Chamber surface passivation method for semi-conductor laser

A laser and semiconductor technology, applied in the direction of semiconductor lasers, lasers, laser parts, etc., can solve the problems of expensive equipment, complex process, instability, etc., and achieve the effect of outstanding passivation effect, simple process method, and improved reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] 1. After the semiconductor laser is cleaved into strips in the air, it is loaded into a special coating fixture, and then placed in a magnetron sputtering vacuum chamber or an ion beam evaporation vacuum chamber;

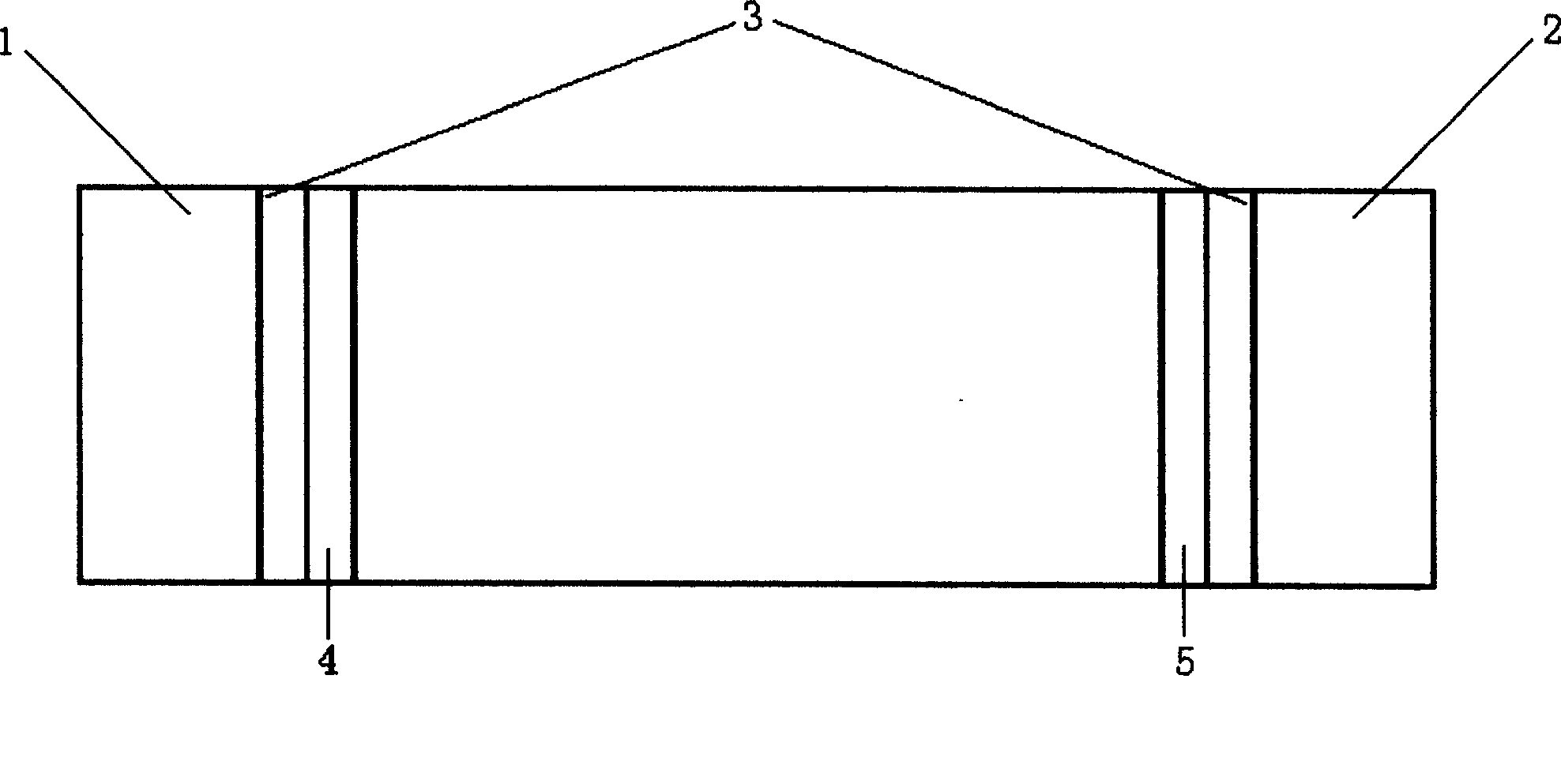

[0021] 2. Hydrogen ion pre-cleaning, that is, bombarding the cleaved cavity surface with hydrogen plasma not less than 105 eV or not less than 50 watts in the electron beam evaporation vacuum chamber or magnetron sputtering vacuum chamber respectively, to remove the oxidation on the cleaved cavity surface At the same time, the hydrogen ions will react with the most electronegative elements within a certain scale on the surface of the cleave cavity surface to generate the hydrogenation of the large electronegative elements. The hydride overflows from the cleaved cavity surface, causing the cavity surface to present positively charged cation characteristics; the hydrogen ion cleaning is carried out on the front cavity surface 4 of the semiconductor laser for 50 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com