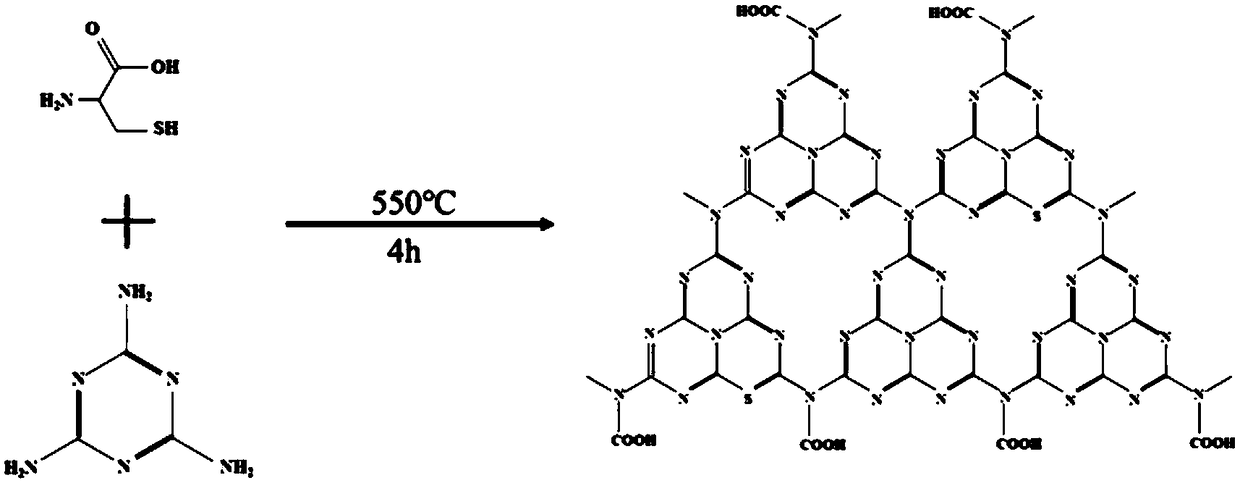

Preparation method of oxygen-sulfur dual-doped graphite phase carbon nitride

A technology of graphite phase carbon nitride and double doping, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of low photocatalytic activity and limited applications, and achieve high photocatalytic activity , Enhanced photocatalytic performance and reduced bandgap width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

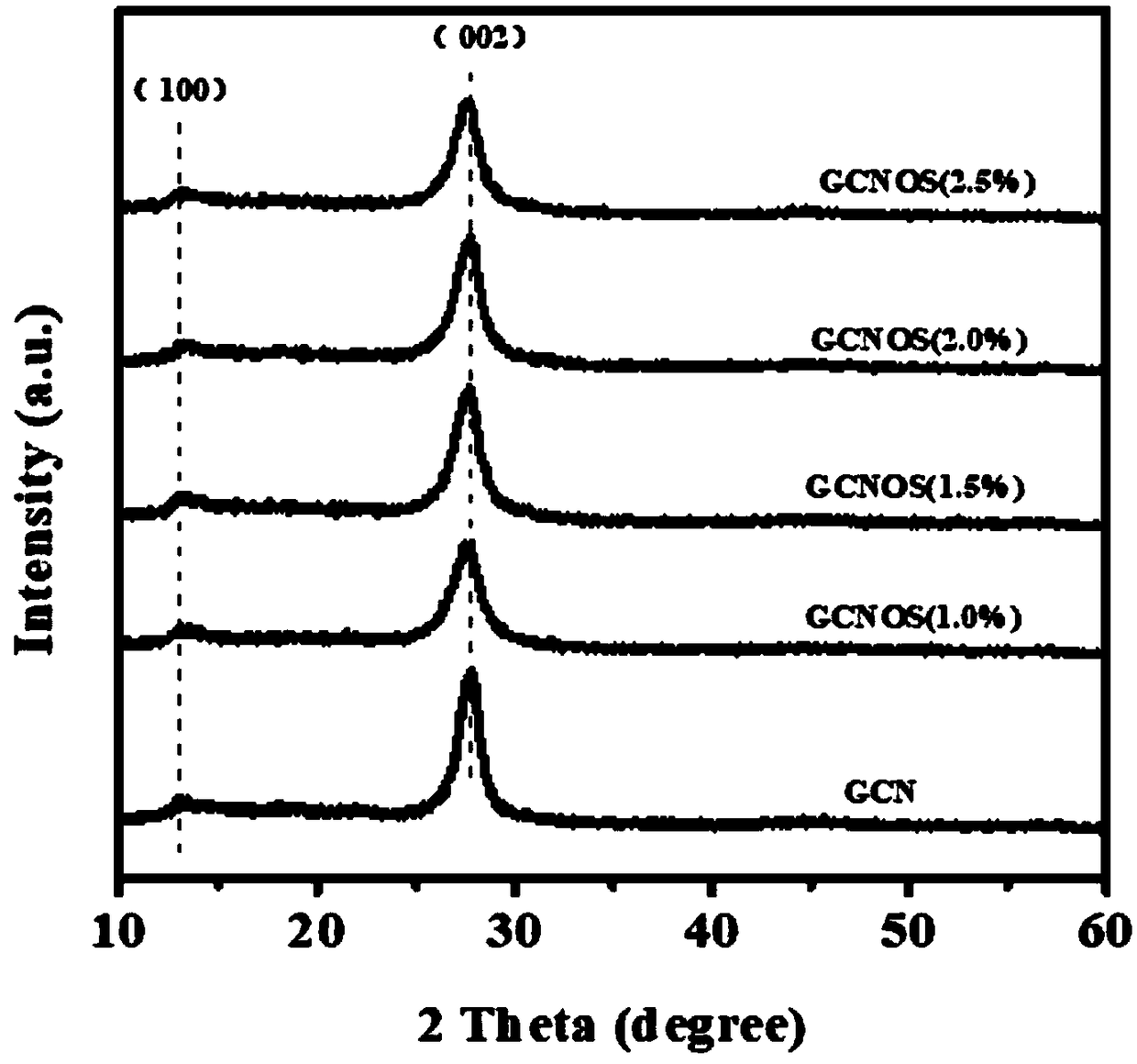

Method used

Image

Examples

Embodiment 1

[0026] Preparation of graphitic carbon nitride:

[0027] (1) Take 10g of melamine, fully grind it in a mortar, and place it in a crucible;

[0028] (2) Put it into a muffle furnace, and bake it at a high temperature of 550°C for 4h, with a heating rate of 2°C / min;

[0029] (3) After cooling to room temperature, centrifuge and wash three times with deionized water, and twice with absolute ethanol until neutral, then put it in an oven at 60°C overnight;

[0030] (4) After drying, grind and sieve to obtain g-C 3 N 4 powder.

[0031] Preparation of GCNOS:

[0032] (1) take by weighing the melamine of 4 parts of 10g;

[0033] (2) Take again by weighing 0.1g, 0.15g, 0.20g, each part of L-cysteine of 0.25g, and put each part of L-cysteine into four parts of 10g of melamine respectively, Grind thoroughly with a mortar, mix it evenly and put it in a crucible;

[0034] (3) Put the four samples into a muffle furnace, and bake them at 550°C for 4 hours at a heating rate of 2°C / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com