Low-cost n-type dual-side solar battery and preparation method thereof

A technology for double-sided solar cells and solar cells, which is applied in the manufacturing of circuits, electrical components, and final products, etc., can solve the problems of difficult market development and high production costs, and achieve the reduction of back doping area, the improvement of conversion efficiency, and the reduction of recombination rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

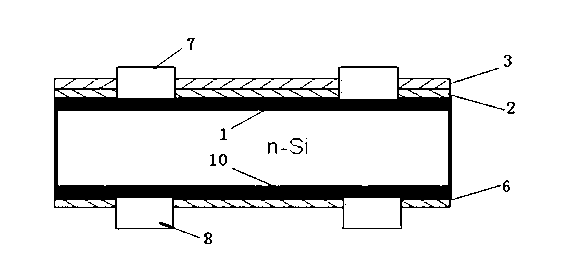

Embodiment 1

[0031] Such as figure 2 As shown, the present invention provides a low-cost n-type double-sided solar cell, the front surface is a boron emitter 1 formed by boron diffusion, a passivation layer 2 and an anti-reflection layer 3 are deposited on the boron emitter, and the back surface of the solar cell The contact position of the back electrode is the local phosphorus back field 4, and the rest are non-doped regions, on which a phosphorus-doped passivation layer 5 is deposited, a metal front electrode 7 is prepared on the front surface, and a metal back electrode 8 is prepared on the back surface .

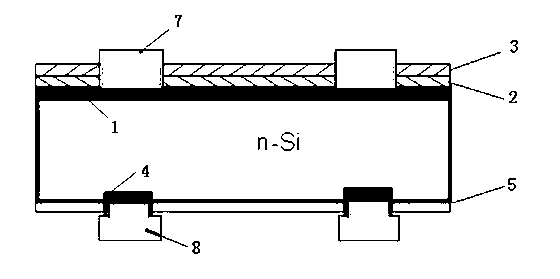

[0032] The preparation method of above-mentioned n-type double-sided solar cell comprises the following steps (such as Figure 4 shown):

[0033] (1) Use n-type silicon wafers with a minority carrier lifetime of more than 50 μs and a resistivity of 0.5-15.0 Ωcm to remove the damaged layer and texture on the surface of the silicon wafer by chemical etching;

[0034] (2) Boron dif...

Embodiment 2

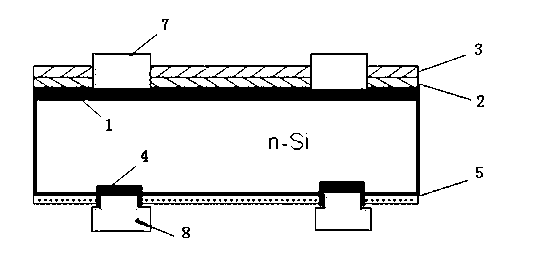

[0041] Such as image 3 As shown, the present invention provides a low-cost n-type double-sided solar cell, the front surface is a boron emitter 1 formed by boron diffusion, a passivation layer 2 and an anti-reflection layer 3 are deposited on the boron emitter, and the back surface of the solar cell The contact position of the back electrode is the local phosphorus back field 4, and the rest are non-doped regions, on which a passivation layer 6 is deposited, and a phosphorus source 9 is sprayed on the passivation layer 6, and a metal front electrode 7 is prepared on the front surface. , a metal back electrode 8 is prepared on the back surface.

[0042] The preparation method of above-mentioned n-type double-sided solar cell comprises the following steps (such as Figure 5 shown):

[0043] (1) Use n-type silicon wafers with a minority carrier lifetime of more than 50 μs and a resistivity of 0.5-15.0 Ωcm to remove the damaged layer and texture on the surface of the silicon wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com