Method for passivating crystal silicon P-type surface

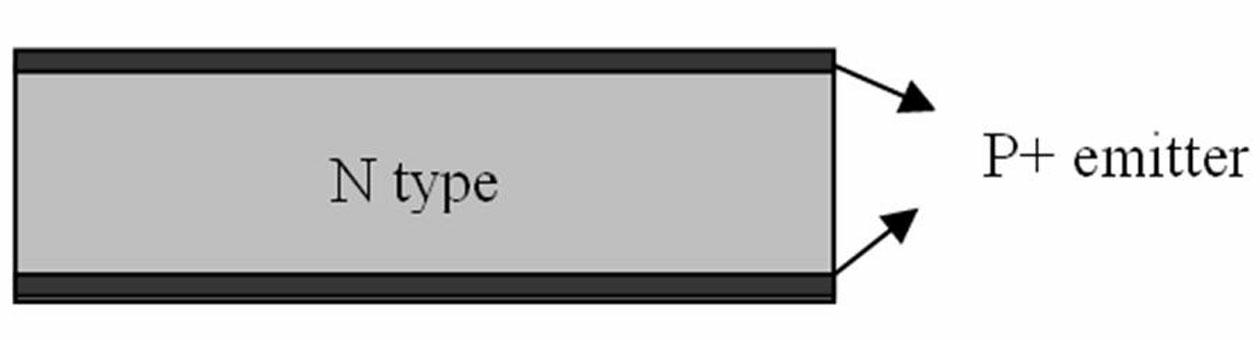

A technology of crystalline silicon and crystalline silicon wafers, which is applied in the field of passivation of the P+ emitter junction surface of N-type batteries, can solve problems such as leakage current generation, and achieve the effects of improving conversion efficiency, reducing recombination rate, and good anti-reflection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A kind of passivation method of crystalline silicon P-type surface, the concrete steps of this method are as follows:

[0023] (1) Use a 1Ωcm N-type crystalline silicon wafer for double-sided boron diffusion, and the diffused sheet resistance is 50 ohms / square, and then remove the borosilicate glass on the surface of the N-type crystalline silicon wafer after boron diffusion, and clean it ;

[0024] (2) Put the cleaned silicon wafer into concentrated nitric acid with a temperature of 110°C and a concentration of 69% for oxidation, and grow a layer of 3nm SiO on the surface of the silicon wafer after 30 minutes 2 TLC;

[0025] (3) In the grown SiO 2 A layer of SiNx film is deposited on the surface of the thin layer by plasma chemical vapor phase PECVD; the thickness of the SiNx film is 75nm, and the refractive index is 2.1.

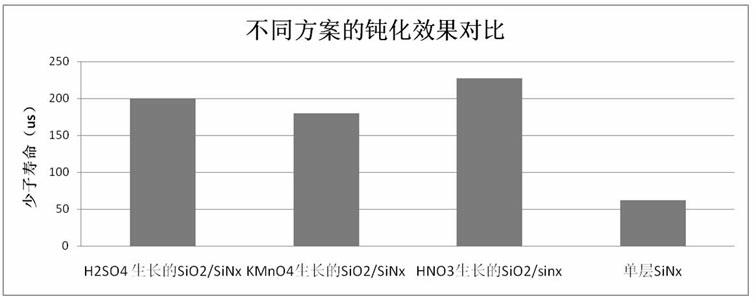

[0026] Compared with the single-layer SiNx produced after sintering by the conventional method, the minority carrier lifetime of the passivated ...

Embodiment 2

[0028] A kind of passivation method of crystalline silicon P-type surface, the concrete steps of this method are as follows:

[0029] (1) Use a 1Ωcm N-type crystalline silicon wafer for double-sided boron diffusion, and the diffused sheet resistance is 50, and then remove the borosilicate glass on the surface of the N-type crystalline silicon wafer after boron diffusion, and clean it;

[0030] (2) Put the cleaned silicon wafer into concentrated sulfuric acid with a temperature of 120°C and a concentration of 90% for oxidation, and grow a layer of 1.1nm SiO on the surface of the silicon wafer after 45 minutes 2 TLC;

[0031] (3) In the grown SiO 2 A layer of SiNx film is deposited on the surface of the thin layer by plasma chemical vapor phase PECVD; the thickness of the SiNx film is 60nm, and the refractive index is 1.9.

Embodiment 3

[0033] A kind of passivation method of crystalline silicon P-type surface, the concrete steps of this method are as follows:

[0034] (1) Use a 1Ωcm N-type crystalline silicon wafer for double-sided boron diffusion, and the diffused sheet resistance is 50, and then remove the borosilicate glass on the surface of the N-type crystalline silicon wafer after boron diffusion, and clean it;

[0035] (2) Put the cleaned silicon wafer into potassium permanganate with a temperature of 70°C and a concentration of 16% for oxidation, and grow a layer of 2nm SiO on the surface of the silicon wafer after 10 minutes 2 TLC;

[0036] (3) In the grown SiO 2 A layer of SiNx film is deposited on the surface of the thin layer by plasma chemical vapor phase PECVD; the thickness of the SiNx film is 100 nm, and the refractive index is 2.2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com