Patents

Literature

185results about How to "Reduce compound rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

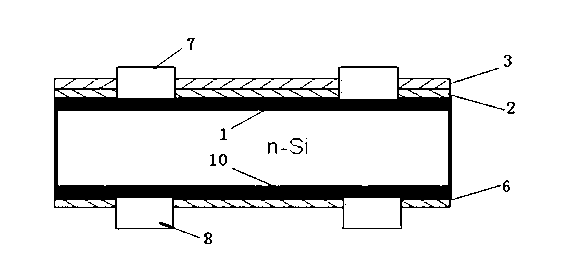

Method for preparing solar cell by using local area back field

ActiveCN101853899AEliminate the etching processSolve the leakFinal product manufactureSemiconductor devicesScreen printingSilver electrode

The invention discloses a method for preparing a solar cell by using a local area back field, which comprises the following steps of: selecting a silicon chip and making the silicon chip into a soft silicon chip, then performing boron or phosphorus dispersion, cleaning a boron-silicon glass layer or a phosphorus-silicon glass layer left on the surface of the silicon chip after the dispersion, depositing a silicon nitride film on the front of the silicon chip by using PECVD, polishing the back of the silicon chip by using hot alkali liquid, and depositing a passive film, performing laser perforation and sputtering an aluminum layer on the polished back; and finally, screen-printing a silver electrode on the front of the silicon chip, and sintering, testing and separating the silicon chip. The method avoids the problem of current leakage caused by lamination during etching; the PECVD process adopted by the passive film on the back is more suitable for large-scale production; the adoption of the back laser perforation improves the manufacturing speed, reduces the process step and avoids pollution brought by corrosive slurry; and the Al layer can be well sintered and contacted with the silicon through pores so that the contact area of the metal and the back surface silicon is smaller and the current carrier compounding rate of the back surface is reduced.

Owner:JA SOLAR TECH YANGZHOU

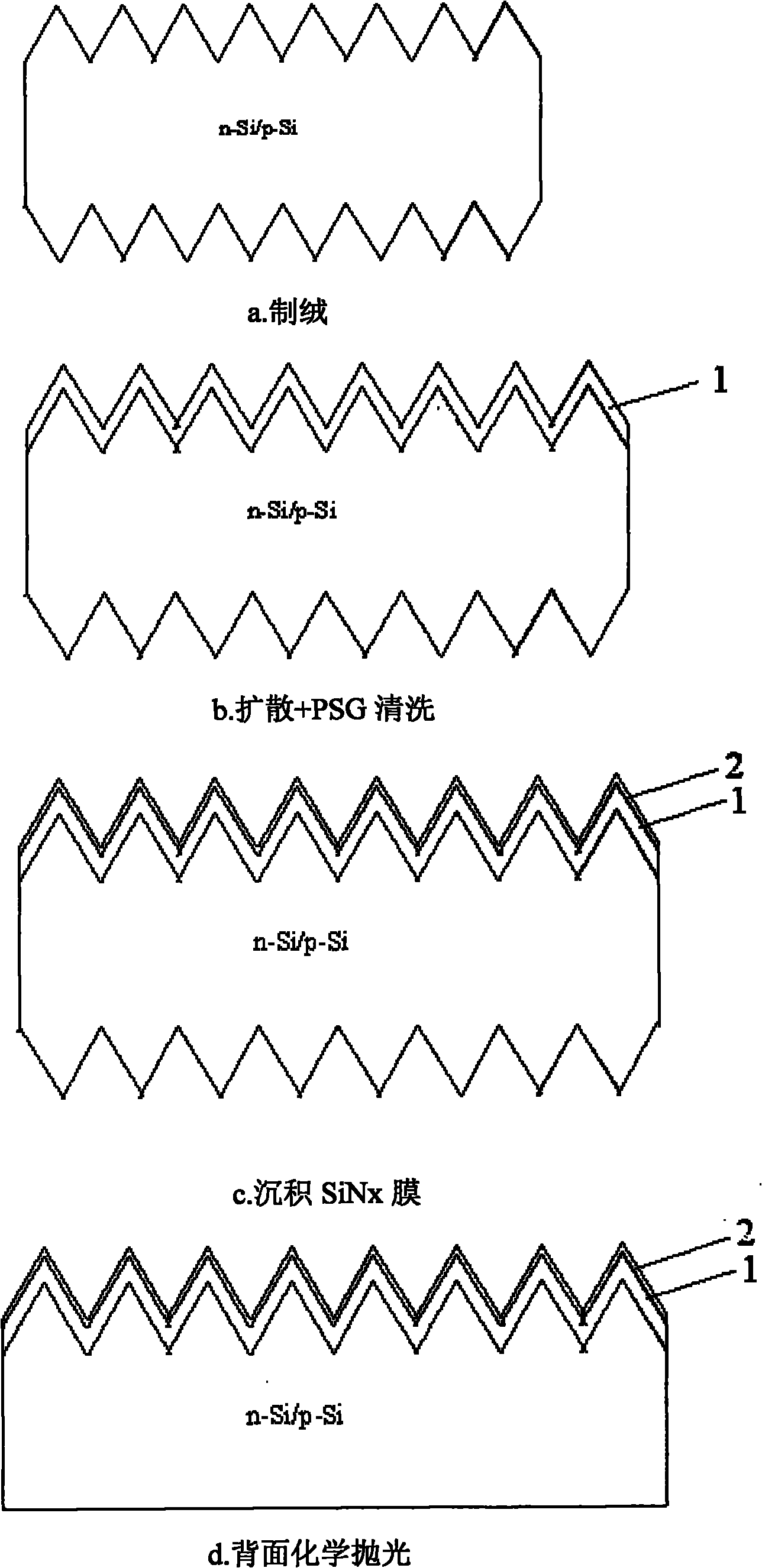

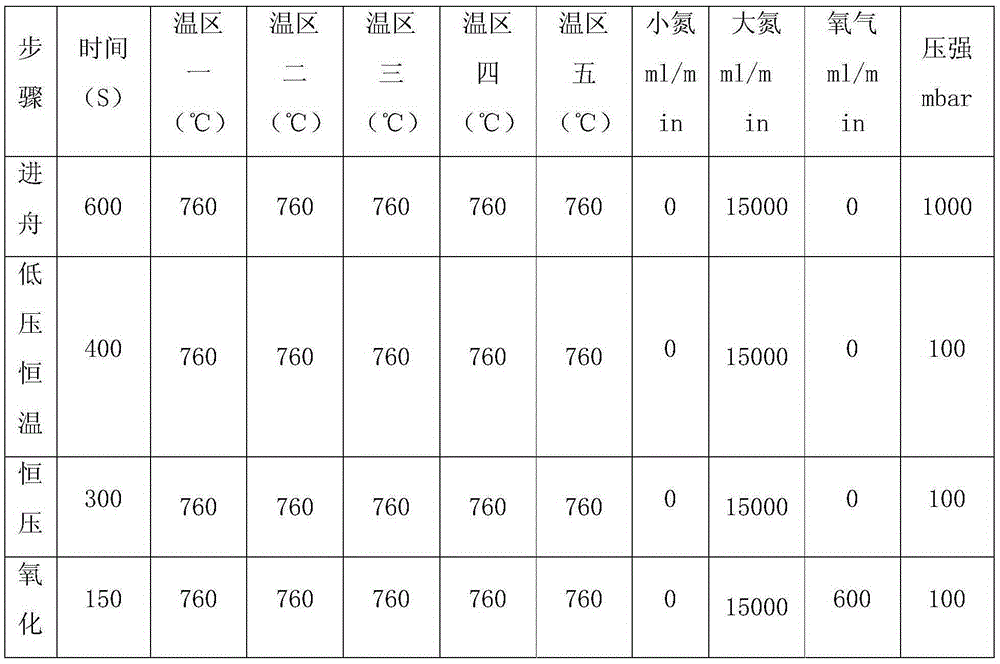

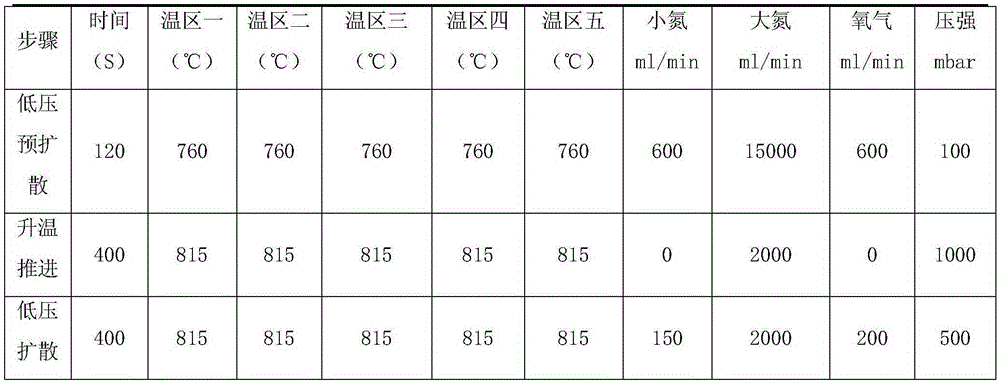

Low-pressure diffusion technology for crystalline silicon cell

ActiveCN105261670AIncrease chance of contactImprove uniformityFinal product manufactureSemiconductor/solid-state device manufacturingDiffusion methodsInternal pressure

The invention discloses a low-pressure diffusion technology for a crystalline silicon cell. The technology comprises the following steps: (1) a high-temperature oxidation before diffusion; (2) a low-pressure diffusion, namely preparing a PN knot by a sub-step diffusion method; and (3) annealing, namely changing internal pressure to remove impurities. According to the low-pressure diffusion technology, the uniformity between diffusion sheets can be improved; the temperature of a temperature zone in a fire hole is lowered, namely the temperature uniformity of various temperature zones of a diffusion tube is improved; the problem of a great fluctuation of sheet resistance of the fire hole of a diffusion furnace is solved; the service lifetime of a vacuum pump is prolonged; and the production cost of a diffusion procedure is reduced.

Owner:HUNAN RED SUN PHOTOELECTRICITY SCI & TECH

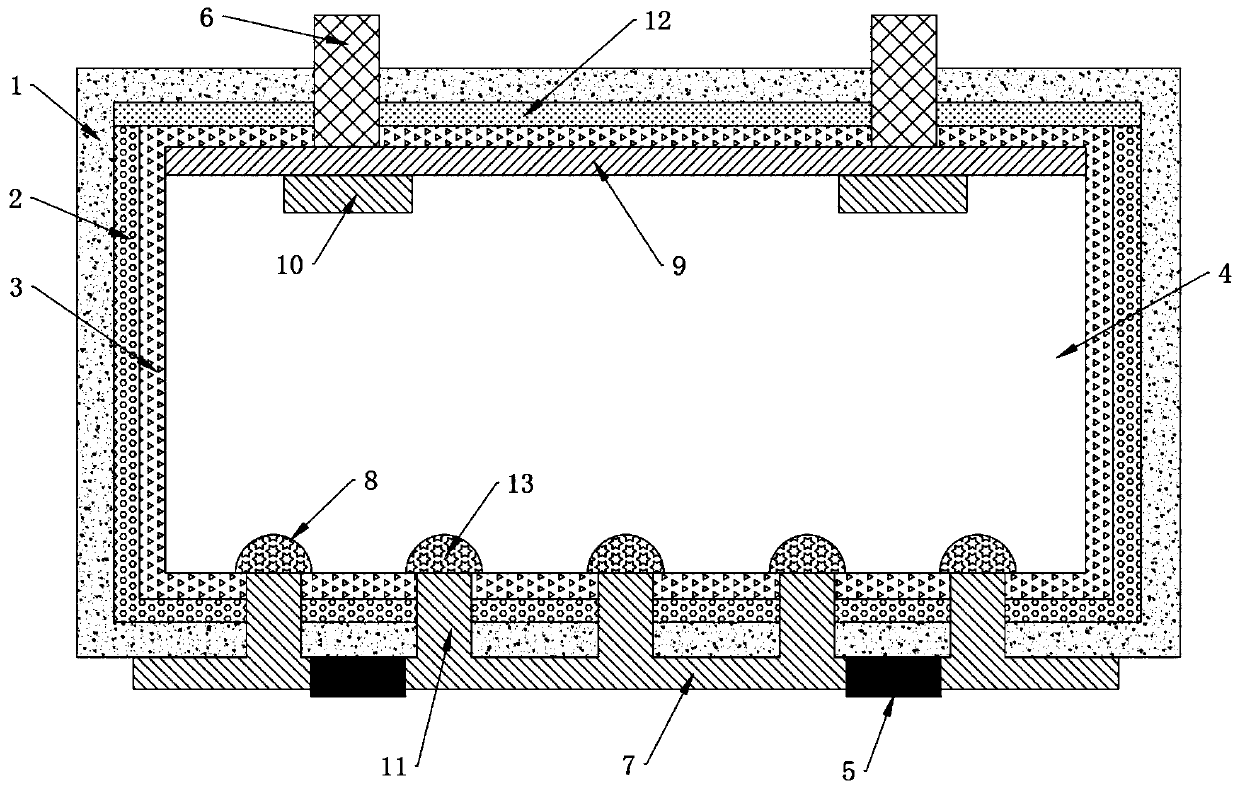

Method for manufacturing back contact solar cell

ActiveCN103794679AReduce compound rateLow costFinal product manufacturePhotovoltaic energy generationEngineeringBand gap

The invention discloses a method for manufacturing a back contact solar cell. According to the method, by means of the combination of the diffusion technology, the patterned dielectric mask technology, the etching technology, the laser insulation technology and the like, p+ doped regions and n+ doped regions which are mutually alternately ranked are manufactured on the back surface of a silicon substrate, band gaps for electric insulation of the p+ / n+ regions are manufactured at the joints of the p+ doped regions and the n+ doped regions, and an n+ front surface field FSF with the low surface doping concentration is manufactured on the front surface of the silicon substrate; the front surface and the back surface of the silicon substrate can be passivated and the front surface of the silicon substrate can be anti-reflected through SiOx, SiNx, AlOx and other dielectric films, and eventually the back contact solar cell is manufactured by achieving metallized contact between the p+ doped regions and the n+ doped regions on the back surface of the silicon substrate through the silk-screen printing process and the co-sintering process. The method for manufacturing the back contact solar cell and an existing process for producing a crystalline silicon solar cell have something in common, no new manufacturing equipment needs to be introduced, all manufacturing procedures can be finished on an existing industrial production line, and therefore cost is low, and the process is simple, reasonable, safe and reliable.

Owner:JA SOLAR TECH YANGZHOU +1

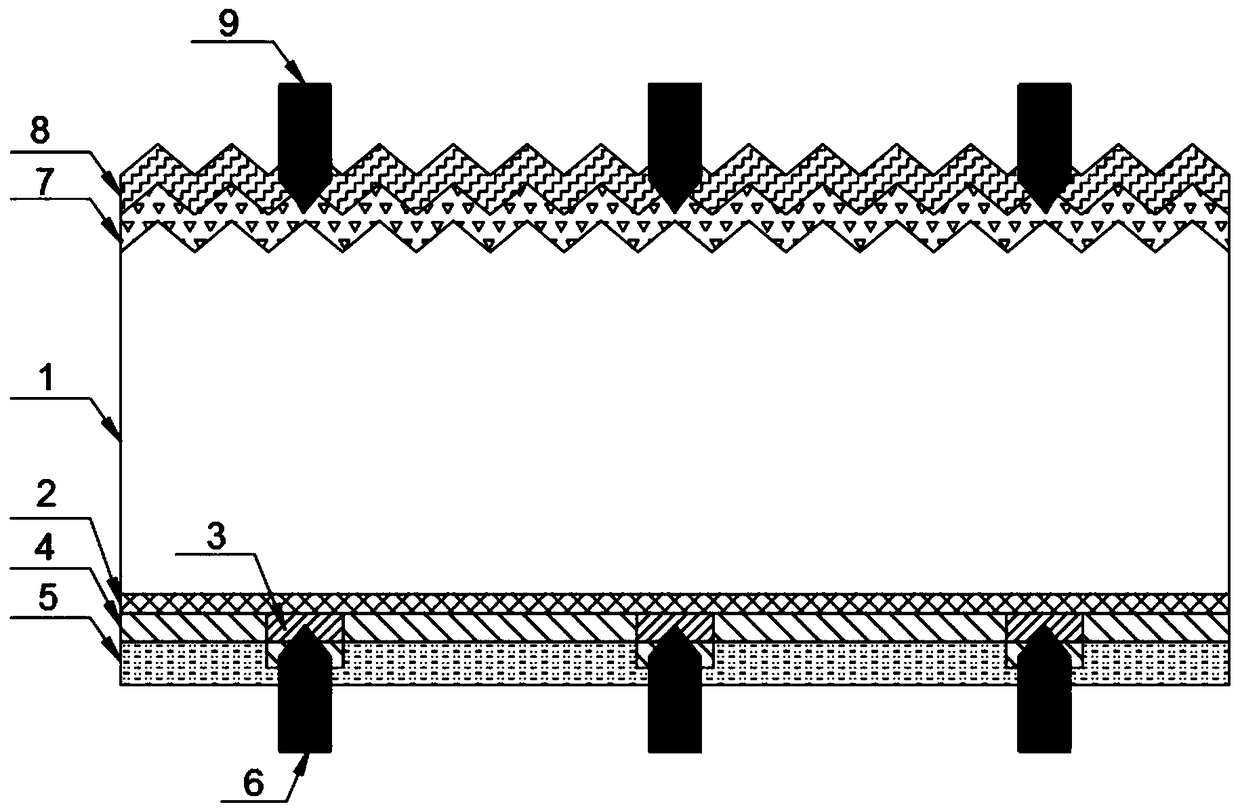

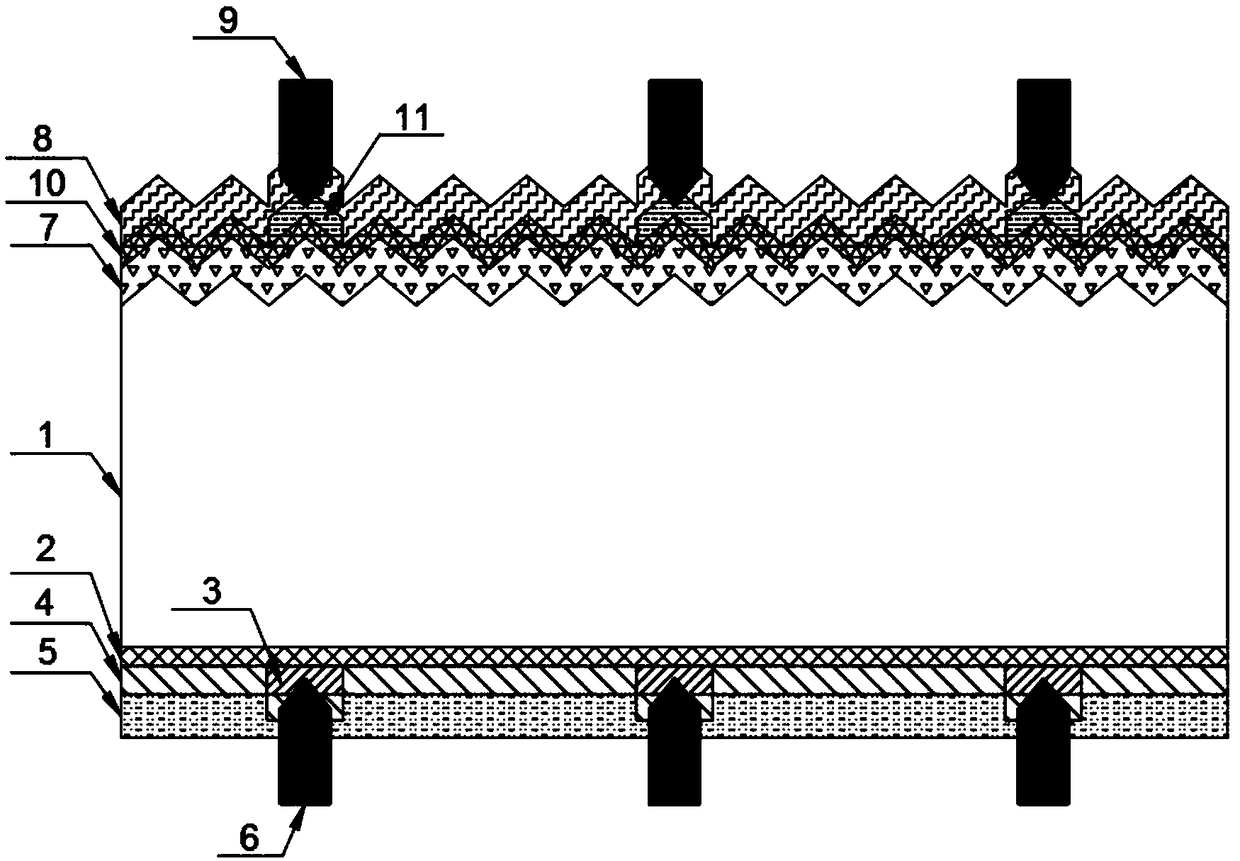

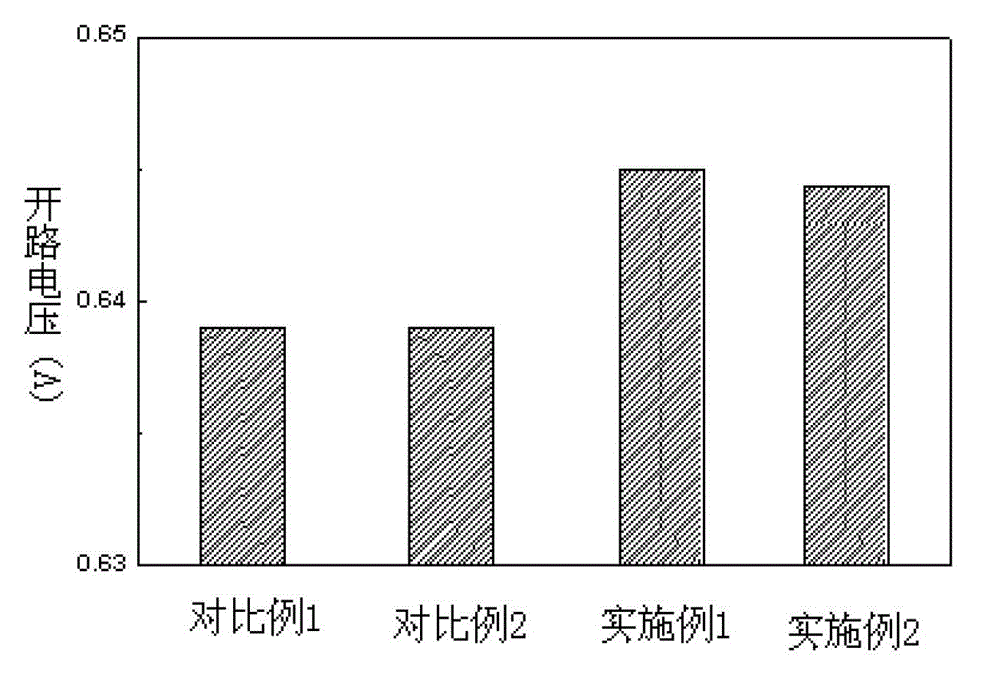

Solar cell with composite dielectric passivation layer structure and preparation process thereof

PendingCN110459615AIncrease short circuit currentIncrease the open circuit voltageFinal product manufacturePhotovoltaic energy generationDielectricRefractive index

The invention discloses a solar cell with a composite dielectric passivation layer structure and a preparation process thereof. A silicon oxide film, an alumina film and a silicon nitride or silicon oxynitride film are deposited in turn on the front, back and sides of a p-type silicon substrate to form a composite dielectric film on the whole surface, and windows are opened locally to lead electrodes out. Through aluminum oxide, silicon dioxide, silicon oxynitride, silicon nitride with different refractive indexes and a back surface passivation layer with a laminated structure of the materials, the back surface recombination rate is greatly reduced, the back reflectivity is improved, the CTM of a module is reduced, and the light attenuation and heat-assisted light attenuation and the anti-PID performance of the cell are improved. The structure can be made on a boron / gallium-doped p-type monocrystalline silicon, p-type polycrystalline silicon or p-type monocrystalline-silicon-like substrate, and a passivation method based on the composite dielectric film passivation structure can be used to manufacture PERC cells, double-sided PERC+ cells and imbricate PERC cells. Based on the preparation process steps and sequence, the corresponding preparation mode and the process parameter range of the laminated structure, the making of the cell can be well completed.

Owner:TONGWEI SOLAR ENERGY CHENGDU CO LID +2

Method for preparing colorful film for protecting solar cell thin grid line metal electrode by adopting mask

InactiveCN101834230ANot easily oxidizedGuaranteed electrical conductivityFinal product manufactureSemiconductor devicesButt jointMetal electrodes

The invention relates to a method for preparing a colorful film for protecting a solar cell thin grid line metal electrode by adopting a mask. In the method, after a solar cell is prepared, a mask is utilized to cover a main grid line metal electrode on the front surface of the solar cell, a film is coated on the area which is not covered by the mask for the second time, and a dielectric layer for protecting the thin grid line metal electrode is prepared to form a structure comprising the dielectric layer, the thin grid line metal electrode and a passivation layer. The method can protect the thin grid line metal electrode against easy oxidation, and the main grid line metal electrode can be normally connected by welding rods. The passivation effect of the front surface can be enhanced through optimizing the passivation layer; the reflectivity of the front surface of the solar cell can be reduced and color regulation can be realized through regulating the dielectric layer; and characters, figures, graphics and the like can be displayed on the front surface of the solar cell through changing a mask pattern. In addition, the secondary film coating method is convenient to be in butt joint with the traditional crystalline silicon solar cell preparation process and is easy for industrialization.

Owner:SUN YAT SEN UNIV

Crystalline silicon solar cell with low series resistor and preparation method thereof

InactiveCN102169909AImprove conductivityGuaranteed power outputFinal product manufactureOther printing apparatusGratingTransparent conducting film

The invention relates to a crystalline silicon solar cell with low series resistor, which comprises a p-n node; a passivation layer, a thin grating metal electrode and a main grating metal electrode are arranged on the front surface of the p-n node, and a back electric field and a back electrode are arranged on the back surface of the p-n node; the thin grating metal electrode, the main grating metal electrode, the back electric field and the back electrode are communicated with the p-n node; and a transparent conducting film is arranged on the full or partial area of the front surface of the crystalline silicon solar cell. The solar cell has a structure having the transparent conducting film, the metal electrodes and the passivation layer, wherein the transparent conducting film can be used for connecting breaking gates so as to reduce the power loss of the breaking gates; the film can reduce the series resistor on the front surface of the cell and enhance the conducting capability of the cell; simultaneously, the crystalline silicon solar cell can play a role in protecting the metal electrode on the front surface of the cell and prevent the metal electrode from oxidizing; and the reflectivity and the color of the crystalline silicon solar cell can be further controlled by adjusting and controlling the transparent conducting film. The invention further discloses a preparation method of the crystalline silicon solar cell.

Owner:SUN YAT SEN UNIV

Silicon-based solar cell, preparation method and photovoltaic module

PendingCN109494261AImprove performanceHigh voltageFinal product manufacturePhotovoltaic energy generationDangling bondP type silicon

The invention discloses a silicon-based solar cell, a preparation method and a photovoltaic module, which belong to the technical field of solar cells. The silicon-based solar cell comprises a P-typecrystalline silicon substrate, a back tunneling passivation layer arranged on the back of the P-type crystalline silicon substrate, a group III element doped back doped silicon layer arranged on a partial region of the back tunneling passivation layer, a gallium oxide layer, a coating layer arranged on the gallium oxide layer, and a back electrode arranged on the coating layer. The gallium oxide layer is arranged on the back doped silicon layer and a region without the back doped silicon layer on the back tunneling passivation layer. In the solar cell, the P-type silicon surface is chemicallypassivated and field-passivated by negative charges carried by the gallium oxide layer. The number of dangling bonds and minority carriers of silicon atoms on the P-type silicon surface is reduced. The recombination rate of minority carriers is reduced. The voltage and current of the solar cell are improved. The photoelectric conversion efficiency of the solar cell is improved.

Owner:JA SOLAR TECH YANGZHOU

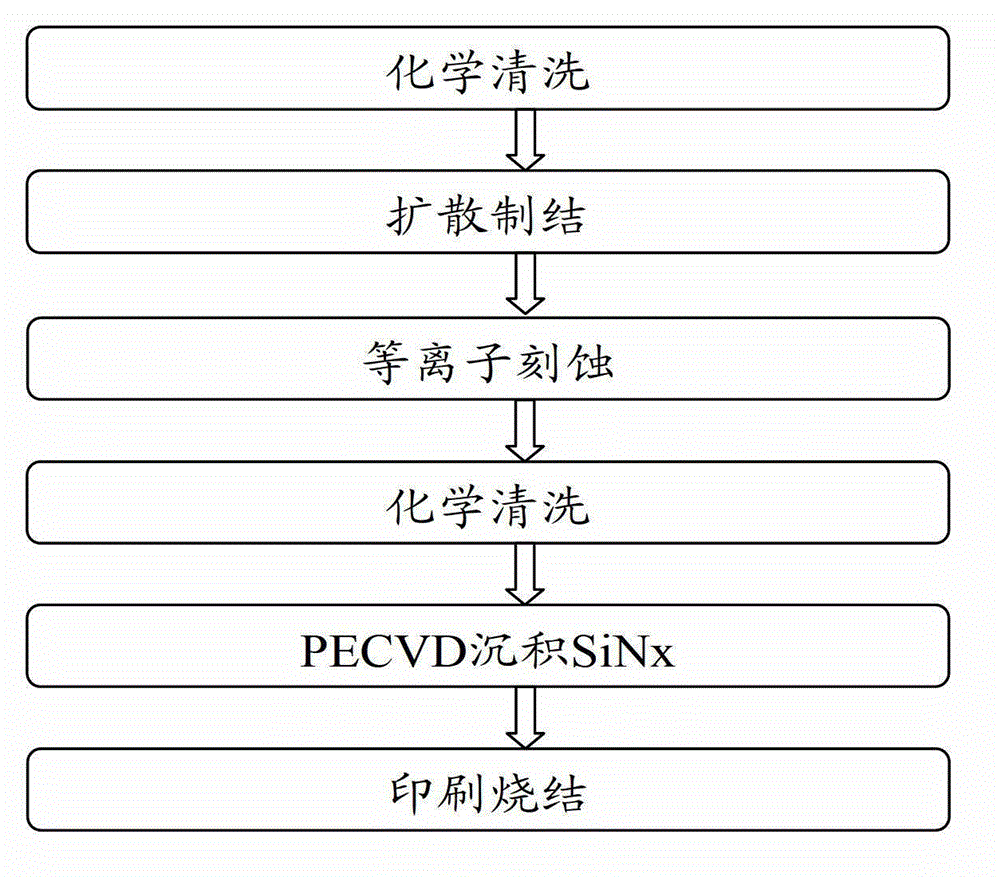

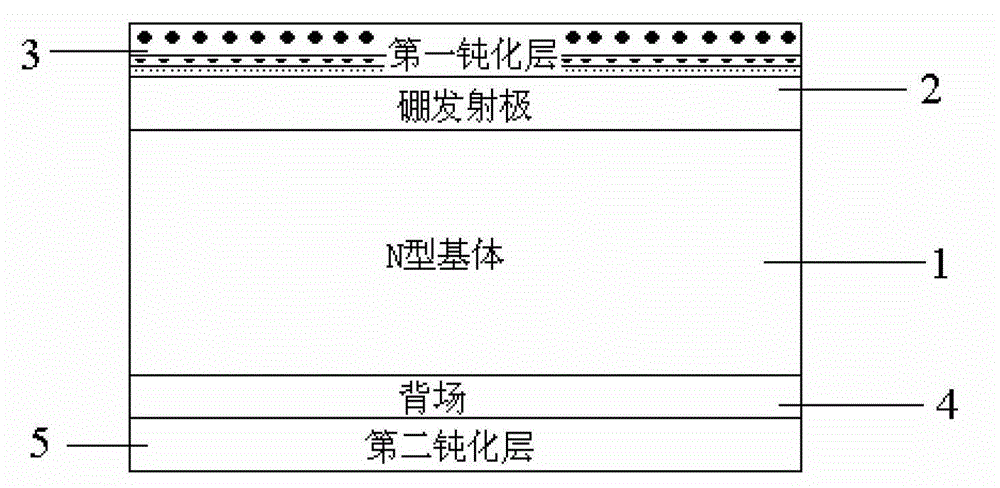

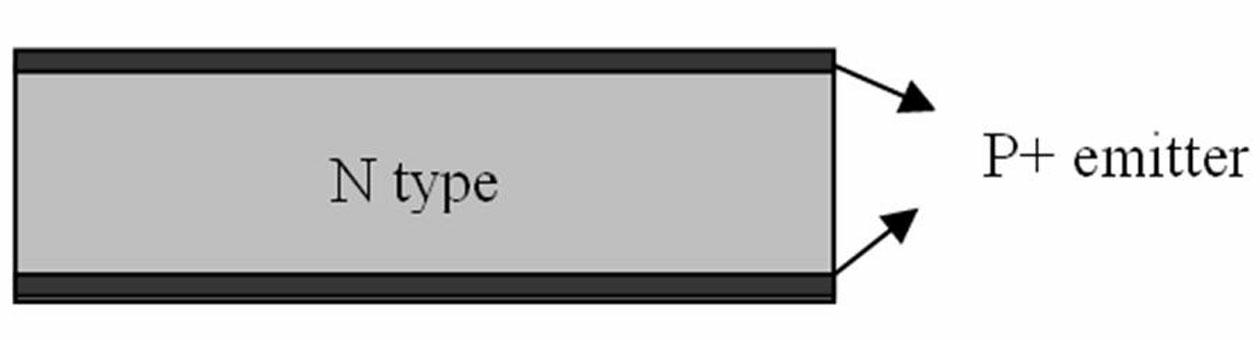

N type crystalline silicon solar battery and manufacturing method thereof

ActiveCN102751337AGood field effect passivationImprove passivation effectPhotovoltaic energy generationSemiconductor devicesCharge carrierCompound (substance)

The invention provides an N type crystalline silicon solar battery and a manufacturing method thereof. The N type crystalline silicon solar battery comprises an N type substrate, a boron emitting electrode and a first passivating layer, wherein the boron emitting electrode is arranged on the front surface of the N type substrate, one surface of the boron emitting electrode, which is far away from the N type substrate, is provided with the first passivating layer, and the first passivating layer is provided with a silicon oxide film, an aluminum oxide film and a silicon nitride film which are arranged from inside to outside. According to the N type crystalline silicon solar battery, the aluminum oxide film on the surface of the boron emitting electrode forms a layer of fixed negative charges at the position of an interface, a few charge carriers which are spread on the surface can be reflected back, the surface recombination rate of photo-generated carriers is reduced, a good field effect pasivating effect is provided, besides, during a sintering process, hydrogen which is enriched in the silicon nitride film can be spread to the position of a SiO2 / Si interface, dangling bonds at the position of the interface are passivated, a good chemical passivating effect is provided, thereby when the silicon nitride film, the aluminum oxide film and the silicon oxide film are utilized to passivate the boron emitting electrode,the field effect passivation and the chemical passivation are provided simultaneously.

Owner:YINGLI ENERGY CHINA

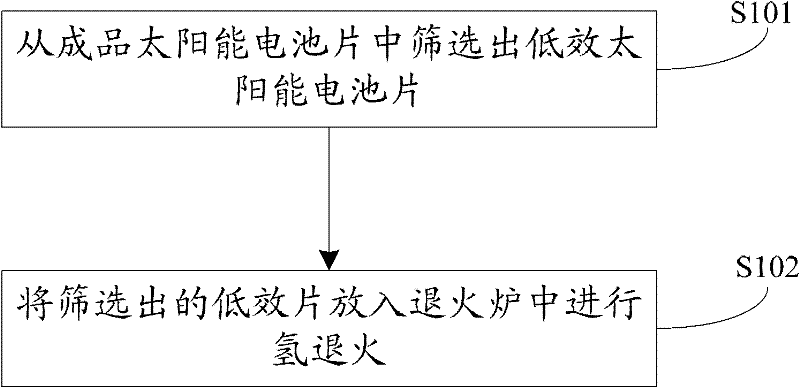

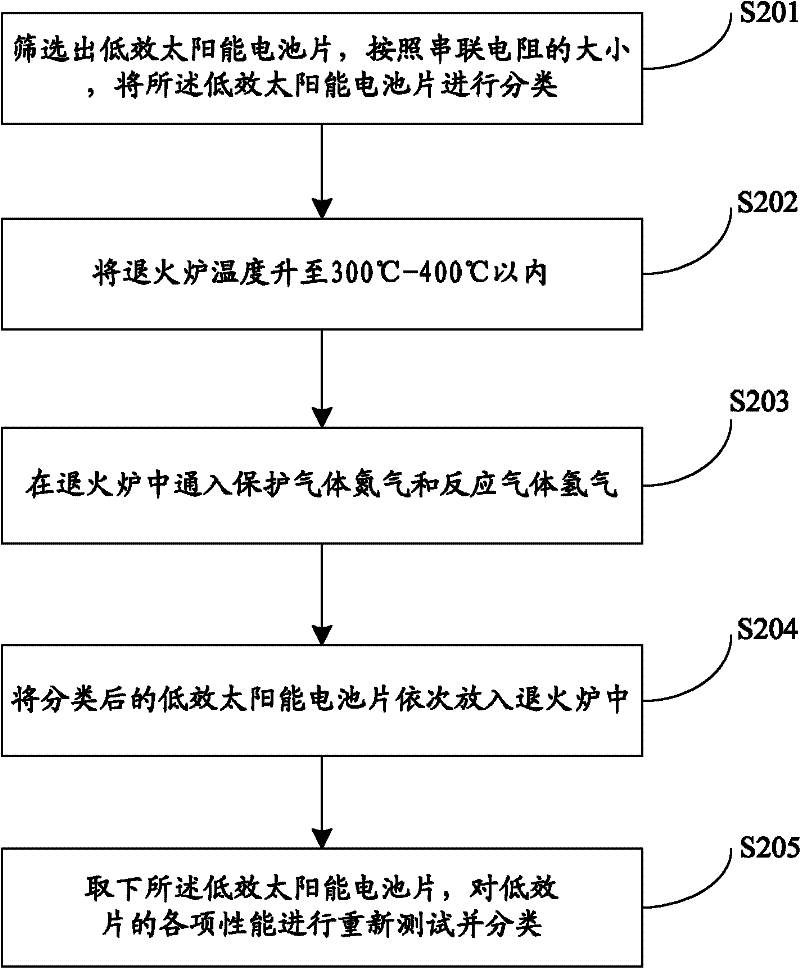

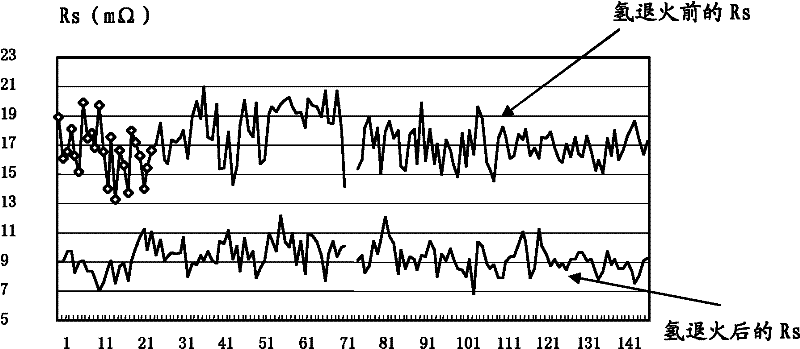

A processing method of inefficient solar cell sheets

InactiveCN102185008AReduce the series resistance RsImprove conductivityFinal product manufactureSemiconductor devicesSolar cellMetal electrodes

The invention discloses a processing method of inefficient solar cell sheets. The processing method comprises the steps of screening out inefficient solar cell sheets from solar cell sheet products, and disposing the inefficient solar cell sheets into an annealing furnace for annealing with hydrogen. In the embodiment of the invention, the inefficient cell sheets are annealed with hydrogen. Since hydrogen can reduce oxide on metal electrodes, the contact resistance between the metal electrodes and silicon is thereby reduced, and accordingly the total series resistance of the inefficient cell sheets is reduced. Moreover, since hydrogen possesses a passivation function, the electroactive impurities are passivated, the recombination rate of carriers on cell surfaces and the lifetime of minority carriers are prolonged. Therefore, the shunt resistance of the cell sheets is improved and the reverse leakage current density is reduced, accordingly the filling factors of the cell sheets are increased and the conversion efficiency is improved.

Owner:JETION SOLAR HLDG

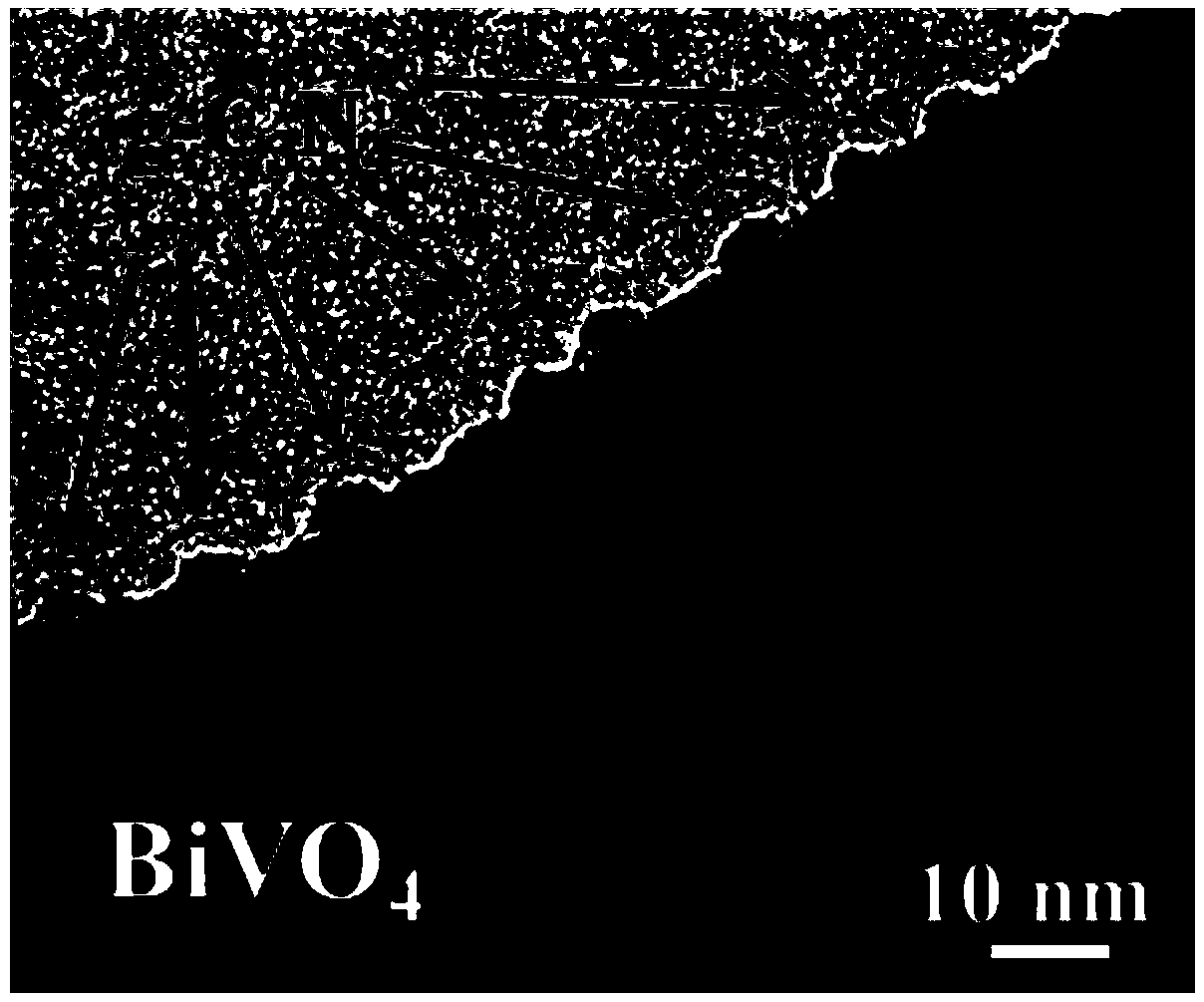

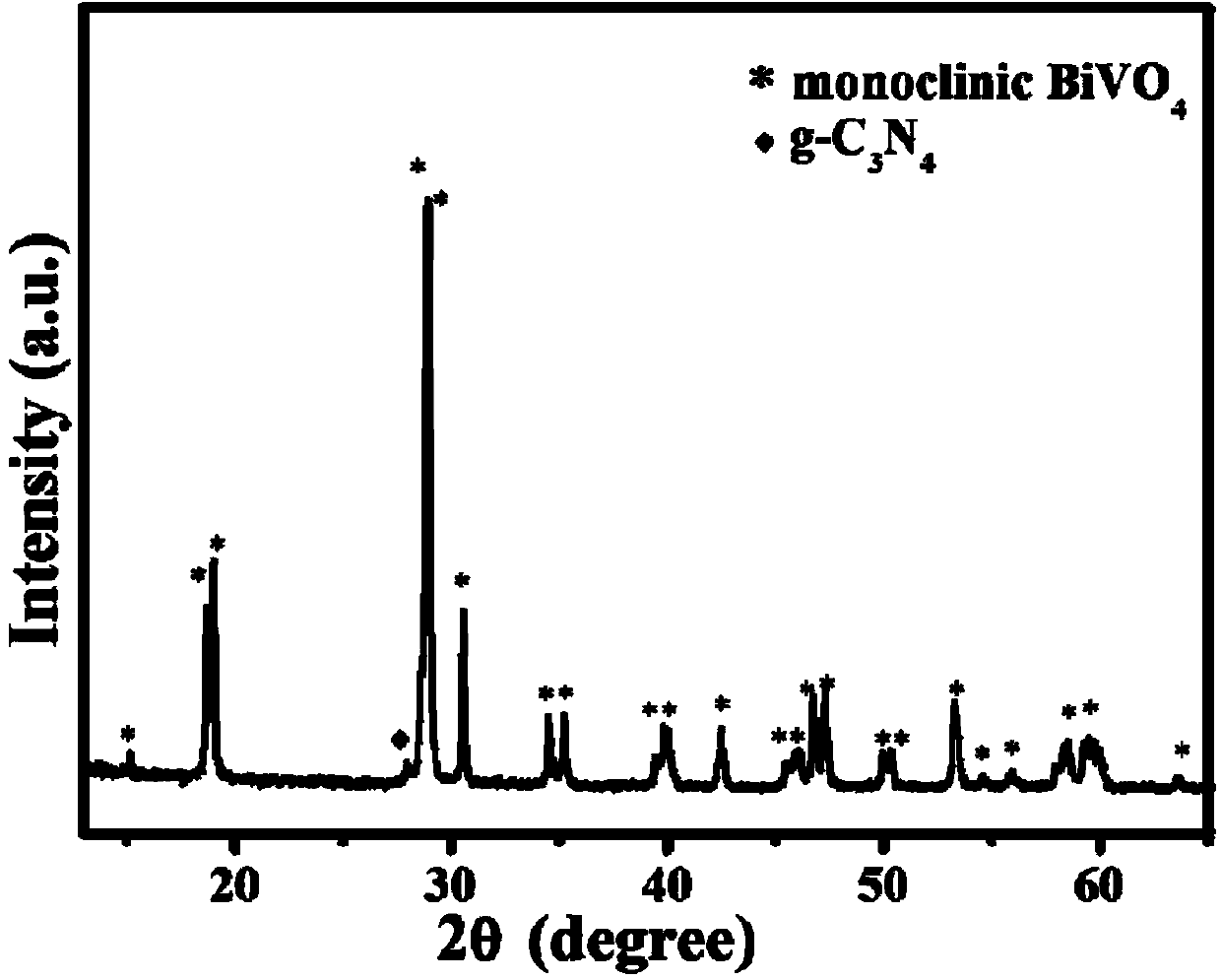

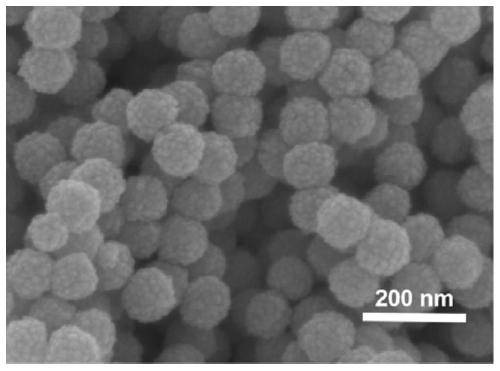

Carbon nitride nano particle modified pucherite composite photocatalyst and preparation method thereof

ActiveCN103990485ALarge specific surface areaSmall sizePhysical/chemical process catalystsWaste minimisationBismuth vanadate

The invention discloses a carbon nitride nano particle modified pucherite composite photocatalyst and a preparation method thereof. Carbon nitride nano particles are dispersedly compounded on the surface of porous pucherite, and the porous pucherite is composed of bent pucherite nanorods; the preparation method comprises the steps of firstly, preparing carbon nitride powder, adding the carbon nitride powder to high-purity water and performing ultrasonic dispersion, adding bismuth nitrate pentahydrate and stirring until the mixture is dissolved completely, adding ammonium metavanadate and continuing to stir, carrying out centrifugal separation, washing and drying to obtain a solid sample, then performing heat treatment, and grinding into powder. According to the carbon nitride nano particle modified pucherite composite photocatalyst, the carbon nitride nano particles are small and are dispersedly compounded on the surface of the porous pucherite, so as to be beneficial to exposure of carbon nitride-pucherite interfaces with high activity and reduction of a charge transferring distance, and therefore, the carbon nitride nano particle modified pucherite composite photocatalyst has wide application prospect in the fields such as environment pollution control and energy; besides, the preparation method of the composite photocatalyst is simple, low in cost and good in repetitiveness, and can well meet the requirement of volume production.

Owner:TIANJIN UNIV

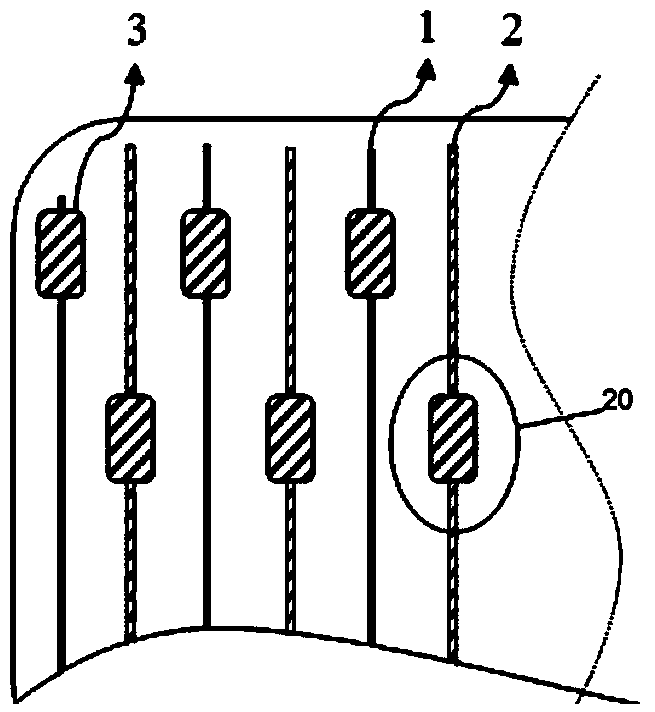

Back-contact back-junction solar battery three-dimension electrode and manufacturing method thereof

InactiveCN103594533AReduce the difficulty of depositionReduced series resistanceFinal product manufacturePhotovoltaic energy generationCharge carrierPrinting ink

The invention discloses a back-contact back-junction solar battery three-dimension electrode and a manufacturing method thereof. The back-contact back-junction solar battery three-dimension electrode comprises a plurality of negative electrode grid lines printed and sintered on n+areas on the back face of a battery, a plurality of positive electrode grid lines which are printed and sintered on p+areas on the back face of the battery and are arrayed with the negative electrode grid lines in a cross finger shape and in a staggered mode, insulating printing ink printed and dried on the positive electrode grid lines and the negative electrode grid lines, and positive main grid electrodes and negative main grid electrodes printed and dried on positive electrode grid lines with insulating printing ink and the negative electrode gird lines with insulating printing ink. The positive main grid electrodes are isolated with the negative electrode grid lines through the insulating printing ink, and the negative main gride electrodes are isolated with the positive electrode grid lines through the insulating printing ink. The back-contact back-junction solar battery three-dimension electrode and the manufacturing method thereof reduce the distance of current carriers transmitted from thin grid electrodes to main grid electrodes, reduce the series resistance of the battery, and reduce electrode sedimenting difficulty and the composite speed rate in positions of the main gride electrodes.

Owner:HEFEI HAREON SOLAR TECH

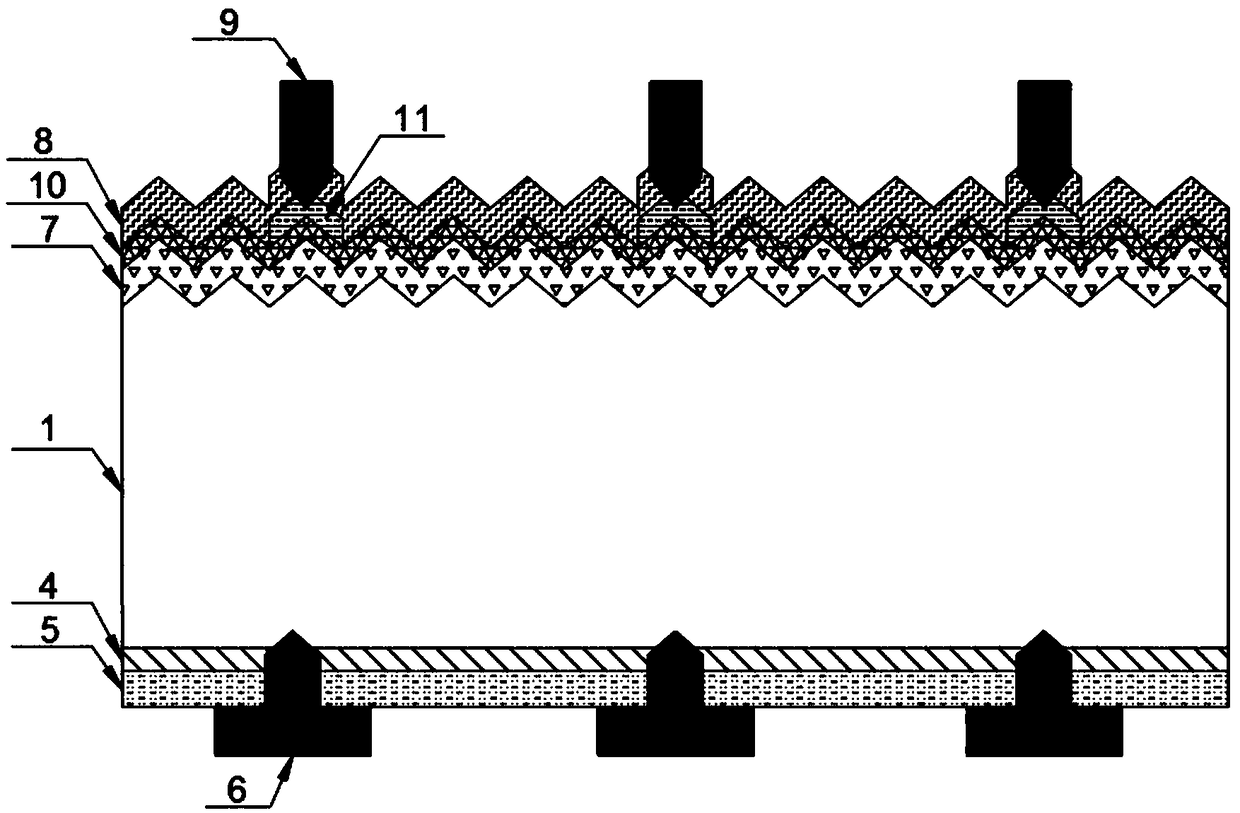

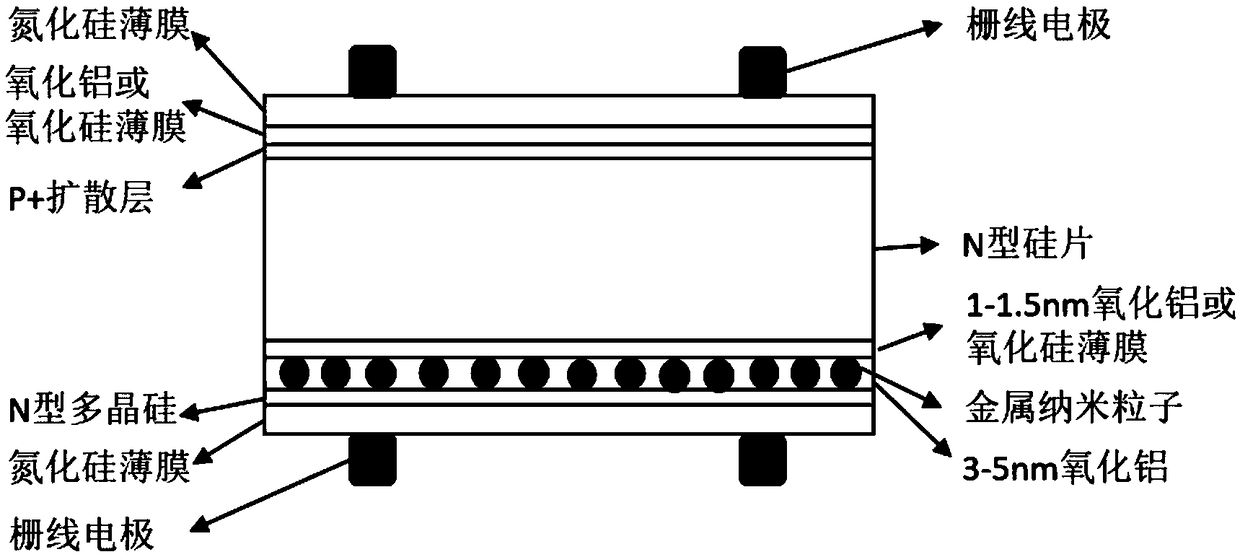

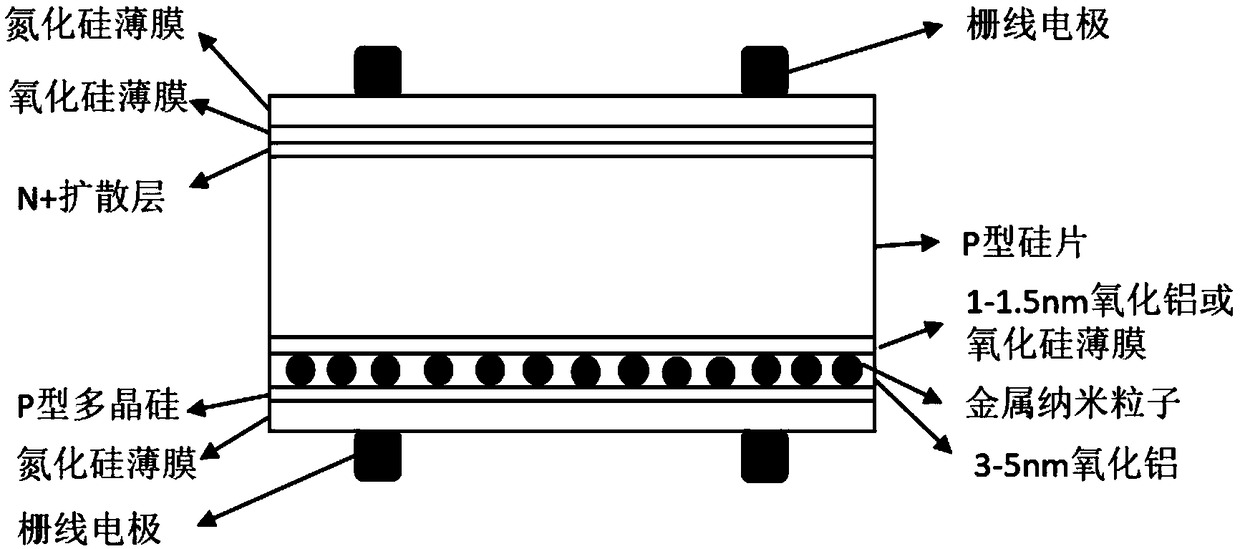

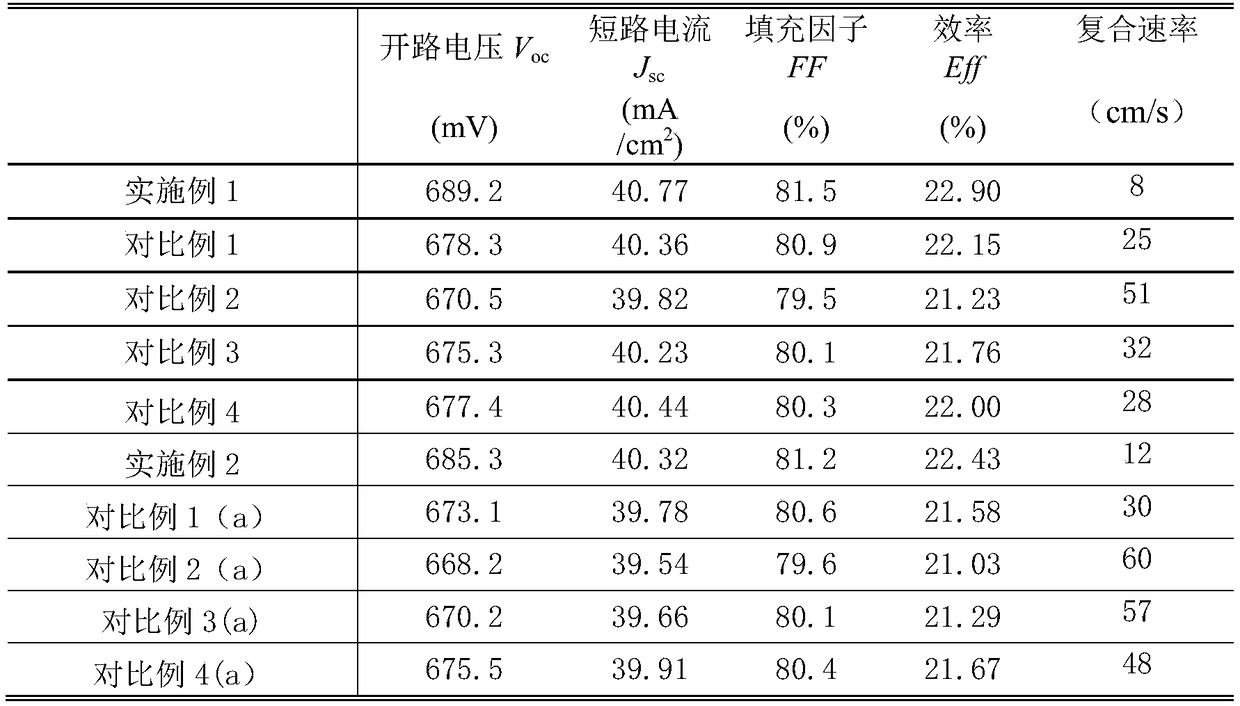

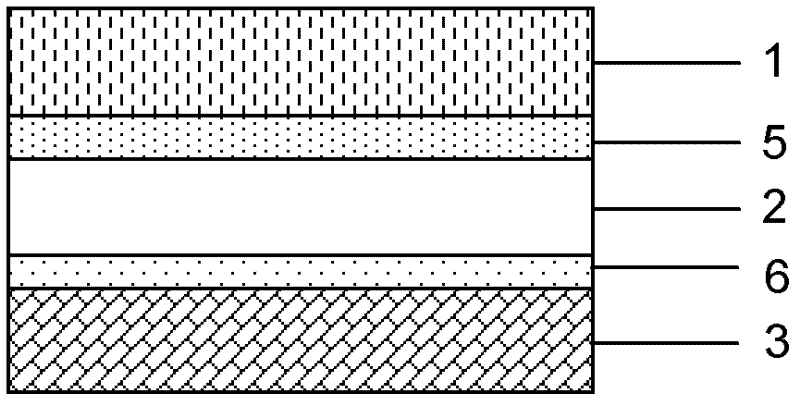

Contact-passivation crystalline silicon solar cell structure and preparation method

ActiveCN109346536AEvenly distributedImprove passivation effectFinal product manufacturePhotovoltaic energy generationElectrical batterySilicon solar cell

The invention discloses a contact-passivation crystalline silicon solar cell structure and a preparation method thereof and belongs to the technical field of a solar cell. An N-type silicon wafer or aP-type silicon wafer is used as a substrate of the solar cell; a structure of an illuminated surface of the N-type silicon wafer substrate sequentially includes a P+ diffusion layer, a silicon oxideor aluminum oxide, silicon nitride film and a grid line electrode from bottom to top; a structure of a back surface of the N-type silicon wafer substrate sequentially includes silicon oxide or aluminum oxide, an metal nanoparticle coated aluminum oxide film, an N-type polycrystalline silicon, the silicon nitride film and the grid line electrode from top to bottom; a structure of an illuminated surface of the P-type silicon wafer substrate sequentially includes an N+ diffusion layer, the silicon oxide film, the silicon nitride film and the grid line electrode from bottom to top; a structure ofa back surface of the P-type silicon wafer substrate sequentially includes silicon oxide or aluminum oxide, the metal nanoparticle coated aluminum oxide film, a P-type polycrystalline silicon, the silicon nitride film and the grid line electrode from top to bottom; the mutual synergistic effect exists between stacked layers; and the obtained solar cell is capable of remarkably improving the cellefficiency.

Owner:CHANGZHOU UNIV +1

N-type crystalline silicon solar cell and preparation method thereof, and photovoltaic module

PendingCN109065639AWide band gapSuitable Optical Refractive IndexFinal product manufacturePhotovoltaic energy generationPrice ratioP type silicon

The invention discloses an N-type crystalline silicon solar cell and a preparation method thereof, a photovoltaic module, belonging to the technical field of solar cells. The N-type crystalline silicon solar cell comprises a front electrode, a front passivation layer, an emitter, an N-type crystalline silicon substrate, a back passivation layer and a back electrode, wherein the front passivation layer comprises a gallium oxide layer in direct contact with the emitter. In this solar cell, the P-type silicon surface of the emitter of the N-type crystalline silicon solar cell is chemically passivated and field passivated by the negative charge carried by the gallium oxide layer, reducing the minority carrier recombination rate at the P-type silicon surface, Furthermore, the gallium oxide layer is utilized to reduce the absorption of incident light and improve the photocurrent density of the solar cell, thereby increasing the voltage and current of the solar cell, improving the photoelectric conversion efficiency of the solar cell, further increasing the output power of the photovoltaic module, reducing the power cost and improving the performance-price ratio of the photovoltaic powergeneration.

Owner:JA SOLAR TECH YANGZHOU

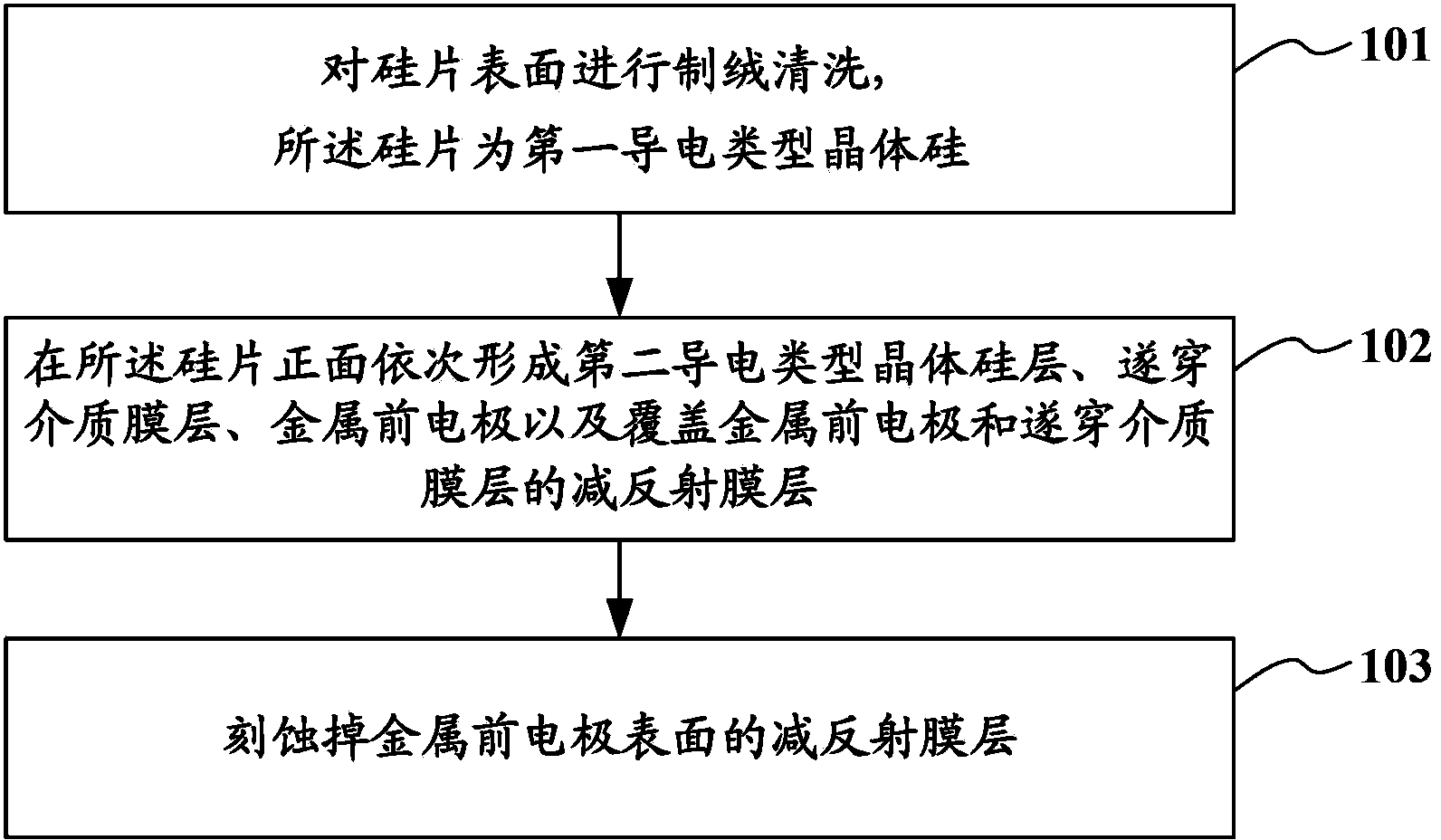

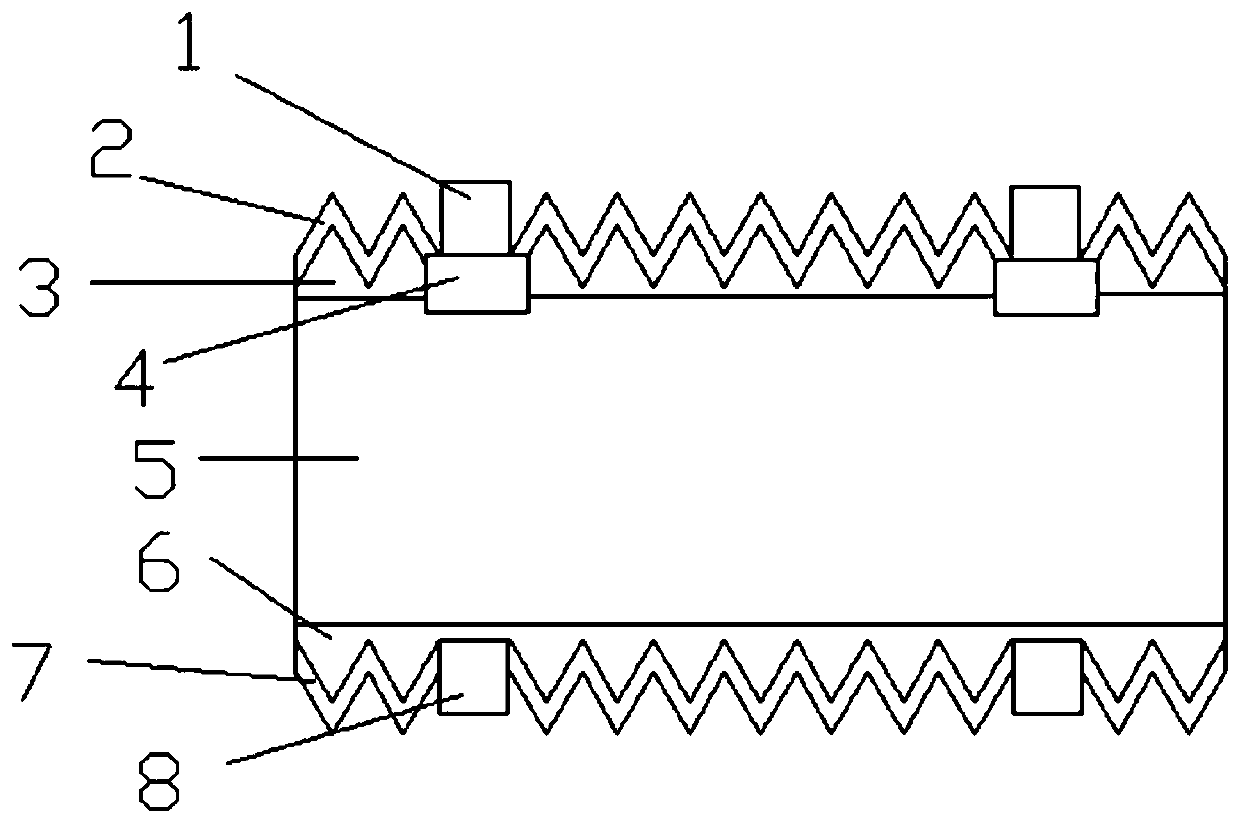

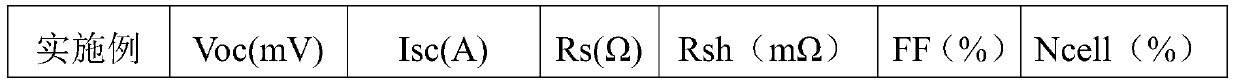

Crystalline silicon solar cell and preparation method thereof

ActiveCN103413838AReduce compound rateLow densityFinal product manufacturePhotovoltaic energy generationCrystalline siliconMetal

The invention relates to the field of the solar photovoltaic technology, and discloses a crystalline silicon solar cell and a preparation method of the crystalline silicon solar cell. The crystalline silicon solar cell comprises a first conduction type crystalline silicon layer, a second conduction type crystalline silicon layer covering the front surface of the first conduction type crystalline silicon layer, a tunneling medium film layer covering the second conduction type crystalline silicon layer, at least one metal front electrode and an antireflection film, wherein the metal front electrode and the antireflection film are located on the tunneling medium film layer, and the thickness of the tunneling medium film layer is 0.1-10 nm. According to the technical scheme, the tunneling medium film layer can not only carry out passivation on the front surface of the first conduction type crystalline silicon layer, but also transmit carriers, thereby lowering the density of dark saturation currents and improving the performance of the solar cell.

Owner:ENN SOLAR ENERGY

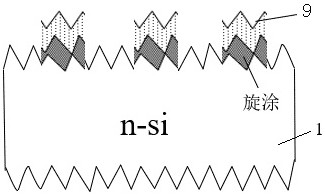

Method for manufacturing N-type selective emitter double-sided battery by spin-coating boron source laser doping

InactiveCN109742172AReduce contact resistanceReduce compound rateFinal product manufacturePhotovoltaic energy generationElectricityElectrical resistance and conductance

The invention relates to a method for manufacturing an N-type selective emitter double-sided battery by spin-coating boron source laser doping. The method comprises the following steps: texturing an N-type silicon wafer; adopting a spin-coating method for spin-coating the front surface of an organic boron source and then drying the organic boron source; carrying out diffusion in a diffusion furnace to form a front lightly doped emitter; carrying out front BSG laser doping to form a heavily doped emitter; cleaning the back surface to remove PSG; carrying out back phosphorus diffusion to form aphosphorus back field; carrying out front and back deposition on an anti-reflective passivation film; and printing front and back electrodes to complete the battery production. Compared with the priorart, the boron source is coated on the front surface of the silicon wafer by adopting the spin coating method, and selective laser doping is carried out by using the BSG formed on the front side after diffusion, so that a region below an electrode is heavily doped with boron, thus the contact resistance is effectively reduced; and a non-electrode region adopts lightly doped boron to reduce the composite of the front surface, so that the electrical performance of the battery is effectively improved.

Owner:EAST CHINA UNIV OF SCI & TECH +1

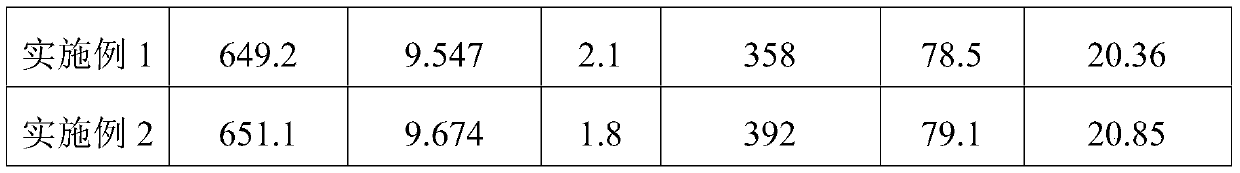

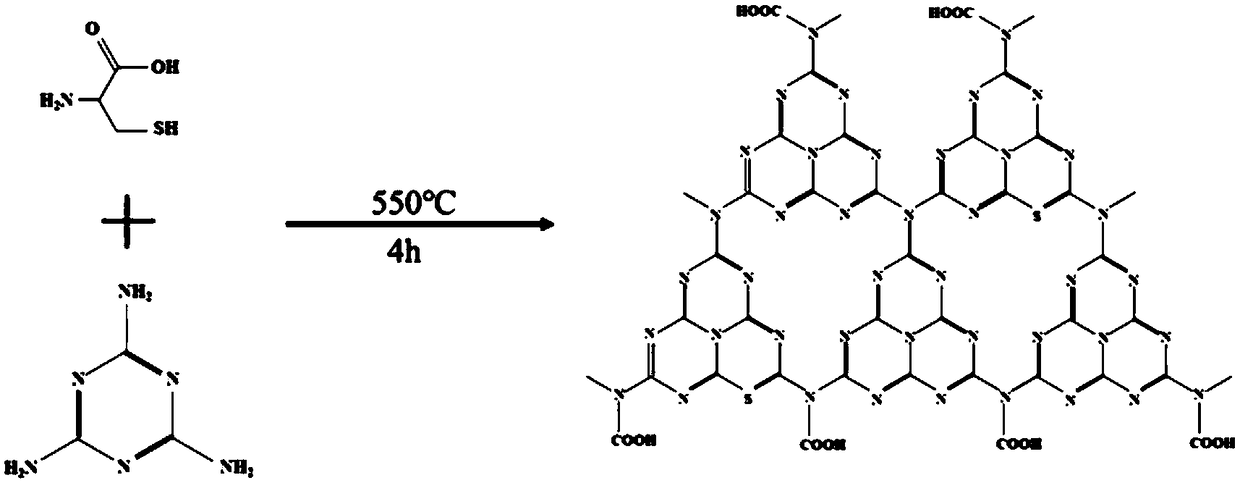

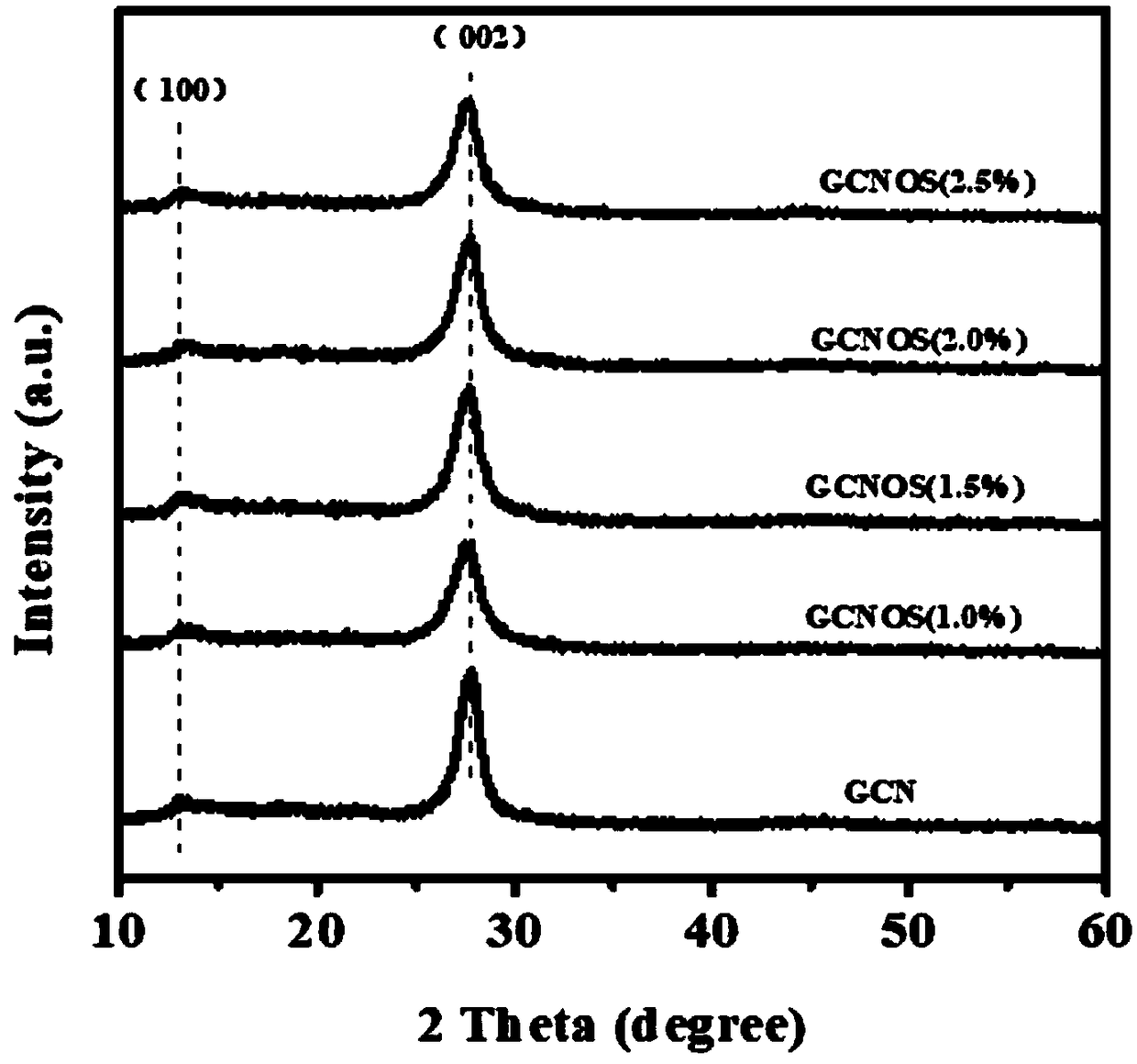

Preparation method of oxygen-sulfur dual-doped graphite phase carbon nitride

InactiveCN108786878AReduced band gapLower impedancePhysical/chemical process catalystsColor/spectral properties measurementsCysteine thiolateSulfur

The invention discloses a preparation method of oxygen-sulfur dual-doped graphite phase carbon nitride. The method comprises the following steps: performing one-step thermal polymerization on melamineand L-cysteine at a temperature of 400-700 DEG C according to a mass ratio (1.5-2.5):100 of the L-cysteine to melamine, thereby obtaining the oxygen-sulfur dual-doped graphite phase carbon nitride. According to dual doping in the invention, the element O and the element S respectively enter the graphite phase carbon nitride in a chemical bond form. The energy gap of the doped graphite phase carbon nitride is reduced, the impedance is reduced, the graphite phase carbon nitride has high photocatalytic activity, and the photocatalytic nitrogen fixation efficiency of 2.0% of GCNOS reaches 0.509 mMg<-1>h<-1> within 240 minutes, and reaches 2.1 times that of the photocatalytic nitrogen fixation efficiency of pure graphite phase carbon nitride.

Owner:NANJING UNIV OF SCI & TECH

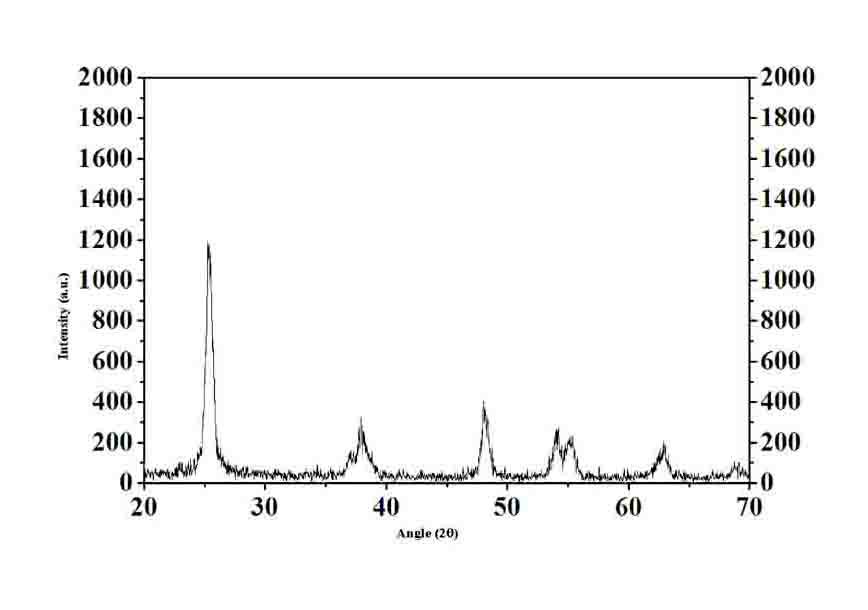

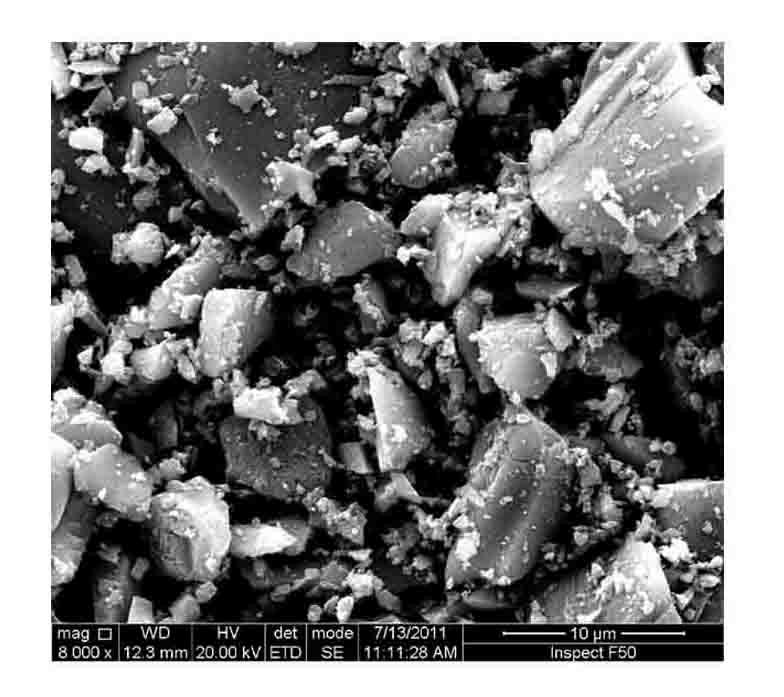

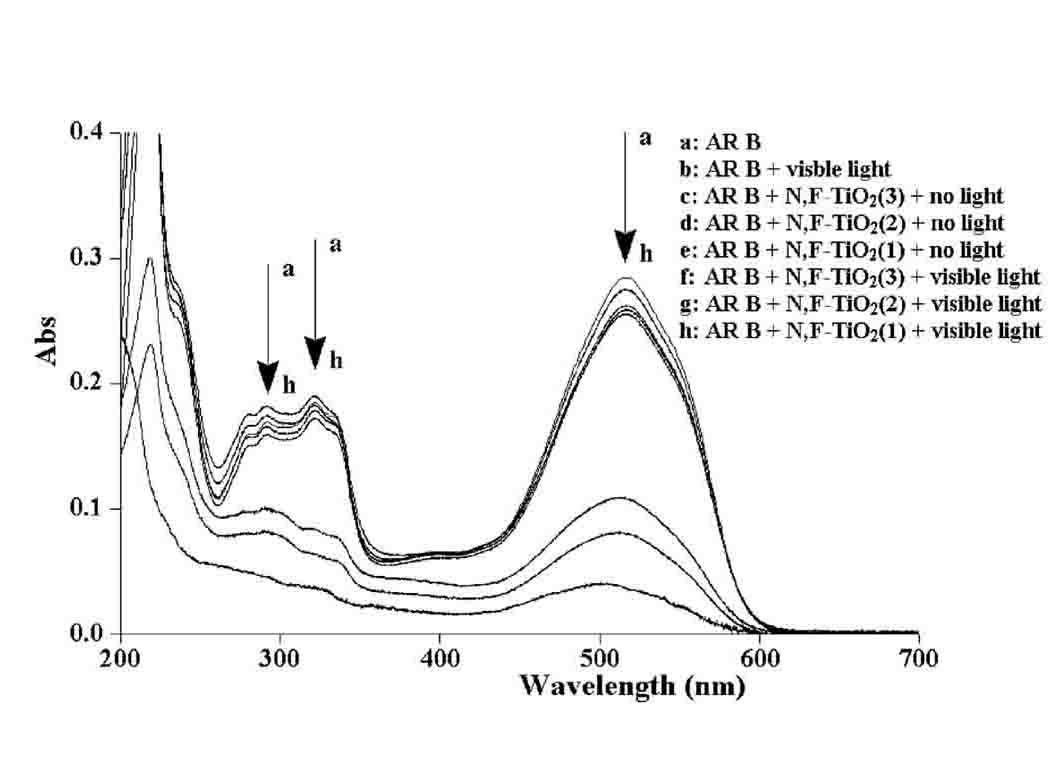

Nitrogen/fluorine-doped titanium dioxide photocatalyst and application thereof in degrading organic pollutants under visible light

ActiveCN102350369AGood photocatalytic performanceImprove photocatalytic performancePhysical/chemical process catalystsWater/sewage treatment by irradiationMuffle furnacePhoto catalysis

The invention relates to a nitrogen / fluorine-doped titanium dioxide photocatalyst and application thereof in degrading organic pollutants under visible light. The technical scheme is as follows: the preparation method comprises the following steps: while evenly stirring, slowly and dropwisely adding tetrabutyl titanate into an ethanol-glacial acetic acid mixed solution, dropwisely adding a hydrofluoric acid solution, and stirring to form a transparent mixed solution A; mixing ammonia water and ethanol, and regulating the pH value to 2 to obtain a solution B; slowly and dropwisely adding the solution B into the solution A to obtain a uniform and transparent sol; aging the uniform and transparent collosol in air to obtain a solid gel; and drying, grinding into powder, and roasting in a muffle furnace at 400-500 DEG C for 40 minutes to 1.5 hours, thereby obtaining the nitrogen / fluorine-doped titanium dioxide photocatalyst. The invention widens the visible light response range of TiO2, and reduces the combination of electrons and holes, thereby increasing the utilization ratio of TiO2 for solar power and enhancing the photocatalytic activity.

Owner:LIAONING UNIVERSITY

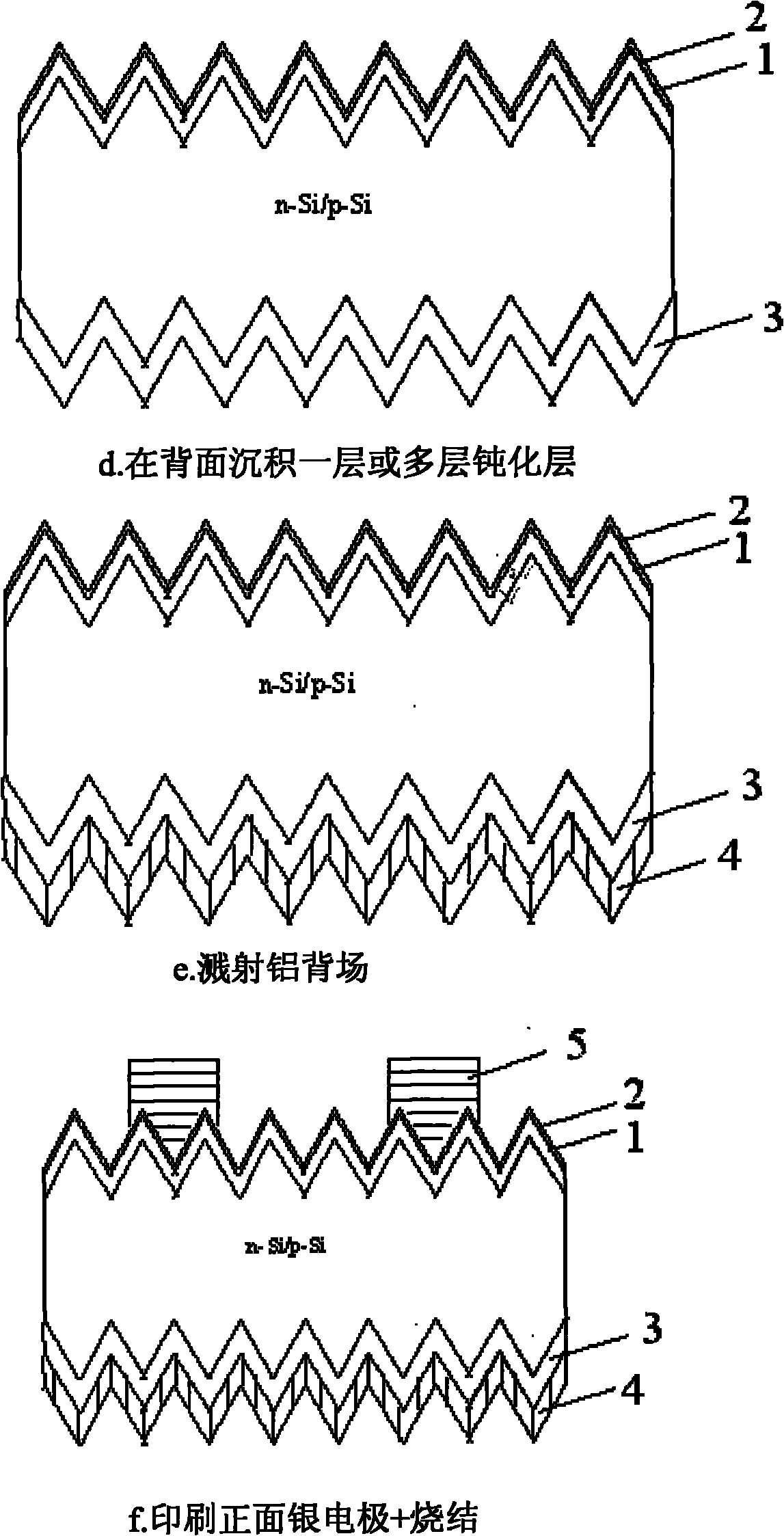

Low-cost n-type dual-side solar battery and preparation method thereof

ActiveCN103077975AReduce compound rateSimple manufacturing processFinal product manufactureSemiconductor devicesManufacturing cost reductionBack surface field

The invention discloses a low-cost n-type dual-side solar battery. The front surface of the solar battery is provided with a boron emitter formed by diffusing boron; a passivation layer and an antireflection layer are deposited on the boron emitter; a back electrode contact position on the back surface of the solar battery is a local phosphorus back surface field, and the rest is a non-doped area; a passivation layer is deposited on the non-doped area; the front surface of the non-doped area is provided with a metal front electrode; and the back surface of the non-doped area is provided with a metal back electrode. The invention further discloses a preparation method of the low-cost n-type dual-side solar battery. Compared with the prior art, the low-cost n-type dual-side solar battery has the beneficial effects that a local n<+>-doped area is formed by using a laser-doped phosphorus-containing film or a coated phosphorus source; and meanwhile, a passivation effect is kept, a front surface field and a back surface field can be formed simultaneously without secondary high-temperature phosphorus diffusion or other masking processes, the manufacturing process of the dual-size n-type solar battery is simplified, and the manufacturing cost is lowered.

Owner:江苏润阳光伏科技有限公司

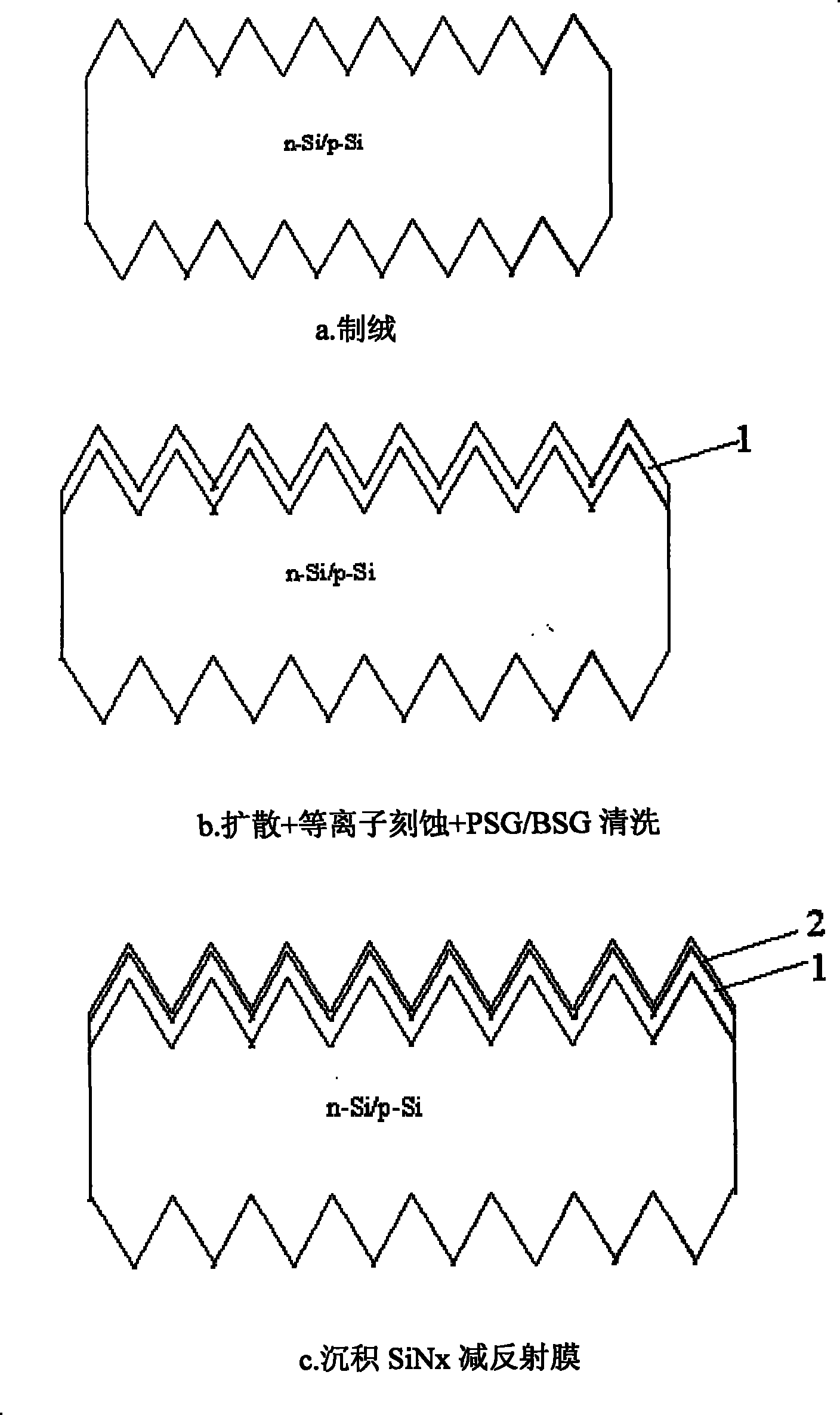

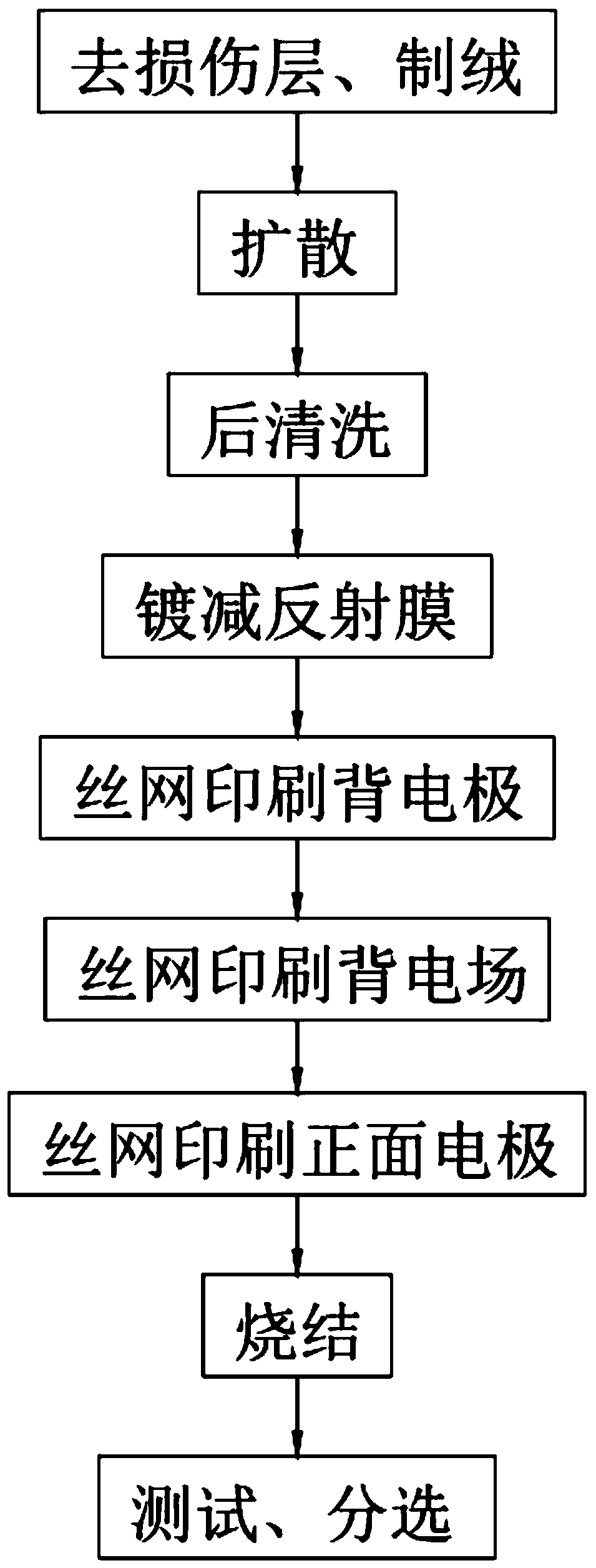

Fabrication method for crystalline silicon solar cell

InactiveCN102332495ASimple processReduce manufacturing costFinal product manufactureSemiconductor devicesEtchingBoron nitride

The invention discloses a fabrication method for a crystalline silicon solar cell. A phosphorous silicon nitride film is deposited on one surface of a P-type crystalline silicon wafer or an N-type crystalline silicon wafer after cleaning and etching, a boron nitride film or a boracic silicon nitride film is deposited on the other surface, the crystalline silicon wafer with deposited films is then annealed under high temperature, so that the elements of phosphorus and boron in the films can be diffused into the crystalline silicon wafer, consequently, the P-type crystalline silicon wafer is formed into a N plus PP plus structure, the N-type crystalline silicon wafer is formed into a P plus NN plus structure, afterwards, metal electrodes are fabricated, and the fabrication of the cell is fulfilled. Compared with the conventional fabrication method, the fabrication method integrates the high-temperature diffusion doping process for forming the PN junction and the preparation process of an antireflection film together, avoids the edge junction etching process, and reduces the usage of phosphorus source and boron source, thus greatly simplifying the process flow and reducing the fabrication cost, and the fabrication method has a broad application prospect in the technical field of solar cell fabrication.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

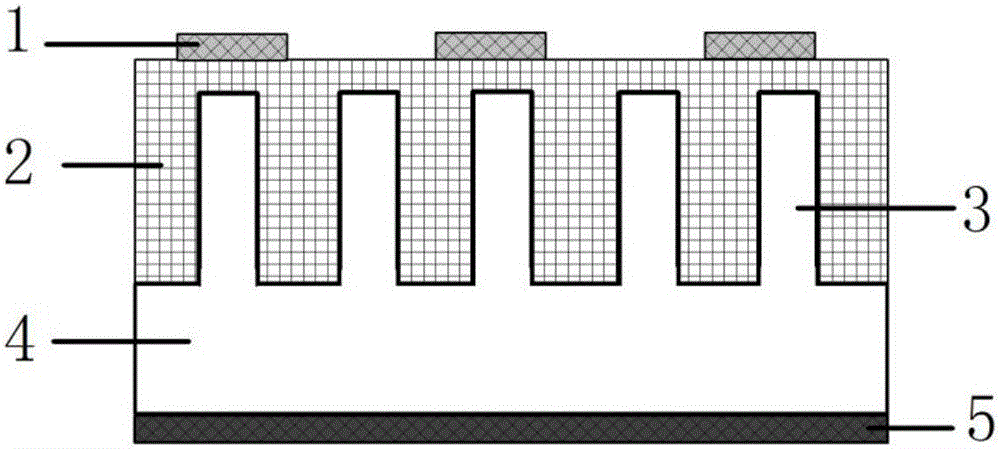

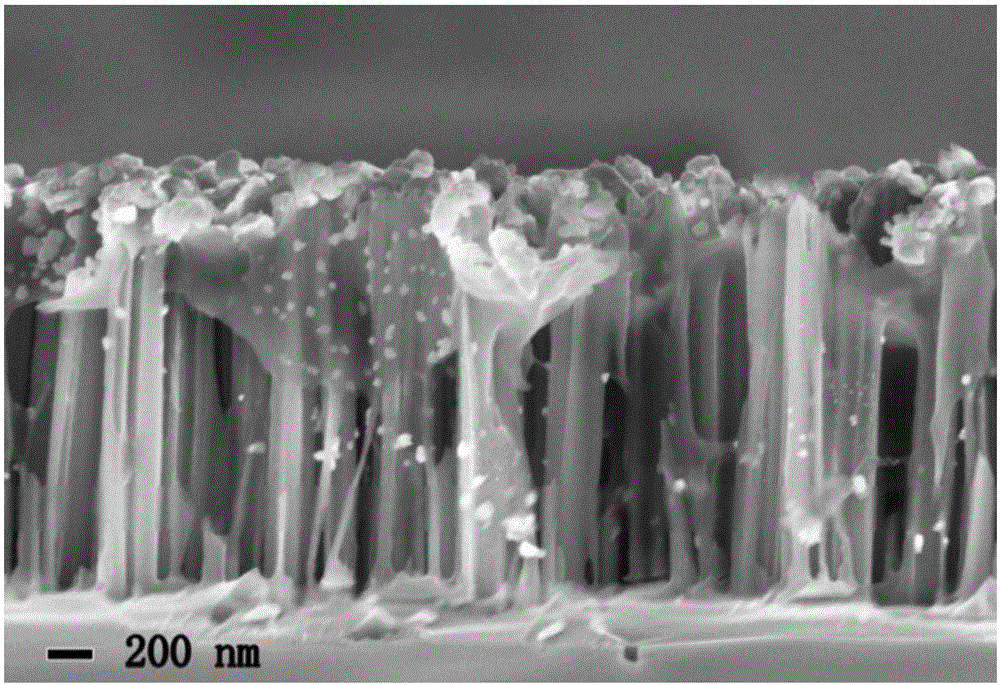

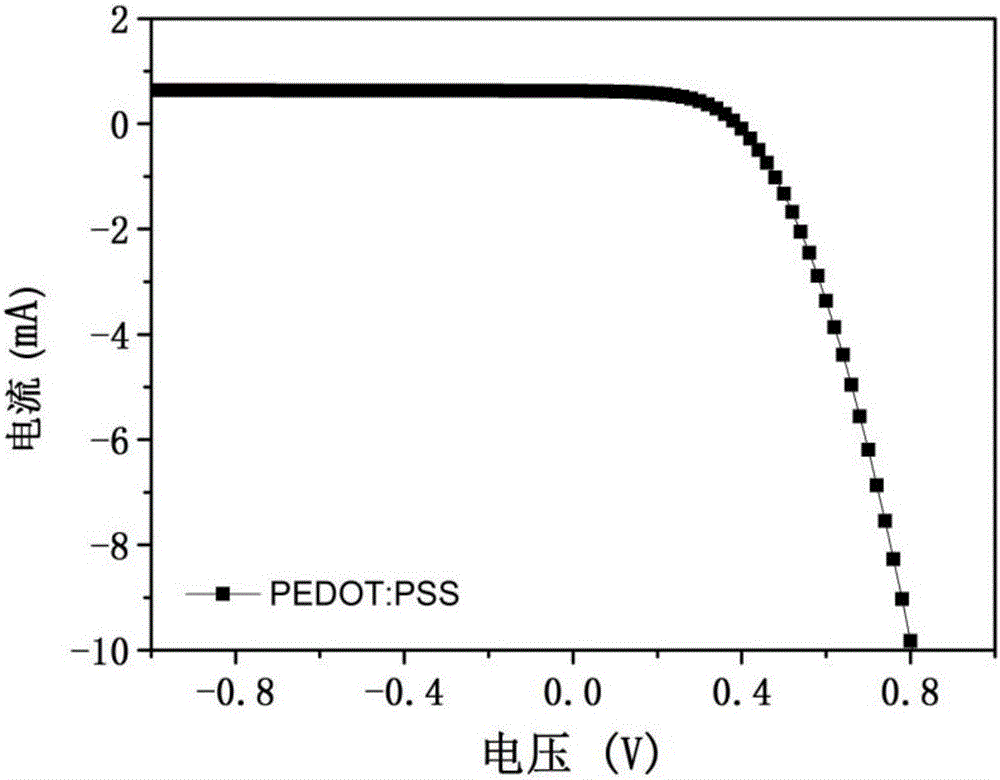

Self-driven wide-spectral-response silicon-based hybrid heterojunction photoelectric sensor and preparation method therefor

ActiveCN105720197AReduce usageReduce manufacturing costFinal product manufactureSolid-state devicesHeterojunctionMicro nano

The invention discloses a self-driven wide-spectral-response silicon-based hybrid heterojunction photoelectric sensor and a preparation method therefor. The photoelectric sensor comprises a metal back electrode, an N type silicon substrate, an N type silicon nanowire array, an organic polymer semiconductor thin film and a sensor positive electrode, wherein the hybrid photoelectric sensor is characterized in that the N type silicon nanowire array and the organic polymer semiconductor thin film form three-dimensional heterojunction contact, so that the transmission path of photo-generated carriers is effectively shortened; the separation efficiency is improved; a surface / interface composite effect is reduced through interface alkylation processing; the silicon-based micro-nano structure is taken as the main light absorption layer and the generation and transmission layers for the photo-generated carriers as well; and a P type organic semiconductor thin film is processed to be used as a hole transport layer. The photoelectric sensor provided by the invention has the characteristics of self powering, wide spectral response, low cost large-area preparation, high photoelectric response speed and the like.

Owner:JINAN UNIVERSITY

Method for preparing point contact electrode at back of solar cell by utilizing laser induced thermit reaction

InactiveCN101546790AAvoid damageReduce compound rateFinal product manufactureSemiconductor devicesBack surface fieldMaterials science

The invention discloses a method for preparing a point contact electrode at the back of a solar cell by utilizing laser induced thermit reaction, which comprises the following steps in sequence: plating a passivation media layer on the back of a silicon substrate; steam-plating an aluminum layer on the passivation media layer; printing or coating thermite on the aluminum layer; and igniting the thermite by the radiation of laser to result in the thermit reaction for generating high temperature so that the aluminum layer and the silicon substrate are molten and then are crystallized and form better ohmic contact and aluminum back surface field. The invention adopts laser to indirectly sinter an electrode, i.e. the laser is used to induce spontaneous reaction of the thermite, high temperature generated by the reaction make aluminum and the silicon from better ohm contact, therefore, the prepared solar cell has smaller series resistance; meanwhile, the aluminum and the silico forms the aluminum back surface field, and the prepared solar cell has bigger short circuit current. By adopting the method of the invention, the laser does not directly radiate a metallic film, which reduces the damage to the silicon to be lowest and further improves the short circuit current of the solar cell.

Owner:SUN YAT SEN UNIV

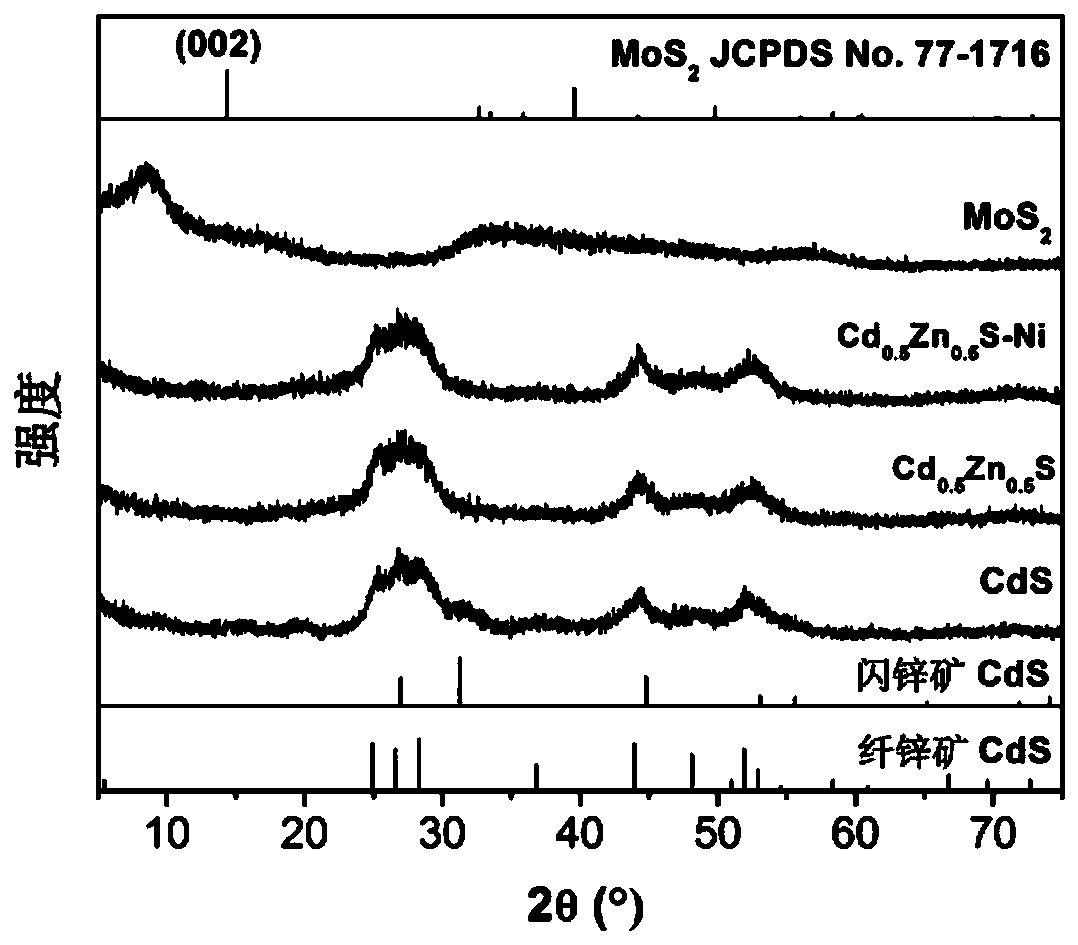

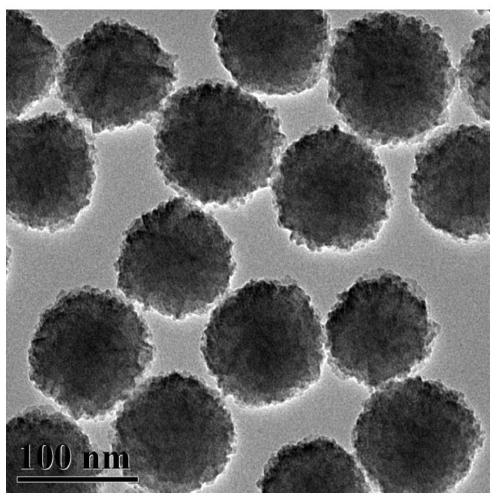

Cd<1-x>Zn<x>S-Ni/MoS<2> composite photocatalyst, and preparation method and application thereof

InactiveCN110227500AIncrease the number ofImprove photocatalytic activityMaterial nanotechnologyCatalyst activation/preparationWater bathsCrystallinity

The invention relates to a Cd<1-x>Zn<x>S-Ni / MoS<2> composite photocatalyst, and a preparation method and application thereof, belonging to the field of inorganic nanomaterials. MoS<2> nanosheets in the composite have low crystallinity and are capable of exposing a large number of hydrogen-producing active sites. The doping of Zn and Ni significantly increases the redox ability of the photogenerated charges of CdS and promotes the separation of the photogenerated charges. Assembled nanospheres with uniform size have good resistance to light corrosion and aggregation. The combination of an ultrasonic water bath method and electrostatic adsorption assembling used for synthesis of the material is simple and controllable; and the composite prepared by using the method can realize high-efficiency photocatalytic decomposition of water for hydrogen production under visible light without loading of precious metals, so energy consumption and cost are greatly reduced. The prepared composite has acatalytic hydrogen production rate of up to 112 mmol / h / g.

Owner:QINGDAO UNIV OF SCI & TECH

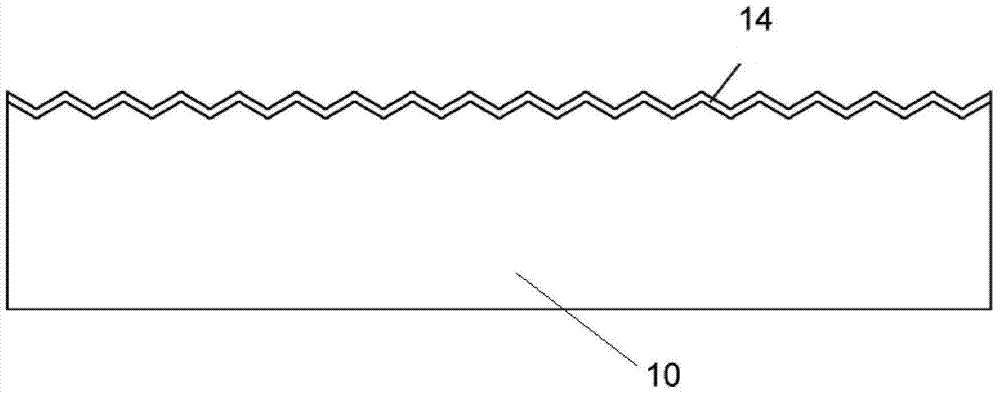

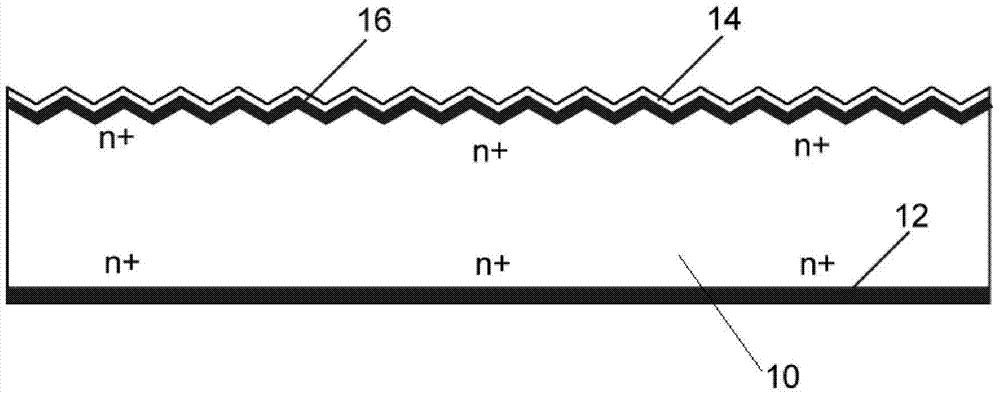

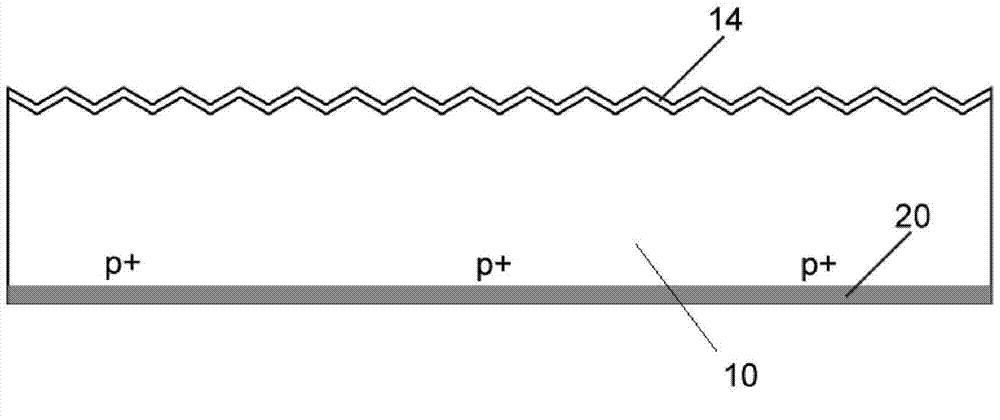

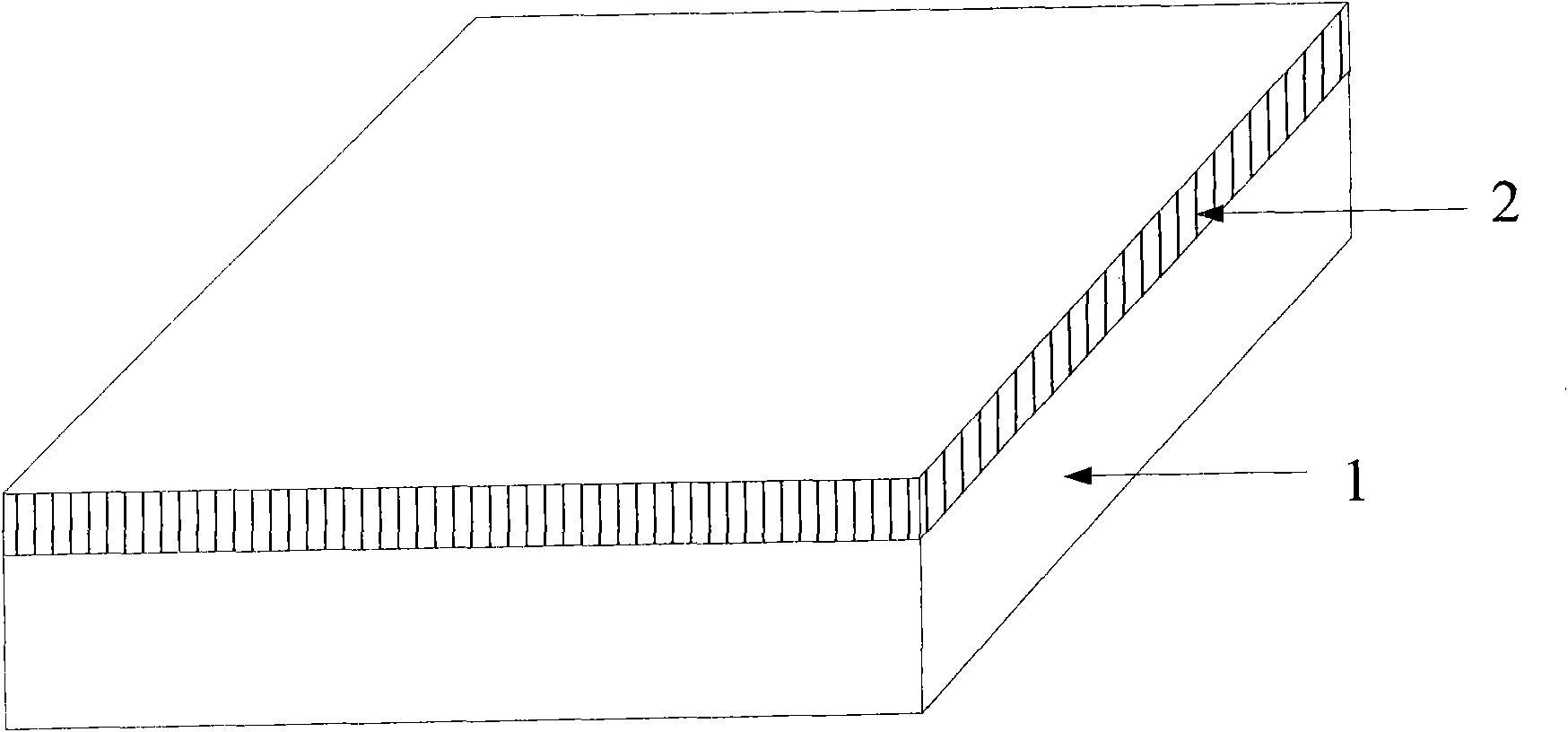

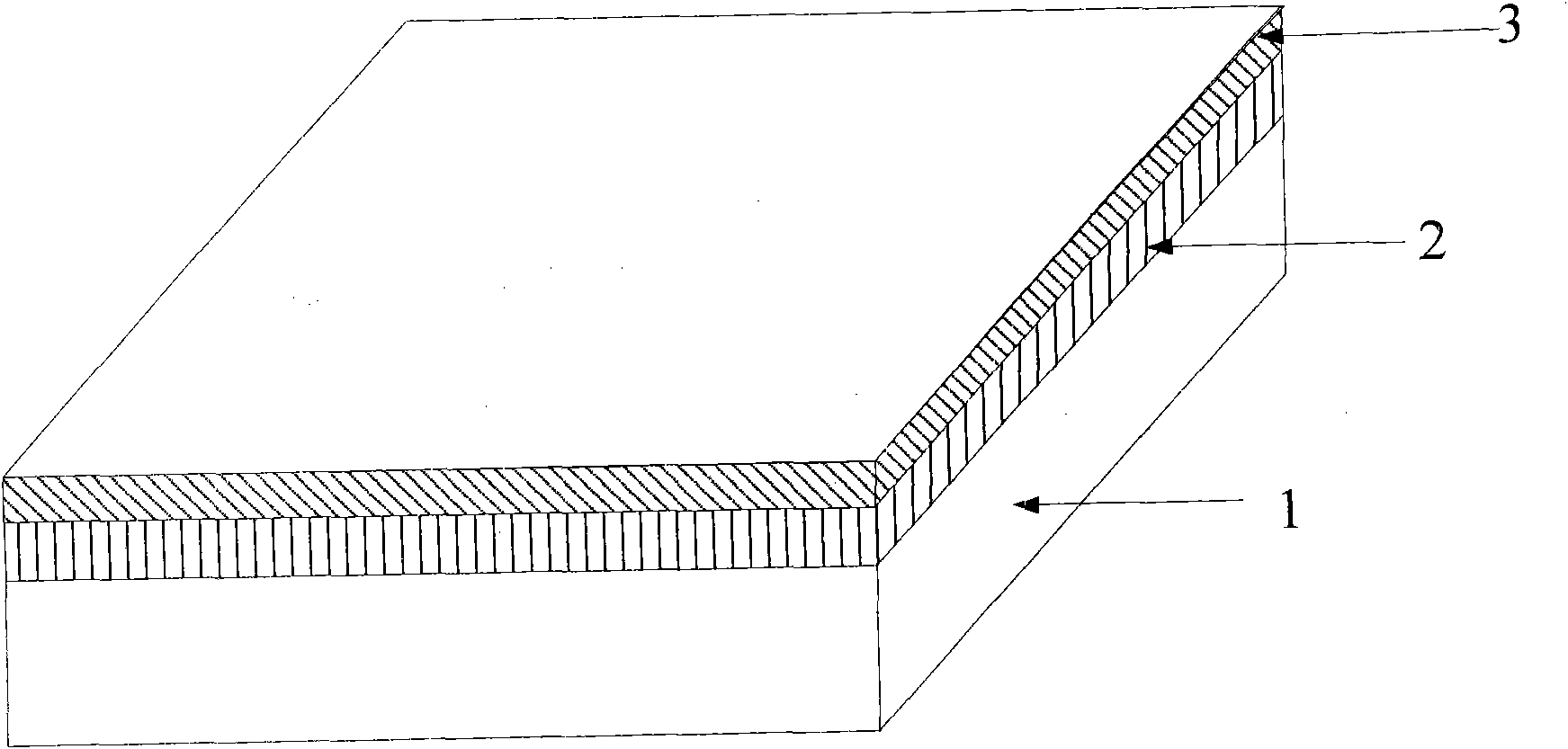

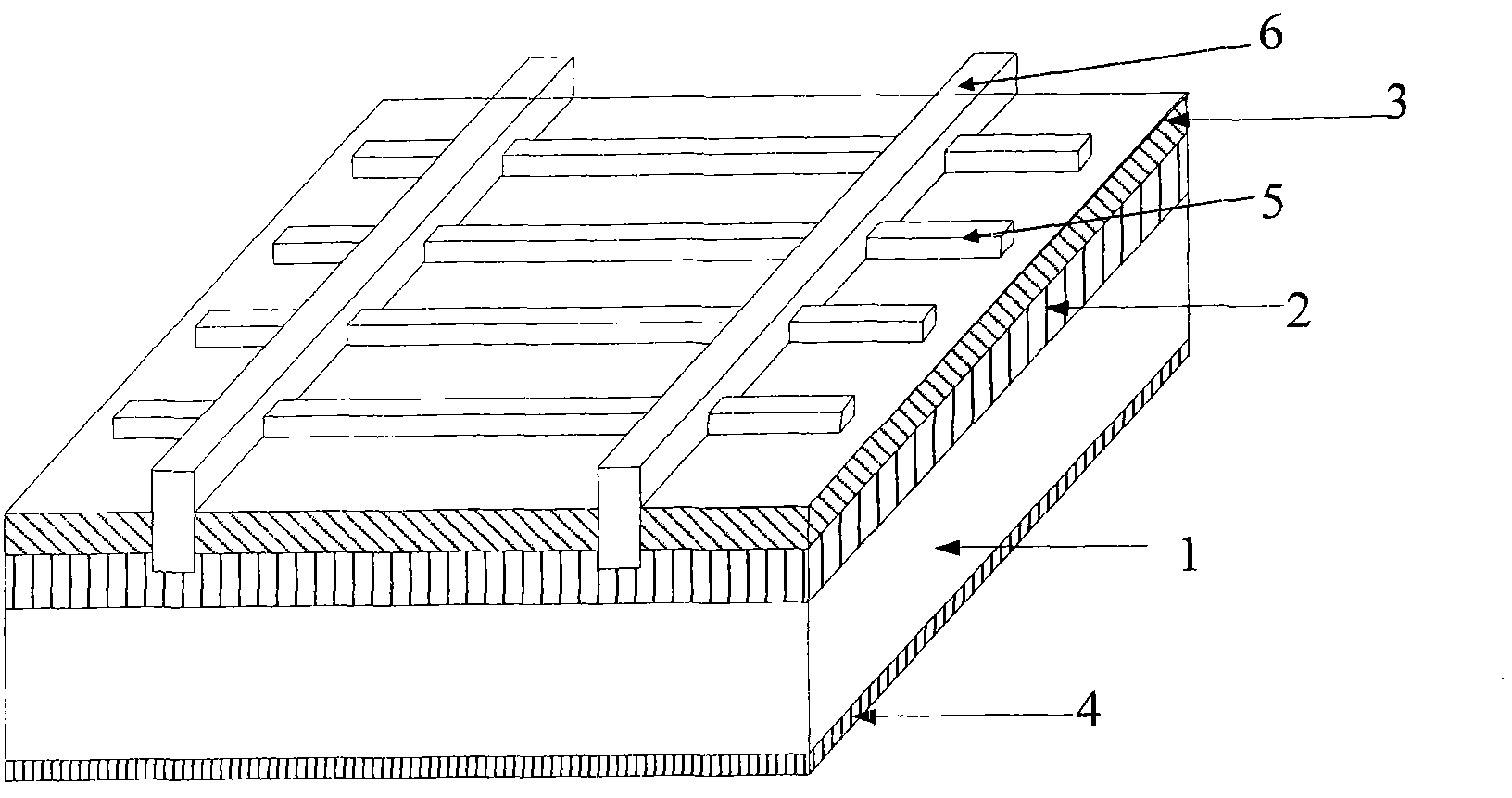

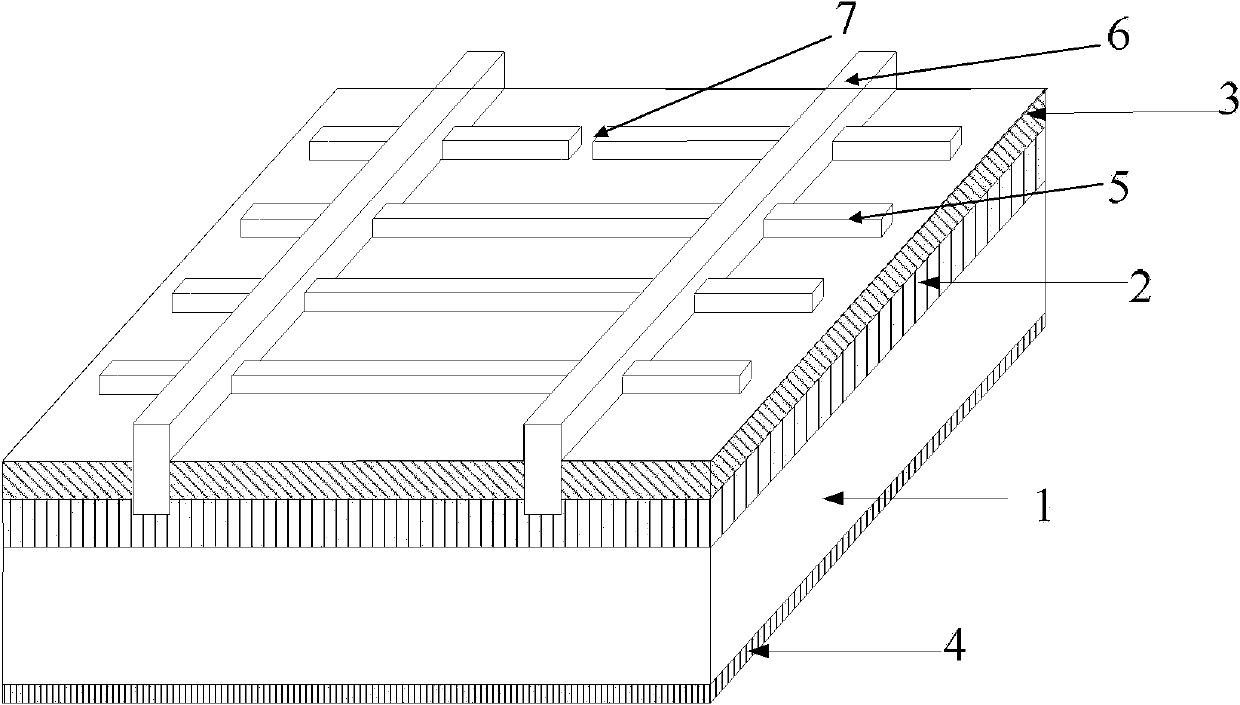

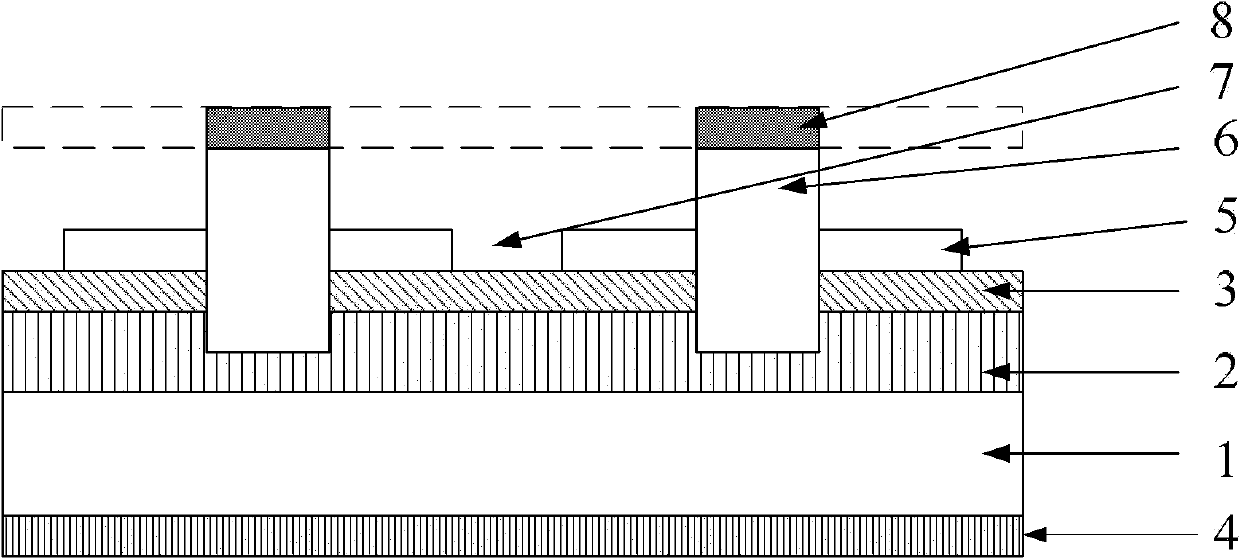

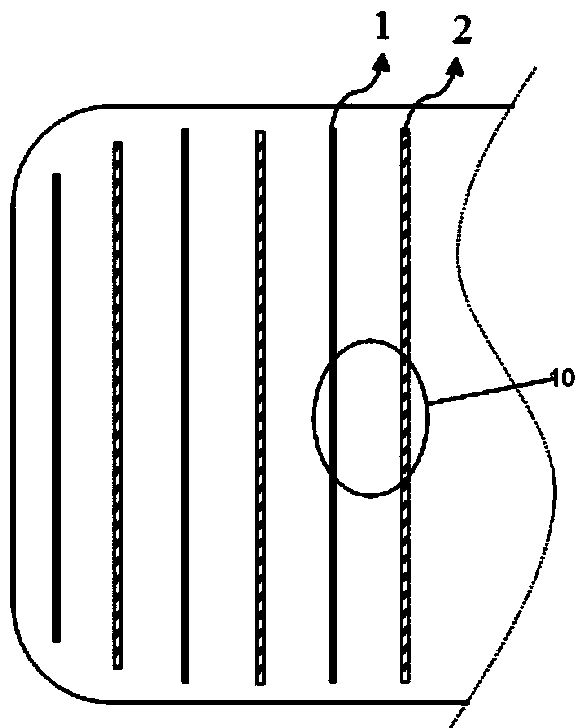

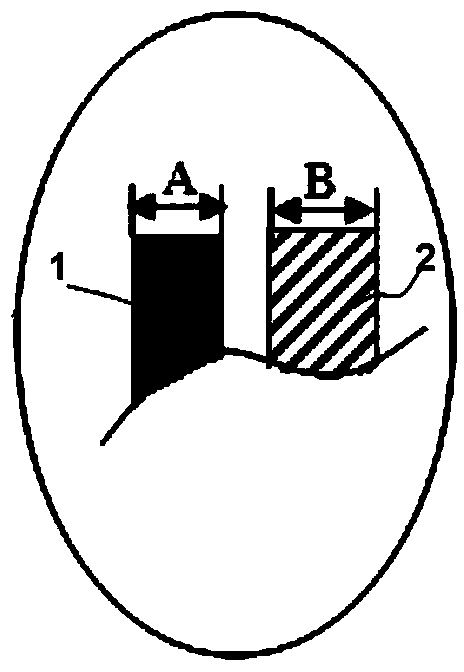

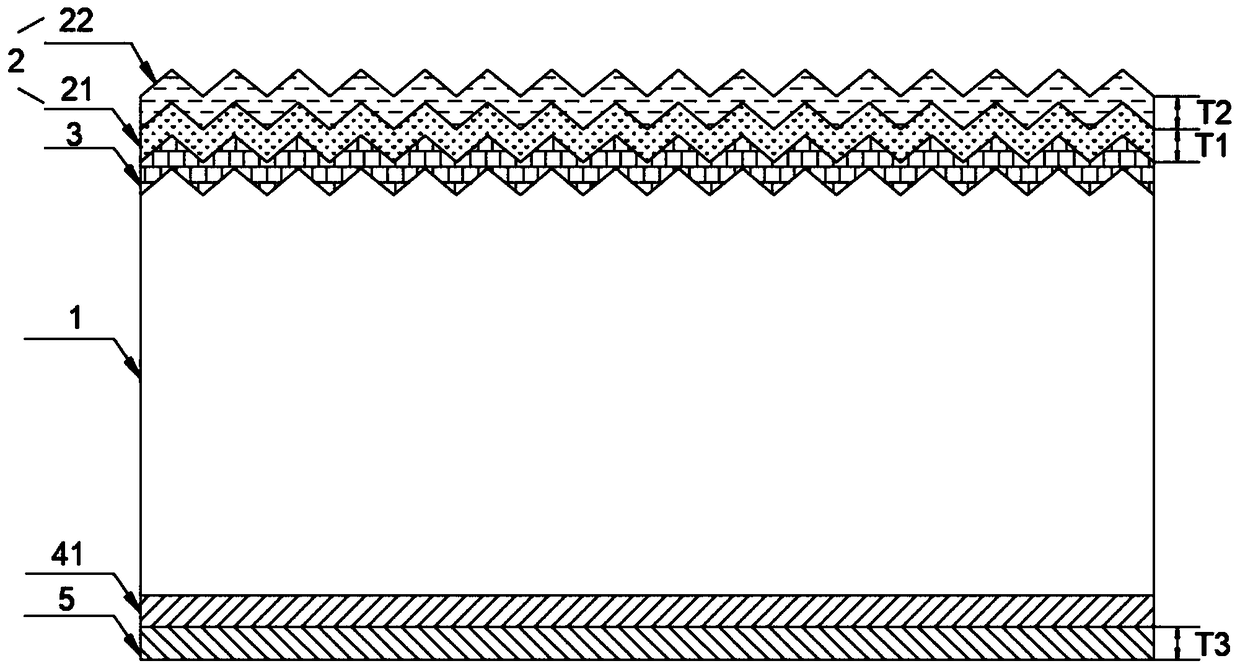

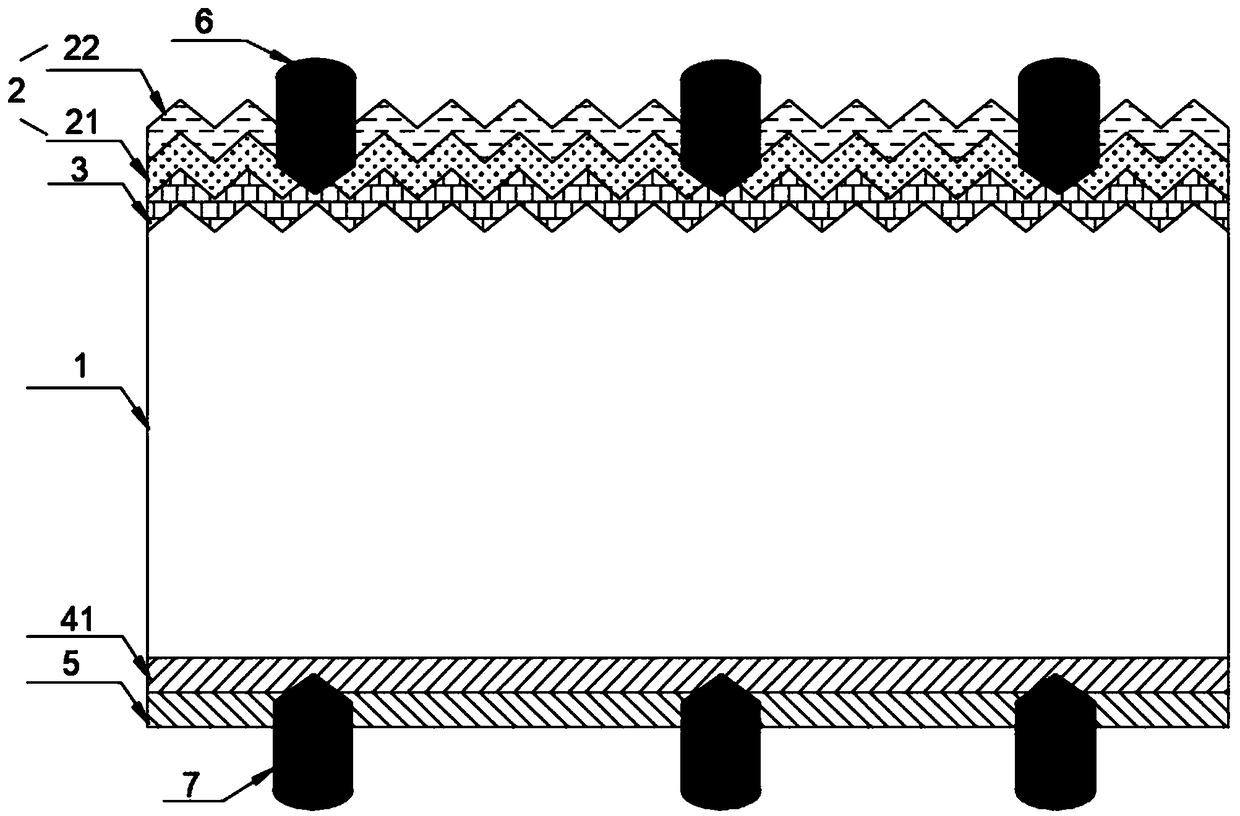

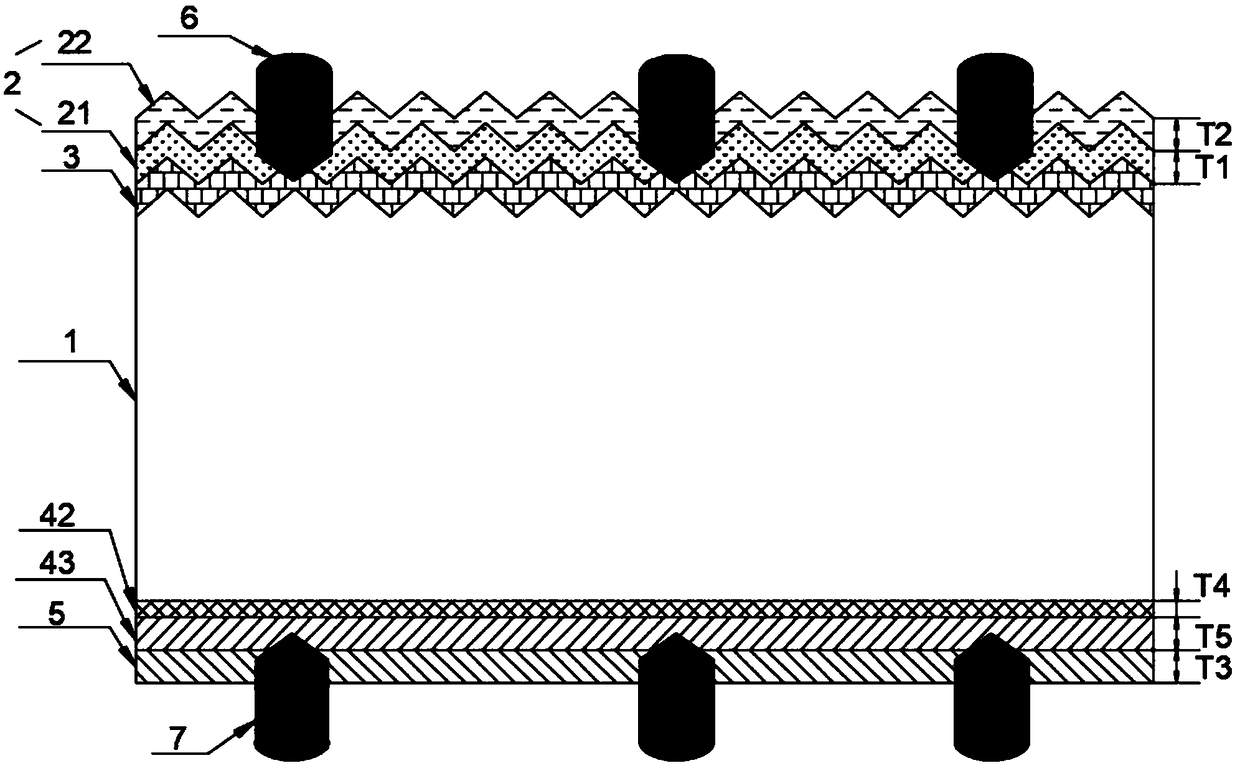

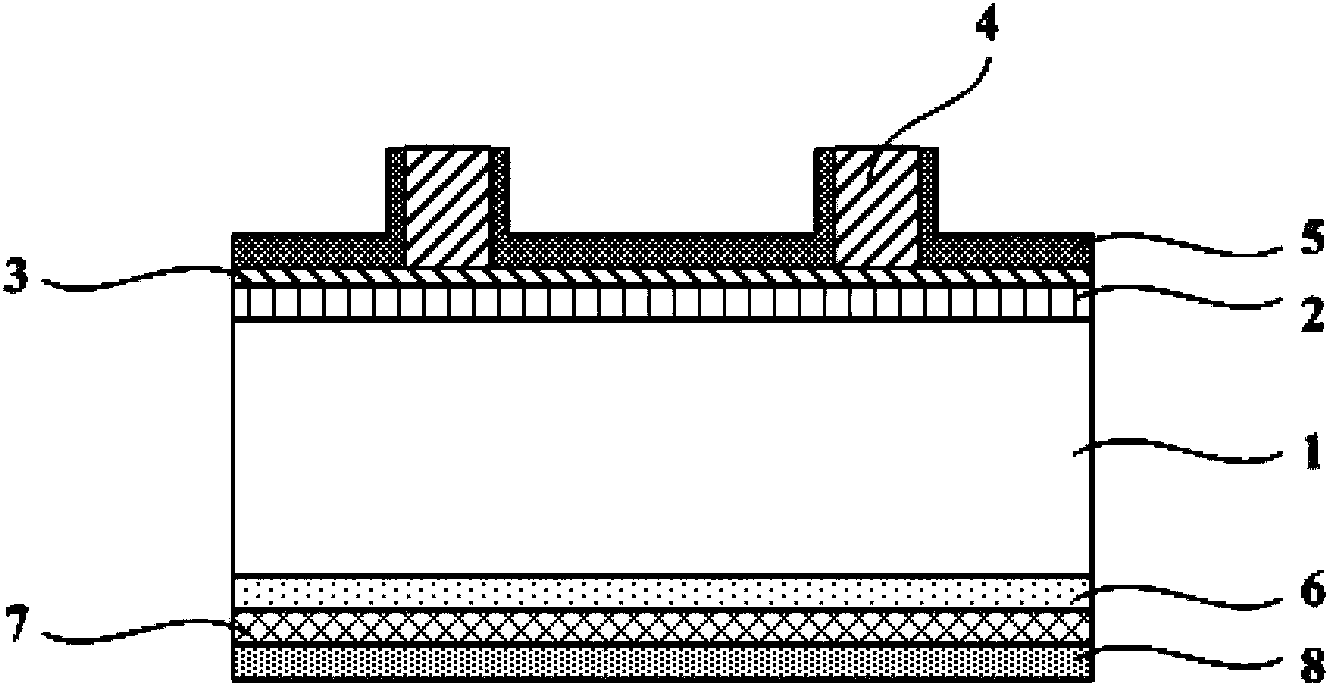

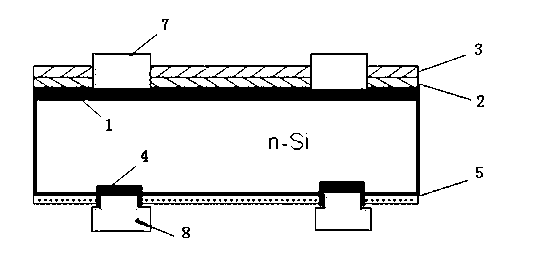

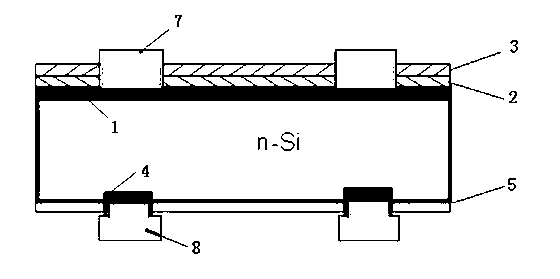

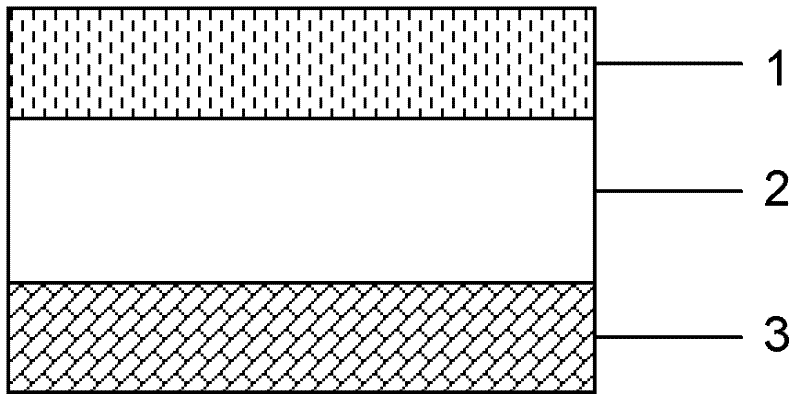

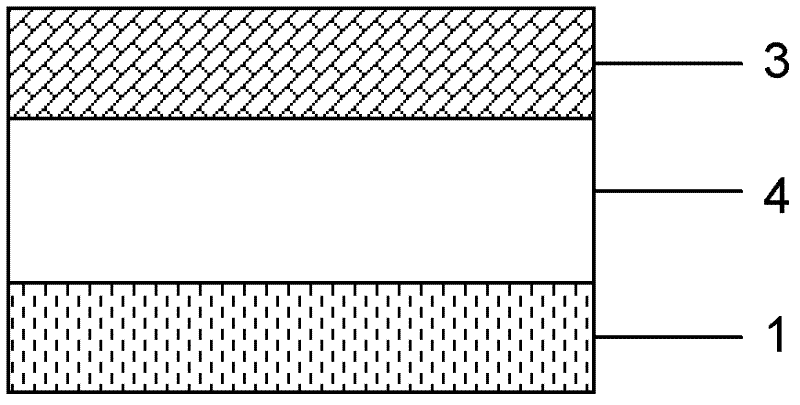

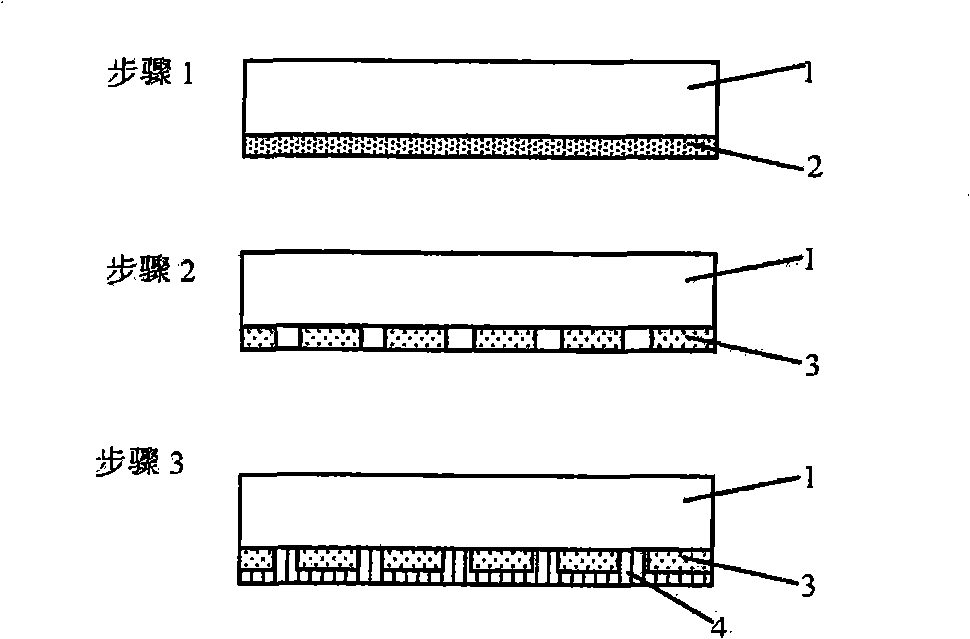

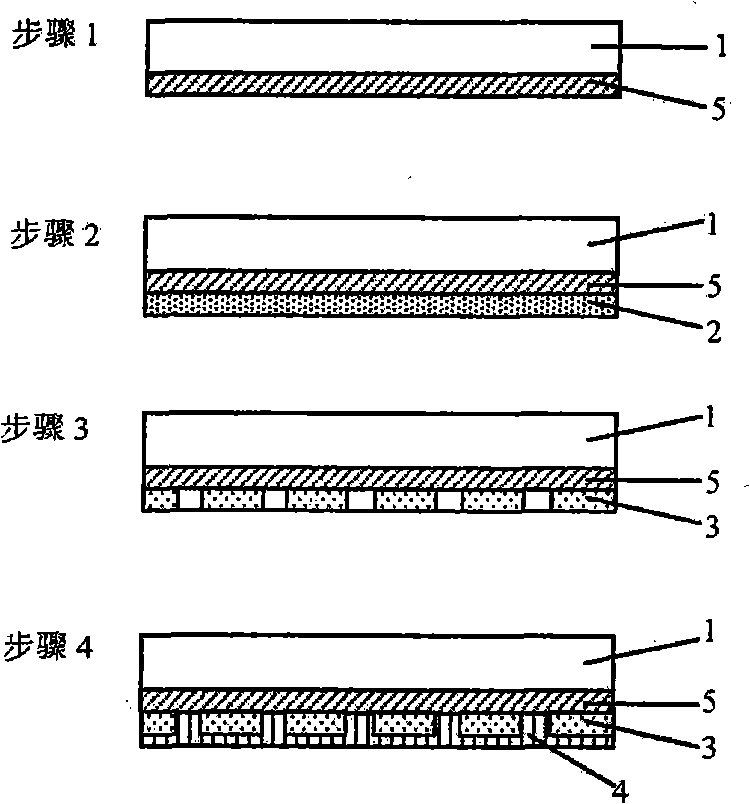

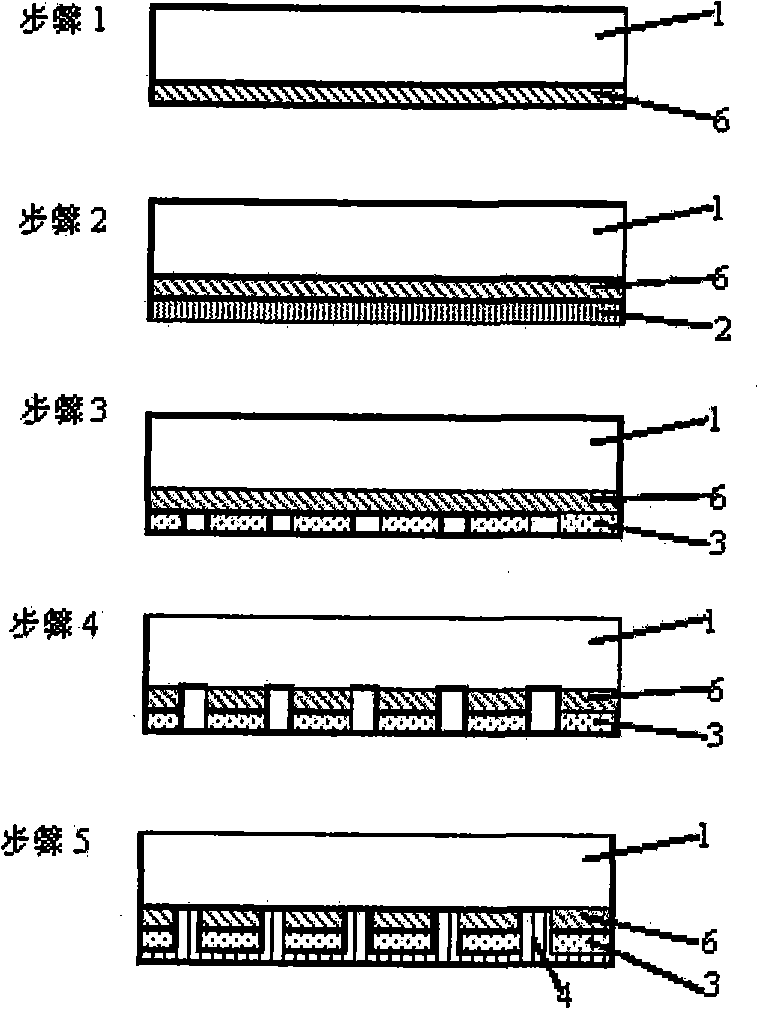

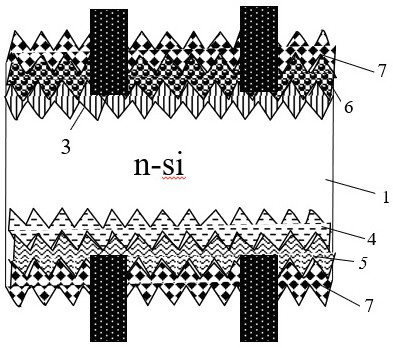

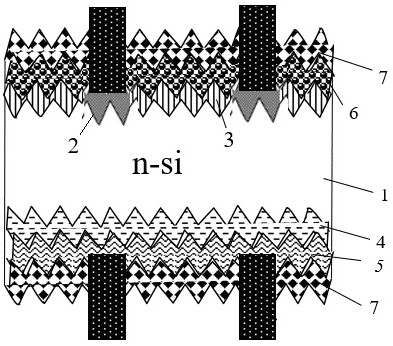

Method for preparing crystal silicon solar cell local back contact

ActiveCN101359702AReduce compound rateFinal product manufactureSemiconductor devicesOhmic contactSilicon solar cell

Disclosed is a method for preparing a crystalline silicon solar cell local back contact, including the following steps: depositing an aluminium layer (2) on a crystalline silicon substrate (1); making the aluminium layer (2) into an anodised aluminium hole array (3) through anodic oxidation, wherein the anodised aluminium hole runs through the whole aluminium layer (2); after that, depositing a back contact electrode (4) on the anodised aluminium hole array (3) and then annealing so as to enable the anodised aluminium hole and the crystalline silicon substrate (1) to be engaged in ohmic contact with each other through the back contact electrode (4).

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

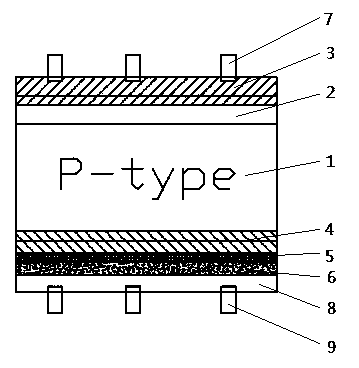

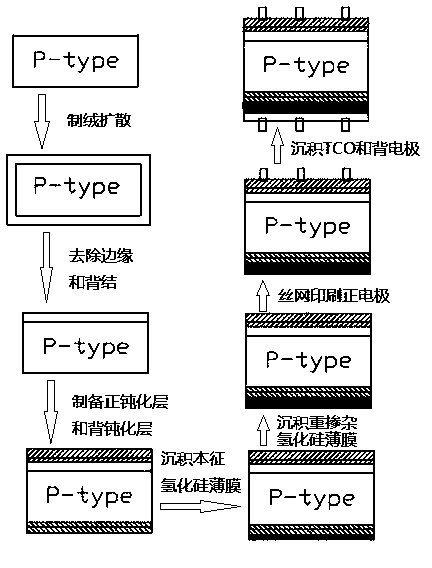

Two-sided passivation efficient heterojunction battery and manufacturing method thereof

InactiveCN103383975AAchieving photoelectric conversion efficiencyEasy to reuseFinal product manufacturePhotovoltaic energy generationHeterojunctionTransparent conducting film

The invention discloses a two-sided passivation efficient heterojunction battery which comprises a crystalline silicon substrate. An amorphous n layer, a positive passivation layer and a positive electrode are sequentially arranged on the front surface of the crystalline silicon substrate. The amorphous n layer and the crystalline silicon substrate form a solar PN junction. A back passivation layer, an intrinsic silicon hydride thin film, a heavy doping silicon hydride thin film, a transparent conducting film TCO and a back electrode are sequentially arranged on the rear surface of the crystalline silicon substrate. The invention further discloses a manufacturing method of the two-sided passivation efficient heterojunction battery. The two-sided passivation efficient heterojunction battery combines common advantages of a traditional crystalline silicon battery and a thin-film battery, lowers the load on the back surface, increases open circuit voltage, enhances long wave absorption, increases short circuit currents, and can realize over 20% of photoelectric conversion efficiency.

Owner:GD SOLAR

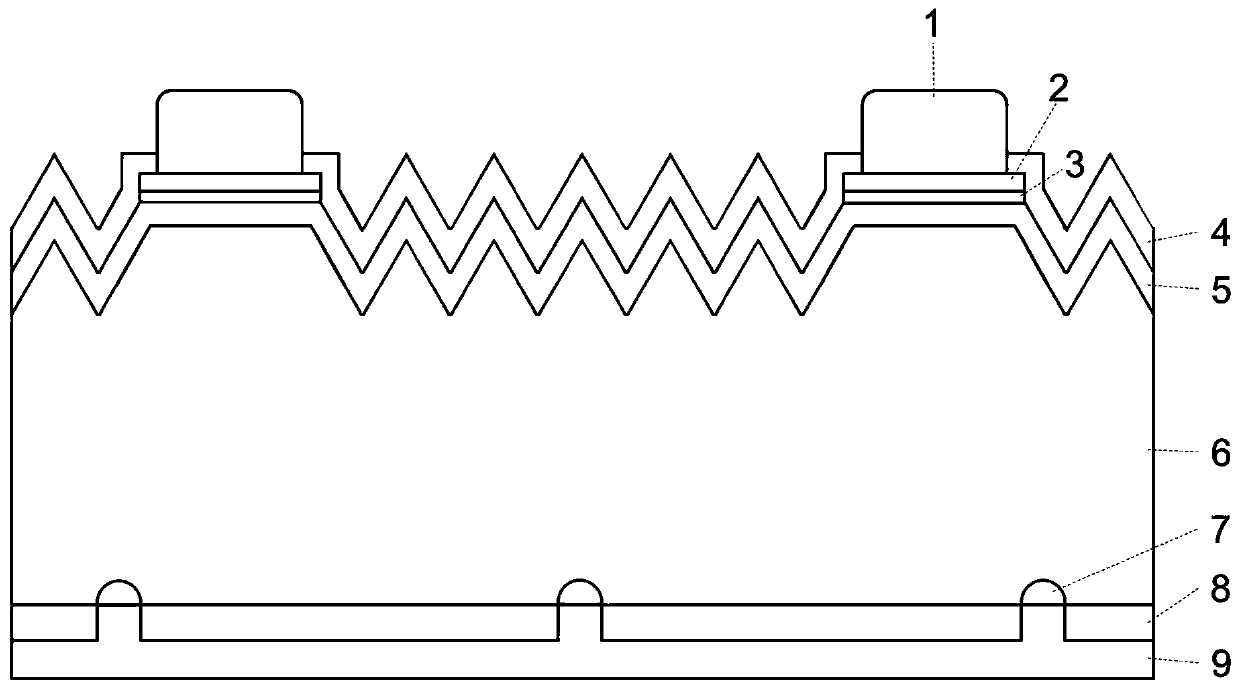

Crystalline silicon solar cell with local passivation contact on front surface and preparation method thereof

ActiveCN110828583AImprove conversion efficiencyReduce compound rateFinal product manufacturePhotovoltaic energy generationCrystallographyOhmic contact

The invention discloses a crystalline silicon solar cell with local passivation contact on a front surface and a preparation method thereof. The crystalline silicon solar cell comprises a front electrode, a front passivation layer, an N-type silicon doped layer, a P-type silicon substrate, a back passivation layer and a back electrode, wherein the back passivation layer is formed on a back surfaceof the P-type silicon substrate, the back electrode is formed on the back passivation layer and partially penetrates through the back passivation layer to form ohmic contact with the P-type silicon substrate, the N-type silicon doped layer is formed on a front surface of the P-type silicon substrate, a graphical silicon oxide thin layer is formed on the N-type silicon doped layer, an N+ type polycrystalline silicon layer is formed on the silicon oxide thin layer in a covering manner, and the front electrode penetrates through the front passivation layer, is formed on an upper surface of the N+ type polycrystalline silicon layer and forms ohmic contact with the N+ type polycrystalline silicon layer. The crystalline silicon solar cell is advantaged in that a composite rate of a metal contact region is further reduced while the composite rate of the non-metal contact area is reduced.

Owner:SUZHOU TALESUN SOLAR TECH CO LTD +1

Manufacturing method of N-type TOPCon solar cell

ActiveCN111628047AReduce the amount of investmentAvoid damageFinal product manufacturePhotovoltaic energy generationPhysical chemistrySilicon oxide

The invention relates to a manufacturing method of an N-type TOPCon solar cell. The manufacturing method comprises the following steps: a, double-sided texturing; b, single-sided spin coating; c, single-sided oxidation: forming a boron-containing silicon oxide layer on a spin coating surface; d, forming a heavily doped region substrate and a lightly doped region substrate: forming an organic masklayer for protecting a heavily doped region at a position corresponding to the metal gate line by using a mask mode, completely removing the boron-containing silicon oxide layer and the boron source outside the coverage area of the organic mask layer by using HF, and then removing the organic mask layer; and e, heavy doping and light doping: specifically, completely pushing the spin-coated boron source into the silicon substrate through a tubular low-pressure diffusion method, forming a heavy doping region is formed, carrying out whole-surface source-through deposition to form a lightly dopedregion, and finally, carrying out high-temperature oxidation to form a BSG layer with the thickness of 80-100nm, and then carrying out normal subsequent processes. According to the invention, a boronselective emitter can obtain higher photoelectric conversion efficiency, so that the conversion efficiency of the solar cell is improved.

Owner:常州顺风太阳能科技有限公司

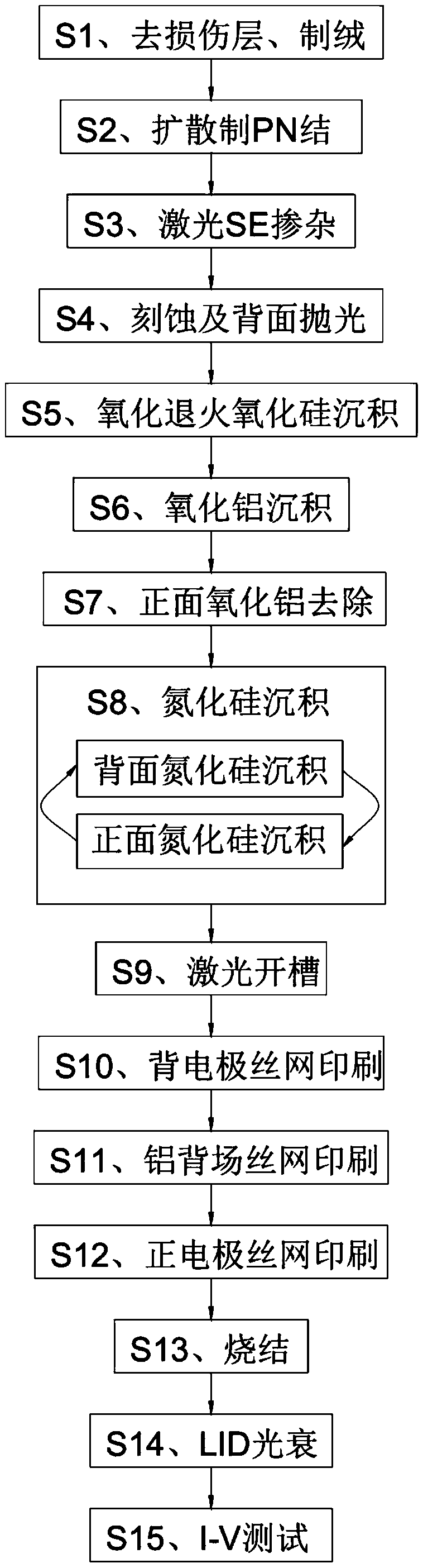

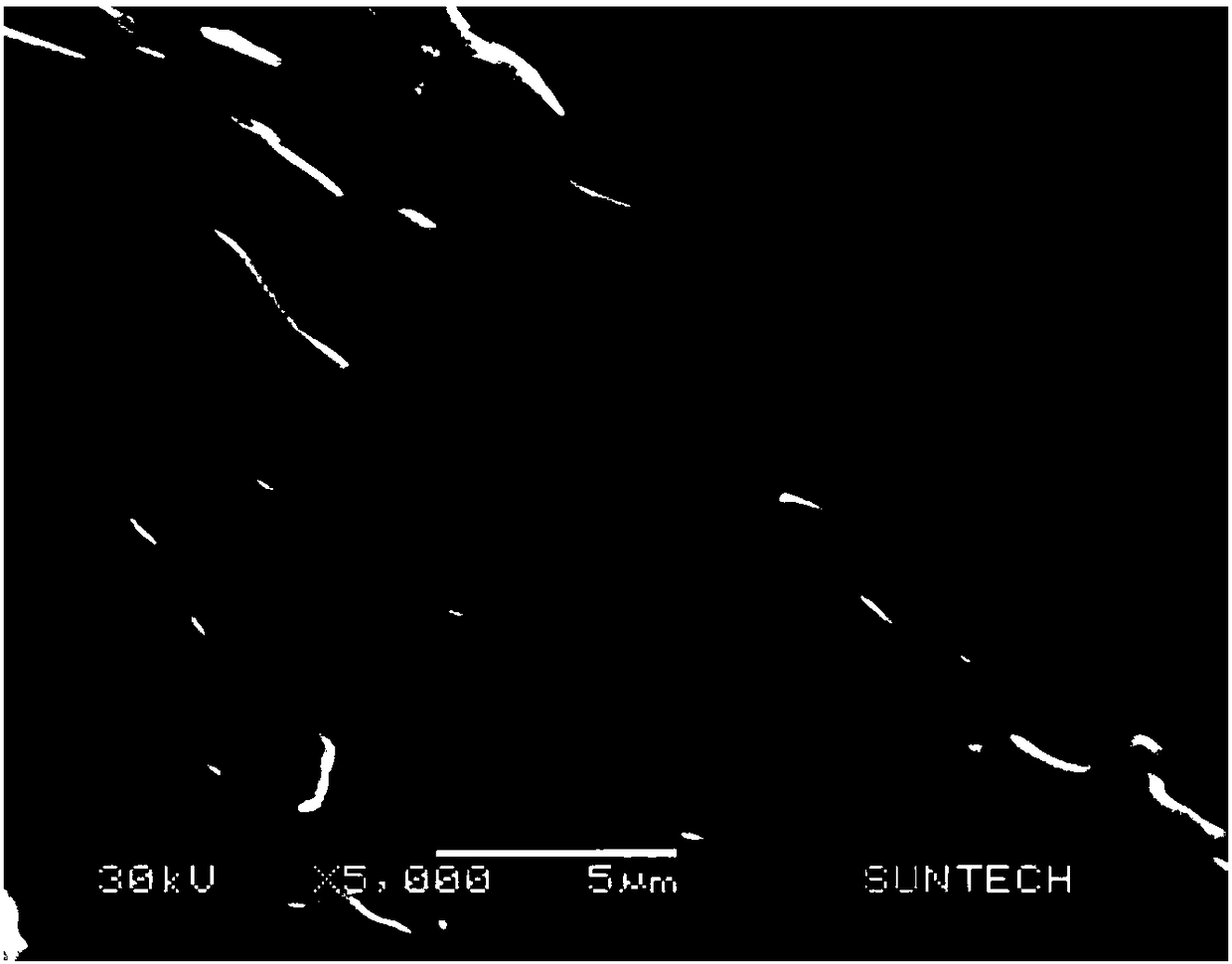

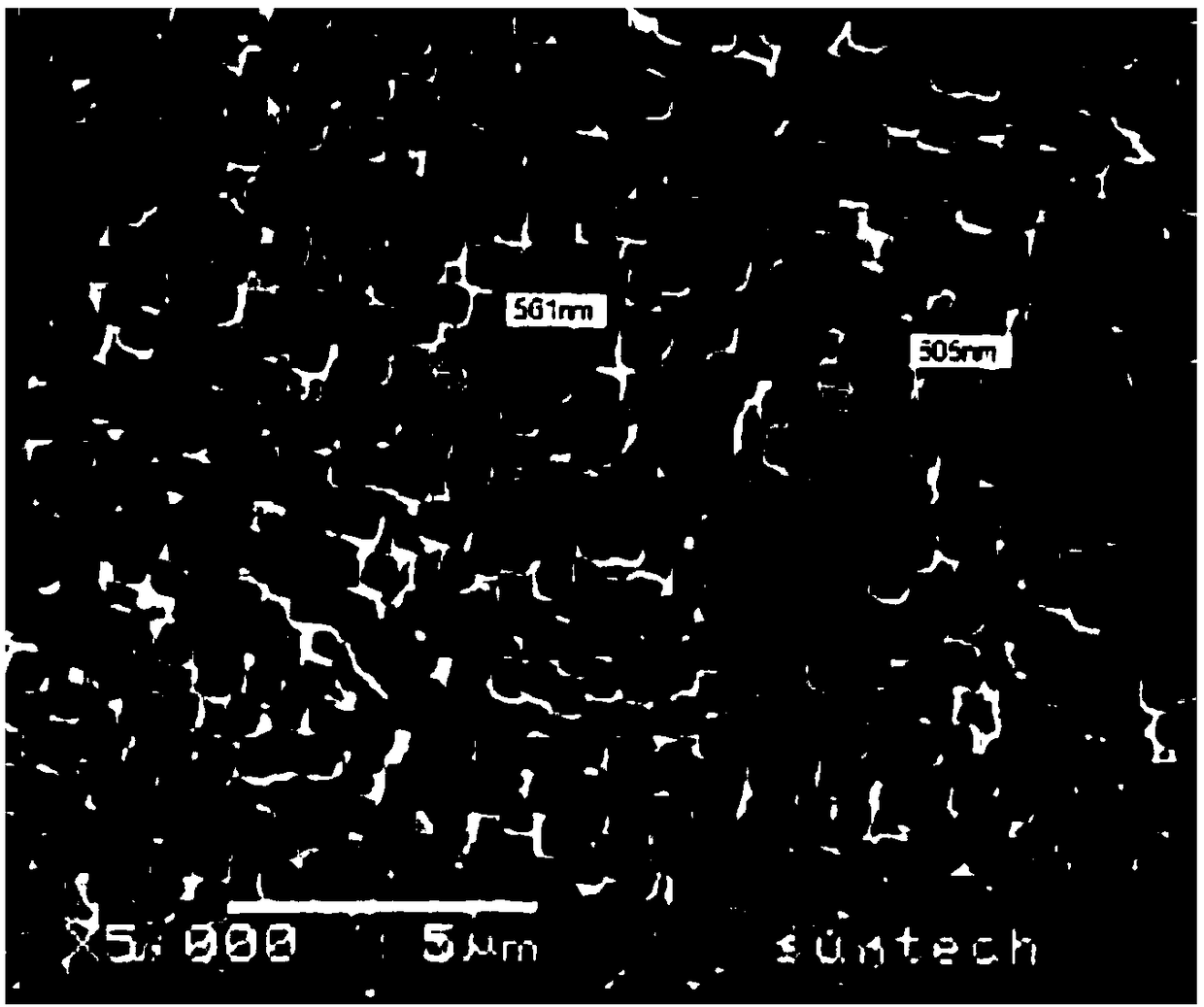

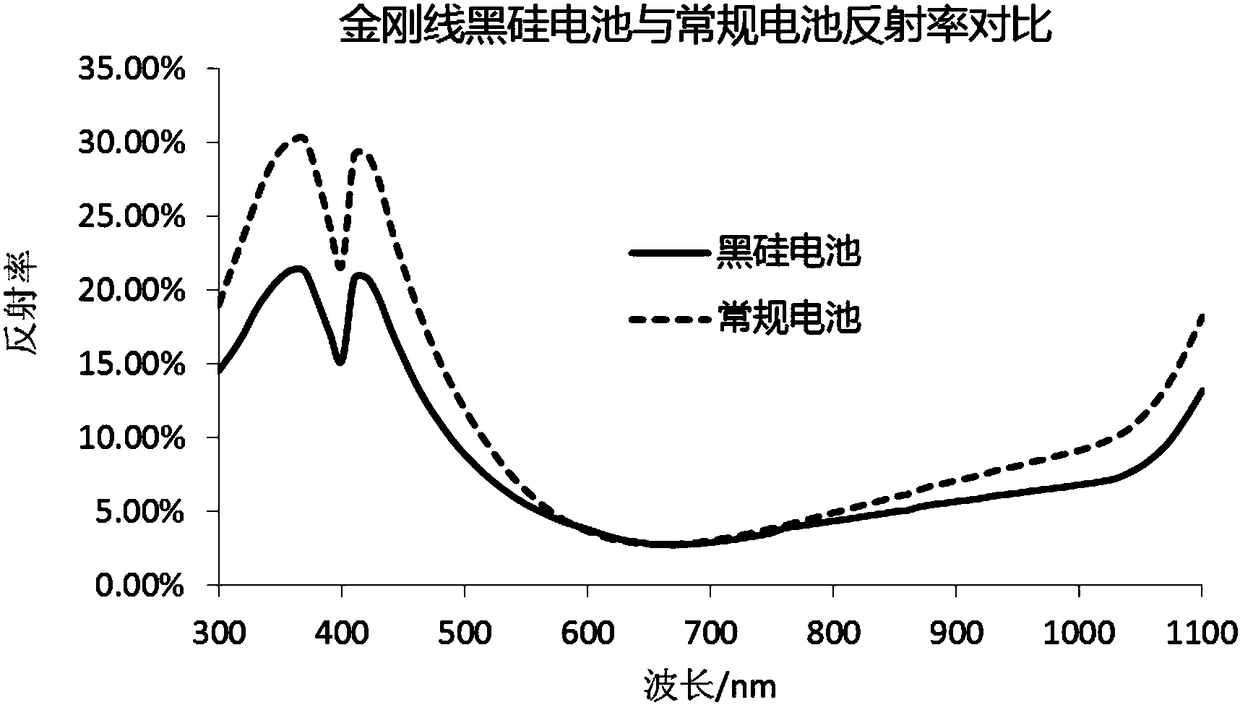

Preparation method for black-silicon poly-silicon PERC cell structure with selective emitter

InactiveCN108365022ASolve the problem of high surface reflectivityImprove conversion efficiencyAfter-treatment detailsFinal product manufactureScreen printingSilver electrode

The invention relates to a preparation method for a black-silicon poly-silicon PERC cell structure with a selective emitter. The preparation method is characterized by comprising the following steps of (1) forming a nanometer texturing surface on a front surface of a silicon wafer, wherein a back surface is a polishing surface; (2) performing front-surface diffusion of the silicon wafer to form anN-type layer, and removing front-surface phosphorosilicate glass and a back-surface pn junction; (3) depositing a silicon nitride anti-reflection film layer on the front surface of the silicon wafer,and depositing a passivation dielectric layer on the back surface; (4) dotting or routing the back surface of the silicon wafer, and printing a silver electrode and aluminum paste; (5) performing low-temperature sintering to form a local aluminum back field; (6) spraying a mixed solution of phosphoric acid and alcohol on the front surface of the silicon wafer, and forming a main grid line regionand a secondary grid line region after heavy doping by laser; and (7) immersing the front surface of the silicon wafer in an electroplating solution, electroplating the front surface of the silicon wafer under an illumination condition, and annealing after electroplating. By the preparation method, the defects that a high-quality fine grid line is difficult to form by silk-screen printing and thegrid line and a selective emitter cannot be enabled to be accurately aligned are overcome, and shielding and leakage current caused by an electrode are minimum.

Owner:WUXI SUNTECH POWER CO LTD

Preparation method of n-type crystalline silicon solar cell based on emitting electrode preparation through laser doping

InactiveCN102368510AEasy to produceLow toxicityFinal product manufactureSemiconductor devicesDielectricScreen printing

The invention discloses a preparation method of an n-type crystalline silicon solar cell based on emitting electrode preparation through laser doping. The method comprises the following steps of: preparing an emitting electrode on an n-type substrate spin-coated with boric acid by using a full lasing area scanning method; passivating the front surface and the back surface of a cell by adopting Al2O3 / SiO2 laminated dielectric films; plating an SiNx antireflection film on the front surface of the cell; forming local open pores on the back surface of the cell by adopting a laser ablation technology; and finally forming the emitting electrode by adopting a conventional screen printing and ablation method, and preparing the cell. The preparation method disclosed by the invention has the advantages of simple procedure and low cost, is beneficial to production of solar cells with high efficiency and can realize large-scale production.

Owner:SUN YAT SEN UNIV

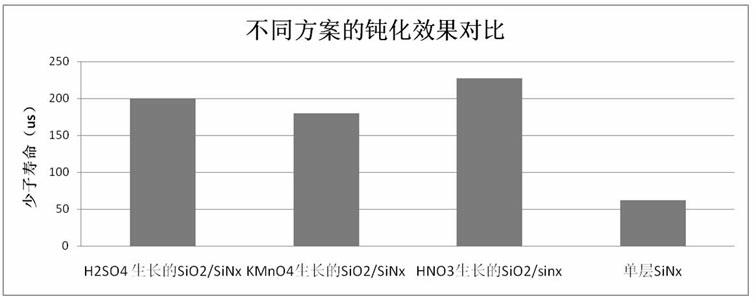

Method for passivating crystal silicon P-type surface

InactiveCN102110742AAvoid it happening againGood passivation effectFinal product manufactureSemiconductor devicesThin layerEngineering

The invention discloses a method for passivating a crystal silicon P-type surface. The method comprises the following steps of: removing the borosilicate glass from the surface of an N-type crystal silicon wafer subjected to boron diffusion and cleaning the surface; generating a thin SiO2 layer on the cleaned silicon wafer surface; depositing a SiNx layer on the surface of the generated SiO2 thin layer by a plasma enhanced chemical vapor deposition (PECVD) method. The method provided by the invention is suitable for industrialization production and has characteristics of simple heat treatment process, good anti-reflection effect and good passivation quality.

Owner:ALTUSVIA ENERGY TAICANG

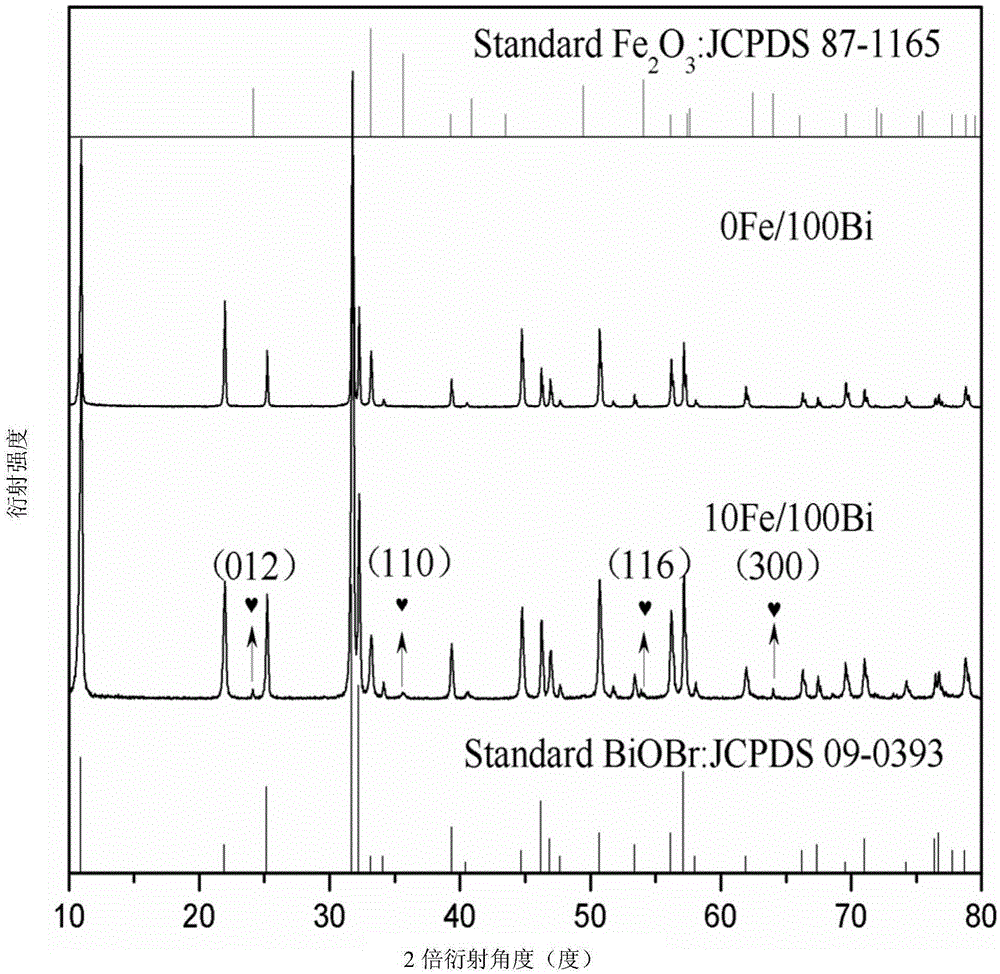

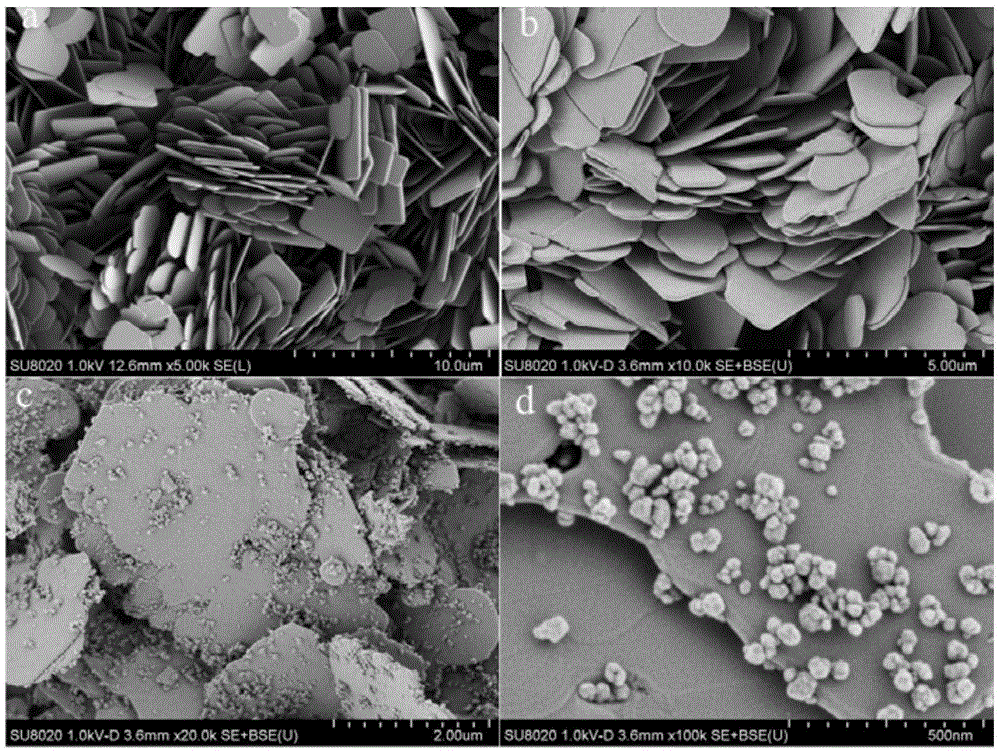

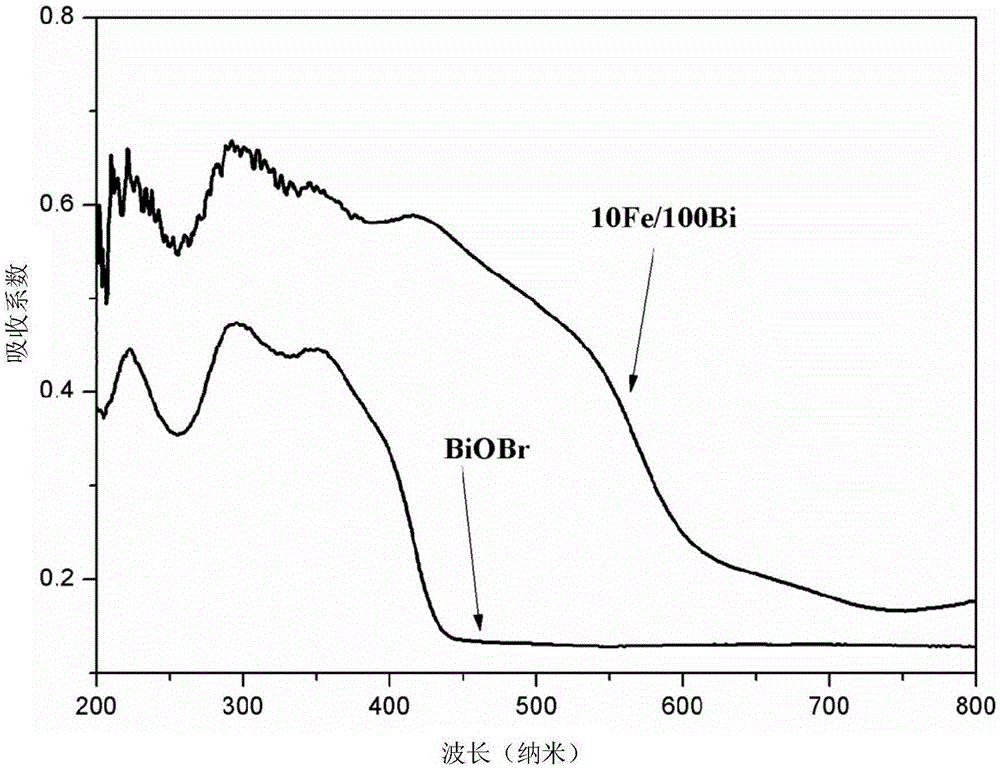

Ferric oxide/bismuth oxybromide composite material and preparation method and application thereof

InactiveCN105344364AImprove photocatalytic performanceOvercoming the problem of low photoelectric conversion efficiencyPhysical/chemical process catalystsWater/sewage treatment by irradiationFerric hydroxideBismuth oxybromide

The invention belongs to the technical field of preparation of composite materials and discloses a ferric oxide / bismuth oxybromide composite material and a preparation method and application thereof. The ferric oxide / bismuth oxybromide composite material is formed by ferric oxide nano-clusters depositing on the surfaces of bismuth oxybromide nano-sheets. The preparation method comprises the steps of adding an alkali solution into a ferric nitrate solution to obtain a ferric hydroxide colloidal solution, adding a KBr solution into a bismuth nitrate solution, performing mixing to obtain a mixed solution, dropwise adding the ferric hydroxide colloidal solution into the mixed solution and performing hydrothermal reaction to obtain the ferric oxide / bismuth oxybromide composite material. The preparation method has the advantages of being simple in preparation process and low in cost, having very good environmental protection benefits and the like, the prepared composite material has excellent photocatalytic performance and is widely applied to the field of photocatalytic degradation of dye wastewater, and the higher catalytic efficiency can be obtained.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com