Method for manufacturing back contact solar cell

A solar cell and back contact technology, applied in the field of solar cells, can solve the problems of difficult to produce back contact cells, complicated production process of back contact cells, high cost of photolithography, etc., so as to increase the effective semiconductor area, eliminate shading loss, The effect of short-circuit current improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The preparation method of the back contact solar cell in the present embodiment comprises the following steps:

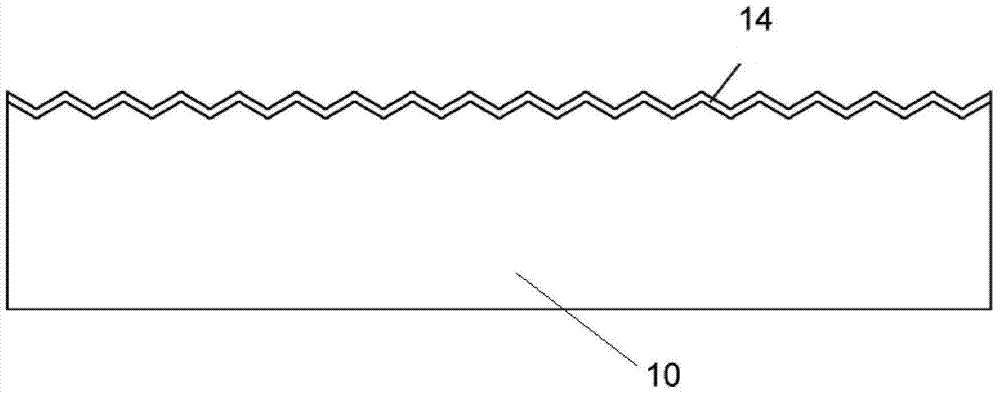

[0057] (1) The selected crystalline silicon substrate is a single crystal silicon substrate with (100) crystal orientation, figure 1 Given is an n-type CZ single crystal silicon substrate 10, the resistivity of which is 1-30Ω·cm, and the thickness of the silicon substrate is 50-300μm. For uneven suede, soak the silicon substrate with a mass concentration of 5-10% hydrochloric acid for 2 minutes, rinse the silicon substrate with deionized water, and deposit a very thin layer of PECVD on the front surface of the silicon substrate after drying. thin silicon oxide (SiO x ) thin film 14, the thickness of the thin film is 5-20nm, the refractive index is 1.4-1.6, and it acts as a diffusion buffer layer;

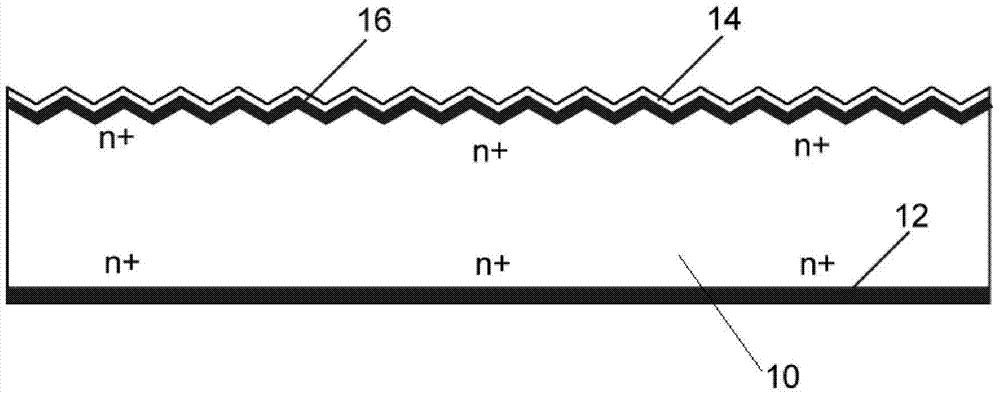

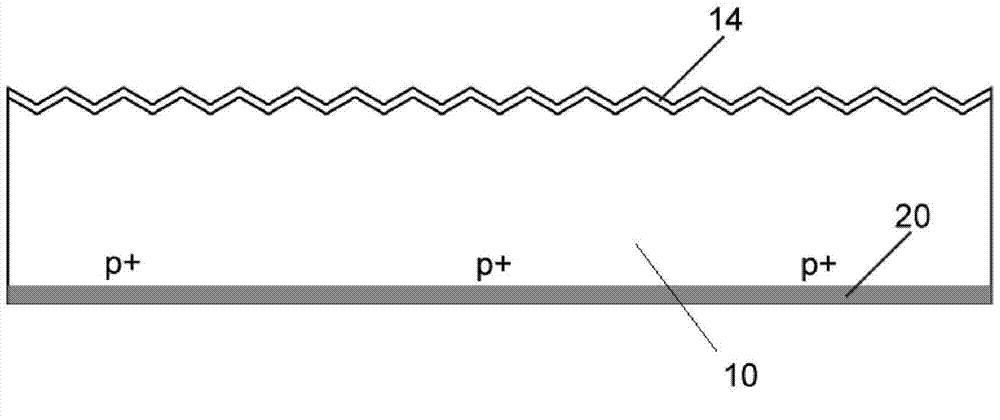

[0058] (2) if Figure 2A As shown, the well-plated SiO x The silicon substrate of the thin film 14 is put into an industrial tubular diffusion furnace for doub...

Embodiment 2

[0067] The preparation method of the back contact solar cell in the present embodiment comprises the following steps:

[0068] (1) The crystalline silicon substrate selected for the patent of this invention is a single crystal silicon substrate with (100) crystal orientation, figure 1 Provided is an n-type single crystal silicon substrate 10 with a volume resistivity of 1-30Ω·cm and a silicon substrate thickness of 50-300μm. The silicon substrate is placed in an aqueous solution of sodium hydroxide alcohol for surface corrosion to form unevenness The textured surface of the silicon substrate is soaked in hydrochloric acid with a mass concentration of 5-10% for 2 minutes, and then the silicon substrate is rinsed with deionized water. After drying, a thin layer is deposited on the front surface of the silicon substrate by PECVD. Silicon oxide (SiO x ) thin film 14, the thickness of the thin film is 5-20nm, the refractive index is 1.4-1.6, and its purpose is to serve as a diffus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com