Crystalline silicon solar cell and preparation method thereof

A solar cell and crystalline silicon technology, applied in the field of solar photovoltaics, can solve the problems of high emission area saturation dark current density, limit the passivation effect of the back side of the silicon wafer, high back field area saturation dark current density, etc., to reduce the saturation dark current density, reducing carrier recombination rate, and reducing the effect of dark current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

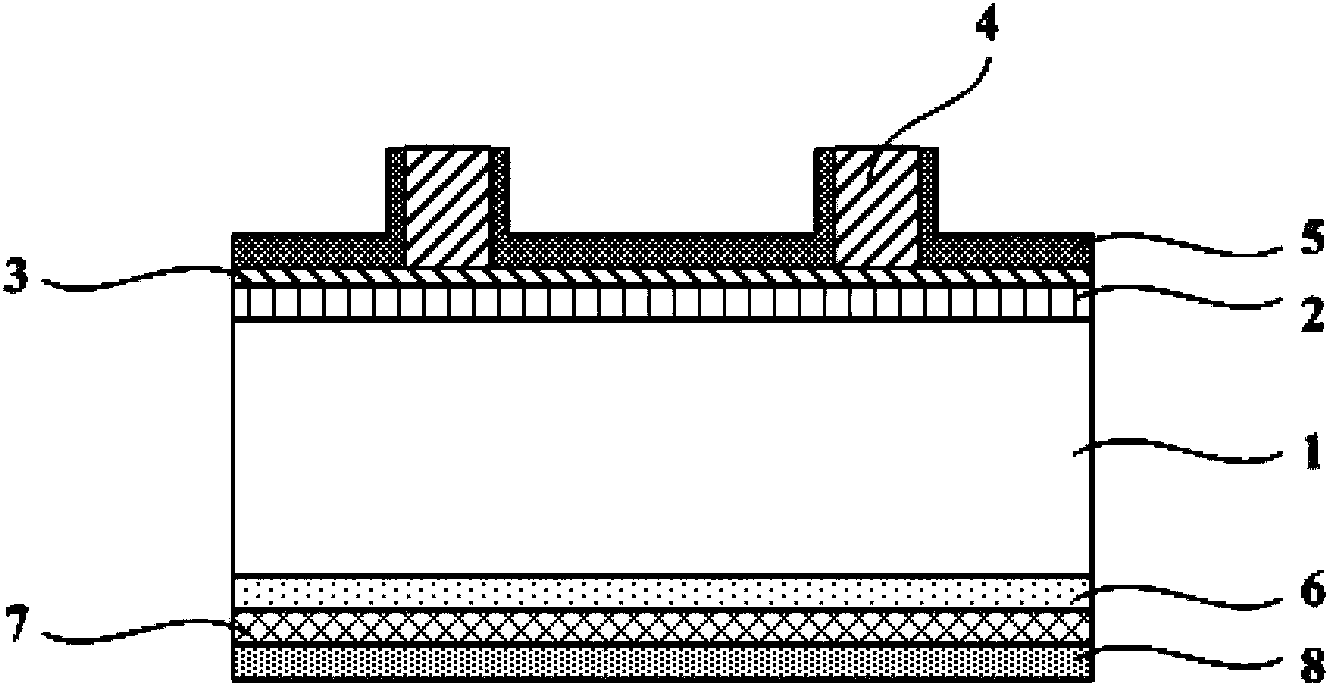

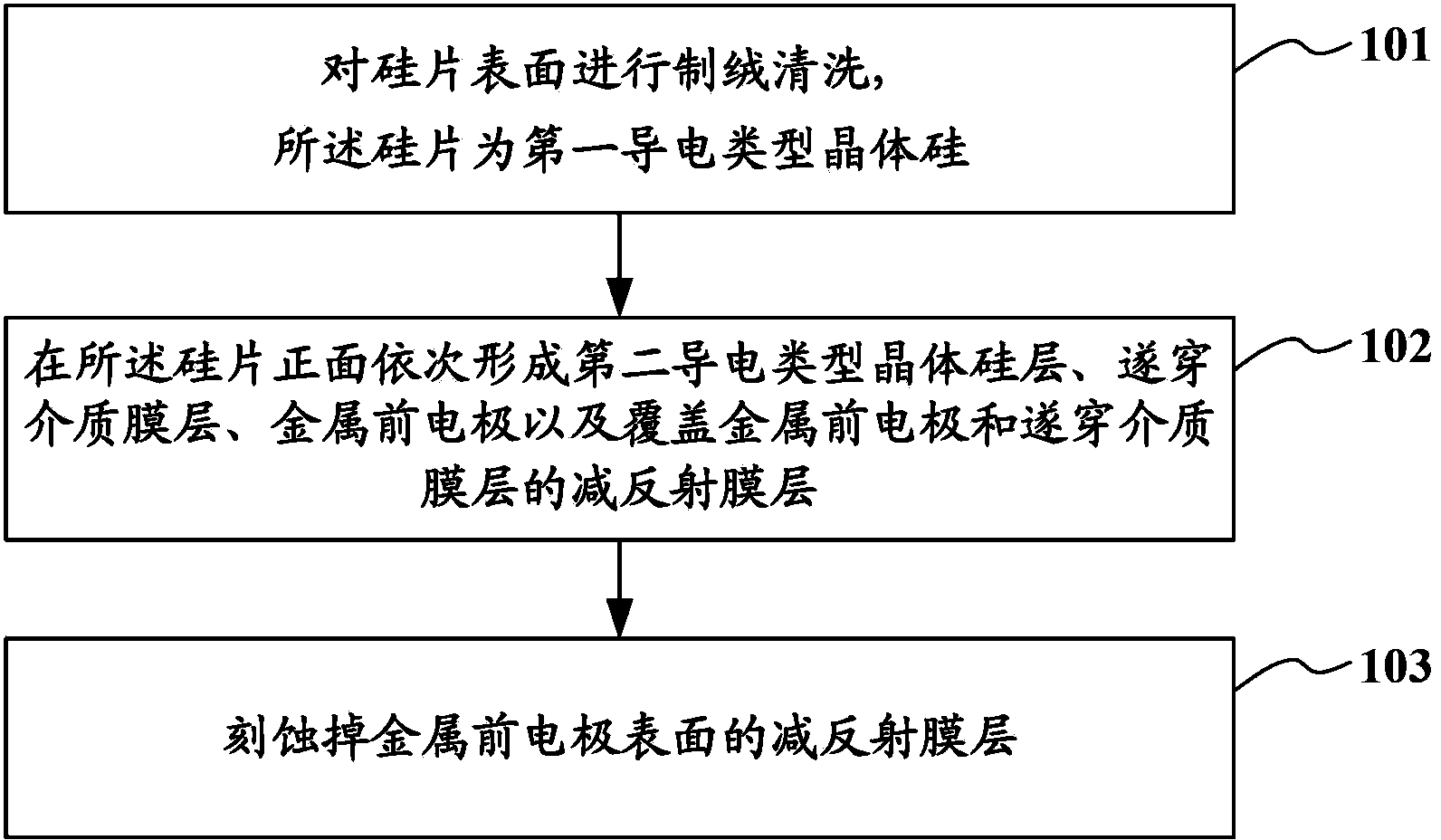

[0042] In order to solve the technical problem that the high carrier recombination rate of the solar cell in the prior art causes the increase of the saturation dark current and eventually leads to product defects, the present invention provides a crystalline silicon solar cell and a preparation method thereof. In this technical scheme, a tunnel dielectric film layer of 0.1-10nm is used to connect the metal front electrode and the second conductivity type crystalline silicon layer. and can effectively transmit the carriers in the emission region to the metal front electrode. Therefore, the technical solution of the present invention reduces the carrier recombination rate, thereby reducing the saturation dark current density in the emission region, and improving the solar cell. performance. In order to make the purpose, technical solution and advantages of the present invention clearer, the following examples are given to further describe the present invention in detail.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com