Sintering equipment, sintering annealing method of battery and battery

A technology for sintering equipment and batteries, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problem of high equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Based on the N-type TOPCon battery, the annealing process of the N-type TOPCon battery can be realized without changing the sintering equipment used in the sintering process in the existing battery preparation method, and the passivation performance of the battery can be improved; at the same time, no additional equipment is required Therefore, while ensuring the improvement of the passivation performance of the battery, the problem in the prior art that additional annealing equipment needs to be added to achieve annealing, which leads to an increase in equipment cost, is reduced.

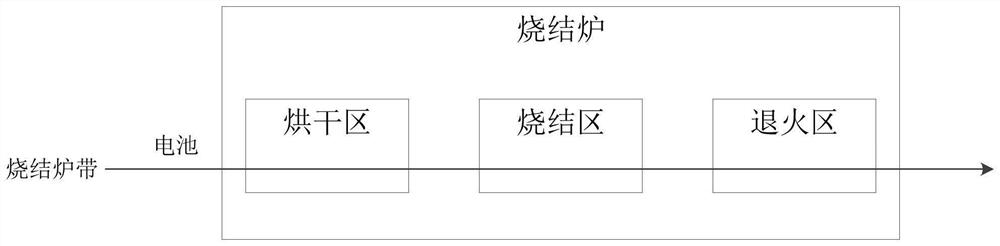

[0036] like figure 1 As shown, the present invention provides a sintering equipment, the sintering equipment is provided with a drying area, a sintering area and an annealing area.

[0037] Among them, the drying area is used to realize the drying process of the battery. The sintering area is used to realize the sintering process of the battery. The annealing area is used to realize the an...

Embodiment 2

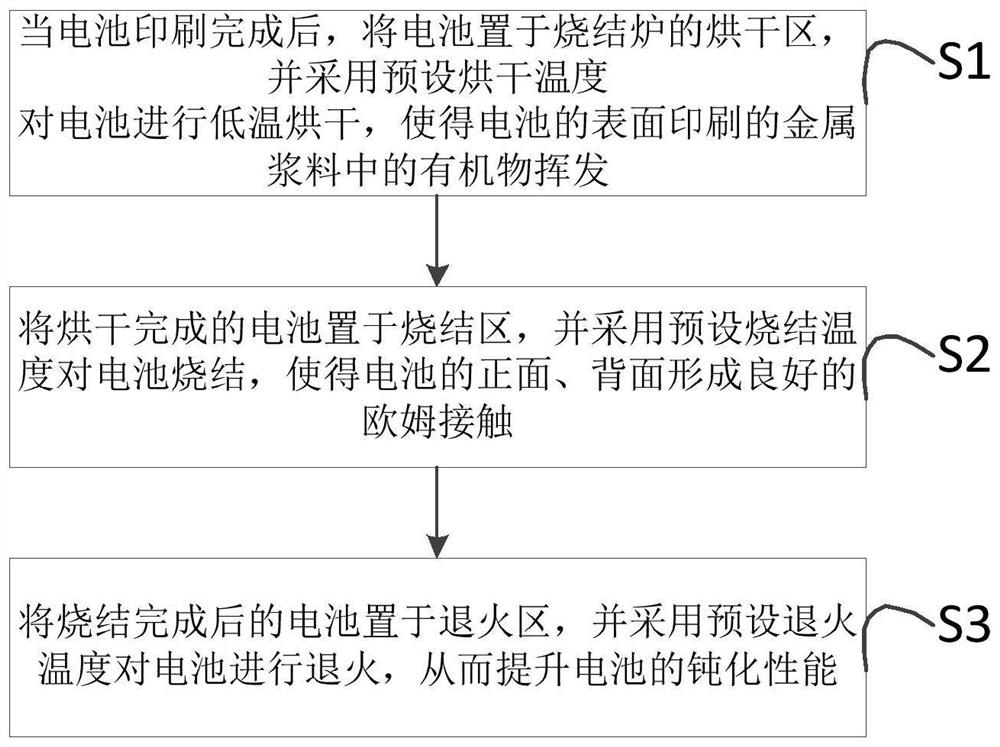

[0051] like figure 2 As shown, the present invention provides a battery sintering annealing method, which is applied to a sintering device provided in Example 1, and the method includes the following steps:

[0052] Step S1. After the battery printing is completed, place the screen-printed battery in the drying zone of the sintering furnace, and dry the battery at a preset drying temperature, so that the organic matter in the metal paste printed on the surface of the battery Volatile.

[0053] Step S2, placing the dried battery in a sintering zone, and sintering the battery at a preset sintering temperature, so that the front and back of the battery form a good ohmic contact.

[0054] Step S3, placing the sintered battery in an annealing zone, and annealing the battery at a preset annealing temperature, thereby improving the passivation performance of the battery.

[0055] Preferably, the drying temperature is 200°-500°.

[0056] Preferably, the preset sintering temperatur...

Embodiment 3

[0103] Preferably, the present invention also provides a method for preparing a battery, which includes the sintering and annealing method for preparing the battery as provided in Embodiment 1 of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com