Crystalline silicon solar cell with low series resistor and preparation method thereof

A technology of solar cells and series resistance, which is applied in the field of solar cells, can solve the problems of increased battery series resistance, increased electrode resistance, and reduced electrode cross-sectional area, to reduce series resistance, reduce recombination rate, and optimize passivation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

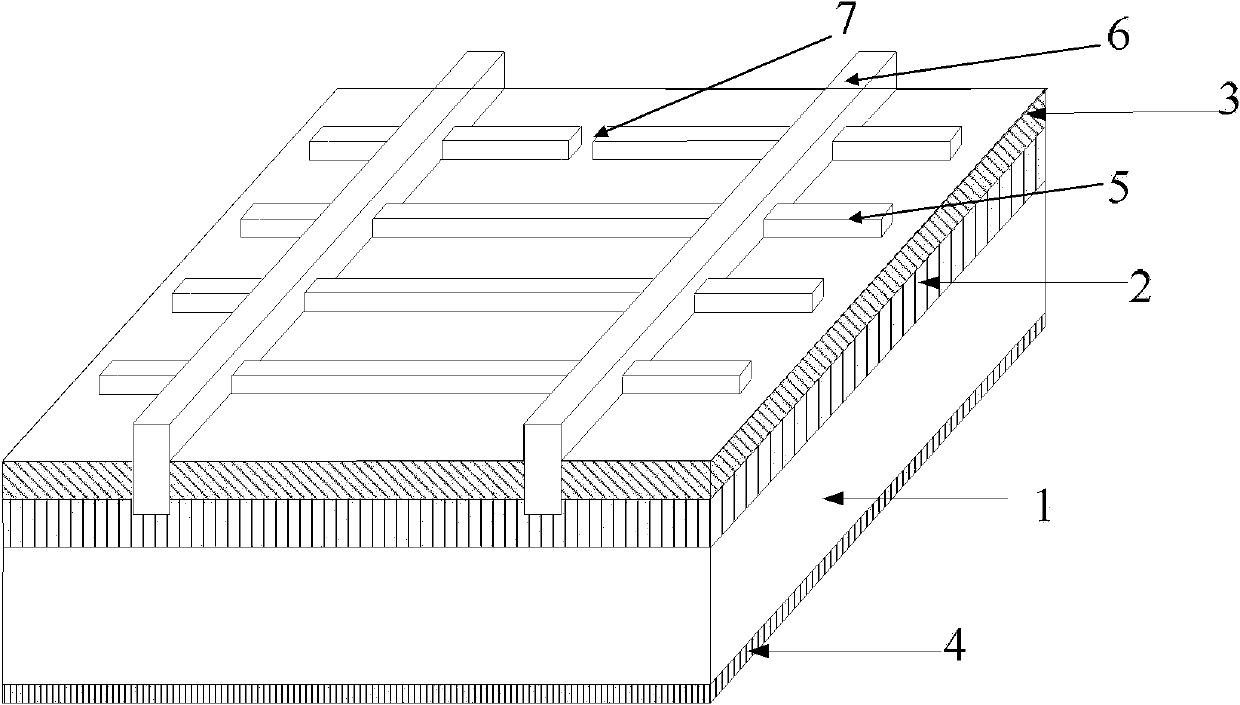

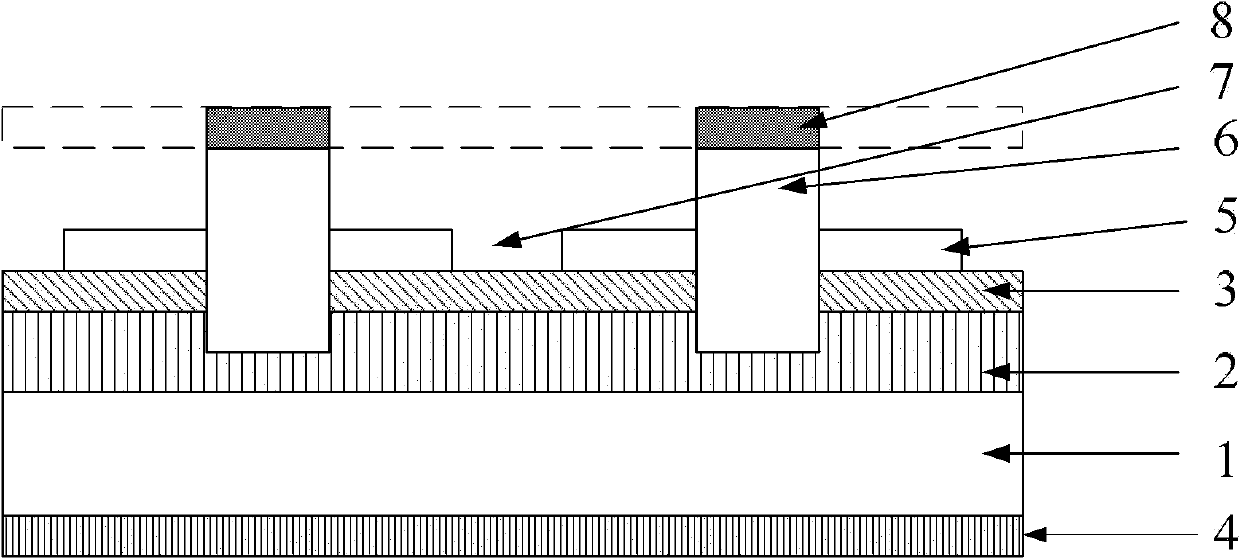

[0032] as attached Figure 1-5 As shown, a crystalline silicon solar cell with low series resistance provided in this embodiment includes a p-n junction p region 1, a p-n junction n region 2, a passivation layer 3 and a thin gate line are arranged on the p-n junction n region 2 The metal electrode 5 and the main grid metal electrode 6 are provided with a back electric field and a back electrode 4 on the p-n junction p region 1, wherein the fine grid line metal electrode 5 and the busbar metal electrode 6 communicate with the p-n junction n region 2 , the back electric field and the back electrode 4 communicate with the p-n junction p region 1, and a transparent conductive film is provided on the front surface of the solar cell, that is, the passivation layer 3, the thin grid metal electrode 5 and the entire area on the main grid metal electrode 6 .

[0033] Among them, the crystalline silicon solar cell in the present invention has the structure of a general crystalline silic...

Embodiment 2

[0035] as attached Figure 1-5 As shown, a crystalline silicon solar cell with low series resistance provided in this embodiment includes a p-n junction p region 1, a p-n junction n region 2, a passivation layer 3 and a thin gate line are arranged on the p-n junction n region 2 The metal electrode 5 and the main grid metal electrode 6 are provided with a back electric field and a back electrode 4 on the p-n junction p region 1, wherein the fine grid line metal electrode 5 and the busbar metal electrode 6 communicate with the p-n junction n region 2 , the back electric field and the back electrode 4 communicate with the p-n junction p region 1, and a transparent conductive film is provided on the front surface of the solar cell, that is, the passivation layer 3, the fine grid metal electrode 5 and the partial area on the main grid metal electrode 6 .

[0036]Among them, by setting a mask on the front surface of the crystalline silicon solar cell and then setting a transparent ...

Embodiment 3

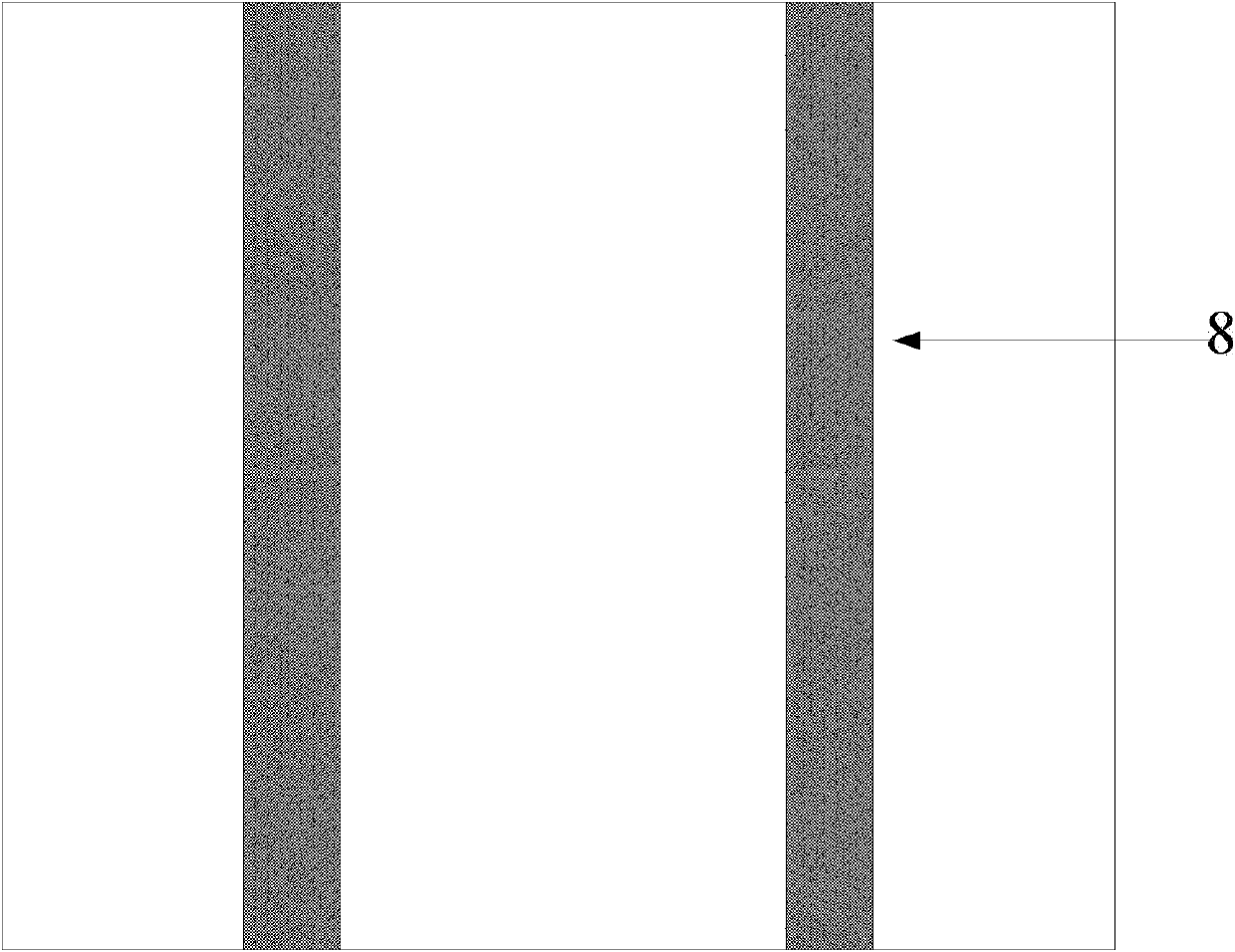

[0038] as attached Figure 1-5 As shown, the general processing steps of a method for preparing a crystalline silicon solar cell with low series resistance are: select the cell, select whether to use a mask and the pattern of the corresponding mask according to actual needs. Use a mask to selectively cover the target area on the front surface of the solar cell, and then use a coating device to plate a transparent conductive film on the area not covered by the mask. Taking mask design as an example, the specific steps are as follows:

[0039] (1) Select the battery. The battery can be a single crystal battery, a polycrystalline battery or a broken grid battery. Take the broken grid battery as an example, such as figure 1 As shown, the battery includes a p-n junction p region 1, a p-n junction n region 2, and a passivation layer 3 is provided on the p-n junction n region 2. The passivation layer 3 can be used by evaporation, sputtering, deposition, ion plating or CVD One or m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com