Patents

Literature

84results about How to "Good passivation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

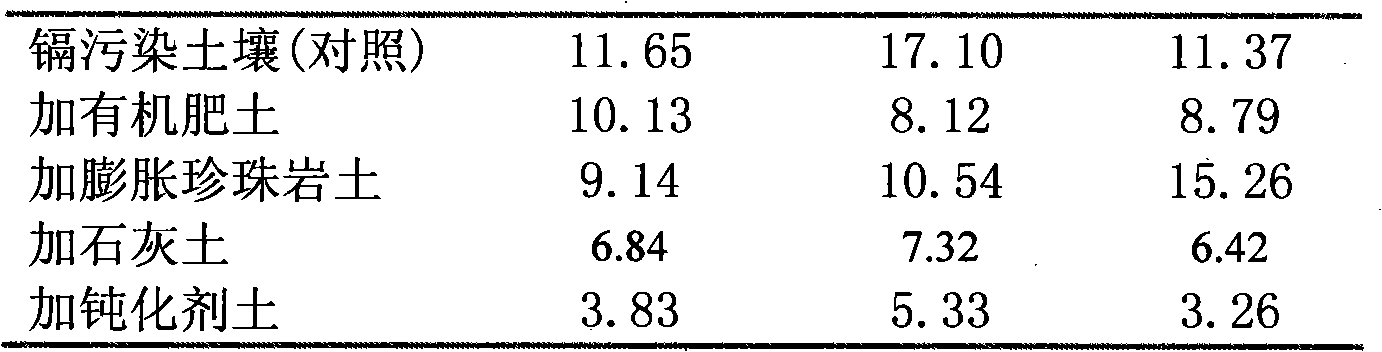

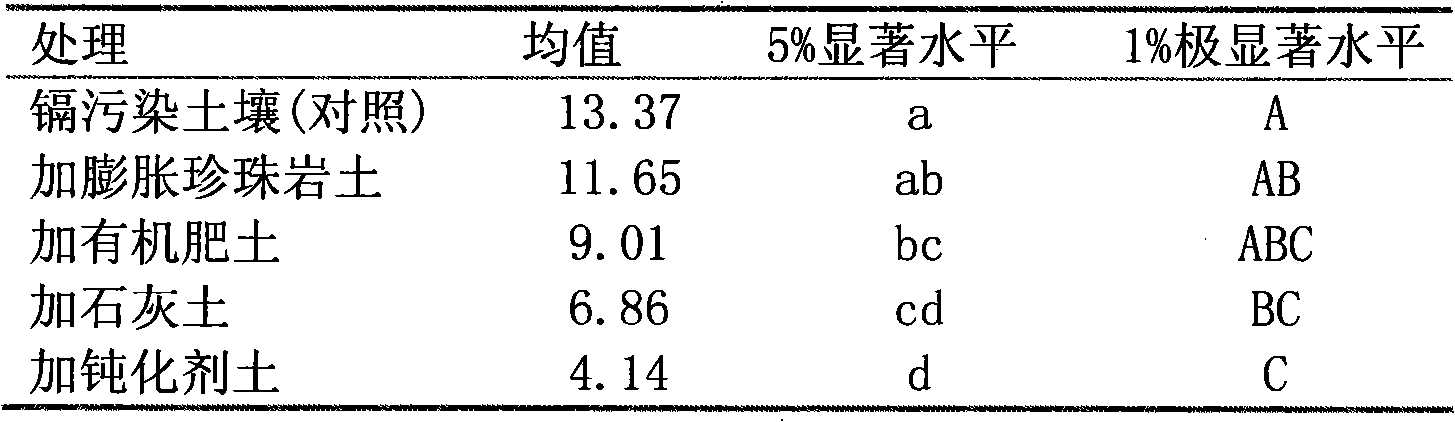

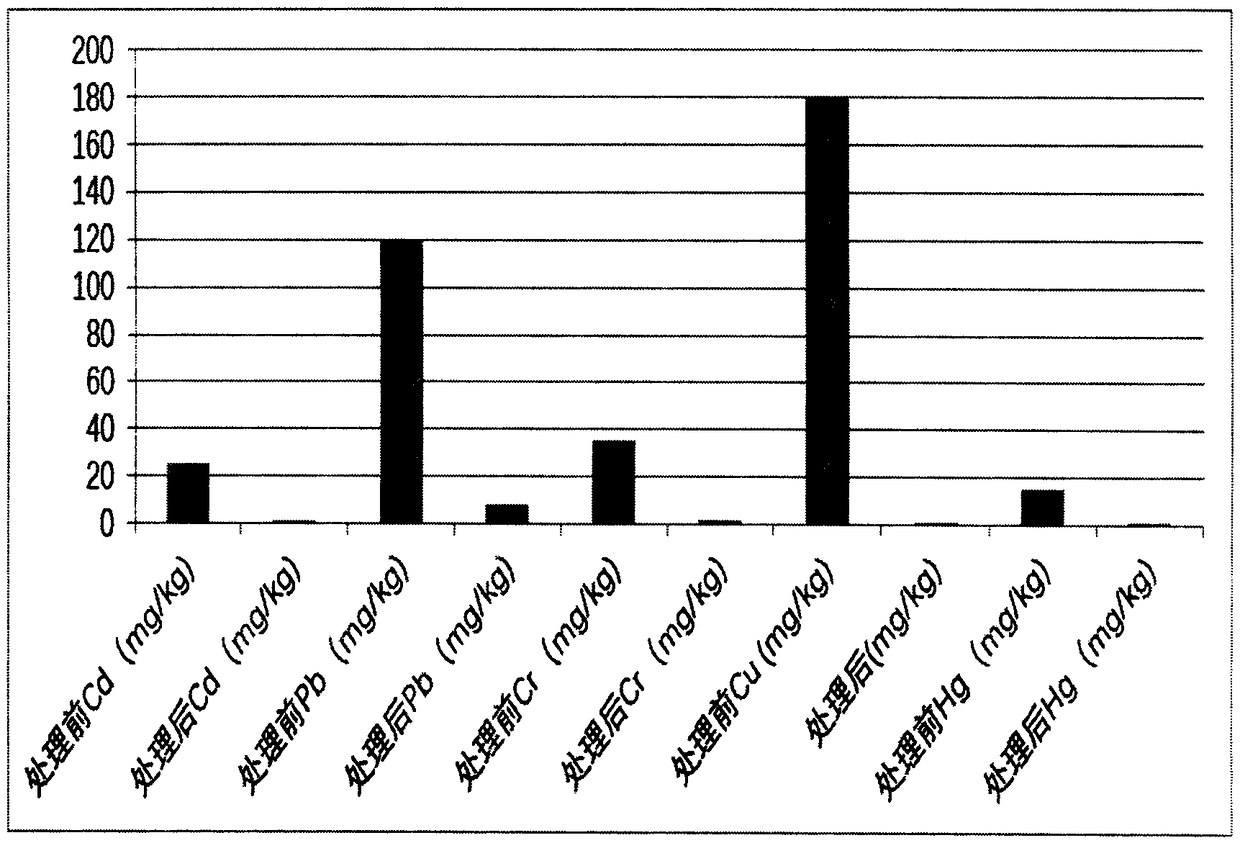

Soil heavy metal passivation agent for vegetable field

InactiveCN101322974AImprove qualityImprove commodityContaminated soil reclamationOrganic fertilisersPollution soilSoil heavy metals

The invention discloses a heavy metal passivator for vegetable field soil. The components of the heavy metal passivator comprise burnt lime, organic fertilizer for heavy metal removal and expanded perlite. The selected expanded perlite has the particle diameter ranging from 0.5 to 1.5cm preferentially. The heavy metal passivator for vegetable field soil provided by the invention passivate heavy metals, which mainly include plumbum, cadimium, chrome, copper, zinc, and the like, causing mild contamination in the vegetable field soil so that safe vegetable products can be produced on the soil slightly contaminated, the ecological function and industry function of the vegetable field soil can be recovered; therefore, the quality and the merchantability of the vegetables are improved. The materials selected for the invention are all common and easy to prepare and have low cost, which is convenient for being popularized. Experiments prove that the heavy metal passivator has extremely remarkable passivation effect on heavy metals as well as has very favorable ecological and economic benefits.

Owner:INST OF SOIL & FERTILIZER ANHUI ACAD OF AGRI SCI

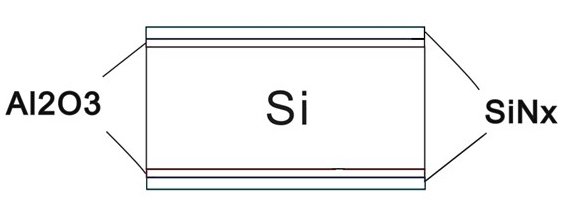

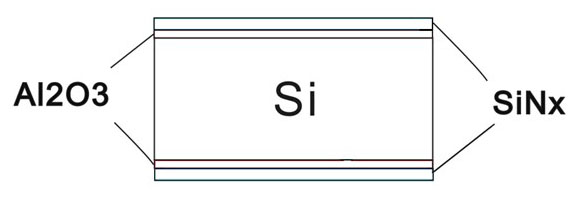

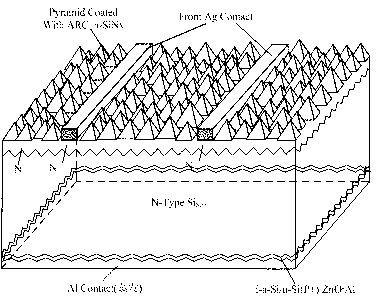

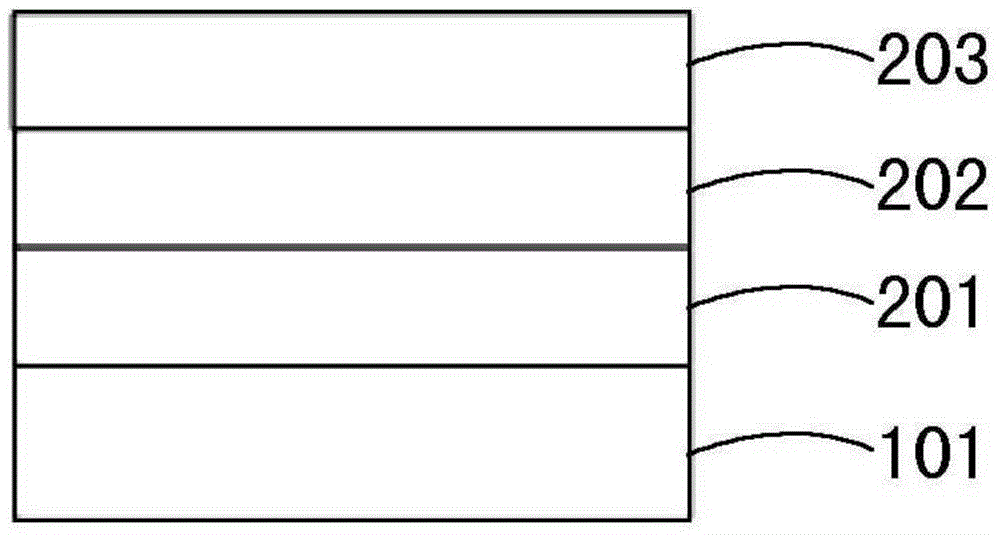

Double-layer passivating method for crystalline silicon solar battery

InactiveCN102064237AEasy to growEasy to industrializeFinal product manufactureVacuum evaporation coatingHydrogenThermal chemical vapor deposition

The invention discloses a double-layer passivating method for a crystalline silicon solar battery, comprising the following steps: (1) selecting a silicon chip, cleaning, and polishing or texturing; (2) growing Al2O3 on the silicon chip obtained in step (1) by an ALD (atomic layer deposition) or PECVD (plasma enhanced chemical vapor deposition) method, wherein the refractive index is 1.5-1.7, the thickness is 10-80nm; (3) growing SiNx on the silicon chip obtained in step (2) by the PECVD or PVD (physical vapor deposition) method, wherein the refractive index is 1.9-2.2, the thickness is 30-150nm; and (4) annealing the sample obtained in step (3) at the temperature of 200-600 DEG C in the atmosphere of N2 or a hydrogen argon gas mixture for 1-30 minutes to obtain a double-layer passivated dielectric film. The passivating method provided by the invention can reduce the surface recombination velocity of the silicon chip to below 10cm / s, can be well applied to surface passivation of a crystalline silicon solar battery, and obtains high conversion efficiency.

Owner:ALTUSVIA ENERGY TAICANG

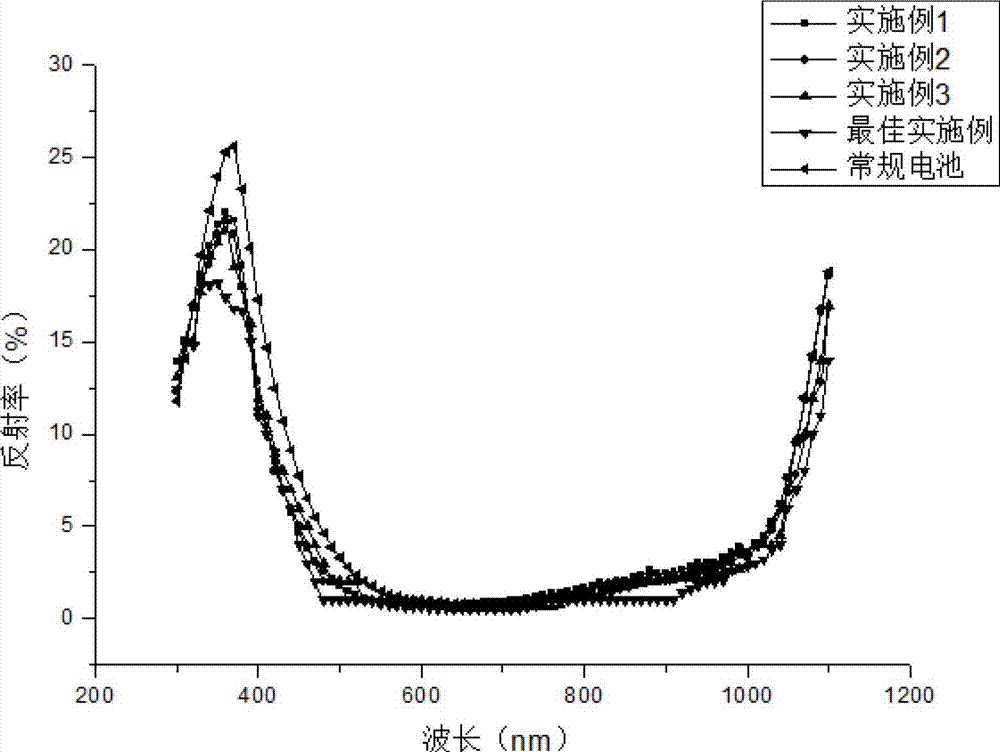

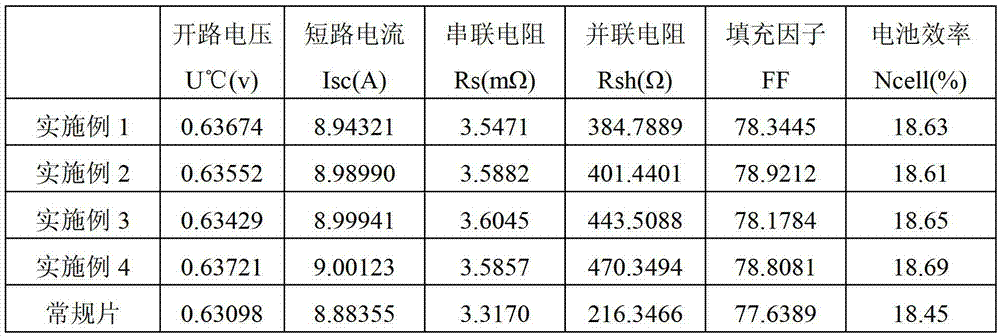

Solar cell passivation antireflection film and preparation technology and method thereof

InactiveCN103094366AReduce reflectivityImprove photoelectric conversion efficiencyFinal product manufactureChemical vapor deposition coatingPower flowRefractive index

The invention discloses a solar cell passivation antireflection film and a preparation technology and a method of the solar cell passivation antireflection film. The preparation technology and the method utilize a plasma enhanced chemical vapor deposition (PECVD), a layer of silicon dioxide film is deposited on the surface of a silicon slice, then a silicon nitride layer with high refractive index is deposited on the prepared silicon dioxide film, and finally a silicon nitride layer with low refractive index is deposited on the silicon nitride layer with high refractive index. The technology and the method have the advantages of being convenient to operate, low in operation cost, good in passivation and good in antireflection performance for the cell surface. The passivation antireflection film prepared by the technology can obviously improve the open circuit voltage, short circuit current and the cell efficiency of the solar cell, compared with a traditional single-layer or double-layer silicon nitride film.

Owner:SUN YAT SEN UNIV

Preparation method of soil heavy metal passivant, and soil Pb passivation method

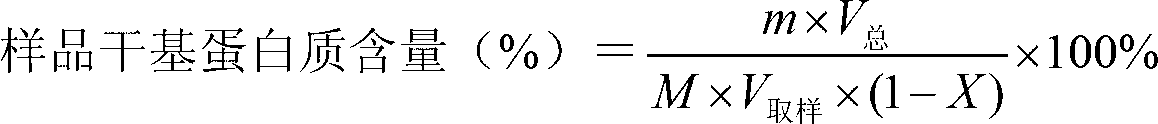

InactiveCN102746849AGood passivation effectLow costAgriculture tools and machinesContaminated soil reclamationWater contentChemistry

The invention relates to a preparation method of a soil heavy metal passivant, and a soil Pb passivation method. The preparation method comprises the following steps: 1, adding an alkaline solution and sieved coal ash to a reaction vessel in proportion, carrying out ultrasonic dispersion stirring to obtain a slurry, and carrying out a hydrothermal crystallization reaction through putting the reaction vessel in an oven; and 2, cooling and centrifuging products obtained after the reaction, washing the products with deionized water, drying, grinding to obtain synthetic zeolite powder, burning rice husk at normal pressure to prepare rice husk ash, and uniformly mixing straw powder, the coal ash, the synthetic zeolite powder and the rice husk ash according to weight percentages to obtain the heavy metal passivant. The loess farmland soil Pb passivation effect can be improved through adjusting conditions comprising the soil pH value, the soil water content, the passivant quality, the passivation time, the passivation temperature and the like. The passivation method has the advantages of low cost, simple operation, strong practicality, good safety, and easy popularization, can passivate soil heavy metals and also can improve the soil properties, so the passivation method has potential application values in soil heavy metal pollution restoration.

Owner:SHAANXI UNIV OF SCI & TECH

Composite passivator for reducing oilseed rape land soil cadmium pollution, preparation method thereof and application of composite passivator

ActiveCN107652981AToxic reductionIncrease resistanceAgriculture tools and machinesOther chemical processesSoil cadmiumCadmium Cation

The invention provides a composite passivator for reducing oilseed rape land soil cadmium pollution, a preparation method thereof and an application of the composite passivator. The composite passivator is prepared from rice husk biochar, humus, limestone, ammonium sulfate, nano-hydroxyapatite, sepiolite and attapulgite. By the aid of the composite passivator, the available cadmium content of soiland the cadmium content of an overground part and an underground part of an oilseed rape can be remarkably reduced, the pH (potential of hydrogen) value of the soil can be improved, the composite passivator can be used for treating extensive heavy metal cadmium polluted oilseed rape land soil, the content of organic matters is greatly increased, and soil physical and chemical properties are obviously improved.

Owner:LIAONING UNIVERSITY

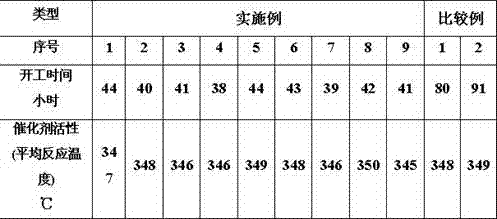

Hydrocracking startup method

ActiveCN107446616AIntensified vulcanization process inside the extenderHigh activityCatalyst protectionMolecular sieve catalystsHydrogenLow nitrogen

The invention discloses a hydrocracking startup method. The hydrocracking startup method comprises the following steps: introducing low-nitrogen startup oil, hydrogen and a sulfurizing reagent into a hydrocracking unit; then carrying out sulfuration on a hydrocracking catalyst at a constant temperature of 220 to 260 DEG C; after the content of hydrogen sulfide in to-be-cycled hydrogen reaches 3000 to 5000 ppm, reducing the adding rate of the sulfurizing reagent and increasing the bed temperature of the hydrocracking catalyst; when the bed temperature of the hydrocracking catalyst reaches 310 to 330 DEG C, increasing the adding rate of the sulfurizing reagent; and continuing constant-temperature sulfuration, then allowing the temperature to rise to 340 to 350 DEG C and introducing raw oil for a reaction, wherein the amount of the hydrocracking catalyst is 0.5 to 8% by weight. The method provided by the invention is short in time for startup, raw material switching and entry into a stable production state, avoids the consumption of a passivating agent and potential hazards during ammonia injection in the startup process, reduces energy consumption, and decreases pollution of the passivating agent to environment and harm of the passivating agent to human beings.

Owner:CHINA PETROLEUM & CHEM CORP +1

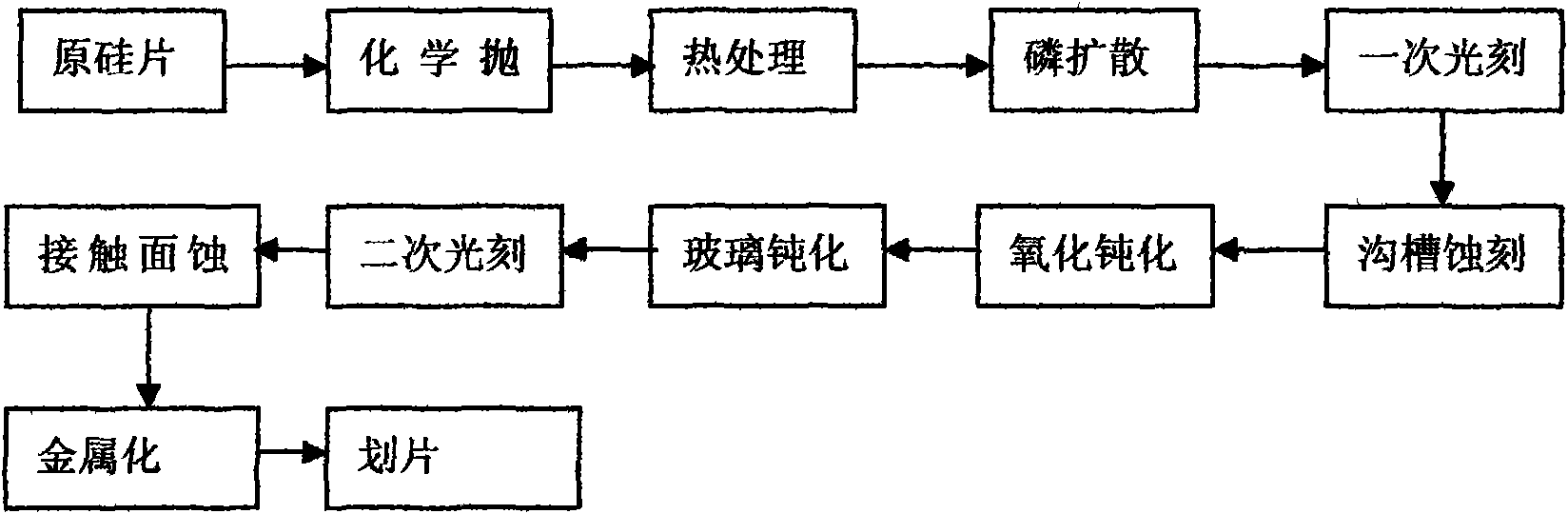

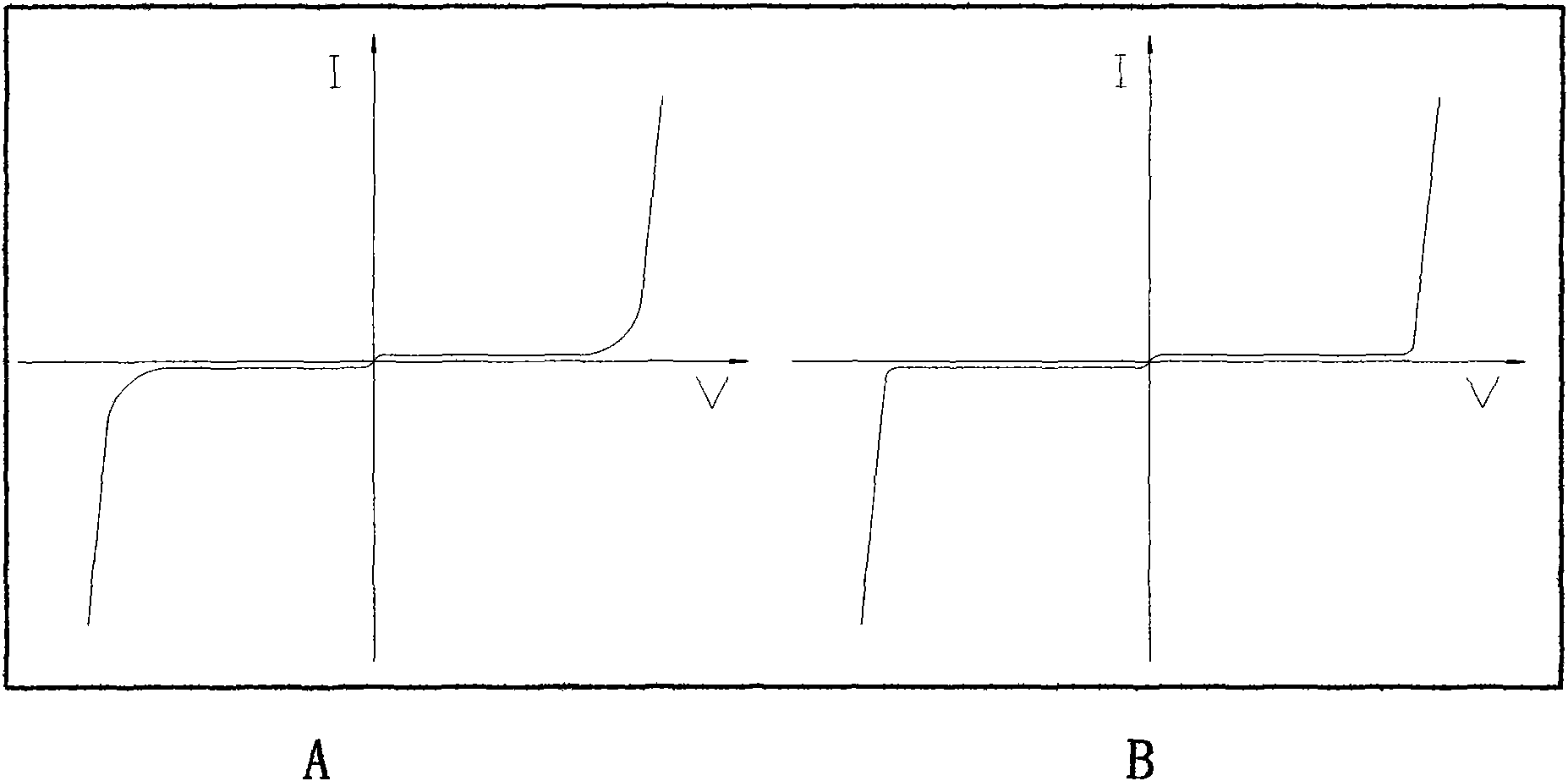

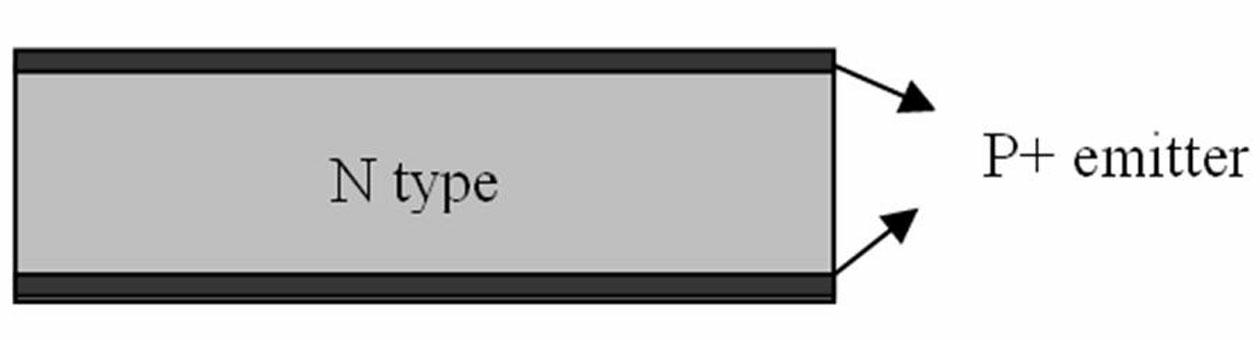

Manufacturing method of low-voltage transient voltage suppression diode chip

ActiveCN101621002APrevent penetrationEnhance the ability to capture alkali metal ionsSemiconductor/solid-state device manufacturingLow voltageCrystal orientation

The invention discloses a manufacturing method of a low-voltage transient voltage suppression diode chip, which is characterized by comprising the following steps: a. selecting a P type crystal orientation monocrystalline silicon piece with resistivity of 0.001-0.02 omega*cm; carrying out chemical polishing and heat treatment gettering technologies on the monocrystalline silicon piece to reduce the defects and the impurity concentration of the surface and near a P / N nodal area of the monocrystalline silicon piece so as to realize the characteristic of low internal current leakage; c. doping chlorine, thermally oxidizing and passivating a P / N nodal surface; and d. bending a P / N node on the edge part of the P / N nodal surface towards a P area through a thermal oxidation technology so as to realize the characteristic of low surface current leakage. The invention can effectively reduce the reverse current leakage.

Owner:BESTBRIGHT ELECTRONICS

Method for inhibiting lepidium meyenii activity

InactiveCN102934680AExtended shelf lifeReduced activityDead plant preservationFood processingMyrosinase activityLepidium meyenii

The invention discloses a method for inhibiting lepidium meyenii myrosinase activity. The method comprises the step that maca is subjected to short-time heat treatment by using stem, wherein fresh lepidium meyenii is blanched in high-temperature steam, such that activity of myrosinase in lepidium meyenii is inhibited or deactivated. The method has high lepidium meyenii myrosinase deactivation efficiency. With the method, myrosinase activity is low, such that lepidium meyenii storage life or shelf life can be prolonged. Also, with the method provided by the invention, glucosinolate content in prepared lepidium meyenii is maintained high, such that lepidium meyenii bioactivity is well maintained, and original nutrients and appearance quality in lepidium meyenii are well preserved. Also, the method is simple and feasible, and energy-saving. The method has the advantages of low cost, good working environment, good sanitary environment, and no pollution.

Owner:THE RES INST OF RESOURCES INSECTS RIRI OF THE CHINESE ACADEMY OF FORESTRY

Chemical for cleaning boiler

InactiveCN102418103ALow cleaning temperatureShorten the timeCetyldimethylbenzylammonium chlorideAcid washing

The invention relates to a chemical for cleaning a boiler, and belongs to the technical field of the chemical cleaning of equipment. The chemical comprises a corrosion-inhibiting acid-washing agent, a bleaching agent and a passivant, wherein the corrosion-inhibiting acid-washing agent consists of 1,3,5,7-tetraaza-adamantane, ethylenediamine tetracetic acid, hydrochloric acid, phosphoric acid, silicon fluoride, hydrazine hydrate, sodium silicate, cetyl dimethyl benzyl ammonium chloride, ammonium thiocyanate, sodium dodecyl benzene sulfonate and the balance of water; the bleaching agent is citric acid solution; and a passivant consists of ethidene diamine, formaldehyde, diammonium phosphate, hydrogen peroxide, sodium nitrite and the water. The chemical has stable chemical properties, low toxicity, a good sustained-release effect and high scale dissolving capacity, and does not have the damage of sour corrosion to the boiler.

Owner:CHANGSHA BLUECLEAN TECH

Method for rapidly sintering solar wafer

InactiveCN102332491AImprove Ag electrode contact resistanceQuality improvementFinal product manufactureSemiconductor devicesBack surface fieldContact resistance

The invention provides a sintering method, and in particular relates to a method for rapidly sintering a solar wafer. A rapid thermal processing way is adopted to sinter large-area cells of silk-screen printing. The method comprises the following steps of: conveying, drying and exhausting cokes, rapidly heating to sinter as well as sintering at a high temperature and cooling. The method has the beneficial effects that the passivation effect is good, the minority carrier lifetime is improved greatly, the contact resistance of a Ag (silver) electrode and the quality of Al-BSFs (aluminum back surface fields) for the cells can be improved, the thermal stress is reduced, the contact resistances of solar cells are reduced obviously so as to improve the utilization of short wave spectra, the evenly good Al-BSFs are formed to improve the open-circuit voltages and filling factors of the cells, the warping of the cells is reduced, and the conversion efficiency and finished product ratio of the cells can be improved.

Owner:浙江天明国际科技有限公司

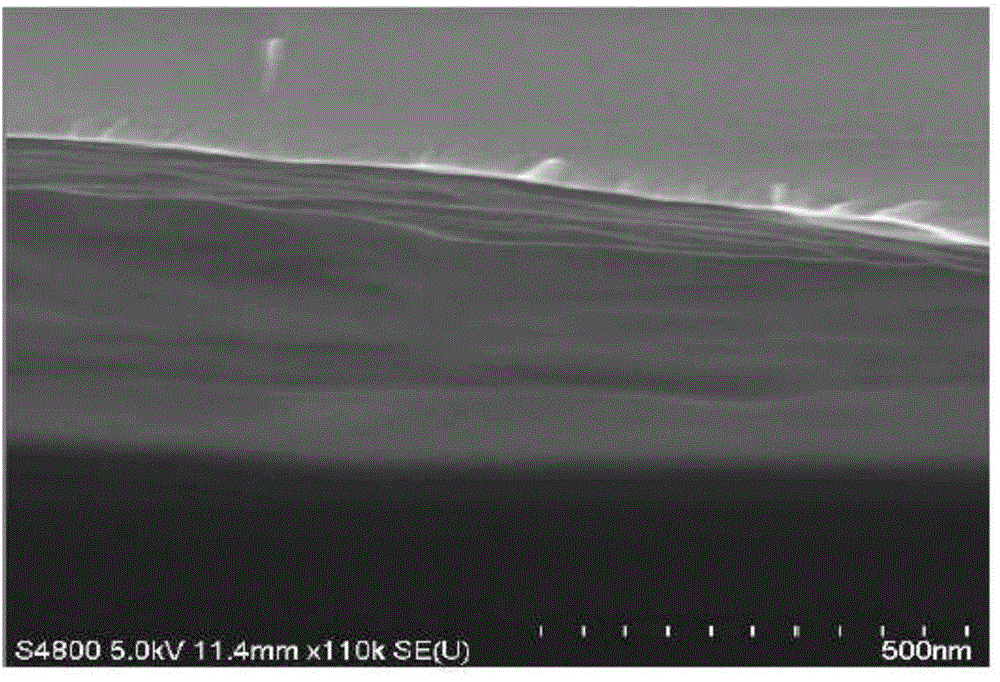

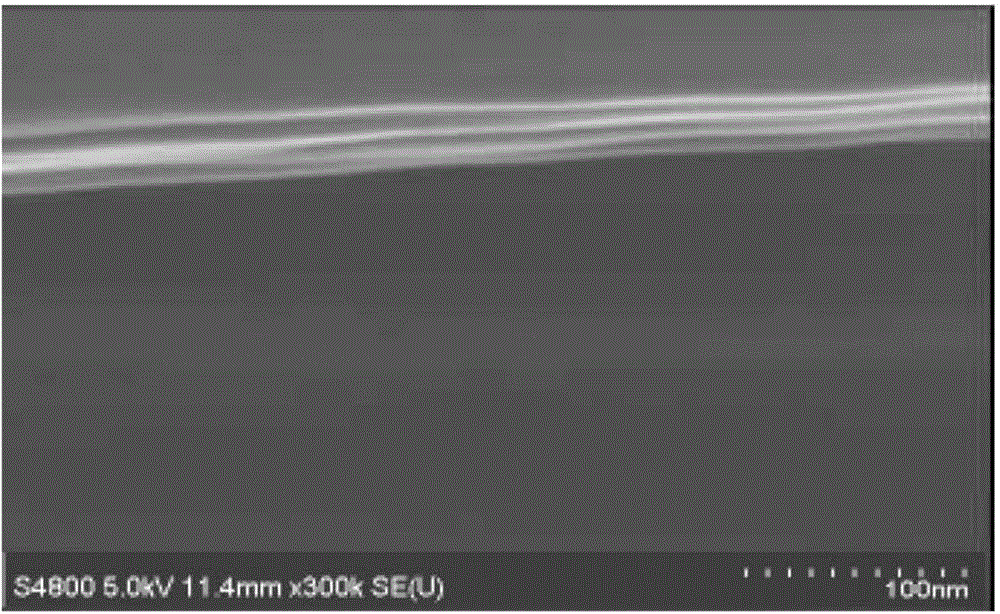

N-type surface tunneling oxidation passivation contact manufacturing method for silicon-based solar cell

InactiveCN107464855AReduce interface state densityReduce surface recombinationFinal product manufacturePhotovoltaic energy generationSurface oxidationPhosphor

The invention relates to an N-type surface tunneling oxidation passivation contact manufacturing method for a silicon-based solar cell, and the method comprises the following steps: (1), washing the surface of a monocrystalline wafer through a solution after a former operation, and removing a surface oxidation layer; (2), carrying out the oxidation of the surface of the monocrystalline wafer, and forming a superthin tunneling oxidation layer; (3), depositing a silicon thin layer above the superthin tunneling oxidation layer through a chemical vapor deposition method, and completing the phosphor doping of the silicon thin layer; (4), carrying out the oxidizing annealing of the silicon wafer, and further improving the micro-structure and performance of the silicon layer; (5), employing a plasma enhanced chemical vapor deposition method to deposit a silicon nitride passivation antireflection layer above the phosphor-doped silicon thin layer; (6), printing a metal electrode on the surface of the silicon nitride passivation antireflection layer, and completing the manufacturing process. The method can greatly reduce the surface recombination of battery pieces, achieves the excellent passivation effect, and increases the open-circuit voltage. A product has good thermal stability, and there is no need to develop the dedicated low-temperature technology, thereby reducing the cost.

Owner:SHANGHAI SHENZHOU NEW ENERGY DEV

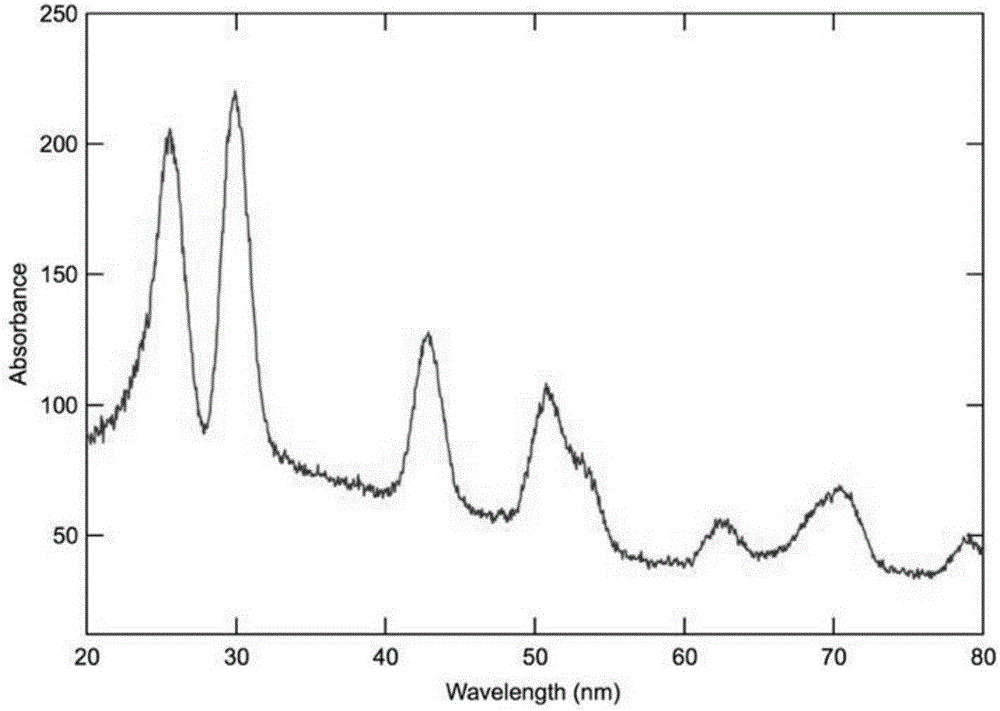

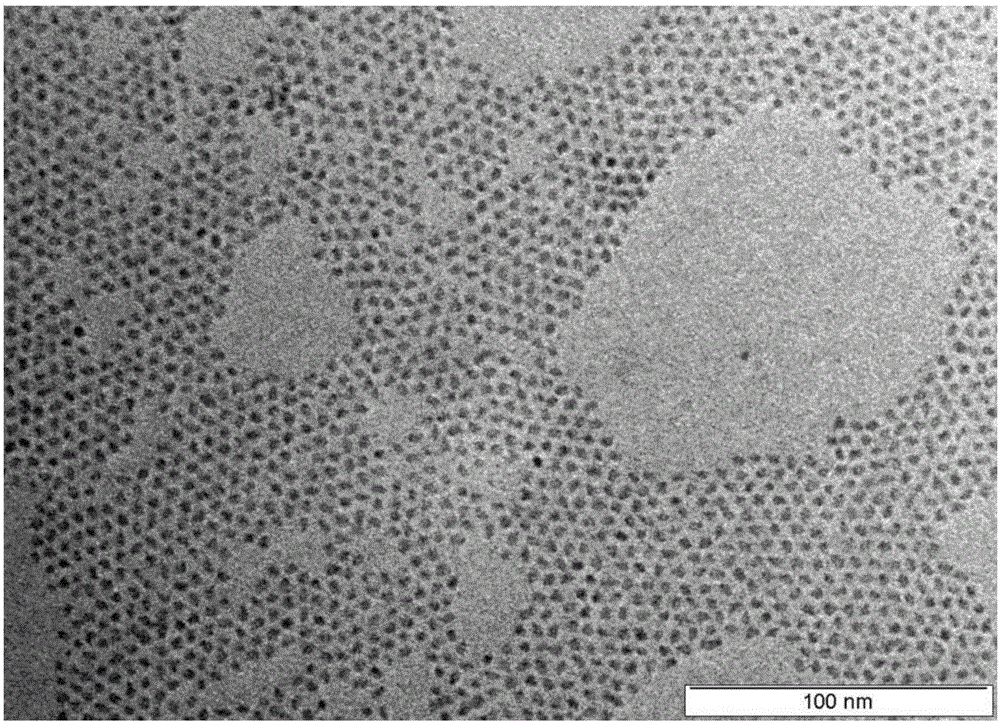

Preparation method of monodisperse PbS quantum dot

The invention belongs to the technical field of preparation of compound semiconductor nanomaterials and particularly relates to a preparation method of a monodisperse PbS quantum dot. The method comprises steps as follows: S1, a halide of lead and oleylamine are mixed, heated to 80-190 DEG C and fully stirred to form a lead precursor, and then the lead precursor is cooled to 20-35 DEG C; S2, thioacetamide and oleylamine are fully stirred at 20-35 DEG C to form a sulfur precursor; S3, the lead precursor and the sulfur precursor are mixed in the molar ratio of Pb and S being (2-5):1, heated to 60-90 DEG C and subjected to heat preservation for a certain period; S4, the solution after heat preservation in S3 is cooled to 20-35 DEG C, and oleic acid is added to remove the residual lead precursor; S5, the PbS quantum dot is obtained after separation and purification. The prepared PbS quantum dot has the characteristics of high crystallinity, size uniformity, oleic acid and halogen mixed passivation, efficient luminescence, high stability and the like.

Owner:深圳市联宝威科技有限公司

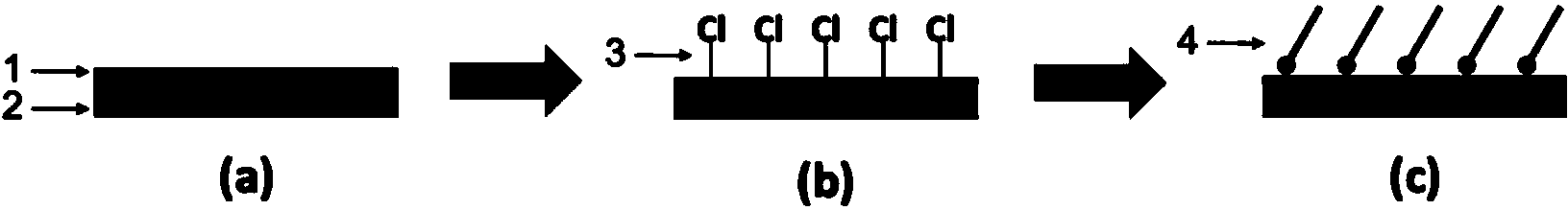

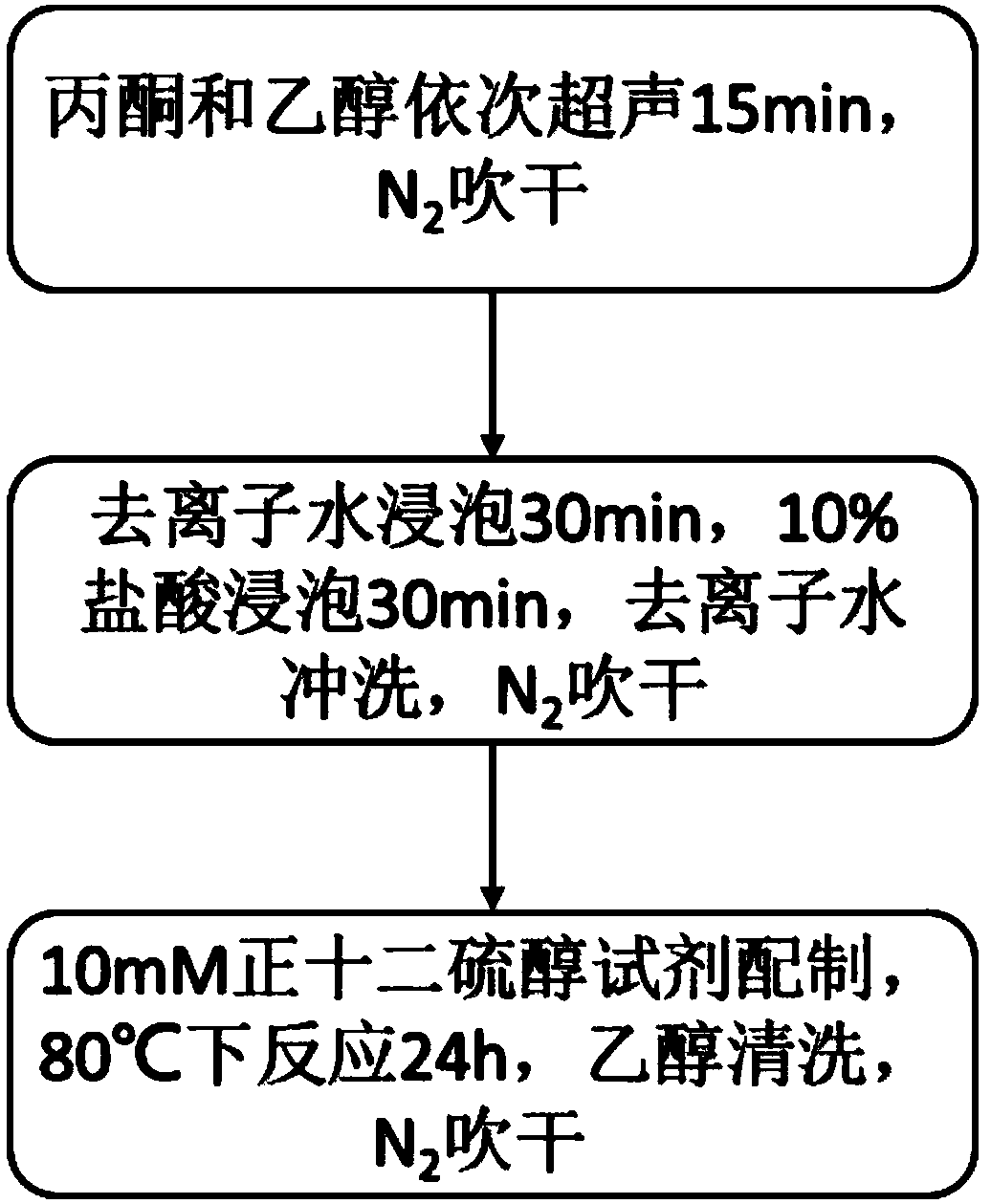

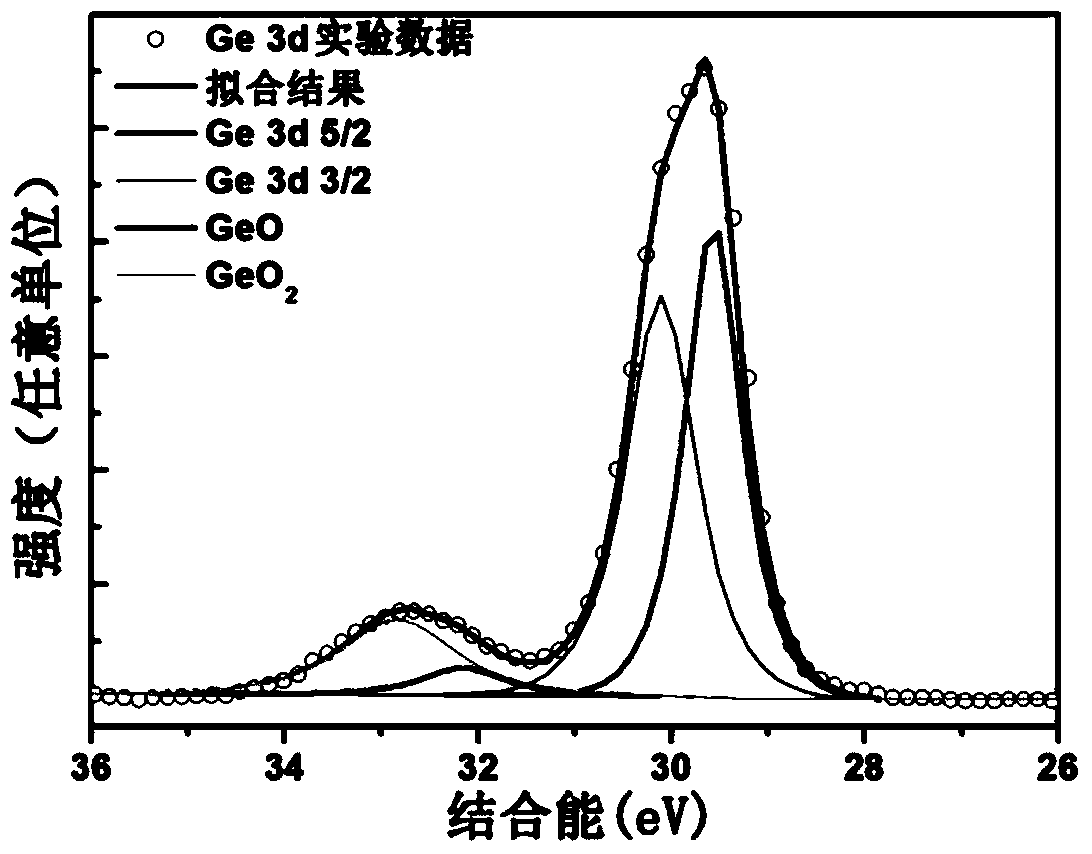

Germanium material surface stabilizing and passivating method

InactiveCN104241116AEfficient removalAchieve primary chlorinationSemiconductor/solid-state device manufacturingAlcoholSurface oxidation

The invention relates to a germanium material surface stabilizing and passivating method. The method includes the steps that the surface of a germanium wafer is cleaned with different reagents, dirt and a surface oxidation layer on the surface of the germanium wafer are effectively removed, and the surface of the germanium wafer is preliminarily chlorinated; a mercaptan reagent is prepared through mixed liquid of ethyl alcohol and water and a self-assembled film is formed on the surface of the germanium wafer under the proper heating passivating condition. The method has the advantages that operation is simple, use is convenient, cost is low, and the passivating effect is obvious.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

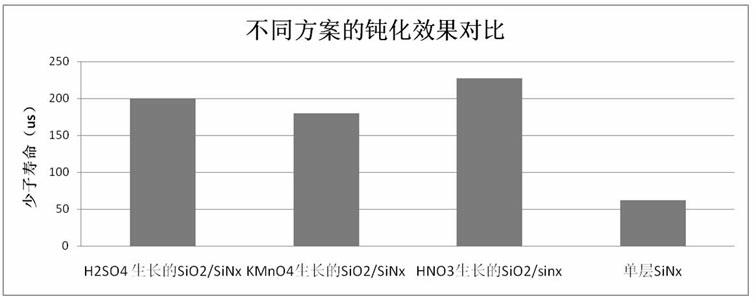

Method for passivating crystal silicon P-type surface

InactiveCN102110742AAvoid it happening againGood passivation effectFinal product manufactureSemiconductor devicesThin layerEngineering

The invention discloses a method for passivating a crystal silicon P-type surface. The method comprises the following steps of: removing the borosilicate glass from the surface of an N-type crystal silicon wafer subjected to boron diffusion and cleaning the surface; generating a thin SiO2 layer on the cleaned silicon wafer surface; depositing a SiNx layer on the surface of the generated SiO2 thin layer by a plasma enhanced chemical vapor deposition (PECVD) method. The method provided by the invention is suitable for industrialization production and has characteristics of simple heat treatment process, good anti-reflection effect and good passivation quality.

Owner:ALTUSVIA ENERGY TAICANG

Method for producing heavy metal passivators for farmland soil and application of heavy metal passivators

InactiveCN108410473AEliminate destructionEliminate hazardsAgriculture tools and machinesContaminated soil reclamationSodium BentonitePhosphate

The invention discloses a method for producing heavy metal passivators for farmland soil and application of the heavy metal passivators, and belongs to the field of environmental protection. The method includes steps of adding calcium polysulfide, potassium sulfide, potassium dihydrogen phosphate, sodium lignosulfonate, potassium humate, bentonite and quicklime into a suspending machine, stirringthe calcium polysulfide, the potassium sulfide, the potassium dihydrogen phosphate, the sodium lignosulfonate, the potassium humate, the bentonite and the quicklime and uniformly mixing the calcium polysulfide, the potassium sulfide, the potassium dihydrogen phosphate, the sodium lignosulfonate, the potassium humate, the bentonite and the quicklime with one another to obtain first mixtures; transferring the first mixtures into a ball mill and smashing the first mixtures; adding sodium silicate and EDTA (ethylene diamine tetraacetic acid) into the first mixtures and uniformly stirring the sodium silicate, the EDTA and the first mixtures. The method and the application have the advantages that the heavy metal passivators which are mixtures can be added into the soil contaminated by differenttypes of heavy metal, accordingly, the different types of heavy metal in the soil can be immobilized and passivated and can be turned into insoluble metal salt or alkali, and the activity, the mobility and the bioavailability of the heavy metal in the soil can be deteriorated to a great extent; contamination of the soil due to the different types of heavy metal can be abated, accordingly, the soil productivity and underground water can be protected, and the food safety can be guaranteed.

Owner:吴洪生

Al2O3 concentration gradient doped ZnO thin film of crystalline silicon solar cell passivation material and preparation method

InactiveCN104037244AStrong chemical passivationStrong field passivation effectFinal product manufacturePhotovoltaic energy generationThin membraneSilicon solar cell

Disclosed are an Al2O3 concentration gradient doped ZnO thin film of a crystalline silicon solar cell passivation material and a preparation method. The preparation method includes performing Al2O3 deposition on the surface of a silicon wafer through atomic deposition to form an Al2O3 layer with the thickness of 1nm-10nm; subsequently, continuing performing n<1> times of ZnO deposition on the Al2O3 layer followed by performing one time of Al2O3 deposition to achieve one-time Al2O3 doped ZnO deposition; performing repeated deposition according to the manner of Al2O3 doped ZnO deposition, wherein the current ZnO deposition is performed for one more time than the previous ZnO deposition so as to form an Al2O3 concentration gradient doped ZnO layer with the thickness of 30nm-100nm; taking out the silicon wafer after deposition is finished and performing annealing to obtain the crystalline silicon solar cell passivation thin film. The Al2O3 concentration gradient doped ZnO thin film and the preparation method have the advantages that the thin film is reasonably designed, the preparation process is easy to operate, a good passivation effect is achieved on a crystalline silicon solar cell, and photoelectric converting efficiency of the cell is high.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

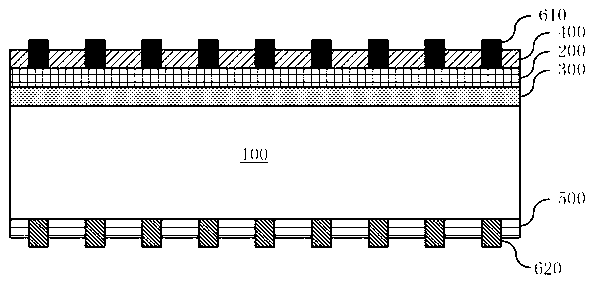

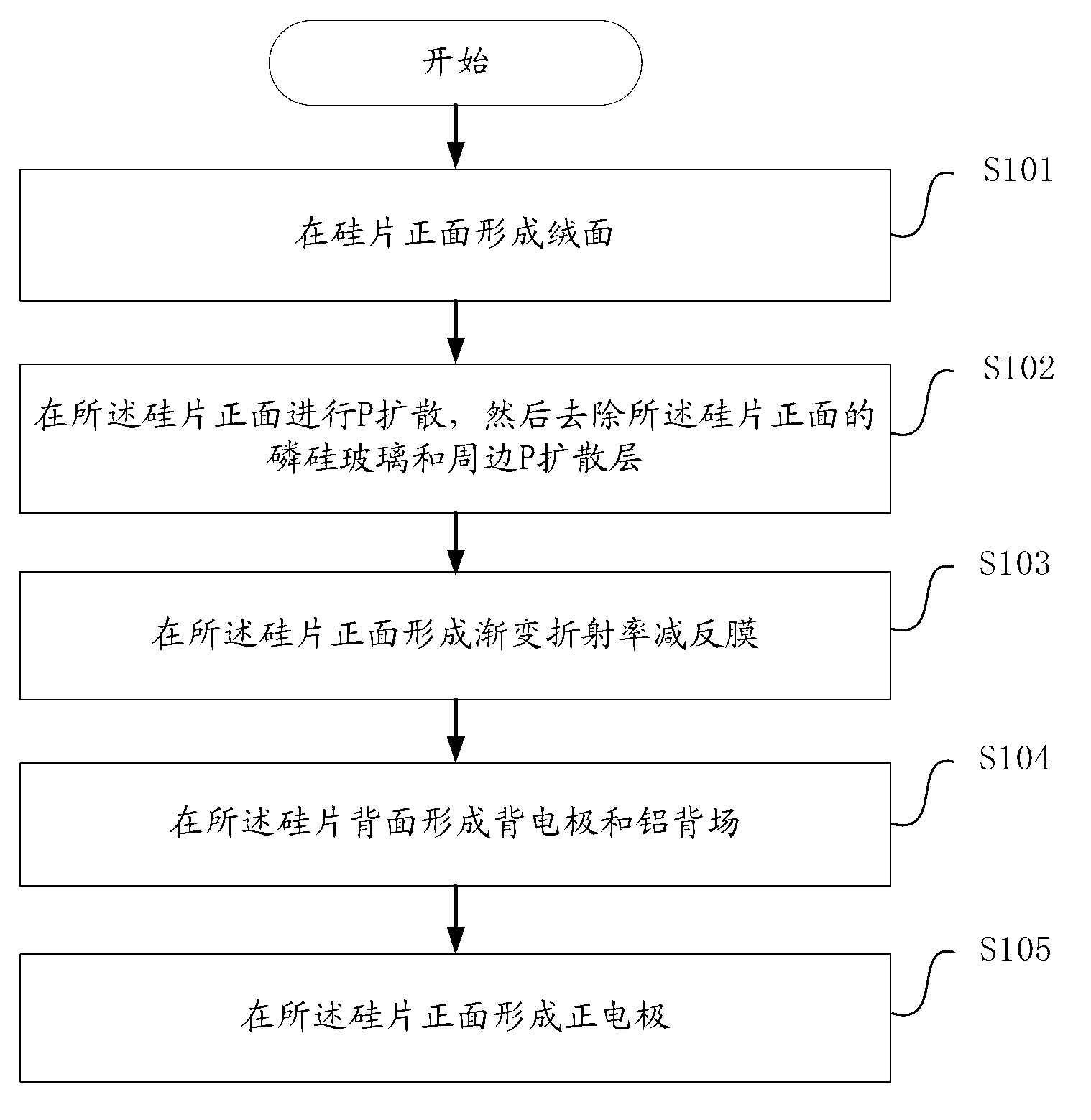

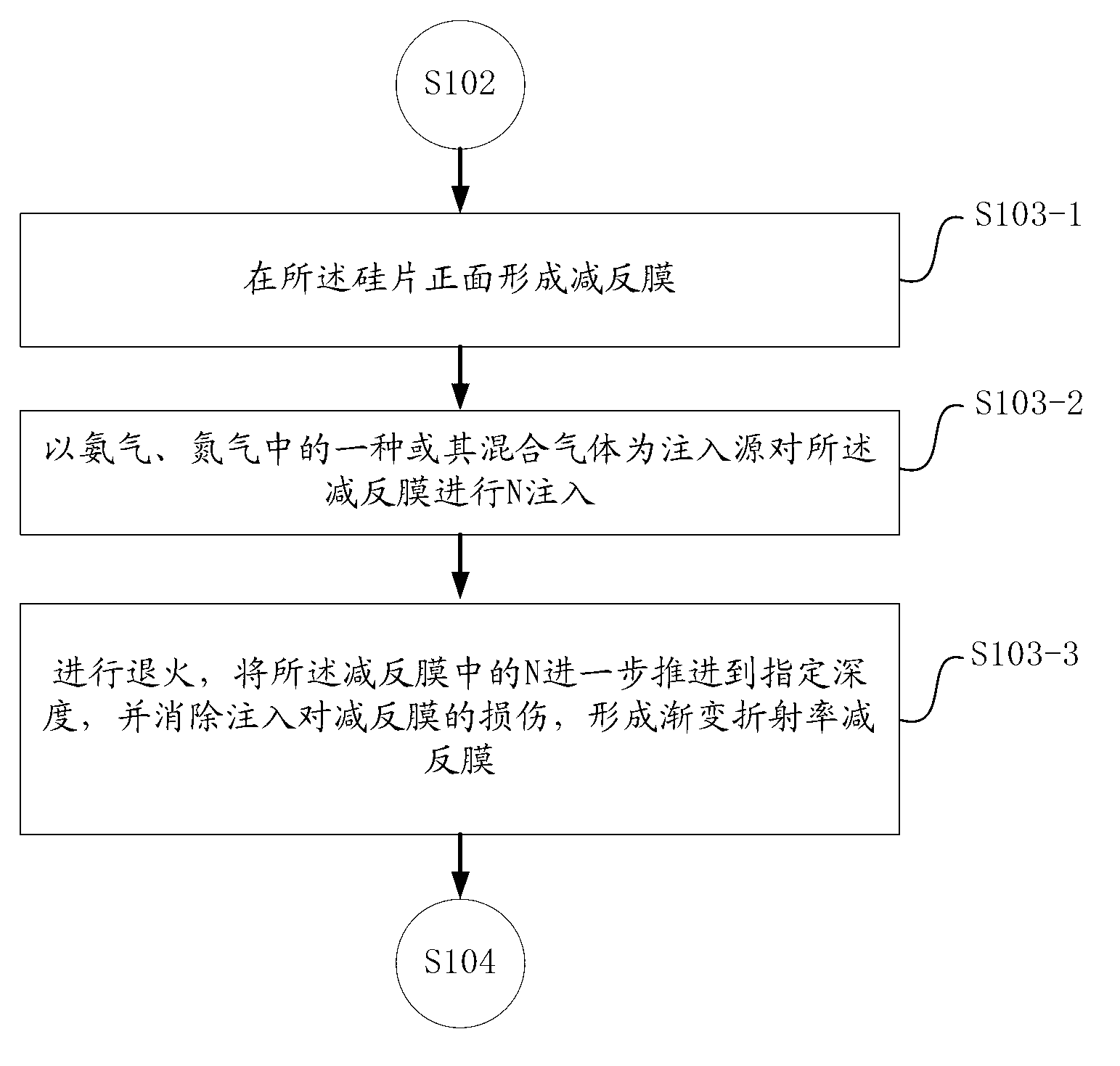

Graduated-refractive-index antireflection-film solar cell and preparation method thereof

ActiveCN103022254AHigh refractive indexLow refractive indexFinal product manufactureSemiconductor devicesRefractive indexBack surface field

The invention discloses a preparation method of a graduated-refractive-index antireflection-film solar cell. The preparation method includes the steps: forming a textured surface on the front side of a silicon wafer; performing P diffusion on the front side of the silicon wafer, and then removing phosphorosilicate glass and a peripheral P diffusion layer on the front side of the silicon wafer; forming a graduated-refractive-index antireflection film on the front side of the silicon wafer; forming a back electrode and an aluminum back-surface field on the back side of the silicon wafer; and forming a positive electrode on the front side of the silicon wafer. Correspondingly, the invention further provides the graduated-refractive-index antireflection-film solar cell. The solar cell prepared by the method is good in electrical property and small in attenuation.

Owner:CHINT NEW ENERGY TECH (HAINING) CO LTD

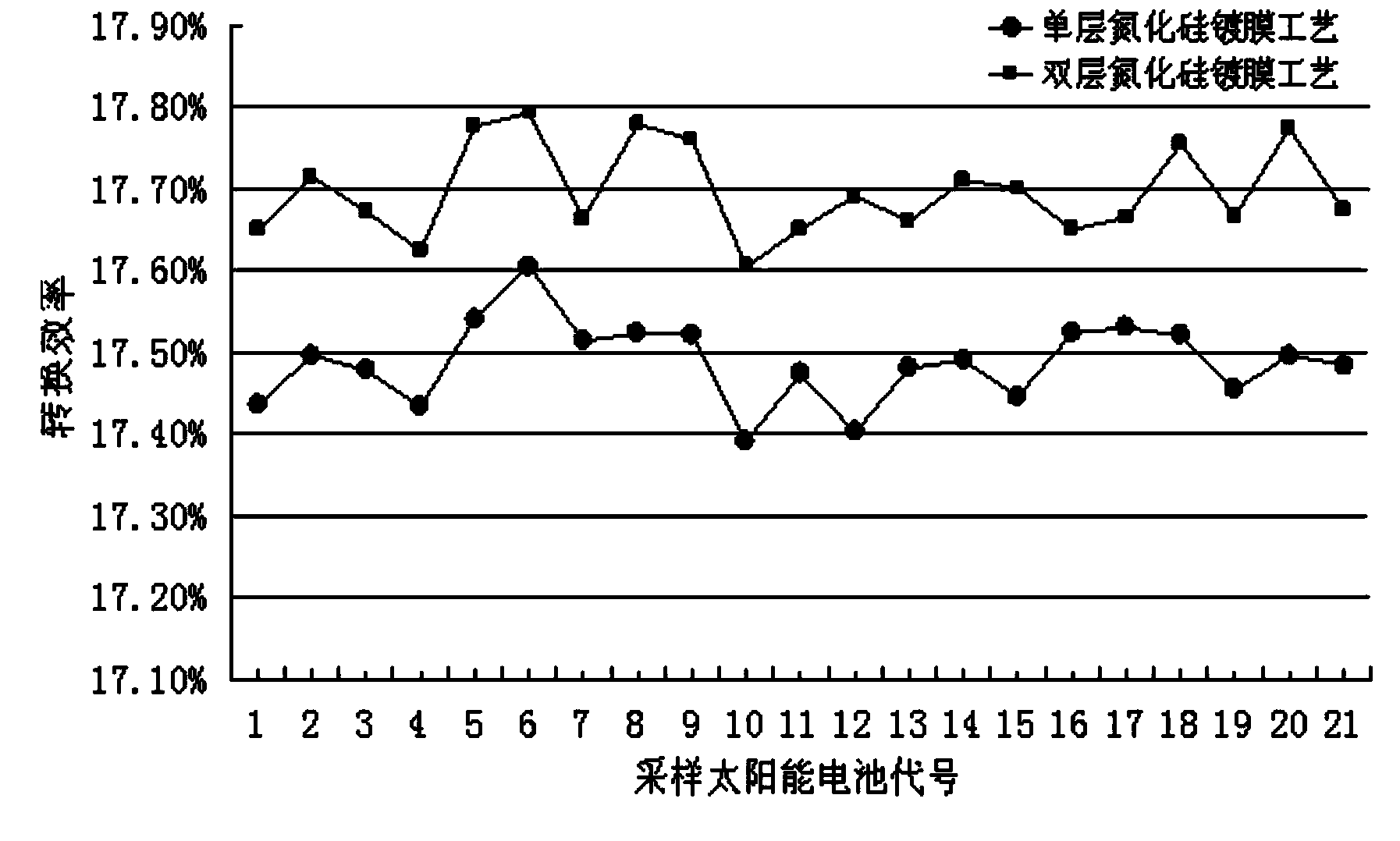

Coating film process for metallurgical grade monocrystalline silicon solar cell double-layer anti-reflection film

ActiveCN103556125AGood passivation effectImprove life expectancyFinal product manufactureChemical vapor deposition coatingSilicon nitrideMonocrystalline silicon

The invention relates to a coating film process for a metallurgical grade monocrystalline silicon solar cell double-layer anti-reflection film. The coating film process is characterized by comprising the following steps: performing vacuum pumping inside a reaction chamber of a coating machine; aerating ammonia gas and silicane for 15s to 20s, controlling the ammonia flow to be 6300sccm to 6400sccm and the silane flow to be 1400sccm to 1500sccm; performing first film coating; performing vacuum pumping inside the reaction chamber, aerating ammonia gas and silicane for 15s to 20s, controlling the ammonia flow to be 7100sccm to 7200sccmand and the silane flow to be 600sccm to 700sccm; performing second film coating; performing vacuum pumping inside the reaction chamber, and aerating N2 until the pressure reaches normal pressure. Proved by trial use, the coating film process combines advantages in various aspects of the silicon nitride film and reaches maximum advantage.

Owner:NINGXIA YINXING ENERGY

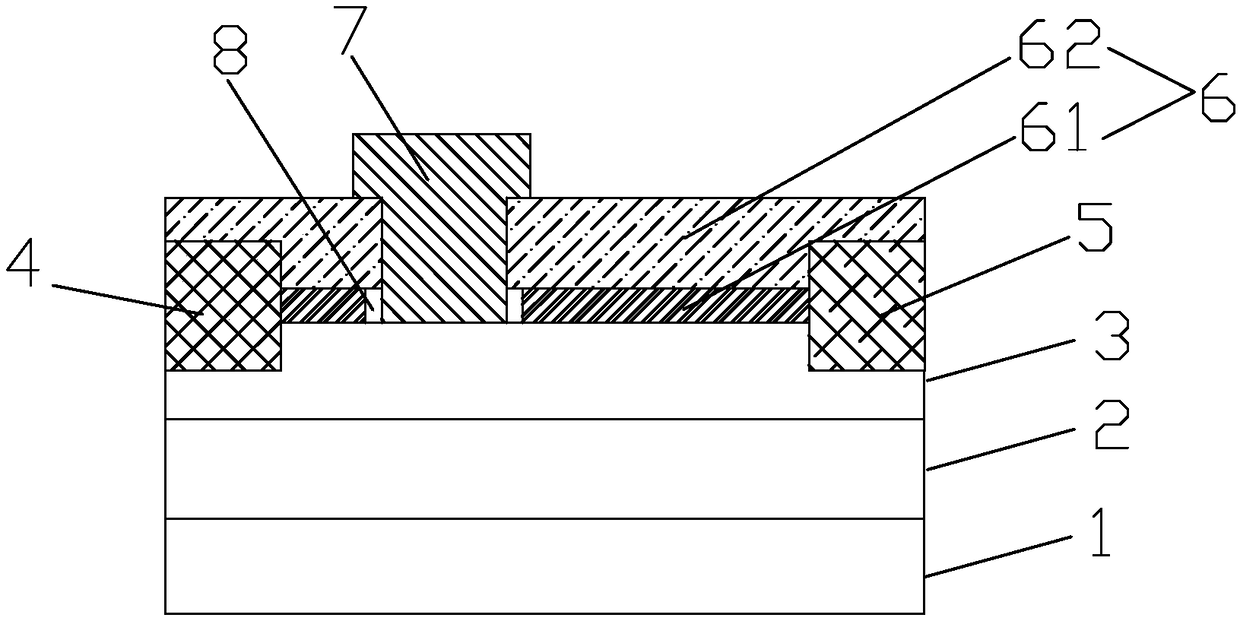

Manufacturing method of silicon-based solar cell P-type surface tunneling oxidation and passivation contact

InactiveCN107482078AReduce interface state densityReduce surface recombinationFinal product manufacturePhotovoltaic energy generationSurface oxidationMetal electrodes

The invention relates to a manufacturing method of silicon-based solar cell P-type surface tunneling oxidation and passivation contact. The manufacturing method comprises the steps of: (1) cleaning the surface of a monocrystalline silicon wafer by using a solution after treatment of a previous process, so as to remove a surface oxide layer; (2) oxidizing the surface of the monocrystalline silicon wafer to form an ultra-thin tunneling oxide layer; (3) depositing a silicon thin layer on the ultra-thin tunneling oxide layer by utilizing a chemical vapor deposition method, and completing boron doping of the silicon thin layer; (4) oxidizing and annealing the silicon wafer, so as to further improve the microstructure and performance of the silicon layer; (5) depositing a silicon nitride passivation anti-reflection layer on the boron-doped silicon thin layer by adopting a plasma-enhanced chemical vapor deposition method; (6) and printing metal electrodes on the surface of the silicon nitride passivation anti-reflection layer, thereby completing the manufacturing process. The manufacturing method can significantly reduce the surface recombination of the cell panels, achieves an excellent passivation effect and increases an open circuit voltage; and the product has good thermal stability, and a special low-temperature process does not need to be developed, thus the cost is reduced.

Owner:SHANGHAI SHENZHOU NEW ENERGY DEV

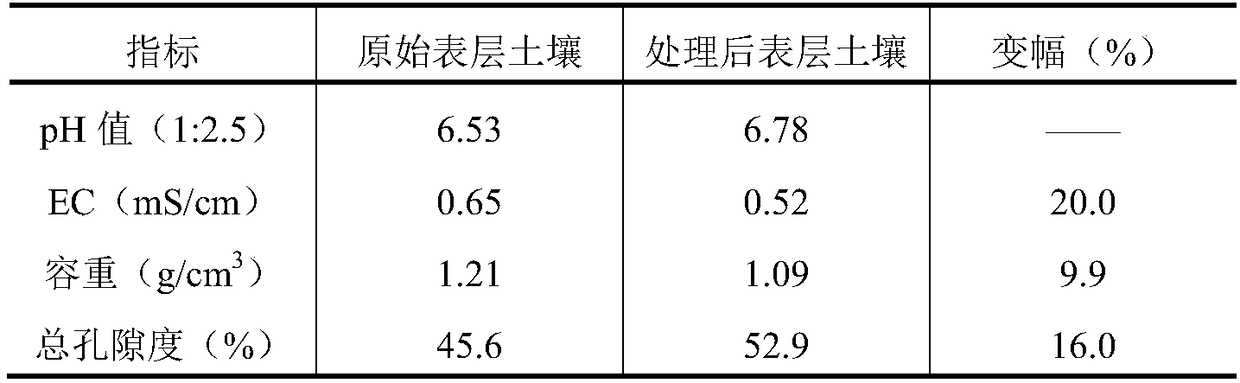

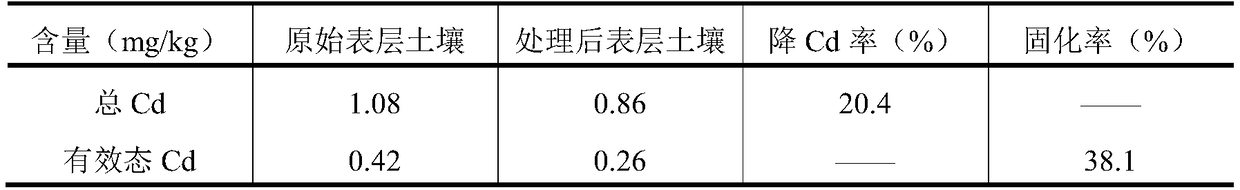

Method for lowering heavy-metal superstandard risk of soil of perennial continuous cropping facilities

InactiveCN108901231AGood passivation effectLow costCereal cultivationOrganic fertilisersContinuous croppingSoil heavy metals

The invention discloses a method for lowering heavy-metal superstandard risk of soil of perennial continuous cropping facilities. Through applying a heavy-metal passivator and combining the methods ofsoil deep-plowing, moisture regulation and control, catch crop planting and the like, the total amount and availability of heavy metals such as Cd and Cu in topsoil of a facility vegetable plot can be obviously lowered, meanwhile, the air and water permeability of the soil is improved, the phenomena such as secondary salinization and acidification of the soil are improved, and thus, the safe production of facility vegetables is guaranteed. The method is suitable for being applied to the soil of the perennial continuous cropping facilities.

Owner:INST OF SOIL & FERTILIZER ANHUI ACAD OF AGRI SCI

Stainless steel passivation liquid and passivation technology thereof

InactiveCN106939420AAvoid harmNo harmMetallic material coating processesAcetic anhydrideSand blasting

The invention discloses stainless steel passivation liquid and a passivation technology thereof. The stainless steel passivation liquid comprises, by weight, 40-50 parts of inorganic acid, 5-15 parts of hydrogen peroxide, 8-12 parts of cyclohexanol, 4-8 parts of 2-ethylhexyl epoxystearate, 4-6 parts of acetic anhydride, 2-4 parts of polyethyleneimine, 3-5 parts of carbomer resin, 2-4 parts of a penetrating agent, 1-3 parts of corrosion inhibitor and 10-20 parts of organic filler. The passivation technology of the stainless steel passivation liquid comprises polishing and rust removal, surface oil removal, first-time water washing, sand blasting, acid pickling passivation, second-time water washing and surface drying. The stainless steel passivation liquid is little in perniciousness, good in passivation effect and not prone to generating corrosive damage on a stainless steel product. The passivation technology is simple, operation is easy, the production cost is low, pollution to the environment is weak, and the standard of green and environment friendliness is met.

Owner:合肥协耀玻璃制品有限公司

Method for improving rice eating quality and storage period

InactiveCN102972521AGood passivation effectReduce waist burst rateSeed preservation by irradiation/electric treatmentSeed preservation by heatingNutrientHorticulture

The present invention relates to a method for improving rice eating quality and storage period, which is characterized in that: a lactic acid solution is slowly added in a manner of atomization, so that the rice is in a weak-acid and high-humidity environment, low-dose X-ray irradiation is used to activate the enzymes in rice for some time, then hot air and microwave are combined to treat the rice to produce moderate gelatinization, and at the same time the insect enzyme bacteria in the rice are killed. The method can significantly improve the eating quality and the storage period of rice, slow humidification by atomization and low temperature and high humidity retarding treatment can effectively reduce the rice fissuring rate, and the loss of nutrients is reduced.

Owner:NANCHANG UNIV

Method for preparing N-type substrate microcrystalline silicon hetero-junction cell based on SE selective emitter junction

InactiveCN103258900AEasy to useSimple processFinal product manufactureSemiconductor devicesScreen printingPhotoelectric conversion

The invention relates to a method for preparing an N-type substrate microcrystalline silicon hetero-junction cell based on an SE selective emitter junction. The method for preparing the N-type substrate microcrystalline silicon hetero-junction cell based on the SE selective emitter junction is characterized in that an N-type silicon wafer serves as a cell substrate, and the method comprises the following steps that the wafer substrate is washed and a texture surface is made, phosphorus ink is printed on the front face of the silicon wafer through a silk screen and drying is carried out, the silicon wafer is diffused and an N+ diffusing layer of the selective emitter junction is formed on the front face of the silicon wafer, secondary washing is carried out on the silicon wafer, an a-SiNx layer is deposited on the N+ diffusing layer, an amorphous silicon / microcrystalline laminating structure is deposited on the back face of the cell, an electrode of the front face of the silicon wafer is printed through the silk screen, and an electrode of the back face of the silicon wafer is sputtered and evaporated. The method for preparing the N-type substrate microcrystalline silicon hetero-junction cell based on the SE selective emitter junction has the advantages that a processing technology is simple and rapid, cost is low, the method can be easily compatible with a cell technology of an existing process, an inactivation effect is excellent, a photoelectric conversion rate is greatly improved, and using performance of the cell is improved.

Owner:GCL SYST INTEGRATION TECH

Chromium-free passivator with high corrosion resistance for batch hot galvanizing

PendingCN113293365AHigh affinityImprove stabilityHot-dipping/immersion processesO-Phosphoric AcidThiourea

The invention discloses a chromium-free passivator with high corrosion resistance for batch hot galvanizing. The chromium-free passivator is a mixed solution composed of silica sol, phosphoric acid, a complexing agent, nitric acid, a silane coupling agent and deionized water. The chromium-free passivator comprises the following components including, by mass, 1%-5% of silica sol, 0.3%-0.8% of phosphoric acid, 2%-8% of a complexing agent, 5%-10% of a silane coupling agent and the balance deionized water, wherein the complexing agent is one or a combination of more of dimercaptopropanol, sodium dimercaptopropane sulfonate, mercaptoethylamine, mercaptoacetic acid, thiourea, ammonium fluoride and 8-hydroxyquinoline. The invention also discloses a preparation method and a use method of the chromium-free passivator with the high corrosion resistance for batch hot galvanizing. The chromium-free passivator for hot galvanizing contains the silane coupling agent and silica sol, the silane coupling agent has the effect of enhancing the affinity between organic matter and inorganic compounds, toxic and harmful substances such as the chromium element and harmful chemicals are not contained, stability is good, the drying speed is high, and the passivating effect is good.

Owner:WUXI EPIC TECH

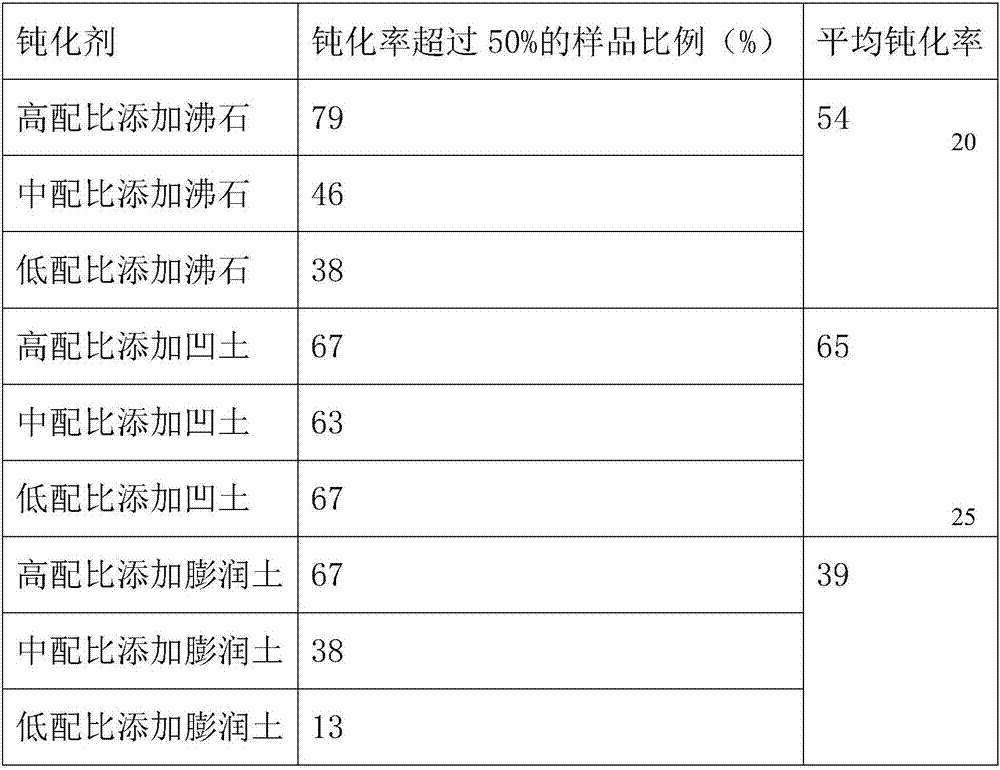

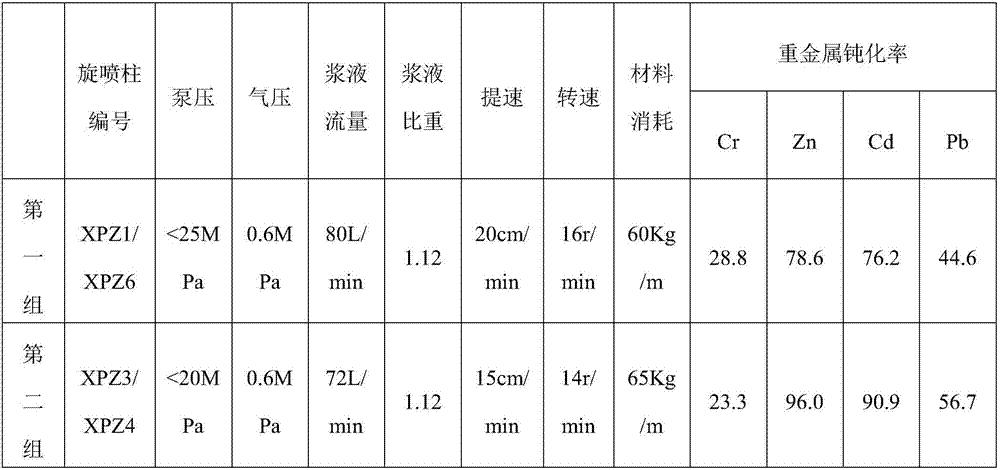

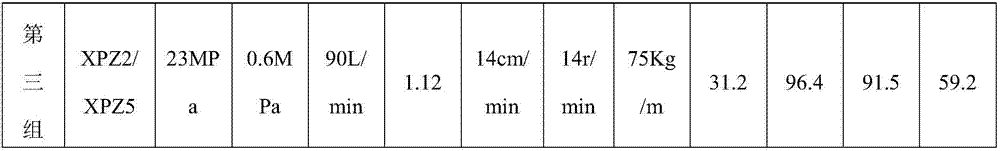

In-situ repair method of tailing sand heavy metal

InactiveCN107470346APromote migrationReduce infiltrationContaminated soil reclamationHigh pressureMaterials science

The invention discloses an in-situ repair method of tailing sand heavy metal. The in-situ repair method of the tailing sand heavy metal is characterized in that a high-pressure jet grouting process is adopted to perform the jet grouting on modified attapulgite-contained pulp into tailing sand in situ, so that the heavy metal is cured.

Owner:NAT RESERACH CENT OF GEOANALYSIS +1

Soil passivation improver, and preparation method and application thereof

InactiveCN106929030ALow chemical adsorption functionGood passivation effectContaminated soil reclamationOrganic fertilisersPotassiumNatural mineral

The invention discloses a soil passivation improver, and a preparation method and an application thereof. The soil passivation improver is prepared by the following steps: crushing bentonite, diatomite, magnesium oxide, ferric oxide and humic acid through a micro-wet ball mill process; spraying water which is 2-5% of the material; and fully grinding the mixture for 2-4 hours. According to the soil passivation improver, the activity of heavy metals in the soil is reduced and the concentration of effective heavy metals is reduced through natural mineral components such as bentonite and diatomite, and magnesium oxide; the air permeability of the soil is improved through the humic acid component, and nitrogen, sulfur, potassium and phosphorus and trace elements necessary to plants are supplemented while the heavy metals are complexed and the effective states of the heavy metals are reduced by means of functional groups, such as quinonyl, alcoholic hydroxyl group, carboxyl and carbonyl, in the humic acid; and meanwhile, fulvic acid rich in the soil is chelated with the heavy metals, so that the absorption amount of the plants on the heavy metals is reduced. The soil passivation improver has a wide application in heavy metal-polluted soil repair.

Owner:GUANGDONG UNIV OF TECH

Method for producing passive metal particle, metal powder or passive lime

The invention relates to a method for producing passive metal particle, metal powder or passive lime. The passive metal particle, the metal powder or the passive lime consists of the following raw materials in part by weight: 1,000 parts of metal particle (metal powder or lime), and 0.5 to 2 parts of efficient compound additives. The efficient compound additives are prepared from three types of organic solutions in proportion and are sprayed in the form of mist on the surface of the metal particle (the metal powder or the lime) rotating quickly in a passivation device by using a special container so as to produce environment-friendly high-quality passive metal particle (or powder) or passive lime. The method has the following advantages: 1) the passivated substances in the method not only have good passivation effect so that the materials can be effectively isolated from the outside for a long time, but also make the materials obtain good dispersity and fluidity to meet the requirements on smelting, and has strong market prospect and competitive strength; and 2) the efficient compound additives are environment-friendly non-toxic harmless substances.

Owner:鞍山市和丰耐火材料有限公司

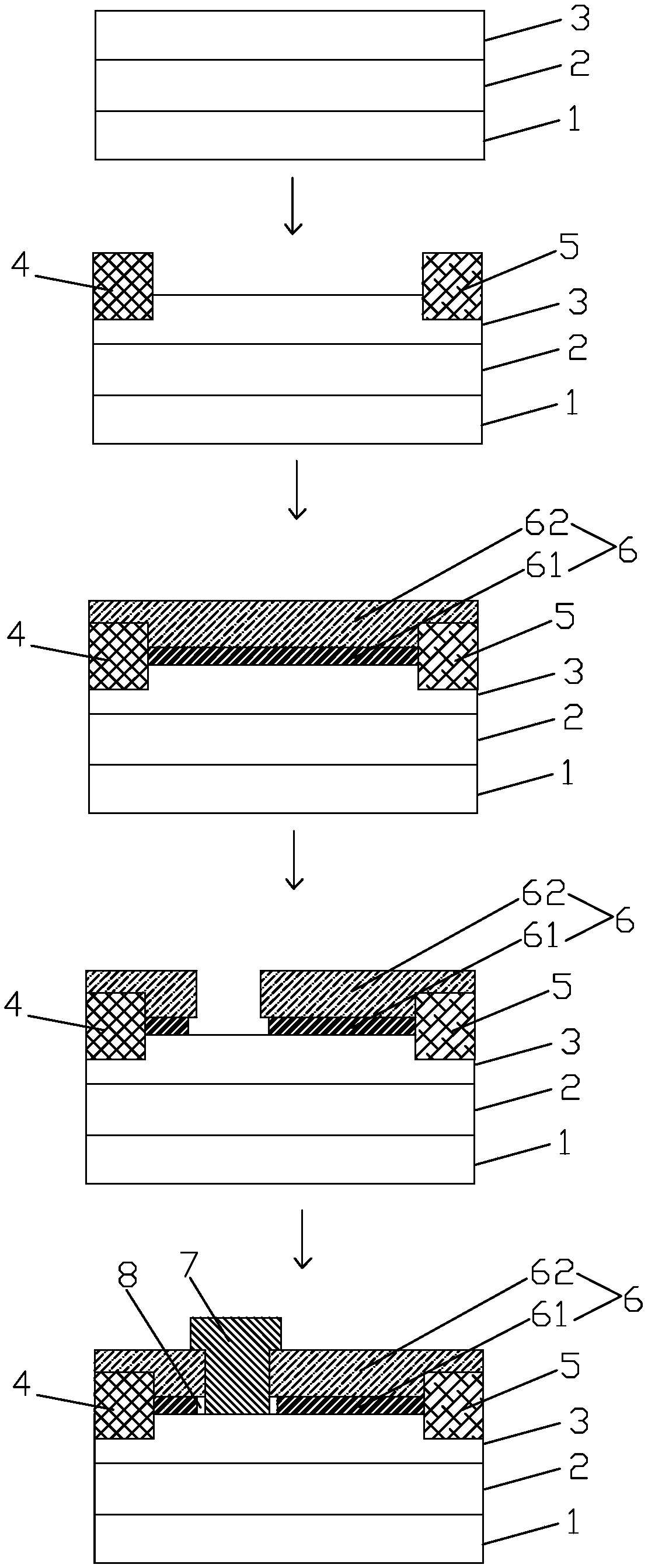

Gallium-nitride transistor employing gap-type composite passivation medium and manufacturing method

ActiveCN108695157AReduce gate leakageGood passivation effectSemiconductor/solid-state device manufacturingSemiconductor devicesPhysical separationGallium nitride

The invention discloses a gallium-nitride transistor employing a gap-type composite passivation medium and a manufacturing method. The composite passivation medium technology is employed, and the composite passivation medium at least comprises a lower dielectric layer and an upper dielectric layer, which are stacked. Moreover, the upper and lower dielectric layers have different etching characteristics. A specific etching method is employed for enabling the window width of the lower dielectric layer to be greater than the window width of the upper dielectric layer, so as to introduce a gap structure in a single passivation layer or multiple passivation layers making contact with a semiconductor and achieve the physical separation of a gate metal with a passivation medium / semiconductor interface, thereby cutting off an electric leakage channel on the surface of a device, and reducing the gate electric leakage on the surface of the device. Meanwhile, the good passivation effect can be maintained while the cutting of the electric leakage channel on the surface is achieved through the control of the width of the gap structure.

Owner:XIAMEN SANAN INTEGRATED CIRCUIT

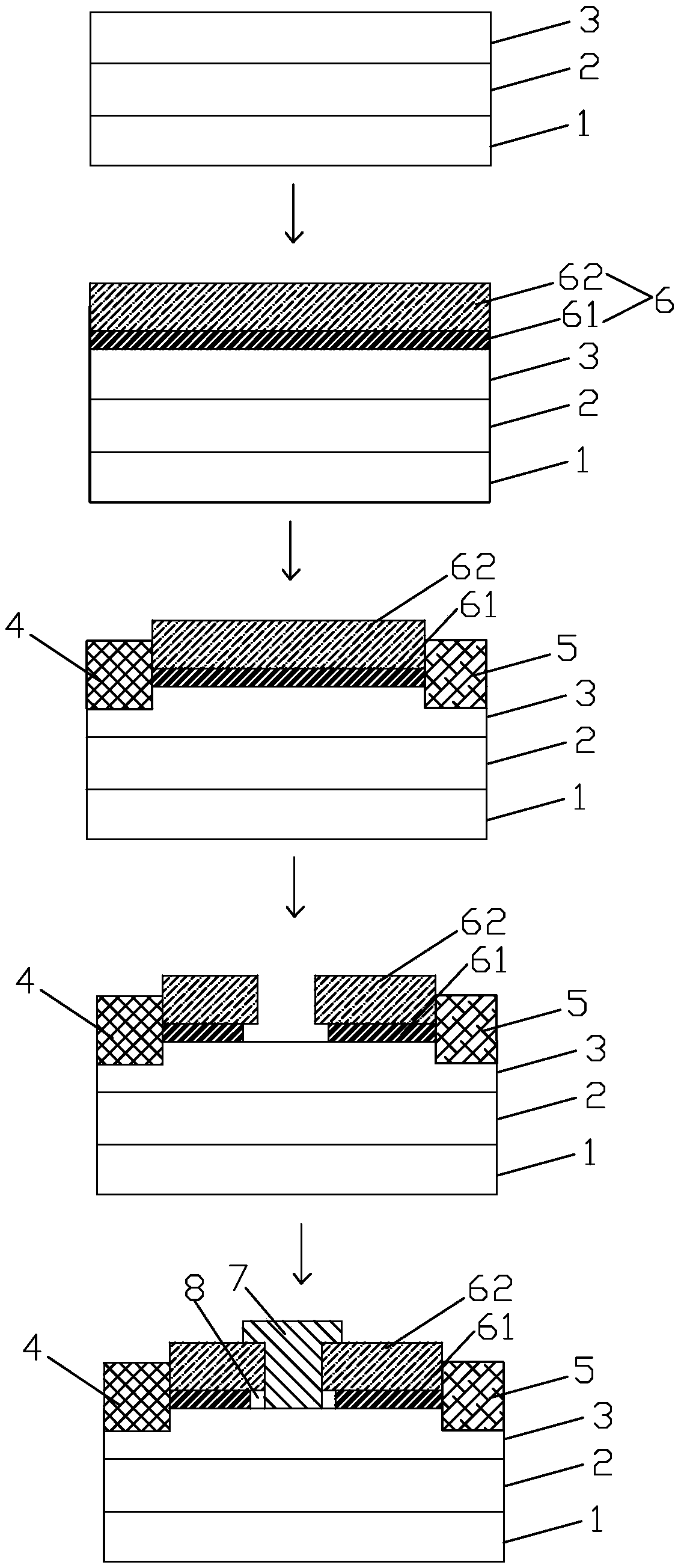

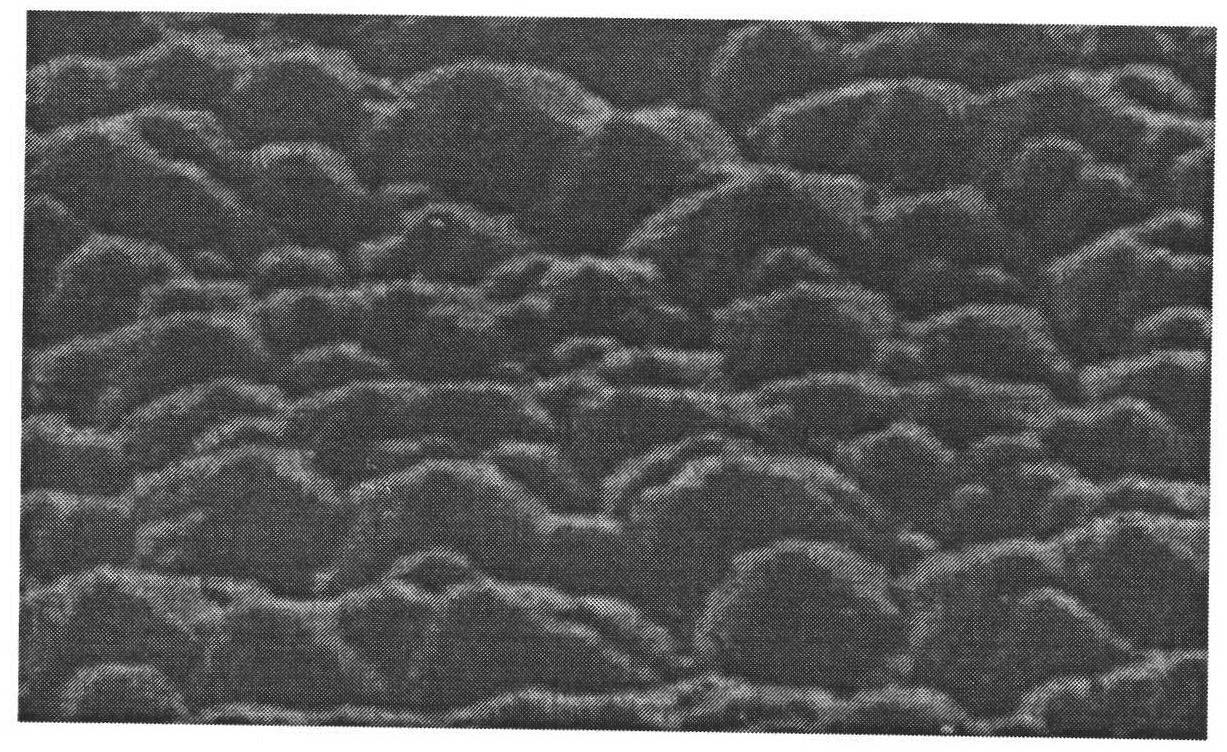

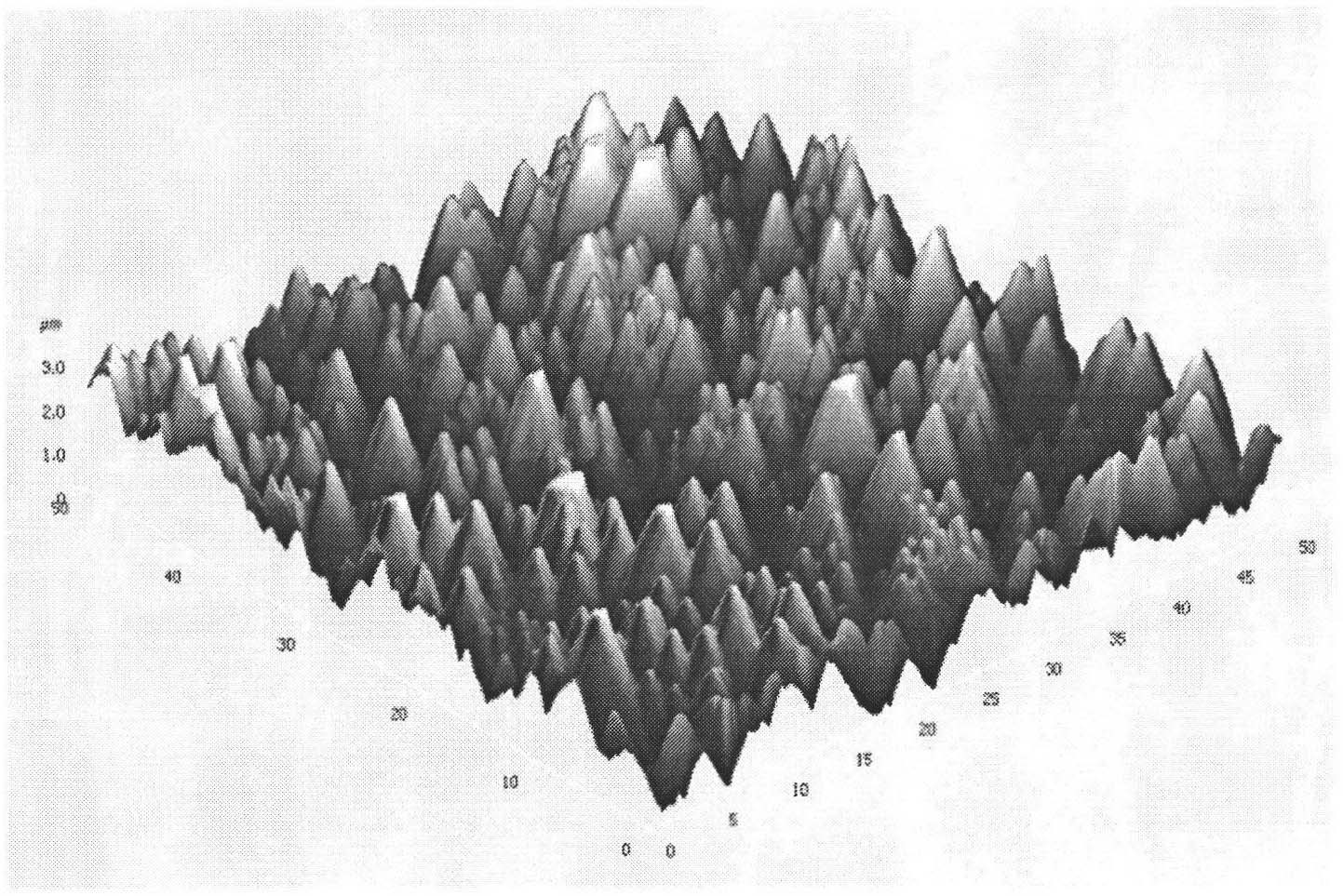

Texture etching solution of monocrystaline silicon solar cell, preparation method, and application thereof

InactiveCN102400225AOvercome timeOvercome uniformity issuesAfter-treatment detailsFinal product manufactureTetramethylammonium hydroxideSilicon solar cell

The invention relates to a texture etching solution of a monocrystaline silicon solar cell, a preparation method, and an application thereof. Raw materials of the texture etching solution comprise the following components, by weight, 1-3% of tetramethylammonium hydroxide, 7-9% of isopropyl alcohol and 88-92% of deionized water. The preparation method comprises: adding the deionized water to a texture etching groove, then adding the tetramethylammonium hydroxide and the isopropyl alcohol, controlling a temperature to 75-85 DEG C, completely and uniformly stirring to obtain the texture etching solution, which is applicable for treatment of silicon wafers. Compared to the prior art, with the present invention, the texture etching solution has a good anisotropic etching characteristic and high etching rate, the etching surface has good homogeneity, the etching solution does not contain free-alkali metal ions, has advantages of no toxicity and easy operation and control, and can provide compatibility with the microelectronic technology.

Owner:SHANGHAI SHENZHOU NEW ENERGY DEV

Antireflective film for solar cell piece and manufacturing method thereof

InactiveCN104091839AGood passivation effectIncrease short circuit currentFinal product manufactureChemical vapor deposition coatingPower flowPhotovoltaic conversion efficiency

The invention provides an antireflective film for a solar cell piece and a manufacturing method of the antireflective film. The antireflective film for the solar cell piece comprises a first silicon nitride layer covering the surface of the solar cell piece, a second silicon nitride layer covering the upper surface of the first silicon nitride layer and a third silicon nitride layer covering the upper surface of the second silicon nitride layer. By means of the antireflective film for the solar cell piece, the three layers of silicon nitride antireflective films are adopted, the good passivating effect can be achieved, the short-circuit current of the metallurgical polycrystalline silicon cell pieces can be improved, the reverse leakage current can be reduced, and photovoltaic conversion efficiency is improved. Meanwhile, according to the manufacturing method of the antireflective film, an intermittent deposition technology is adopted, that is, a certain dead time is added between depositions of the two layers of silicon nitride thin films, so that the growth of all layers of silicon nitride thin films is complete as much as possible, the manufactured metallurgical polycrystalline silicon cells are more even in color of appearance, the chromatic aberration rate of the surfaces of the cell pieces is reduced by about 5% from the original 30%, and the yield of the metallurgical polycrystalline silicon cells is improved greatly.

Owner:INNER MONGOLIA RIYUE SOLAR ENERGY TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com