Method for repairing base plate of thin film transistor

A technology for repairing thin film transistors and substrates, which is applied in the field of repairing thin film transistor substrates, can solve problems such as increased manufacturing cost of thin film transistor substrates, and achieve the effect of saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

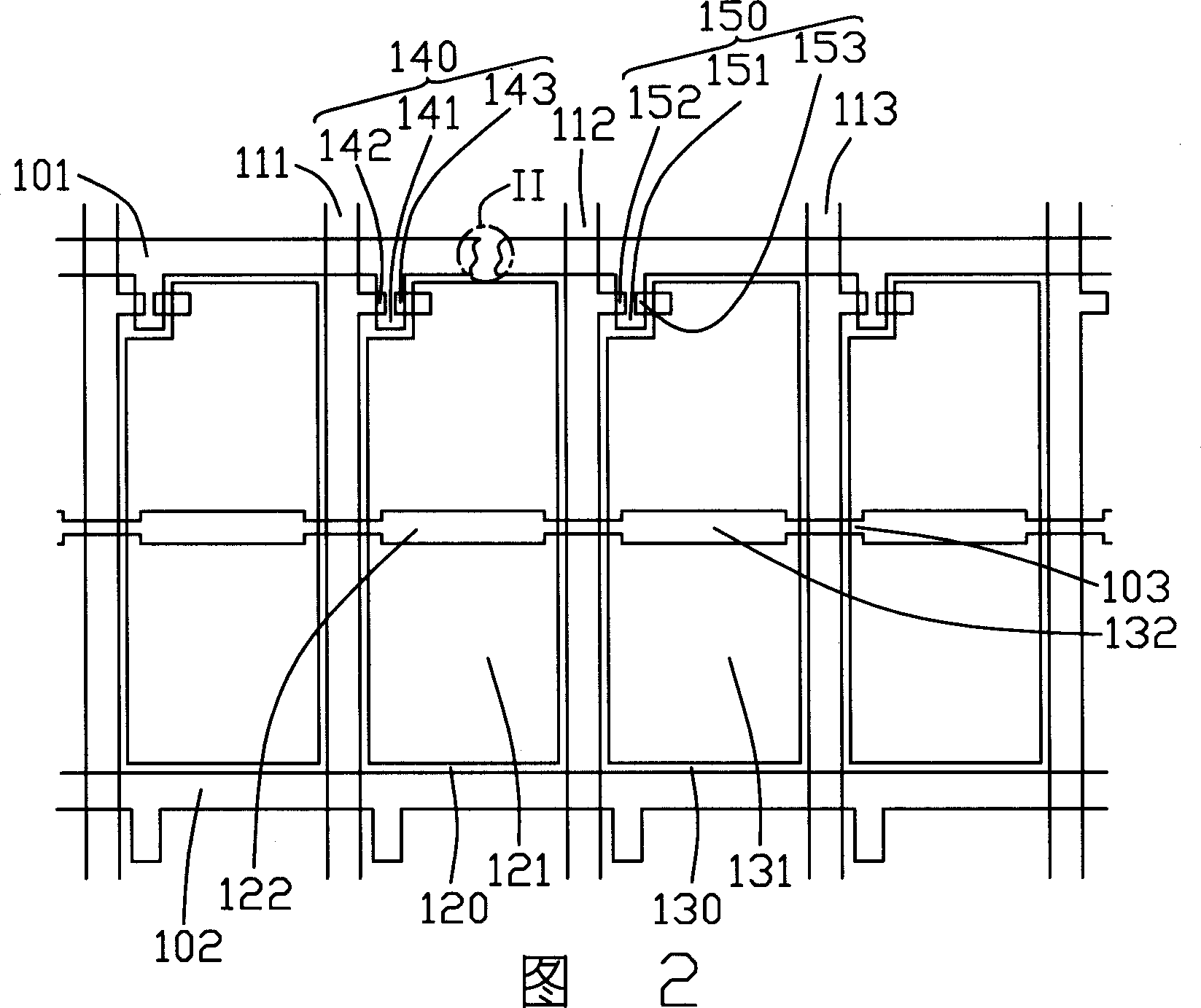

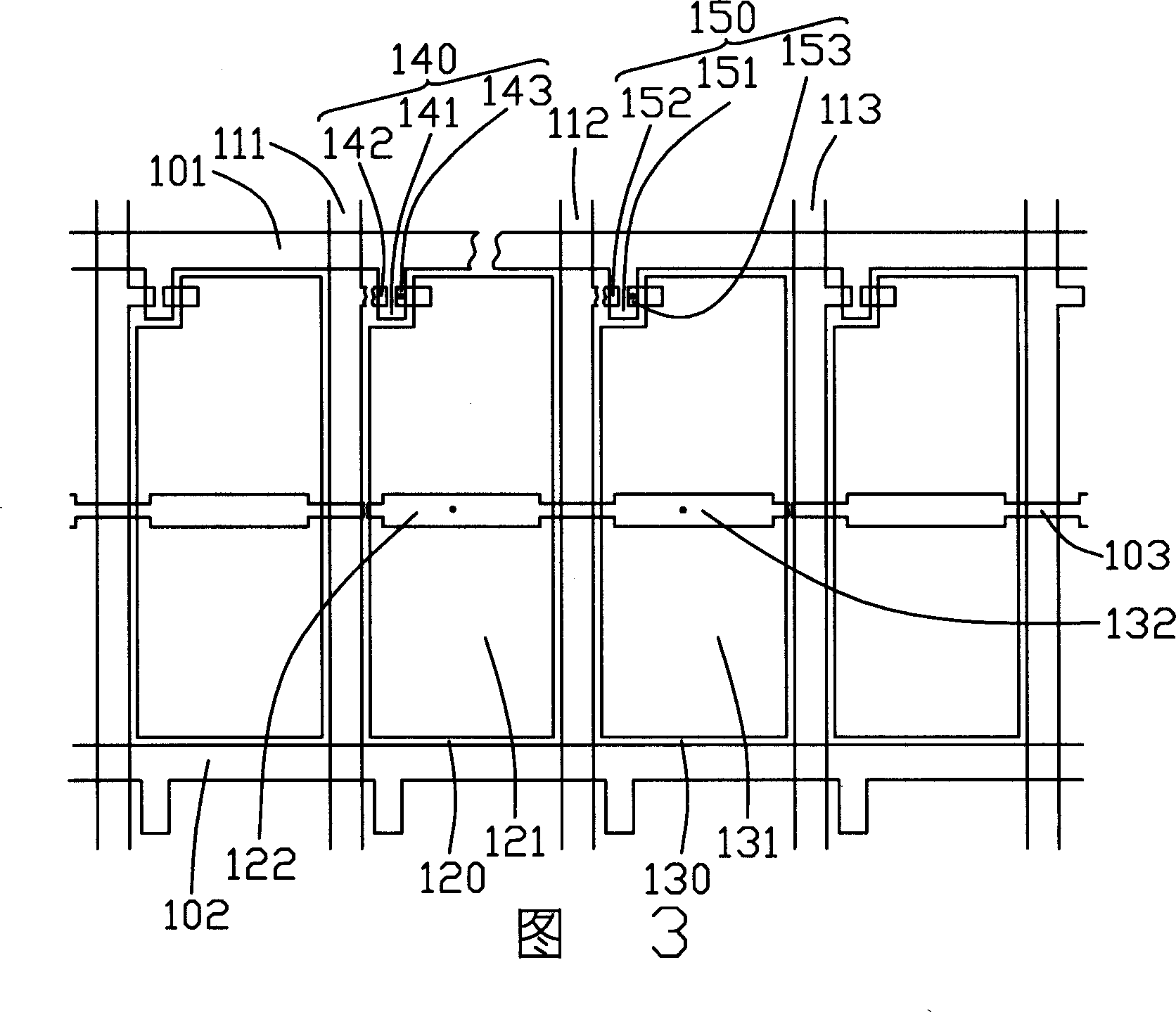

[0014] Please refer to FIG. 2 , which is a partial plan view of a TFT substrate with a gate line disconnected. The gate lines 101 and 102 perpendicularly cross the data lines 111 , 112 and 113 to define two pixel units 120 and 130 . The pixel unit 120 includes a pixel electrode 121 and a storage capacitor electrode 122 disposed below the pixel electrode 121 and forming a storage capacitor with the pixel electrode 121 . The pixel unit 130 includes a pixel electrode 131 and a storage capacitor electrode 132 disposed below the pixel electrode 131 and forming a storage capacitor with the pixel electrode 131 . The storage capacitor electrodes 122 , 132 and other storage capacitor electrodes in the same row are electrically connected through a connection line 103 . Two thin film transistors 140 and 150 are arranged at the corners of the two pixel units 120 and 130 respectively, the thin film transistor 140 includes a gate 141 electrically connected to the gate line 101 , a source 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com