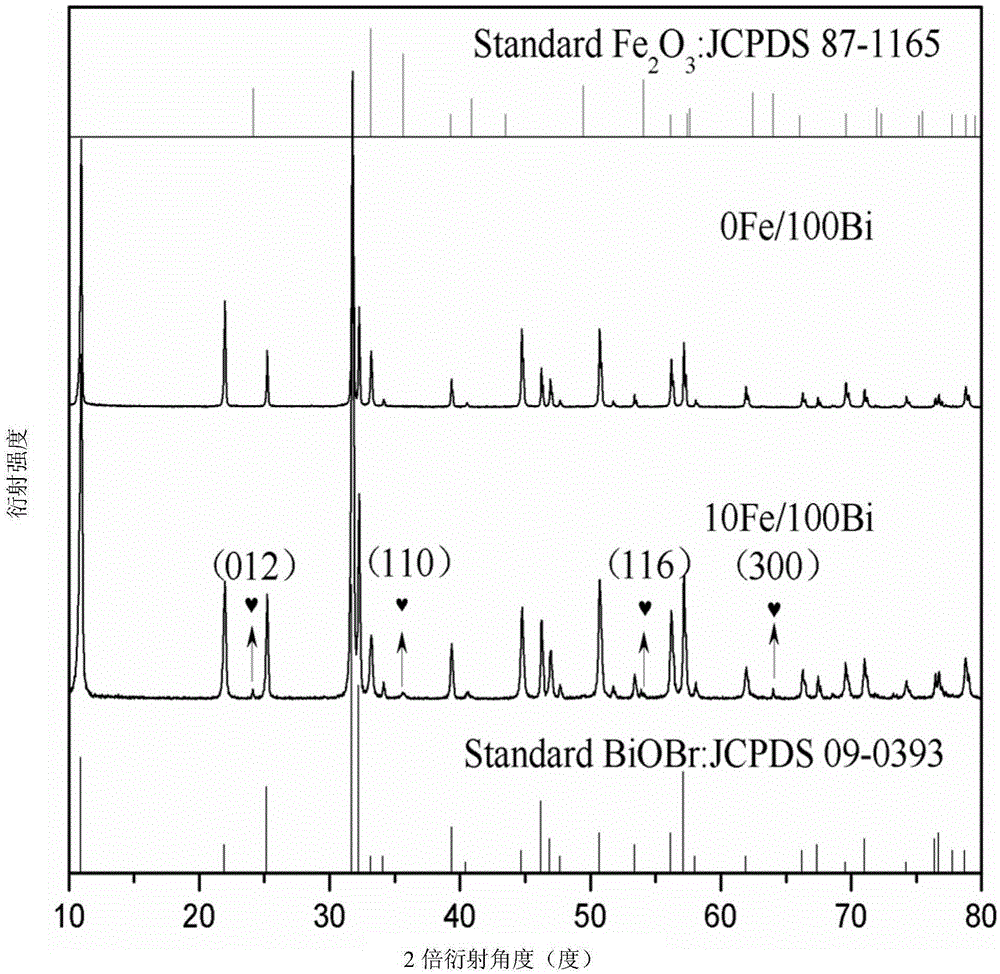

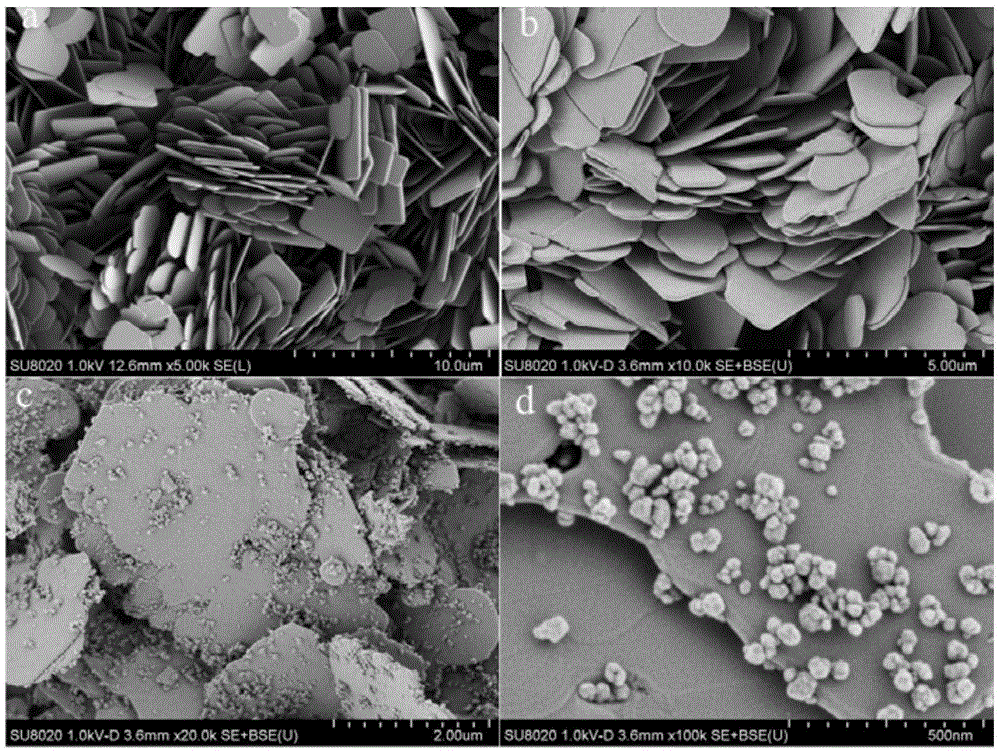

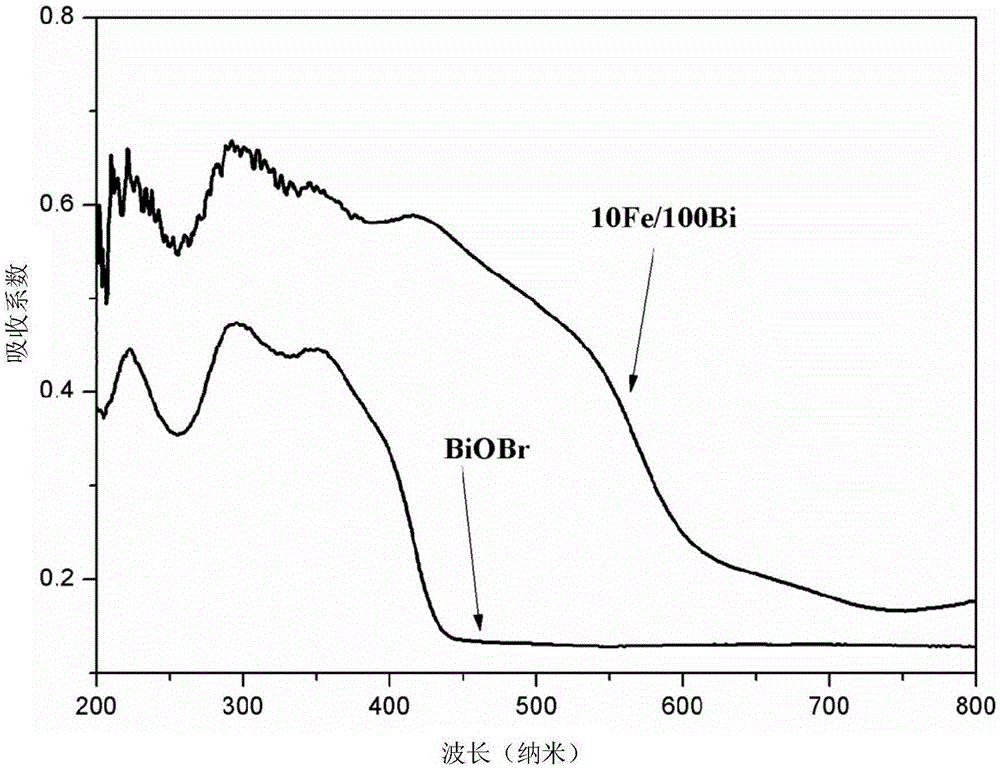

Ferric oxide/bismuth oxybromide composite material and preparation method and application thereof

A technology of bismuth oxybromide and composite materials, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problem of easy recombination of visible light absorption efficiency, easy recombination of photogenerated electrons and holes, and unfavorable complexes. Photocatalytic performance and other problems, to overcome the low photoelectric conversion efficiency, improved photocatalytic performance, and superior photocatalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of iron oxide / bismuth oxybromide composite material, comprising the following steps:

[0038] (1) the sodium hydroxide that takes by weighing 0.48g is dissolved in the water of 10mL and is made into the sodium hydroxide solution that concentration is 1.2mol / L, and the ferric nitrate nonahydrate that takes 1.616g is dissolved in the water of 90mL and makes ferric nitrate solution; Then add 10 mL of 1.2 mol / L sodium hydroxide solution into the ferric nitrate solution to obtain a 0.04 mol / L ferric hydroxide colloidal solution.

[0039] (2) Weigh 0.97g bismuth nitrate pentahydrate and disperse it in 25mL water to make bismuth nitrate solution, weigh 0.238gKBr and dissolve it in 10mL water to make KBr solution; then add 10mLKBr solution to the bismuth nitrate solution and stir for half an hour , to obtain a mixed solution, the pH value of the mixed solution is 1-2.

[0040] (3) Add 5mL of ferric hydroxide colloidal solution in step (1) to the mixed solu...

Embodiment 2

[0042] A preparation method of iron oxide / bismuth oxybromide composite material, comprising the following steps:

[0043] (1) the sodium hydroxide that takes by weighing 0.48g is dissolved in the water of 10mL and is made into the sodium hydroxide solution that concentration is 1.2mol / L, and the ferric nitrate nonahydrate that takes 1.616g is dissolved in the water of 90mL and makes ferric nitrate solution; Then add 10 mL of 1.2 mol / L sodium hydroxide solution into the ferric nitrate solution to obtain a 0.04 mol / L ferric hydroxide colloidal solution.

[0044] (2) Weigh 0.97g bismuth nitrate pentahydrate and disperse it in 25mL water to make bismuth nitrate solution, weigh 0.238gKBr and dissolve it in 10mL water to make KBr solution; then add 10mLKBr solution to the bismuth nitrate solution and stir for half an hour , to obtain a mixed solution, the pH value of the mixed solution is 1-2.

[0045] (3) Add 10mL of ferric hydroxide colloidal solution in step (1) to the mixed sol...

Embodiment 3

[0050] A preparation method of iron oxide / bismuth oxybromide composite material, comprising the following steps:

[0051] (1) the sodium hydroxide that takes by weighing 0.48g is dissolved in the water of 10mL and is made into the sodium hydroxide solution that concentration is 1.2mol / L, and the ferric nitrate nonahydrate that takes 1.616g is dissolved in the water of 90mL and makes ferric nitrate solution; Then add 10 mL of 1.2 mol / L sodium hydroxide solution into the ferric nitrate solution to obtain a 0.04 mol / L ferric hydroxide colloidal solution.

[0052] (2) Weigh 0.97g bismuth nitrate pentahydrate and disperse it in 25mL water to make bismuth nitrate solution, weigh 0.238gKBr and dissolve it in 10mL water to make KBr solution; then add 10mLKBr solution to the bismuth nitrate solution and stir for half an hour , to obtain a mixed solution, the pH value of the mixed solution is 1-2.

[0053] (3) Add 15mL of ferric hydroxide colloidal solution in step (1) to the mixed sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com