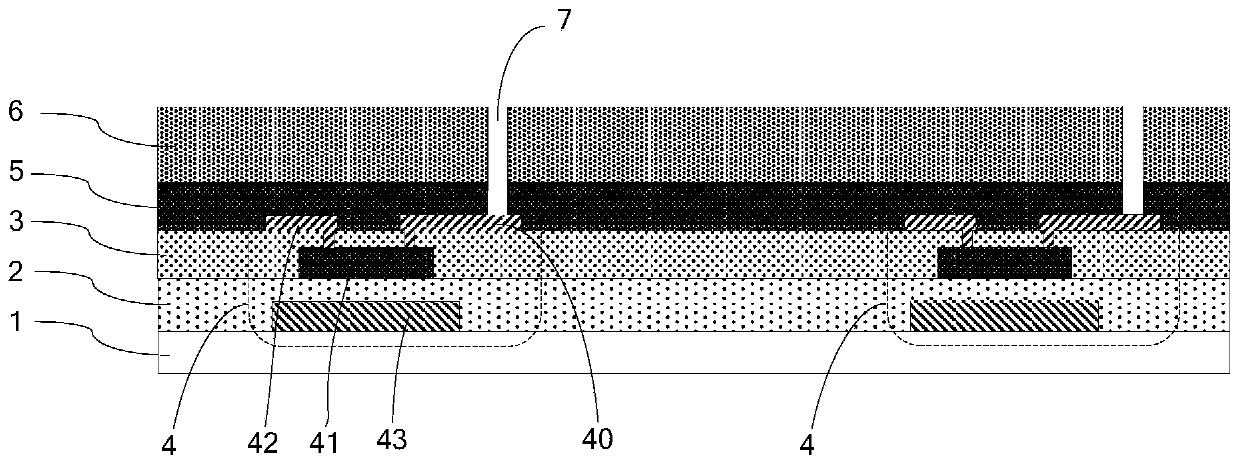

Display substrate, preparation method thereof, and display device

ActiveCN110752236ASolve the increase in production costsReduce adverse effectsSolid-state devicesSemiconductor/solid-state device manufacturingUltraviolet lightsDisplay device

The invention provides a display substrate, a preparation method thereof, and a display device, and relates to the technical field of display devices. The display substrate comprises a driving structure layer and a light-emitting structure layer which are arranged on a base in an overlapped mode, the driving structure layer comprises a thin film transistor, the light-emitting structure layer comprises a first electrode and a shielding layer used for shielding ultraviolet light (UV), and the front projection of the shielding layer on the base contains the front projection of the thin film transistor on the base. According to the display substrate in the embodiment of the invention, the problem that in the preparation process of the display substrate, a UV mask plate is adopted, and consequently, the production cost is increased can be solved.

Owner:BOE TECH GRP CO LTD +1

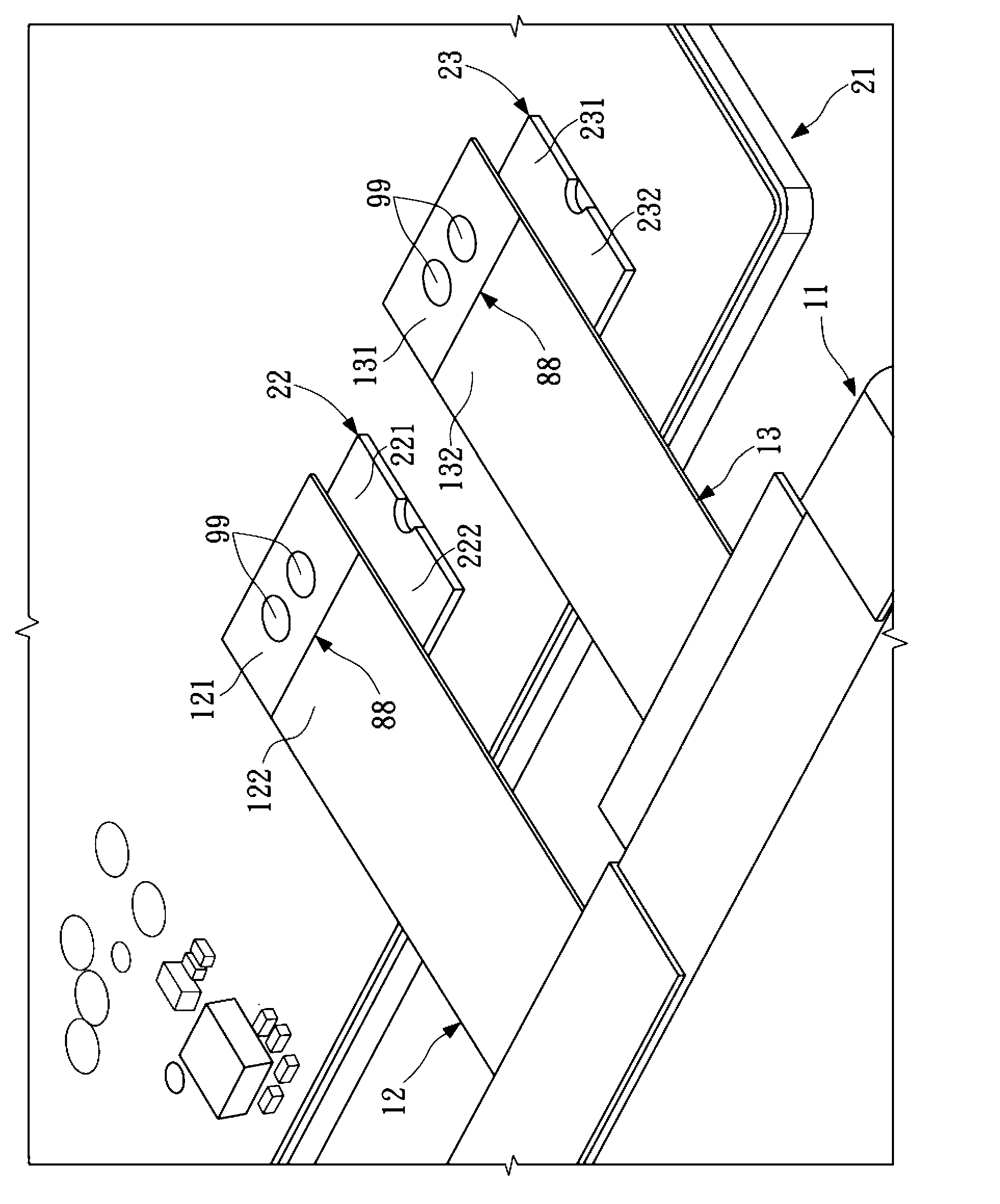

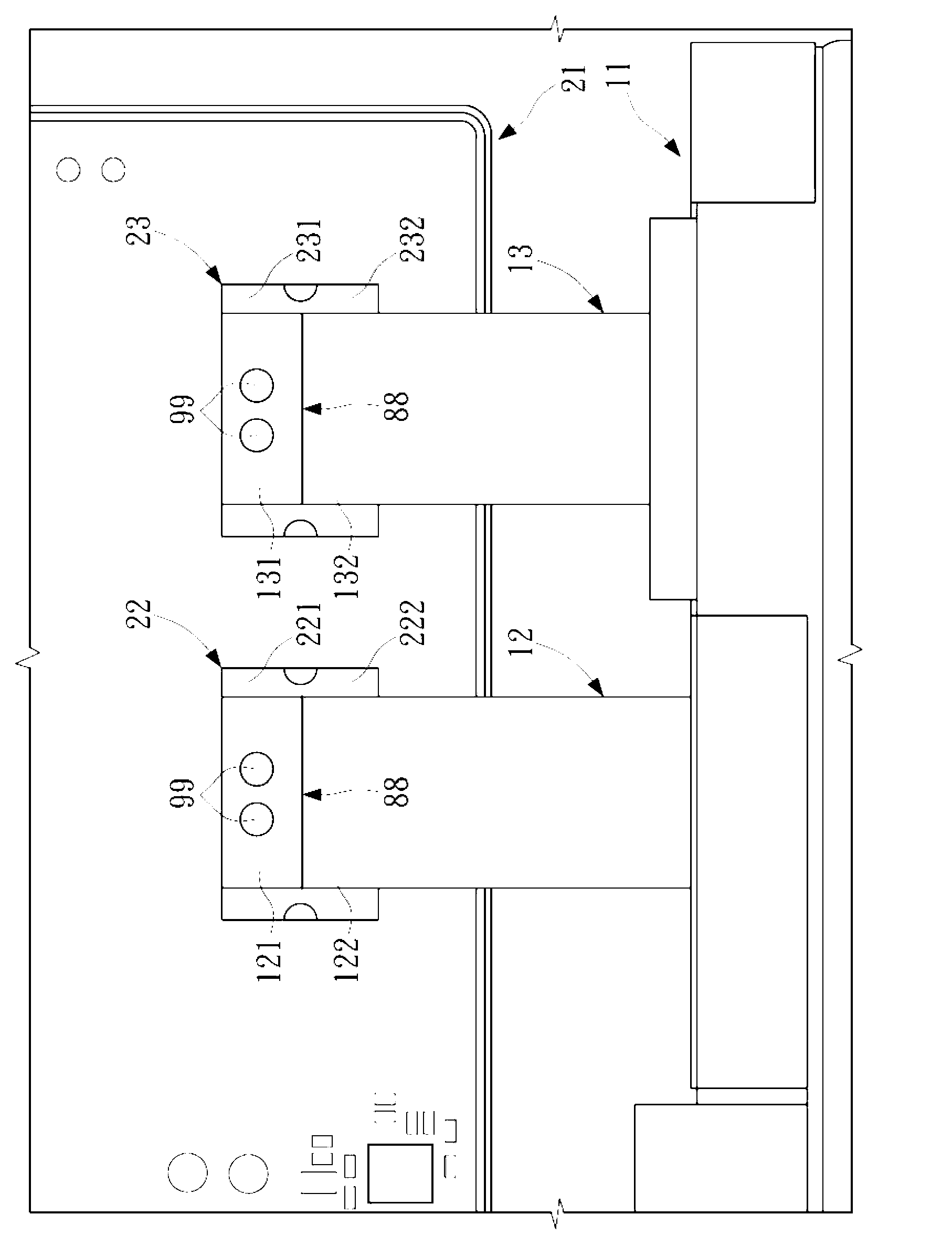

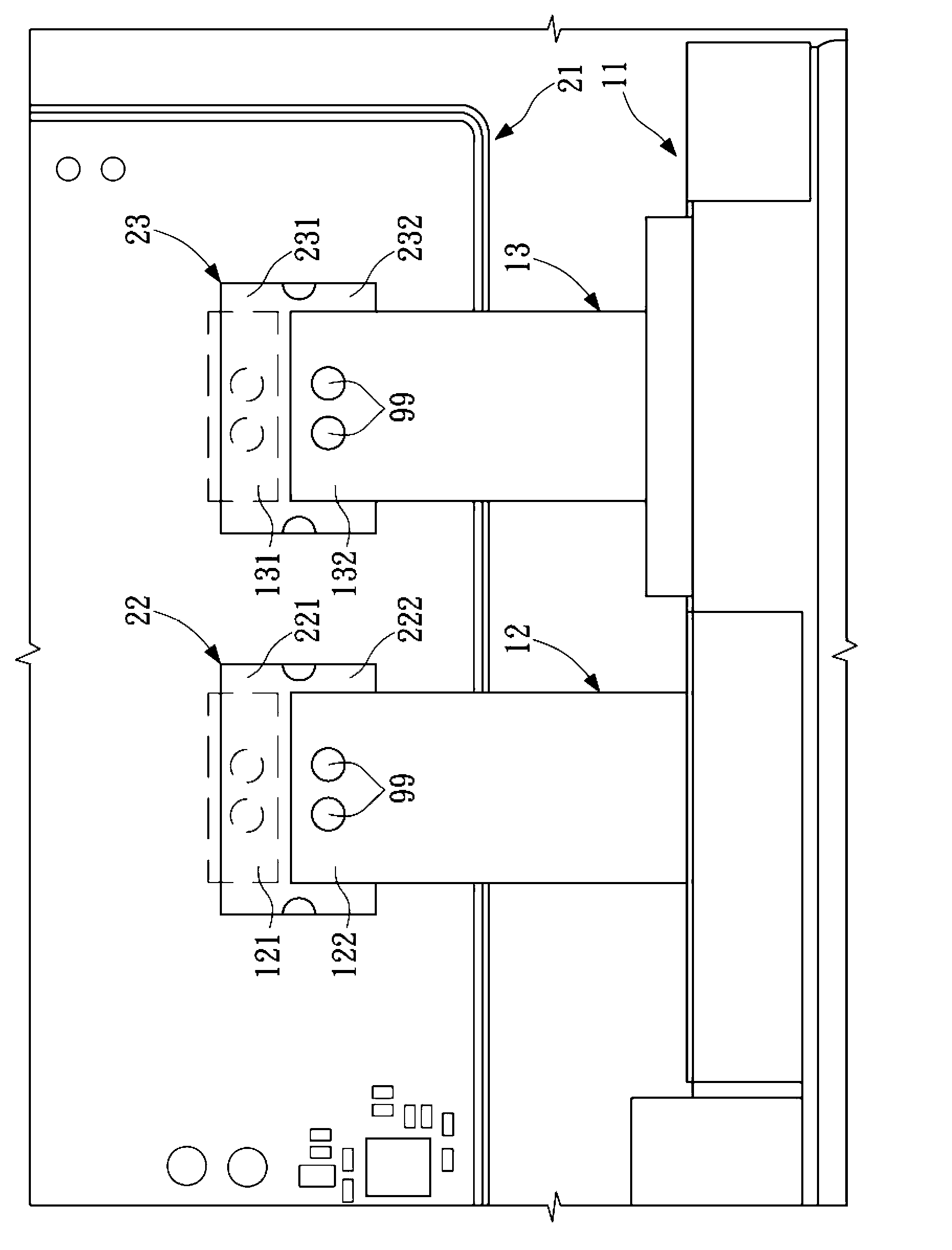

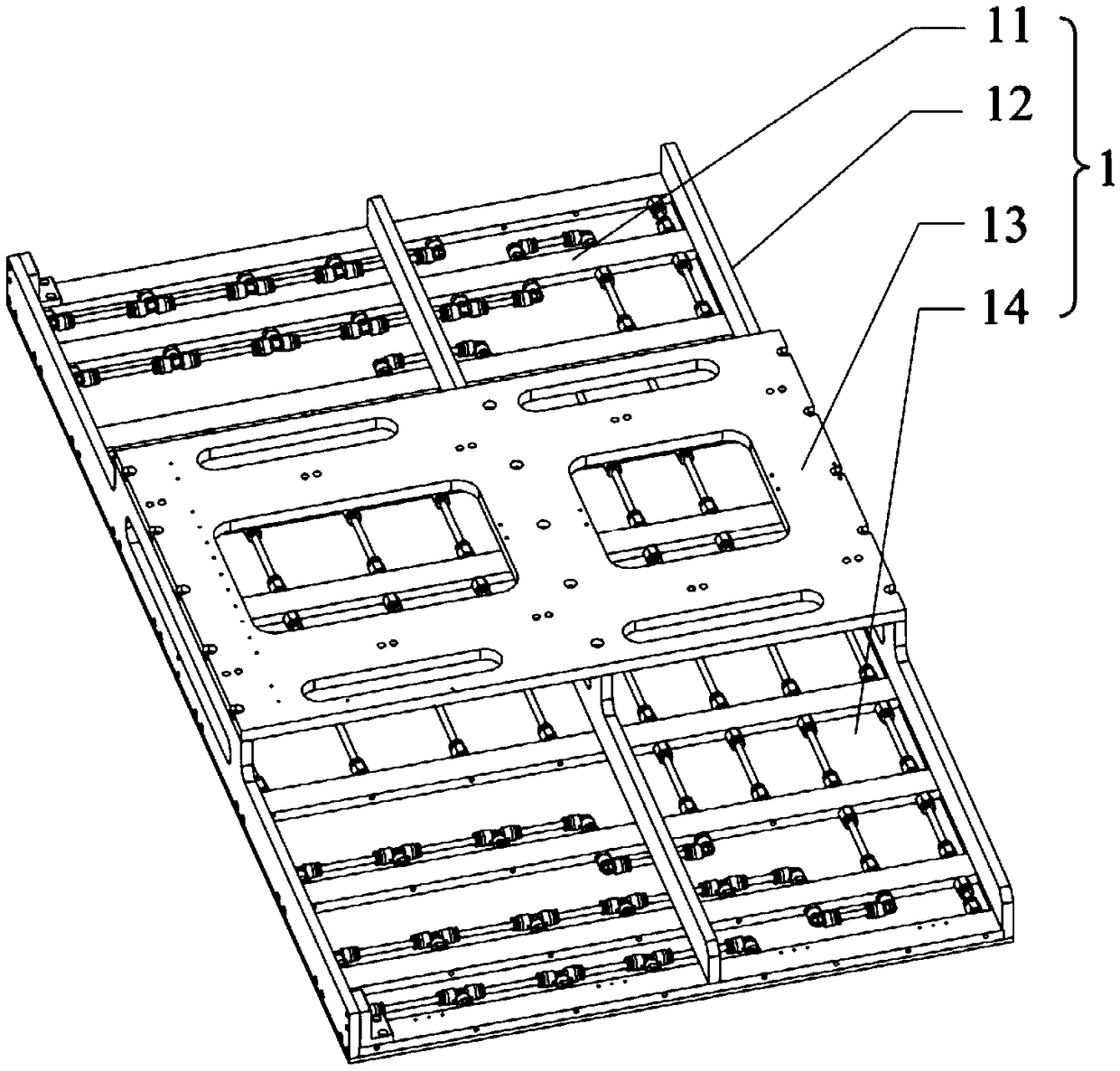

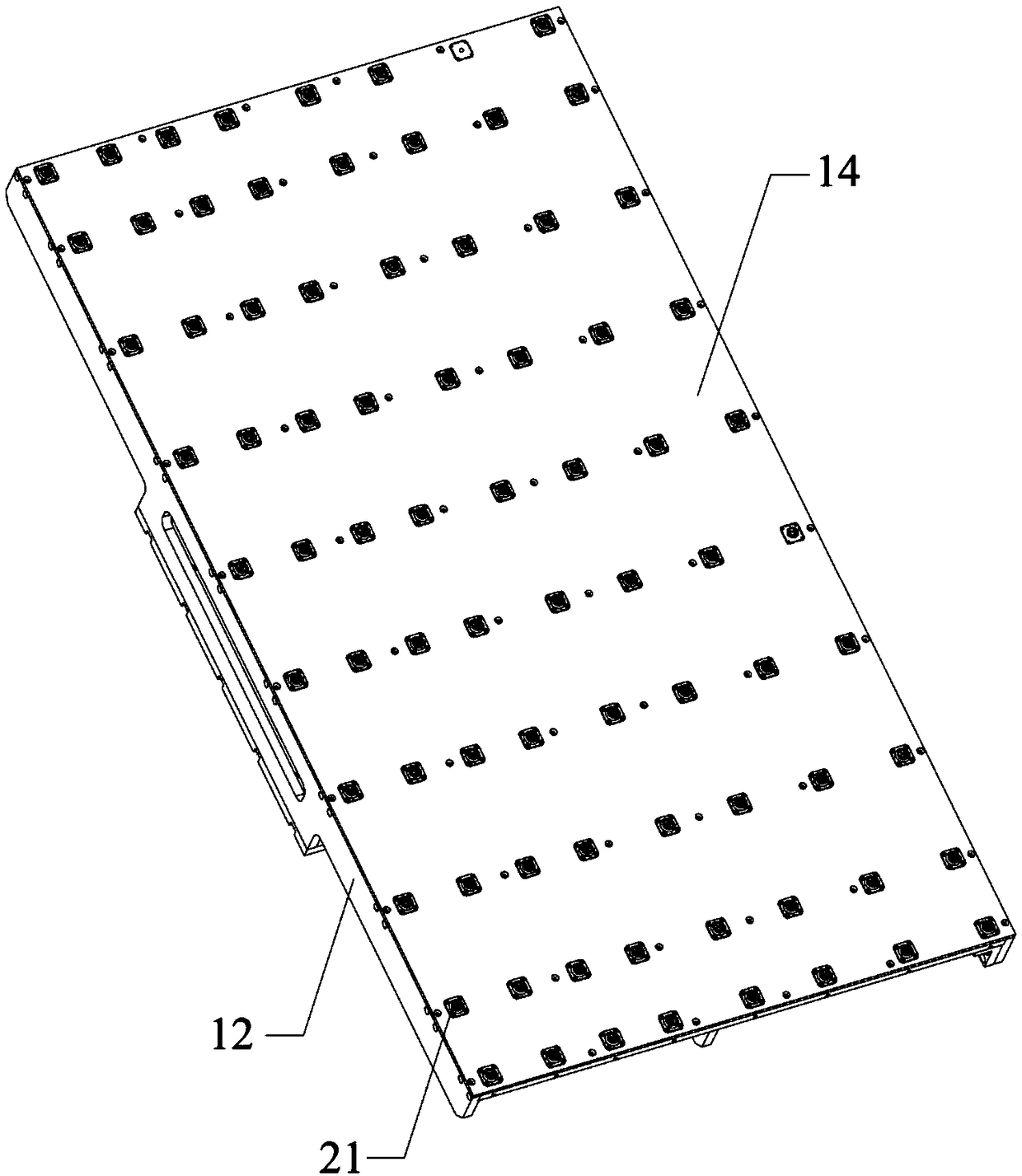

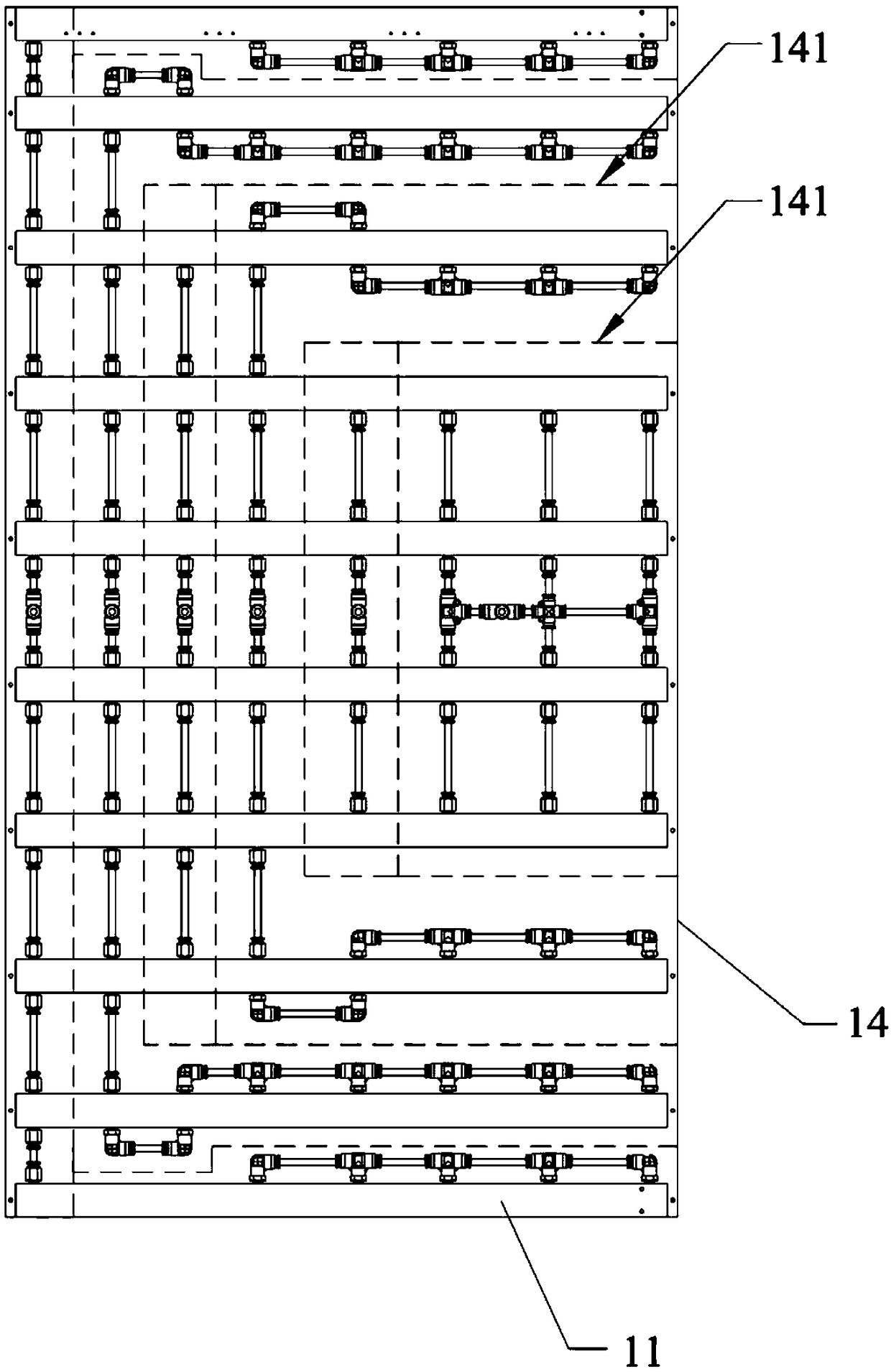

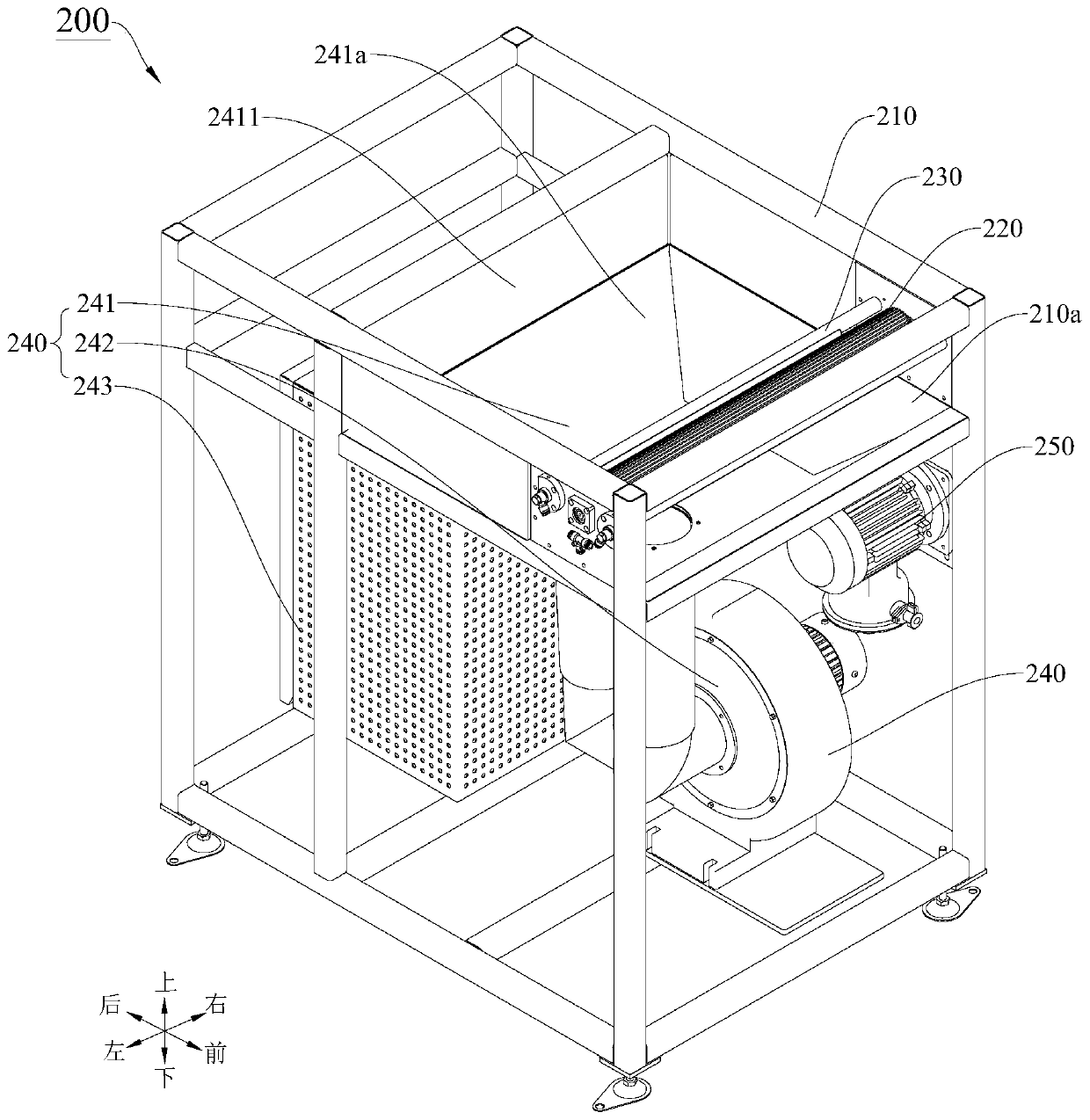

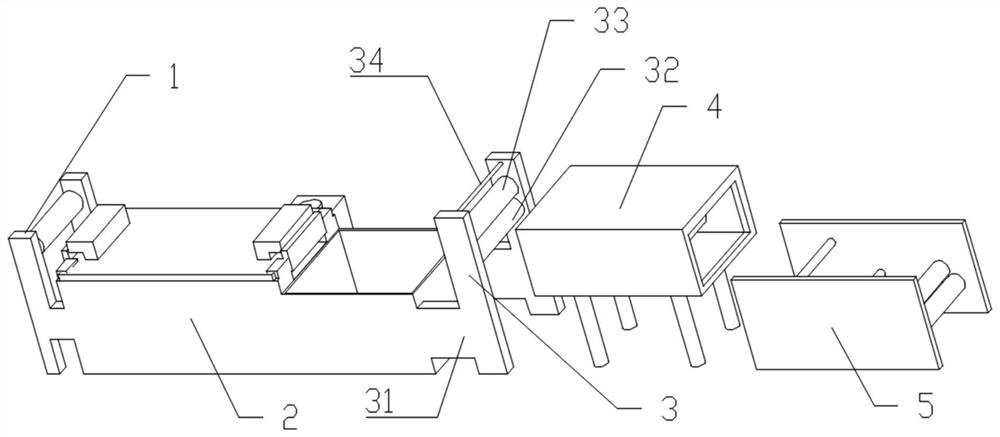

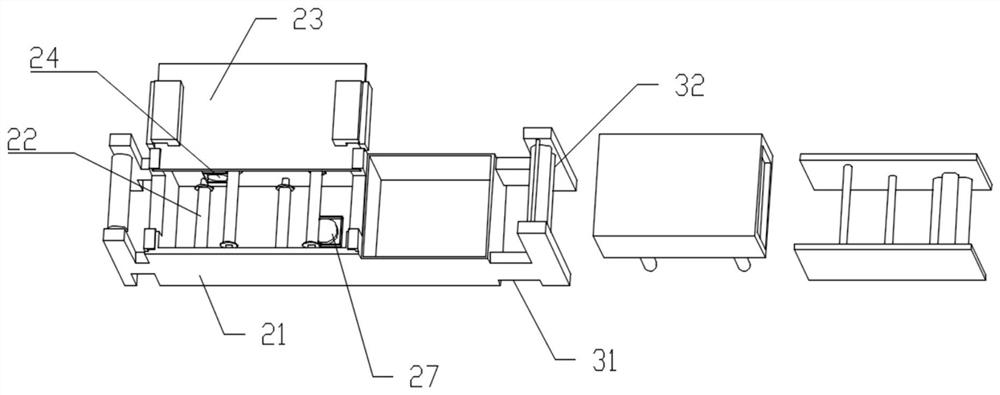

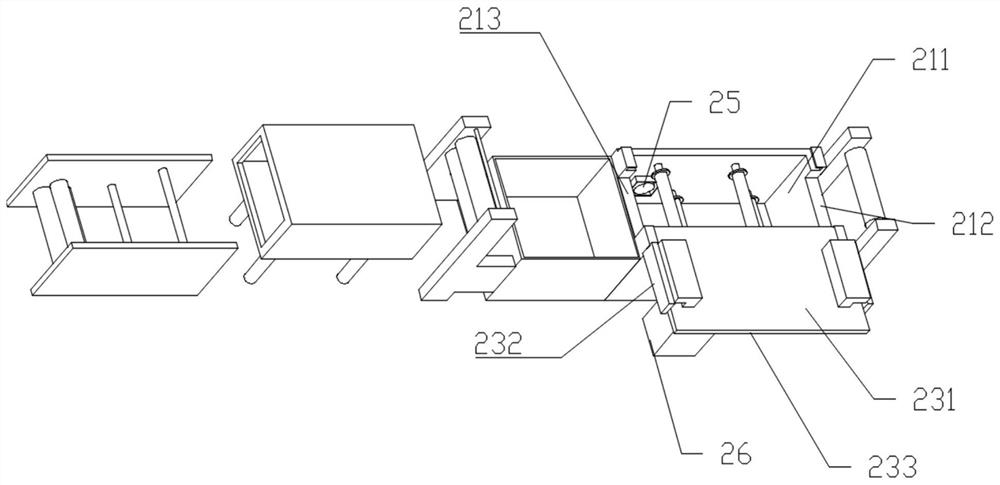

Transferring and loading mechanism

PendingCN109110500AImprove versatilitySolve the increase in production costsConveyorsCharge manipulationSurface platePulp and paper industry

The invention relates to the technical field of display panel transferring and loading, and particularly discloses a transferring and loading mechanism. The transferring and loading mechanism comprises a first bracket and complex numbers of first suction cup assemblies. The first bracket is divided into complex numbers of installation areas; the first suction cup assemblies correspond one to one to the installation areas; each first suction cup assembly comprises complex numbers of first vacuum suction cups, and the complex numbers of first vacuum suction cups of each suction cup assembly areconnected through gas circuits; and the first vacuum suction cups of the complex numbers of first suction cup assemblies are located in a same plane. According to the transferring and loading mechanism, a plurality of suction cup groups are arranged on the first bracket, adsorption ranges with different sizes can be combined out through the multiple suction cup groups, and thus the transferring and loading mechanism can be suitable for panels with different sizes.

Owner:SUZHOU JINGLAI OPTO CO LTD

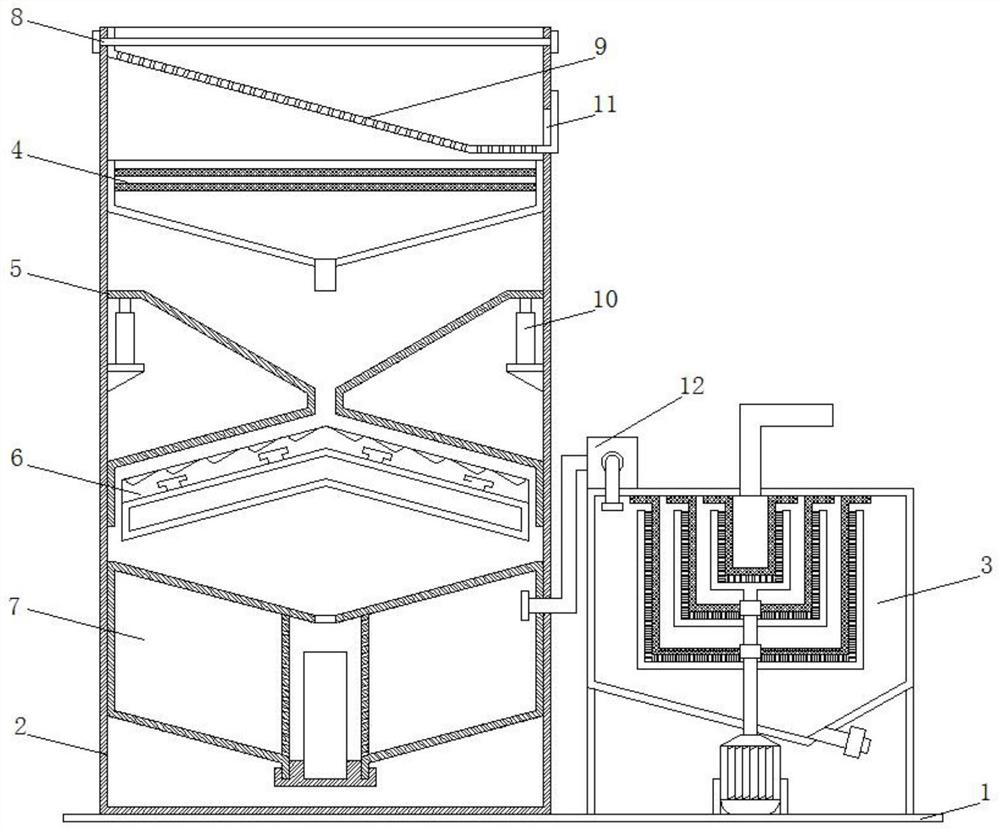

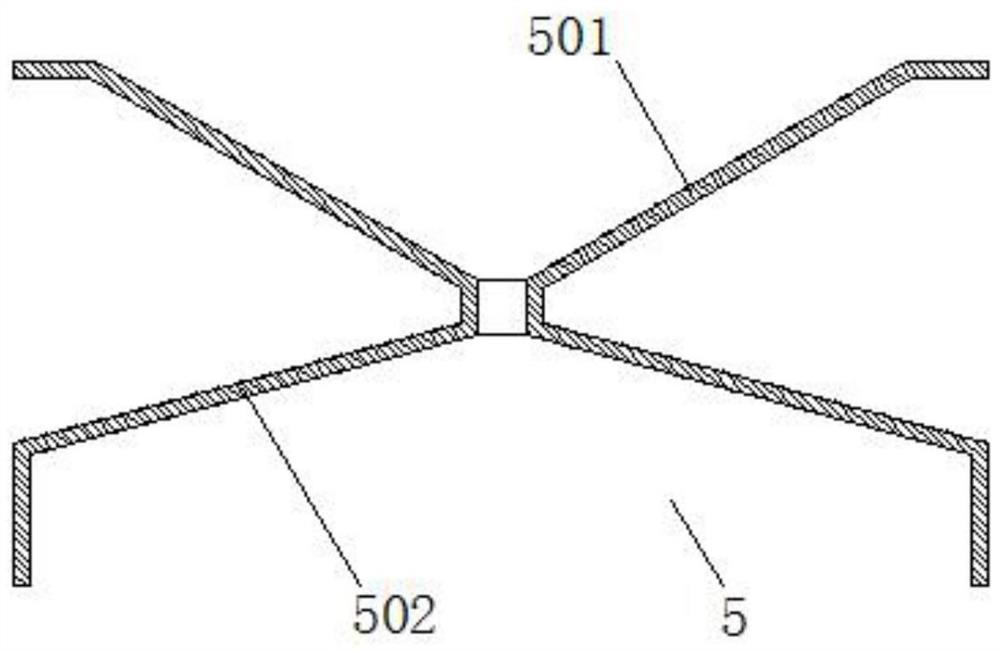

Cutting fluid treatment device for industrial processing machine tool

ActiveCN112774859AAvoid wastingFully adsorbedMagnetic separationFiltration circuitsMachine toolCutting fluid

The invention provides a cutting fluid treatment device for an industrial processing machine tool, and belongs to the technical field of processing machine tools. The problems that an existing cutting fluid for the machine tool cannot be reused, waste is caused, and the production cost is increased are solved. The device comprises a bottom plate, an outer box, an overflow mechanism, a filtering mechanism, a fluid director, an adsorption mechanism and a precipitation adsorption mechanism. The bottom plate is fixedly connected with the outer box and the overflow mechanism, and the filtering mechanism, the fluid director, the adsorption mechanism and the precipitation adsorption mechanism are sequentially and fixedly connected to the interior of the outer box from top to bottom. The fluid director comprises an upper flow guide hopper and a lower flow guide groove. The two ends of the upper flow guide hopper are fixedly connected with the inner wall of the outer box through telescopic rods, the bottom of the upper flow guide hopper communicates with a lower flow guide groove matched with the adsorption mechanism, the fixing frame is matched with the lower flow guide groove and fixedly connected with the inner wall of the outer box, a first electromagnet is fixed into the fixing frame, and the upper surface of the fixing frame is clamped with the adsorption plate. A plurality of precipitation tanks are equidistantly formed in the upper surface of the adsorption plate. The device is mainly used for treating the cutting fluid for the machine tool.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

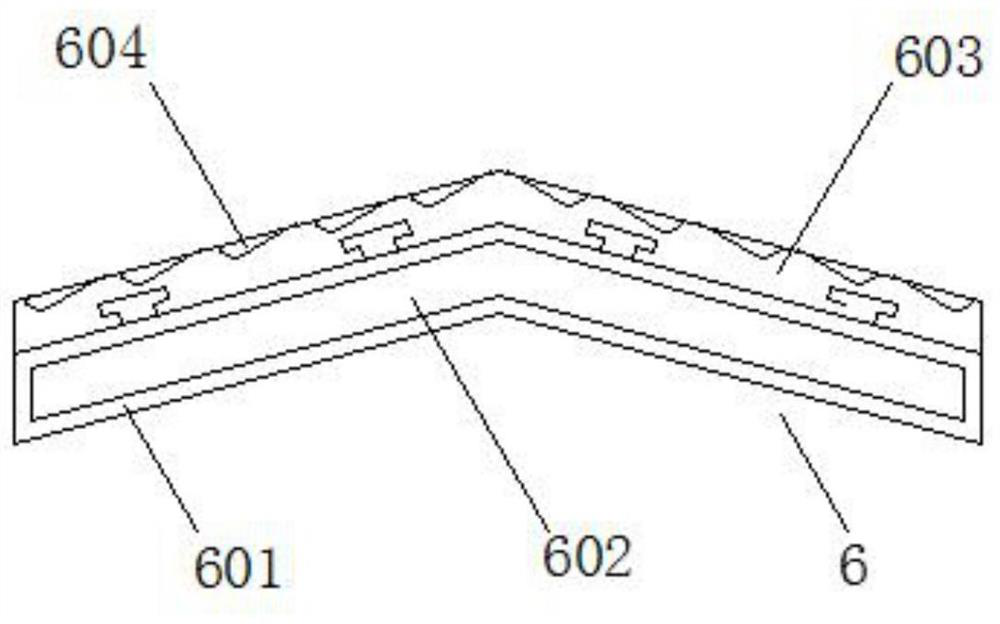

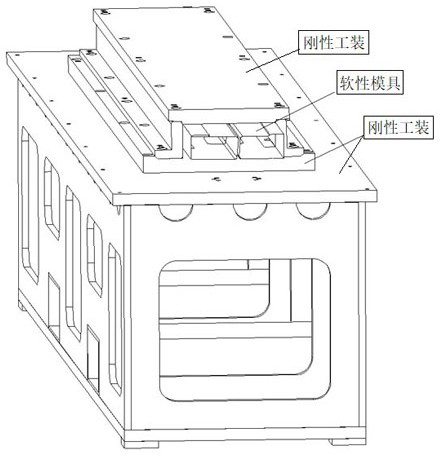

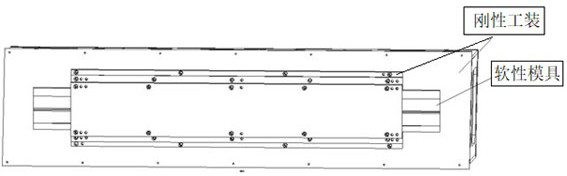

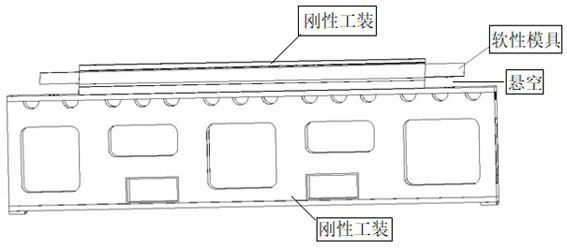

End packaging method for assisting in forming I-shaped beam through long and thin soft mold

PendingCN114770998AReduce dosageTo achieve the effect of cost reduction and efficiency increaseDomestic articlesShaped beamMetal forming

The invention discloses an end packaging method for an I-shaped beam formed by a slender soft mold in an auxiliary mode, rubber and sealing rubber strip filling between the soft mold and a metal tool is canceled, a gap between the soft mold on the left side and the right side of an I-shaped beam part is filled with the sealing rubber strip, the sealing rubber strip is suspended along the bottom of the end of the soft mold, and a sealing rubber support is formed; sealing rubber strips are uniformly laid on the surface of the end part of the soft mold, and sealing rubber strips are also laid at the bottom of the sealing rubber support, so that the soft mold is completely sealed with the I-shaped beam part and the metal forming tool; and finally, an isolating membrane, a breathable felt and a vacuum bag are placed on the surface of the laid sealing rubber strip, the vacuum bag is sealed according to the position of the sealing rubber strip, and the sealing rubber strip is vacuumized and compacted. The use amount of sealing rubber strips and rubber is greatly reduced, the effects of reducing cost and increasing efficiency are achieved, the risk of bag explosion is eliminated, the production qualification rate of parts is increased, the scheme is simple, the effect is good, and the practical value is good.

Owner:航天海鹰(镇江)特种材料有限公司

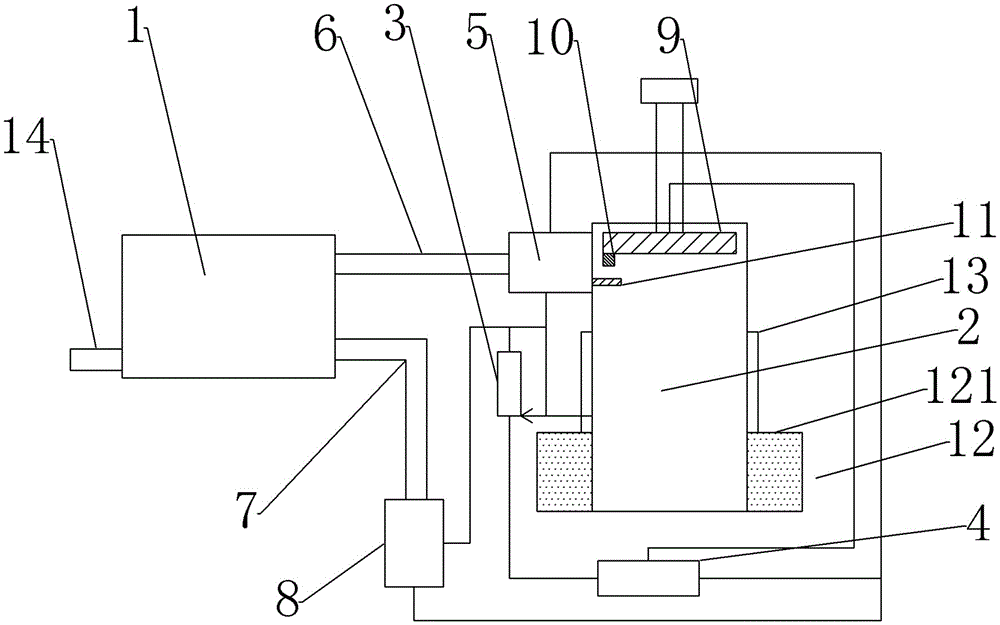

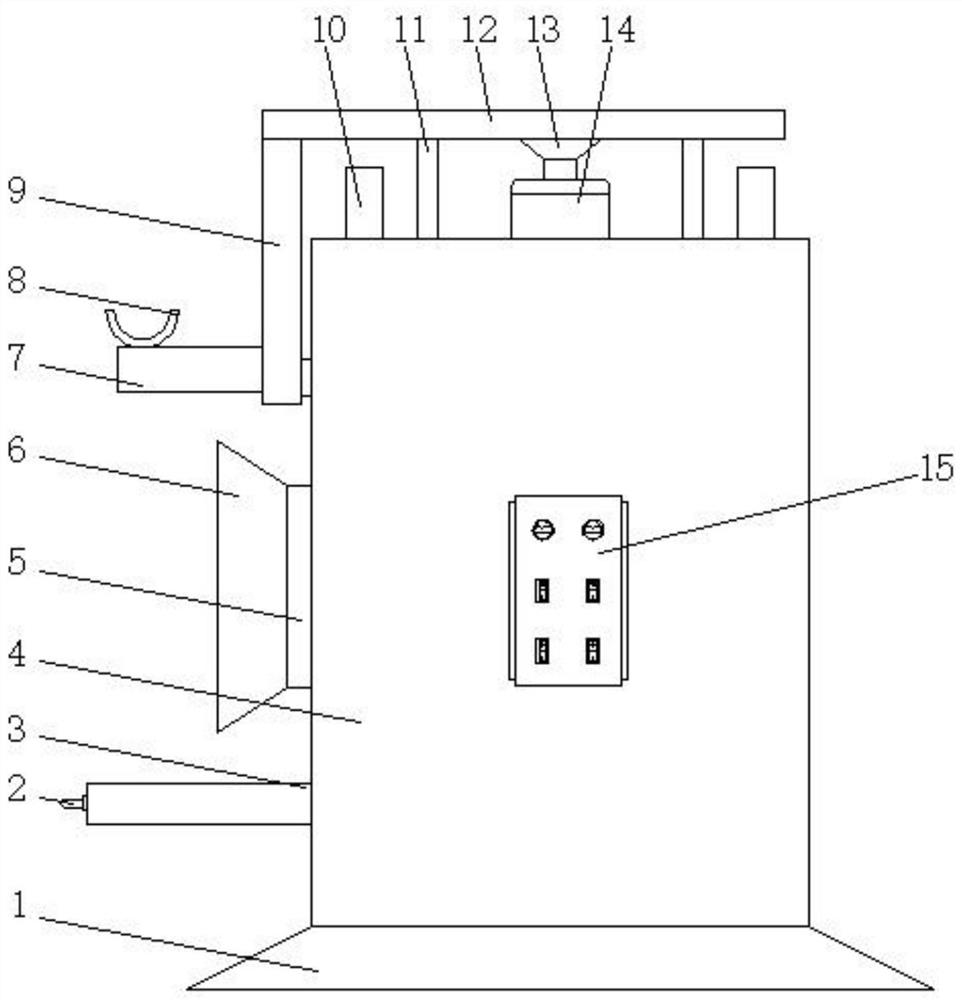

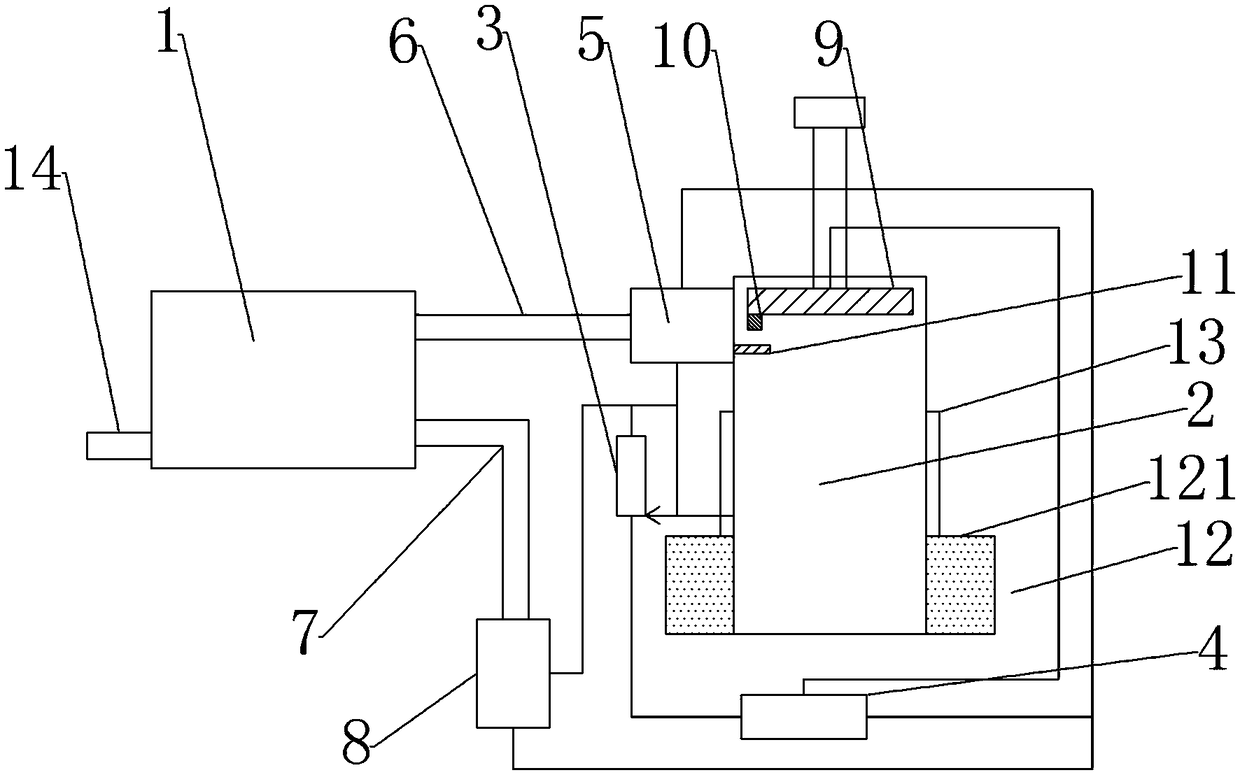

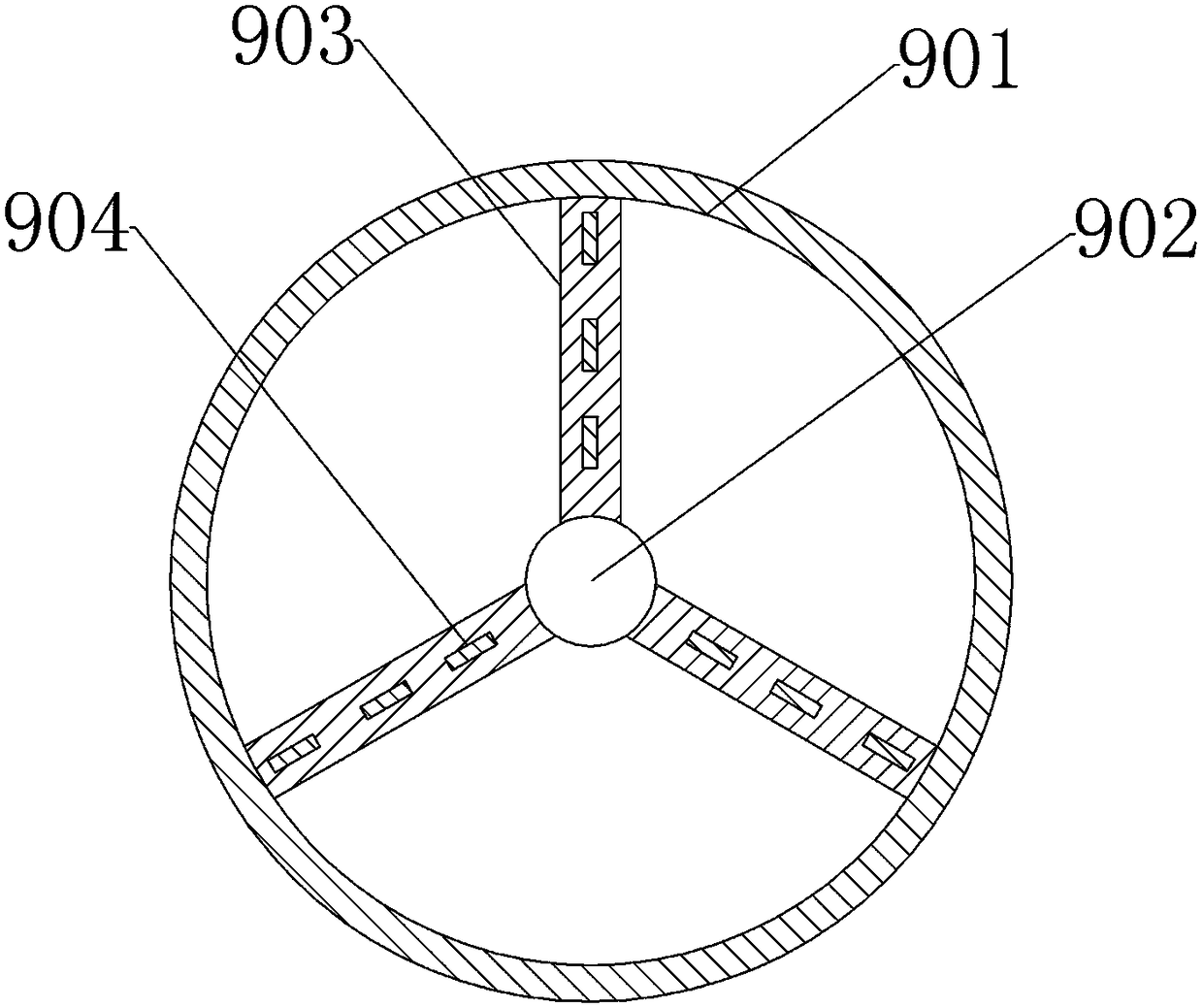

Wearable medical product mainboard function testing device

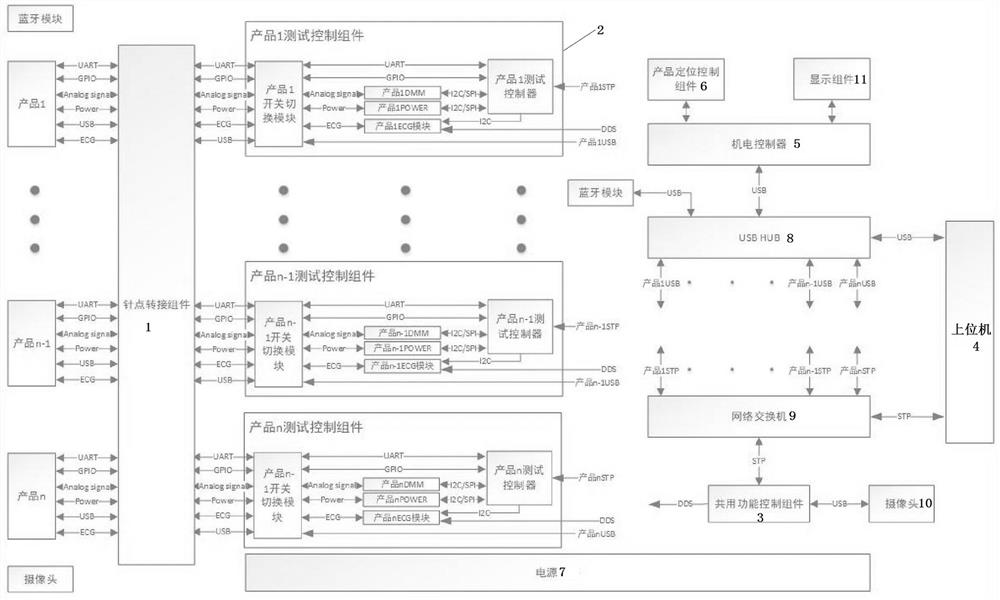

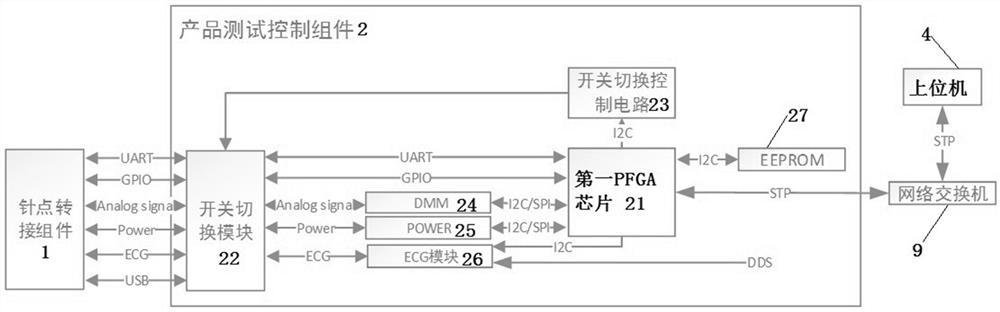

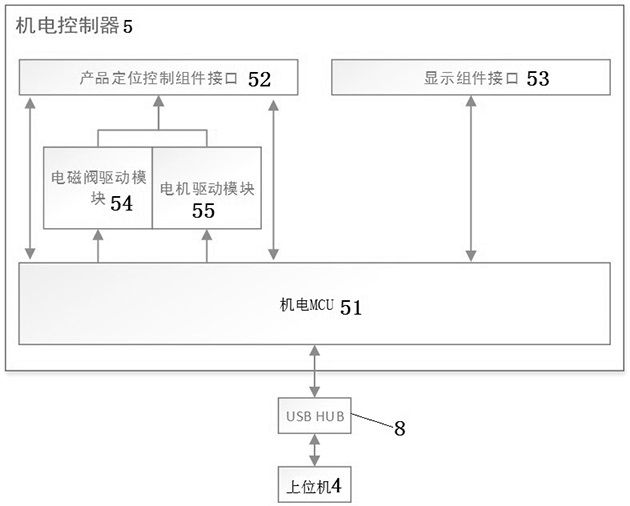

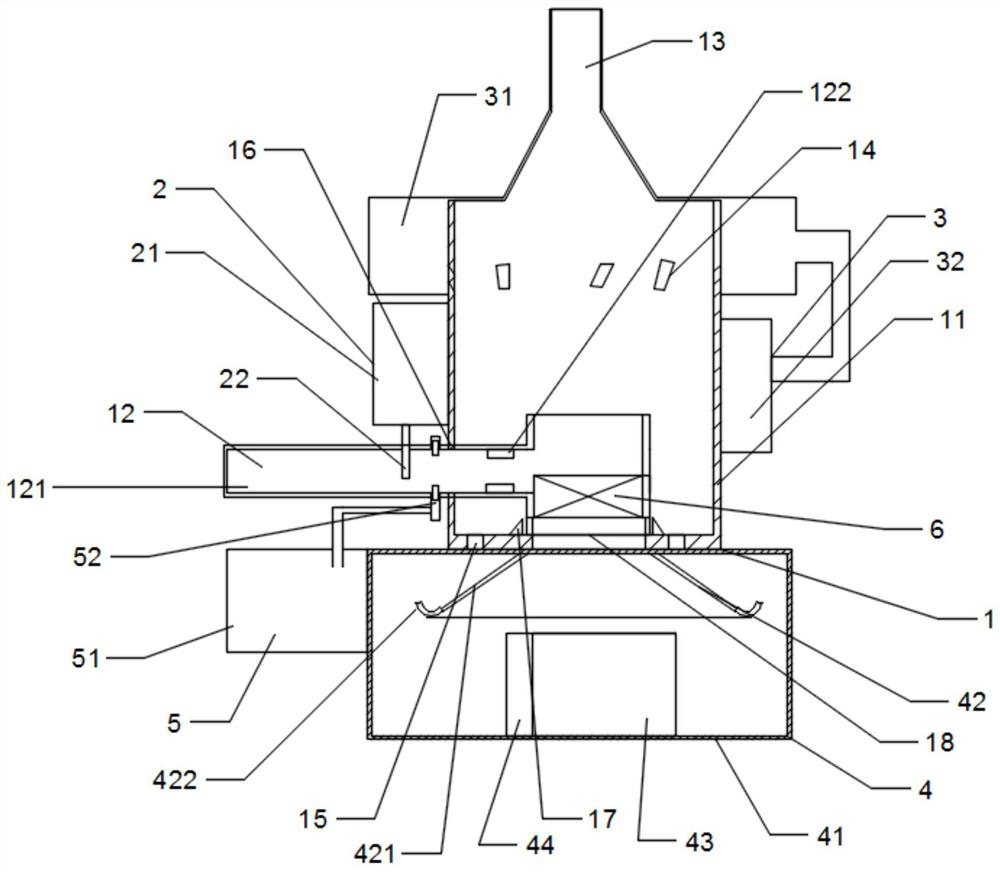

PendingCN112763897AImprove efficiencySolve the increase in production costsElectronic circuit testingEmbedded systemMedical product

A wearable medical product mainboard function testing device provided by the invention is high in efficiency, ensures the testing quality and has no damage to the product quality. The device comprises a pin point switching assembly (1), a plurality of product test control assemblies (2), a common function control assembly (3), an upper computer (4), an electromechanical controller (5), a product positioning controller assembly (6), a power supply (7), a USB HUB (8), a network switch (9), a wireless module and a camera (10). Each group of test pin points provided by the pin point switching assembly is connected with a product to be tested. Each test needle point is connected with one product test control assembly, the other end of each product test control assembly is connected with the shared function control assembly, the USB HUB and the network switch, and the shared function control assembly is further connected with the network switch and the camera. The invention can be applied to the field of wearable medical equipment.

Owner:珠海市运泰利自动化设备有限公司

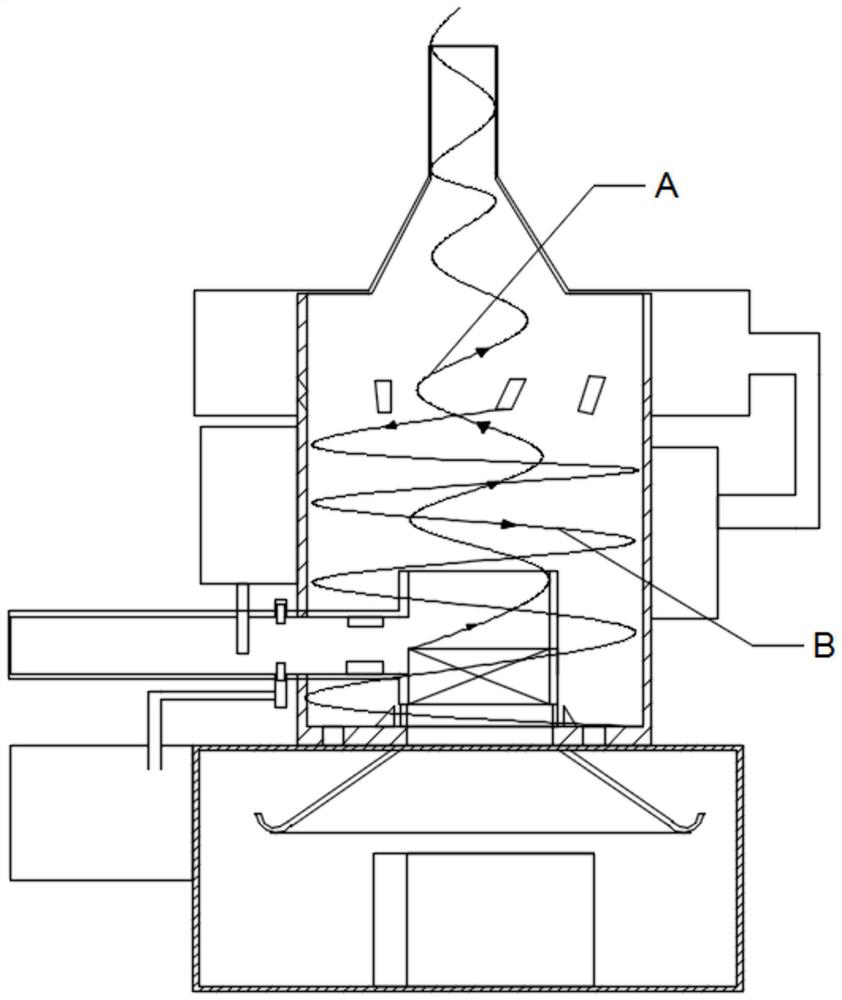

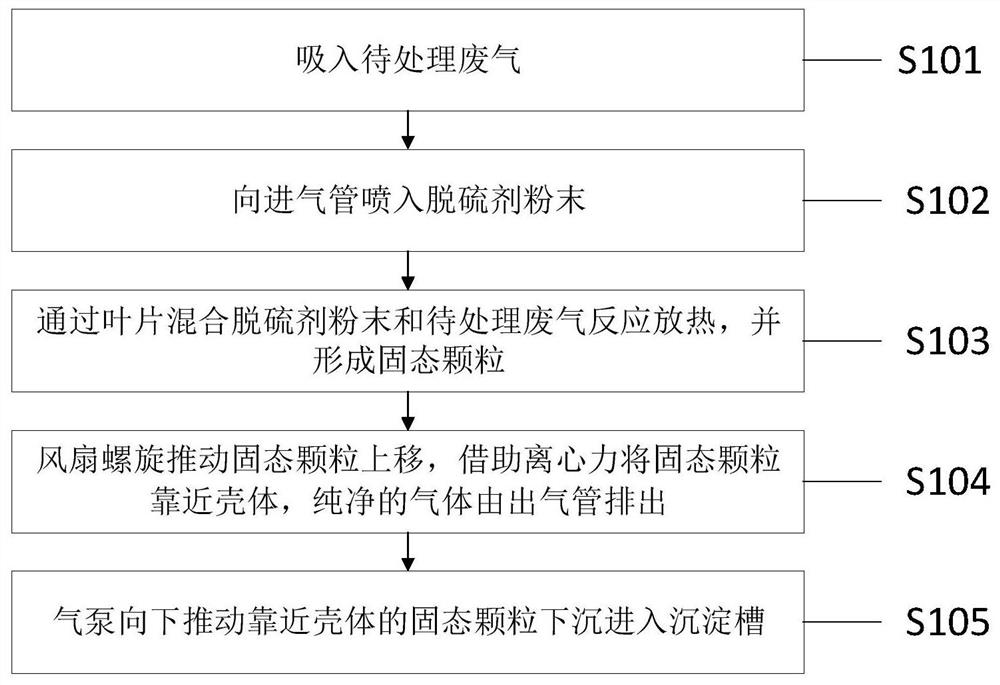

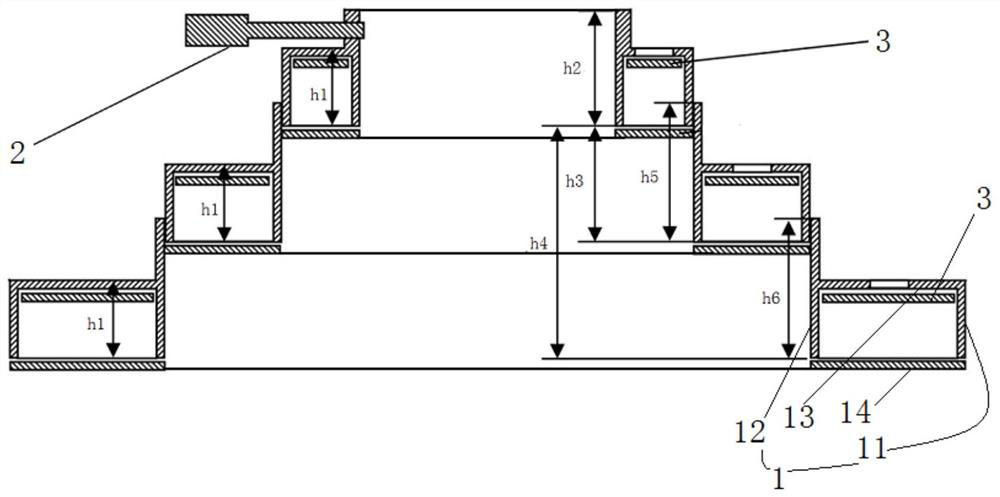

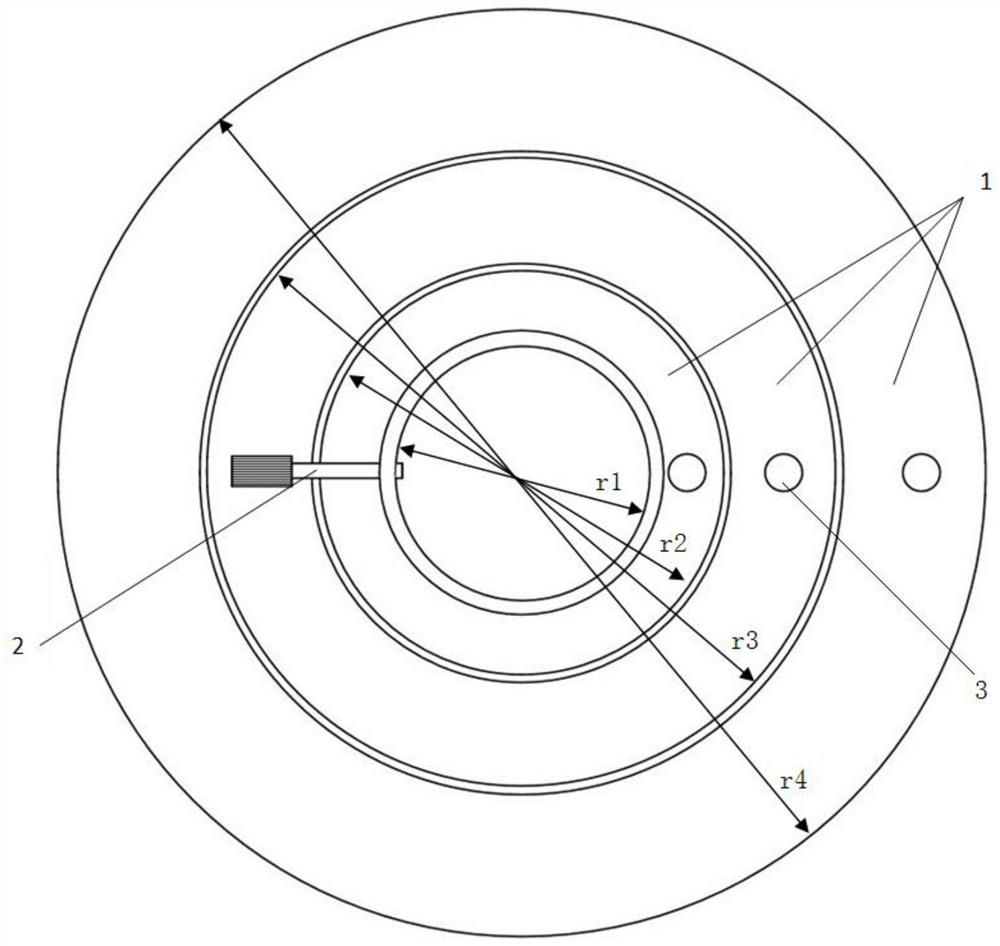

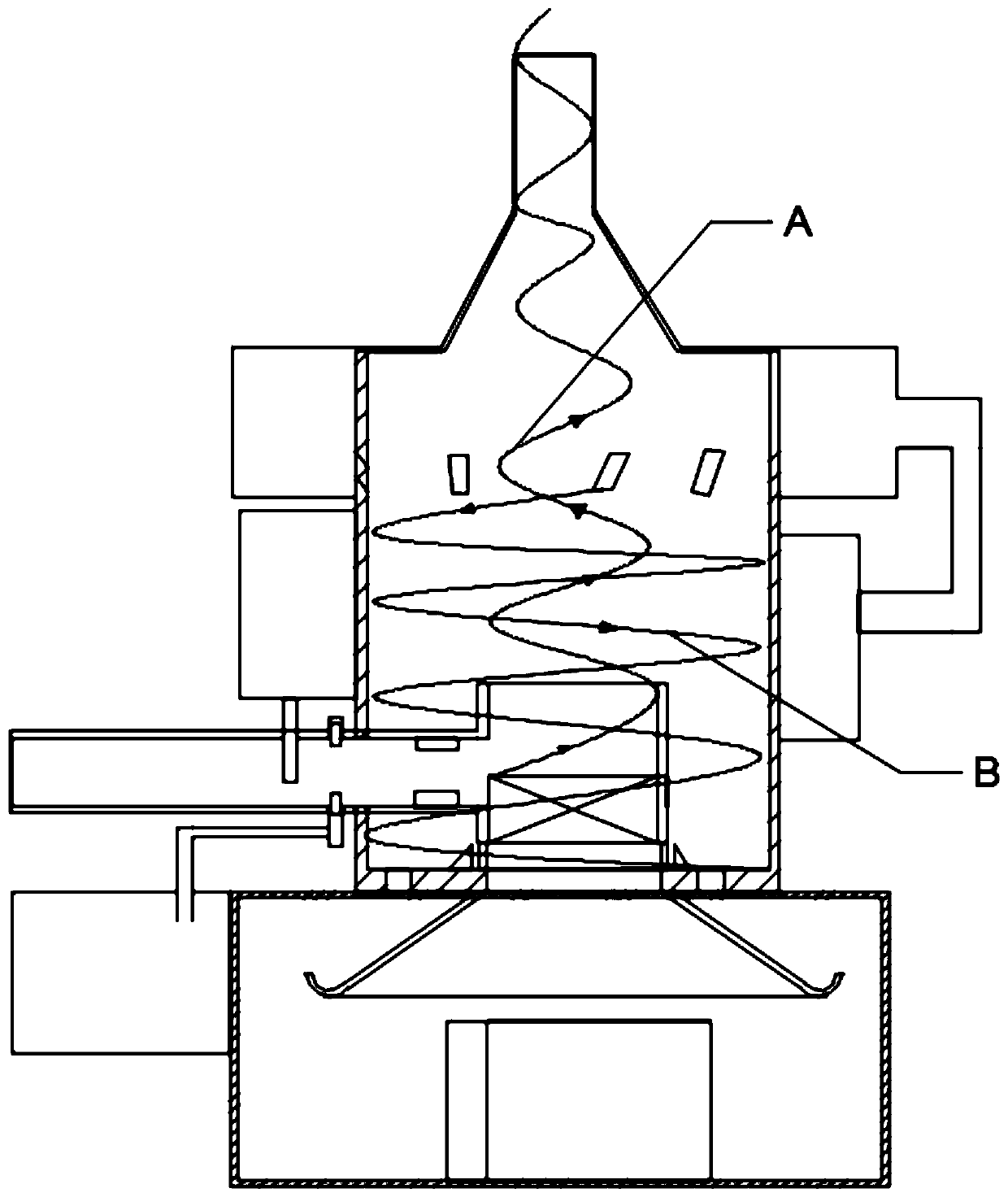

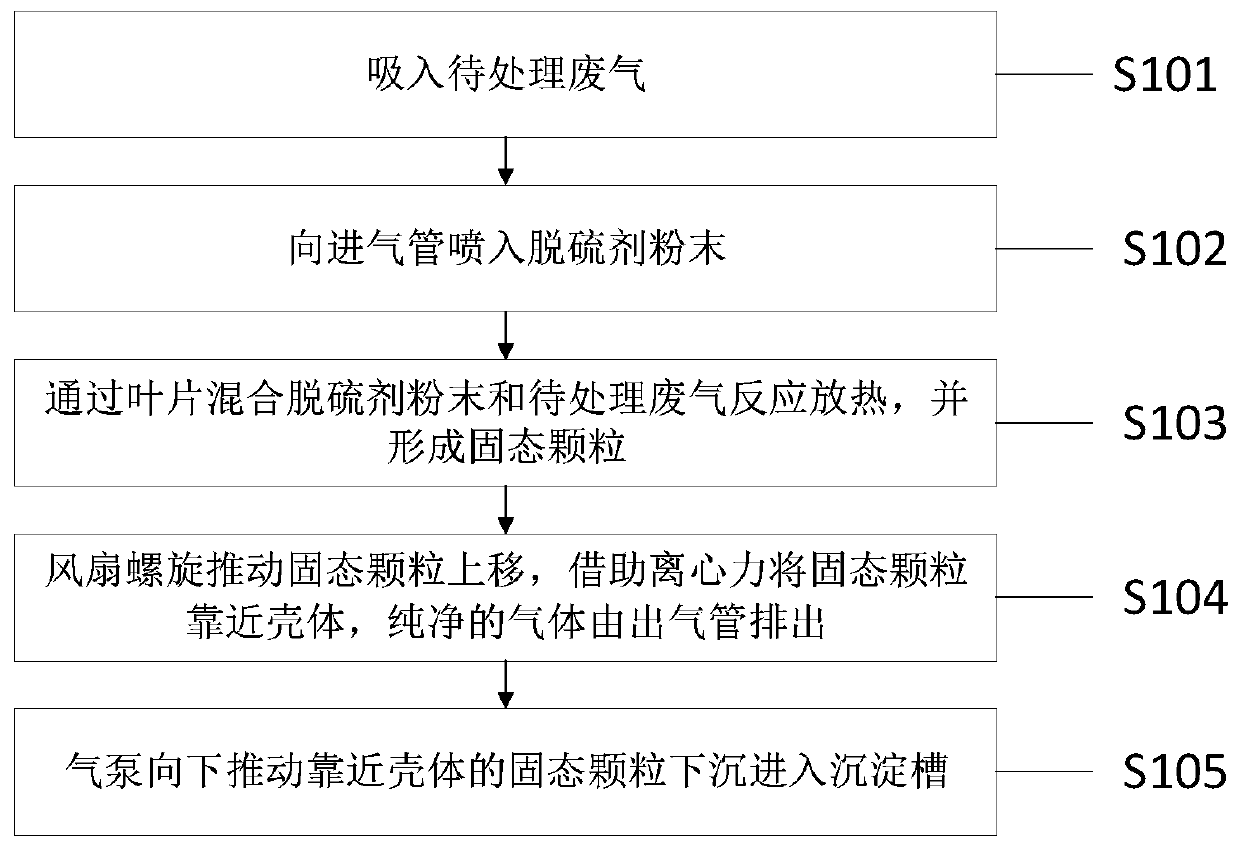

A kind of flue gas semi-dry desulfurization device and method

ActiveCN111545042BSolve the increase in production costsReduce manufacturing costGas treatmentDispersed particle separationFlue gasAir pump

The invention discloses a flue gas semi-dry desulfurization device and method, comprising a shell component, a desulfurization component, a dust removal component, a fan and a sedimentation tank. and extends into the shell, the outlet pipe is fixedly connected with the shell and away from the intake pipe, the desulfurization assembly includes a desulfurization agent tank and a first nozzle, the first nozzle is fixedly connected with the desulfurization agent tank, and extends into the intake pipe, and the fan is connected to the shell. It is fixedly connected and passes through the air intake pipe. The dust removal component includes an air induction pipe and an air pump. The air induction pipe is fixedly connected to the shell, and the air pump and the air induction pipe are fixedly connected. The generated solid particles move outward due to centrifugal force, and are introduced into the sedimentation tank through the air pump downward for precipitation. The pure air is discharged from the air outlet without reheating, thereby reducing the production cost.

Owner:江苏峰峰鸿运环保科技发展有限公司

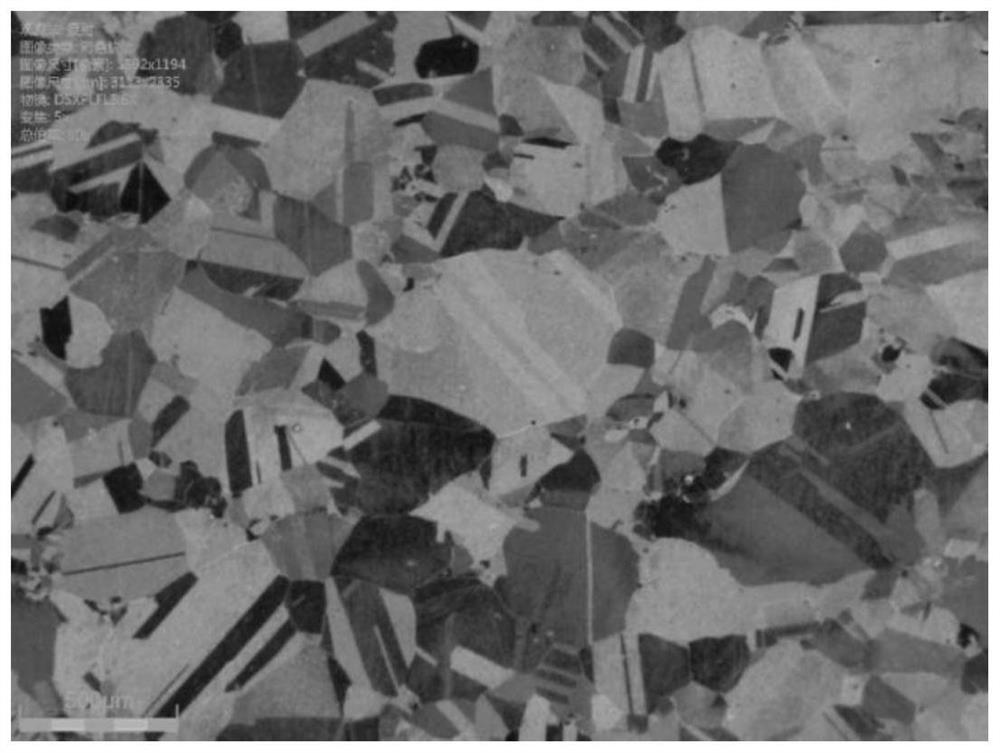

Grain orientation imaging picture acquisition auxiliary device and acquisition method

ActiveCN112540454ASolve the problem of low scattering and diffraction efficiencyLow costMicroscopesColored whiteEngineering

The invention discloses a grain orientation imaging picture acquisition auxiliary device and an acquisition method. The grain orientation imaging picture acquisition auxiliary device comprises an upper-layer annular cavity, a middle-layer annular cavity and a lower-layer annular cavity which are sequentially fixed in a stepped mode. The cavity comprises an outer side face body, an inner side facebody, a top face body and a bottom face body which are sequentially and fixedly sealed to form the cavity. The bottom face body is made of a white semitransparent transparent material; annular lamp bodies with different primary colors are installed in cavities of the three layers. Light rays of the lamp body are diffused through the bottom face body to form an annular surface light source, light rays of the annular surface light source irradiate the alloy grain surface on the object placing table, and then an optical digital microscope obtains a large-area grain orientation imaging picture. Because the brightness of the three layers of light sources with different colors reflected by the grains with different orientations is different, the colors of the grains with different orientations in the obtained image are different, and the colors of the grains with the same orientation are the same, a grain orientation imaging picture is obtained; the problems that the production cost is increased, the electron backscatter diffraction efficiency is low and the phase dyeing technology universality is poor due to the fact that the cost for purchasing electron backscatter diffraction equipment or phase dyeing technology research and development is increased are solved.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

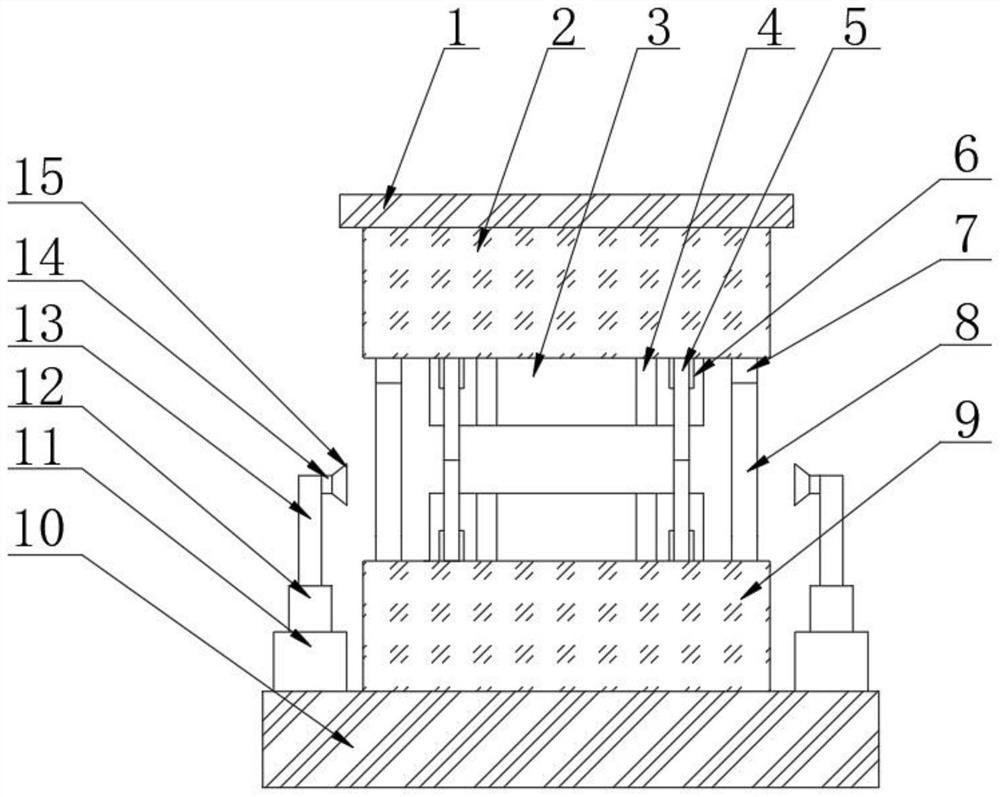

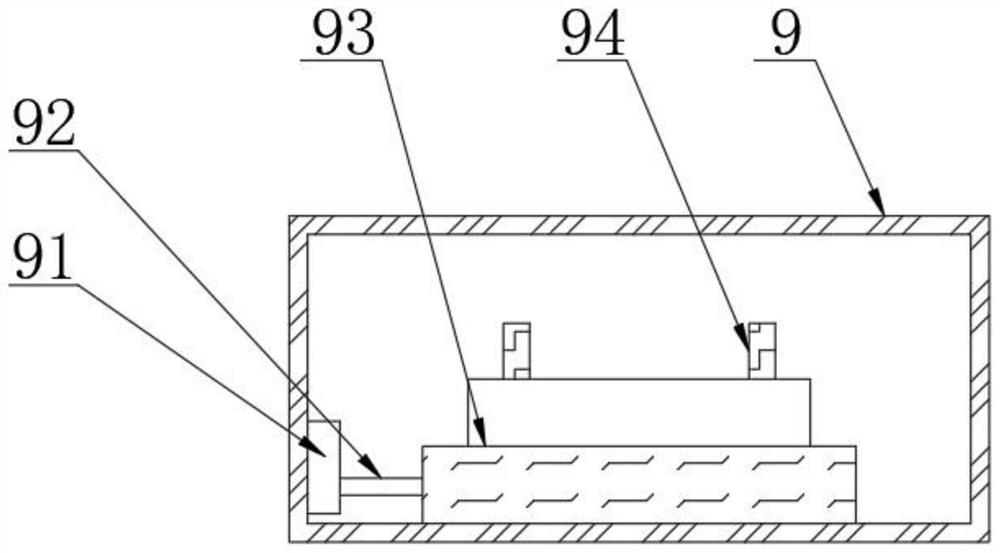

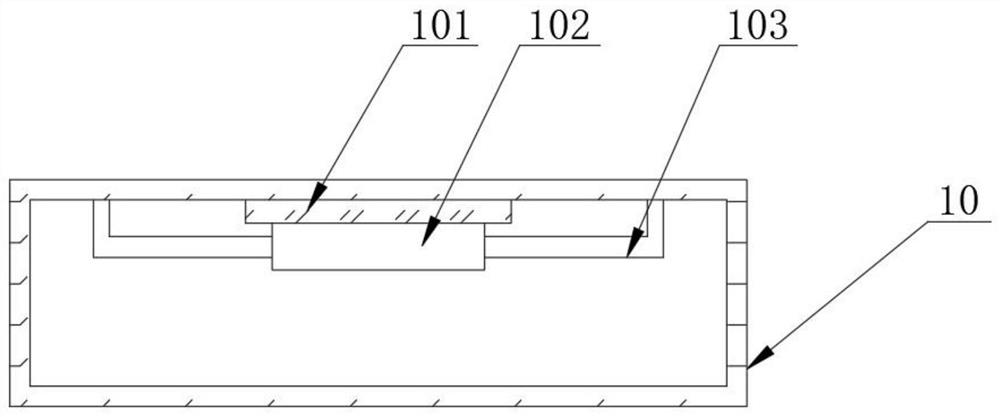

Mold core guide structure of plastic mold and plastic mold thereof

The invention discloses a mold core guide structure of a plastic mold and the plastic mold thereof and particularly relates to the field of plastic molds. The mold core guide structure comprises an upper fixing plate and an upper extrusion mold, wherein the plastic mold is welded to the bottom of the upper extrusion mold; mold cores are fixedly mounted on two sides of the interior of the plastic mold; guide columns are fixedly mounted on two sides of the bottom of the upper extrusion mold; two sides of each guide column are fixedly sleeved with guide sleeves; and upper fixing columns are welded to the two sides of the bottom of the upper extrusion die. According to the mold core guide structure of the plastic mold and the plastic mold thereof, a shaping device is arranged; when the raw materials need to be heated when the the raw materials are processed, so that the raw materials need to be subjected to thermoplastic molding; when thermoplastic molding is completed, the raw materials are not shaped, so that the shaping device can automatically cool the periphery of plastic when thermoplastic molding of the plastic is completed during usage of the mold core, then the plastic is rapidly shaped; the problem of the damage of the plastic is avoided, and the problem that the plastic production cost is increased is also solved, so that the mold core guide structure ensures that the damage of the plastic is avoided; meanwhile, the production cost is also reduced.

Owner:无锡市百韧机械科技有限公司

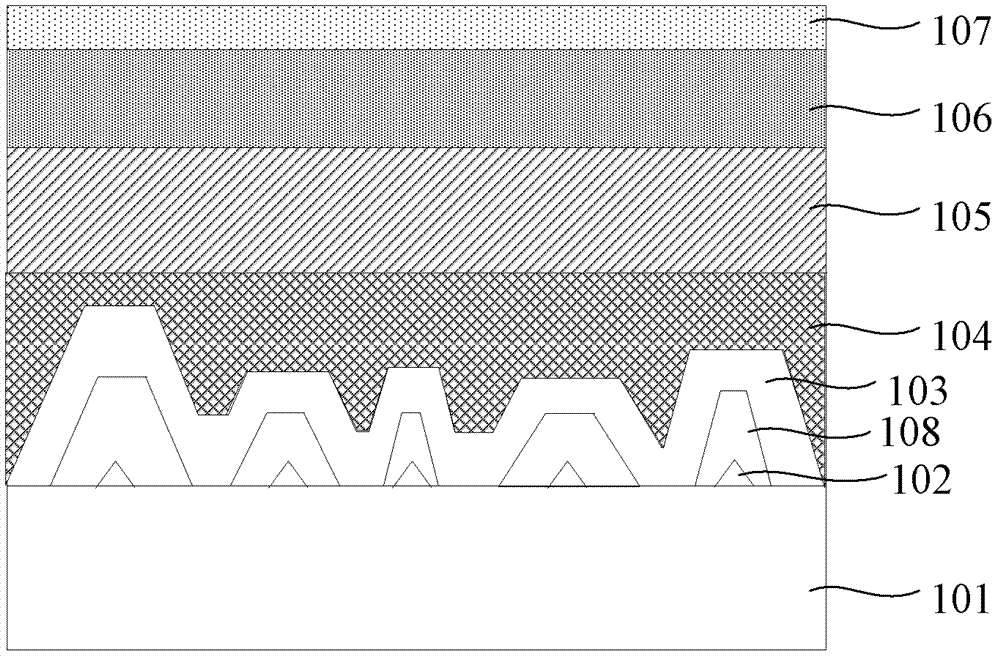

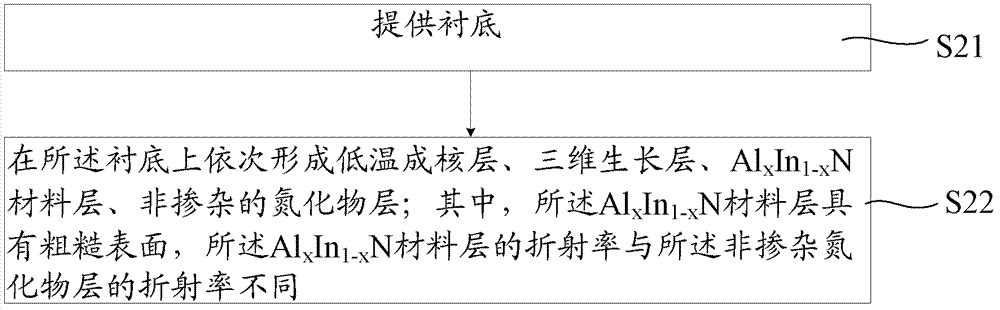

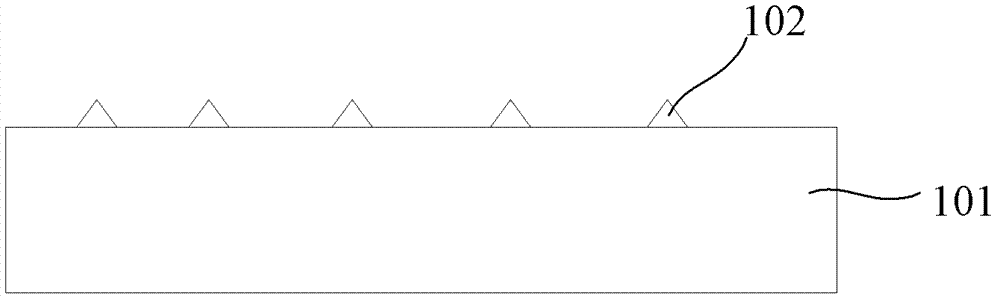

Nitride light emitting diode (LED) structure and preparation method thereof

InactiveCN102270718BExtended critical angleChange direction of transmissionSemiconductor devicesRough surfaceQuantum efficiency

The invention discloses a nitride light emitting diode (LED) structure, which comprises a substrate, a low-temperature nucleation layer and an undoped nitride layer, wherein the low-temperature nucleation layer and the undoped nitride layer grow on the substrate; a three-dimensional growth layer grows on the low-temperature nucleation layer; an AlxIn(1-x)N material layer is arranged between the three-dimensional growth layer and the undoped nitride layer and provided with a rough surface; the refractive index of the AlxIn(1-x)N material layer is different from that of the undoped nitride layer; and the x is more than 0 and less than 1. The invention also provides a preparation method of the nitride LED structure. The nitride LED structure provided by the invention changes the transmissiondirection of light rays due to a scattering effect, expands the critical angle of emergent light, and improves the light extraction efficiency and the external quantum efficiency. The preparation method provided by the invention can be compatible with the ordinary LED epitaxial growth process and is completed in a reaction chamber at one time, and extra machining or processing technologies are not needed.

Owner:ENRAYTEK OPTOELECTRONICS

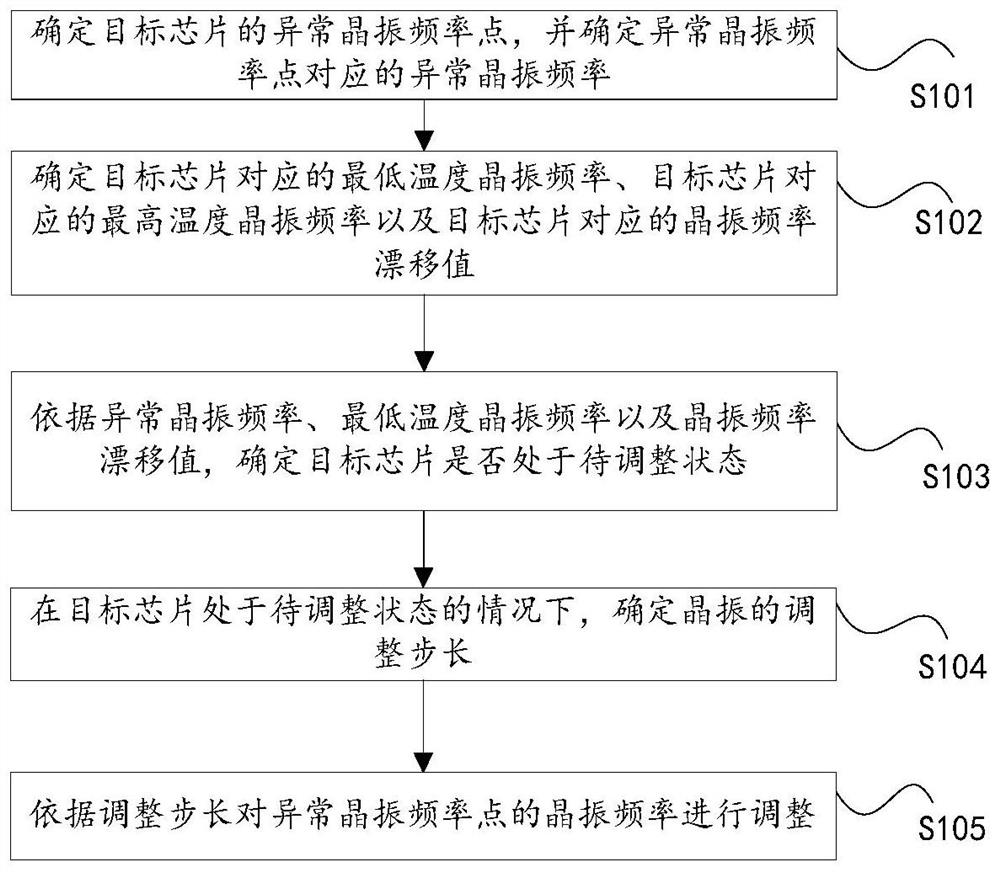

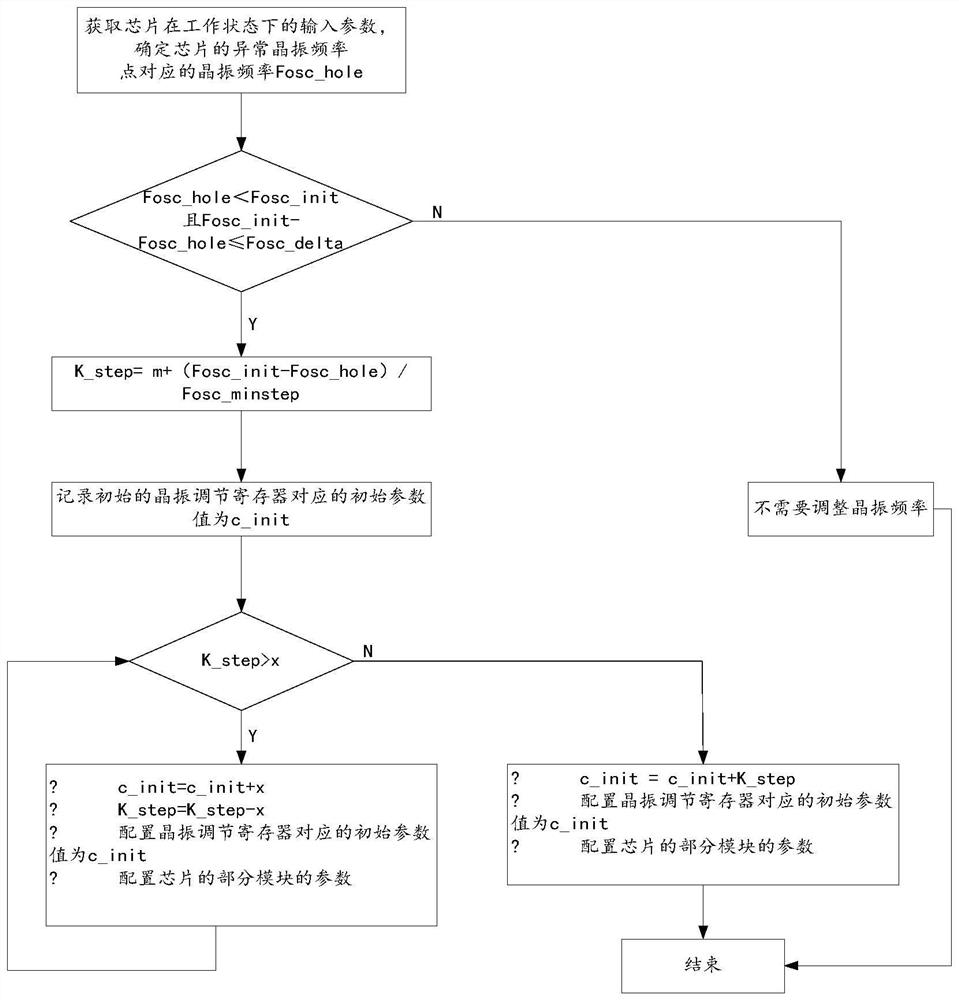

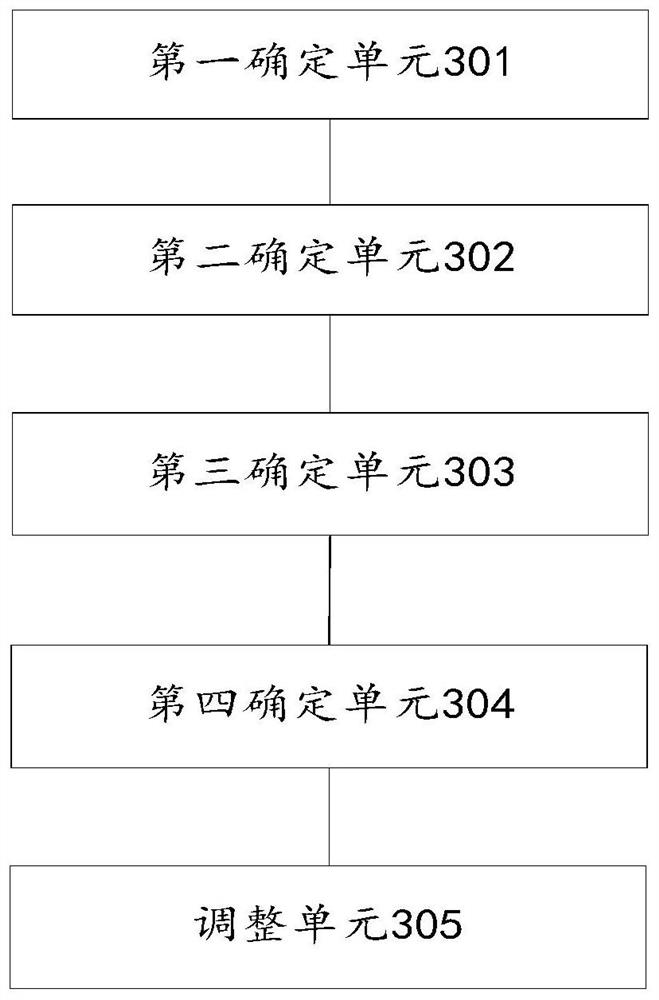

Method and device for adjusting chip crystal oscillator frequency

PendingCN114650050ASolve the increase in production costsCrystal frequency automatic adjustmentGenerator stabilizationEngineeringMechanical engineering

The invention discloses a method and device for adjusting the frequency of a chip crystal oscillator. The method comprises the following steps: determining an abnormal crystal oscillator frequency point of a target chip, and determining an abnormal crystal oscillator frequency corresponding to the abnormal crystal oscillator frequency point; determining a lowest temperature crystal oscillator frequency corresponding to the target chip, a highest temperature crystal oscillator frequency corresponding to the target chip and a crystal oscillator frequency drift value corresponding to the target chip; determining whether the target chip is in a to-be-adjusted state or not according to the abnormal crystal oscillator frequency, the lowest temperature crystal oscillator frequency and the crystal oscillator frequency drift value; when the target chip is in the to-be-adjusted state, determining the adjustment step length of the crystal oscillator; and adjusting the crystal oscillator frequency of the abnormal crystal oscillator frequency point according to the adjustment step length. According to the invention, the problem that the manufacturing cost of the chip is increased due to the technical means adopted for preventing the drift of the internal frequency of the chip in the prior art is solved.

Owner:ANALOGIX CHINA SEMICON +1

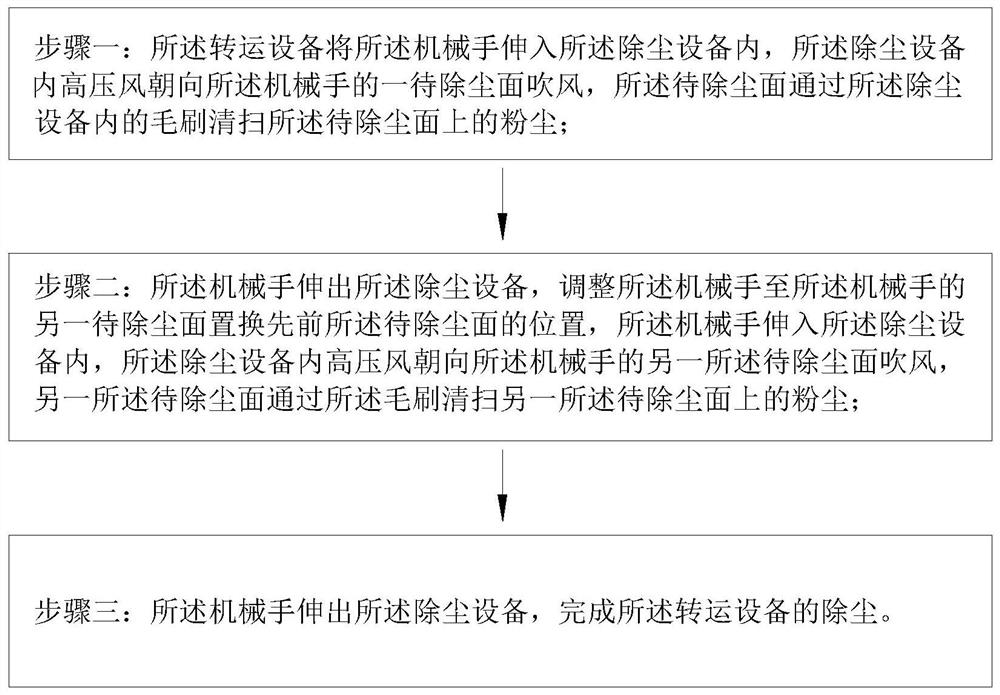

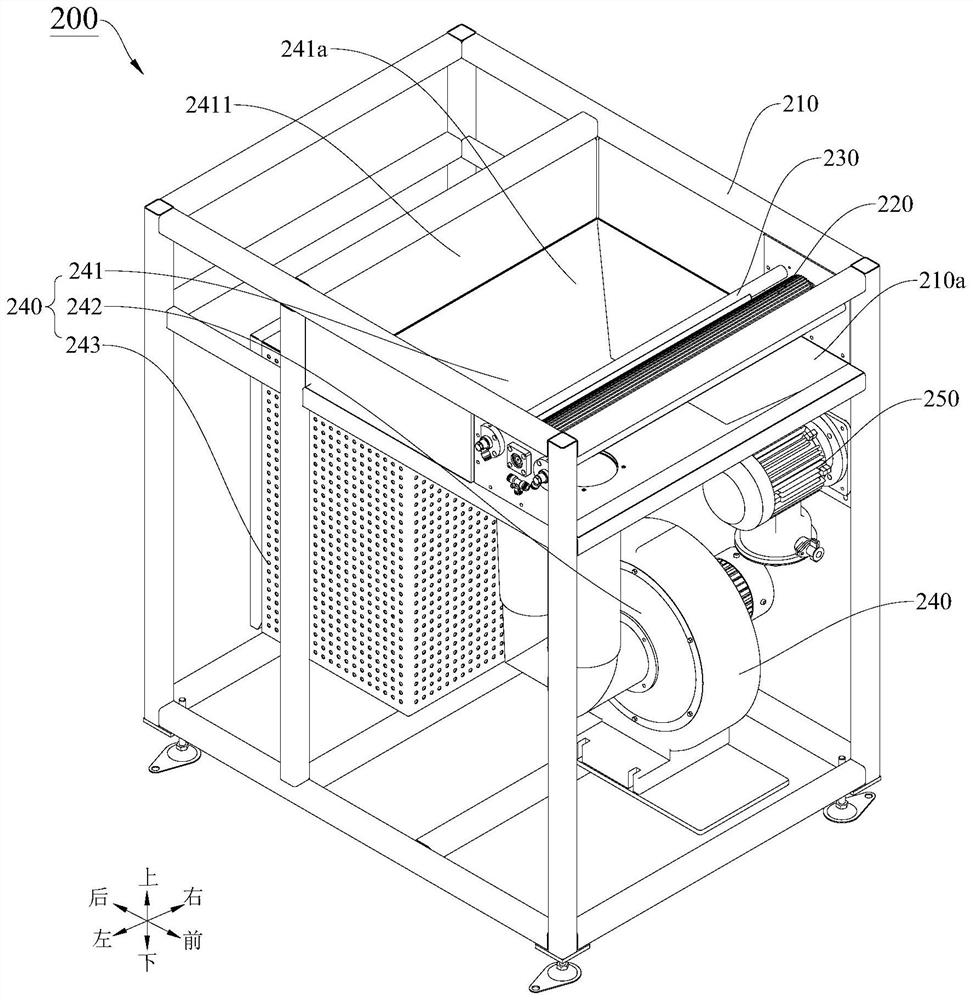

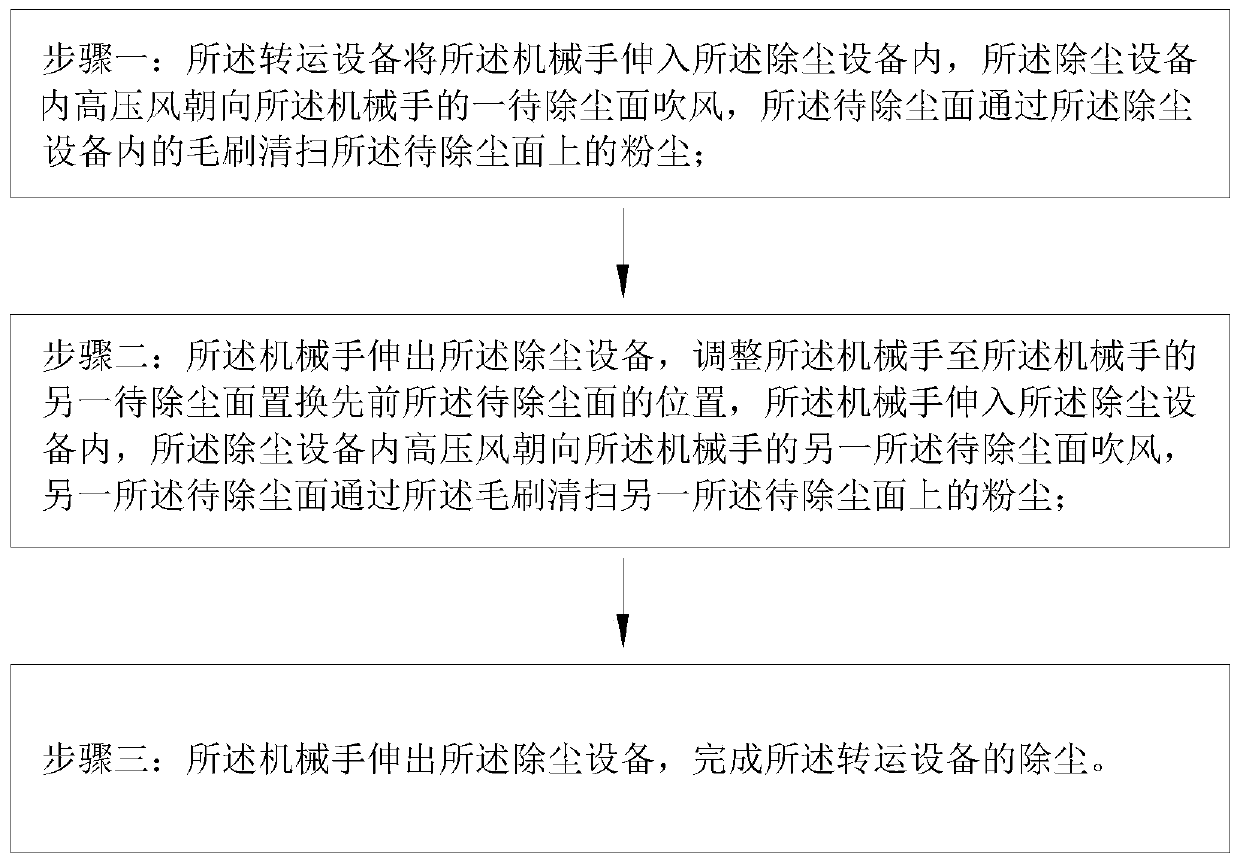

Method to prevent positive and negative electrode dust cross-contamination in baking process

ActiveCN111001639BSolve the increase in production costsEliminates the risk of cross-contaminationFinal product manufacturePrimary cellsDust controlProcess engineering

The invention discloses a method for preventing cross-contamination of positive and negative dust in the baking process, comprising: transfer equipment and at least two sets of dust removal equipment, the transfer equipment has a manipulator; the method for preventing cross-contamination of positive and negative dust in the baking process includes: transfer The equipment is dedusted in the dedusting equipment for positive dedusting and dedusting in the dedusting equipment for negative dedusting; the dedusting of the transfer equipment in the dedusting equipment includes the following steps: Step 1: The manipulator extends into the dedusting equipment, and the high-pressure air is directed towards the dedusting surface of the manipulator Blow the air, and use the brush to clean the dust on the surface to be dedusted; Step 2: The manipulator extends the dust removal equipment, adjusts the position of the dedusting surface, and the manipulator extends into the dedusting equipment; Step 3: The manipulator extends the dedusting equipment. The invention solves the problem of dust cross-contamination when the positive and negative coils exist at the same time, solves the problem of excessive equipment cost, can save equipment investment cost, and reduce the production cost of electric cores.

Owner:昆山聚创新能源科技有限公司

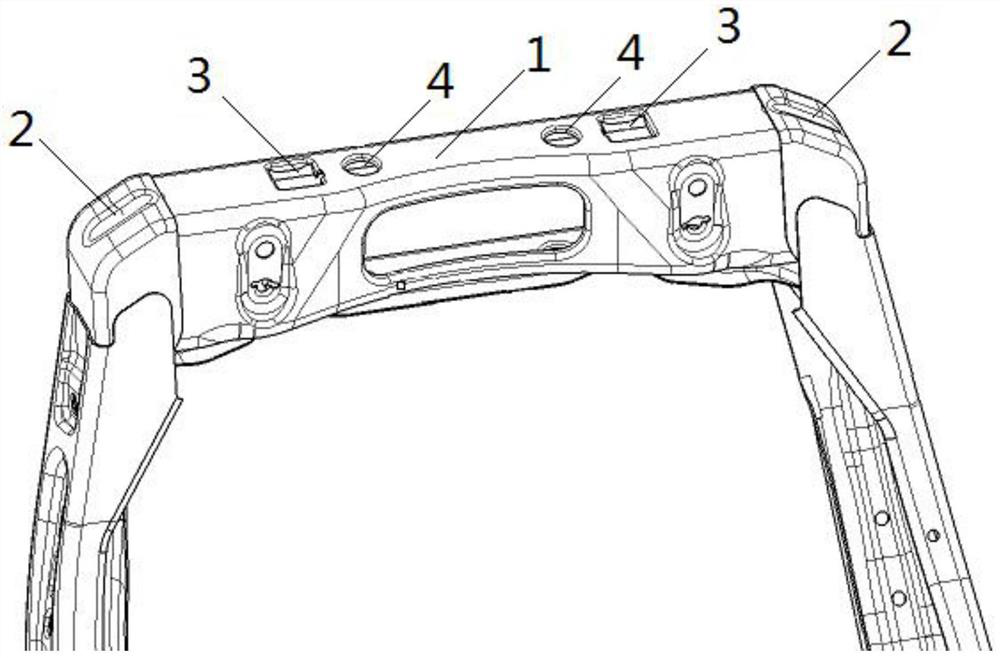

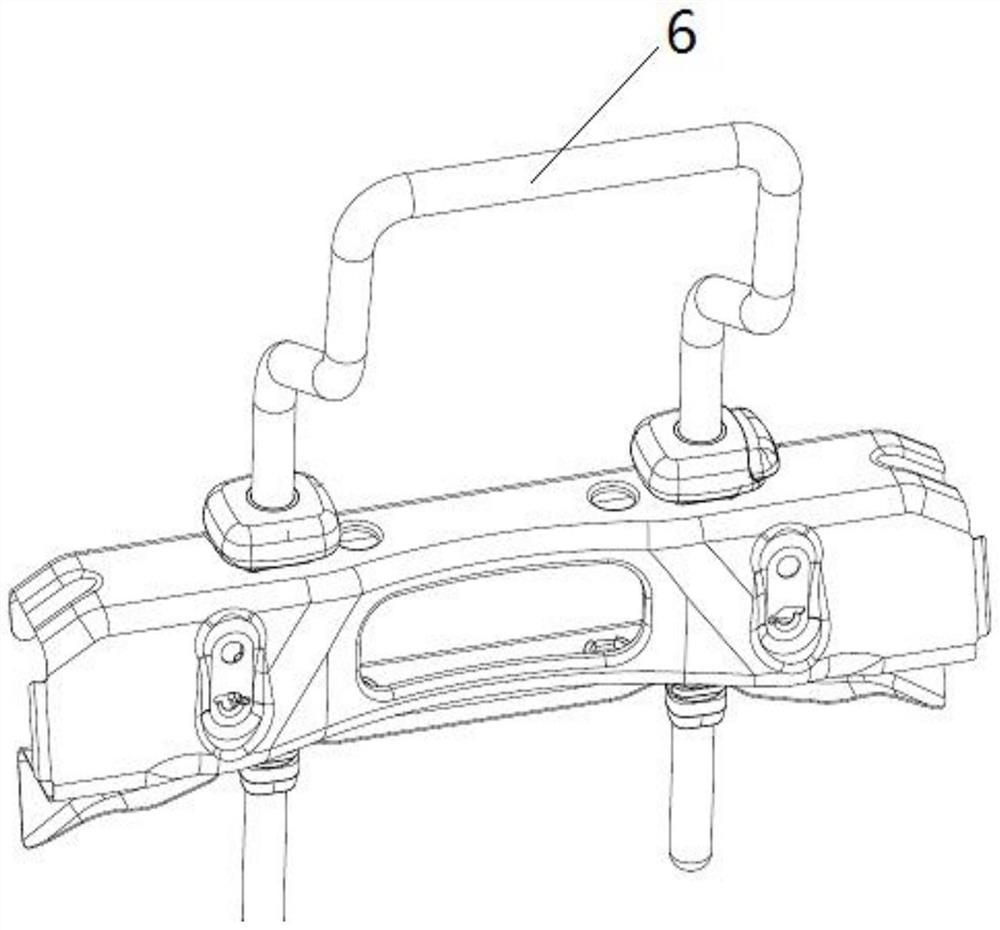

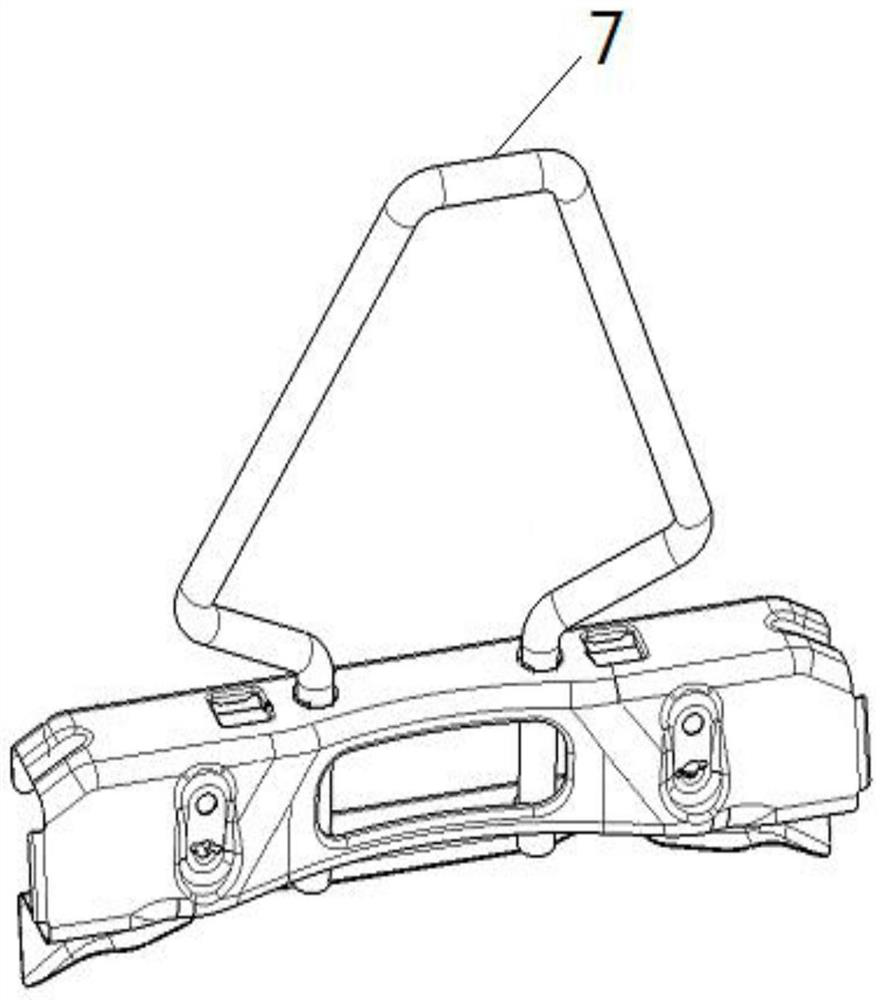

Backrest cross beam structure and seat comprising backrest cross beam structure

The invention discloses a backrest cross beam structure and a seat comprising the backrest cross beam structure, and relates to the technical field of automobile seats. The backrest cross beam structure comprises a beam body, a first headrest pipe, a second headrest pipe and a third headrest pipe, grooves are formed in the two sides of the beam body, two first through holes are formed in the upper end face of the beam body side by side at intervals, and two second through holes are further formed in the upper end face of the beam body side by side at intervals, the two second through holes are formed between the two first through holes, the two ends of the first headrest pipes are placed in the grooves respectively, the two ends of the second headrest pipes penetrate through the first through holes in a one-to-one correspondence mode, the second headrest pipes can freely slide in the height direction of the cross beam body, and the two ends of the third headrest pipes penetrate through the second through holes in a one-to-one correspondence mode; therefore, the problem that the manufacturing cost is increased due to the fact that the seat backrest is matched with different headrests in the prior art is solved.

Owner:上海国琻汽车科技有限公司

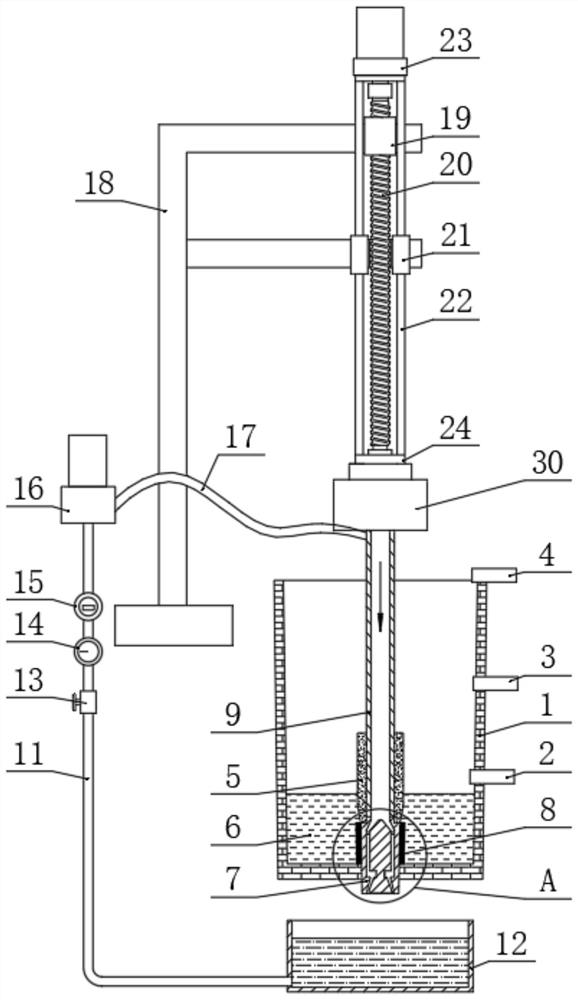

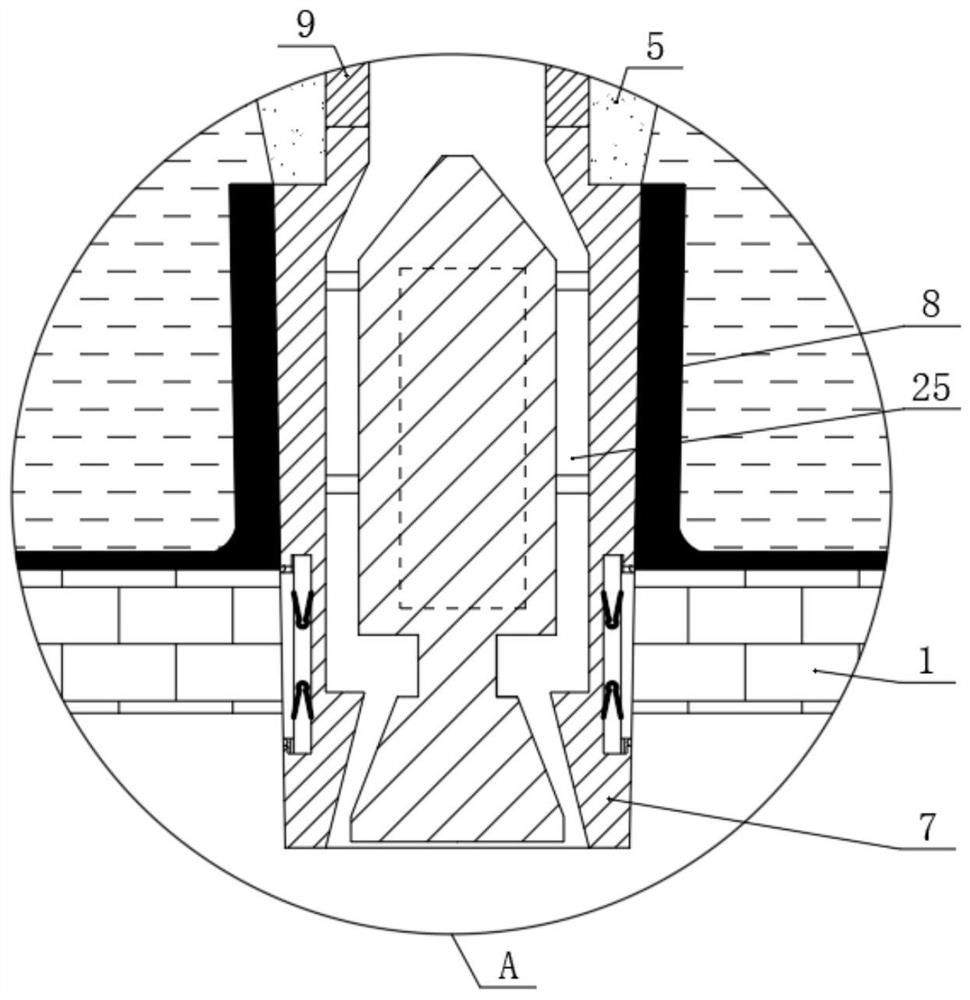

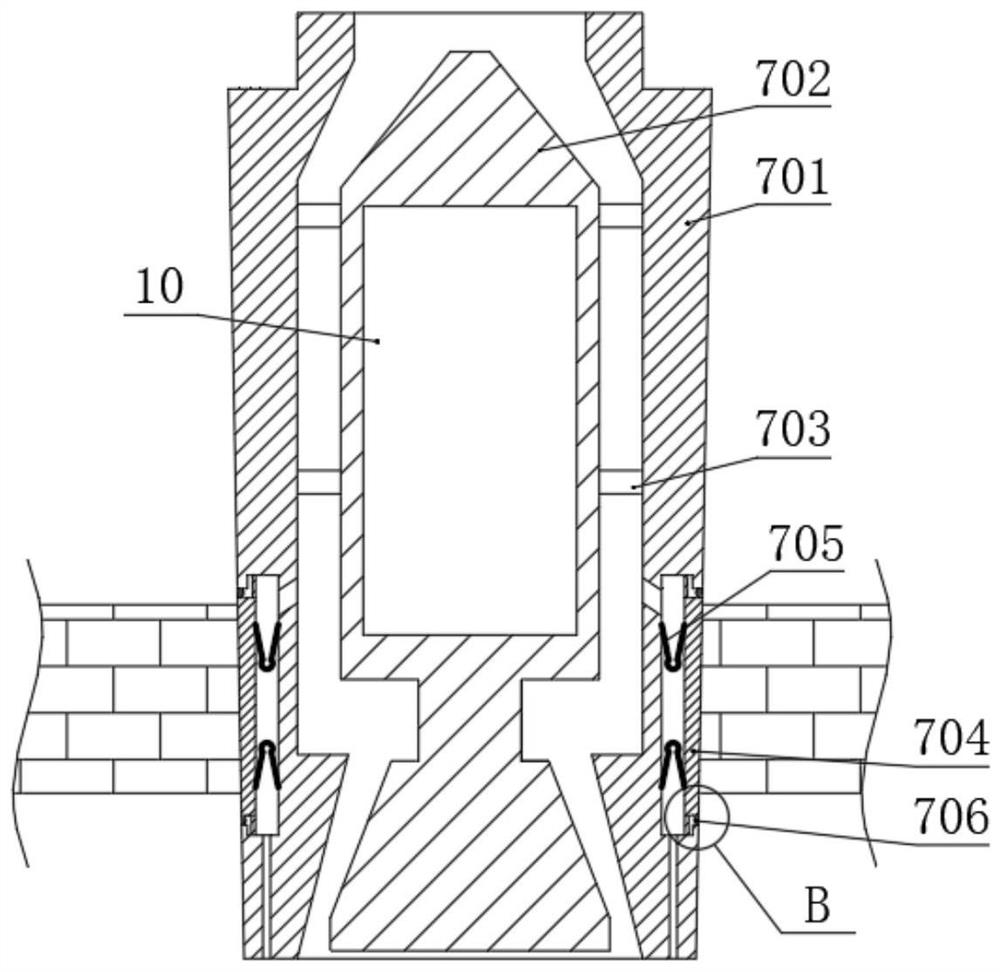

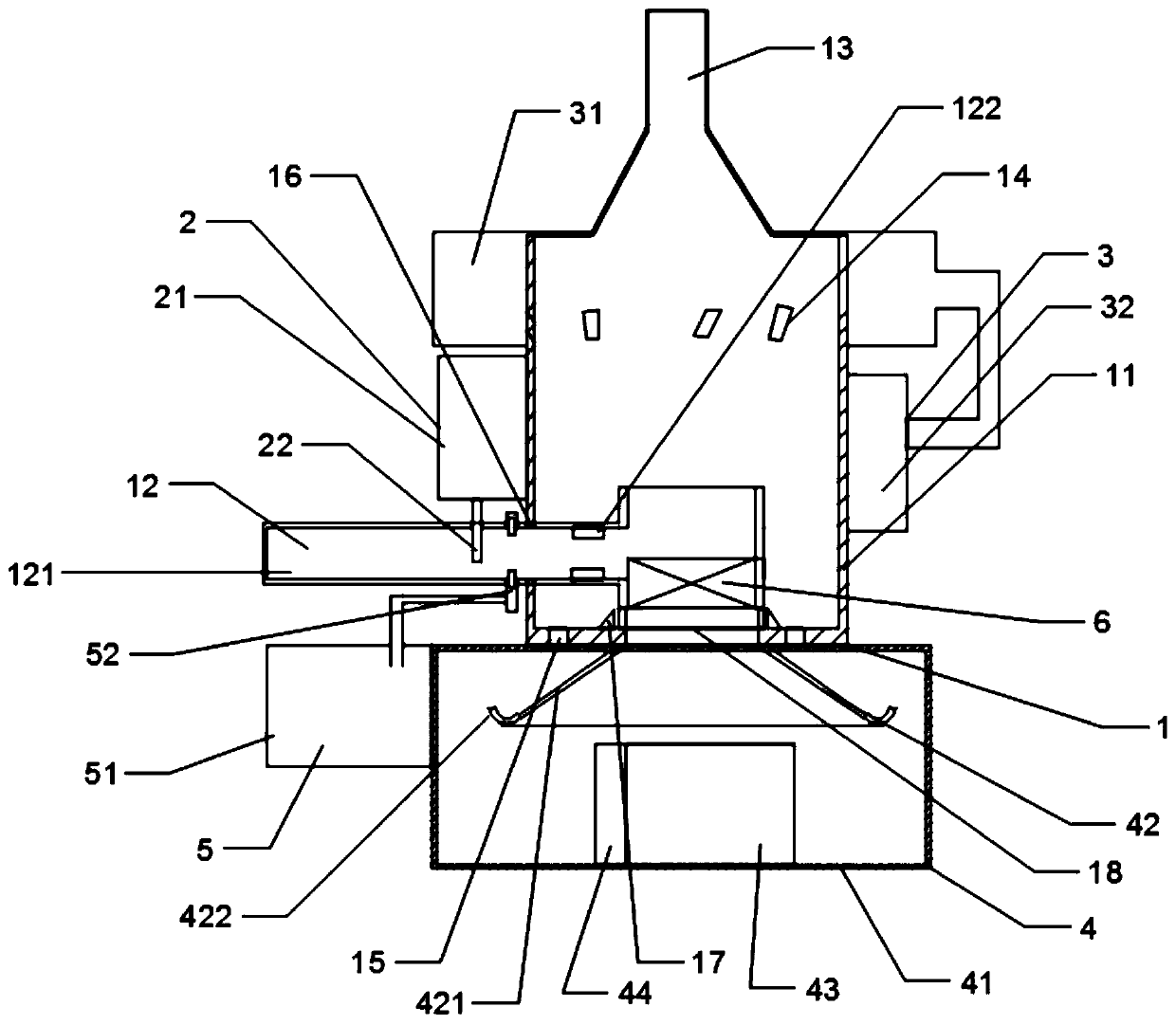

Hollow cast ingot inner hole casting device

ActiveCN113976842AReduce the amount of smeltingReduce wasteNuclear energy generationIngot casting plantsIngot castingMolding machine

The invention discloses a hollow cast ingot inner hole casting device which comprises an ingot mold. A cooling forming mechanism is inserted into the ingot mold, a lifting mechanism is arranged above the cooling forming mechanism, a connecting pipe is arranged at the top end of the cooling forming mechanism, and a connecting seat is arranged at the top end of the connecting pipe. The top of the connecting seat is fixedly connected with the driving end of the lifting mechanism, an oscillator is arranged in the cooling forming mechanism, and a cooling mechanism is in fluid communication with the liquid inlet end of the cooling forming mechanism. By arranging the ingot mold with the mounting hole in the bottom, cooperating with the crystallizer and cooperating with the lifting mechanism, a metal ingot with a hollow structure can be cast, casting defects are remarkably reduced, troubles caused by later secondary transferring and drilling are avoided, metal material waste caused by drilling is reduced, the metal smelting amount is effectively reduced, the purposes of energy conservation and emission reduction are achieved, production efficiency is improved, ingot casting quality is improved, and the problem that production cost is increased is solved.

Owner:内蒙古展华科技有限公司 +1

Flue gas semi-dry desulfurization device and method

ActiveCN111545042ASolve the increase in production costsReduce manufacturing costGas treatmentDispersed particle separationProcess engineeringFlue gas

The invention discloses a flue gas semi-dry desulfurization device and method. The device comprises a shell assembly, a desulfurization assembly, a dedusting assembly, a fan and a precipitation tank;the shell assembly comprises a shell, an air inlet pipe and an air outlet pipe; the air inlet pipe is fixedly connected with the shell and extends into the shell; the air outlet pipe is fixedly connected with the shell and away from the air inlet pipe. The desulfurization assembly comprises a desulfurizing agent box and a first spray head; the first spray head is fixedly connected with the desulfurizing agent box; the first spray head extends into the air inlet pipe, a fan and the shell are fixedly connected, and the first spray head penetrates through the air inlet pipe; the dedusting assembly comprises an induced draft pipe and an air pump; the induced draft pipe is fixedly connected with the shell, an air pump is fixedly connected with the induced draft pipe, a desulfurizing agent in the air inlet pipe is mixed with flue gas, then the mixture is blown out through the fan, generated solid particles move outwards due to centrifugal force and are downwards introduced into the precipitation tank through airflow of the air pump for precipitation, pure air is exhausted through the air outlet pipe, reheating is not needed, and thus the production cost is reduced.

Owner:江苏峰峰鸿运环保科技发展有限公司

Method for preventing positive and negative electrode dust cross contamination in baking process

ActiveCN111001639AEliminates the risk of cross-contaminationReduce manufacturing costFinal product manufacturePrimary cellsRobot handDust control

The invention discloses a method for preventing positive and negative electrode dust cross contamination in a baking process. According to the method, transfer equipment and at least two sets of dustremoval equipment are adopted, wherein the transfer equipment removes dust in the positive electrode dust removal equipment and the negative electrode dust removal equipment. The dust removal of the transfer equipment comprises the following steps that: 1, a mechanical arm stretches into the dust removal equipment, high-pressure air blows towards a to-be-dedusted surface of the mechanical arm, anddust on the to-be-dedusted surface is swept through a brush; 2, the mechanical arm extends out of the dust removal equipment, the position of the to-be-dedusted surface is adjusted, and the mechanical arm extends into the dust removal equipment; and 3, the mechanical arm extends out of the dust removal equipment. With the method of the invention adopted, the problem of dust cross contamination when dust exists on a positive electrode roll and a negative electrode roll at the same time is solved; the problem of excessively high equipment cost is solved; equipment investment cost can be solved;and battery cell production cost can be decreased.

Owner:昆山聚创新能源科技有限公司

Consumption-reducing ss non-woven fabric production line

ActiveCN112226960AFirmly attachedEasy to moveLiquid/gas/vapor removalTextile treatment machine arrangementsProcess engineeringNonwoven fabric

The invention discloses a consumption-reducing ss non-woven fabric production line. An unwinding machine, a dye vat, a mangle, a drying machine and a lapper are sequentially arranged, a plurality of guide rollers of the dye vat are rotatably mounted in a vat body, a push plate is slidably connected with the vat body, a first fan and a second fan are mounted at the inner side of the vat body in a staggered manner, a filling device is mounted at one side of the vat body, a support of the mangle is installed at one side of the vat body, and a first roller and a second roller are rotationally connected with the support. The push plate is arranged on the vat body, so that heat dissipation can be reduced, energy consumption can be reduced, meanwhile, a first draught fan and a second draught fanare additionally arranged to rotate in a first groove so that dye can fully flow, sedimentation is avoided, the utilization rate of the dye is increased, and therefore the production cost during clothdyeing can be reduced; and the problem that the production cost is increased due to too high energy consumption during production of an existing production line is solved.

Owner:CHANGZHOU JUWU MACHINERY

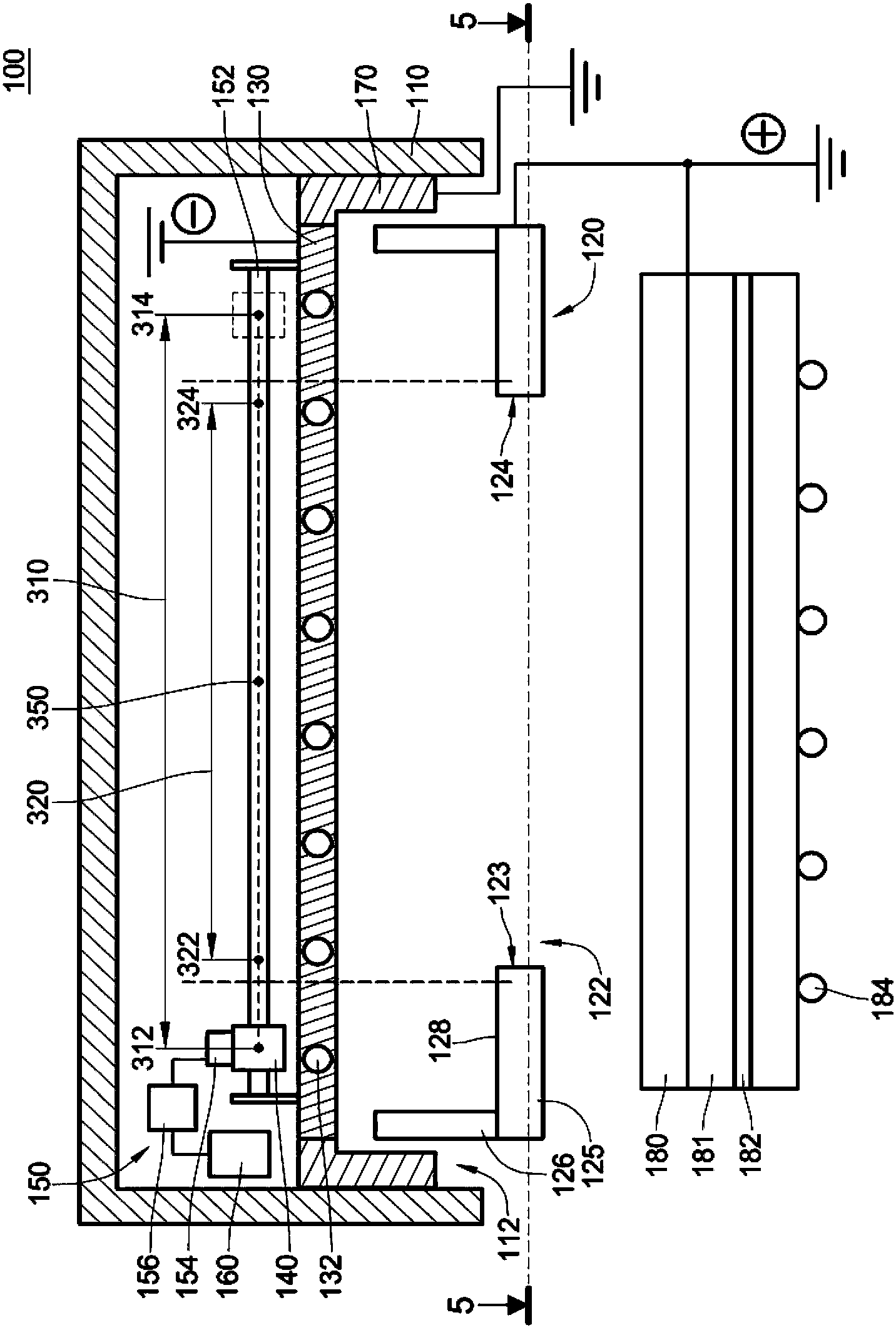

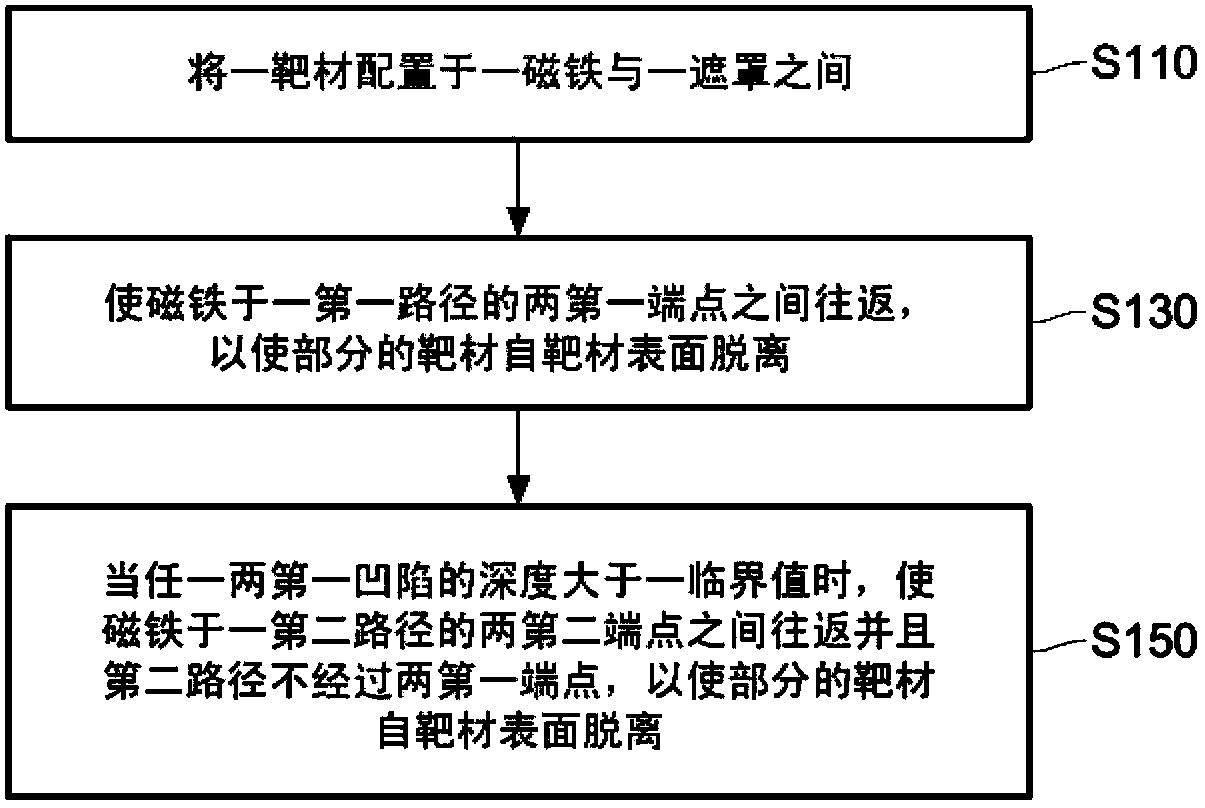

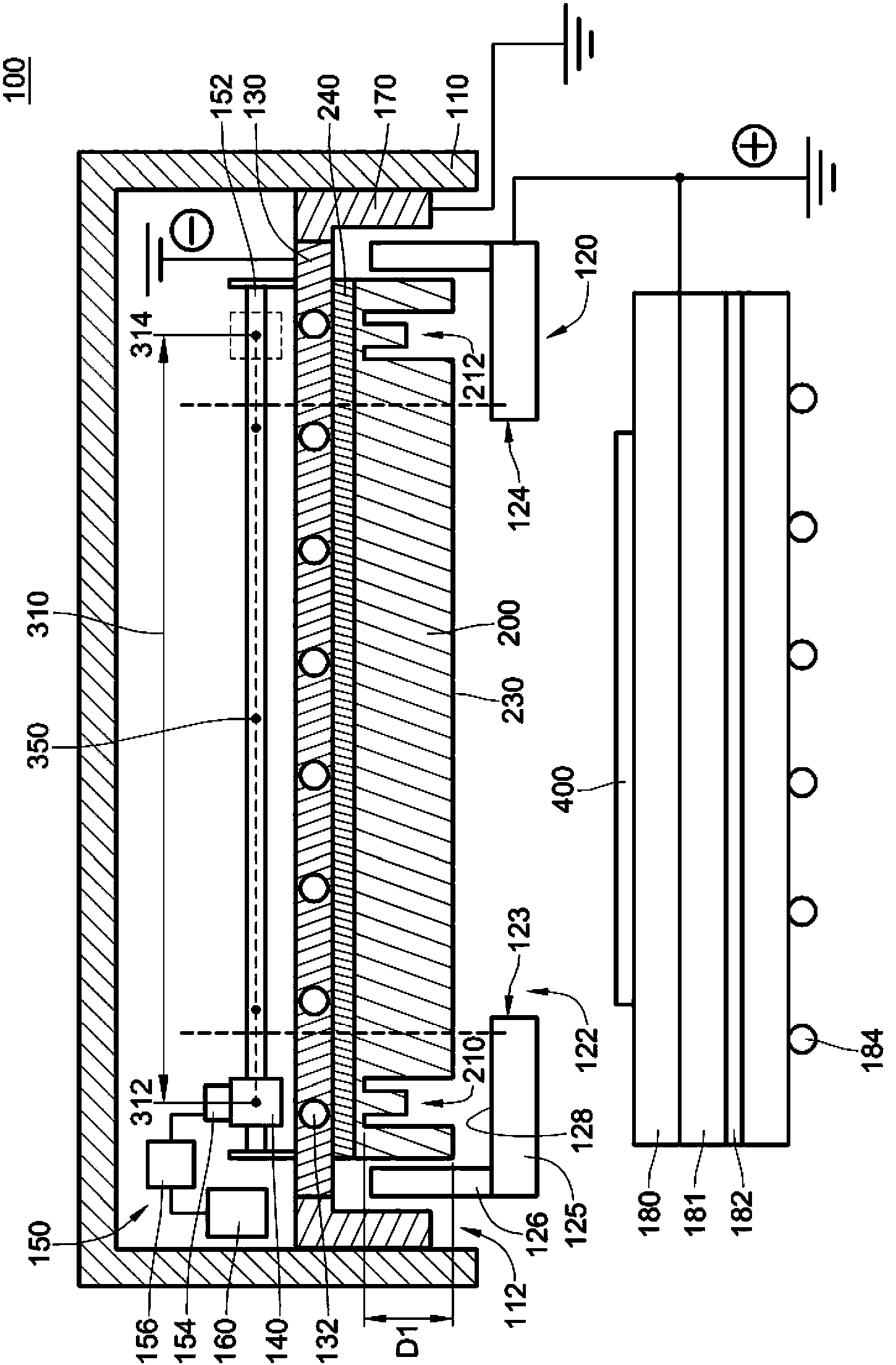

Sputtering machine and control method for magnet thereof

InactiveCN102817001BEfficient use ofUniform detachmentVacuum evaporation coatingSputtering coatingEngineeringMechanical engineering

A sputtering machine and a control method for a magnet thereof. The sputtering machine comprises a cavity chamber, a target material loading plate, a cover, a magnet, a drive mechanism and a programming controller. The cavity chamber has an opening. The target material loading plate is positioned in the cavity chamber. The cover covers the opening of the cavity chamber, and has a covering opening which is smaller than the cavity chamber opening and exposes the target material loading plate. The magnet is arranged in the cavity chamber. The drive mechanism is in connection with the magnet to drive the magnet to move on the target material loading plate. The programming controller is connected to the drive mechanism to drive the magnet to move along a first path with two first end points and a second path with two second end points, wherein both the first path and the second path span the covering opening, and the two second end points are between the two first end points. The space of magnet took up of the two first end points is not overlapped with that of the two second end points.

Owner:AU OPTRONICS CORP

Polygonatum odoratum noodles, processing method and equipment thereof

PendingCN112335835APrevent fallingSolve the increase in production costsDrying gas arrangementsDrying machines with local agitationPolygonum odoratumPolygonatum odoratum

The invention belongs to the technical field of noodles, and particularly relates to a polygonatum odoratum noodle processing equipment, which comprises a base, a box is fixedly connected to the uppersurface of the base, a first electric pushing rod is fixedly connected to the upper surface of the box, a pushing plate is fixedly connected to the upper surface of the first electric pushing rod, and a pulling plate is fixedly connected to the bottom surface of the pushing plate. And two supporting rods are fixedly connected to one side surface of the pulling plate, a U-shaped clamp is fixedly connected to the upper surface of each supporting rod, a control panel is fixedly connected to the front surface of the box, and a single-chip microcomputer is fixedly connected to the inner top wall of the box. According to the invention, the arrangement of an exhaust fan and an air bellow can provide wind power for a sealing cover, dirt such as dust can be filtered through a filter screen, so that the sealing cover blows air to noodles through air outlet holes, a second electric pushing rod is matched with an adjusting rod to enable the sealing cover to swing, so that wind is blown more uniformly, the noodle airing speed is improved, the production efficiency is improved.

Owner:邵东路源农业有限公司

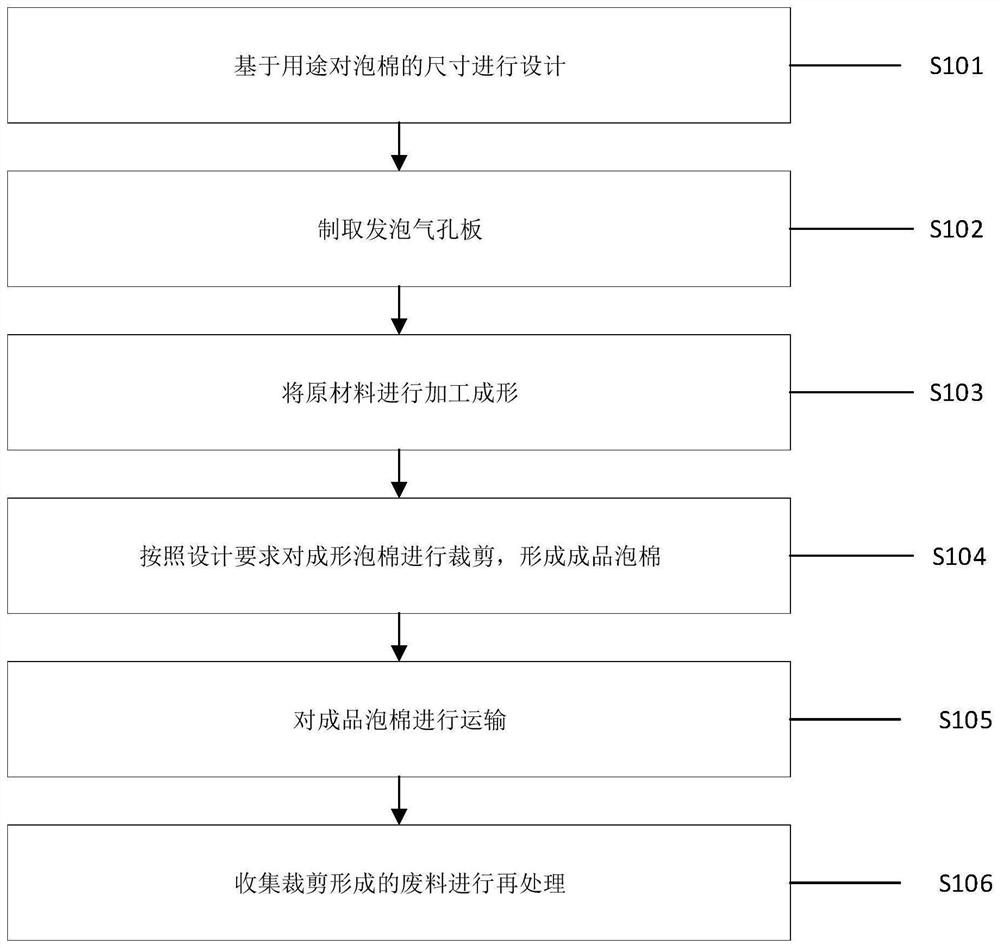

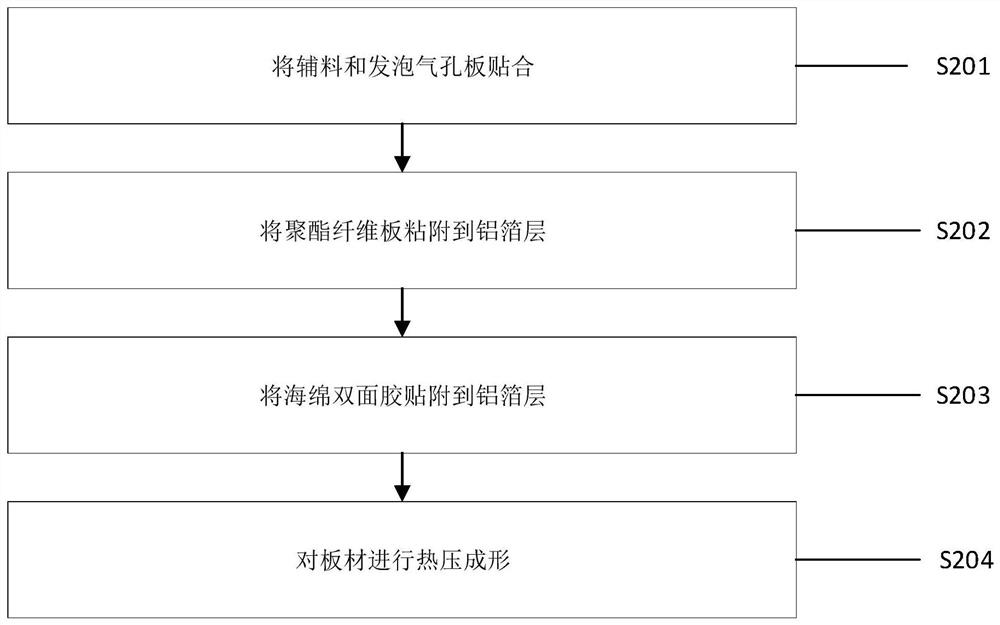

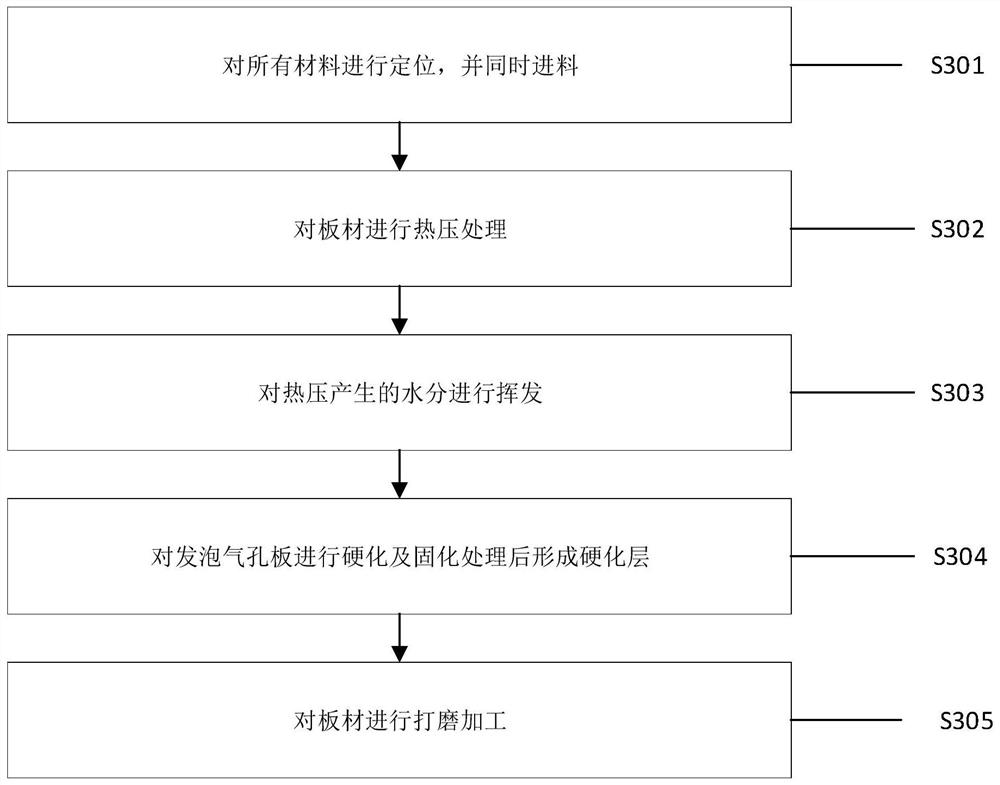

Hot press molding process for automobile sound insulation foam

The invention discloses a hot press molding process for automobile sound insulation foam. The hot press molding for the automobile sound insulation foam process comprises the following steps of designing the size of the foam based on purposes; preparing a foaming pore plate; processing and forming raw materials; cutting the formed foam according to design requirements to form finished foam; and collecting waste materials formed by cutting, and retreating the collected waste materials. The foaming pore plate is adopted for attraction, a polyester fiber plate is used for sound insulation, then cutting is conducted according to the specified shape after plate machining is completed, meanwhile, the size of the foam is designed in advance based on the product size, the generation of the waste materials is reduced, and finally the waste materials are recycled and re-machined, so that the utilization rate of the materials can be increased, and the problem that the production cost is increaseddue to the fact that an existing process generates more waste materials is solved.

Owner:南通华阁汽车配件有限公司

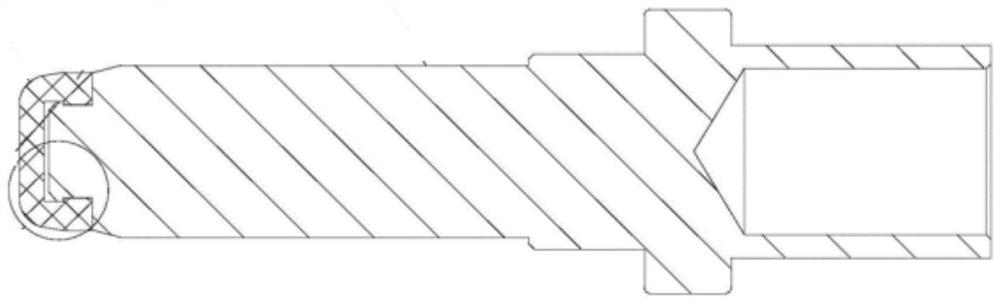

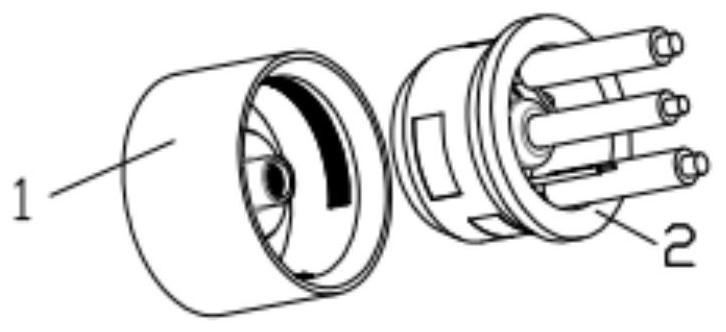

Connecting terminal

ActiveCN112838400ASolve the increase in production costsRealize the anti-arc functionCoupling contact membersControl signalStructural engineering

The invention provides a connecting terminal which comprises a female end frame and a male end frame, first reed grooves are symmetrically formed in the inner wall of the female end frame and used for containing a positive reed and a negative reed, a boss is arranged in the female end frame in the axial direction, second reed grooves are symmetrically formed in the outer circumferential face of the boss and used for containing a first signal reed and a second signal reed, the boss extends out of a shaft neck in the axial direction, and a third reed groove is formed in the surface of the inner circumference of the shaft neck and used for containing a ground wire reed. A first copper bar groove and a second copper bar groove are symmetrically formed in the outer circumferential surface of the male end frame, a positive electrode pre-connection copper bar and a negative electrode pre-connection copper bar are placed in the first copper bar groove, a positive electrode copper bar and a negative electrode copper bar are placed in the second copper bar groove, a third copper bar groove is symmetrically formed in the inner circumferential surface of the male end frame, a first signal copper bar and a second signal copper bar are placed in the third copper bar groove, a ground wire needle is fixed to the axis position of the male end frame, the connecting and disconnecting processes are achieved through longitudinal movement of the male end frame, the arc discharge prevention function is achieved through a mechanical movement mode instead of an electronic control signal, the structure is simple, and cost is low.

Owner:GUOCHUANG INNOVATION CENTER OF MOBILE ENERGY (JIANGSU) CO.,LTD.

Recovery unit for concrete block cutting process

The invention relates to the technical field of concrete block machining, in particular to a recycling device used in the concrete block cutting process. Compared with the prior art, in the scheme, a waste elevator and a water suction pump are electrically connected with a power source through a slide rheostat, and the sliding end of the slide rheostat is fixedly connected with a waste collecting tank and further electrically connected with the fixed end, away from the power source, of the slide rheostat. The waste collecting tank is further provided with a crushing device electrically connected with the power source. The waste collecting tank is connected to the outer portion of the crushing device in a sleeving manner and is in sliding connection with the crushing device. A self-reset switch is arranged at the bottom of the crushing device. An operation panel corresponding to the self-reset switch is fixedly connected to the side wall of the waste collecting tank. A stirrer is arranged in the waste collecting tank, a liquid storage pond in which a solution is injected is arranged below the waste collecting tank, and the waste collecting tank is located in the liquid storage pond. The recycling device can solve the problems that an existing recycling device cannot automatically clean a blocked inlet of a waste storage tank, the workload is increased, and the device cost is high.

Owner:重庆市泰日建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com