Method for manufacturing N-type selective emitter double-sided battery by spin-coating boron source laser doping

A technology of laser doping and double-sided batteries, applied in photovoltaic power generation, circuits, electrical components, etc., to achieve the effects of reducing contact resistance, improving electrical performance, and reducing the rate of minority carrier recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

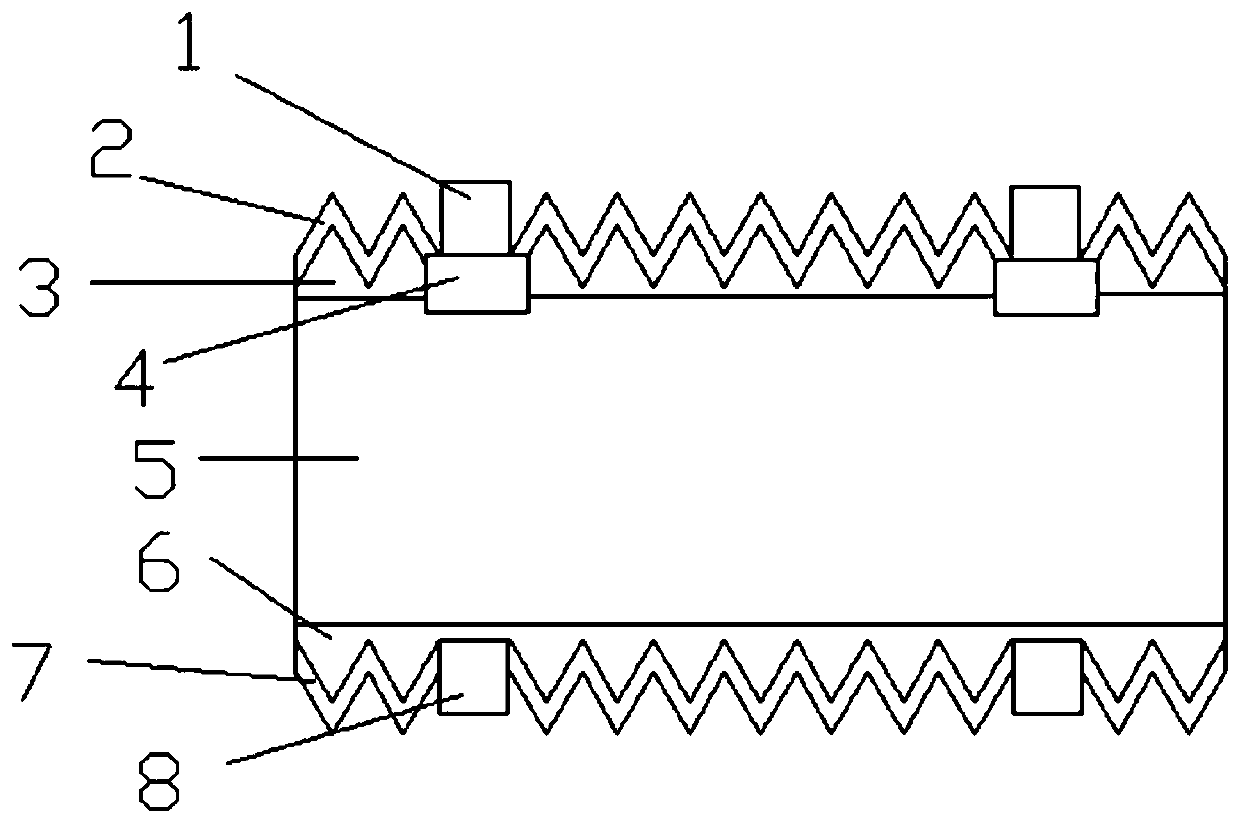

Image

Examples

preparation example Construction

[0019] A method for fabricating N-type selective emitter double-sided batteries by spin-coating boron source laser doping solves some problems existing in the prior art in industrialization. In the production of N-type double-sided cells, one of the main factors restricting cell efficiency is the high contact resistance between the electrode metallization and the silicon body and the increase in the minority carrier recombination rate caused by the high boron doping concentration on the surface. The invention adopts spin-coated boron source to coat the front surface, diffuses in a diffusion furnace to form a lightly doped emitter, and adopts BSG laser doping formed after diffusion to form a heavily doped emitter. The preparation method of the boron source used in this method is simple, and the cost is lower than other boron diffusion methods. The selective emitter is doped with BSG laser formed after the boron source is diffused. Compared with other selective emitters, the oper...

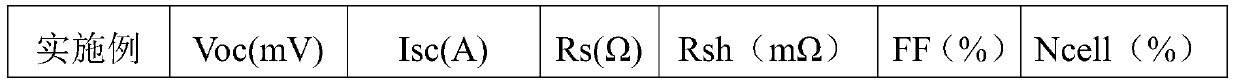

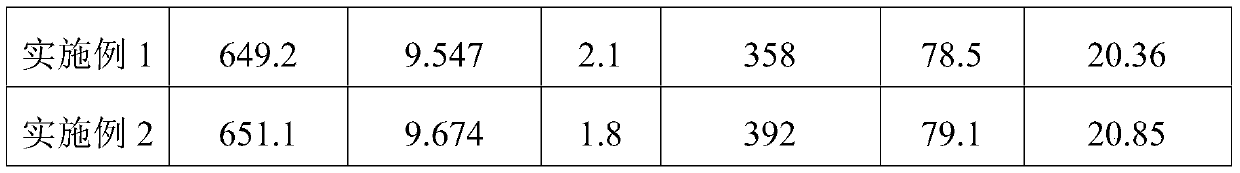

Embodiment 1

[0030] Use an N-type silicon wafer with a resistivity of 1 to 8, dry it after making texture, first spin coat 1ml of pre-wetting liquid on the surface of the silicon wafer, and then spin coat 0.5ml of boron source, and set the spin coating speed at 2500r / min. The rotation time is 5s, and finally the organic phase in the boron source is dried at 200°C. The silicon wafer with spin-coated boron source is placed in a tubular diffusion furnace to diffuse to form a front emitter, and the front surface resistance is controlled between 60-70.

[0031] After the above operations are completed, use 5% to 10% HF acid to clean and remove the oxide on the back of the silicon wafer, and the phosphorus-doped back field on the back uses PClO 3 Formed by high-temperature diffusion method, the diffusion resistance is controlled at 60-100ohm / sq.

[0032] Further, use 5% to 10% HF acid to clean and remove the oxides on the front and back, and use SiN X / SiO 2 The passivation anti-reflection fi...

Embodiment 2

[0035] Use an N-type silicon wafer with a resistivity of 1 to 8, dry it after making texture, first spin coat 1ml of pre-wetting liquid on the surface of the silicon wafer, and then spin coat 0.5ml of boron source, and set the spin coating speed at 2500r / min. The rotation time is 5s, and finally the organic phase in the boron source is dried at 200°C. Put the spin-coated boron source silicon wafer into the tubular diffusion furnace to diffuse to form a lightly doped emitter. After diffusion, a thick BSG is formed on the surface of the silicon wafer, and laser doping is used to form a heavily doped emitter.

[0036] In the above embodiments, the square resistance of the lightly doped emitter region is 80˜200 ohm / sq, and the square resistance of the heavily doped emitter region is 10˜70 ohm / sq.

[0037] After the above operations are completed, use 5% to 10% HF acid to clean and remove the oxide on the back of the silicon wafer, and the phosphorus-doped back field on the back us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com