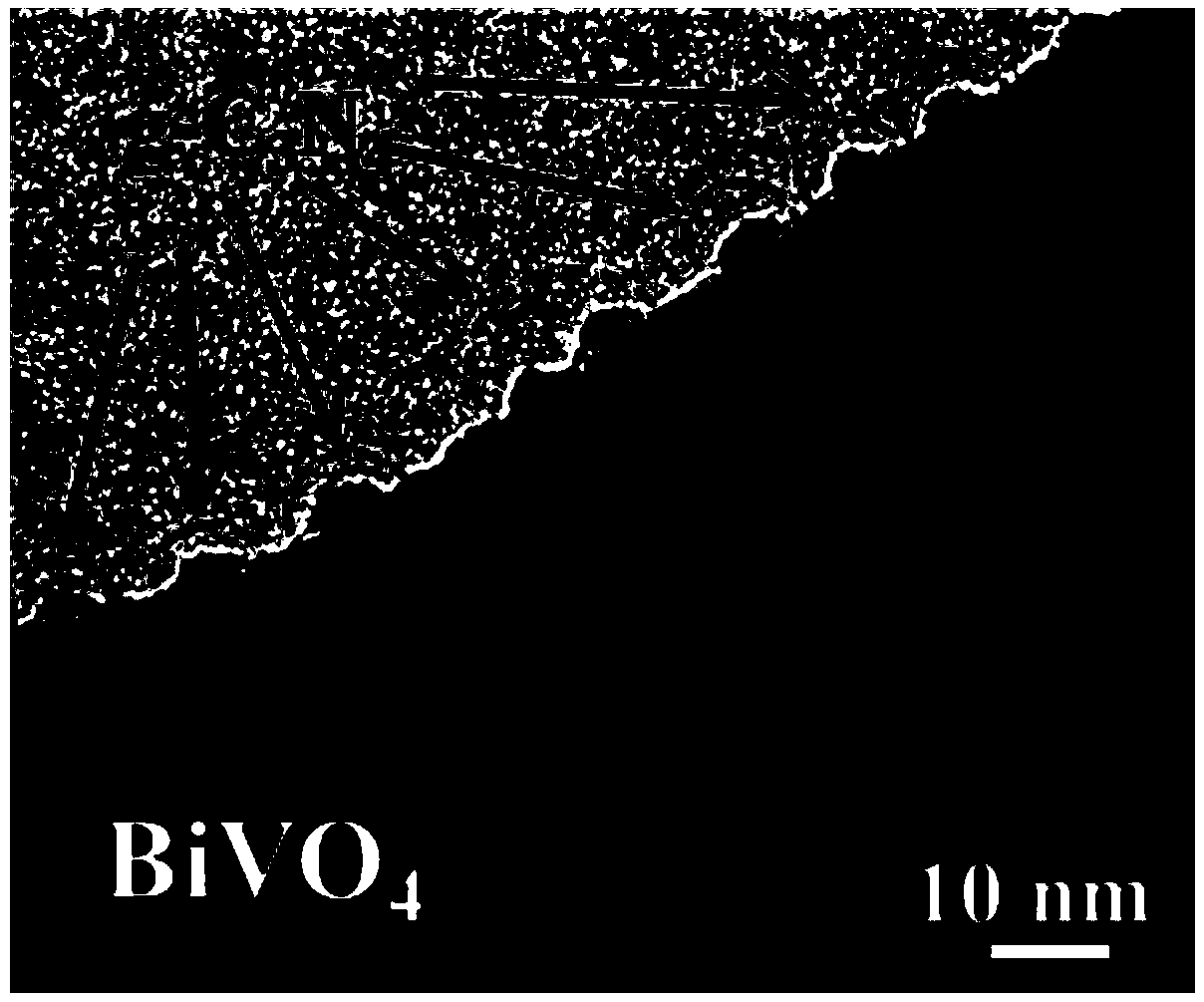

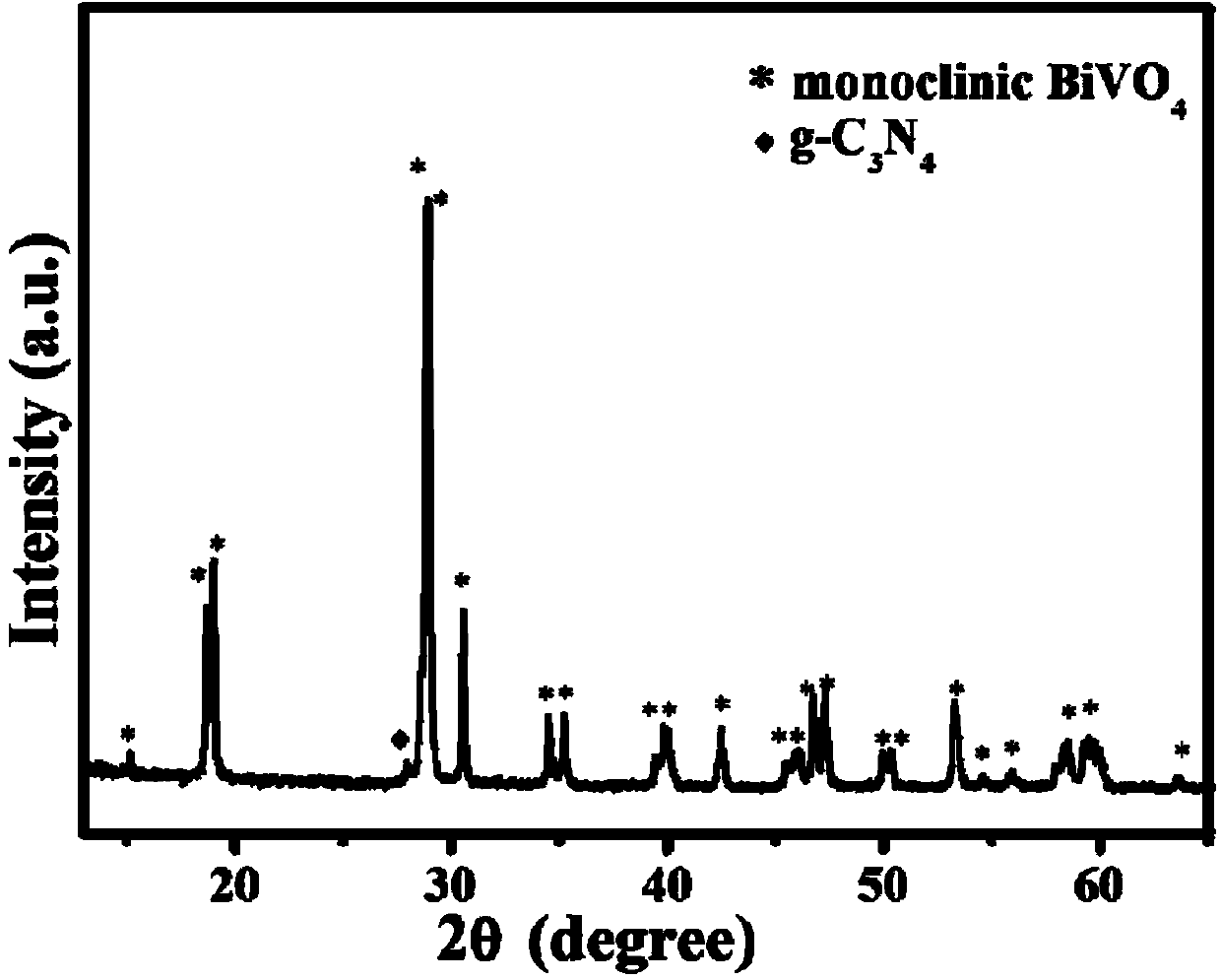

Carbon nitride nano particle modified pucherite composite photocatalyst and preparation method thereof

A nanoparticle, carbon nitride technology, which is applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc. Insufficient exposure, large size of composite photocatalyst, etc., to achieve the effect of superior photocatalytic performance, good visible light response performance, and improved photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The first step is to take a certain amount of melamine powder and add it to the crucible, cover the crucible to form a semi-closed environment, and then put it into the muffle furnace controlled by the temperature program, and increase the temperature by 10°C / min. The room temperature was raised to 500°C and kept at this temperature for 2h.

[0041] In the second step, the temperature of the muffle furnace was raised to 520° C. at a rate of 2° C. / min, and kept at this temperature for 2 hours for further deamination. After cooling to room temperature, the obtained product was ground in an agate mortar to obtain carbon nitride powder.

[0042] In the third step, take 15 parts (0.552 g) of carbon nitride obtained in the second step by weight, add it into high-purity water, and perform ultrasonic dispersion treatment for 30 minutes to make it uniformly dispersed.

[0043] In the fourth step, under the condition of vigorous stirring, 3 parts by weight (0.582 g) of bismuth n...

Embodiment 2

[0054] The first step is to take a certain amount of melamine powder and add it to the crucible, cover the crucible to form a semi-closed environment, and then put it into a muffle furnace controlled by temperature programming, and increase the temperature by 15°C / min. The room temperature was raised to 500°C and kept at this temperature for 4h.

[0055] In the second step, the temperature of the muffle furnace was raised to 550° C. at a rate of 2° C. / min, and kept at this temperature for 4 hours for further deamination. After cooling to room temperature, the obtained product was ground in an agate mortar to obtain carbon nitride powder.

[0056] In the third step, take 15 parts (0.552 g) of carbon nitride obtained in the second step by weight, add it into high-purity water, and perform ultrasonic dispersion treatment for 30 minutes to make it uniformly dispersed.

[0057] In the fourth step, under the condition of vigorous stirring, 3 parts by weight (0.582 g) of bismuth nit...

Embodiment 3

[0063] The first step is to take a certain amount of melamine powder and add it to the crucible, cover the crucible to form a semi-closed environment, and then put it into the muffle furnace controlled by the temperature program, and increase the temperature by 5°C / min. The room temperature was raised to 490°C and kept at this temperature for 3h.

[0064] In the second step, the temperature of the muffle furnace was raised to 540° C. at a rate of 2° C. / min, and kept at this temperature for 3 hours for further deamination. After cooling to room temperature, the obtained product was ground in an agate mortar to obtain carbon nitride powder.

[0065] In the third step, take 15 parts (0.552 g) of carbon nitride obtained in the second step by weight, add it into high-purity water, and perform ultrasonic dispersion treatment for 30 minutes to make it uniformly dispersed.

[0066] In the fourth step, under the condition of vigorous stirring, 1 part by weight (0.194 g) of bismuth nit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com